Double Fed Induction Generator Control Design Based on a Fuzzy Logic Controller for an Oscillating Water Column System

Abstract

1. Introduction

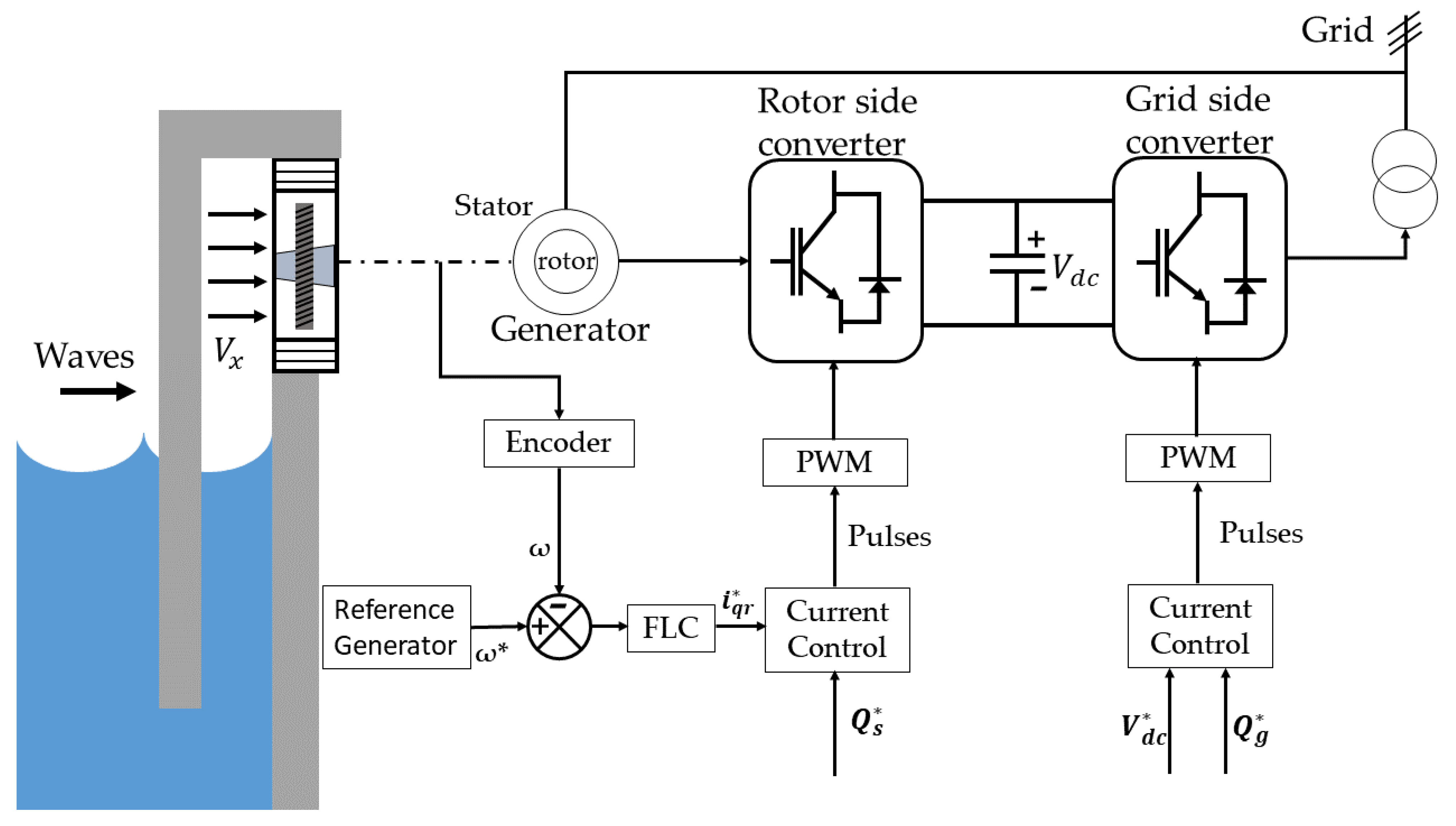

2. Materials and Methods

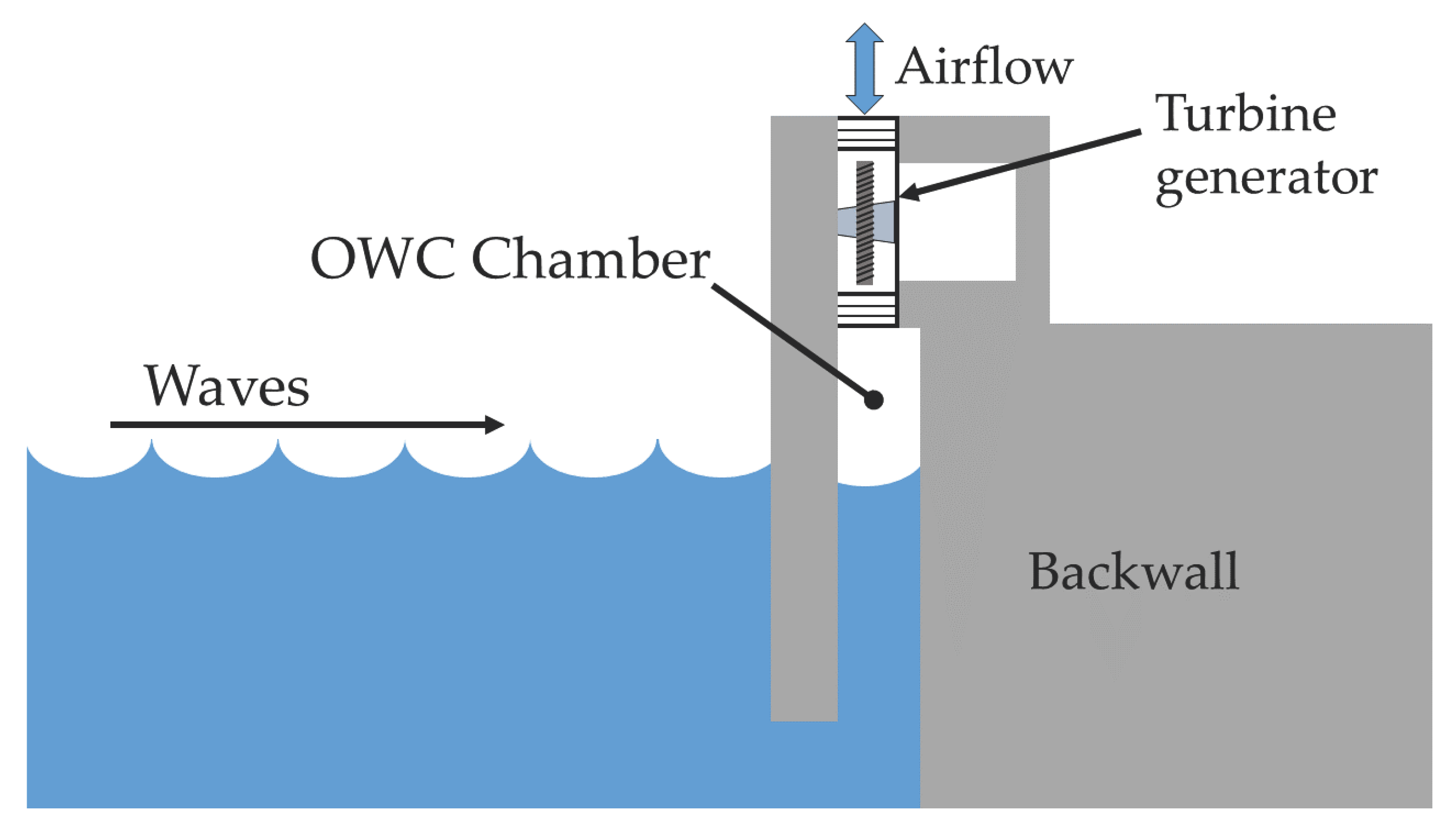

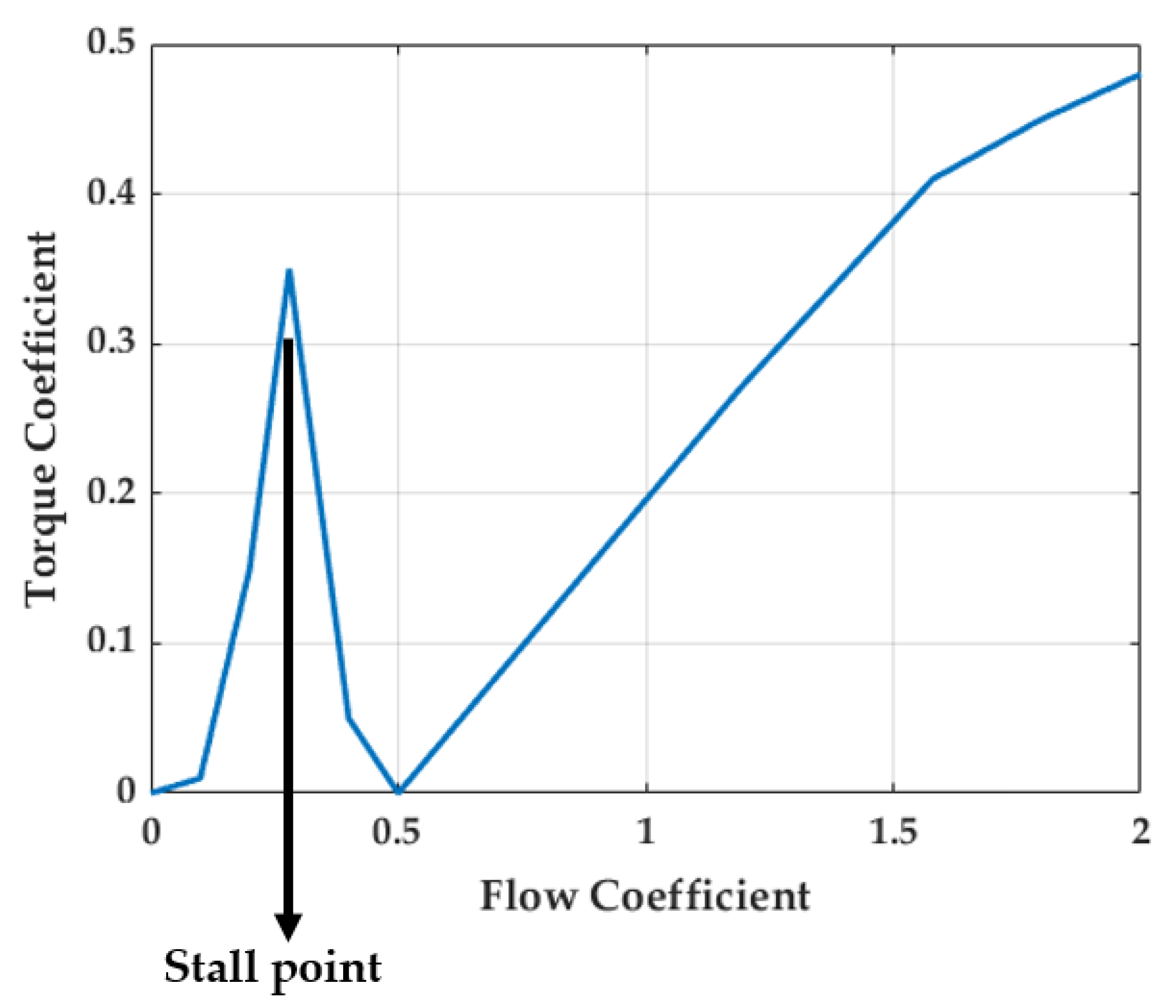

2.1. OWC Plant Model

- and : q-d components for the stator current.

- and : q-d components for the rotor current.

- , , : Inductances of stator, rotor, and mutual, respectively.

- : angular velocity the synchronous reference.

- and : q-d components of the rotor voltage.

- .

- p: pole numbers.

