Online Synthesis of an Optimal Battery State-of-Charge Reference Trajectory for a Plug-in Hybrid Electric City Bus

Abstract

1. Introduction

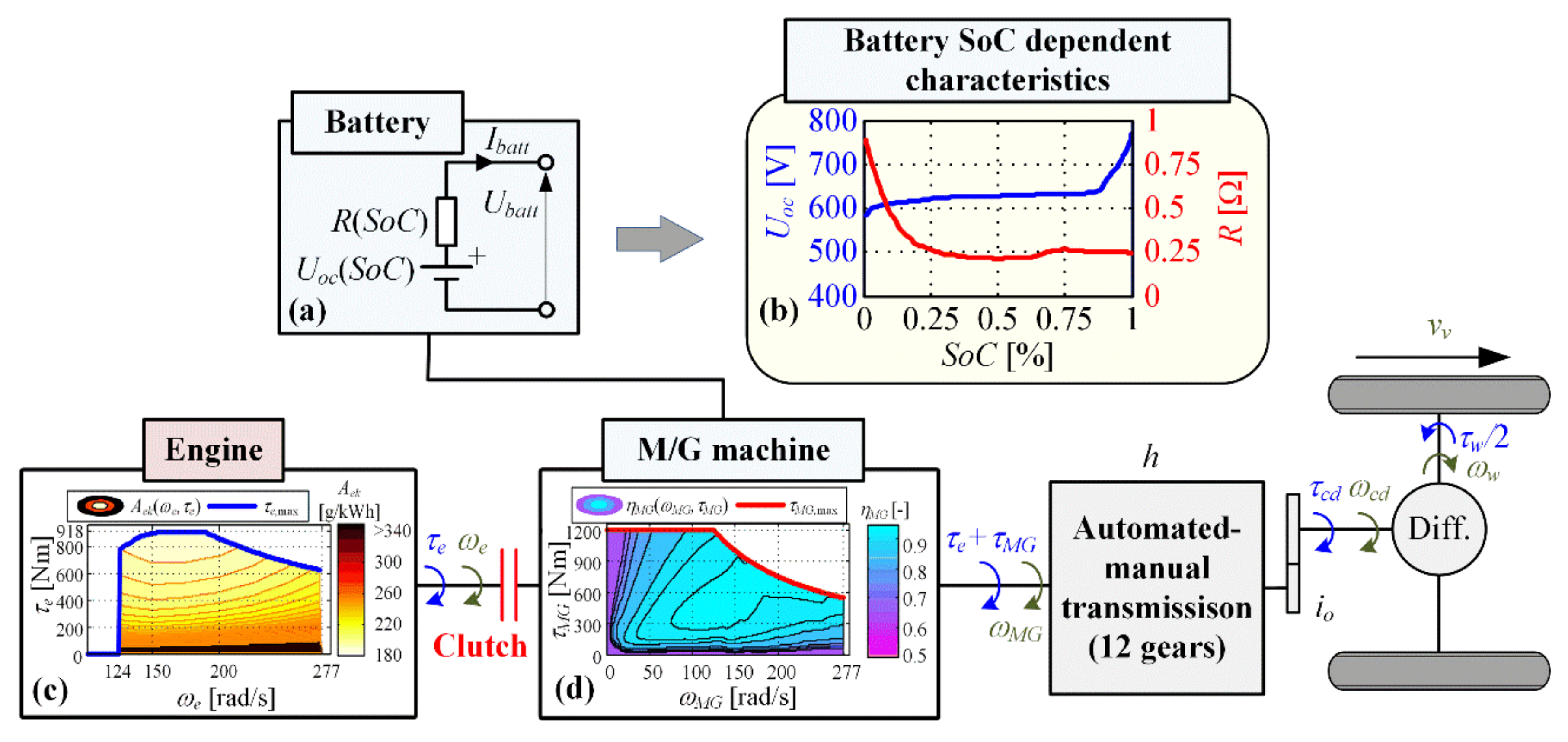

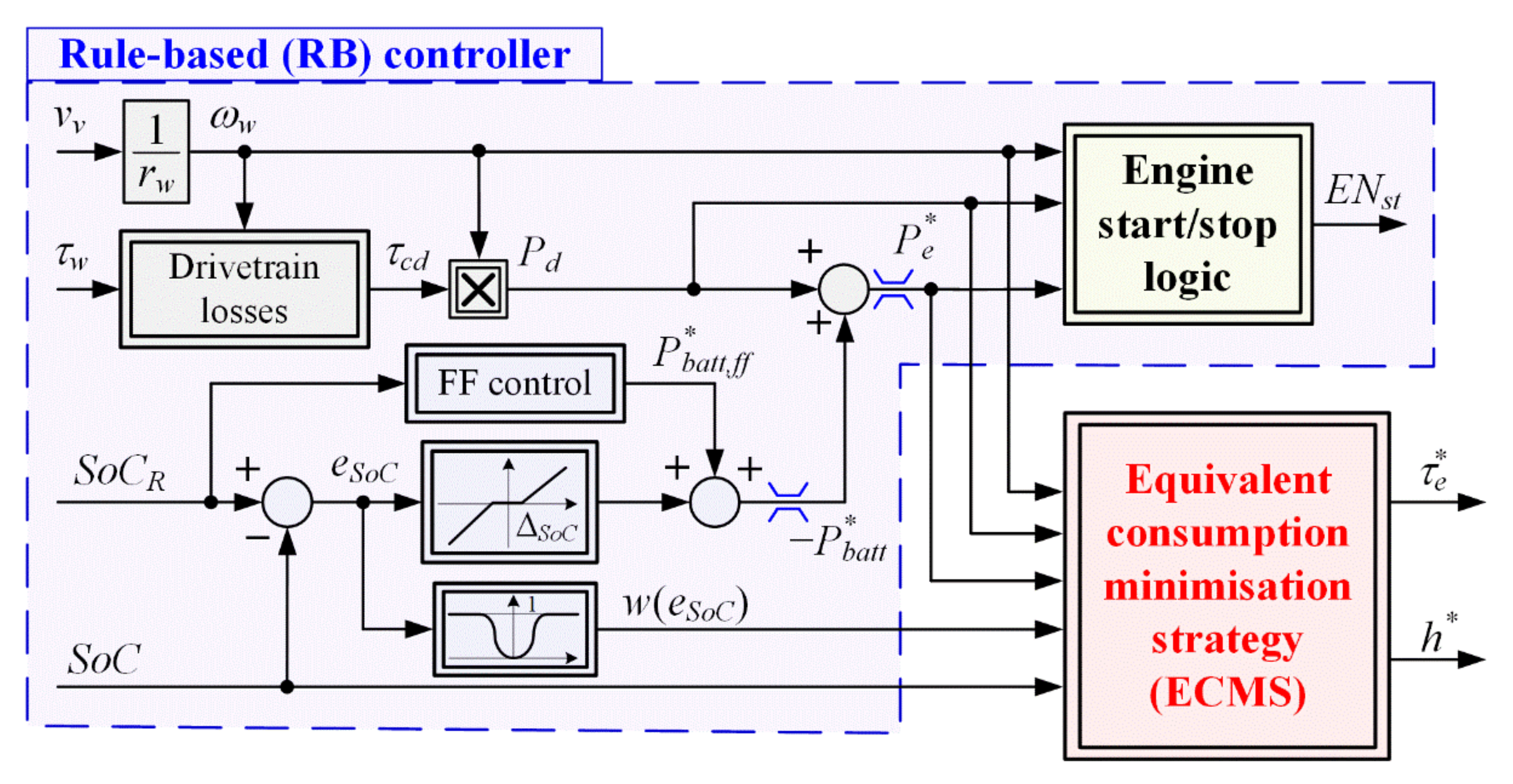

2. Powertrain Model and Control Strategy

2.1. Model

2.2. Control Strategy

3. Control Variable Optimization

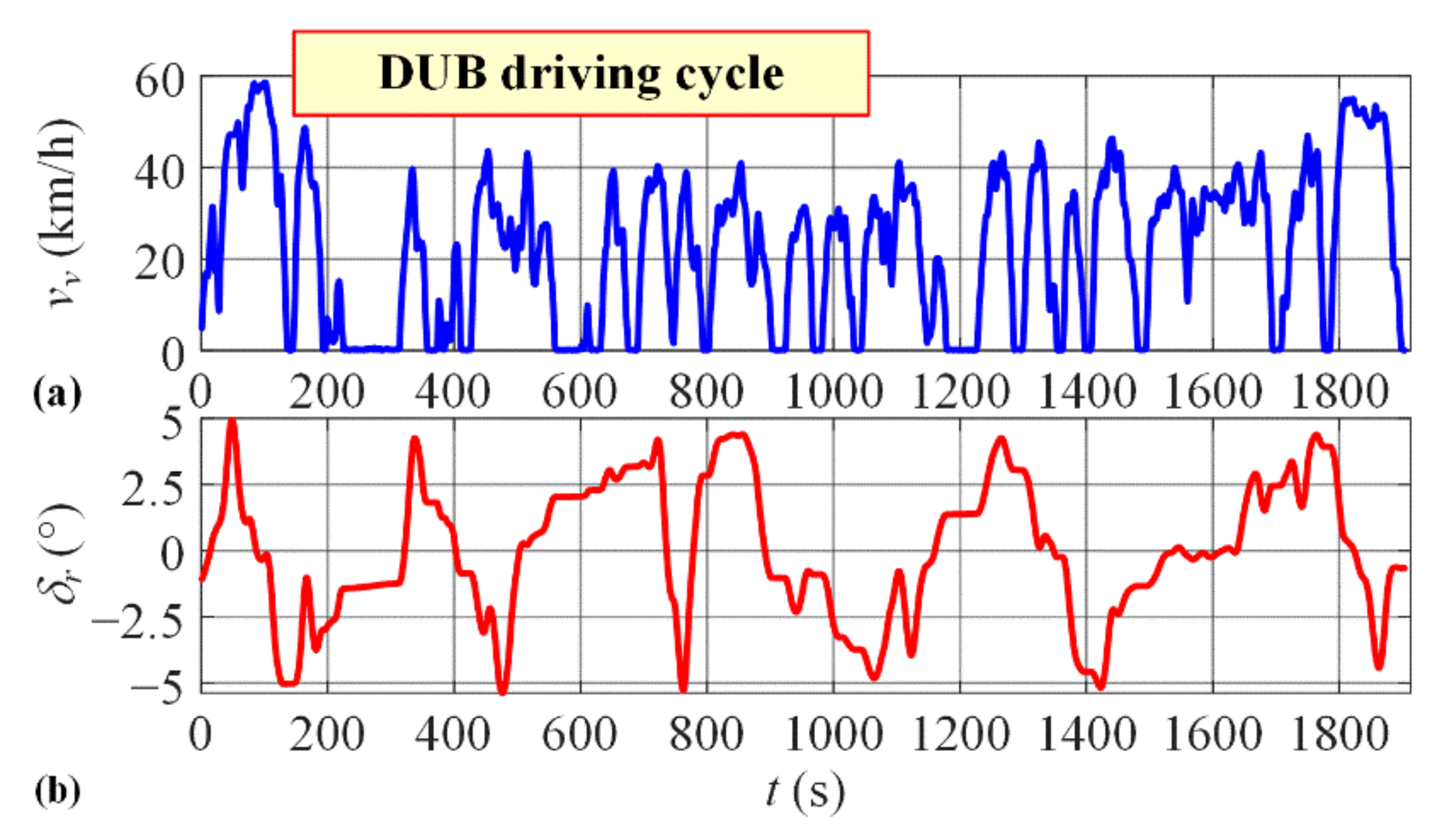

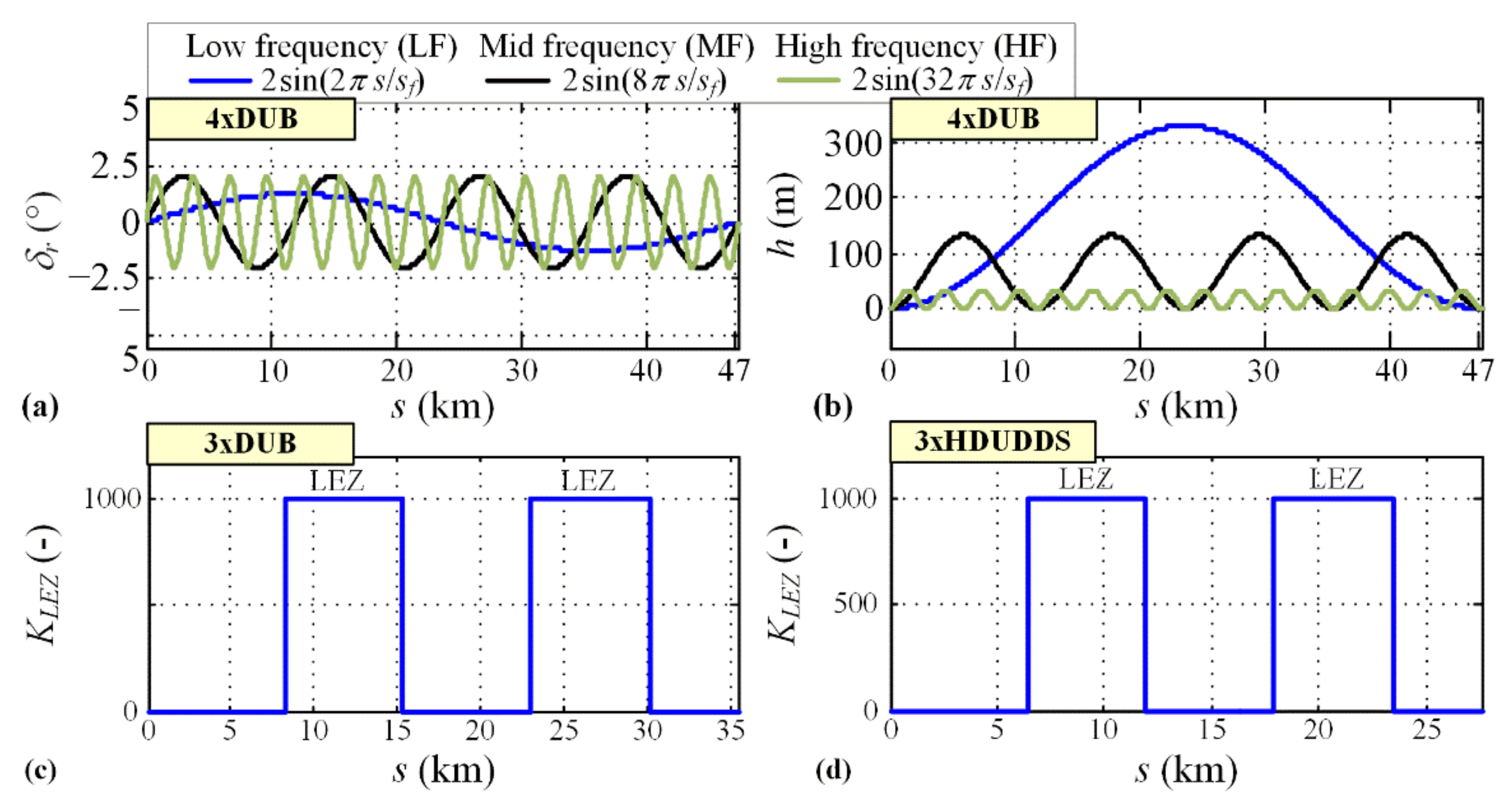

3.1. Driving Cycle Scenarios

3.2. Optimal Problem Formulation

3.3. Optimization Results

4. Synthesis of Battery SoC Reference Trajectory

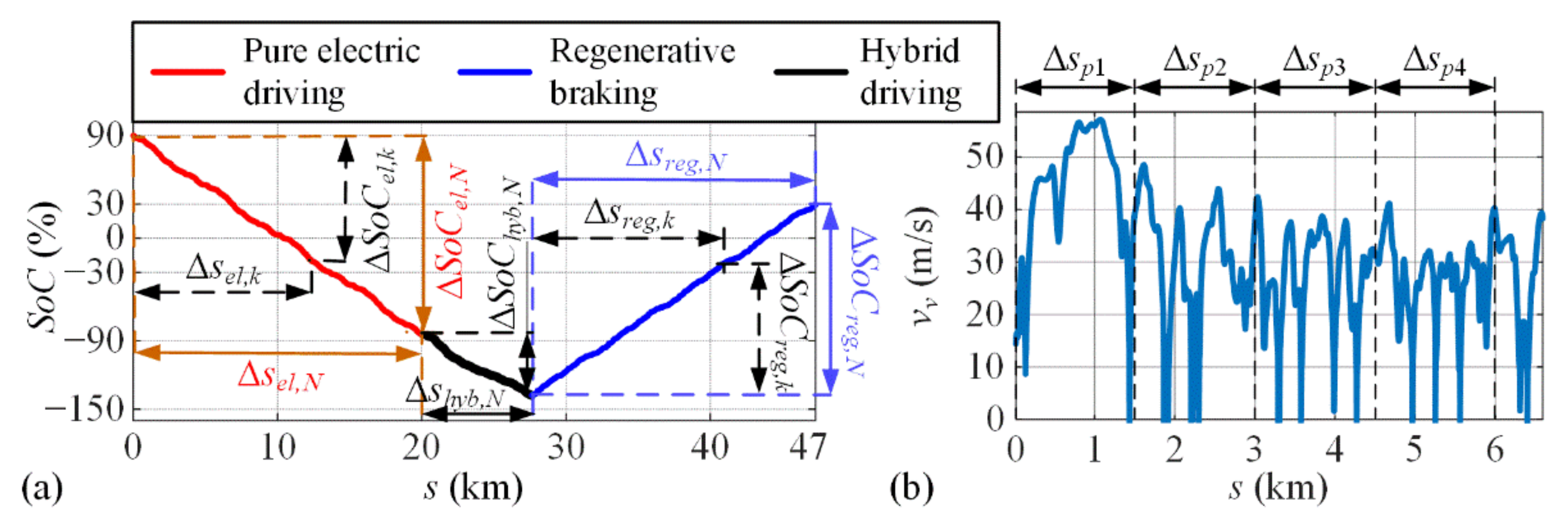

