1. Introduction

Winding configuration design plays an important role in motor design. There are many classification methods using various kinds of parameters for all types of windings [

1]. According to the number of slots per pole per phase and q being an integer or not, the windings can be divided into integer slot and fractional slot windings. Integer slot windings have been widely used in PM-assisted synchronous reluctance motors (PMASynRMs) [

2,

3] due to their advantages of low space MMF harmonics and high reluctance torque production. However, a major drawback of PMASynRM with integer slot winding is the high torque ripple, which is caused by the interaction of the spatial harmonics of electrical loading and the high saliency and anisotropy of the rotor. Compared with integer slot winding, the interest in fractional slot winding is increasing quickly. The advantages of fractional slot winding are proposed in [

4] and [

5]; they include low copper losses, low torque ripple, and other benefits. A theory for fractional slot multi-layer windings [

6] involves an improved method for winding configuration. The torque ripple significantly affects the motor performance. Therefore, the reduction of torque ripple is particularly important. The method of improving the torque performance by changing the structure of rotor was proposed in [

7], and an experiment was reported in [

8], in which the torque of the skewed rotor is compared with the non-skewed rotor in PMASynRMs and SynRMs; it also compared the torque of symmetric and asymmetric flux-barrier rotors. It can be concluded that with a rotor skewing, the average torque decreases slightly, but the torque ripple decreases to about one-third. Meanwhile, with an asymmetrical rotor (machaon geometry), the average torque remains the same, and the torque ripple decreases. In addition, the chosen number of flux-barriers is presented in [

9], and a design approach is given for transverse laminated type SynRMs in [

10]: After choosing the number of the separation points (

nr), a separate shaping of barrier flux and rib flux can be designed for quasi-sinusoidal magnetic potential distribution. Finally, according to the experimental comparison, it can be concluded that a rotor of the transverse laminated type is fully compatible with the realization of a low-torque-ripple machine. The optimization of the flux barrier angle and shifted asymmetrical angle is proposed in [

11] to solve the high torque ripple problem of 36-slot/6-pole motor; this study confirms that the torque ripple of conventional PMASynRMs with symmetrical flux barrier structure and skewed structure is very large for 36/6 integer slot windings. For PMASynRMs, most of their structures have adopted additional structures to reduce torque ripple. The reason for the large torque ripple of the 36/6 motor in this article is that the asymmetric structure is not used to eliminate specific harmonics, and some high torque harmonics are produced by the integer number of slots per pole per phase; thus, it is very important to seek winding structures with low torque ripple using PMASynRMs.

In conventional winding configuration methods, after the determination of the number of phases

m, the number of slots

Q, and the number of pole pairs

p, the subsequent method is normally to design the winding layout. The classical theory of the star of slots diagram [

12] can handle many complicated windings, and the whole process of distributing the winding is a graphical display. However, for an arbitrary winding with

m-phase, the number of slots

Q, and pole pairs

p, this theory cannot qualify the feasibility of winding distributions to phases directly. Moreover, for some windings with a large number of slots or multi-phase windings, it is a laborious and time-consuming process. Therefore, it is very important to find the simplest winding distribution method according to every slot-pole combination when the number of phases is given.

An improved fractional-slot theory is proposed in [

13,

14]. This theory can handle double-layer windings with odd phase and constant coil throw or single-layer windings with an odd phase and constant odd coil throw. In addition, for winding structures determined to be the two-slot and three-slot pitch coils, an analysis of the feasibility of the slot-pole combinations in the fractional slot PM machines is provided by [

15,

16], respectively. A novel winding configuration theory is proposed for multi-layer fractional slot concentrated windings in [

17]. This study proposes two 3-phase motors: 8-slot/6-pole, 88 turns per slot and 11-slot/10-pole, 100 turns per slot. It can be seen that the number of turns is extremely large, so it requires a sufficiently wide slot area; this method is not valid for distributed windings. Recently, a new coil arrangement for a 4-phase motor has been presented and applied in switched reluctance motors [

18], consisting of a symmetrical winding structure. As for asymmetrical multi-phase windings and other conditions, these theories are no longer feasible. A theory of unbalanced winding structures has been proposed [

19], but the number of slots is not generic. There are some specific asymmetrical windings, such as a dual 3-phase asymmetrical winding, 12-slot and 10-pole [

20]; a dual 5-phase asymmetrical winding, 20-slot and 18-pole [

21]; and a 9-phase 3-layer asymmetrical winding, 117-slot and 36-pole [

22]. Moreover, the 39-slot motors are discussed in [

23,

24], but there is very little research on other slot-pole combinations. There has not been a systematic study of all unconventional slot-pole combination winding configuration methods.

Compared with these papers, the superiority of this paper is reflected in the applicability of slot-pole combinations and the versatility of phase numbers. The novelty comes mainly from two features. (1) A classification theory of slot-pole combinations is proposed, which can be applied to 3-phase and multi-phase motors with any number of slots. All kinds of numbers of slots and poles can be divided into conventional balanced winding (CBW), unbalanced winding (UBW), unconventional even slot winding (UESW), and unconventional odd slot winding (UOSW). (2) The phase separation method: a slot sorting table distributed to phases is proposed in this article to avoid the difficulties of the star of slots diagram, and for any slot-pole combinations, this method can give a winding configuration, which has an excellent torque performance. The winding magneto motive force (MMF) has great influence on torque ripple [

25], and the torque ripple can be reduced by changing the MMF [

26]. The effect of stator MMF on torque performance by the winding configuration is analyzed by comparing air gap magnetic density under two kinds of rotor: (1) a rotor with a double layer flux-barrier and PM and (2) a rotor without a flux-barrier. The relationship between MMF harmonics of rotor and stator and torque ripple is analyzed according to the magnetic co-energy theory. Then, the torque FEA is given to verify this conclusion using harmonic analysis. In this paper, the rotors do not take any torque ripple reduction measures, such as rotor skewing, pole-shifting, asymmetric flux barrier, and different angles of barriers. The purpose is to prove that these winding configurations can also achieve the effect of reducing torque ripple, which can avoid the difficulty of motor rotor manufacturing. Finally, UBW, UOSW, and UESW can inhibit low torque ripple compared with CBW. In addition, radial force and power loss analysis are carried out; the effects produced by UBW, UESW, and UOSW compared to CBW in these two aspects are acceptable.

2. Classification Theory of Slot-Pole Combinations

First, it is necessary to define some winding parameters for the classification of slot-pole combinations: the number of phases

