Abstract

Cities and nations worldwide are pledging to energy and carbon neutral objectives that imply a huge contribution from buildings. High-performance targets, either zero energy or zero carbon, are typically difficult to be reached by single buildings, but groups of properly-managed buildings might reach these ambitious goals. For this purpose we need tools and experiences to model, monitor, manage and optimize buildings and their neighborhood-level systems. The paper describes the activities pursued for the deployment of an advanced energy management system for a multi-carrier energy grid of an existing neighborhood in the area of Milan. The activities included: (i) development of a detailed monitoring plan, (ii) deployment of the monitoring plan, (iii) development of a virtual model of the neighborhood and simulation of the energy performance. Comparisons against early-stage energy monitoring data proved promising and the generation system showed high efficiency (EER equal to 5.84), to be further exploited.

1. Introduction

Cities consume about 75% of total primary energy and emit between 50% and 60% of the world’s total greenhouse gases [,]; a large share of it depends on buildings that, in the European Union (EU), represent about 36% of CO2 emissions and account for 40% of the final energy use [,,]. Any roadmap to decarbonization should therefore include sound solutions for the building stock management and renovation. As nearly 80% of the energy consumed by buildings refers to its operation, proper energy management may substantially allow the increase of buildings’ energy efficiency [,]. Single building interventions, although useful, are limited in their effects, and do not allow to maximize the benefits of sharing (costs, energy, etc.) among buildings. Micro-grids, connecting from a few buildings to a whole neighborhood, represent a technical option to enable the sharing of information and energy among buildings, providing a fundamental structure to promote waste heat recovery [,], energy communities and demand-response programs, but also to implement a remote control and management of buildings to decrease their energy use while enhancing occupants’ comfort. Intelligent buildings or smart buildings [,,], have been studied for a long time, and currently building management systems (BMS) are commonly applied also in residential buildings [,,,], at least in the form of remote monitoring and management. These advanced control systems boost building management, enabling communication between users and building appliances, through remote monitoring and control [,,]. The current challenge of applied research relates to the management of groups of buildings together, in order to improve the overall efficiency of a neighborhood and its integration with the city’s energy networks (power grid, district heating and cooling, data networks) [,]. This broad challenge includes a series of sub-challenges: (i) modeling the built environment to simulate the neighborhood energy dynamics [,,,], both for new constructions and for existing ones, (ii) planning an adequate monitoring and management, (iii) deploying the plan by integrating existing buildings with and energy management system (EMS), i.e., a platform allowing the visualization (dashboard) of monitored data, and some sort of control.

Early examples of neighborhood networks exist in the form of micro-grids [,,,] where the only energy carrier is electricity. The current energy transition [,], pushing toward an electrification of the major final energy uses, makes these examples very interesting for new neighborhoods and cities; however, most of the existing cities are characterised by a much more complex energy structure that requires a further level of management systems, i.e., multi-carrier EMS. Typically, the networks that need to be integrated are the power grid, district heating and cooling networks (both local and city-wide), natural gas networks and data networks [,,]. This integration overtakes the traditional sectorial division of the design and operation of energy systems, arising the necessity to simulate the system complexity according to a holistic approach [] and to perform advanced operational analyses through energy modeling tools []. With a proper balance between complexity and accuracy, simulations can be considered as a key practice to support the systems performance assessment and operation []. Moreover, the continuous calibration of dynamic energy models against monitoring data is a key point to minimize the performance gap [,,,] and to obtain reliable energy performance forecast to be used by energy management actions.

With the aim of assessing possibilities and limitations of the current level of technology, Regione Lombardia funded a research project named “Sustainable Lifestyle: Merlata Smart Grid” that involved the Department of Energy of Politecnico di Milano together with three industrial partners: Euromilano, Siemens and Future Energy. The project intended to deploy a real pilot of a multi-carrier EMS, able to monitor and manage the energy uses of seven existing residential tower buildings in the suburbs of Milan, Italy. The buildings are connected to the city’s district heating system for heating and domestic hot water (DHW) supply, to a local cooling district system, based on a loop of underground water working as a thermal sink for electric chillers, and to the national power grid.

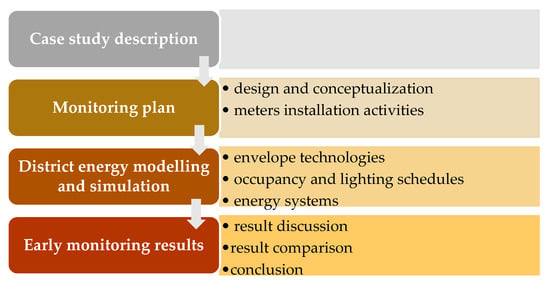

The activities included: (i) the detailed mapping of the exiting systems, both at apartment, building, and neighborhood level; (ii) the development of a detailed monitoring plan and its deployment with the integration of existing information and communication technologies (ICT) in the new multi-carrier EMS (Section 3); (iii) the creation of a dynamic simulation model for system performance evaluation and optimization (Section 4); and (iv) an early comparison between simulation output and energy monitoring data (Section 5). The paper summarizes the integrated approach used in the project (Figure 1), where dynamic simulation was used, trying to balance complexity and accuracy, as a tool to inform the monitoring plan, thus proving to be both a design and an operational useful tools, especially when neighborhood-level issues need to be challenged.

Figure 1.

Schematic representation of the paper’s structure.

2. The Case Study

The case study is a neighborhood of seven tower buildings (called B1, B2, B5, B7, B9, B10 and B11), part of a new residential district under development in Milan, that overall involves a large urban surface of 920,000 m2 and, once completed, will include a large residential area of 4500 apartments, a school, and a few other commercial uses.

The district is divided in eleven parcels and the current study focuses on one of them (Figure 2). The seven tower buildings in the parcel have different heights, volumes and envelope technologies, and count for an aggregate volume of 111,000 m3 and about 400 apartments of different size and typology, as shown in Table 1.

Figure 2.

Layout of the parcel of the district under analysis.

Table 1.

Number of apartments per typology and buildings.

All the buildings have a sub-station connecting them with a district heating system (delivery temperature of 110 °C), for space heating (SH) and domestic hot water (DHW) production. The cooling of the indoor spaces is provided via electric chillers exchanging heat with groundwater, that works as a heat sink for the whole parcel. The eleven parcels are then connected with each other, in order to provide resilience to the system in case of malfunctioning on some of the loops. Overall, the underground systems will be provided by thirteen supply wells and fourteen re-injection wells. Each apartment is conditioned via radiant floors both for heating and cooling, integrated by controlled mechanical ventilation (CMV) with heat recovery. A small photovoltaic array with a total pick power of 39.3 kWp is installed on the roofs of the seven buildings.

