Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells

Abstract

:1. Introduction

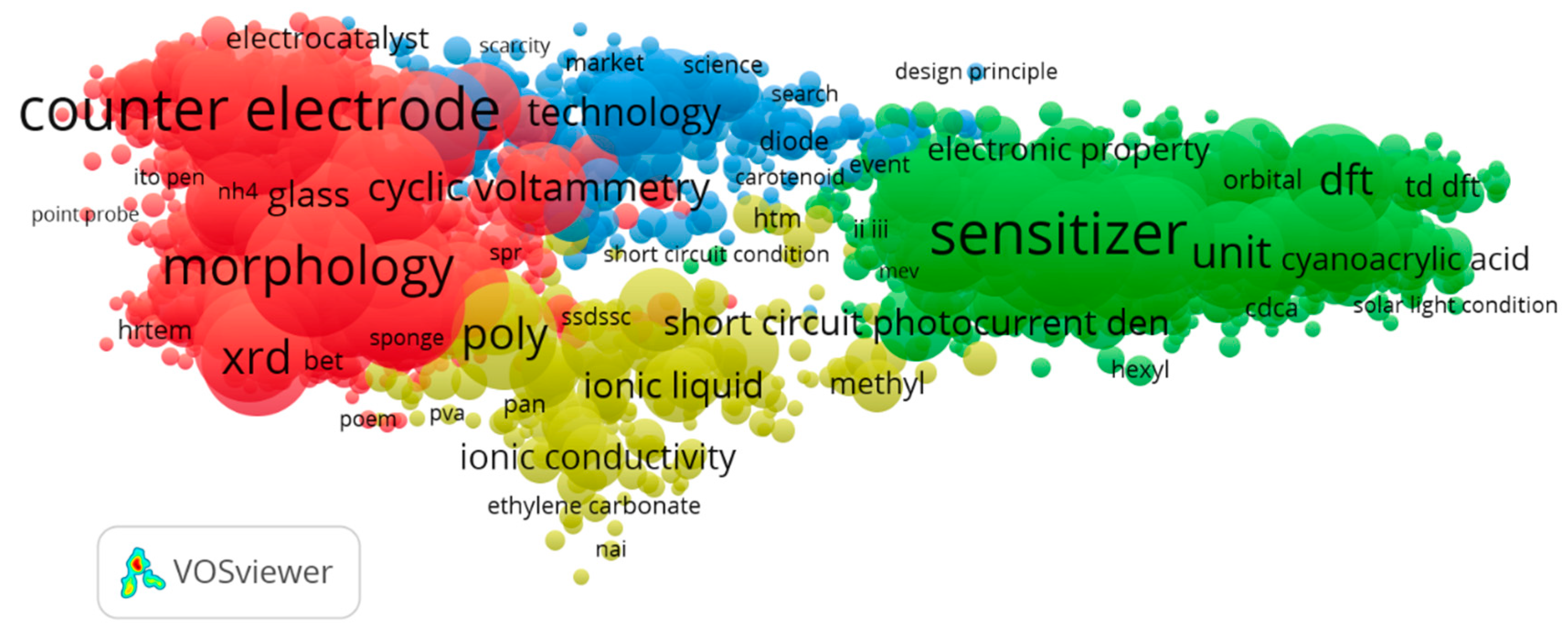

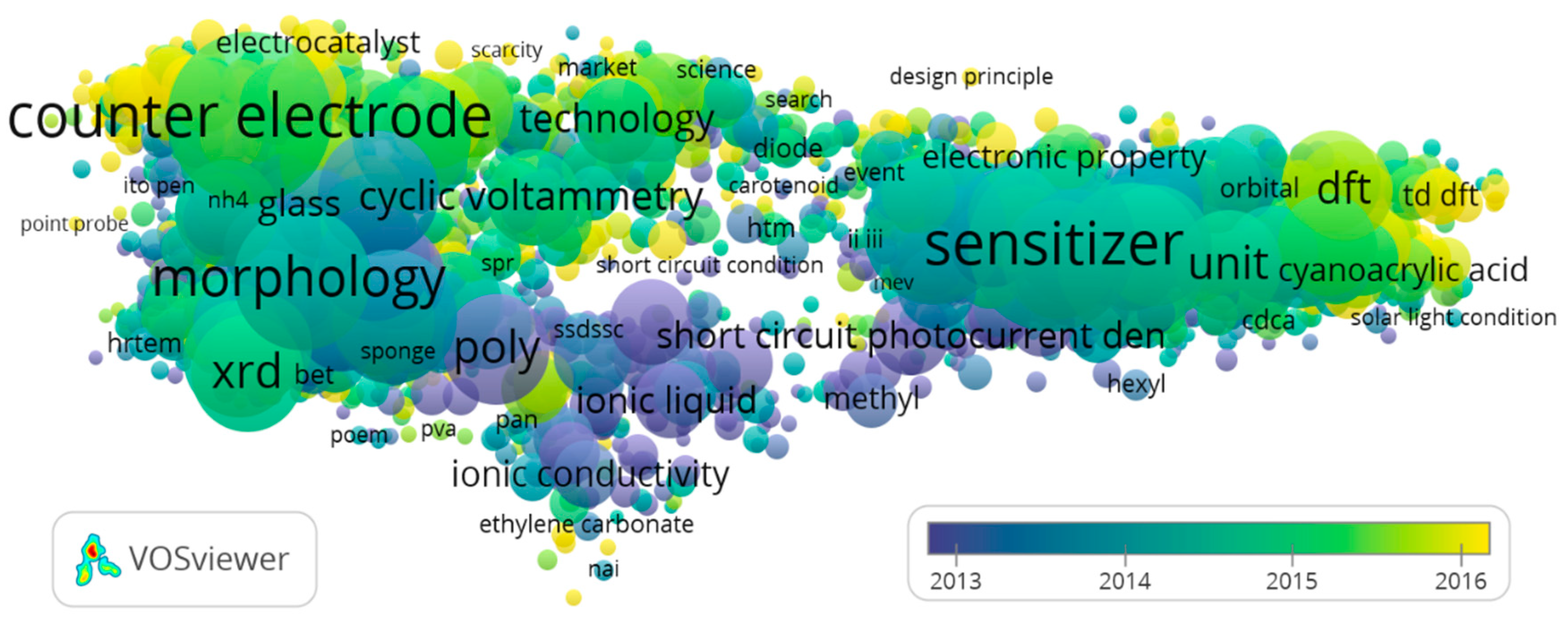

2. Relevance of Sustainability in DSSC Research

- Download abstracts and titles from the web of science with the search results of “dye sensitized solar cell” (24,441 results).

- Create map based on text data (term map).

- Read data from bibliographic database files.

- Select web of science data.

- Title and abstract.

- Binary counting (only the presence or absence of a word matters not the number of the occurrences).

- Minimum number of occurrences (10).