4.1. Offline Synthesis of Linear SoC Reference Trajectory for Zero Road Case

4.1.1. Case 1: No LEZ Presence

4.1.2. Case 2: LEZ Presence

4.2. Offline Synthesis of a Nonlinear SoC Reference Trajectory for Varying Road Grades

4.3. Online Synthesis of SoC Reference Trajectory

4.3.1. Online Prediction of PHEV Powertrain Operation Features

4.3.2. Online Synthesis Method

5. Simulation Results

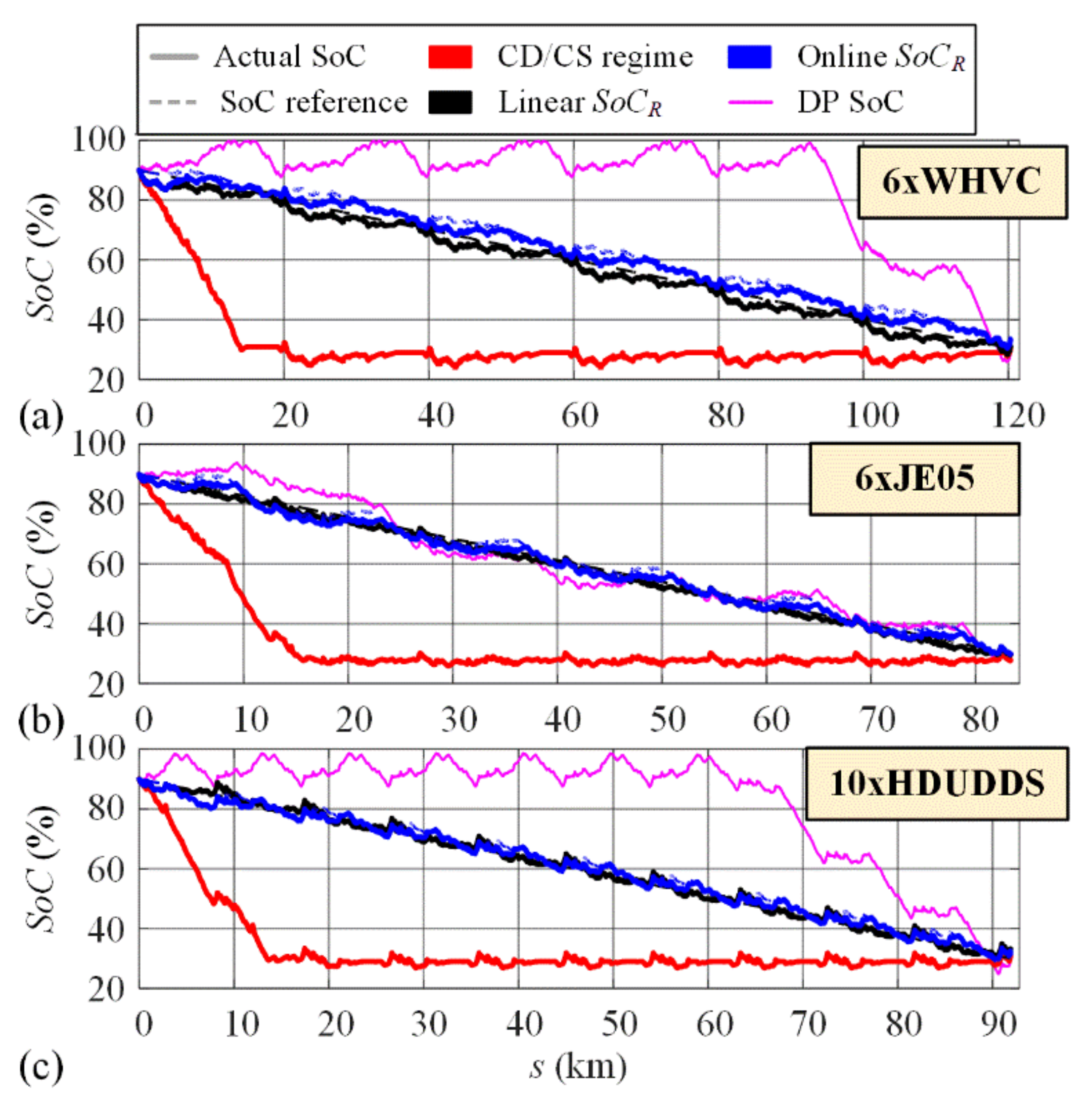

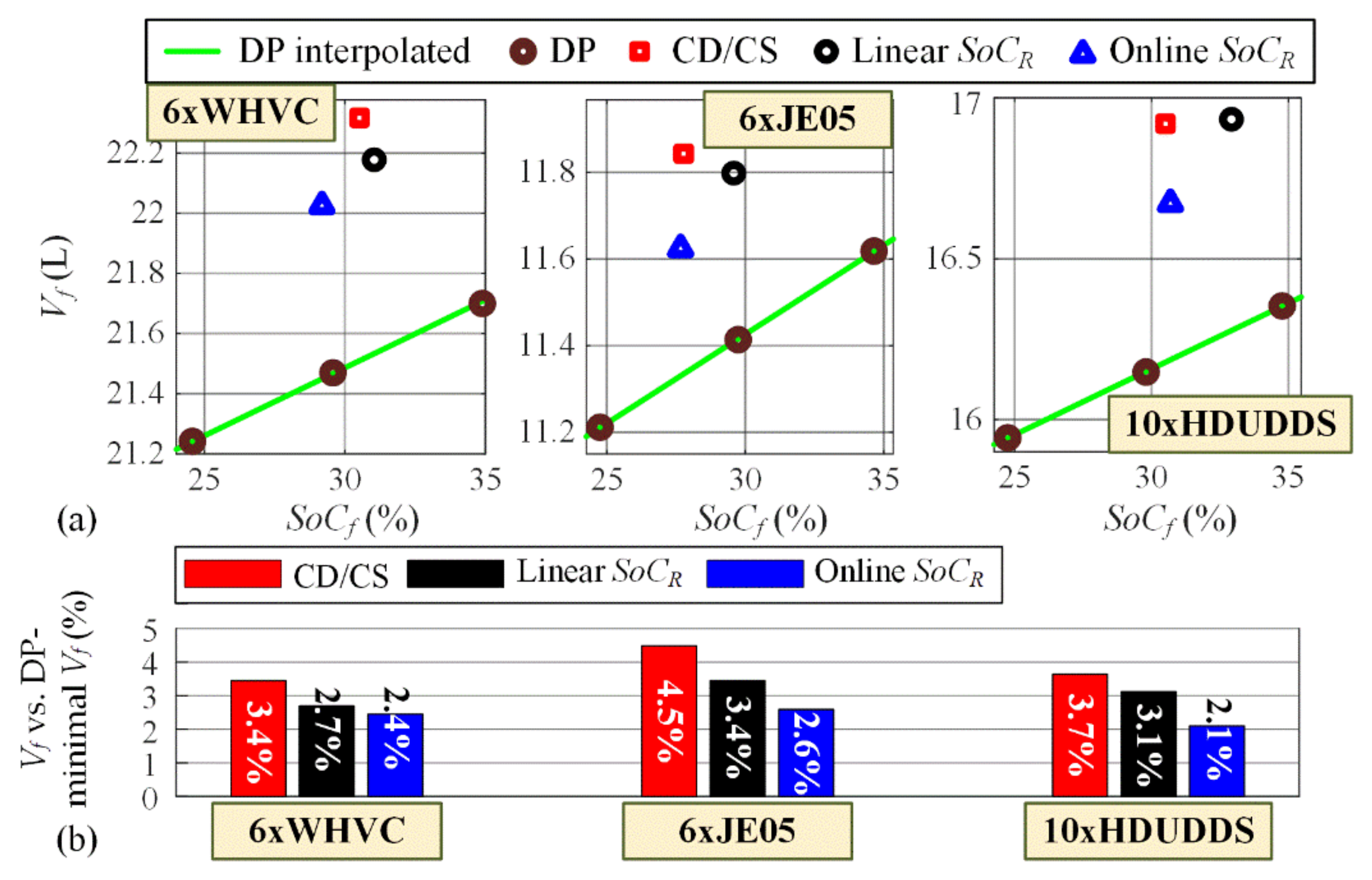

5.1. Scenarios with no LEZ Presence

5.1.1. Zero Road Grade

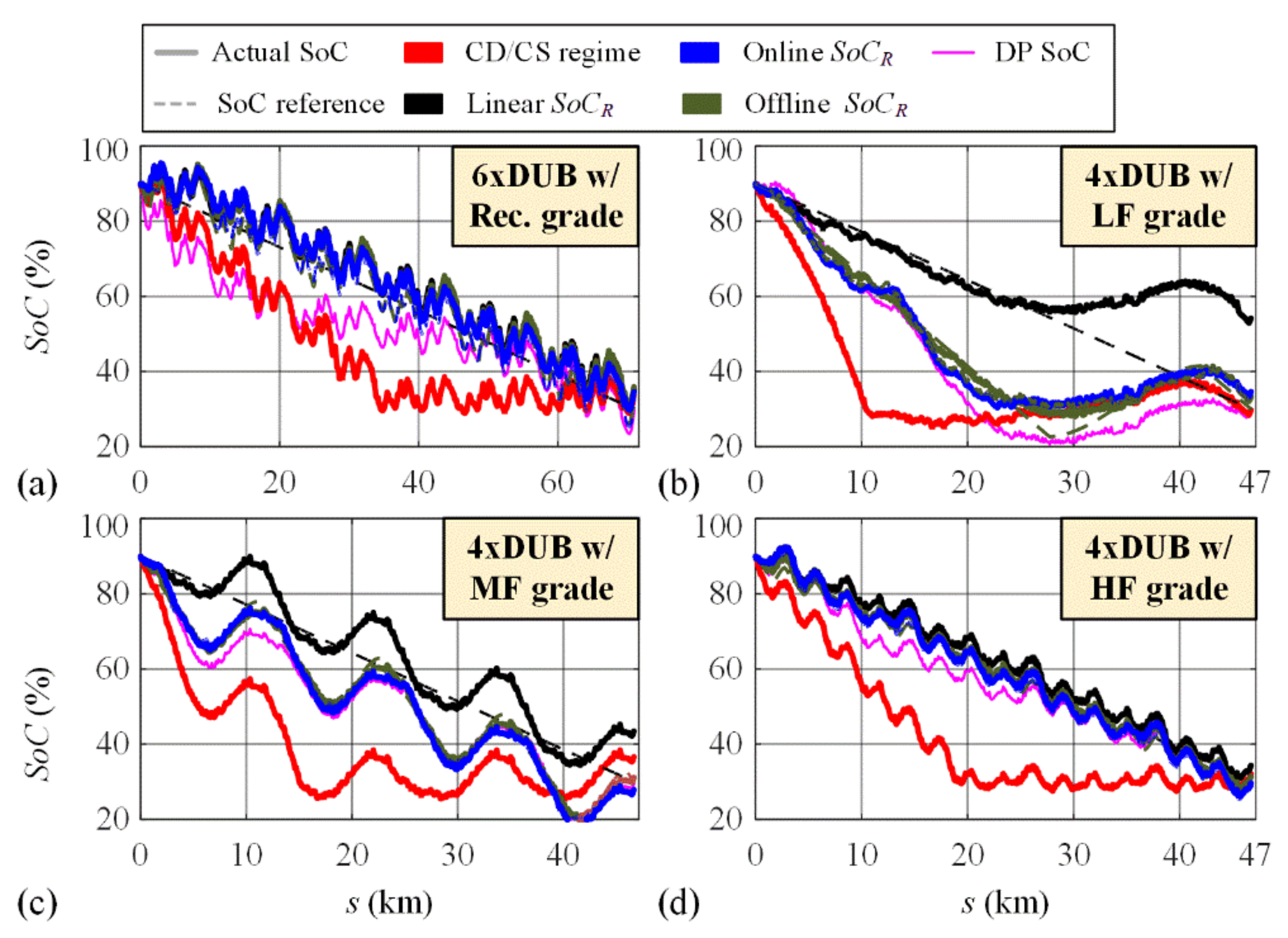