3. Monitoring Plan

The design of sustainable multi-carrier energy systems relies on the correct evaluation of the heating and cooling generation system operation, the daily profile of the buildings’ energy use and the smart management of operational aspects. In this respect, the monitoring of the real performance, through the acquisition of field measures, can provide multiple benefit to the smart management of complex energy systems. Within this project, a monitoring plan has been conceived and applied for achieving three main purposes: (i) characterizing the energy flows at different construction scale (building, parcel and district); (ii) providing data for the mechanical system performance optimization; (iii) improve the system management quality. The mechanical systems optimization includes the optimization of the cooling generation system energy efficiency, with a focus on the two chillers, distribution pumps, exploitation of ground-water as heat sink, and management of water supply and return temperatures, in order to guarantee thermal comfort and limit the heat loss/gain. To improve the quality of operational management and support the energy manager activities, the monitoring plan aims at detecting in real-time: (i) system failure alarms, (ii) temperatures and water flow rates operating off-range (e.g., the groundwater return temperature must be monitored to avoid injection of overheated water to the ground), (iii) the energy produced and consumed by the generation systems (chillers and district heating).

The measures required to meet the abovementioned goals were the breakdowns by the different energy carriers (electricity and heat) serving different mechanical systems: (i) heating and cooling system, (ii) domestic hot water, (iii) controlled mechanical ventilation, (iv) lighting and appliances and (v) photovoltaic solar field. For each construction scale (building, parcel and district) and each mechanical system, specific indicators have been set out and suitable meters for the detection of the desired parameters have been identified. For each indicator, we defined the related sensors and the quantity and quality of the parameters to be measured. In particular, we collected information on: (i) the number of required meters, (ii) the specific measured parameters, (iii) the parameters’ unit of measure, (iv) the owner of the acquired information, if suitable, (v) the accuracy of the meter, (vi) the resolution of the meter, (vii) the available frequency of the data acquisition, and (viii) the desired frequency of the data recording or transmission, (ix) the transmission data protocols. All these data have been collected in a matrix, where we listed and differentiate among the meters already available on field and those to be installed (Table 2). This document was needed to better understand the state of the art of the existing monitoring instruments to be integrated or updated according to the goals of the monitoring plan.

Table 2.

Monitoring matrix.

Furthermore, a tree diagram outlining all the acquired measures was produced. The diagram contains a breakdown of the information of all the measured parameters for: (i) the three monitoring goals; (ii) the type of performed analysis; (iii) the considered level of analysis, i.e., the construction scale or the specific investigated mechanical system; (iv) the monitoring target (i.e., heating system, cooling system, DHW system); (v) the monitoring indicator; and (vi) the equations to be implemented in the EMS platform. The diagrams of the three monitoring goals are provided as a Supplementary Materials to this publication (Figures S1–S3).

3.1. New Meters Installation and Data Acquisition System

Beside the identification of the parameters to be measured and acquired to reach the three fundamental goals of the district energy monitoring, the monitoring plan depicted the state of the art of the pre-existing instruments to be integrated with new meters for data measuring. Therefore, a gap analysis has been conducted starting from the information collected by the monitoring plan, aiming at identifying the additional meters to be installed to complete the data collection and the most suitable data acquisition and transmission architecture. Indeed, onsite inspections highlighted the existence of some local sensors and control systems, installed concurrently to the mechanical systems and buildings constructions. The main goal of such systems was to locally govern the mechanical systems operation and to control logics for meeting the energy requirement of each single building, therefore hampering a higher-level management that involve the distributed energy grid of the parcel and, eventually, the district. The practical implementation of the monitoring plan consisted, thus, in two main steps: (i) a market analysis to identify the new devices according to the requirements listed in the monitoring plan and (ii) the integration of the existing devices in the broader monitoring system, by building new infrastructures, including physical interconnection and informatic system, that enables the acquisition of the measured parameters. Then, a software application which enabled a structured data acquisition and transmission has been conceived and developed, to ensure the remotely accessibility and usability of the information in real time, for the purpose of the project. The communication protocol used are Modbus, M-Bus and analogic signals.

Hereafter a short overview of the existing and new devices is provided.

3.1.1. Cooling System

The cooling system consists of two main sections. The district cooling loop, interconnecting the entire district for the exploitation of groundwater, and the cooling power stations, where the electric chillers and the circulating pumps serving each parcel are located.

In the cooling power station under analysis, a pre-existing thermal meter allows to detect the thermal energy provided by the chillers (or the heat exchangers when the free cooling mode is used) to the seven buildings. New devices have been installed to measure the electric energy absorbed by the chillers, consisting in three-phase electric power meters connected to the power station’s electric panel. Additional thermal meters, consisting in two temperature sensors, one ultrasonic flow rate sensor and a local calculator have been installed to detect the thermal energy exchanged between each chiller and the buildings and between the district colling loop and each chiller. The circulating pumps’ electric consumption was detected by installing dedicated communication devices, which allowed to transfer the required parameters (i.e., electric energy, ON/OFF status, fluid flow rate, operational mode, alarms) via Modbus protocol. The installation of the new communication devices on the circulating pumps allowed the detection of some problems in the operational logic of the circulators, which followed standard on-off mode, even if they were equipped for working at different speed and flow rate. This problem has been solved during the new devices’ integration.

As regards the district cooling loop, pre-existing sensors allowed the detection of the temperatures of the thermal storage tank, at different heights, and the temperature of the water re-injected into the ground. Other devices allowed local measurement (i.e., only at the wells’ location) of the flow rate and pressure of the water extracted by each of the three extraction wells. Furthermore, the electric consumption of the cooling loop circulators, alarms and operation mode were collected by local control panels. These devices have required the installation of physical data transmission infrastructures, that allowed to transfer the measured parameters from the local devices to the data acquisition system.

3.1.2. Heating and DHW Systems

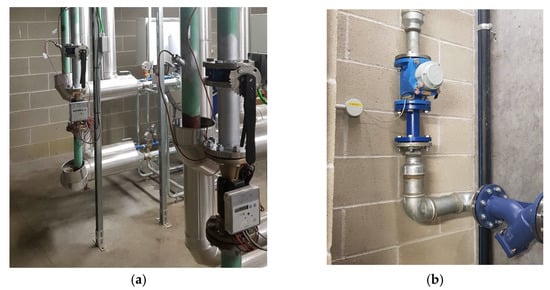

The parcel heating system is served by a district heating system that satisfies the energy needs for space hating and DHW, by means of heat exchangers. Each building is served by two dedicated heat exchangers, one for the space hating and one for the DHW. The thermal energy provided by each heat exchanger has been detected by installing thermal meters (consisting in two temperature sensors and one ultrasonic flow rate sensor) on the pipelines conveying the fluid from the heat exchanger to the distribution circuit (Figure 3). This system integrates very well with the data acquisition system, via M-Bus wire, and allows to limit the pressure drops.

Figure 3.

New installed measurements devices: (a) thermal meters installed on the heat exchanger (consisting in two temperature sensors, one ultrasonic flow rate sensor) and (b) volumetric flow rate meters, installed on the main water adduction pipe in each building.