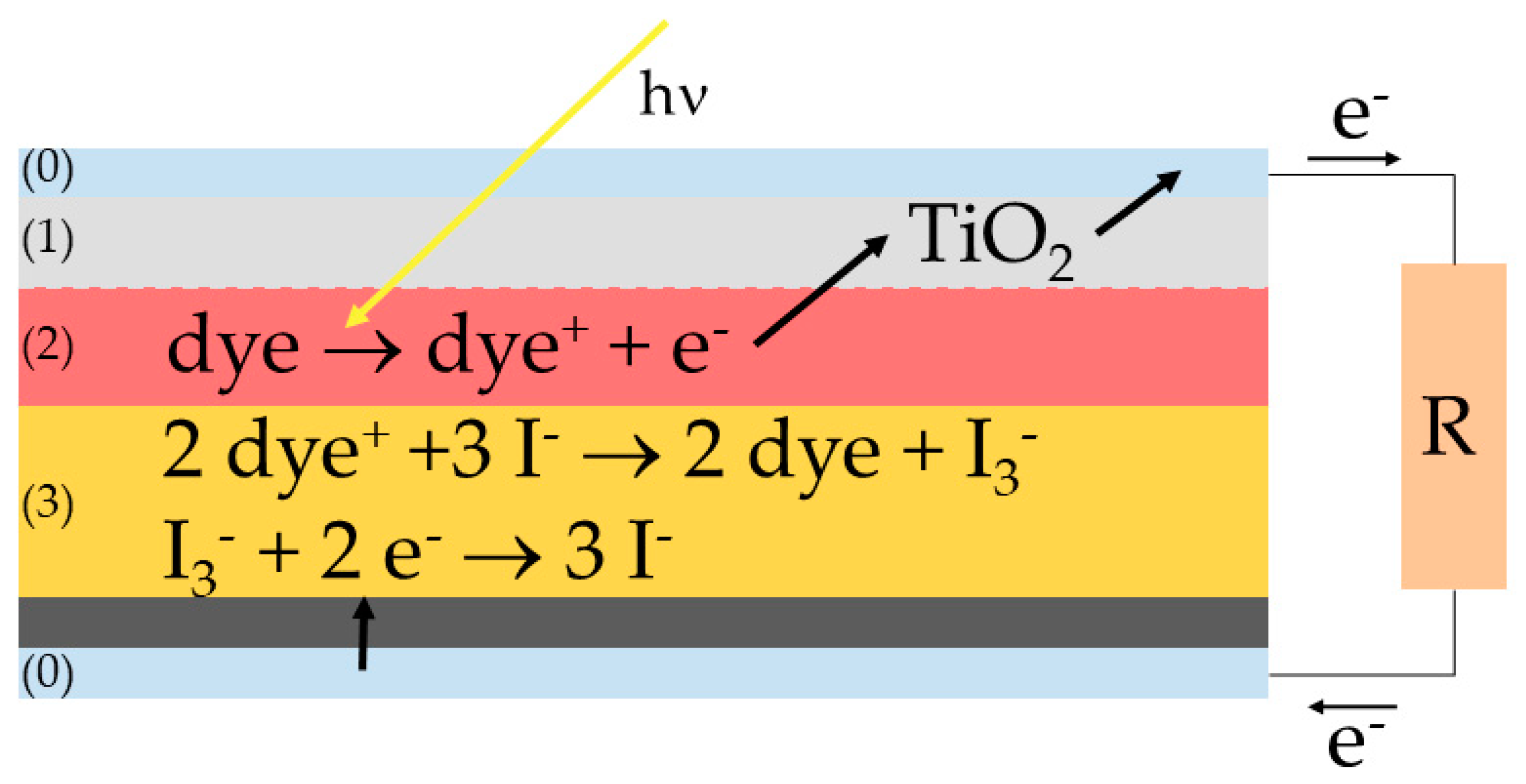

3. Fundamental Structure of a DSSC

4. Using Recycled Material to Build DSSCs

5. Increasing the Longevity of DSSC

6. Outlook and Development: Scaling up and Estimation of Recycling Material

- Use of critical raw materials or precious metals: this problem occurs when toxic and rare materials are used to increase cell efficiency. However, it is possible to use non-toxic, abundant materials. Therefore, this main problem can be addressed by designing DSSCs without toxic materials.

- Performance degradation due to electrolyte stability: the use of solid-state or quasi-solid-state electrolytes based on biopolymers could address this problem.

- High energy demand for producing transparent conductive oxide (TCO)/glass: This statement comes from life cycle analysis (LCA) with a cradle-to-gate perspective. Cradle-to-gate determines the scope of the life cycle assessment. Here, cradle stands for the extraction of the raw material. Further steps are the transport and processing of the product. Gate stands for the point at which the product leaves the company. In this LCA, all environmental impacts within the scope, from raw material extraction to product completion, were assessed. The impacts thereafter—the transport, the use phase and the disposal or a possible recycling process—were not considered. If it were possible to use recycled glass for DSSCs or even allow recycling of DSSCs, the energy requirement would decrease. A new LCA needs to be calculated to re-evaluate the environmental impact of glass-based DSSCs with a cradle-to-cradle approach.