m, the number of slots

Q, and the number of pole pairs

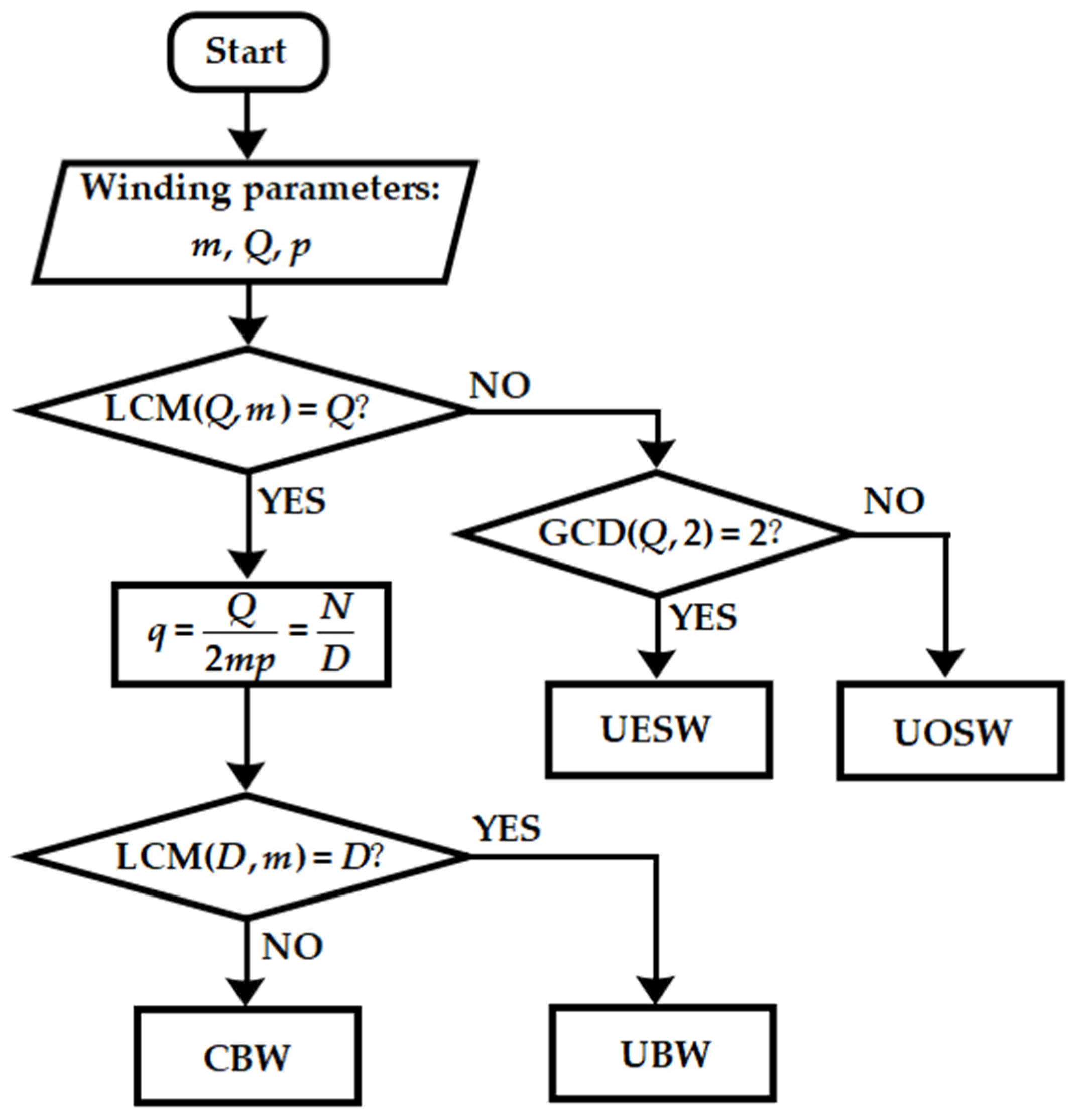

p. The winding classification process is shown in

Figure 1. The number of slots can be divided into two categories by using the least common multiple (LCM) between

Q and

m.

If Equation (1) is equal to Q, the stator slot number is divisible by m, the phase coil pitches will be the same, and all stator slots have equally displaced coils. In this case, the number of slots is defined as the conventional slot number.

If Equation (1) is not equal to Q, the stator slot number is not divisible by m, the phase coil pitches will be different, the coils of stator slots will not be displaced equally, and some slots will be displaced multiple layers of coils. In this case, the number of slots is defined as the unconventional slot number.

Different methods are adopted for the slot-pole classification of conventional and unconventional number of slots.

For conventional slot number winding, two categories are used in accordance with the Minimalist Division of slot per pole per phase

q in Equation (2).

where

D and

N are the denominator and the numerator of the fraction of

q, respectively. The least common multiple (LCM) between

D and

m can be obtained.

If the LCM between D and m is not equal to D, the stator slots will be distributed symmetrically by phases. In this case, the slot-pole combination is defined as the conventional balanced winding (CBW) because of the symmetry between phases.

If the LCM between D and m is equal to D, the stator winding layout will produce an asymmetric winding structure. In this case, the slot-pole combination is defined as the unbalanced winding (UBW) because of the asymmetry between phases. For a 3-phase motor, this winding structure only appears when p is a multiple of 3 (p = 3, 6, 9…).

For unconventional slot number winding, there are odd and even slots, and the limit conditions of winding turns (Nc) are different for the two cases. Therefore, unconventional slot number windings are divided into unconventional odd slot windings (UOSWs) and unconventional even slot windings (UESWs). Note that there is no winding where q is an integer in unconventional slot number windings.

4. Analysis and Comparison of Performance

In this section, a set of slot-pole combination schemes are selected to establish the model for the four winding configuration methods. The slot-pole combinations of four motors are as follows:

M1: 36-slot and 6-pole (CBW);

M2: 33-slot and 6-pole (UBW);

M3: 34-slot and 6-pole (UESW);

M4: 35-slot and 6-pole (UOSW).

The air-gap flux density waveforms and their harmonics in these models are analyzed and compared in the PMASynRM equipped with rotor with 2-layer flux-barrier and without flux-barrier by the two-dimensional FEA. It is interesting to note that although the winding material used in the finite element simulation is copper, this kind of winding configuration method does not have the limitation of the conductor material. This method is feasible if the used conductors meet the basic requirements, such as slot full rate, heat dissipation conditions, etc.

4.1. Winding Model Establishment

For

M1 and

M2, slots can be sorted according to slot distance parameter

α in Equation (3). Then, slots of

M1 can be distributed directly into phases, but slots of

M2 take corresponding measures to distribute to phase according to the value of

N. Clearly,

M2 belongs to type

B. The results of slot distribution are shown in

Table 9 and

Table 10, respectively.

