Corner Separation Control Using a New Combined Slotted Configuration in a High-Turning Compressor Cascade under Different Solidities

Abstract

1. Introduction

2. Cascade Models and Numerical Methods

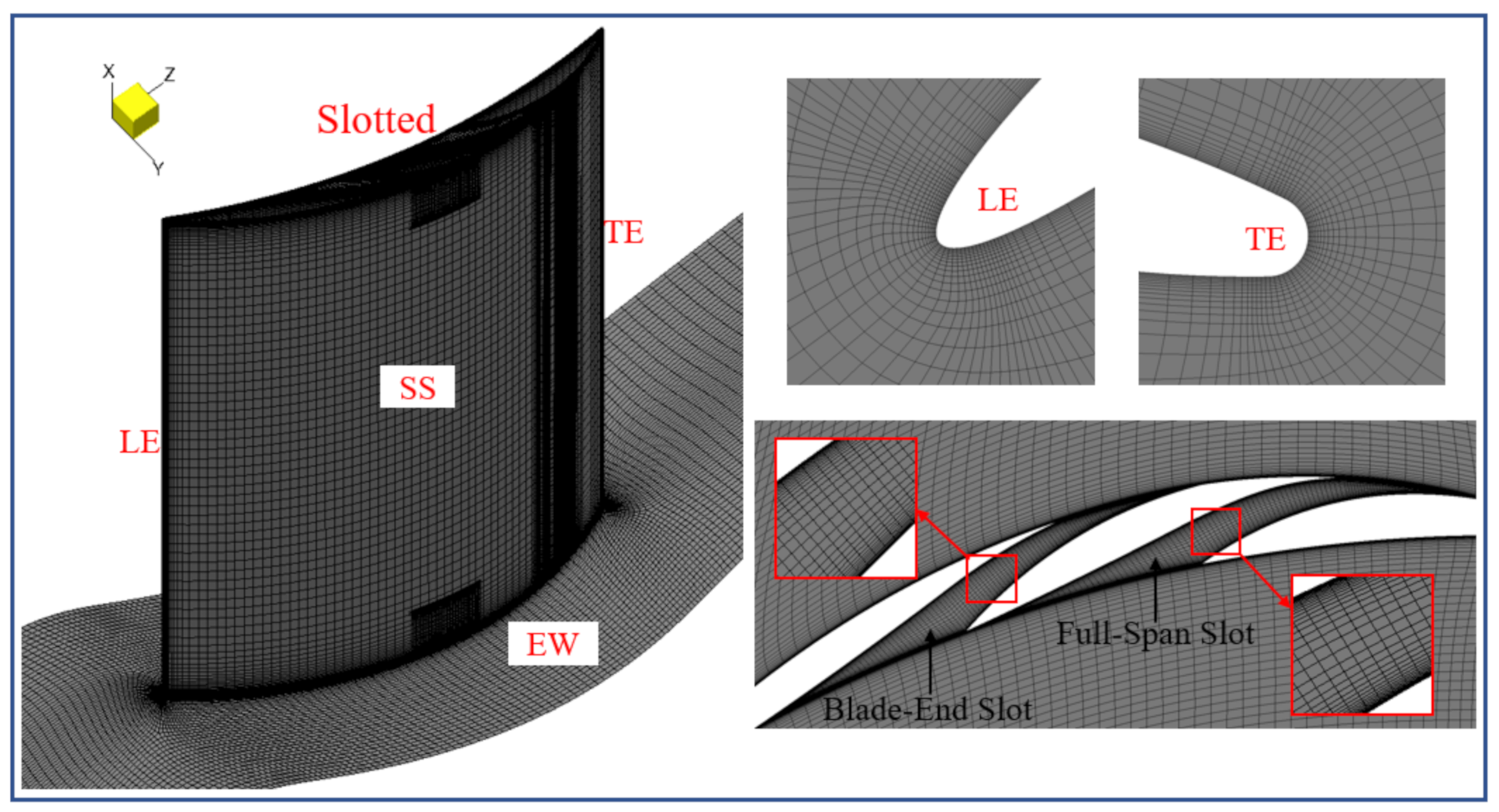

2.1. Original Cascade and Combined Slotted Cascade

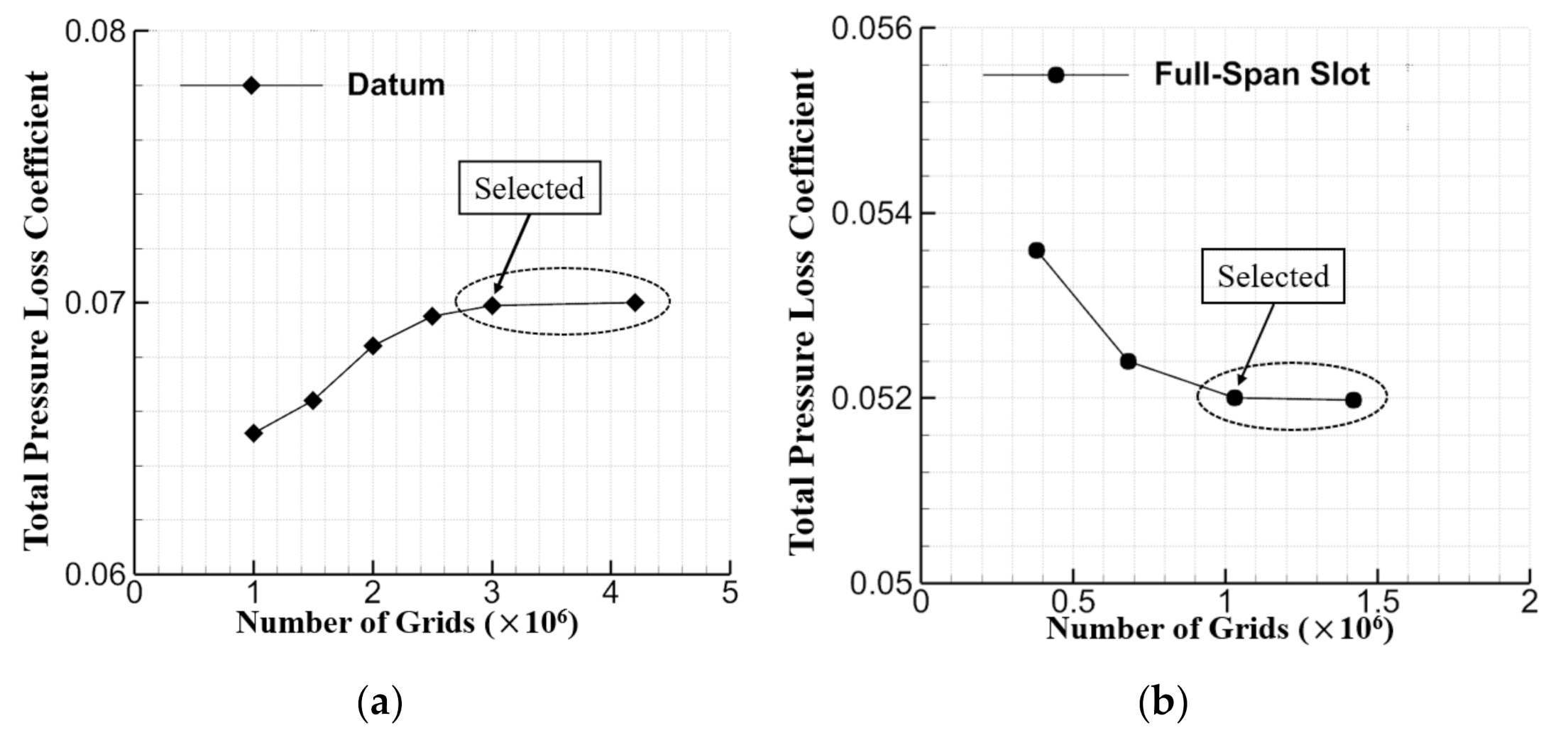

2.2. Gird and Numerical Technique

2.3. Simulation Results Validation

3. Results and Discussion

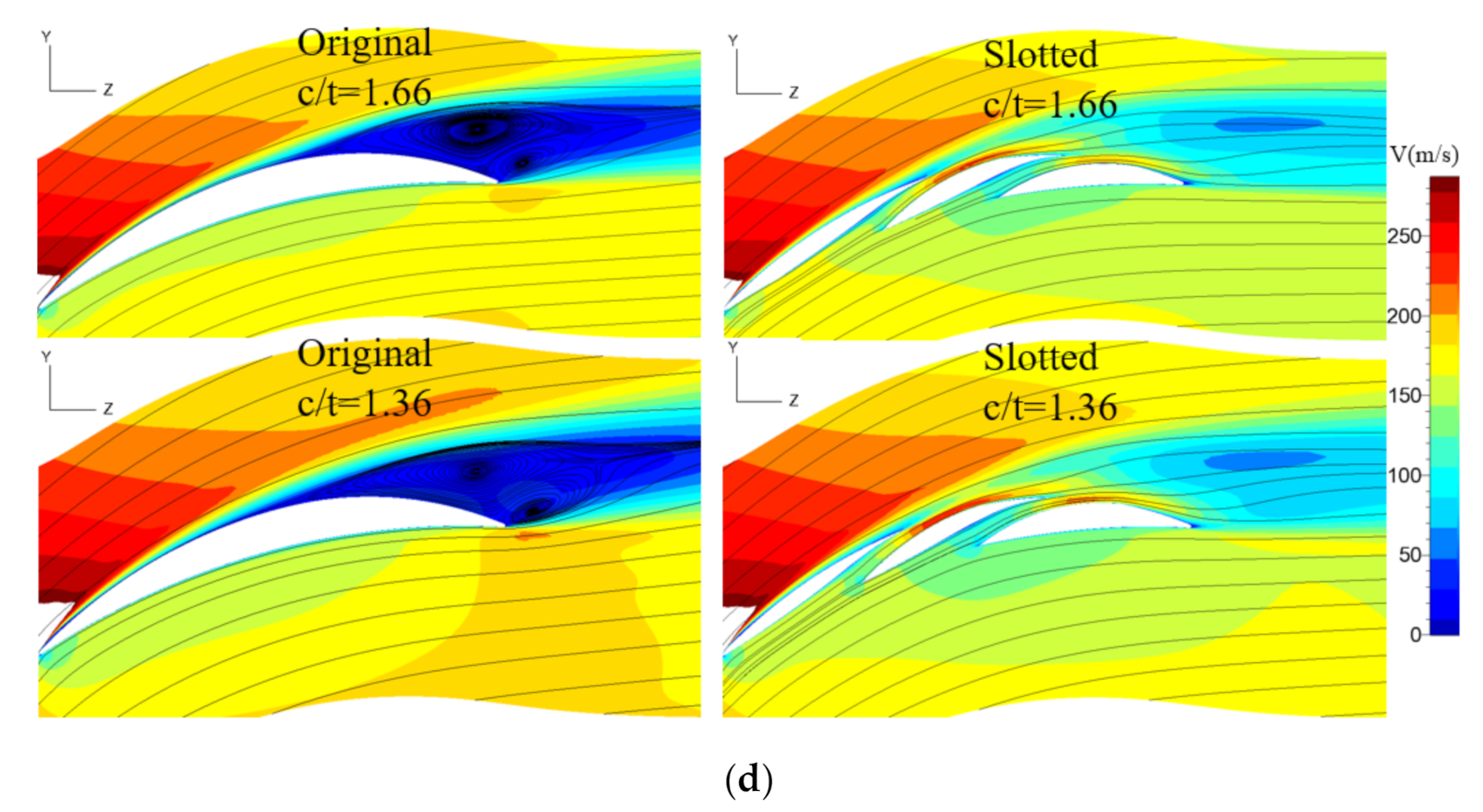

