The numerical calculations, applying the full scale floater and respective turbine, were carried out using OpenFAST v2.3.0 [

36,

37]. To model the NREL 5-MW turbine the publicly available OpenFAST model was used for the simulations presented in this paper [

28]. Nevertheless, different pre-processing steps were mandatory in order to adapt the OpenFAST model to comply with the physical model tested in Nantes. As described in

Section 2.1, some of the properties of the turbine differ from the exact scaled values due to scaling issues. This is why the respective properties of the NREL 5-MW as implemented in OpenFAST have been updated to meet with the characteristics of the scaled model. The

GICON®-TLP was implemented with its dimensions as described in [

14,

30]. Some changes were necessary to account for the correct damping and mooring implementation. All changes with regard to the turbine and the substructure will be elucidated in the following. All values given in this and the following sections are for the full scale floater except those mentioned.

3.2. Substructure and Hydrodynamics

HydroDyn offers different approaches for the calculation of the hydrodynamic loads on fixed and floating substructures for wind turbines. The strip theory approach which is also known as Morison-Theory approach is applicable to members which can be considered as “hydraulic transparent”. Such members have a diameter to deep water wave length (D/L) ratio of less than 0.05. For such slender members, diffraction, radiation and dissipation are considered to be negligible [

38]. For the

GICON®-TLP, with its 14 m in diameter buoyancy bodies, hydraulic transparency cannot be assumed for many sea states. For the decay tests on the other hand, strip theory might be considered as applicable as the influence of diffraction and radiation are expected to be small. However, for the sake of consistency, the model described in this paper implements another available approach based on potential flow theory and an augmentation to account for additional drag loads [

39]. This approach was chosen, having in mind that the results of combined wind and wave tests will also be compared with those from OpenFAST in the near future. Considering the further evaluation, it is found to be reasonable to apply the same approach for the hydrodynamic modelling in OpenFAST for decay tests as well as for different sea states, where the potential flow approach is expected to deliver more reasonable results.

By use of ANSYS AQWA, the potential flow solution for different wave frequencies and directions (from –

to

with 34 intermediates) has been computed for the substructure in the frequency domain. In this computation, only the hull (the wetted surface) of the floating substructure without moorings, anchor or wind turbine was considered. By use of the Matlab Tool AQWA2WAMIT, the results of the AQWA computation were converted to the WAMIT file format, which is expected by HydroDyn [

39].

As described above, a hybrid approach will take the viscous drag effects from the strip theory solution into account as this is not otherwise considered in the potential flow solution. Determining respective drag coefficients

for the different members depends on the Reynolds number Re and the Keulegan-Carpenter number (KC). This means that for different flow regimes like different waves and currents, drag coefficients would vary. Due to suggested drag and inertia coefficient values by the DNVGL,

can be considered as independent from

for values below 10 [

27]. For the decay tests without waves and current

is below 10.

is calculated as per Equation (

6).

Herein

V is the maximum amplitude of the flow velocity of the oscillating body as presented in Table 3,

T the period of the oscillation, as derived from the model tests and

L, is a characteristic length. It is represented by the pile diameter of 3 m respectively the buoyancy bodies diameter of 14 m. The arising

values are shown in

Table 2.

This is especially critical for varying sea states such as irregular waves and unsteady currents. For the decay tests, however, Re is considered constant and was calculated as per Equation (

7).

Herein,

u is the current velocity,

D is the pile diameter and

is the fluid kinematic viscosity. It was estimated that the water temperature is 15

C. For this temperature the kinematic viscosity for fresh water is considered to equal

m

2/s [

40].

u has been obtained for surge and sway decay tests directly while the rotating velocity about the z-axis for yaw has been calculated based on the angular velocity. The respective Re have been calculated accordingly. The results are shown in

Table 3. The pile diameter for all tubes (vertical and horizontal) is three and for the buoyancy bodies 14 m.