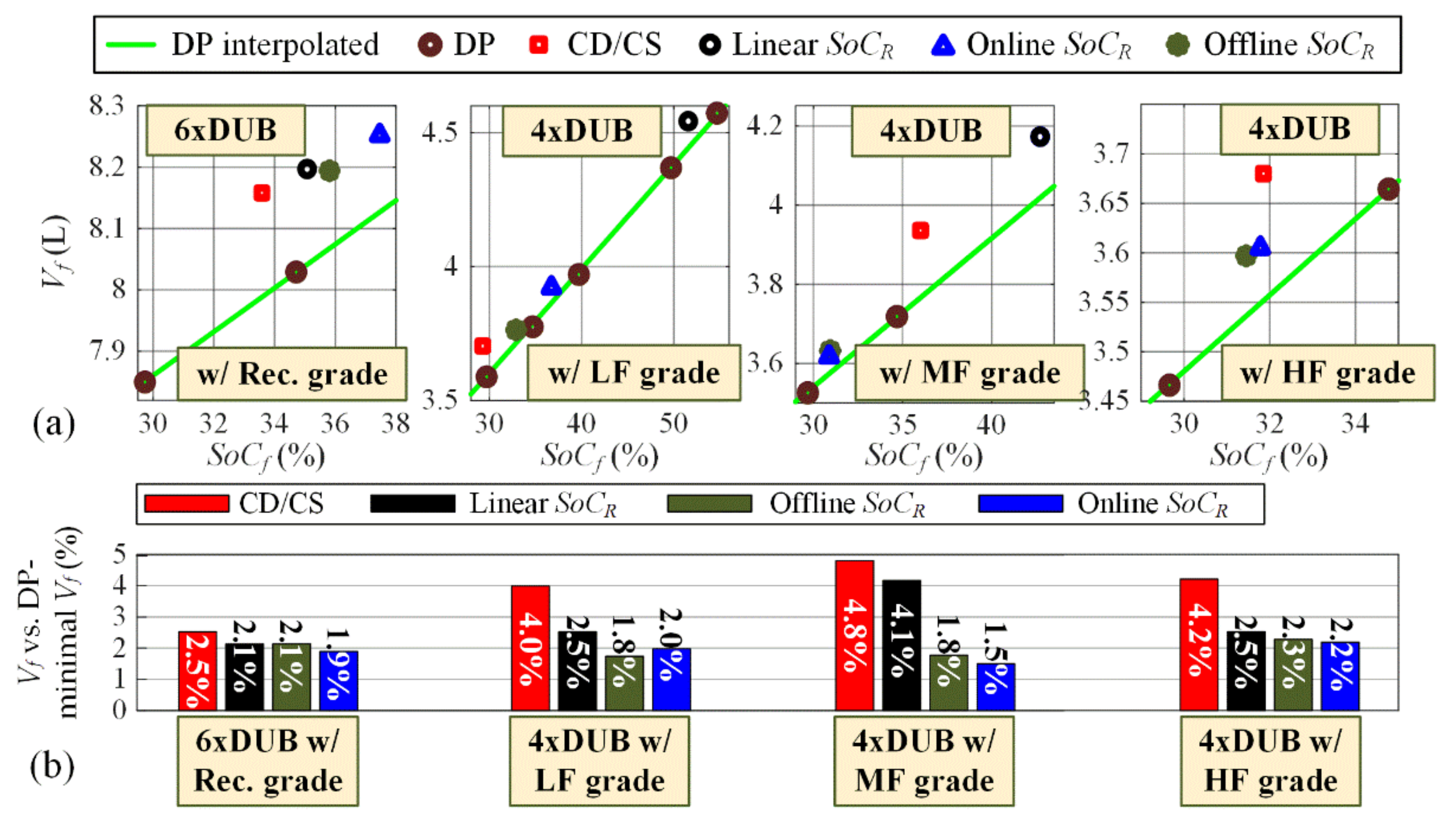

5.1.2. Varying Road Grade

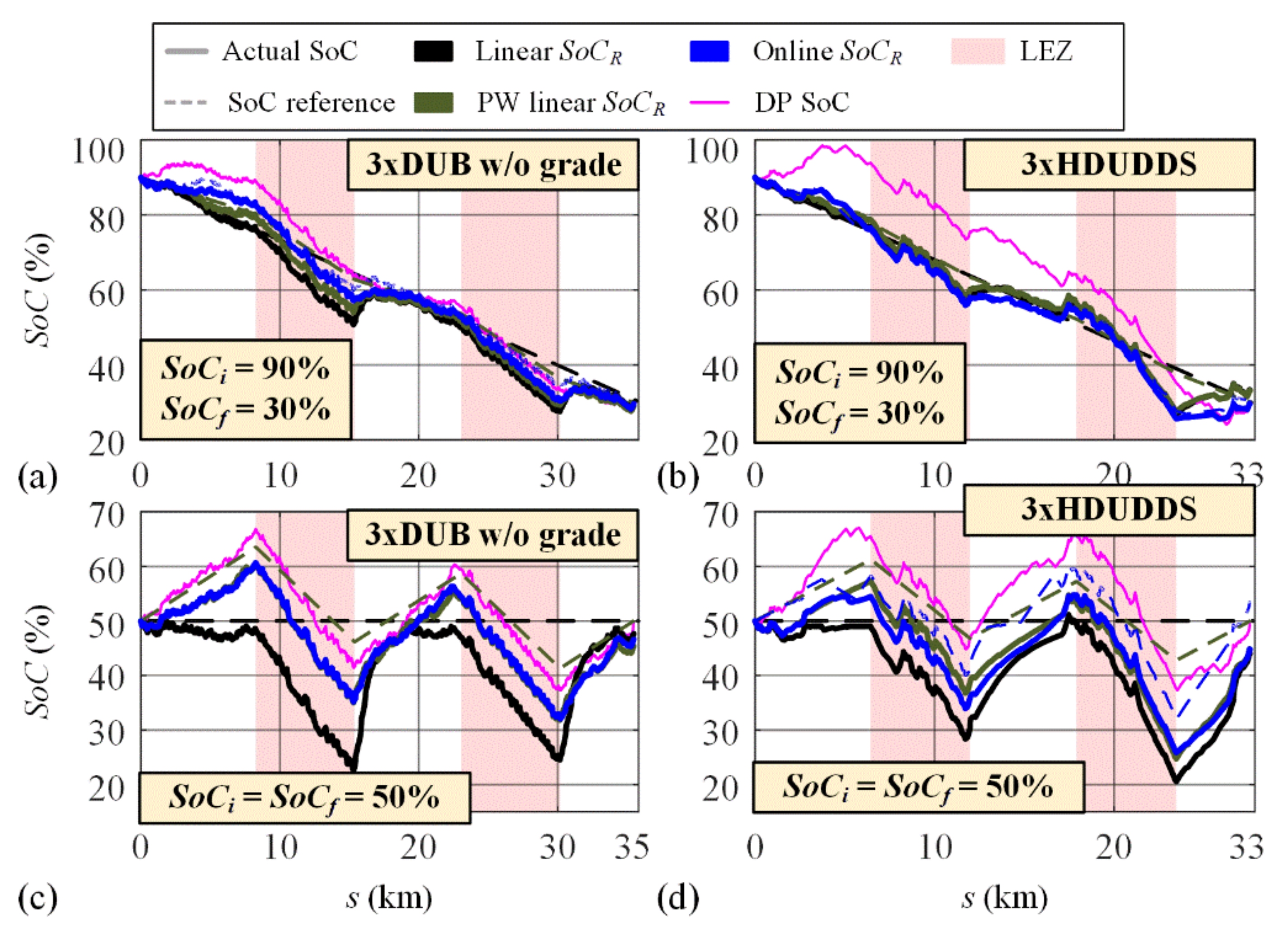

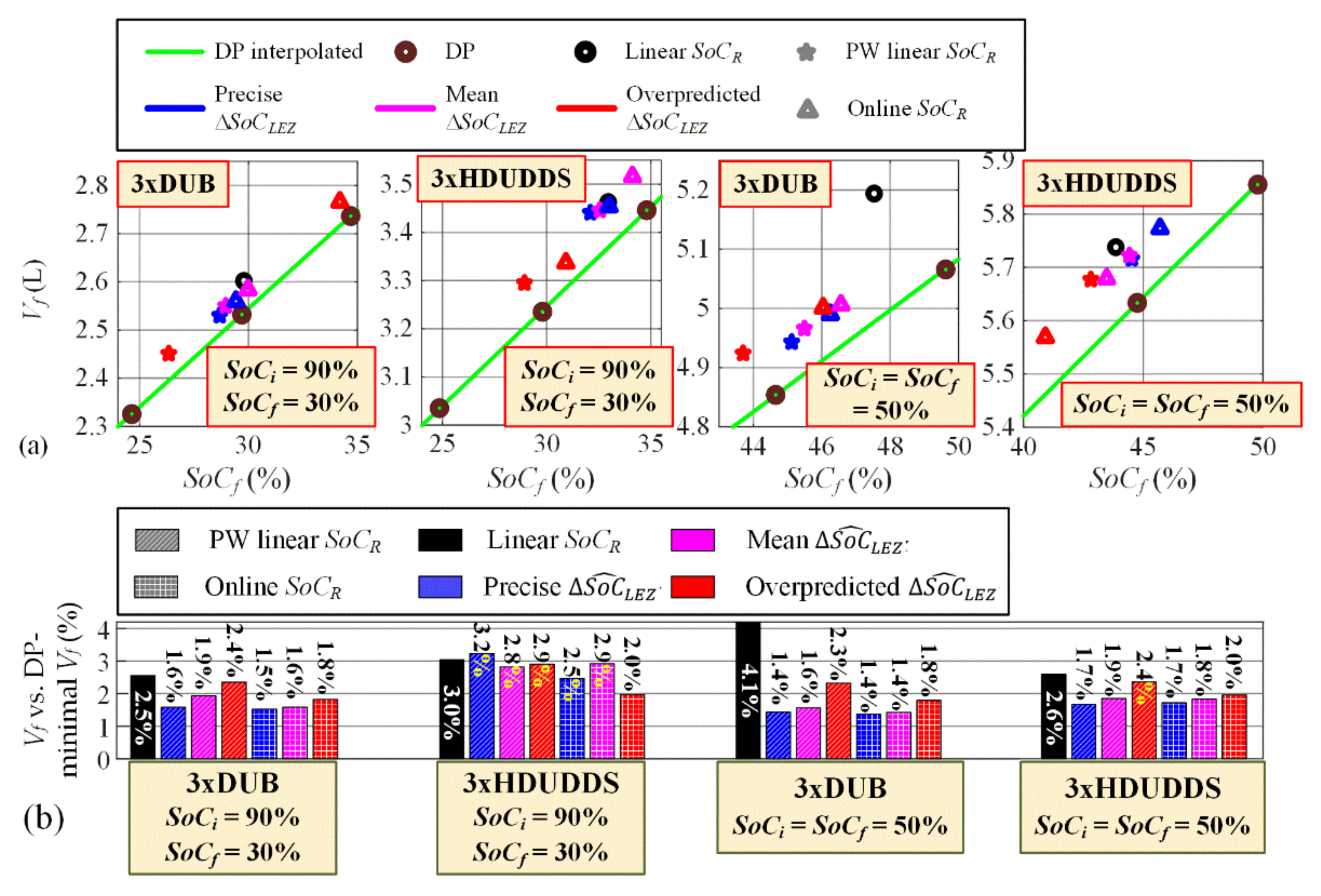

5.2. LEZ Scenarios with Zero Road Grade

5.3. Robustness Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

List of Abbreviations

| BLND | Blended (mode) |

| CD | Charge depleting (mode) |

| CS | Charge sustaining (mode) |

| DP | Dynamic programming |

| ECMS | Equivalent consumption minimization strategy |

| EREV | Extended range electric vehicle |

| FF | Feedforward (control) |

| GSD | Gear shift delay (algorithm) |

| HF | High frequency (grade) |