- Sustainability aspects related to unsafe waste management: if non-toxic material is used, it is easier to define specific waste management as well as to close material loops and recycle DSSCs.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baruch-Mordo, S.; Kiesecker, J.; Kennedy, C.M.; Oakleaf, J.R.; Opperman, J.J. Erratum: From Paris to Practice: Sustainable Implementation of Renewable Energy Goals. Environ. Res. Lett. 2019, 14, 024013. [Google Scholar] [CrossRef]

- Coverage, R. Dye Sensitized Solar Cell Market Growth Report, 2020–2027. 2021. Available online: https://www.Grandviewresearch.Com/Industry-Analysis/Dye-Sensitized-S (accessed on 19 June 2021).

- Mariotti, N.; Bonomo, M.; Fagiolari, L.; Barbero, N.; Gerbaldi, C.; Bella, F.; Barolo, C. Recent advances in eco-friendly and cost-effective materials towards sustainable dye-sensitized solar cells. Green Chem. 2020, 22, 7168–7218. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, W.; Xu, D.; Xu, Q.; Xie, J.; Chen, X.; Zhang, T.; Xiong, C.; He, Y.; Zhang, Y.; et al. Outdoor testing and ageing of dye-sensitized solar cells for building integrated photovoltaics. Sol. Energy 2018, 165, 233–239. [Google Scholar] [CrossRef]

- Kawakita, J. Trends of Research and Development of Dye-Sensitized Solar Cells. Sci. Technol. Trends 2010, 35, 70–82. [Google Scholar]

- Trancik, J.E.; Cross-Call, D. Energy Technologies Evaluated against Climate Targets Using a Cost and Carbon Trade-off Curve. Environ. Sci. Technol. 2013, 47, 6673–6680. [Google Scholar] [CrossRef] [PubMed]

- van Sark, W.G.J.H.M.; Schoen, T. Photovoltaic System and Components Price Development in The Netherlands. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 2866–2869. [Google Scholar]