Furthermore, the total amount of water taken from the public aqueduct and serving for DHW, additional apartment cooling and common spaces irrigation, has been measured via volumetric flow rate meters, which has been installed on the main water adduction pipe in each building (Figure 3).

3.1.3. Buildings Distribution Circuits

The heating, cooling and DHW energy flows within each building were already measured through pre-existing devices. New installations concerned the detection of the electric energy consumption of the circulating pumps on the distribution circuits. The values have been collected by electric power meters installed on the wiring circuit connecting each pump to the general electricity control panel.

3.1.4. Controlled Mechanical Ventilation (CMV)

Three temperature sensors were installed in the supply, extraction and expulsion ducts of each of the seven heat recovery units of the CMV system, each of which serves a single building. The temperature of the external air has been detected by one sensor for all the seven buildings. The air flow rate has been acquired, for each heat recovery units, via hot wire anemometers fixed in the middle of the extraction duct, since the supply duct did not guarantee the device installation requirements (the device must not be installed near turbulence points such as curves, section restrictions, filters). The electric consumptions have been detected by installing additional data transmission infrastructures, that allowed to transfer the measured parameters from the local electric control panels to the data acquisition system.

3.1.5. Photovoltaic System

Similarly to the CMV systems, the performance of the PV systems (produced electric energy, electric current and tension) have been measured by an dedicated detection and acquisition system. The PV is, nevertheless, made of quite small building-level sub-systems, used just to feed lifts and the lighting system in the staircases.

3.1.6. Lighting and Appliances

The electricity consumptions of the buildings have been acquired by using electric multimeters. These devices allow to monitor and acquire all the parameters available from the buildings’ general electricity control panels.

3.1.7. Single Apartment Mechanical Systems and Indoor Comfort Conditions

Within this study the parameters related to the heating and cooling systems, DHW and indoor comfort conditions have been monitored for fifteen apartments. They include thermal meters measuring the energy delivered to each apartment, both in cooling and in heating mode; a flow-rate meter for domestic hot- and cold-water consumptions; indoor set point temperature; indoor temperature and indoor relative humidity. A pre-existing measuring infrastructure was present and managed by the system’s manufacturer. At this scale, thus, the data acquisition required a REST-API interface with manufacturer database. The electric energy consumption characterization for each apartment required the installation of dedicated multimeters.

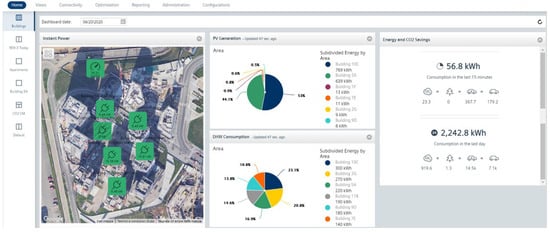

3.2. Energy Management System

The EMS software has been conceived to facilitate the data analysis based on the three aforementioned goals of (i) characterizing the energy flows; (ii) mechanical systems operational optimization; (iii) operational management. The EMS allows the data visualization according to the monitoring plan or to the geographical devices’ localization. Furthermore, customized reports can be set, to show whichever data the energy manager wants to compare, allowing the visualization at the desired time resolution (it is possible to visualize raw data and data aggregated from hourly to yearly time series). It is also possible to download the data in several file format. Figure 4 shows an example of the EMS data visualization interface. To enable the EMS development, the data registered by new and existing devices have been collected on local databases which are interrogated through REST-API protocol to be transferred on the cloud. This required the development of a dedicated software which enables to interrogate the local database in real-time and make the data available in the EMS platform.

Figure 4.

EMS data visualization interface. Cooling energy delivered to the buildings.

4. Modeling

4.1. Buildings’ Modeling

Table 3 summarizes the geometrical characteristics of the seven buildings under analysis, which differs in volume, heights, and window to wall ratio (WWR). The buildings differ also in envelope technologies. The thermal transmittances of the envelope components of each building are summarized in Table 4.

Table 3.

Geometrical characteristics of the buildings on parcel R09/3 [].

Table 4.

Thermal transmittances of envelope technologies [W/(m2K)]. M1: external wall; M2: external wall adjacent to concrete structure; M5: internal wall between apartments; M6: internal wall adjacent to unheated spaces; P1: floor between apartments; P2: floor slab between apartments and unheated spaces; S4: roof. [].

A dynamic model of the seven buildings has been developed using TRNSYS 18 []. Firstly, the modeling concerned the buildings’ energy needs for space heating and cooling, considering buildings’ geometrical and envelope characteristics. Then, the buildings’ models have been coupled with a detailed modeling of the HVAC (Heating Ventilation and Air-Conditioning) systems (see Section 4.2). The developing of a well-managed distributed energy resources and their correct interaction with the build environment strongly rely on the reliable evaluation of daily energy use of buildings, at high spatial and temporal resolution [,]. However, when it comes to the assessment of a large portion of the built environment, at neighborhood or city level, the implementation of detailed physic-based models is usually complex and time consuming. Therefore, at larger scale, simplified “bottom-up” approaches or statistical “top-down” models are commonly used []. The envelope modeling approach in this study was meant to find a compromise between detailed modeling and the required computational effort. The model allowed to characterize the energy needs for space heating and cooling starting from the apartment level. Therefore, a reference floor has been considered, including all the most frequent apartment typologies (two, three and four-rooms apartments (see Table 1), simulated for all the seven existing buildings at different heights, including lowest floor (first floor), intermediate and top floor. Each building has been simulated considering its real position on the parcel, and the effect of other building and surrounding shadows have been considered. The model preserves the specific envelope technologies of each building. The lowest apartment ceiling and the upper apartment floor have been considered as adiabatic since they face apartments with similar characteristics. The floor slab of the lowest apartments faces the ground floor including the entrance hall, that has been considered as an unheated space. The intermediate apartments’ floors and ceilings present adiabatic conditions. The upper apartment ceiling and all the vertical walls face the external environment.