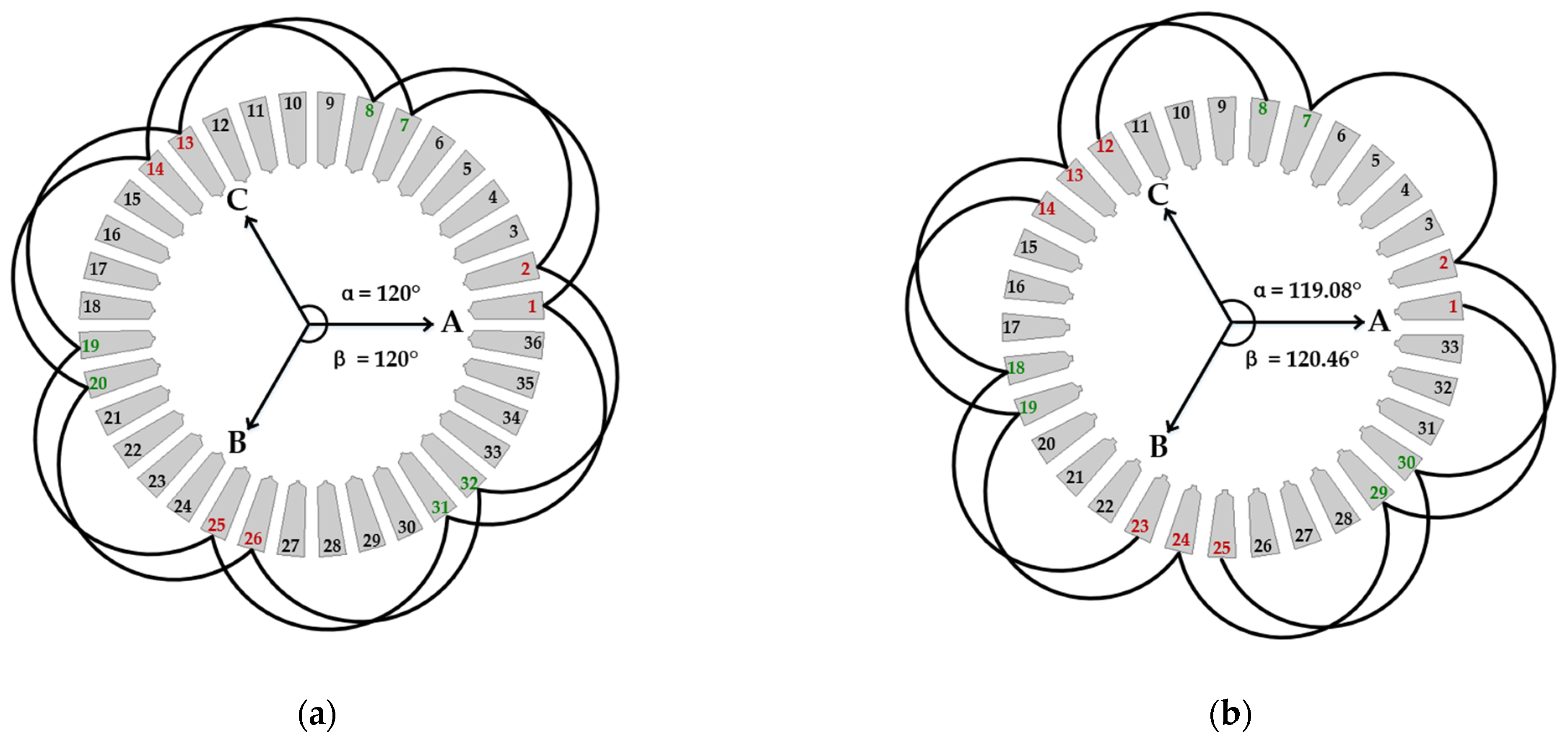

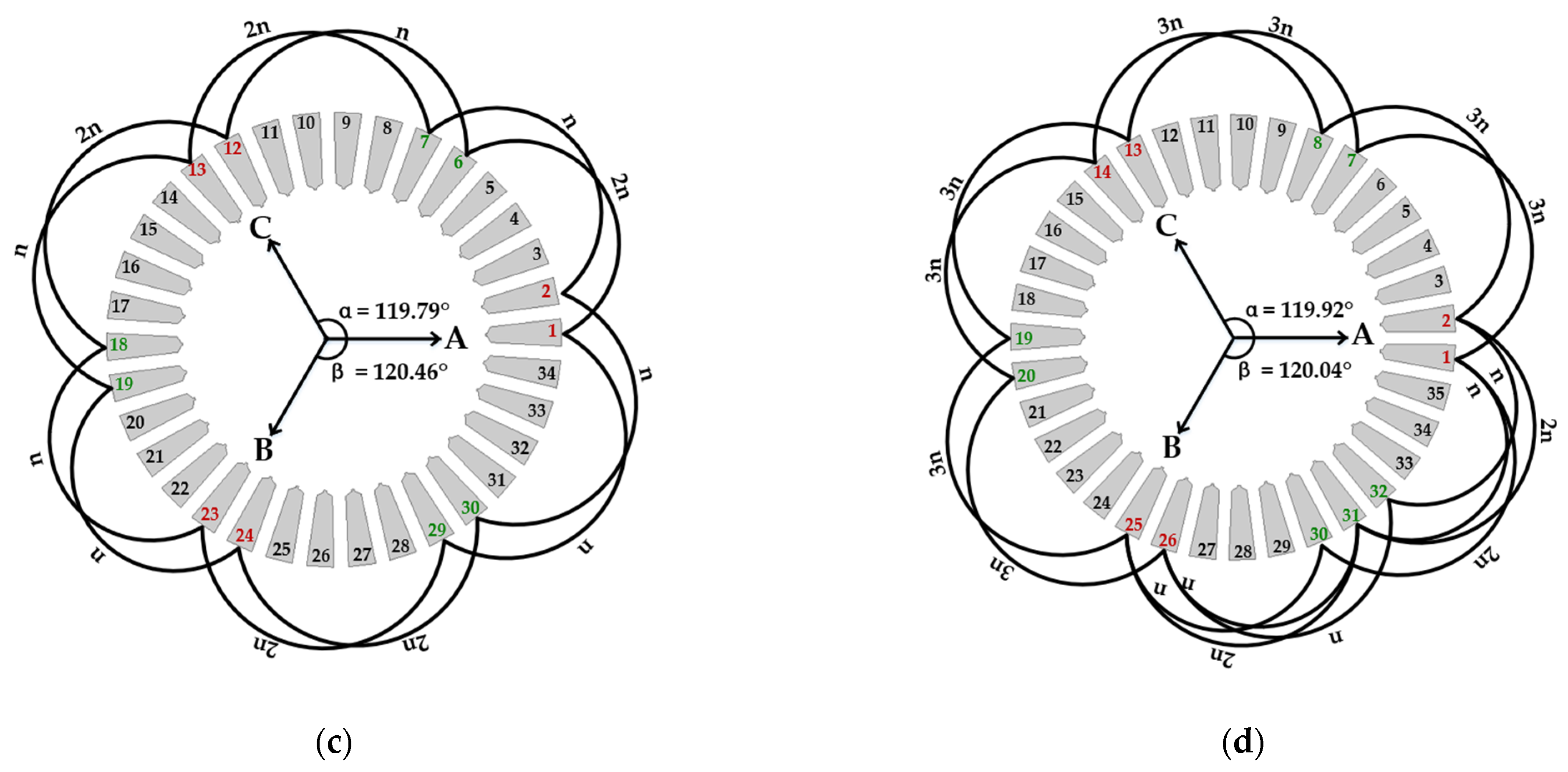

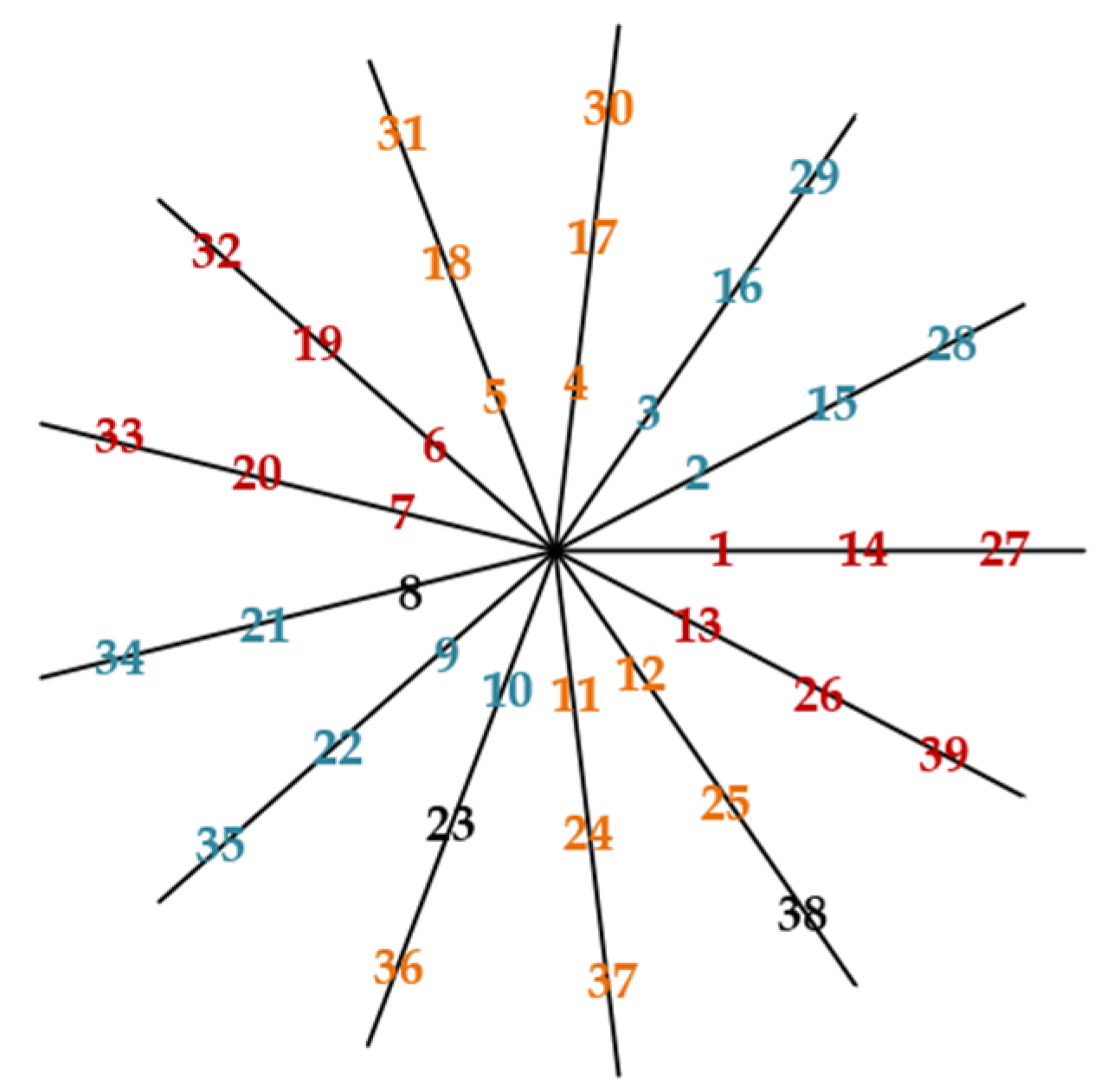

Because the winding parameters of UESW are even, it is hard to obtain a definite slot distance parameter. Its slot distribution to phases can be conducted using the star of slot diagram, which is shown in

Figure 2 and is based on

M3. Assuming that the number of turns in each slot is 3

n, and

n is an integer, it can be seen that the common slots of 3-phase winding of UESW only exist at phase A-B and B-C. The number of turns is represented by the length of the slot voltage vector, and the number of inside circles arranged behind the end of every slot voltage vector represents the serial number of slots.

For the winding configuration of

M4, it is necessary to obtain the slot distance parameter

β using Equation (4). It can be determined that it belongs to type

B. The results of distribution to phases are given in

Table 11. The turn distribution of common slots can be achieved according to

Table 8.