- Rebitzer, G. Integrating Life Cycle Costing and Life Cycle Assessment for Managing Costs and Environmental Impacts in Supply Chains. Cost Manag. Supply Chain. 2002, 127–146. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation and McKinsey. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015; p. 100. [Google Scholar]

- The Ellen MacArthur Foundation. Towards the Circular Economy. An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; p. 96. [Google Scholar]

- Ehrmann, A.; Błachowicz, T. Solarstrom aus Früchtetee. Phys. Unserer Zeit 2020, 51, 196–200. [Google Scholar] [CrossRef]

- Kohn, S.; Großerhode, C.; Storck, J.L.; Grötsch, G.; Cornelißen, C.; Streitenberger, A.; Grassmann, C.; Schwarz-Pfeiffer, A.; Ehrmann, A. Commercially available teas as possible dyes for dye-sensitized solar cells. Optik 2019, 185, 178–182. [Google Scholar] [CrossRef]

- Gossen, K.; Storck, J.; Ehrmann, A. Influence of solvents on Aloe vera gel performance in dye-sensitized solar cells. Optik 2019, 180, 615–618. [Google Scholar] [CrossRef]

- Storck, J.; Dotter, M.; Adabra, S.; Surjawidjaja, M.; Brockhagen, B.; Grothe, T. Long-Term Stability Improvement of Non-Toxic Dye-Sensitized Solar Cells via Poly (ethylene oxide) Gel Electrolytes for Future Textile-Based Solar Cells. Polymers 2020, 12, 3035. [Google Scholar] [CrossRef]

- Junger, I.J.; Großerhode, C.; Storck, J.L.; Kohn, S.; Grethe, T.; Grassmann, C.; Schwarz-Pfeiffer, A.; Grimmelsmann, N.; Meissner, H.; Blachowicz, T.; et al. Influence of graphite-coating methods on the DSSC performance. Optik 2018, 174, 40–45. [Google Scholar] [CrossRef]

- Sun, P.-P.; Li, Q.-S.; Yang, L.-N.; Sun, Z.-Z.; Li, Z.-S. Theoretical investigation on structural and electronic properties of organic dye C258 on TiO2(101) surface in dye-sensitized solar cells. Phys. Chem. Chem. Phys. 2014, 16, 21827–21837. [Google Scholar] [CrossRef] [PubMed]

- Ehrmann, A.; Blachowicz, T. Comment on Dye-sensitized solar cells using Aloe Vera and Cladode of Cactus extracts as natural sensitizers. Chem. Phys. Lett. 2019, 714, 227–229. [Google Scholar] [CrossRef]

- Ehrmann, A.; Blachowicz, T. Recent coating materials for textile-based solar cells. AIMS Mater. Sci. 2019, 6, 234–251. [Google Scholar] [CrossRef]

- Ganta, D.; Jara, J.; Villanueva, R. Dye-sensitized solar cells using Aloe Vera and Cladode of Cactus extracts as natural sensitizers. Chem. Phys. Lett. 2017, 679, 97–101. [Google Scholar] [CrossRef]

- Junger, I.J.; Tellioglu, A.; Ehrmann, A. Refilling DSSCs as a method to ensure longevity. Optik 2018, 160, 255–258. [Google Scholar] [CrossRef]

- Gossen, K.; Ehrmann, A. Glycerin-based electrolyte for reduced drying of dye-sensitized solar cells. Optik 2020, 207, 163772. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Freitag, M.; Teuscher, J.; Saygili, Y.; Zhang, X.; Giordano, F.; Liska, P.; Hua, J.; Zakeeruddin, S.M.; Moser, J.-E.; Grätzel, M.; et al. Dye-sensitized solar cells for efficient power generation under ambient lighting. Nat. Photonics 2017, 11, 372–378. [Google Scholar] [CrossRef]

- Chen, K.F.; Liu, C.H.; Huang, H.K.; Tsai, C.H.; Chen, F.R. Polyvinyl Butyral-Based Thin Film Polymeric Electrolyte for Dye-Sensitized Solar Cell with Long-Term Stability. Int. J. Electrochem. Sci. 2013, 8, 3524–3539. [Google Scholar]

- Baxter, J.B. Commercialization of dye sensitized solar cells: Present status and future research needs to improve efficiency, stability, and manufacturing. J. Vac. Sci. Technol. A 2012, 30, 020801. [Google Scholar] [CrossRef]

- Parisi, M.; Maranghi, S.; Vesce, L.; Sinicropi, A.; Di Carlo, A.; Basosi, R. Prospective life cycle assessment of third-generation photovoltaics at the pre-industrial scale: A long-term scenario approach. Renew. Sustain. Energy Rev. 2020, 121, 109703. [Google Scholar] [CrossRef]