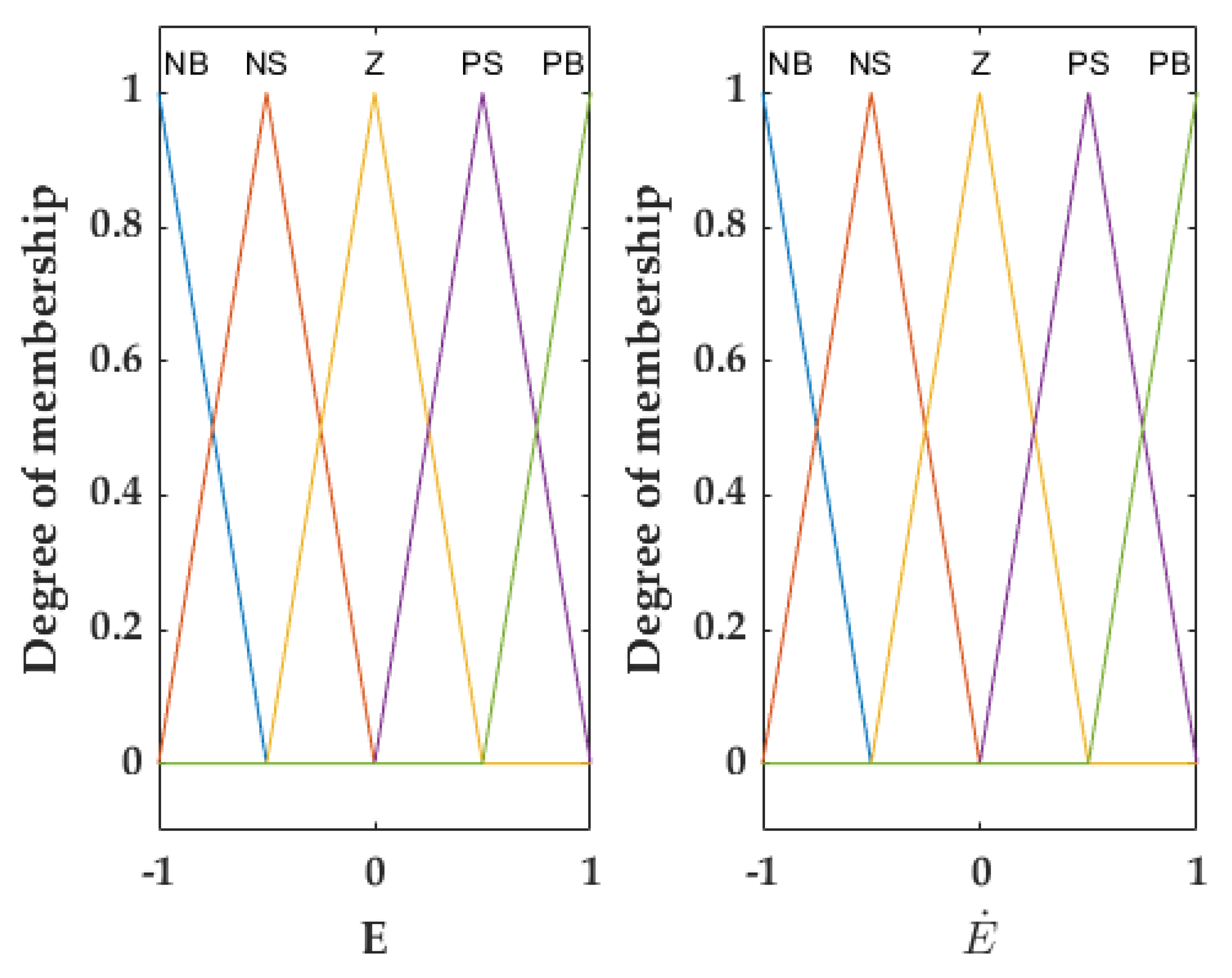

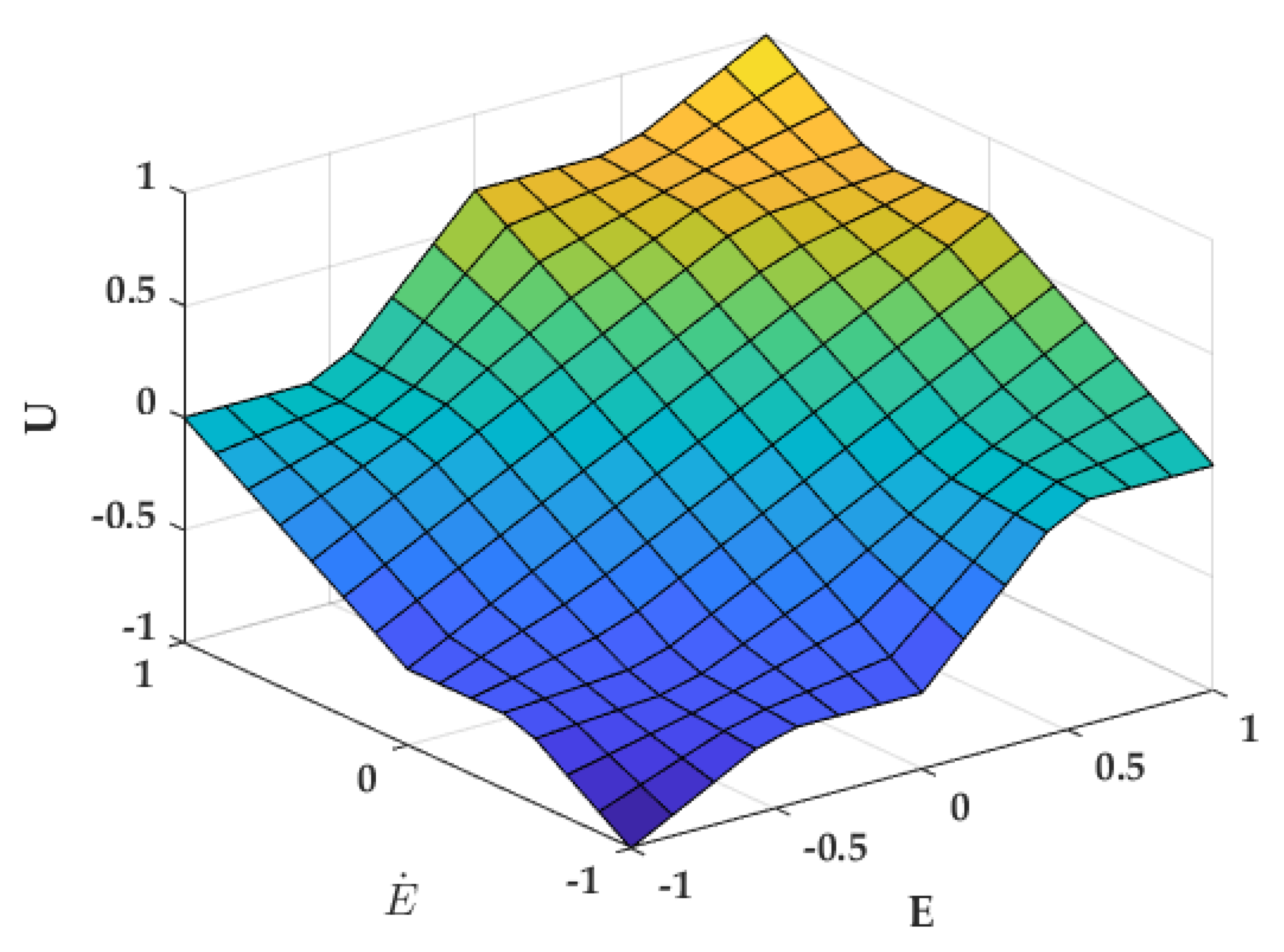

2.2. Type-1 Fuzzy Logic Controller

2.3. Simulation Design

3. Results