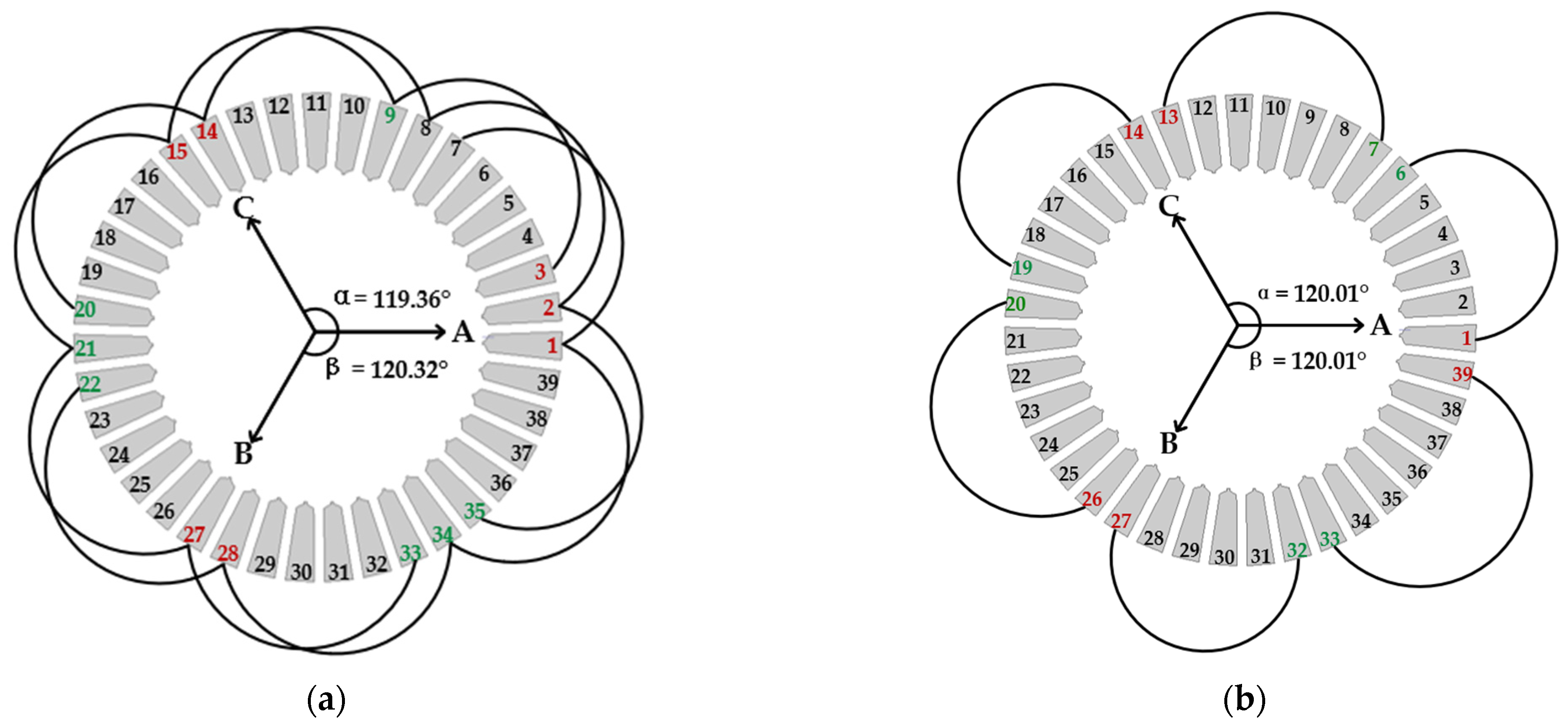

The phase-A coil connection diagrams of the four windings are given in

Figure 3; this figure shows the phase angles between phase vectors of the winding. CBW, UBW, and UESW can be achieved by two-layer winding, but for UOSW, a multi-layer structure may occur. Moreover, there is a limitation of turns in UESW and UOSW; the number of UOSW coil turns per slot is 6

n, and in UESW the coil turns per slot is 3

n, where

n is an integer.

The respective winding factors are given in

Table 12, and there is a slight asymmetry for the three winding configurations, except for CBW. It can be seen that the stronger asymmetry, the smaller winding factor and the greater the winding factor difference between the phases.

4.2. Air-Gap Flux Density Analysis

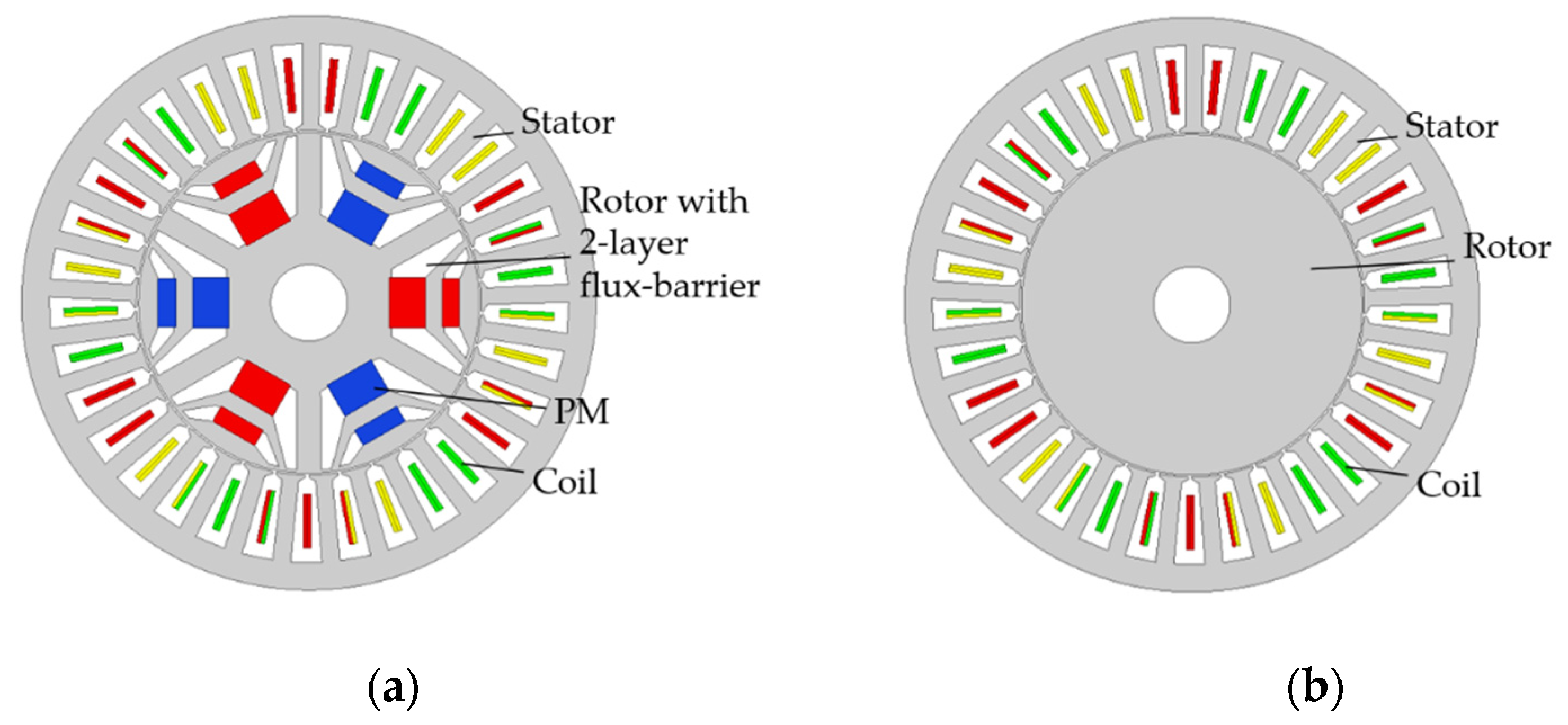

There are two different motor models of the rotor with double layer flux-barrier and the rotor without flux-barrier as shown in

Figure 4. The two models have the same structure, except for the flux-barrier and permanent magnet (PM). The permanent magnets used in the FEA are ferrite permanent magnet material: for Y30BH, the residual magnetic induction intensity of this material is

Br = 0.38~0.40 T, the magnetic induction coercive force

HCb = 224~240 kA/m, and the maximum magnetic energy product (

BH)

max = 27.1~30.3 kJ/m

3.