| LEZ | Low emission zone |

| LF | Low frequency (grade) |

| M/G | Motor/generator (machine) |

| MF | Medium frequency (grade) |

| MPC | Model predictive control |

| PHEV | Plug-in hybrid electric vehicle |

| PMP | Pontryagin’s minimum principle |

| RB | Rule-based (controller) |

| SoC | (Battery) State-of-charge |

Appendix A. PHEV Model Parameters

| Gear | 1. | 2. | 3. | 4. | 5. | 6. |

| Gear ratio (-) | 14.94 | 11.73 | 9.04 | 7.09 | 5.54 | 4.35 |

| Gear | 7. | 8. | 9. | 10. | 11. | 12. |

| Gear ratio (-) | 3.44 | 2.70 | 2.08 | 1.63 | 1.27 | 1.00 |

Appendix B. Control Parameters

Appendix C

References

- Guzzella, L.; Sciaretta, A. Vehicle Propulsion Systems, 2nd ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Škugor, B.; Cipek, M.; Deur, J. Control variables optimization and feedback control strategy design for the blended operating regime of an extended range electric vehicle. SAE Int. J. Altern. Powertrains 2014, 3, 152–162. [Google Scholar] [CrossRef]

- Martinez, C.M.; Hu, X.; Cao, D.; Velenis, E.; Gao, B.; Wellers, M. Energy Management in Plug-in Hybrid Electric Vehicles: Recent Progress and a Connected Vehicles Perspective. IEEE Trans. Veh. Technol. 