For cylinders, different drag coefficients are suggested. For Re =

DNVGL recommends

[

40]. However, as worked out in

Table 3 Re is beyond

for the decay tests. Clauss et al. suggest a more sophisticated approach, which might be less conservative but closer to physical behavior. He suggests to assume

for Re

and

for Re >

. For

, the transitional phase, a range from 0.7 to 1.2 is suggested for

[

41]. This approach has been adopted for surge and sway decay. For yaw, the horizontal tubes are not subjected perpendicular to the flow, and it is not sure if a coefficient of

is correct. Though, for the scope of this paper, this difficulty will be regarded as of minor influence and

is assumed also for the horizontal tubes for yaw decay. Determining the velocities for heave roll and pitch is, again due to the high stiffness of the mooring setup, difficult as the motions are small. However, the velocity for these decay tests are expected, due to the dominating influence of the moorings, to be rather higher than lower compared to those for surge, sway and yaw. Thus,

seems also a reasonable value for heave, roll and pitch.

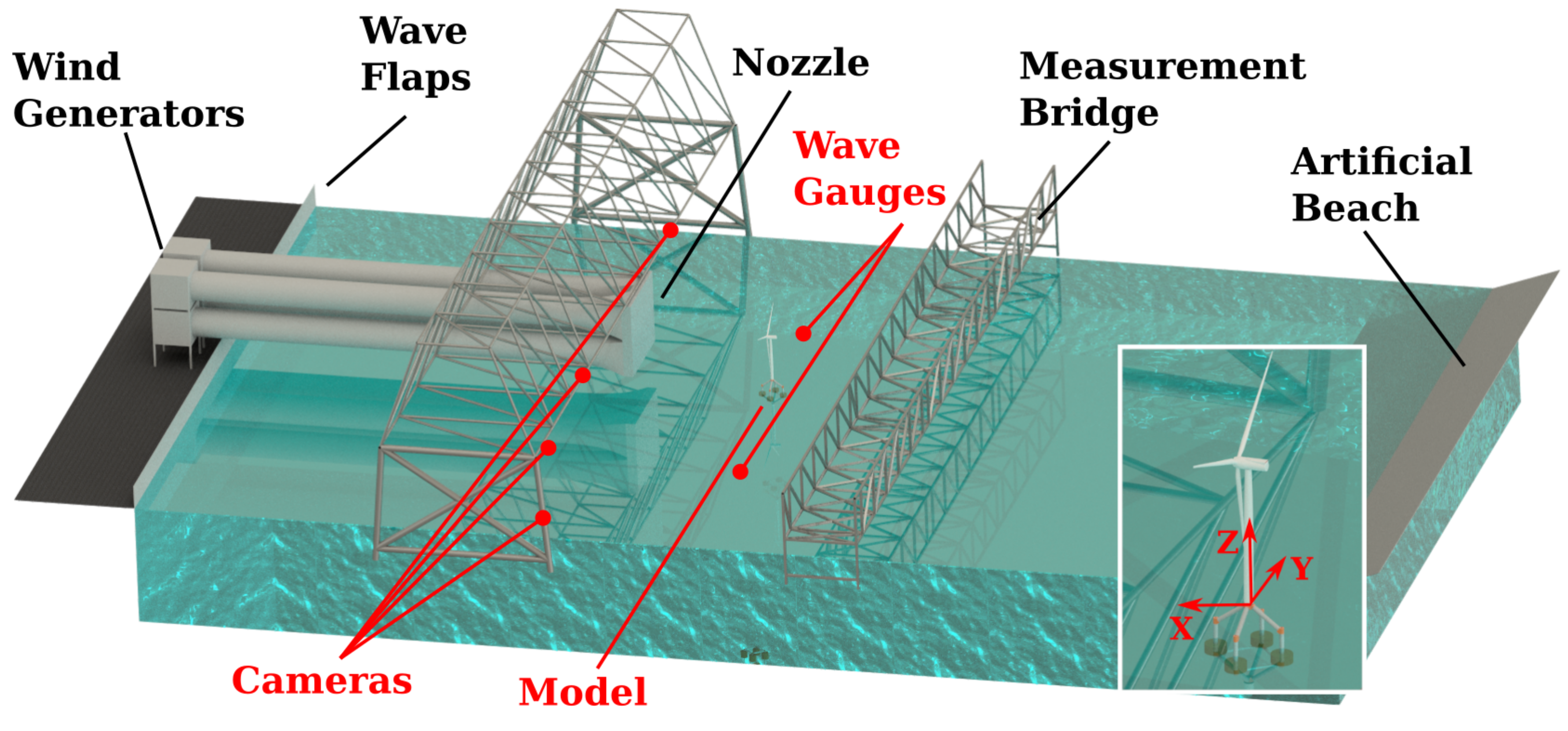

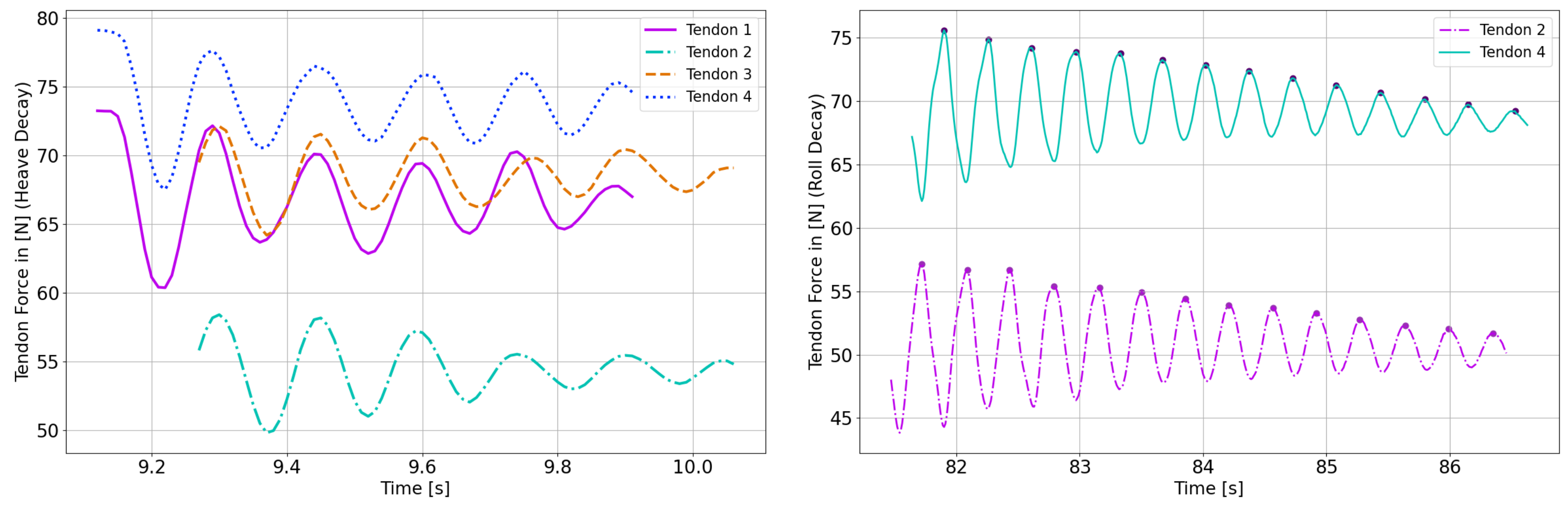

The strip theory model of the TLP in HydroDyn was set up with a respective alignment as in the physical model tests as shown in

Figure 2. Thirty-four joints have been defined including those four at the bottom of the TLP at −30.70 m below MSL, where the moorings are attached, as well as the joint at 37.25 m above MSL where the intersection between substructure and tower is located. The water depth is 200 m corresponding to the 4 m from the attachment point of the moorings to still water level for the tank tests.