- Vellini, M.; Gambini, M.; Prattella, V. Environmental impacts of PV technology throughout the life cycle: Importance of the end-of-life management for Si-panels and CdTe-panels. Energy 2017, 138, 1099–1111. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Kang, M.-S.; Kim, J.H.; Won, J.; Kang, Y.S. Oligomer Approaches for Solid-State Dye-Sensitized Solar Cells Employing Polymer Electrolytes. J. Phys. Chem. C 2007, 111, 5222–5228. [Google Scholar] [CrossRef]

- Kim, J.H.; Kang, M.-S.; Kim, Y.J.; Won, J.; Park, N.-G.; Kang, Y.S. Dye-sensitized nanocrystalline solar cells based on composite polymer electrolytes containing fumed silica nanoparticles. Chem. Commun. 2004, 4, 1662–1663. [Google Scholar] [CrossRef]

- Gong, J.; Liang, J.; Sumathy, K. Review on dye-sensitized solar cells (DSSCs): Fundamental concepts and novel materials. Renew. Sustain. Energy Rev. 2012, 16, 5848–5860. [Google Scholar] [CrossRef]

- Storck, J.L.; Dotter, M.; Brockhagen, B.; Grothe, T. Evaluation of Novel Glycerol/PEO Gel PolymerElectrolytes for Non-Toxic Dye-Sensitized Solar Cellswith Natural Dyes Regarding Long-Term Stabilityand Reproducibility. Crystals 2020, 10, 1158. [Google Scholar] [CrossRef]

- Kuchariková, L.; Tillová, E.; Bokůvka, O. Recycling and Properties of Recycled Aluminium Alloys Used in the Transportation Industry. Transp. Probl. 2017, 11, 117–122. [Google Scholar] [CrossRef] [Green Version]

- Daut, I.; Fitra, M.; Irwanto, M.; Gomesh, N.; Irwan, Y.M. TiO2 Dye Sensitized Solar Cells Cathode Using Recycle Battery. J. Phys. Conf. Ser. 2013, 423, 012055. [Google Scholar] [CrossRef] [Green Version]

- Gomesh, N.; Shafawi, M.; Irwanto, M.; Yusoff, M.I.; Fitra, M.; Mariun, N.; Nair, G. Performance Improvement of Dye Sensitized Solar Cell by Using Recycle Material for Counter Electrode. Appl. Mech. Mater. 2013, 446-447, 823–826. [Google Scholar] [CrossRef]

- Hölscher, F.; Trümper, P.-R.; Junger, I.J.; Schwenzfeier-Hellkamp, E.; Ehrmann, A. Application methods for graphite as catalyzer in dye-sensitized solar cells. Optik 2019, 178, 1276–1279. [Google Scholar] [CrossRef]

- Muchuweni, E.; Martincigh, B.S.; Nyamori, V.O. Recent advances in graphene-based materials for dye-sensitized solar cell fabrication. RSC Adv. 2020, 10, 44453–44469. [Google Scholar] [CrossRef]

- Chen, C.C.; Chang, F.C.; Liao, C.Y.; Paul Wang, H. Copper Nanowires on Recycled Conducting Glass for DSSC Electrodes; TechConnect Briefs: Danville, CA, USA, 2012. [Google Scholar]

- Ayaz, M.; Khan Kasi, J.; Khan Kasi, A.; Ali, M. Toward Eco Green Energy: Fabrication of DSSC from Recycled Phone Screen. Open Access J. Resist. Econ. Int. J. Resist. Econ. 2016, 4, 2345–4954. [Google Scholar]

- Zhu, W.; Chai, W.; Chen, D.; Xi, H.; Chen, D.; Chang, J.; Zhang, J.; Zhang, C.; Hao, Y. Recycling of FTO/TiO2 Substrates: Route toward Simultaneously High-Performance and Cost-Efficient Carbon-Based, All-Inorganic CsPbIBr2 Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 4549–4557. [Google Scholar] [CrossRef]

- Bai, Y.; Mora-Sero, I.N.; De Angelis, F.; Bisquert, J.; Wang, P. Titanium Dioxide Nanomaterials for Photovoltaic Applications. Chem. Rev. 2014, 114, 10095–10130. [Google Scholar] [CrossRef]

- Food Watch. Mineral Oil in Food—Results of the Foodwatch Test; Food Watch: Berlin, Germany, 2015; pp. 1–26. [Google Scholar]

- Mariotti, N.; Bonomo, M.; Barolo, C. Emerging Photovoltaic Technologies and Eco-Design—Criticisms and Potential Improvements. In Reliability and Ecological Aspects of Photovoltaic Modules; Gok, A., Ed.; IntechOpen: London, UK, 2020. [Google Scholar]