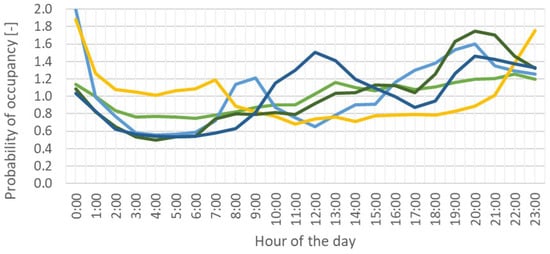

Occupant Behavior

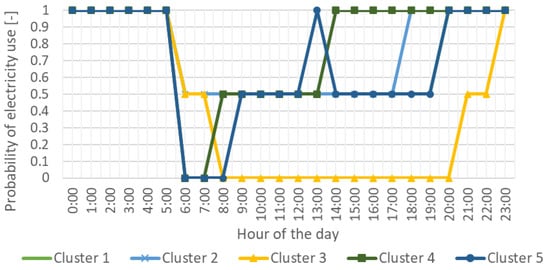

No building or city uses energy, but people do. Therefore, it is crucial to model correctly occupant behavior in building simulations, notably for the energy assessment of high efficiency buildings, whose behavior is highly depending on the users [,]. In this study the occupant behavior has been described by using stochastic schedules of occupancy and occupant-related electric energy use by lights and appliances have been used. The schedules have been developed using a data driven procedure, that enabled the identification of five clusters of daily probability of occurrence for the occupancy and five clusters of daily probability of occurrence for the appliances’ and lights’ electric energy use (Figure 5), by means of machine learning techniques applied on metered data of a residential building located in Milan []. The metered data are referred to a residential building which presents similar characteristics, apartments typologies and location (a suburban area of Milan) with the buildings hereby analyzed. The clusters, consisting in a daily hourly profile of the probability of occurrence of defined occupancy or energy uses, have been combined randomly to generate fifteen yearly annual schedules to be assigned to the modeled apartments. The profiles have then been multiplied for the average value of electric energy use and the number of people for each apartment typology. These values have been derived from the same database used for the profiles generation (Table 5) [].

Figure 5.

From the top: the five clusters of daily probability of occurrence for the appliances’ and lights’ electric energy use and the five clusters of daily probability of occurrence for the occupancy [].

Table 5.

Number of people for apartment typology and maximum mean value of electric energy uses.

4.2. HVAC System Modeling

The simulation process consists of two steps performed using TRNSYS 18; firstly, the apartments’ systems are simulated and then the district network is analyzed. In the first phase, each apartment is modeled as a thermal zone in the Type 56 (TRNBuild—multizone building model) interacting with other types which model the HVAC components. The load profiles obtained for all the buildings have been then used as input for the district network. The simulations have been run with one-hour timestep.

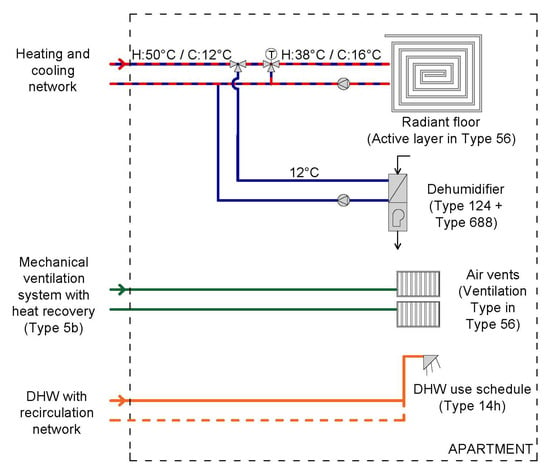

4.2.1. Apartment System Layout

A general scheme of the system layout is reported in Figure 6. Each apartment is equipped with radiant floor panels for both heating and cooling, moreover a dehumidifier is installed for the humidity control during the cooling mode. Both the systems are fed by a building centralized network, which provides also the DHW. In addition, a centralized mechanical ventilation system guarantees constant air change rates to each apartment.

Figure 6.

Scheme of the apartment system layout.

The radiant floor system and the dehumidifier, with their own control subsystems, have been modeled for each apartment, while the mechanical ventilation system and the DHW profiles have been managed at building level.

- Radiant floor panels

Radiant floor panels have been modeled in TRNBuild as “Active layers” placed in the floor stratigraphy, including the data related to the pipe’s characteristics (spacing 0.1 m, outside diameter 0.02 m, wall thickness 0.002 m, wall conductivity 0.35 W/m/K). In function of the number of loops (Table 6), the pipe length is calculated and the software evaluates the heat exchange based on the inlet flow rate and temperature. In each apartment, the Active layers are directly connected to the heating and cooling network in terms of inlet and outlet water flow rate and temperature.

Table 6.

Radiant floor specifications for the thermal zones.

The room thermostat has been modeled as a differential controller with hysteresis (Type 2) to control the zone air temperature according to the seasonal set point temperature profiles (in the heating season daytime setpoint at 20 °C and night-time setback 16 °C, in the cooling season daytime setpoint at 26 °C) with a dead-band temperature difference fixed at ±1 °C. The ON/OFF signal regulates the single speed pump (Type 114) of the water circuit. In addition, the circuit is equipped with a three-way valve which regulates the flow rates to keep the inlet water temperature at the fixed value (38 °C in the heating season and 16 °C in the cooling one).

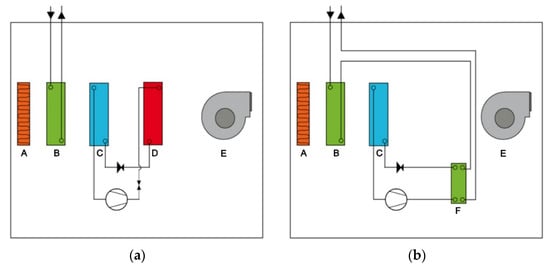

- Dehumidifier

A dehumidifier REHOM 20L/G 1.3 is installed in each apartment. As shown in the functioning schemes in Figure 7, the air taken from the zone undergoes a pre-cooling by the cooling coil (B), fed by the cold-water circuit at 12 °C, and then is dehumidified and cooled by the evaporator (C). The two condensers allow a double functioning: the heat of condensation can be used for the air post-heating in the air-cooled condenser (D) or discarded through the water-cooled condenser (F).

Figure 7.

Functioning scheme of the dehumidifier REHOM 20L/G 1.3 (A = filter, B = pre-cooling coil, C = evaporator, D = air cooled condenser, E = fan, F = water cooled condenser). (a) mode with air condenser. (b) mode with water condenser.

The pre-cooling coil has been modeled with Type 124 (Simple Cooling Coil—Partially Wet), following the manufacturer’s datasheet. Type 688 (Unitary Dehumidifier) has been used for the refrigeration cycle; the type input “Heat Rejection Indicator” allows to pass form the air cooled condenser mode to the water cooled condenser mode, when the zone temperature is higher than 1 °C compared to the setpoint. The controller Type 2 maintains the zone humidity between 10.5 e 12 gv/kgda during the summer period, toggling the pump (Type 114) of the cold-water circuit and the fan of the dehumidifier (in Type 688).

- Mechanical ventilation system

In each apartment an air change rate of 0.6 vol/h is provided by the mechanical ventilation system. This is equipped with a heat recovery device which allows to pre-heat or pre-cool the external air, recovering the heat from the exhaust air. This device is modeled as a counter-flow heat exchanger (Type 5b) calibrated on the commercial product’s performance corresponding to a heat exchange efficiency equal to 88.5%. The air temperature, humidity and flow rate are provided to the thermal zones as ventilation characteristics in the TRNBuild model.