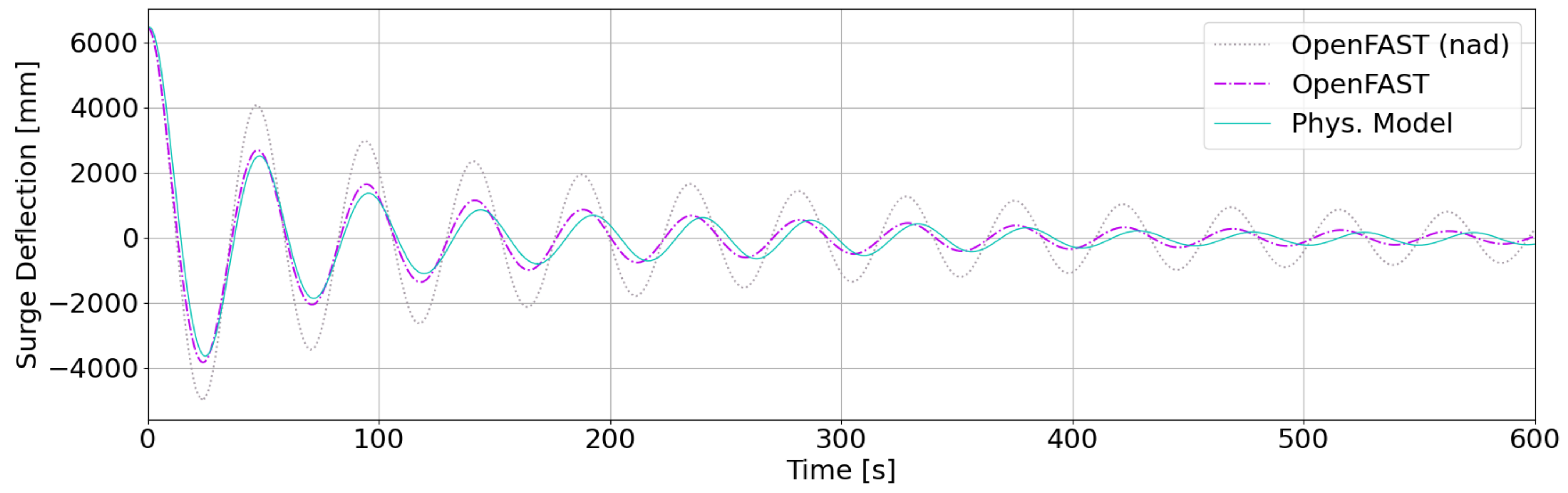

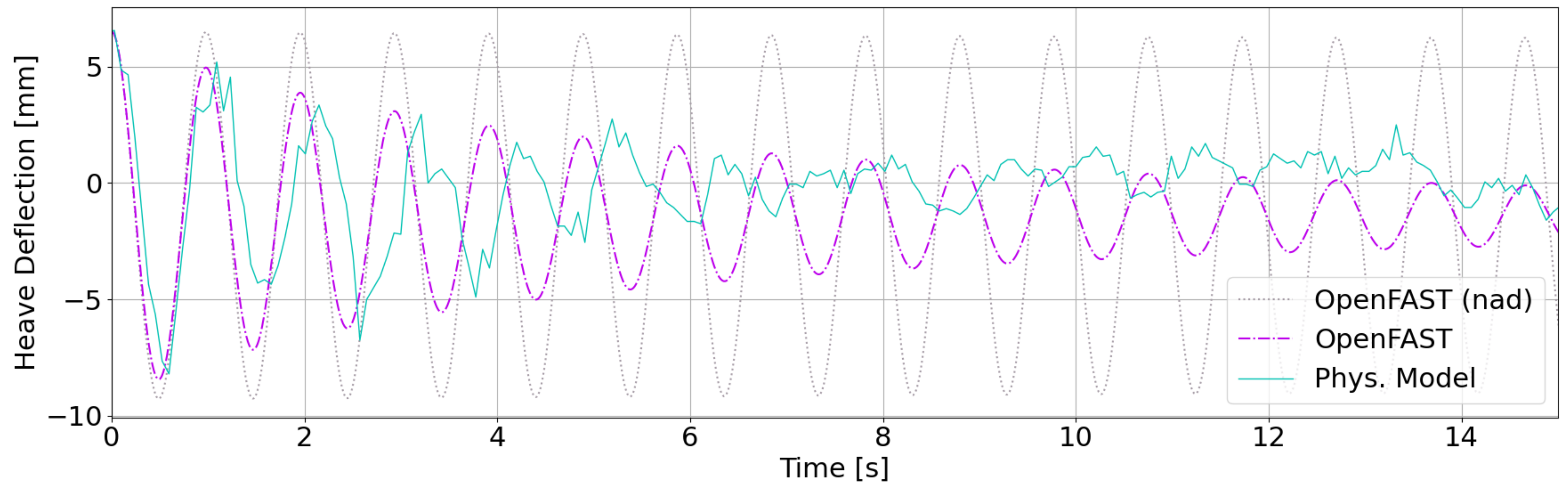

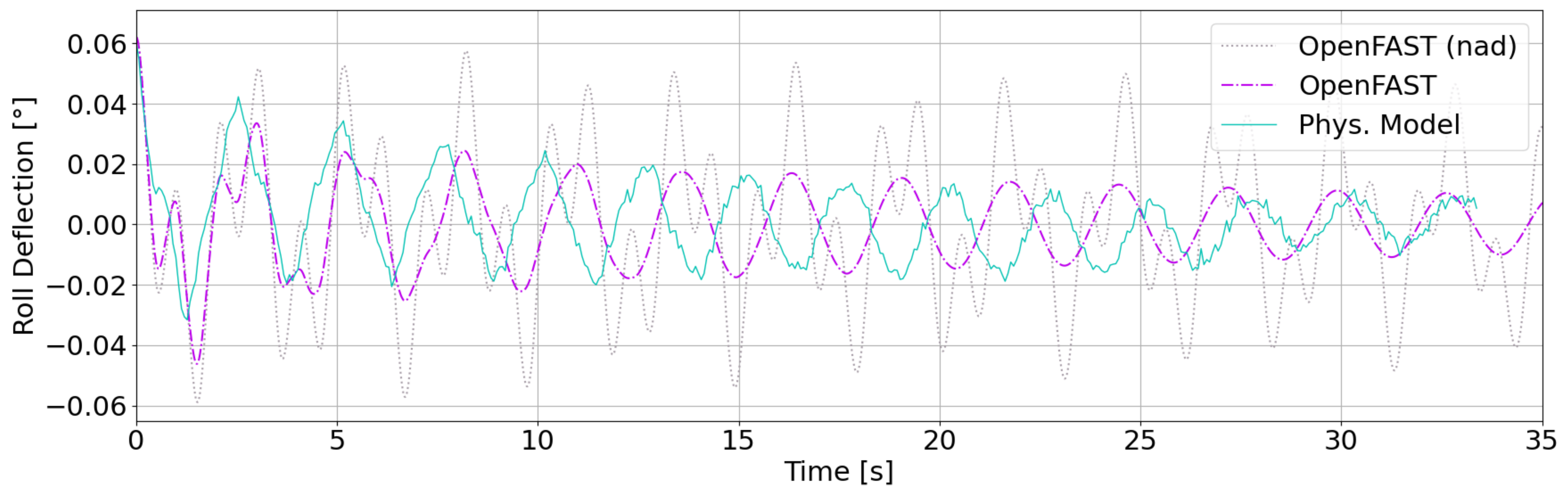

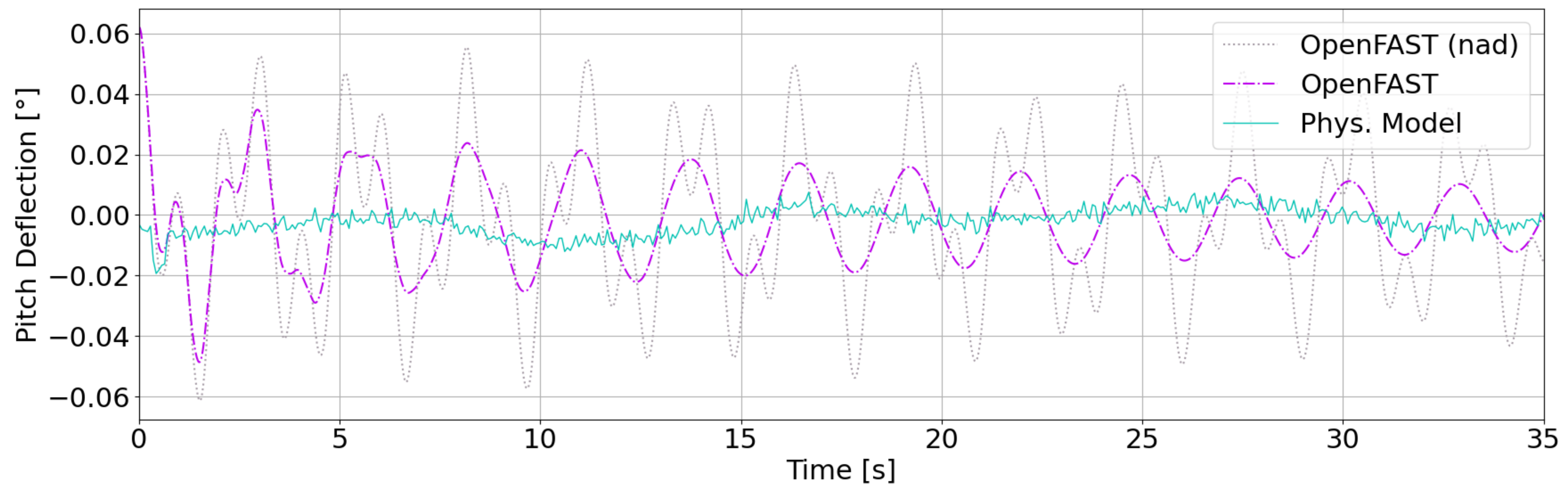

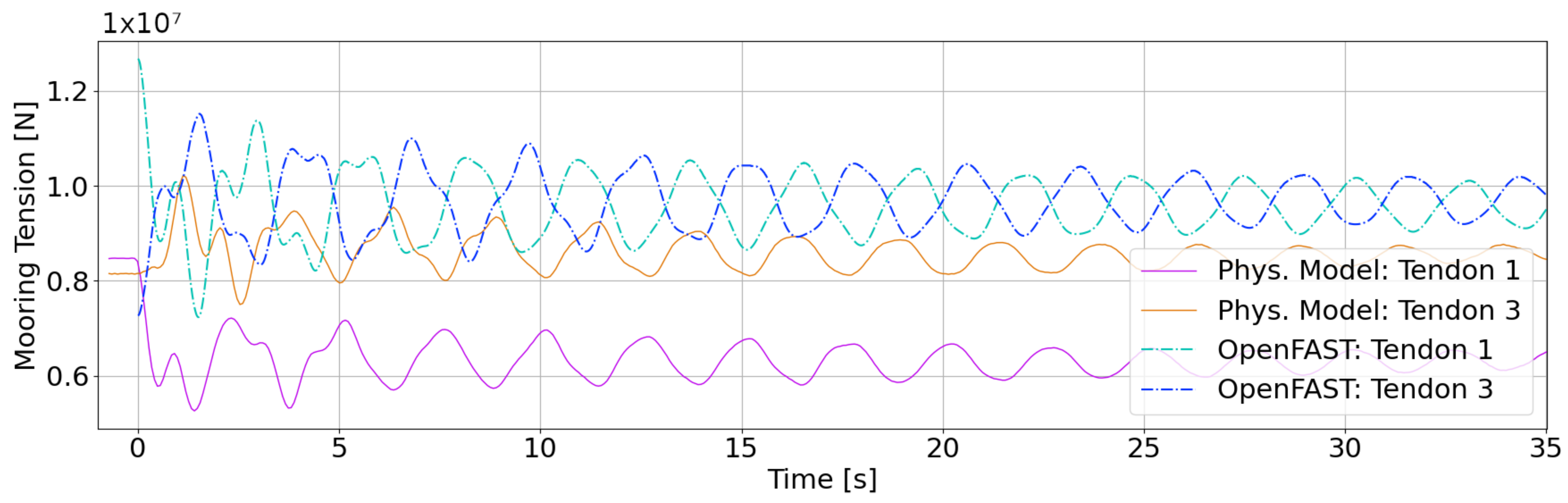

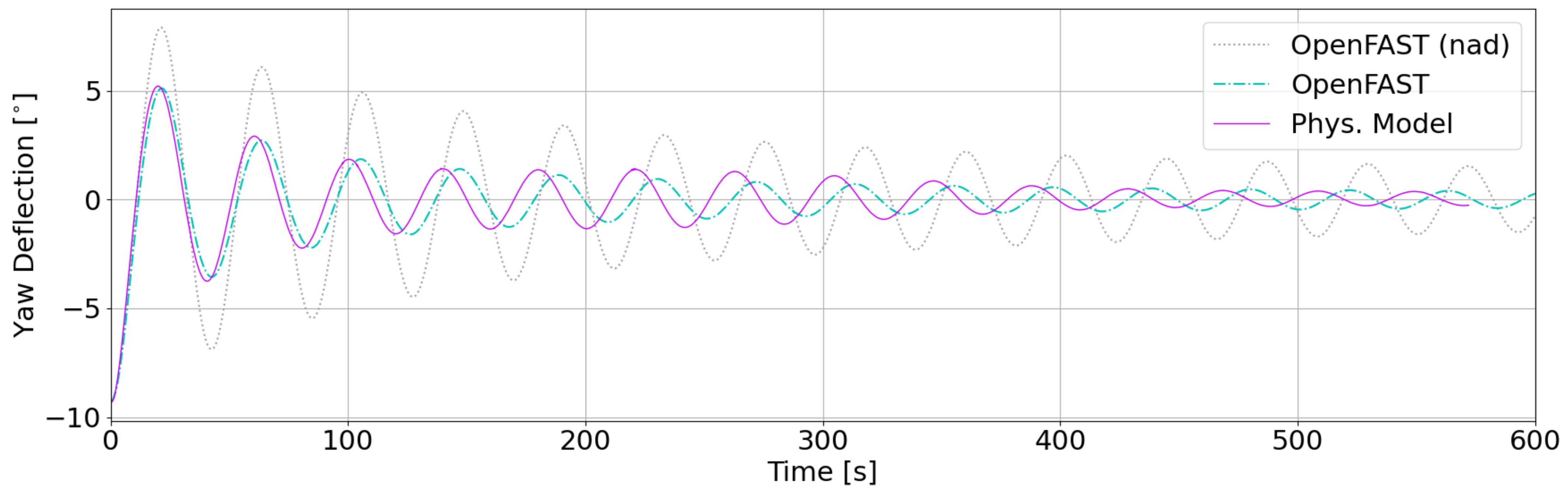

It was observed when comparing the computational model with the results from the tank tests that OpenFAST underestimates the damping of the system. This behavior is known [

39,

42]. This is why additional damping by use of the additional linear damping (AddBLin) and the additional quadratic damping matrix (AddBQuad) was implemented to better agree with the results from the