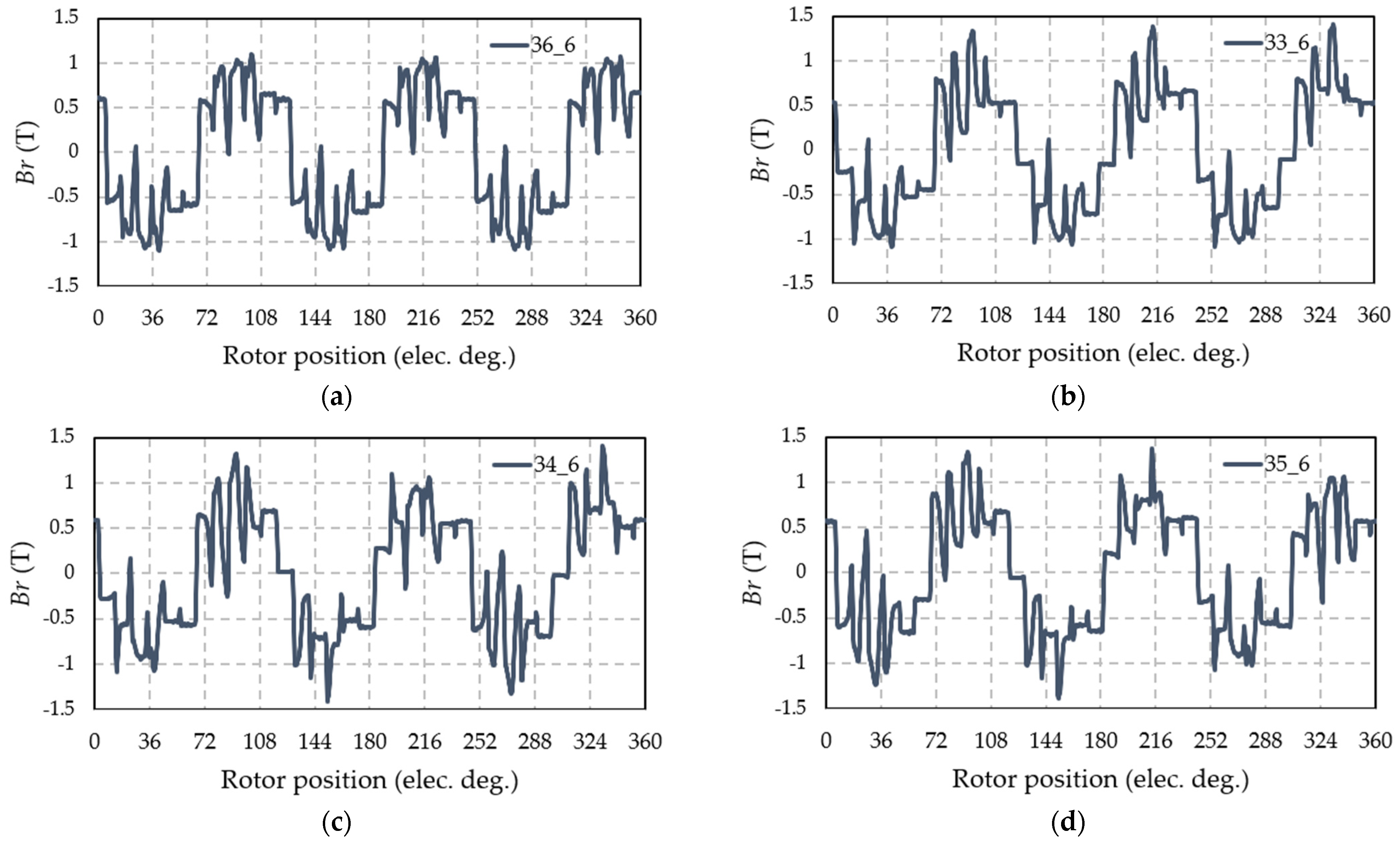

The air-gap flux density wave form and harmonic of these models are analyzed and compared by two-dimensional FEA. The simulation results and the harmonic content results obtained by Fourier analysis are simulated under the two rotor models.