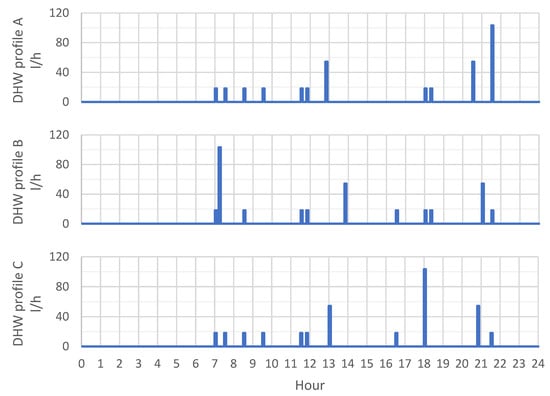

- Domestic hot water production

The DHW uses have been evaluated in a separated simulation with a timestep of 0.1 h, using three daily use profiles (Figure 8) corresponding to 36 L/day/person of DHW at 60 °C. These have been combined in stochastic manner with the annual occupancy profiles of each apartment. The DHW consumptions are obtained considering 15 °C as main water temperature and 55 °C as the actual temperature of the water delivered to each apartment. Moreover, the heat losses from recirculation pipes (Type 31) have been evaluated, in order to obtain the total energy consumed by the entire building for the DHW production.

Figure 8.

DHW use schedule (water at 60 °C, timestep 0.1 h).

4.2.2. District Systems Layout

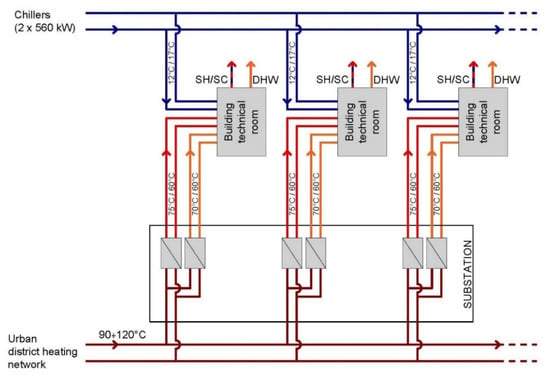

The urban district heating network supplies heat to three substations, where three couples of heat exchangers (one for the SH and one for DHW) are linked to the buildings’ technical room. These last are also connected to the cooling network of the district which is fed by two chillers. Figure 9 schematically reports a portion of the district network.

Figure 9.

Scheme of the district systems layout.

The energy load files obtained from the simulations at building level have been used to evaluate the energy consumptions at district level.

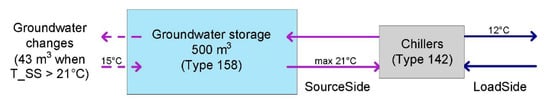

For the heating internal distribution network and heat exchangers, an average value of thermal losses has been estimated equal to 10% of the users’ energy demand.

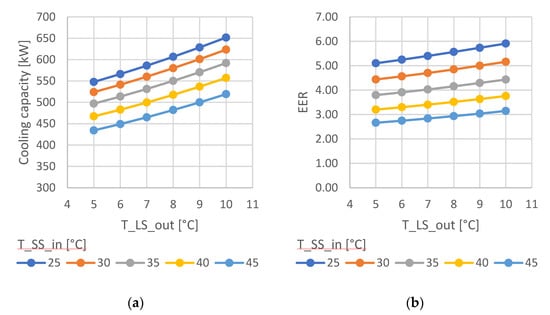

The district cooling network is fed by two groundwater source chillers CLIVET WSH-XSC 180F installed in parallel. Their cooling capacity is 560 kW/each at nominal conditions with load-side outlet temperature (T_LS_out) of 7 °C and source-side inlet (T_SS_in) at 30 °C. Groundwater is collected in a 500 m3 tank that periodically is partially depleted and refilled to maintain the temperature at the chiller inlet below 21 °C. The system scheme is reported in Figure 10. The tank has been modeled with Type 158; when the temperature at the chiller source side inlet rises above 21 °C a water volume of 43 m3 is changed. The two chillers have been modeled by Type 142 (water-cooled chiller), according to the performance maps derived by the manufacturer’s datasheet. The performance maps are two (Figure 11), in the first one the dependent variable is the cooling capacity and in the other one it is the EER (Energy Efficiency Ratio), while the independent variables are in both the cases the source side (SS) and load side (LS) water temperatures.

Figure 10.

Groundwater cooling system modeling scheme.

Figure 11.

Chiller CLIVET WSH-XSC 180F performance map. (a) Cooling capacity; (b) Energy Efficiency Ratio (EER).

Table 7 reports the primary energy (PE) conversion factors for the district heating system of West Milan and for the electricity.

Table 7.

Primary energy conversion factors for district heating in West Milan (source: A2A Calore e Servizi S.r.l. []) and for electricity (source: Lombardy regional regulation DDUO 2456/2017 []).

5. Results and Discussion

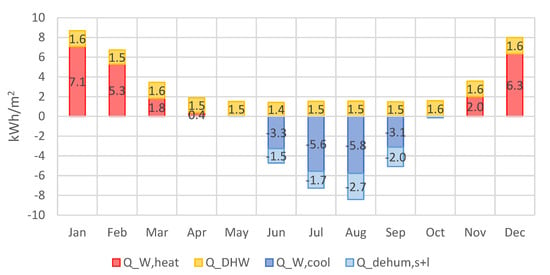

5.1. Simulation Results

The monthly values of the energy supplied to all the apartments of the parcel under analysis are represented in Figure 12. The space heating energy (Q_W,heat) reaches the annual value of 23 kWh/m2/year (653 MWh/year), while the DHW production requires 18.5 kWh/m2/year (523 MWh/year). For the summer system operation, Q_W,cool represents the cooling energy supplied by the water systems (i.e., the radiant floor and the pre-cooling and condensing coils of the dehumidifiers), while Q_dehum,s+l is the cooling and dehumidification effect performed by the dehumidifiers’ refrigeration cycle. The summer load (both sensible and latent) is met by the combined action of these two systems. Q_W,cool is equal to 17.8 kWh/m2/year (505 MWh/year), while Q_dehum,s+l amounts to 7.9 kWh/m2/year (223 MWh/year). These results are consistent with benchmark energy needs of newly constructed buildings in compliance with actual energy saving regulations. There is no sharp predominance in the annual values for each use: 34% of the thermal energy needs are for space heating, 38% for space cooling, and 28% for DHW production. The latter value remarks that the DHW production gets importance in the framework of highly efficient buildings.

Figure 12.

Monthly energy for heating, DHW and cooling supplied to the users of the parcel.