- Iftikhar, H.; Sonai, G.G.; Hashmi, S.G.; Nogueira, A.F.; Lund, P.D. Progress on Electrolytes Development in Dye-Sensitized Solar Cells. Materials 2019, 12, 1998. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.M.; Islam, D.; Rashid, T.U. Biopolymer-Based Electrolytes for Dye-Sensitized Solar Cells: A Critical Review. Energy Fuels 2020, 34, 15634–15671. [Google Scholar] [CrossRef]

- Singh, R.; Polu, A.R.; Bhattacharya, B.; Rhee, H.-W.; Varlikli, C.; Singh, P.K. Perspectives for solid biopolymer electrolytes in dye sensitized solar cell and battery application. Renew. Sustain. Energy Rev. 2016, 65, 1098–1117. [Google Scholar] [CrossRef] [Green Version]

- Galliano, S.; Bella, F.; Bonomo, M.; Viscardi, G.; Gerbaldi, C.; Boschloo, G.; Barolo, C. Hydrogel Electrolytes Based on Xanthan Gum: Green Route Towards Stable Dye-Sensitized Solar Cells. Nanomaterials 2020, 10, 1585. [Google Scholar] [CrossRef]

- Bella, F.; Gerbaldi, C.; Barolo, C.; Grätzel, M. Aqueous dye-sensitized solar cells. Chem. Soc. Rev. 2015, 44, 3431–3473. [Google Scholar] [CrossRef] [Green Version]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef]

- Hellert, C.; Klemt, C.; Scheidt, U.; Junger, I.J.; Schwenzfeier-Hellkamp, E.; Ehrmann, A. Rehydrating dye sensitized solar cells. AIMS Energy 2017, 5, 397–403. [Google Scholar] [CrossRef]

- Chen, R.-T.; Liao, C.-F. Evaluation and Optimization to Recycle Used TiO2 Photoelectrode for Dye-Sensitized Solar Cells. Int. J. Photoenergy 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Chiang, Y.-F.; Chen, R.-T.; Shen, P.-S.; Chen, P.; Guo, T.-F. Extension lifetime for dye-sensitized solar cells through multiple dye adsorption/desorption process. J. Power Sources 2013, 225, 257–262. [Google Scholar] [CrossRef]

- Wei, Q.S.; Aizat, M.F.; Diyanti, A.; Ishak, W.M.F.; Salleh, H.; Wong, K.N.S.W.S.; Adli, H.K. Kappaphycus alvarezii sp., Sargassum polycystum sp. and Manihot esculenta sp. as photo-sensitizers in dye-sensitized solar cells. AIP Conf. Proc. 2019. [Google Scholar] [CrossRef]

- Mamun, A.; Trabelsi, M.; Klöcker, M.; Sabantina, L.; Großerhode, C.; Blachowicz, T.; Grötsch, G.; Cornelißen, C.; Streitenberger, A.; Ehrmann, A. Electrospun Nanofiber Mats with Embedded Non-Sintered TiO2 for Dye-Sensitized Solar Cells (DSSCs). Fibers 2019, 7, 60. [Google Scholar] [CrossRef] [Green Version]

- Mozaffari, S.; Nateghi, M.R.; Zarandi, M.B. An overview of the Challenges in the commercialization of dye sensitized solar cells. Renew. Sustain. Energy Rev. 2017, 71, 675–686. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Basosi, R. The evolution of the dye sensitized solar cells from Grätzel prototype to up-scaled solar applications: A life cycle assessment approach. Renew. Sustain. Energy Rev. 2014, 39, 124–138. [Google Scholar] [CrossRef]

- Gonçalves, L.M.; Bermudez, V.D.Z.; Ribeiro, H.A.; Mendes, A. Dye-sensitized solar cells: A safe bet for the future. Energy Environ. Sci. 2008, 1, 655–667. [Google Scholar] [CrossRef] [Green Version]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H. Dye-Sensitized Solar Cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Hardin, B.E.; Snaith, H.J.; McGehee, M.D. The renaissance of dye-sensitized solar cells. Nat. Photonics 2012, 6, 162–169. [Google Scholar] [CrossRef]

- Pramananda, V.; Fityay, T.A.H.; Misran, E. Anthocyanin as natural dye in DSSC fabrication: A review. IOP Conf. Ser.: Mater. Sci. Eng. 2021, 1122, 012104. [Google Scholar] [CrossRef]

- Kakiage, K.; Aoyama, Y.; Yano, T.; Oya, K.; Fujisawa, J.-I.; Hanaya, M. Highly-efficient dye-sensitized solar cells with collaborative sensitization by silyl-anchor and carboxy-anchor dyes. Chem. Commun. 2015, 51, 15894–15897. [Google Scholar] [CrossRef]