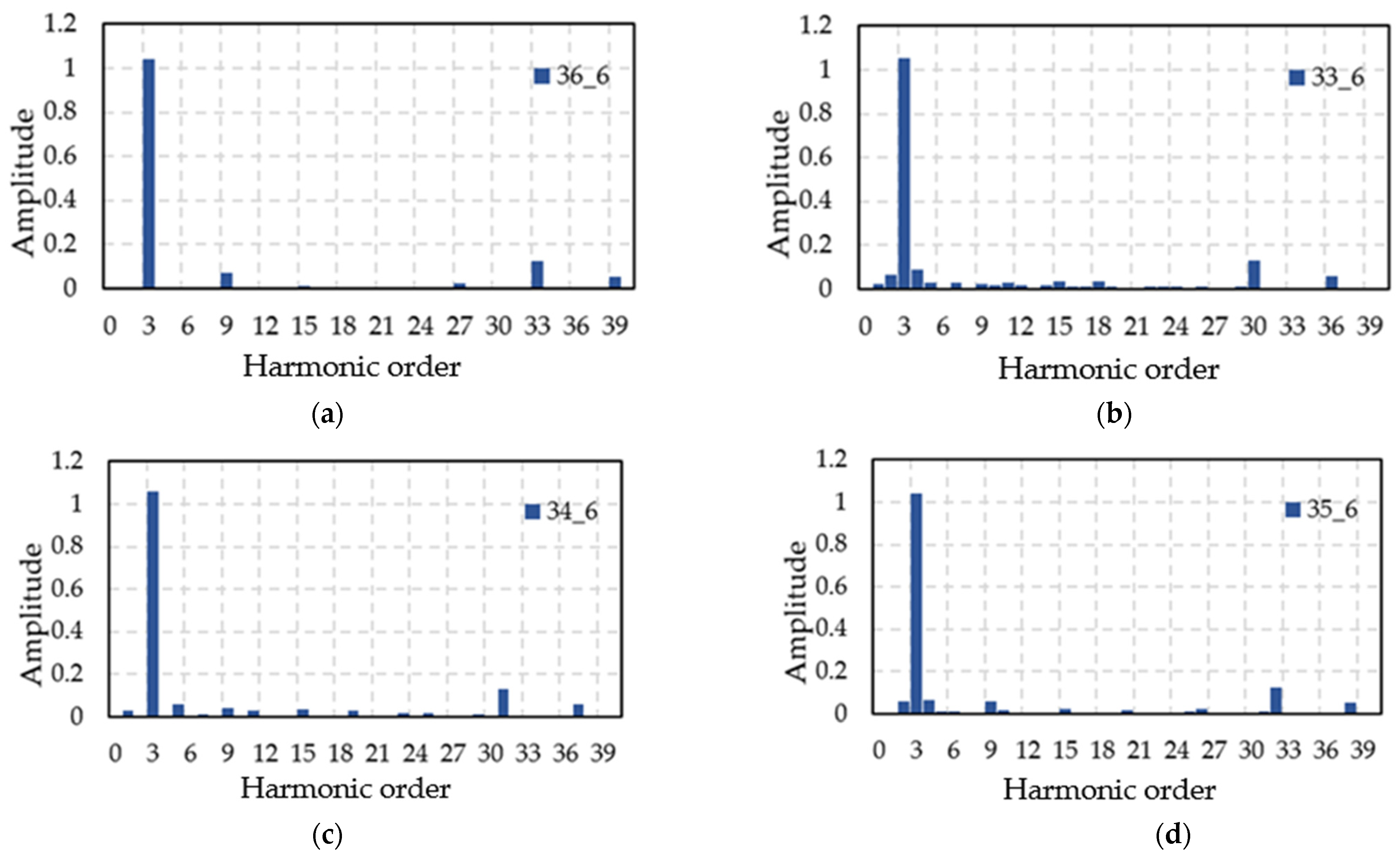

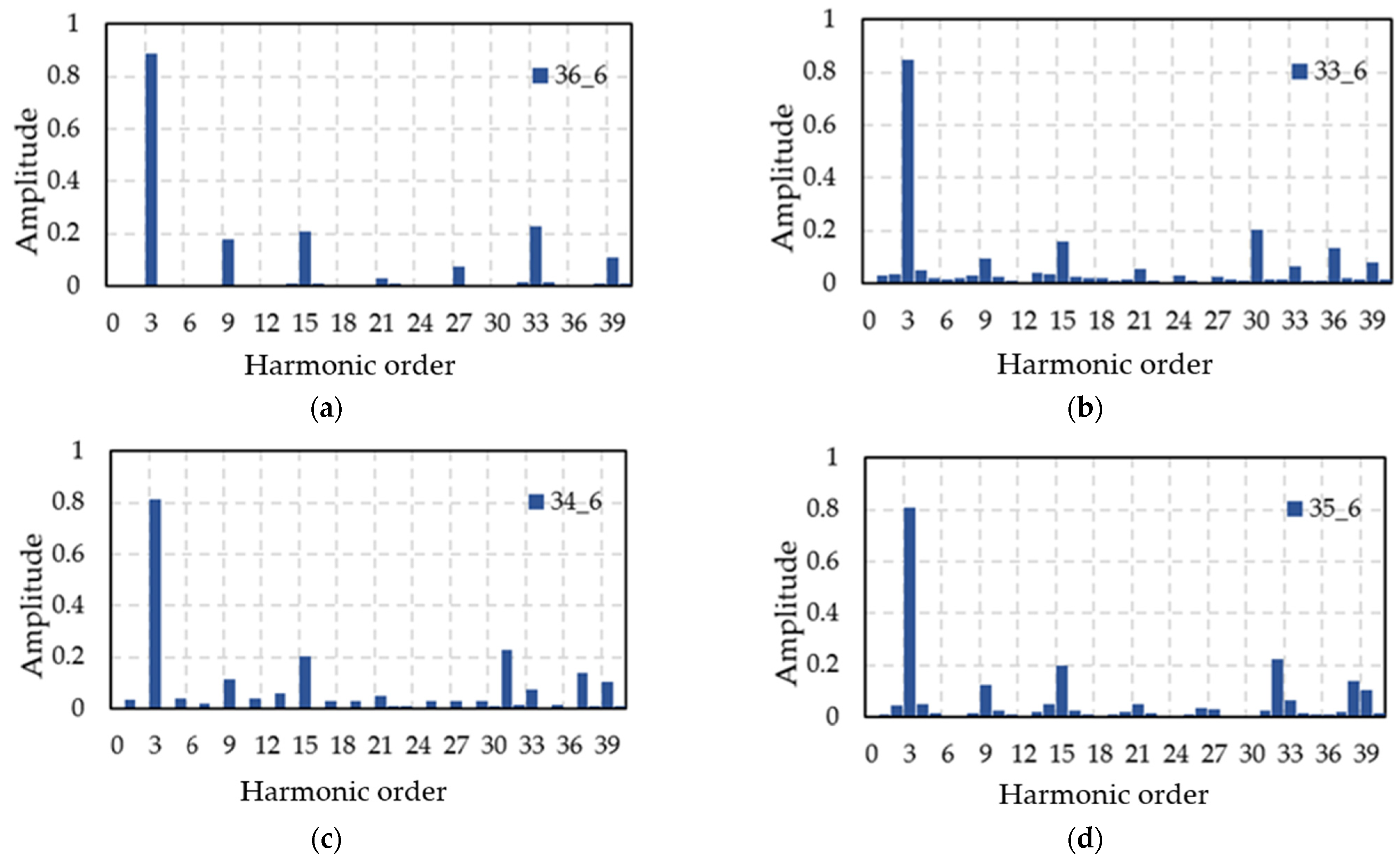

There is a very important theory that the same part of the air-gap flux density harmonics under the two rotors comes from the stator magneto motive force (MMF), and the different part between the two air-gap flux density comes from the rotor MMF. The air gap magnetic density waveforms and harmonic components of the four windings under the model without flux-barrier rotor are shown in

Figure 5 and

Figure 6, and the model with two-layer flux-barrier rotor are shown in

Figure 7 and

Figure 8.

In order to analyze the relationship between torque harmonic order and MMF harmonics of stator and rotor, the following simple analysis is carried out. Assuming that the symmetrical winding passes through the symmetrical current, and each spatial harmonic order of stator analyzed above is summarized, the total stator MMF synthesized by each phase is calculated in accordance with Equation (8). Assuming that

δ is the lagging electrical angle of the rotor MMF harmonic behind the harmonic of stator, and all of these harmonics are rotating at a constant speed, the rotor MMF is calculated in accordance with Equation (9).

where

u is the spatial harmonic order of rotor MMF,

u = 2

k + 1,

k = 0, 1, 2, …,

Fu is the spatial harmonic amplitude of rotor MMF, and

θ is the angle between the rotor pole axis and the phase-A winding axis of the stator along the air gap; its changing direction represents the harmonic rotation direction.

With the assumption that the core permeability of the motor is infinite, the air gap flux density generated by the stator and rotor MMF are calculated in accordance with Equations (10) and (11), respectively. When the saturation of the magnetic field is ignored, the air gap synthetic flux density is calculated in accordance with Equation (12).

where

μ0 is vacuum permeability and

g is the equivalent gas gap length. For the linear air gap, the magnetic energy of the motor is equal to the magnetic co-energy. The solution process is shown in Equation (13), and it is simplified by the orthogonality of the trigonometric function in Equation (14). Then the expression of torque can be obtained by Equation (15).

where

r is the average air gap radius,

D is the average air gap diameter,

l is the stator laminated core length, and

V is the unit air gap volume.

Using Equation (15), it can be found that only the harmonic interaction of stator and rotor MMF with the same spatial order produces electromagnetic torque; because the rotation speed of harmonics is different from that of fundamental wave, the torque produced by harmonics are pulsating components.

Figure 5 shows the air-gap flux density of the stator MMF alone, and

Figure 7 shows the air-gap flux density common to the stator MMF and rotor MMF. The harmonic order is unified in the mechanical period by the analysis of the air gap flux density harmonics shown in

Figure 6 and

Figure 8. It can be found that the air gap magnetic density harmonic components mainly contain four odd harmonic orders in an electric period—3rd, 5th, 11th and 13th—and there are more fractional harmonics for UBW, UOSW, and UESW.

The 3rd and 5th harmonics are mainly produced by rotor MMF, but the content of the two components in stator MMF is relatively low, so there is little fluctuation of torque. For CBW, both the stator and rotor produce the 11th and 13th harmonics, so it will produce larger torque fluctuation. But for UBW, UOSW, and UESW, because the 11th and 13th harmonics are only produced in the rotor MMF and there are no harmonics where u and v are equal, the ripple is not produced. In the above analysis, we can see that the three winding schemes, except the CBW, can reduce the torque ripple because of the offset harmonic order.