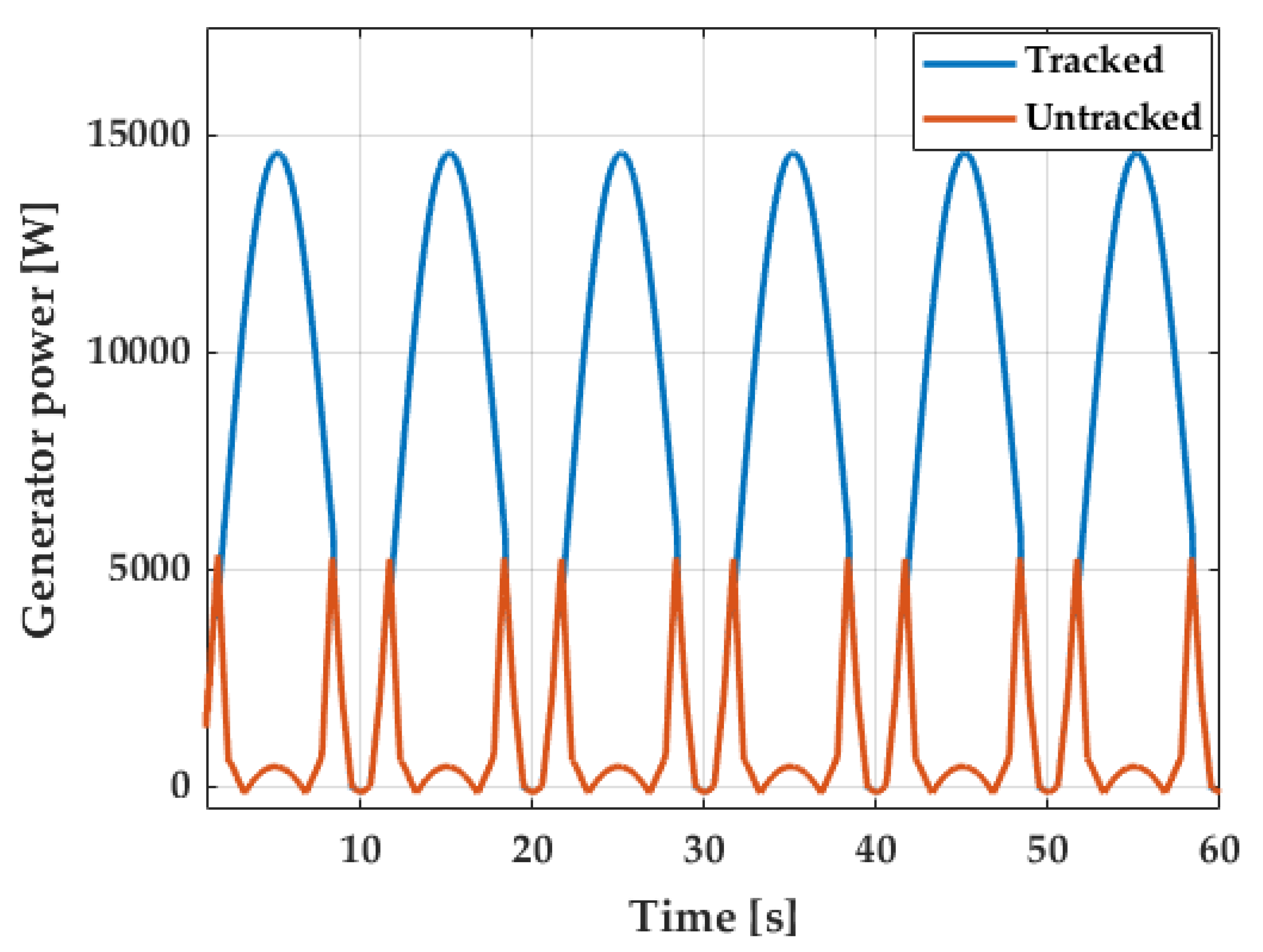

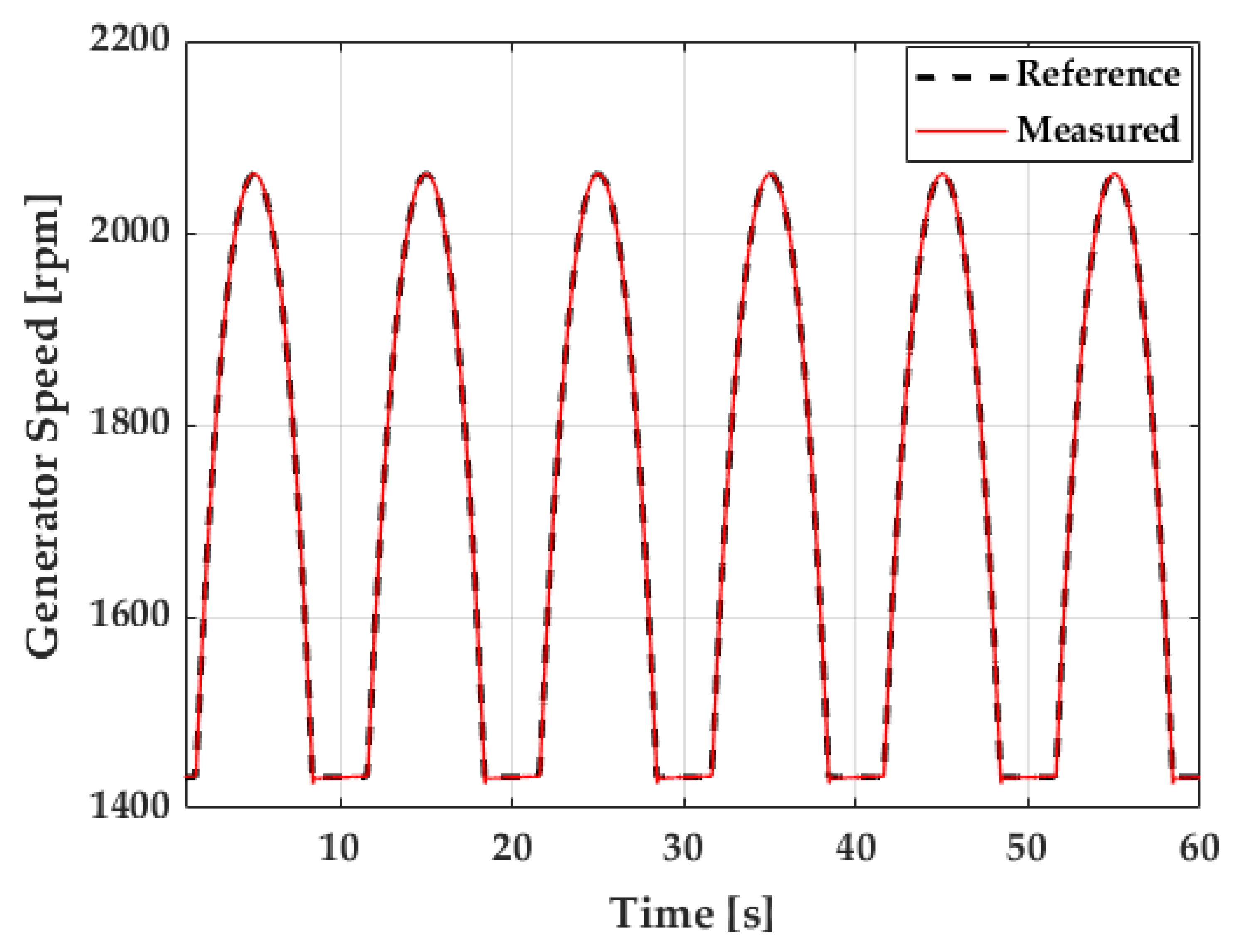

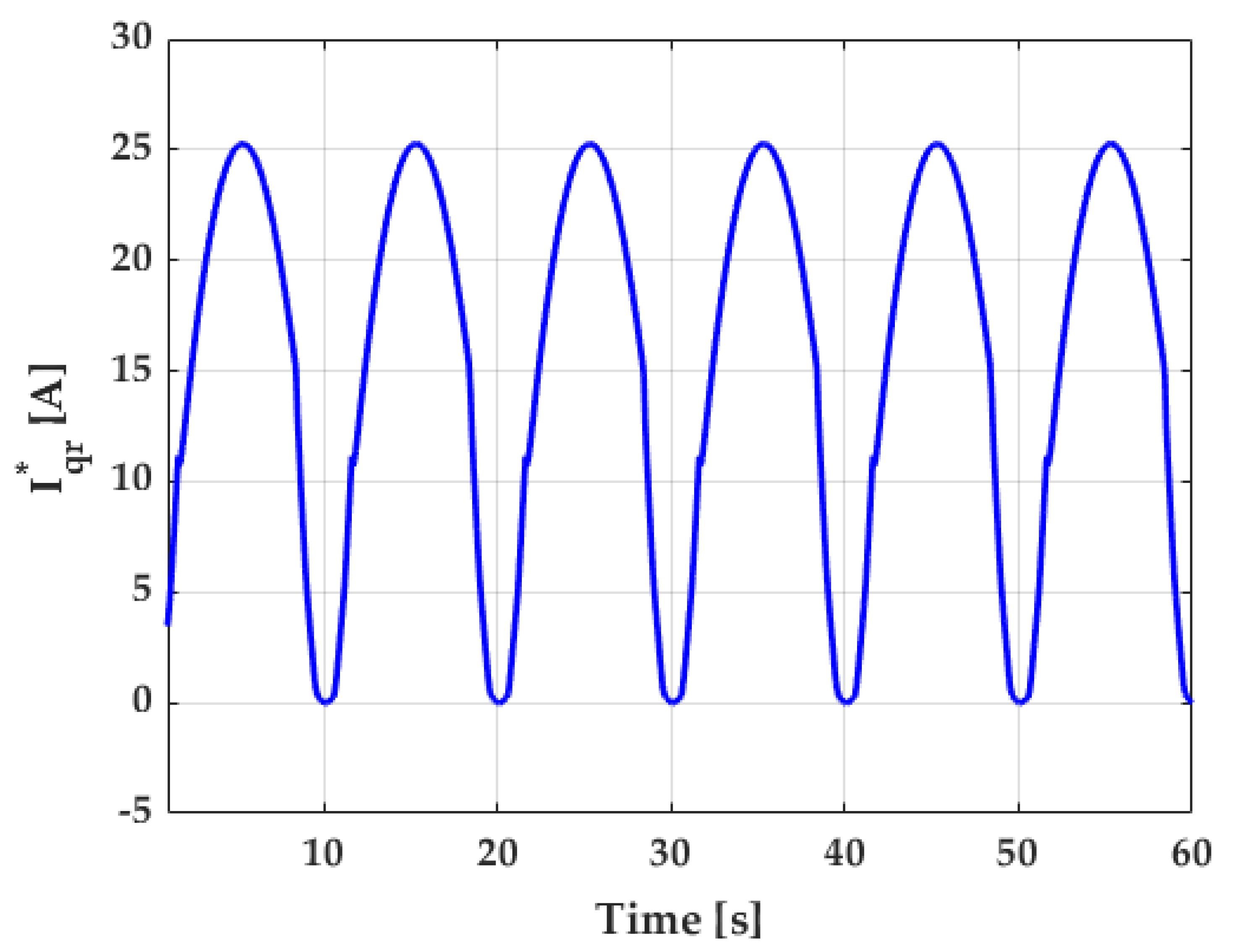

3.1. Simulation Results at 750 Pa