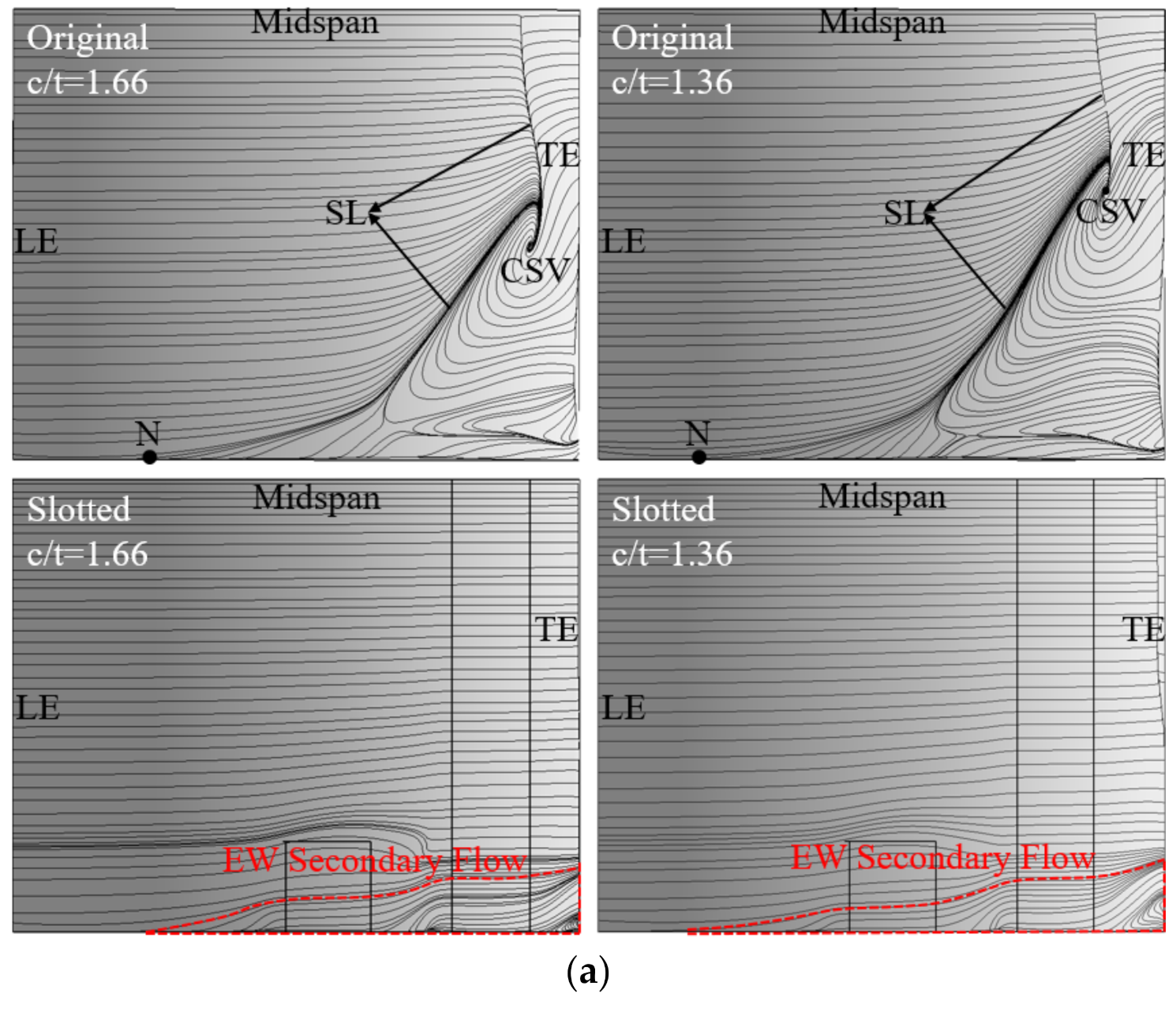

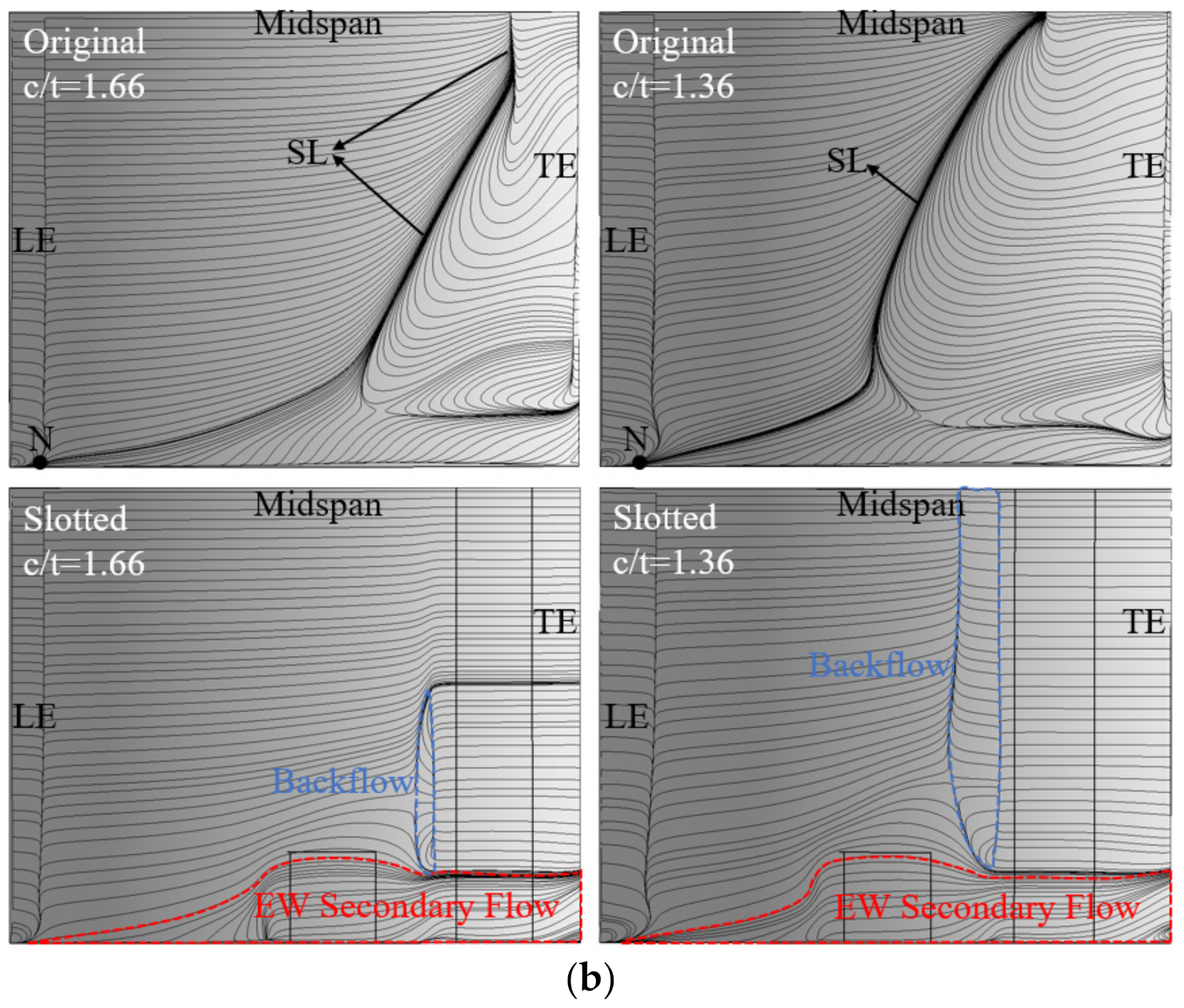

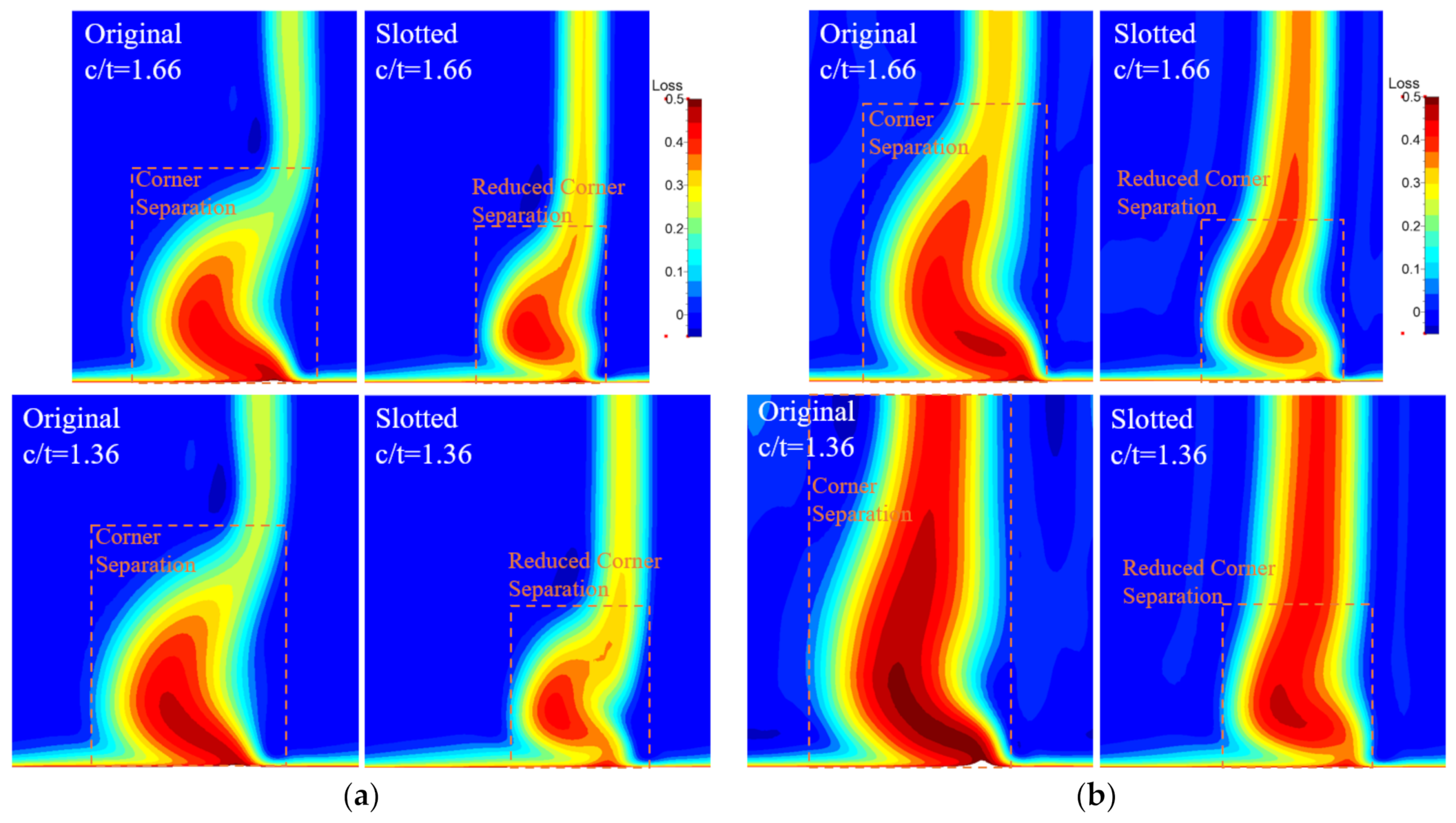

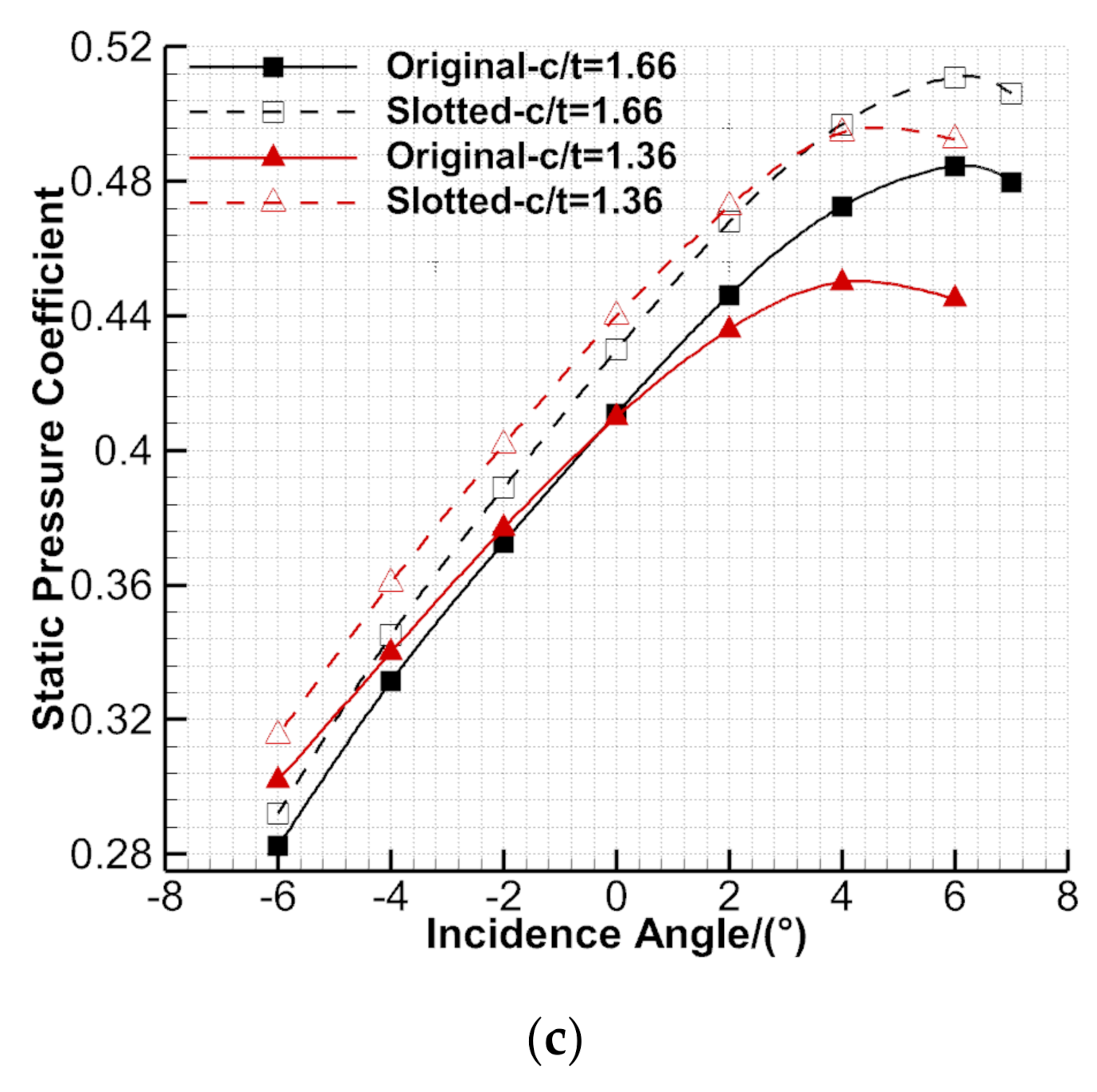

3.1. Flow Patterns and Pressure Diffusing Capacity

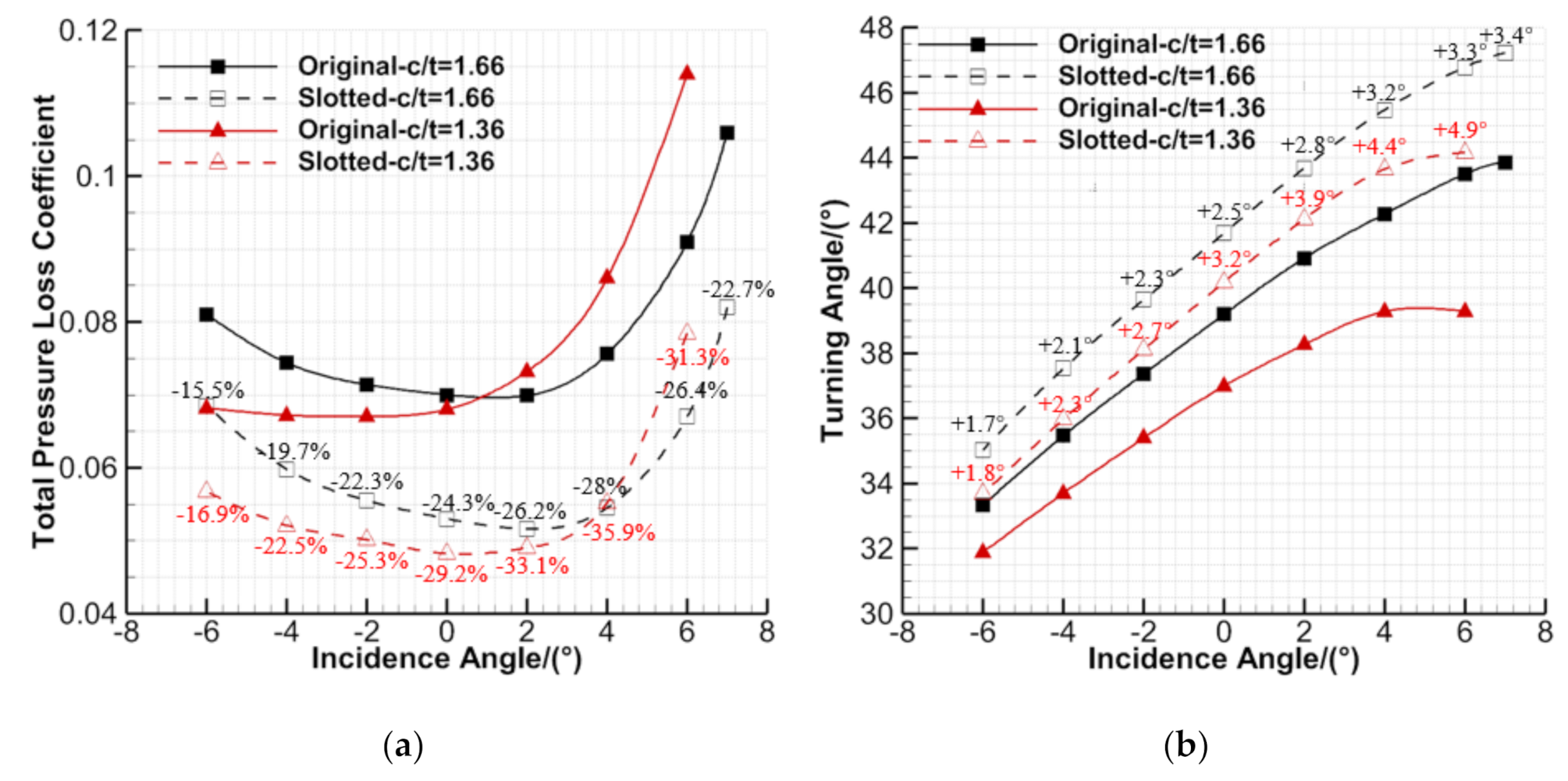

3.2. Loss and Turning Angle

3.3. Overall Performance

4. Conclusions

- The slot configuration designed in this research has a great self-adaptability to incidence angles. The fluid in the blade-end and