experimental results. The matrices are applied at the intersection of the tower centerline and the mean sea level which Jonkman calls the “Wamit Reference Point” [

39]. Basically, due to the symmetry of the platform additional damping for surge and sway should coincide. Though, there is a slight mismatch between surge and sway envelope curve seen in the tank tests. This is led back to the influence of the turbine on the overall system. Thus, damping for surge is a little bit higher, compared to the damping for sway. As the aerodynamic effects should not be taken account in the HydroDyn tuning the B

and B

were adjusted for a good agreement with sway damping. Furthermore, due to the aforementioned symmetry B

and B

as well as B

and B

were equalized. This approach is considered reasonable due to the aerodynamic effects of the rotor and the respective representation in OpenFAST. Also for heave, roll and pitch the damping was tuned in order to agree well with the results from the tank tests. Linear and quadratic damping matrices as implemented in OpenFAST are shown in

Table 4 and

Table 5. Herein B

corresponds to the damping for surge and B

for sway motion. B

in analogy represents damping for heave while B

represents pitch and B

roll damping. Finally B

corresponds to the yaw damping [

42]. The additional damping matrices have been determined for and applied to the full scale floater as implemented in OpenFAST. In that way, the matrices are valid for the given geometry and Froude number.

As addressed in

Section 2.2 the platform unintentionally became heavier than expected due to a leak. The water ingressed, and its weight was calculated and, based on these findings, the structure weight was adjusted to account for the further ballasting. Furthermore, the inertia properties and the center of gravity (COG) were adjusted, respectively. The final values are shown in

Table 6.