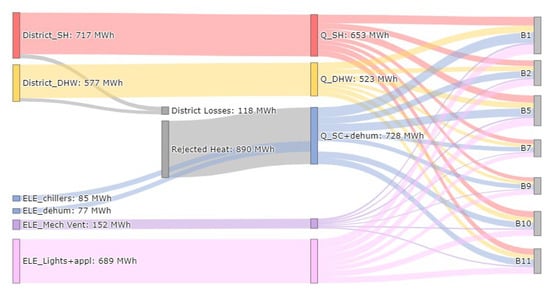

In Figure 13, a detailed representation of the energy fluxes in the parcel is reported via a Sankey diagram. According to the definitions of the European standard EN ISO 52000-1 [], the energy fluxes go from the delivered energy, whose energy carrier is specified as “District” (for the urban district heating) and “ELE” (for the electricity import), to the end users’ needs (grouped into the buildings “B#”). From the district heating network 1294 MWh/year are required; 55% is used for space heating (25.3 kWh/m2/year) and the rest for domestic hot water production (20.3 kWh/m2/year). The heat losses of the heating network in the parcel are also displayed, accounting for 4.2 kWh/m2/year, around 9% of the district delivered energy for the space heating and DHW production, thus the seasonal efficiency of the parcel network stands at 91%. The electrical uses for lights and appliances installed in each apartment are about 70% of total electrical consumptions (24.3 kWh/m2/year); whereas, among the electrical consumptions related to HVAC systems, about 50% is due to mechanical ventilation systems (5.4 kWh/m2/year). To guarantee the summer thermo-hygrometric comfort, a total electrical energy of 5.7 kWh/m2/year is required, shared between the consumption of the dehumidifiers of each apartment (2.7 kWh/m2/year with a seasonal EER value of 2.90) and the chillers (3.0 kWh/m2/year). For the cooling generation, in addition to the electric energy supplied and the cooling effect produced, the heat rejection is specified as the sum of the condensation heat of the dehumidifiers and the heat rejected by the chillers through the groundwater wells.

Figure 13.

Sankey diagram of the energy flows in the parcel.

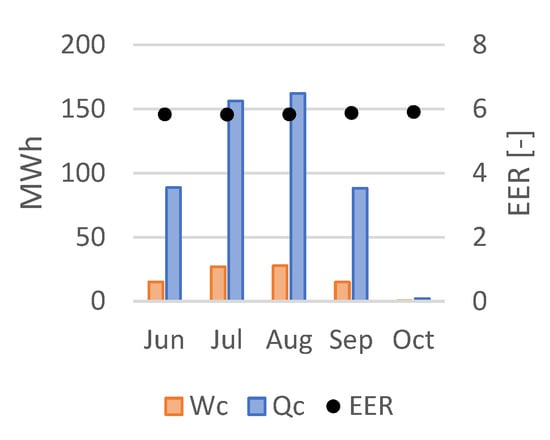

For the chillers, Figure 14 depicts the monthly values of the cooling energy supplied to the network (Qc), the electric energy consumptions (Wc) and the average efficiency EER. Yearly, the electricity consumptions amount to 85 MWh, with seasonal EER equal to 5.84.

Figure 14.

Monthly values of the chillers’ cooling energy (Qc), electric consumptions (Wc) and average efficiency ratio (EER).

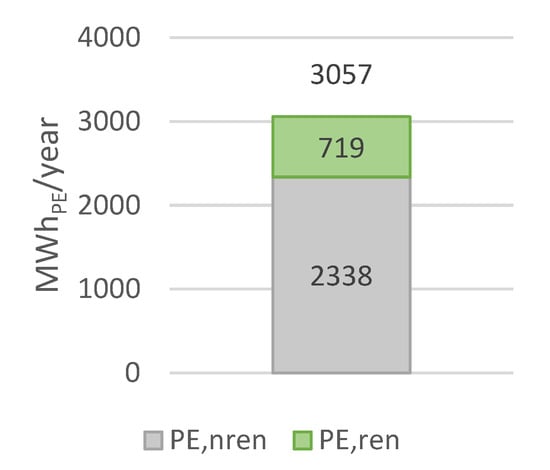

Figure 15 shows the primary energy consumptions of the entire parcel; the total PE is equal to 3057 MWh/year (107.6 kWh/m2/year). The renewable share is 24% (25.3 kWh/m2/year).

Figure 15.

Annual primary energy for the thermal and electrical use of block R9.

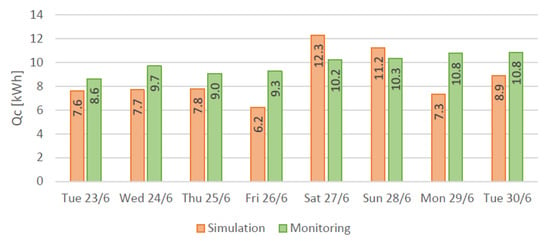

5.2. Early Monitoring Results

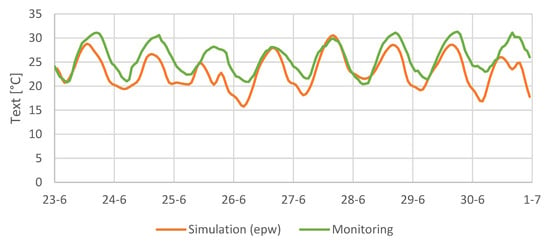

At the moment, the available monitoring data are limited to a short period at the end of June 2020. Figure 16 summarizes the daily values, from June 23rd to June 30th, of the cooling energy produced by the two chillers, and compares the monitoring data and the dynamic simulation results. The difference between the two series spans between +17% and −49%. From an overall analysis of the data, it can be noticed that some modeling assumptions can be among the reasons of those discrepancies; in particular, during the weekend the cooling energy need is overestimated by the model (+17% and +8%), contrary to weekdays (between −13% and −49%). In addition, the external weather conditions definitely play an important role, as highlighted by Figure 17, where the trend of the actual external air temperature is plotted against the weather file used in the simulations (“ITA_Milano-Linate.160800_IGDG.epw” []). On average the actual temperatures are 2.8 °C higher than the typical year represented in the epw file, used by simulations.

Figure 16.

Comparison between simulation results and monitoring data of the cooling energy supplied to the network by both the chillers (Qc), in the period 23–30 June 2020.

Figure 17.

Comparison between simulation epw weather file Milano-Linate 160800 (IGDG) and actual weather conditions in the period 23–30 June 2020.

6. Conclusions

The paper reported the energy analysis of an existing residential neighborhood made of seven tower buildings in the suburbs of Milan. The work has been performed to provide a better monitoring and management of a complex neighborhood network that is undergoing a rapid expansion and soon will include much more buildings and functions.

A detailed monitoring plan has been developed, and deployed on site, by integrating existing devices and installing new ones. An EMS has been designed to provide fault detection, optimization, and remote control. To support all of these activities and to further guide the district in its evolution, a dynamic energy model has been developed with a high level of detail. Early monitoring results show a good agreement with the simulation ones; however, a further calibration of the model is required, as soon as the monitoring data flow will be finalized, and enough data will be gathered to perform it properly. The small discrepancy between simulation output and early monitoring data, may depend on occupation schedules; in particular, the COVID-19 pandemic, substantially changed occupation and energy schedules in residential buildings during 2020, as function of the spreading of smart-working models. This further highlights the importance of occupation and energy use patterns modeling for proper simulation and operational management of buildings and energy networks/grids.