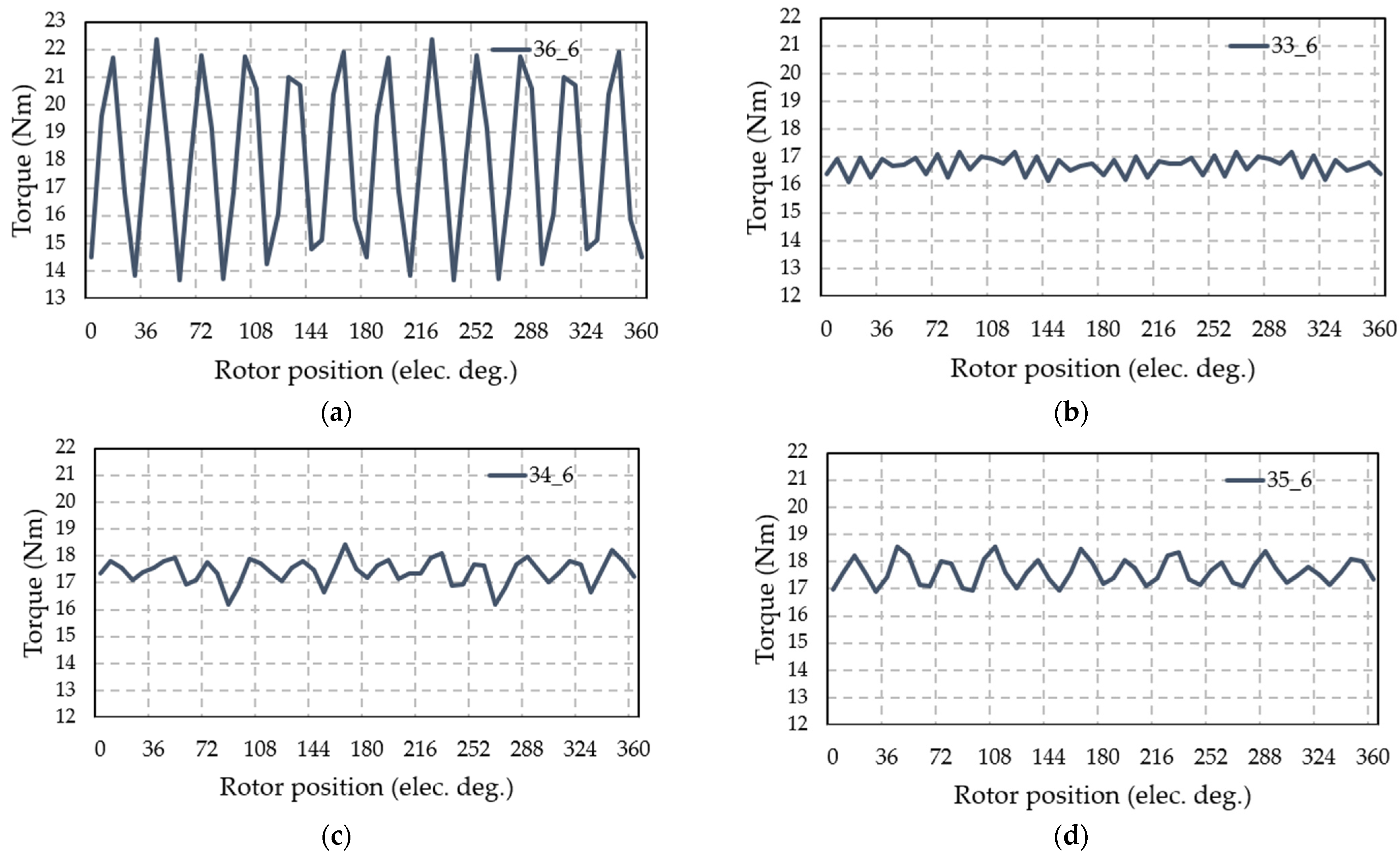

4.3. Torque Ripple Analysis

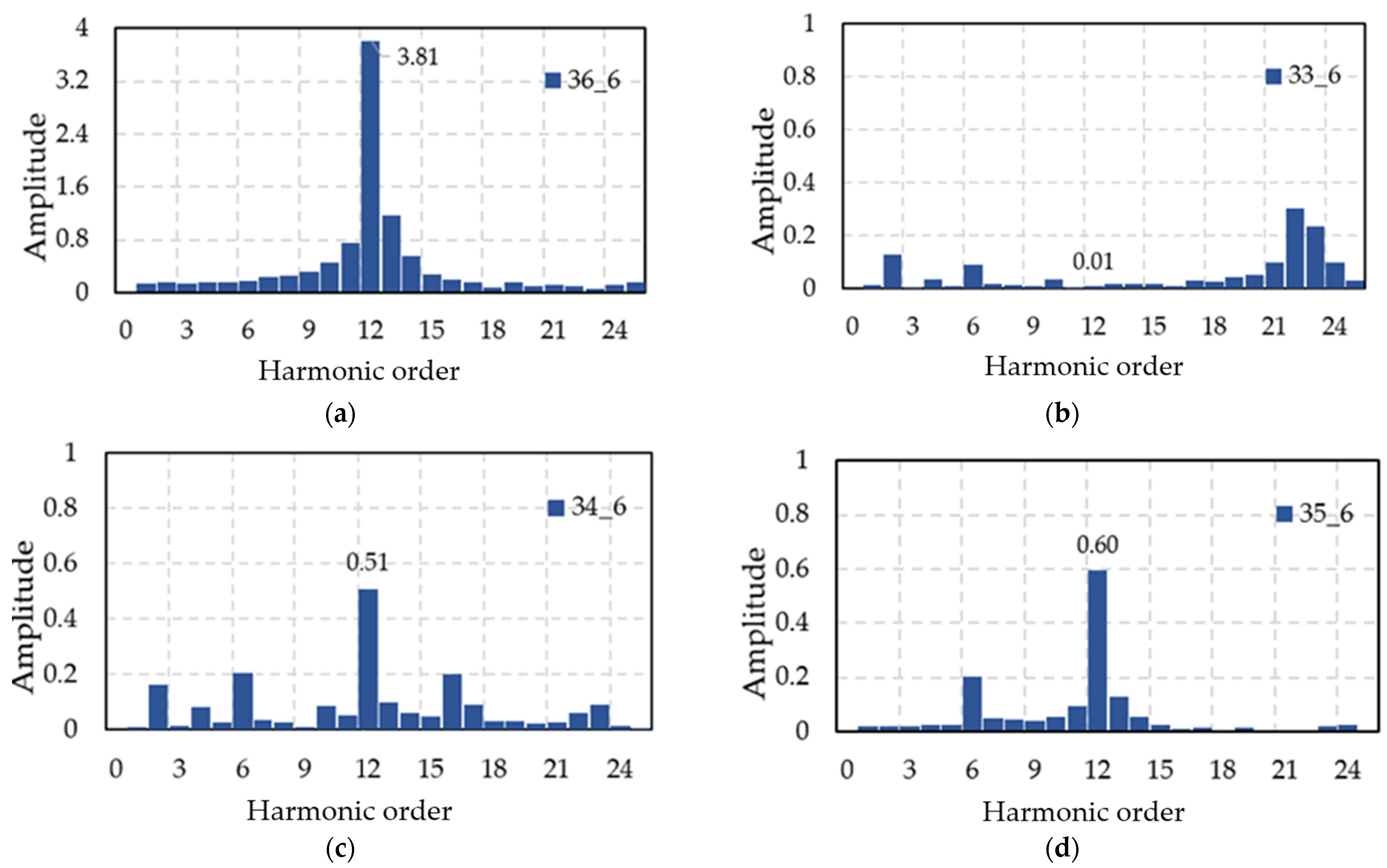

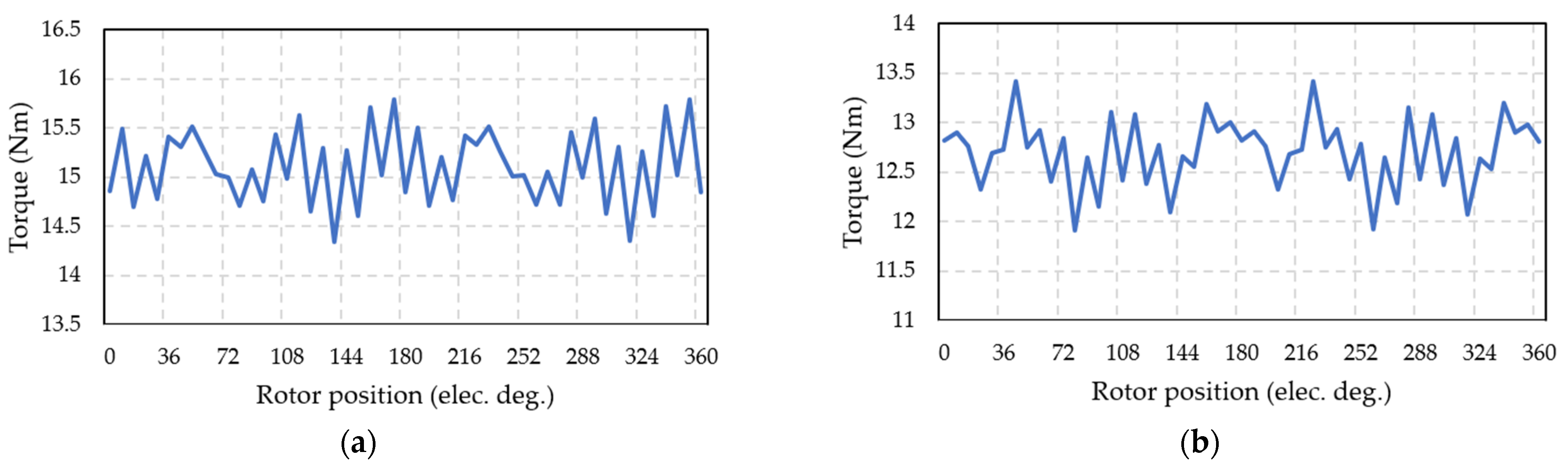

The torque ripple simulations of four kinds of winding configurations with two-layer flux-barrier rotor are used to verify the conclusion of reducing torque ripple obtained from air gap magnetic density harmonic analysis. Their torque wave forms and harmonics ignoring fundamental wave are shown in

Figure 9 and

Figure 10, respectively.

θ is the current angle, and the value of

M1,

M2,

M3, and

M4 are 60°, 58°, 62°, and 62°, respectively. The average torque is 18.05, 16.73, 17.43, and 17.63 Nm, and the torque ripple is 48.08%, 6.35%, 12.85%, and 9.41%, respectively. When the torque ripple is reduced in

M2,

M3, and

M4, the average torque is also reduced slightly. Because the reduction of average torque is small compared with torque ripple, it can be ignored.

In

Figure 10, it can be seen that the main harmonic of

M1 is the 12th, and the amplitude of the four motors is 3.81, 0.01, 0.51, and 0.60. It is verified that the 11th and 13th harmonics of the air gap magnetic density are the main factors producing torque ripple, and six-pole combination with 33-slot can reduce the 12th harmonic well. Thus, it can be concluded that UBW, UOSW, and UESW can reduce torque ripple, among which the reduction of UBW is the most effective.