3.2. Simulation Results at 1100 Pa

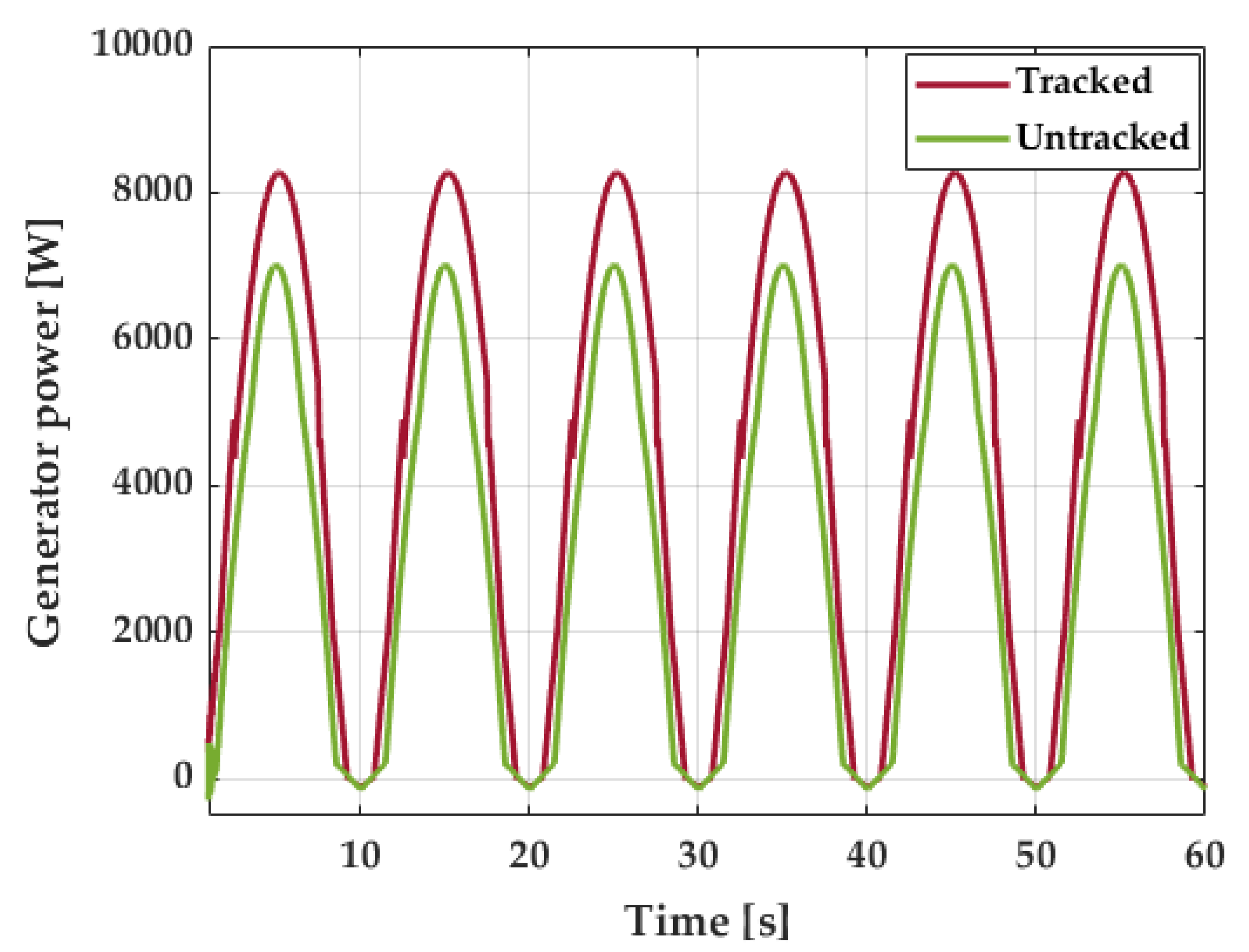

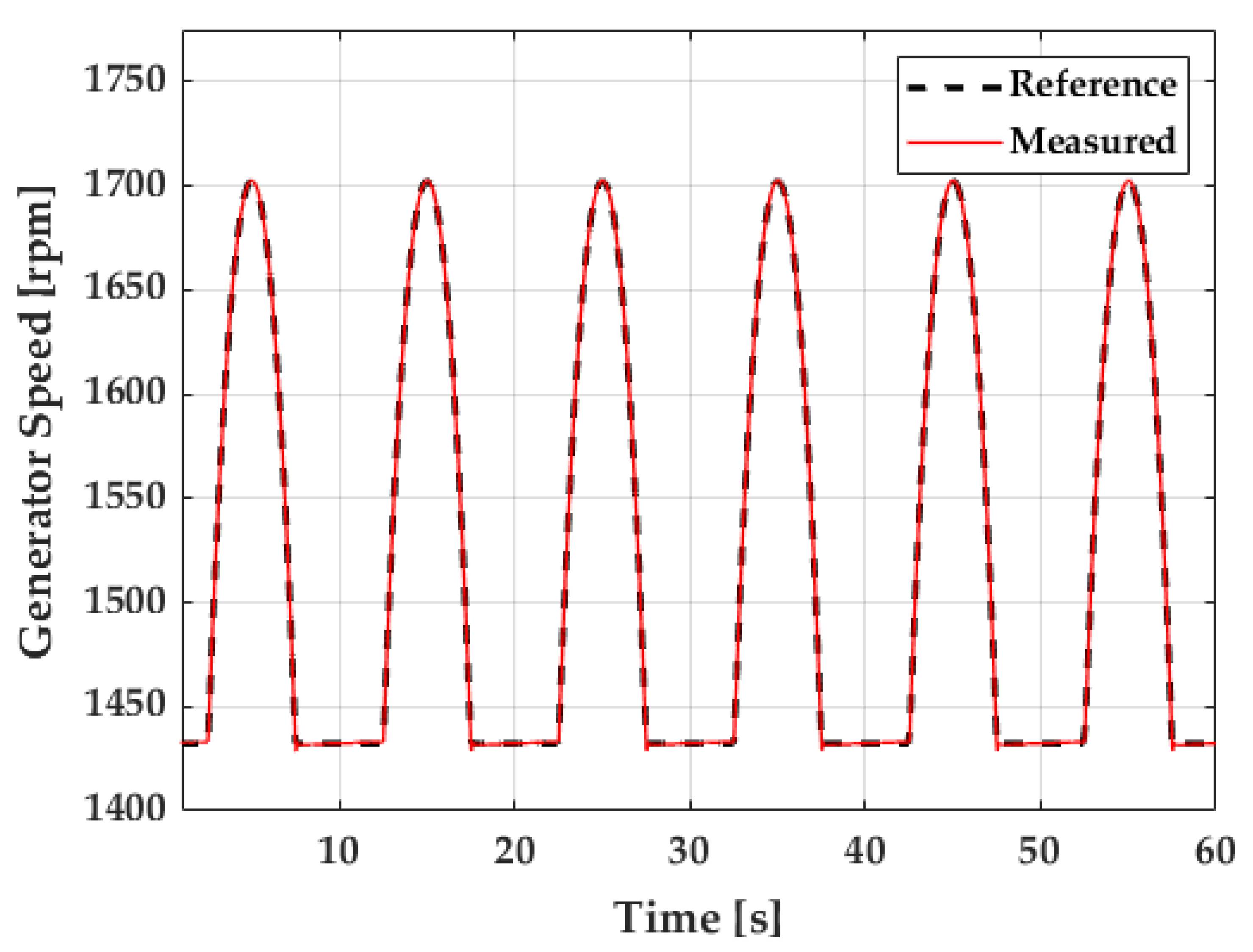

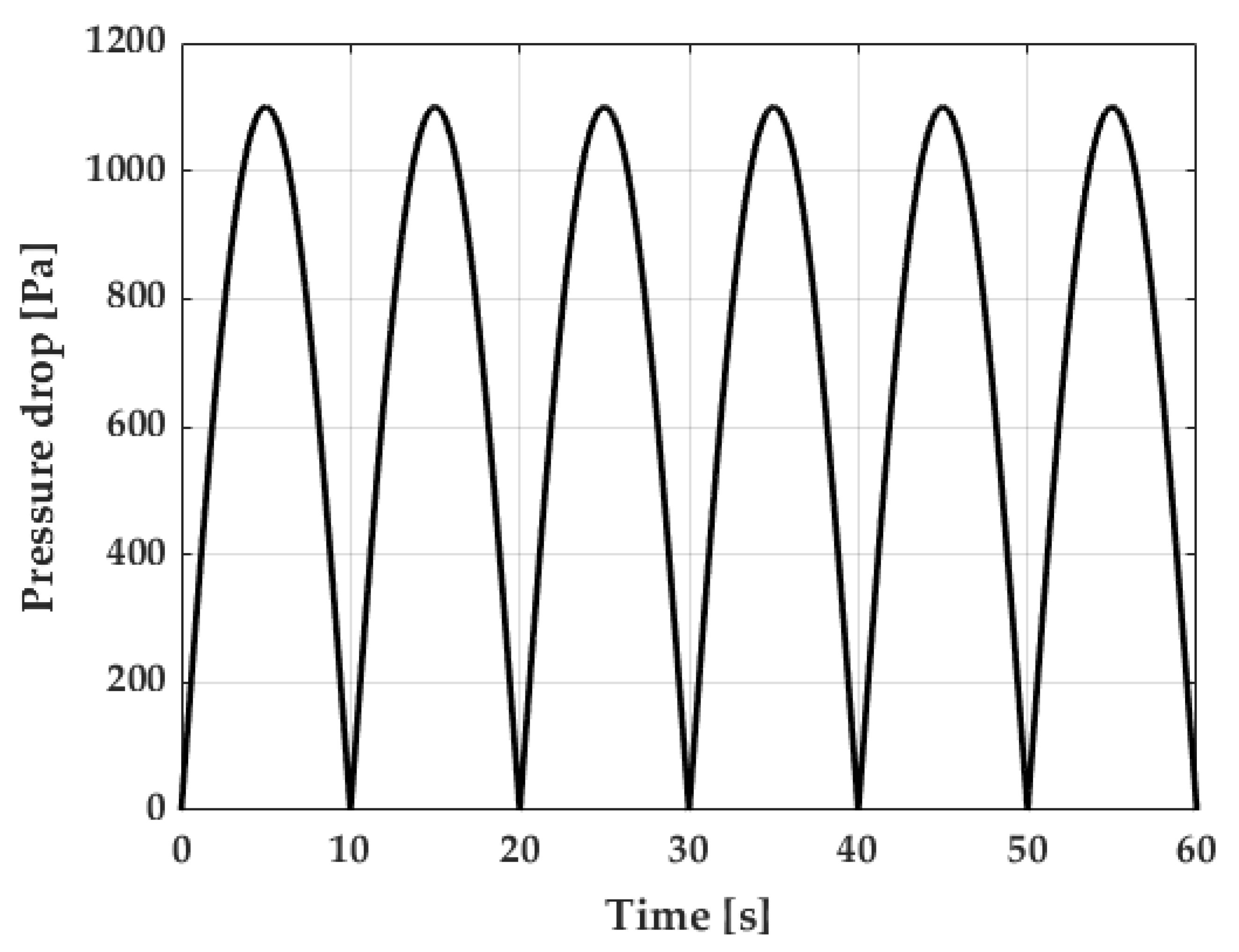

3.3. Simulation Results at Variable Pressure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| OWC | Oscillating water column |