full-span slots can be accelerated to the mainstream velocity of the blade SS side at the slot outlet under different incidence angles, which ensures the significant re-energizing effect of the slot jet on the low-momentum fluid in the boundary layer. Therefore, the flow separation can be controlled well in the combined slotted cascade within the full incidence angle range.

- There exists the PV and CSV (or separation zone) in the original cascade passage, which is the main reason for its serious corner separation. Under the combined blowing effect of the blade-end and full-span slots jets, the PV can be reduced and the CSV can be effectively weakened in the combined slotted cascade. Thus, the corner separation is reduced remarkably in the combined slotted cascade, contributing to lower total pressure loss, higher turning angle and a broadening of the flow passage.

- The corner separation range of the original cascade becomes larger as the blade solidity decreases from 1.66 to 1.36 under the incidence angles of 0° and 6°. However the development of the EW secondary flow before the full-span slot outlet can be effectively suppressed by the blade-end slot jet and when combined with the full-span slot jet blowing effect, the corner separation range can be reduced in the combined slotted cascade at the two blade solidities.

- With the decrease in the blade solidity from 1.66 to 1.36, the blade loading and the blade TE static pressure coefficient of the original cascade are increased and decreased under the incidence angles of 0° and 6°, respectively. However, the slot jet significantly improves the flow patterns behind the slot outlet in the combined slotted cascade, hence its blade loading is increased behind the slot outlet at the two blade solidities compared with that of the original cascade and its blade TE static pressure coefficient is also increased remarkably.