Results refer, at the moment, just to the case study and the specific location; some hints from the process are nevertheless available and might inform similar neighborhood energy modeling and monitoring projects, where the proposed methodological approach may be replicated:

- Complex neighborhood/district energy networks should always be built together with an EMS to provide remote control. System faults are highly probable, and optimization is needed from the first operational day;

- Space heating and DHW production are relevant uses (respectively 34% and 28% of the thermal energy needs), and geothermal energy might be used to cover them with higher efficiencies;

- The use of centralized water-source cooling systems should be promoted under the specific boundary conditions, due to the high efficiency (EER equal to 5.84) compared to individual air-source systems;

- Lights and appliances are a large share of the electricity use (about 70% of total electrical consumptions), a higher occupant engagement should, thus, be promoted;

- In order to reach a level of decarbonization in line with the Municipality’s targets, the neighborhood needs to substantially increase its share of renewable energy.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/en14123716/s1, Figure S1: Energy flows, Figure S2: System optimization, Figure S3: System management quality.

Author Contributions

Conceptualization, F.C., R.S., M.P. and P.C.; methodology, F.C., R.S., M.P. and P.C.; software, R.S., M.P. and P.C.; formal analysis, F.C., R.S., M.P. and P.C.; writing—original draft preparation, F.C., R.S., M.P. and P.C.; writing—review and editing, F.C., R.S., M.P., P.C., and S.F.; visualization, M.P., P.C., and S.F.; supervision, F.C. and M.M.; project administration, F.C.; funding acquisition, F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by REGIONE LOMBARDIA, grant number 379365, project Sustainable Lifestyle: Merlata Smart Grid.

Acknowledgments

The authors wish to acknowledge Euromilano, Siemens, Future Energy and Eng. Ivan Roncelli for the support and shared work.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- UN-Habitat Energy. UN-Habitat. Available online: https://new.unhabitat.org/topic/energy (accessed on 26 March 2021).

- Causone, F.; Sangalli, A.; Pagliano, L.; Carlucci, S. Assessing energy performance of smart cities. Build. Serv. Eng. Res. Technol. 2018, 39, 99–116. [Google Scholar] [CrossRef] [Green Version]

- IEA European Union 2020—Analysis—IEA. Available online: https://www.iea.org/reports/european-union-2020 (accessed on 26 March 2021).

- European Commission Energy Performance of Buildings Directive. Energy. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en?redir=1 (accessed on 26 March 2021).

- European Commission. New Rules for Greener and Smarter Buildings will Increase Quality of Life for All Europeans. Available online: https://ec.europa.eu/info/news/new-rules-greener-and-smarter-buildings-will-increase-quality-life-all-europeans-2019-apr-15_en (accessed on 26 March 2021).

- Park, K.; Kim, Y.; Kim, S.; Kim, K.; Lee, W.; Park, H. Building Energy Management System based on Smart Grid. In Proceedings of the 2011 IEEE 33rd International Telecommunications Energy Conference (INTELEC), Amsterdam, The Netherlands, 9–13 October 2011; pp. 1–4. [Google Scholar]

- Zucker, G.; Judex, F.; Blöchle, M.; Köstl, M.; Widl, E.; Hauer, S.; Bres, A.; Zeilinger, J. A new method for optimizing operation of large neighborhoods of buildings using thermal simulation. Energy Build. 2016, 125, 153–160. [Google Scholar] [CrossRef]

- Aprile, M.; Scoccia, R.; Dénarié, A.; Kiss, P.; Dombrovszky, M.; Gwerder, D.; Schuetz, P.; Elguezabal, P.; Arregi, B. District power-to-heat/cool complemented by sewage heat recovery. Energies 2019, 12, 364. [Google Scholar] [CrossRef] [Green Version]

- Dénarié, A.; Muscherà, M.; Calderoni, M.; Motta, M. Industrial excess heat recovery in district heating: Data assessment methodology and application to a real case study in Milano, Italy. Energy 2019, 166, 170–182. [Google Scholar] [CrossRef]

- King, J.C. Perry Smart Buildings: Using Smart Technology to Save Energy in Existing Buildings. Am. Counc. Energy-Efficient Econ. 2017, 1–46. [Google Scholar]

- Wurtz, F.; Delinchant, B. “Smart buildings” integrated in “smart grids”: A key challenge for the energy transition by using physical models and optimization with a “human-in-the-loop” approach. Comptes Rendus Phys. 2017, 18, 428–444. [Google Scholar] [CrossRef]

- Kim, H.; Choi, H.; Kang, H.; An, J.; Yeom, S.; Hong, T. A systematic review of the smart energy conservation system: From smart homes to sustainable smart cities. Renew. Sustain. Energy Rev. 2021, 140, 110755. [Google Scholar] [CrossRef]

- Causone, F.; Tatti, A.; Pietrobon, M.; Zanghirella, F.; Pagliano, L. Yearly operational performance of a nZEB in the Mediterranean climate. Energy Build. 2019, 198, 243–260. [Google Scholar] [CrossRef] [Green Version]

- Anda, M.; Temmen, J. Smart metering for residential energy efficiency: The use of community based social marketing for behavioural change and smart grid introduction. Renew. Energy 2014, 67, 119–127. [Google Scholar] [CrossRef]

- Paetz, A.G.; Dütschke, E.; Fichtner, W. Smart Homes as a Means to Sustainable Energy Consumption: A Study of Consumer Perceptions. J. Consum. Policy 2012, 35, 23–41. [Google Scholar] [CrossRef]

- Sirombo, E.; Filippi, M.; Catalano, A.; Sica, A. Building monitoring system in a large social housing intervention in Northern Italy. Energy Procedia 2017, 140, 386–397. [Google Scholar] [CrossRef]

- Lobaccaro, G.; Carlucci, S.; Löfström, E. A Review of Systems and Technologies for Smart Homes and Smart Grids. Energies 2016, 9, 348. [Google Scholar] [CrossRef] [Green Version]

- Shakeri, M.; Pasupuleti, J.; Amin, N.; Rokonuzzaman, M.; Low, F.W.; Yaw, C.T.; Asim, N.; Samsudin, N.A.; Tiong, S.K.; Hen, C.K.; et al. An Overview of the Building Energy Management System Considering the Demand Response Programs, Smart Strategies and Smart Grid. Energies 2020, 13, 3299. [Google Scholar] [CrossRef]

- Fonseca, J.A.; Nguyen, T.-A.; Schlueter, A.; Marechal, F. City Energy Analyst (CEA): Integrated framework for analysis and optimization of building energy systems in neighborhoods and city districts. Energy Build. 2016, 113, 202–226. [Google Scholar] [CrossRef]