| WTG | Wind turbine generator |

| DFIG | Doubly-fed induction generator |

| VFC | Voltage and frequency control |

| FC | Full converter |

| PID | Proportional-integral-derivative |

| FOPID | Fractional order proportional-integral-derivative |

| SMC | Sliding mode control |

| ANN | Artificial neural networks |

| FLC | Fuzzy logic control |

| ARG | Airflow reference follower |

| NB | Negative big |

| NM | Negative medium |

| NS | Negative small |

| Z | Zero |

| PS | Positive small |

| PM | Positive medium |

| PB | Positive big |

| RSC | Rotor side converter |

| GSC | Grid side converter |

| PWM | Pulse-width-modulation |

References

- Lupíšek, A.; Trubačík, T.; Holub, P. Czech Building Stock: Renovation Wave Scenarios and Potential for CO2 Savings until 2050. Energies 2021, 14, 2455. [Google Scholar] [CrossRef]

- European Commission. Energy: Roadmap 2050, Impact Assesment and Scenario Analysis; The European Commission: Brussels, Belgium, 2011. [Google Scholar]

- International Energy Agency. Renewables 2020; Technical Report; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Shehata, A.S.; Xiao, Q.; Saqr, K.M.; Alexander, D. Wells turbine for wave energy conversion: A review. Int. J. Energy Res. 2017, 41, 6–38. [Google Scholar] [CrossRef]

- Wan, C.; Yang, C.; Fang, Q.; You, Z.; Geng, J.; Wang, Y. Hydrodynamic Investigation of a Dual-Cylindrical OWC Wave Energy Converter Integrated into a Fixed Caisson Breakwater. Energies 2020, 13, 896. [Google Scholar] [CrossRef]

- Belibassakis, K.; Bonovas, M.; Rusu, E. A Novel Method for Estimating Wave Energy Converter Performance in Variable Bathymetry Regions and Applications. Energies 2018, 11, 2092. [Google Scholar] [CrossRef]

- Li, C.; Hang, Z.; Zhang, H.; Guo, Q.; Zhu, Y.; Terzija, V. Evaluation of DFIGs’ Primary Frequency Regulation Capability for Power Systems with High Penetration of Wind Power. Energies 2020, 13, 6178. [Google Scholar] [CrossRef]

- Pena, R.; Clare, J.; Asher, G. A doubly fed induction generator using back-to-back PWM converters supplying an isolated load from a variable speed wind turbine. Electr. Power Appl. IEE Proc. 1996, 143, 380–387. [Google Scholar] [CrossRef]

- Gomez, L.A.G.; Grilo, A.P.; Salles, M.B.C.; Sguarezi Filho, A.J. Combined Control of DFIG-Based Wind Turbine and Battery Energy Storage System for Frequency Response in Microgrids. Energies 2020, 13, 894. [Google Scholar] [CrossRef]

- Lu, K.H.; Hong, C.M.; Han, Z.; Yu, L. New Intelligent Control Strategy Hybrid Grey—RCMAC Algorithm for Ocean Wave Power Generation Systems. Energies 2020, 13, 241. [Google Scholar] [CrossRef]

- Pavel, C.C.; Lacal-Arántegui, R.; Marmier, A.; Schüler, D.; Tzimas, E.; Buchert, M.; Jenseit, W.; Blagoeva, D. Substitution strategies for reducing the use of rare earths in wind turbines. Resour. Policy 2017, 52, 349–357. [Google Scholar] [CrossRef]

- Mishra, S.K.; Mohanta, D.K.; Appasani, B.; Kabalci, E. OWC-Based Ocean Wave Energy Plants; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Lekube, J.; Garrido, A.J.; Garrido, I.; Otaola, E.; Maseda, J. Flow Control in Wells Turbines for Harnessing Maximum Wave Power. Sensors 2018, 18, 535. [Google Scholar] [CrossRef] [PubMed]

- Barambones, O.; Cortajarena, J.A.; Gonzalez de Durana, J.M.; Alkorta, P. A real time sliding mode control for a wave energy converter based on a wells turbine. Ocean Eng. 2018, 163, 275–287. [Google Scholar] [CrossRef]

- Jayashankar, V.; Udayakumar, K.; Karthikeyan, B.; Manivannan, K.; Venkatraman, N.; Rangaprasad, S. Maximizing power output from a wave energy plant. In Proceedings of the 2000 IEEE Power Engineering Society Winter Meeting, Singapore, 23–27 January 2000; Volume 3, pp. 1796–1801. [Google Scholar] [CrossRef]

- Oshnoei, A.; Khezri, R.; Muyeen, S.; Blaabjerg, F. On the Contribution of Wind Farms in Automatic Generation Control: Review and New Control Approach. Appl. Sci. 2018, 8, 1848. [Google Scholar] [CrossRef]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.A.; Hosseinnia, S.H.; Petlenkov, E.; Ates, A.; Cech, M. Towards Industrialization of FOPID Controllers: A Survey on Milestones of Fractional-Order Control and Pathways for Future Developments. IEEE Access 2021, 9, 21016–21042. [Google Scholar] [CrossRef]

- Fragoso, S.; Garrido, J.; Vázquez, F.; Morilla, F. Comparative Analysis of Decoupling Control Methodologies and H infinity Multivariable Robust Control for Variable-Speed, Variable-Pitch Wind Turbines: Application to a Lab-Scale Wind Turbine. Sustainability 2017, 9, 713. [Google Scholar] [CrossRef]

- Xiong, L.; Li, P.; Li, H.; Wang, J. Sliding Mode Control of DFIG Wind Turbines with a Fast Exponential Reaching Law. Energies 2017, 10, 1788. [Google Scholar] [CrossRef]

- Utkin, V.; Lee, H. Chattering Problem in Sliding Mode Control Systems. IFAC Proc. Vol. 2006, 39, 1. [Google Scholar] [CrossRef]

- Chien, T.H.; Huang, Y.C.; Hsu, Y.Y. Neural Network-Based Supplementary Frequency Controller for a DFIG Wind Farm. Energies 2020, 13, 5320. [Google Scholar] [CrossRef]

- Cifuentes, J.; Marulanda, G.; Bello, A.; Reneses, J. Air Temperature Forecasting Using Machine Learning Techniques: A Review. Energies 2020, 13, 4215. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Sadati, N.; Zamani, I. H infinity disturbance attenuation of fuzzy large-scale systems. In Proceedings of the 2011 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE 2011), Taipei, Taiwan, 27–30 June 2011; pp. 2364–2368. [Google Scholar] [CrossRef]

- Sałabun, W.; Więckowski, J.; Shekhovtsov, A.; Palczewski, K.; Jaszczak, S.; Wątróbski, J. How to Apply Fuzzy MISO PID in the Industry? An Empirical Study Case on Simulation of Crane Relocating Containers. Electronics 2020, 9, 2017. [Google Scholar] [CrossRef]