- The combined slotted configuration has a significant adaptability to the low blade solidity (or high loading) condition. By adopting the combined slotted configuration, the total pressure loss, turning angle and static pressure coefficient of the original cascade can be increased by −23.2%, 2.7° and 4.7 %, respectively, on average when the blade solidity is 1.66, while they can be increased by −27.7%, 3.3° and 7.6%, respectively, on average when the blade solidity is 1.36. Moreover, the lower solidity combined slotted cascade can achieve stronger pressure diffusing capacities than the higher solidity original cascade with smaller total pressure loss. Therefore, the combined slotted configuration shows a certain potential in increasing the aeroengine thrust-to-weight ratio by decreasing the compressor single-stage blade number.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Total pressure loss coefficient | |

| Static pressure coefficient | |

| Inlet total pressure | |

| Local total pressure | |

| Inlet static pressure | |

| Local static pressure | |

| Turning angle | |

| Inlet flow angle | |

| Outlet flow angle | |

| Geometric inlet angle | |

| Geometric outlet angle | |

| Stagger angle | |

| i | Incidence angle |

| c | Blade chord |

| Ca | Axial blade chord |

| H | Blade height |

| t | Blade pitch |

| Inlet Mach number | |

| Blade-chord-based Reynolds number | |

| Blade-end slot outlet throat width | |

| Full-span slot outlet throat width | |

| Blade-end slot lower wall outlet curve radius | |

| Full-span slot lower wall outlet curve radius | |

| N | Starting point of the corner separation line |

Abbreviations

| EW | End-wall |

| PS | Pressure surface |

| SS | Suction surface |

| LE | Leading edge |

| TE | Trailing edge |

| CSV | Concentrated shedding vortex |

| PV | Passage vortex |

| SV | Separation vortex |

| WV | Wall vortex |

| CV | Corner vortex |

| AO | Axial overlap |

| RANS | Reynolds Averaged Navier-Stokes |

| LES | Large-eddy simulation |

| DDES | Delayed detached eddy simulation |

References

- Wennerstrom, A.J. Highly loaded axial flow compressors: History and current developments. J. Turbomach. 1990, 112, 567–578. [Google Scholar] [CrossRef]

- Wisler, D.C. Loss reduction in axial-flow compressors through low-speed model testing. J. Eng. Gas Turbines Power 1985, 107, 354–363. [Google Scholar] [CrossRef]

- Li, R.Y.; Gao, L.M.; Ma, C.; Lin, S.Y.; Zhao, L. Corner separation dynamics in a high-speed compressor cascade based on detached-eddy simulation. Aerosp. Sci. Technol. 2020, 99, 105730. [Google Scholar] [CrossRef]

- Gand, F.; Monnier, J.-C.; Deluc, J.-M.; Choffat, A. Experimental study of the corner flow separation on a simplified junction. AIAA J. 2015, 53, 1–9. [Google Scholar] [CrossRef]

- Taylor, J.V.; Miller, R.J. Competing three-dimensional mechanisms in compressor flows. J. Turbomach. 2016, 139, 021009. [Google Scholar] [CrossRef]

- He, C.; Ma, Y.F.; Liu, X.H.; Sun, D.K.; Sun, X.F. Aerodynamic instabilities of swept airfoil design in transonic axial-flow compressors. AIAA J. 2018, 56, 1–16. [Google Scholar] [CrossRef]

- Gao, F.; Ma, W.; Zambonini, G.; Boudet, J.; Ottavy, X.; Lu, L.P.; Shao, L. Large-eddy simulation of 3-D corner separation in a linear compressor cascade. Phys. Fluids 2015, 27, 085105. [Google Scholar] [CrossRef]

- Scillitoe, A.D.; Tucker, P.G.; Adami, P. Numerical investigation of three-dimensional separation in an axial flow compressor: The influence of freestream turbulence intensity and endwall boundary layer state. J. Turbomach. 2016, 139, 021011. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Y.W.; Li, Q.S.; Lu, L.P. Turbulence characteristics in corner separation in a highly loaded linear compressor cascade. Aerosp. Sci. Technol. 2018, 75, 139–154. [Google Scholar] [CrossRef]

- Li, J.; Hu, J.; Zhang, C.K. Investigation of vortical structures and turbulence characteristics in corner separation in an axial compressor stator using DDES. Energies 2020, 13, 2123. [Google Scholar] [CrossRef]

- Denton, J.D. Loss mechanisms in turbomachines. J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- Cumpsty, N.A.; Greitzer, E.M. Ideas and methods of turbomachinery aerodynamics: A historical view. J. Propuls. Power 2004, 20, 15–26. [Google Scholar] [CrossRef]

- MacMartin, D.G.; Tillman, T.G. Flow control opportunities in gas turbine engines. In Proceedings of the Fluids 2000 Conference and Exhibit, Proceedings of the Fluid Dynamics and Co-Located Conferences, Denver, CO, USA, 19–22 June 2000. [Google Scholar]

- Ankit, S.; Francis, L. Topological studies of three-dimensional flows in a high pressure compressor stator blade row without and with boundary layer aspiration. Chin. J. Aeronaut. 2011, 24, 541–549. [Google Scholar]

- Mao, X.C.; Liu, B.; Yuan, F.Z. Numerical and experimental study of separation control by boundary layer aspiration in a highly-loaded axial compressor cascade. J. Appl. Fluid Mech. 2018, 11, 433–446. [Google Scholar] [CrossRef]

- Qin, Y.; Song, Y.P.; Chen, F.; Wang, R.Y.; Liu, H.P. Active flow control by means of endwall synthetic jet on a high-speed compressor stator cascade. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 232, 641–659. [Google Scholar] [CrossRef]

- Liu, H.P.; Yu, Y.C.; Chen, H.L.; Yu, M.H.; Zhang, D.F. A parametric investigation of endwall vortex generator jet on the secondary flow control for a high turning compressor cascade. J. Therm. Sci. Technol. 2017, 12, JTST0006. [Google Scholar] [CrossRef]