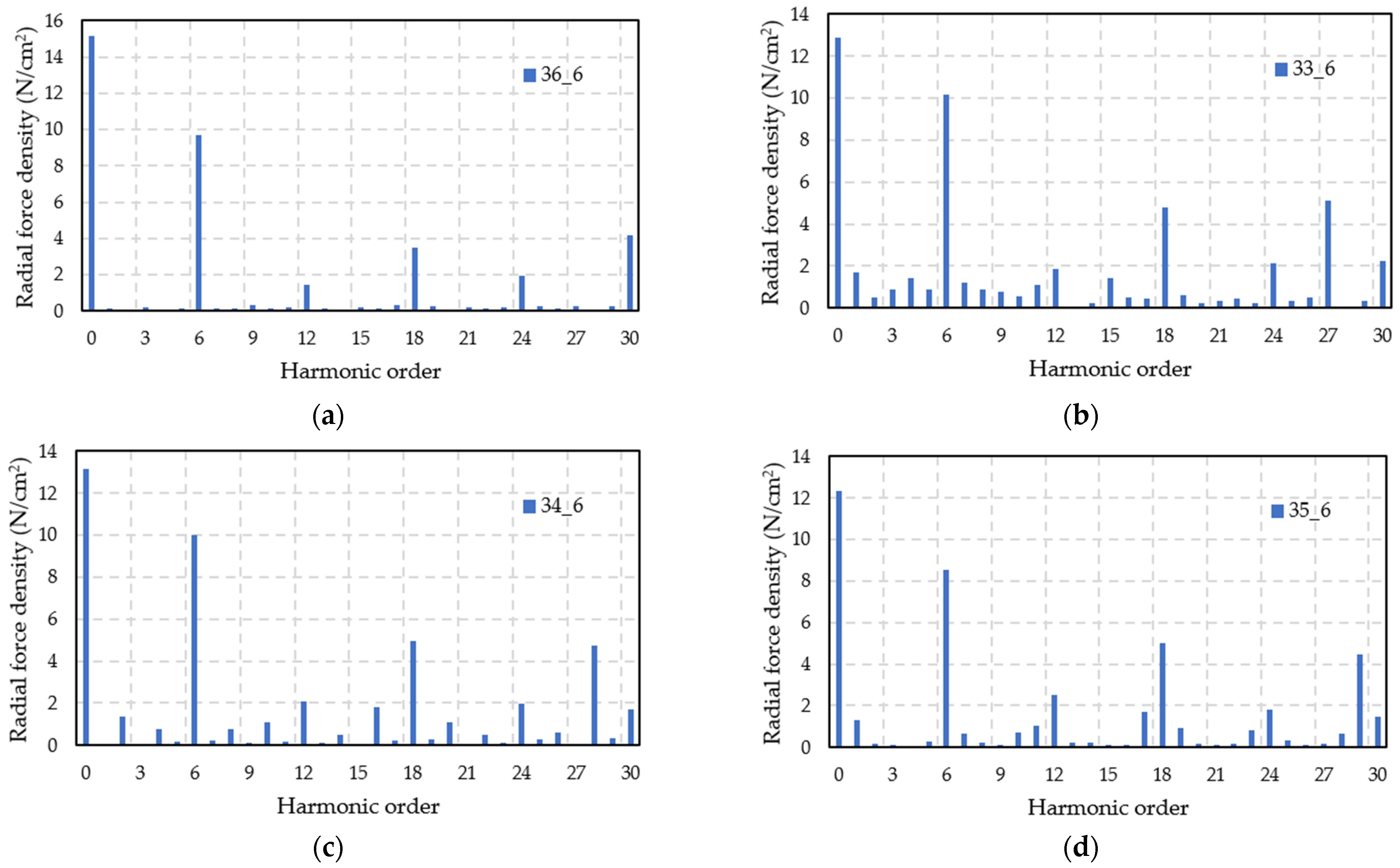

4.4. Radial Force Analysis

Figure 11 shows the radial force density harmonics of

M1,

M2,

M3, and

M4; it can be seen that the main orders of these four motors are 6

kth, and

M2,

M3, and

M4 harmonic contents have a slight increase compared with

M1.

There are some conclusions we can obtain from the harmonic analysis.

In terms of harmonic components, all low-order harmonics from the 1st to 12th increase in M2 (UBW) and the even-order harmonics are the main components in M3 (UESW) because of the even number of slots. For the M4 motor, the (6k ± 1)th harmonics are more obvious.

As for the magnitude of the radial force density, the fundamental amplitude of M2, M3, and M4 is lower than the counterpart of M1. However, for the 6th harmonics, M1, M2, and M3 are similar, and M4 is significantly lower.

Taking into account the unbalanced electromagnetic force, in M2 and M4, the first radial force harmonic generated by the odd number of slots will produce the unbalanced electromagnetic force. The performance in vibration and noise is worse than even slot motors M1 and M3. At the same time, due to the large number of harmonics of M2, its vibration and noise are more complicated.

4.5. Power Loss Analysis

The power losses include four parts: copper losses

pCu, core losses

pFe, mechanical losses

pm, and stray losses

ps. They can be expressed as

The copper losses,

pCu, can be calculated by

where

I is the stator phase current,

R is the phase resistance,

ρ is the resistivity,

Lav is the average length of the coils,

Nc is the coil turns, and

d is the conductor diameter. For the four motors

M1,

M2,

M3, and

M4, the phase current

I is equal, the conductors they use are the same type of copper,

ρ = 1.7 × 10

−8 Ω·m, and

Nc is equal to 24. The copper losses of

M1,

M2,

M3, and

M4 are 451.719 W, 404.392 W, 405.803 W, and 409.664 W, respectively. The reason for the greater losses of

M1 is the longer end windings determined by the coil throw

y and the greater number of conductors determined by the number of slots

Qs.The core losses

pFe are presented as follows:

where

kh, kc, and

ke are the hysteresis loss factor, eddy current loss factor, and excess factor, respectively. These are related to the material properties of silicon steel sheets.

Bm is the amplitude of the sine flux density, and

f is the sine wave frequency. The air-gap flux density waveforms and harmonics of the four motors are shown in

Figure 7 and

Figure 8. The harmonics of Fourier analysis are sine waves, so they can be applied to Equation (19). The third is the main component, and the core losses of high-order harmonics are small. It is approximated that the

pFe of

M1 is larger than the other three motors, because its third of flux density is larger. The materials used in the stator and rotor models are DW310_35, and

kh, kc, and

ke are equal to 179, 0.403, and 0, respectively. The core losses in FEA of

M1,

M2,

M3, and

M4 are 1.447 W, 1.166 W, 1.279 W, and 1.384 W, respectively.

The mechanical losses,

pm, can be analyzed by

where

pfw and

pb are friction and windage losses and bearing losses, respectively.

Cf and

Cb are friction coefficient and bearing coefficient, respectively.

k is the roughness factor of the rotor surface,

ρ is the gas density,

ω,

r, and

l are the angular velocity, radius, and length of rotor, respectively, and

D is the diameter of bearing. This is related to the bearing, rotor, lubricants, and the quality of the motor. Therefore, when the size of the motor is the same, the adding or removing of a few slots has little effect on the mechanical losses.

The stray losses,

ps, are equivalent to the following:

where

is an empirical losses parameter,

IN is the rated phase current, and

PN is the rated power. The phase currents of the four motors are equal, so their stray losses are approximately equal.

where

η is the efficiency of motors,

P1 is the input power, and

φ is the power factor angle. The phase currents

I of motors are 23 A and the power factor angles

φ are 22.539°, 24.987°, 24.891° and 27.322°. The input power calculation results are 4308.829 W, 3626.364 W, 3702.672 W, and 3647.004 W. Assuming that the other losses except copper losses and core losses are 2% of the respective input power, the calculated efficiency of these four motors is 87.48%, 86.82%, 87.01%, and 86.73%. The calculated results are displayed in

Table 13. Overall, the degree of efficiency reduction of

M2,

M3, and

M4, compared with

M1, is acceptable.

6. Conclusions

This paper presents a theory of four kinds of winding configurations and various slot-pole combinations, classified as CBW, UBW, UESW, and UOSW. It simplifies the winding distribution to phases. In addition, the torque ripple of the last three kinds of windings are lower compared with CBW.

The air-gap flux density wave form and harmonics of models with double layer flux-barrier and PM rotor and without flux-barrier rotor are analyzed and compared using two-dimensional FEA. It can be verified that the winding configuration of UBW, UESW, and UOSW can reduce the torque ripple compared with CBW through the relationship between MMF harmonics of stator and rotor. Thus, it is important to select a better winding configuration for PMASynRMs to obtain a smooth torque. The effects produced by UBW, UESW, and UOSW in the radial forces and power losses compared to CBW are acceptable.