- Tao, C.W.; Taur, J.S. Robust fuzzy control for a plant with fuzzy linear model. IEEE Trans. Fuzzy Syst. 2005, 13, 30–41. [Google Scholar] [CrossRef]

- Coleman, C.P.; Godbole, D. A comparison of robustness: Fuzzy logic, PID, and sliding mode control. In Proceedings of the 1994 IEEE 3rd International Fuzzy Systems Conference, Orlando, FL, USA, 26–29 June 1994; pp. 1654–1659. [Google Scholar] [CrossRef]

- Gerlach, L.; Bocklisch, T. Experts versus Algorithms? Optimized Fuzzy Logic Energy Management of Autonomous PV Hybrid Systems with Battery and H2 Storage. Energies 2021, 14, 1777. [Google Scholar] [CrossRef]

- Napole, C.; Barambones, O.; Calvo, I.; Derbeli, M.; Silaa, M.Y.; Velasco, J. Advances in Tracking Control for Piezoelectric Actuators Using Fuzzy Logic and Hammerstein-Wiener Compensation. Mathematics 2020, 8, 2071. [Google Scholar] [CrossRef]

- Alberdi, M.; Amundarain, M.; Maseda, F.J.; Barambones, O. Stalling behavior improvement by appropriately choosing the rotor resistance value in wave power generation plants. In Proceedings of the 2009 International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009; pp. 64–67. [Google Scholar] [CrossRef]

- Barambones, O.; Gonzalez de Durana, J.; Calvo, I. Adaptive Sliding Mode Control for a Double Fed Induction Generator Used in an Oscillating Water Column System. Energies 2018, 11, 2939. [Google Scholar] [CrossRef]

- Sarmento, A.J.N.A.; Gato, L.M.C.; Falcao, A.D.O. Turbine-controlled wave energy absorption by oscillating water column devices. Ocean Eng. 1990, 17, 481–497. [Google Scholar] [CrossRef]

- Barambones, O.; De La Sent, M.; Alkorta, P. A robust control of double-feed induction generator for wind power generation. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 94–99. [Google Scholar] [CrossRef]

- Fletcher, J.; Yang, J. Introduction to the Doubly-Fed Induction Generator for Wind Power Applications. In Paths to Sustainable Energy; Nathwani, J., Ng, A., Eds.; IntechOpen: Rijeka, Croatia, 2010; Chapter 14. [Google Scholar] [CrossRef]

- Mendel, J. Type-1 Fuzzy Systems: Design Methods and Applications. In Uncertain Rule-Based Fuzzy Logic Systems: Introduction and New Directions; Springer International Publishing: Cham, Switzerland, 2003; Chapter 4; pp. 229–234. [Google Scholar] [CrossRef]

- Liang, Y.; He, Y.; Niu, Y. Microgrid Frequency Fluctuation Attenuation Using Improved Fuzzy Adaptive Damping-Based VSG Considering Dynamics and Allowable Deviation. Energies 2020, 13, 4885. [Google Scholar] [CrossRef]

- Khudoyberdiev, A.; Ahmad, S.; Ullah, I.; Kim, D. An Optimization Scheme Based on Fuzzy Logic Control for Efficient Energy Consumption in Hydroponics Environment. Energies 2020, 13, 289. [Google Scholar] [CrossRef]

- Sheng, W.; Li, H. A Method for Energy and Resource Assessment of Waves in Finite Water Depths. Energies 2017, 10, 460. [Google Scholar] [CrossRef]

- Medeiros, A.; Ramos, T.; de Oliveira, J.T.; Medeiros Júnior, M.F. Direct Voltage Control of a Doubly Fed Induction Generator by Means of Optimal Strategy. Energies 2020, 13, 770. [Google Scholar] [CrossRef]

- Martinez, M.I.; Tapia, G.; Susperregui, A.; Camblong, H. Sliding-Mode Control for DFIG Rotor- and Grid-Side Converters Under Unbalanced and Harmonically Distorted Grid Voltage. IEEE Trans. Energy Convers. 2012, 27, 328–339. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, C.; Hu, M. Improved Control Strategy for DFIG Wind Turbines for Low Voltage Ride Through. Energies 2013, 6, 1181–1197. [Google Scholar] [CrossRef]

- Pang, B.; Dai, H.; Li, F.; Nian, H. Coordinated Control of RSC and GSC for DFIG System under Harmonically Distorted Grid Considering Inter-Harmonics. Energies 2020, 13, 28. [Google Scholar] [CrossRef]

| E∖ | NB | NS | Z | PS | PB |

|---|---|---|---|---|---|

| NB | NB | NM | NM | NS | Z |

| NS | NM | NM | NS | Z | Z |

| Z | NM | NS | Z | PS | PM |

| PS | Z | Z | PS | PM | PM |

| PB | Z | PS | PM | PM | PB |

| Properties | Values | Units |

|---|---|---|

| Number of blades | 8 | - |

| Turbine torque coefficient | 0.7079 | |

| Turbine radius | 0.7285 | m |

| Cross-sectional area | 1.1763 | |

| Blade height | 0.4 | m |

| Chord length | 0.38 | m |

| Properties | Values | Units |

|---|---|---|

| Stator voltage | 380 | V |

| Rotor voltage | 190 | V |

| Rated stator current | 18 | V |

| Rated rotor current | 24 | A |

| Rated speed | 1447 at 50 Hz | r.p.m. |

| Rated torque | 50 | Nm |

| Stator resistance | 0.275 | |

| Rotor resistance | 0.325 | |

| Magnetizing inductance | 0.0664 | H |

| Stator leakage inductance | 0.00264 | H |

| Rotor leakage inductance | 0.00372 | H |

| Inertia moment | 0.07 | kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Napole, C.; Barambones, O.; Derbeli, M.; Cortajarena, J.A.; Calvo, I.; Alkorta, P.; Bustamante, P.F. Double Fed Induction Generator Control Design Based on a Fuzzy Logic Controller for an Oscillating Water Column System. Energies 2021, 14, 3499. https://doi.org/10.3390/en14123499

Napole C, Barambones O, Derbeli M, Cortajarena JA, Calvo I, Alkorta P, Bustamante PF. Double Fed Induction Generator Control Design Based on a Fuzzy Logic Controller for an Oscillating Water Column System. Energies. 2021; 14(12):3499. https://doi.org/10.3390/en14123499

Chicago/Turabian StyleNapole, Cristian, Oscar Barambones, Mohamed Derbeli, José Antonio Cortajarena, Isidro Calvo, Patxi Alkorta, and Pablo Fernandez Bustamante. 2021. "Double Fed Induction Generator Control Design Based on a Fuzzy Logic Controller for an Oscillating Water Column System" Energies 14, no. 12: 3499. https://doi.org/10.3390/en14123499

APA StyleNapole, C., Barambones, O., Derbeli, M., Cortajarena, J. A., Calvo, I., Alkorta, P., & Bustamante, P. F. (2021). Double Fed Induction Generator Control Design Based on a Fuzzy Logic Controller for an Oscillating Water Column System. Energies, 14(12), 3499. https://doi.org/10.3390/en14123499