- Hu, M.; Xiao, F.; Wang, S. Neighborhood-level coordination and negotiation techniques for managing demand-side flexibility in residential microgrids. Renew. Sustain. Energy Rev. 2021, 135, 110248. [Google Scholar] [CrossRef]

- Ferrando, M.; Causone, F. An Overview Of Urban Building Energy Modelling (UBEM) Tools. In Proceedings of the Building Simulation 2019: 16th Conference of IBPSA, Rome, Italy, 2–4 September 2020; Volume 16, pp. 3452–3459. [Google Scholar]

- Ferrando, M.; Causone, F.; Hong, T.; Chen, Y. Urban building energy modeling (UBEM) tools: A state-of-the-art review of bottom-up physics-based approaches. Sustain. Cities Soc. 2020, 62, 102408. [Google Scholar] [CrossRef]

- Causone, F.; Pelle, M. Building stock simulation to support the development of a district multi-energy grid. E3S Web Conf. 2019, 111, 6027. [Google Scholar] [CrossRef]

- Carnieletto, L.; Ferrando, M.; Teso, L.; Sun, K.; Zhang, W.; Causone, F.; Romagnoni, P.; Zarrella, A.; Hong, T. Italian prototype building models for urban scale building performance simulation. Build. Environ. 2021, 192, 107590. [Google Scholar] [CrossRef]

- Tuballa, M.L.; Abundo, M.L. A review of the development of Smart Grid technologies. Renew. Sustain. Energy Rev. 2016, 59, 710–725. [Google Scholar] [CrossRef]

- Ajaz, W.; Bernell, D. California’s adoption of microgrids: A tale of symbiotic regimes and energy transitions. Renew. Sustain. Energy Rev. 2021, 138, 110568. [Google Scholar] [CrossRef]

- Mostafa, M.H.; Abdel Aleem, S.H.E.; Ali, S.G.; Abdelaziz, A.Y. Energy-management solutions for microgrids. In Distributed Energy Resources in Microgrids: Integration, Challenges and Optimization; Elsevier: Amsterdam, The Netherlands, 2019; pp. 483–515. ISBN 9780128177747. [Google Scholar]

- European University Association. Energy Transition and the Future of Energy Research, Innovation and Education: An Action Agenda for European Universities. Int. J. Prod. Res. 2017, 53, 59. [Google Scholar]

- Conci, M.; Schneider, J. A District Approach to Building Renovation for the Integral Energy Redevelopment of Existing Residential Areas. Sustainability 2017, 9, 747. [Google Scholar] [CrossRef] [Green Version]

- Ipakchi, A.; Albuyeh, F. Grid of the future. IEEE Power Energy Mag. 2009, 7, 52–62. [Google Scholar] [CrossRef]

- Mattoni, B.; Nardecchia, F.; Bisegna, F. Towards the development of a smart district: The application of an holistic planning approach. Sustain. Cities Soc. 2019, 48, 101570. [Google Scholar] [CrossRef]

- Allegrini, J.; Orehounig, K.; Mavromatidis, G.; Ruesch, F.; Dorer, V.; Evins, R. A review of modelling approaches and tools for the simulation of district-scale energy systems. Renew. Sustain. Energy Rev. 2015, 52, 1391–1404. [Google Scholar] [CrossRef]

- Schweiger, G.; Heimrath, R.; Falay, B.; O’Donovan, K.; Nageler, P.; Pertschy, R.; Engel, G.; Streicher, W.; Leusbrock, I. District energy systems: Modelling paradigms and general-purpose tools. Energy 2018, 164, 1326–1340. [Google Scholar] [CrossRef]

- Salvia, G.; Morello, E.; Rotondo, F.; Sangalli, A.; Causone, F.; Erba, S.; Pagliano, L. Performance gap and occupant behavior in building retrofit: Focus on dynamics of change and continuity in the practice of indoor heating. Sustainability 2020, 12, 5820. [Google Scholar] [CrossRef]

- Kampelis, N.; Papayiannis, G.I.; Kolokotsa, D.; Galanis, G.N.; Isidori, D.; Cristalli, C.; Yannacopoulos, A.N. An integrated energy simulation model for buildings. Energies 2020, 13, 1170. [Google Scholar] [CrossRef] [Green Version]

- Angelotti, A.; Ballabio, M.; Mazzarella, L.; Cornaro, C.; Parente, G.; Frasca, F.; Prada, A.; Baggio, P.; Ballarini, I.; De Luca, G.; et al. Dynamic Simulation of existing buildings: Considerations on the Model Calibration. In Proceedings of the Building Simulation 2019: 16th Conference of IBPSA, Rome, Italy, 2–4 September 2020; Volume 16, pp. 4165–4172. [Google Scholar]

- Fabrizio, E.; Monetti, V. Methodologies and Advancements in the Calibration of Building Energy Models. Energies 2015, 8, 2548–2574. [Google Scholar] [CrossRef] [Green Version]

- The Solar Energy Laboratory—University of Wisconsin-Madison TRNSYS 18—A TRaNsient SYstem Simulation program. Available online: https://sel.me.wisc.edu/trnsys/ (accessed on 31 March 2021).

- Causone, F.; Sangalli, A.; Pagliano, L.; Carlucci, S. An Exergy Analysis for Milano Smart City. Energy Procedia 2017, 111, 867–876. [Google Scholar] [CrossRef] [Green Version]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart energy and smart energy systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Caputo, P.; Costa, G.; Ferrari, S. A supporting method for defining energy strategies in the building sector at urban scale. Energy Policy 2013, 55, 261–270. [Google Scholar] [CrossRef]

- Guerra Santin, O.; Itard, L.; Visscher, H. The effect of occupancy and building characteristics on energy use for space and water heating in Dutch residential stock. Energy Build. 2009, 41, 1223–1232. [Google Scholar] [CrossRef]

- Causone, F.; Carlucci, S.; Ferrando, M.; Marchenko, A.; Erba, S. A data-driven procedure to model occupancy and occupant-related electric load profiles in residential buildings for energy simulation. Energy Build. 2019, 202, 109342. [Google Scholar] [CrossRef]

- A2A Calore e Servizi S.r.l. Certificazione Energetica in Presenza di Teleriscaldamento (Milano Ovest). 2018. Available online: http://www.a2acaloreservizi.eu/home/cms/a2a_caloreservizi/impianti_reti/area_milano/.

- Regione Lombardia. DDUO 2456/2017; Associazione Nazionale per l’Isolamento Termico e Acustico: Milano, Italy, 2017. [Google Scholar]

- International Organisation for Standardisation. EN ISO 52000-1:2017 Energy Performance of Buildings—Overarching EPB Assessment Part1: General Framework and Procedures; International Organisation for Standardisation: Geneva, Switzerland, 2017. [Google Scholar]

- Weather Data by Location. EnergyPlus. Available online: https://energyplus.net/weather-location/europe_wmo_region_6/ITA//ITA_Milano-Linate.160800_IGDG (accessed on 31 March 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).