- Zhao, W.F.; Zheng, Q.; Jiang, B.; Lin, A.Q. A passive control method of hub corner stall in a 1.5-stage axial compressor under low-speed conditions. Energies 2020, 13, 2691. [Google Scholar] [CrossRef]

- Kan, X.X.; Wu, W.Y.; Yang, L.; Zhong, J.J. Effects of end-bend and curved blades on the flow field and loss of a compressor linear cascade in the design condition. J. Therm. Sci. 2019, 28, 801–810. [Google Scholar] [CrossRef]

- Cao, Z.Y.; Liu, B.; Zhang, T.; Xu, Y.B.; Zhao, H. Non-axisymmetric endwall profiling in a highly loaded compressor cascade. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 233, 275–292. [Google Scholar] [CrossRef]

- Pan, R.C.; Song, Z.Y.; Liu, B. Optimization Design and Analysis of Supersonic Tandem Rotor Blades. Energies 2020, 13, 3228. [Google Scholar] [CrossRef]

- Tang, Y.M.; Liu, Y.W.; Lu, L.P. Passive separation control with blade-end slots in a highly loaded compressor cascade. AIAA J. 2019, 58, 85–97. [Google Scholar] [CrossRef]

- Hu, J.G.; Wang, R.G.; Huang, D.Q. Flow control mechanisms of a combined approach using blade slot and vortex generator in compressor cascade. Aerosp. Sci. Technol. 2018, 78, 320–331. [Google Scholar] [CrossRef]

- Zweifel, O. The spacing of turbo-machine blading, especially with large angular deflection. Brown Boveri Rev. 1945, 32, 436–444. [Google Scholar]

- Lieblein, S.; Schwenk, F.C.; Broderick, R.L. Diffusion Factor for Estimating Losses and Limiting Blade Loadings in Axial-Flow-Compressor Blade Elements; No. NACA-RM-E53D01; National Advisory Committee for Aeronautics, Lewis Flight Propulsion Lab: Cleveland, OH, USA, 1953. [Google Scholar]

- Sans, J.; Resmini, M.; Brouckaert, J.F.; Hiernaux, S. Numerical investigation of the solidity effect on linear compressor cascades. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Tang, Y.M.; Liu, Y.W.; Lu, L.P. Solidity effect on corner separation and its control in a high-speed low aspect ratio compressor cascade. Int. J. Mech. Sci. 2018, 142–143, 304–321. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, R.G.; Cao, Z.H.; Zhang, X.Y. Effect of slot position and slot structure on performance of cascade. Acta Aerodyn. Sin. 2008, 26, 400–404. (In Chinese) [Google Scholar]

- Sun, J.J.; Liu, Y.W.; Lu, L.P.; Xavier, O. Control of corner separation by slot at the root of the blade. J. Eng. Thermophys. 2019, 40, 2769–2776. (In Chinese) [Google Scholar]

- Jones, G.S.; Viken, A.E.; Washburn, L.N.; Jenkins, L.N.; Cagle, C.M. An active flow circulation controlled flap concept for general aviation aircraft applications. In Proceedings of the 1st Flow Control Conference, St. Louis, MO, USA, 24–26 June 2002; AIAA Paper: Reston, VA, USA, 2002; p. 3157. [Google Scholar]

- NUMECA International. Fine/Turbo v8.7, User Manual; NUMECA International: Brussels, Belgium, 2009. [Google Scholar]

- Spalart, P.R.; Allmaras, S.R. A one-equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992; AIAA Paper: Reston, VA, USA, 1992; p. 439. [Google Scholar]

- NUMECA International. AutoGrid5 v8.7, User Manual; NUMECA International: Brussels, Belgium, 2009. [Google Scholar]

- NUMECA International. IGG v8.7, User Manual; NUMECA International: Brussels, Belgium, 2009. [Google Scholar]

- Mao, X.C.; Liu, B.; Tang, T.Q. Effect of casing aspiration on the tip leakage flow in the axial flow compressor cascade. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 225–239. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Chord c/mm | 63 |

| Blade height H/mm | 100 |

| Aspect ratio H/c | 1.59 |

| Blade pitch t/mm | 37.95 |

| Blade solidity c/t | 1.66 |

| Stagger angle /(°) | 15.4 |

| Geometric inlet angle /(°) | 40.17 |

| Geometric outlet angle /(°) | −13.21 |

| Inlet Mach number | 0.7 |

| 770,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Qing, Y.; Liu, B.; Mao, X. Corner Separation Control Using a New Combined Slotted Configuration in a High-Turning Compressor Cascade under Different Solidities. Energies 2021, 14, 3376. https://doi.org/10.3390/en14123376

Wang H, Qing Y, Liu B, Mao X. Corner Separation Control Using a New Combined Slotted Configuration in a High-Turning Compressor Cascade under Different Solidities. Energies. 2021; 14(12):3376. https://doi.org/10.3390/en14123376

Chicago/Turabian StyleWang, Hejian, Yanshan Qing, Bo Liu, and Xiaochen Mao. 2021. "Corner Separation Control Using a New Combined Slotted Configuration in a High-Turning Compressor Cascade under Different Solidities" Energies 14, no. 12: 3376. https://doi.org/10.3390/en14123376

APA StyleWang, H., Qing, Y., Liu, B., & Mao, X. (2021). Corner Separation Control Using a New Combined Slotted Configuration in a High-Turning Compressor Cascade under Different Solidities. Energies, 14(12), 3376. https://doi.org/10.3390/en14123376