- Yella, A.; Lee, H.-W.; Tsao, H.N.; Yi, C.; Chandiran, A.K.; Nazeeruddin, M.K.; Diau, E.W.-G.; Yeh, C.-Y.; Zakeeruddin, S.M.; Grätzel, M. Porphyrin-Sensitized Solar Cells with Cobalt (II/III)-Based Redox Electrolyte Exceed 12 Percent Efficiency. Science 2011, 334, 629–634. [Google Scholar] [CrossRef]

- Wang, X.-F.; Zhan, C.-H.; Maoka, T.; Wada, Y.; Koyama, Y. Fabrication of dye-sensitized solar cells using chlorophylls c1 and c2 and their oxidized forms c1′ and c2′ from Undaria pinnatifida (Wakame). Chem. Phys. Lett. 2007, 447, 79–85. [Google Scholar] [CrossRef]

- Zulkifli, A.M.; Said, N.I.A.M.; Aziz, S.B.; Dannoun, E.M.A.; Hisham, S.; Shah, S.; Abu Bakar, A.; Zainal, Z.H.; Tajuddin, H.A.; Hadi, J.M.; et al. Characteristics of Dye-Sensitized Solar Cell Assembled from Modified Chitosan-Based Gel Polymer Electrolytes Incorporated with Potassium Iodide. Molecues 2020, 25, 4115. [Google Scholar] [CrossRef]

- Magni, M.; Giannuzzi, R.; Colombo, A.; Cipolla, M.P.; Dragonetti, C.; Caramori, S.; Carli, S.; Grisorio, R.; Suranna, G.P.; Bignozzi, C.A.; et al. Tetracoordinated Bis-phenanthroline Copper-Complex Couple as Efficient Redox Mediators for Dye Solar Cells. Inorg. Chem. 2016, 55, 5245–5253. [Google Scholar] [CrossRef] [PubMed]

- Bella, F.; Sacco, A.; Salvador, G.P.; Bianco, S.; Tresso, E.; Pirri, C.; Bongiovanni, R. First Pseudohalogen Polymer Electrolyte for Dye-Sensitized Solar Cells Promising for In Situ Photopolymerization. J. Phys. Chem. C 2013, 117, 20421–20430. [Google Scholar] [CrossRef]

- Kokal, R.K.; Bhattacharya, S.; Cardoso, L.S.; Miranda, P.B.; Soma, V.R.; Chetti, P.; Melepurath, D.; Raavi, S.S.K. Low cost ‘green’ dye sensitized solar cells based on New Fuchsin dye with aqueous electrolyte and platinum-free counter electrodes. Sol. Energy 2019, 188, 913–923. [Google Scholar] [CrossRef]

- Meng, K.; Thampi, K.R. Efficient Quasisolid Dye- and Quantum-Dot-Sensitized Solar Cells Using Thiolate/Disulfide Redox Couple and CoS Counter Electrode. ACS Appl. Mater. Interfaces 2014, 6, 20768–20775. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Li, K.; Luo, Y.; Guo, X.; Li, D.; Deng, M.; Huang, S.; Meng, Q. A flexible carbon counter electrode for dye-sensitized solar cells. Carbon 2009, 47, 2704–2708. [Google Scholar] [CrossRef]

- Kavan, L.; Yum, J.H.; Grätzel, M. Optically Transparent Cathode for Dye-Sensitized Solar Cells Based on Graphene Nanoplatelets. ACS Nano 2010, 5, 165–172. [Google Scholar] [CrossRef]

- Peri, R.; P, M.K.; B, M. Improved performance of dye-sensitized solar cells upon sintering of a PEDOT cathode at various temperatures. RSC Adv. 2020, 10, 4521–4528. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Zhao, G.; Shao, L.-L.; Yuan, Z.-Y.; Jing, Q.-S.; Huang, K.-J.; Huang, Z.-Y.; Zhao, X.-H.; Zou, G.-D. Controlled Synthesis of Nickel Encapsulated into Nitrogen-Doped Carbon Nanotubes with Covalent Bonded Interfaces: The Structural and Electronic Modulation Strategy for an Efficient Electrocatalyst in Dye-Sensitized Solar Cells. Chem. Mater. 2017, 29, 9680–9694. [Google Scholar] [CrossRef]

- Fayad, R.; Shoker, T.A.; Ghaddar, T.H. High photo-currents with a zwitterionic thiocyanate-free dye in aqueous-based dye sensitized solar cells. Dalton Trans. 2016, 45, 5622–5628. [Google Scholar] [CrossRef] [PubMed]

- de Wild-Scholten, M.J.; Veltkamp, A.C. Environmental Life Cycle Analysis of Large Area Dye Sensitized Solar Modules; Status and Outlook. In Proceedings of the 22nd European Photovoltaic Solar Energy Conference and Exhibition, Milan, Italy, 3 September 2007; pp. 3–7. [Google Scholar]

- McDonald, N.; Pearce, J. Producer responsibility and recycling solar photovoltaic modules. Energy Policy 2010, 38, 7041–7047. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- EUR-Lex—32012L0019—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32012L0019 (accessed on 8 June 2021).

- Schmidt-Bleek, F. Green Lies. Nothing for the Environment, Everything for Business—How Politics and Industry are Ruining the World; Ludwig Verlag: Munich, Germany, 2014. [Google Scholar]

- Blanco, C.F.; Cucurachi, S.; Peijnenburg, W.J.G.M.; Beames, A.; Vijver, M.G. Are Technological Developments Improving the Environmental Sustainability of Photovoltaic Electricity? Energy Technol. 2020, 8, 1901064. [Google Scholar] [CrossRef] [Green Version]

- Wortmann, M.; Layland, A.S.; Frese, N.; Kahmann, U.; Grothe, T.; Storck, J.L.; Blachowicz, T.; Grzybowski, J.; Hüsgen, B.; Ehrmann, A. On the reliability of highly magnified micrographs for structural analysis in materials science. Sci. Rep. 2020, 10, 1–8. [Google Scholar] [CrossRef]

- Baker, M. 1,500 scientists lift the lid on reproducibility. Nat. Cell Biol. 2016, 533, 452–454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- NBSP. Reproducibility and Replicability in Science; National Academies Press: Washington, DC, USA, 2019. [Google Scholar] [CrossRef]

| Term | Appearances | Average Publication Date |

|---|---|---|

| sensitizer | 2810 | 2014.43 (June 2014) |

| counter electrode | 2769 | 2015.10 (February 2015) |

| molecule | 2086 | 2014.16 (February 2014) |

| group | 2263 | 2014.58 (July 2014) |

| morphology | 1899 | 2014.44 (June 2014) |

| organic dye | 1396 | 2014.61 (August 2014) |

| series | 1357 | 2014.43 (June 2014) |

| substrate | 1474 | 2013.57 (July 2013) |

| xrd (x ray diffraction) | 1316 | 2014.84 (November 2014) |

| Material | Application | Efficiency |

|---|---|---|

| Carbon from batteries | Counter electrode | Not stated [34] |

| Carbon from batteries | Counter electrode | 8.2% [35] |

| Carbon from pencils | Counter electrode | 7.23% [35] |

| Telephone screens | Conductive glass | 0.0244% [39] |

| TFT-LCD | Conductive glass | 3.94% [38] |

| Perovskite cells | Conductive glass with TiO2 | 9.12% [40] |

| Dye | Advantage | Disadvantage | Efficiency |

|---|---|---|---|

| D—π-A/Adeka 1 | High stability and PCE | Cobalt-based electrolyte | 12.5% [61] |

| Zn-Porphyrin/YD2-o-C8 | High stability and PCE | Cobalt-based electrolyte | 11.9% [62] |

| Chlorophylls/Chlorophyll cl | Natural dye | Low stability and PCE | 3.4% [63] |

| Flavonoids/Anthocyanin | Natural dye | Low stability and PCE | 1.1% [64] |

| Redox Couple | Advantage | Disadvantage | Efficiency |

|---|---|---|---|

| Pseudo-halogens | Suitable for quasi-solid electrolytes | Toxicity, use of selenium | 2.6% [66] |

| Iron-based complexes | Water as solvent | Low stability | 2.9% [67] |

| Copper-based complexes | Low toxicity dye | Organic solvent-based electrolyte | 4.4% [65] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schoden, F.; Dotter, M.; Knefelkamp, D.; Blachowicz, T.; Schwenzfeier Hellkamp, E. Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells. Energies 2021, 14, 3741. https://doi.org/10.3390/en14133741

Schoden F, Dotter M, Knefelkamp D, Blachowicz T, Schwenzfeier Hellkamp E. Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells. Energies. 2021; 14(13):3741. https://doi.org/10.3390/en14133741

Chicago/Turabian StyleSchoden, Fabian, Marius Dotter, Dörthe Knefelkamp, Tomasz Blachowicz, and Eva Schwenzfeier Hellkamp. 2021. "Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells" Energies 14, no. 13: 3741. https://doi.org/10.3390/en14133741

APA StyleSchoden, F., Dotter, M., Knefelkamp, D., Blachowicz, T., & Schwenzfeier Hellkamp, E. (2021). Review of State of the Art Recycling Methods in the Context of Dye Sensitized Solar Cells. Energies, 14(13), 3741. https://doi.org/10.3390/en14133741