2017, 66, 4534–4549. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Onori, S.; Tribioli, L. Adaptive Pontryagin’s Minimum Principle supervisory controller design for the plug-in hybrid GM Chevrolet Volt. Appl. Energy 2015, 147, 224–234. [Google Scholar] [CrossRef]

- Xie, S.; Li, H.; Xin, Z.; Liu, T.; Wei, L. A pontryagin minimum principle-based adaptive equivalent consumption minimum strategy for a plug-in hybrid electric bus on a fixed route. Energies 2017, 10, 1379. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Xin, Z.; Brighton, J. Pontryagin’s Minimum Principle based model predictive control of energy management for a plug-in hybrid electric bus. Appl. Energy 2019, 236, 893–905. [Google Scholar] [CrossRef]

- Soldo, J.; Skugor, B.; Deur, J. Optimal Energy Management Control of a Parallel Plug-In Hybrid Electric Vehicle in the Presence of Low-Emission Zones. SAE Tech. Pap. 1215, 2019-01-1215. [Google Scholar] [CrossRef]

- Soldo, J.; Škugor, B.; Deur, J. Synthesis of Optimal Battery State-of-Charge Trajectory for Blended Regime of Plug-in Hybrid Electric Vehicles in the Presence of Low-Emission Zones and Varying Road Grades. Energies 2019, 12, 4296. [Google Scholar] [CrossRef]

- Yu, H.; Kuang, M.; McGee, R. Trip-oriented energy management control strategy for plug-in hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2014, 22, 1323–1336. [Google Scholar]

- Schmid, R.; Buerger, J.; Bajcinca, N. Energy Management Strategy for Plug-in-Hybrid Electric Vehicles Based on Predictive PMP. IEEE Trans. Control Syst. Technol. 2021, 1–13. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Qin, D.; Lei, Z. Energy management of plug-in hybrid electric vehicles using road grade preview. In Proceedings of the IET International Conference on Intelligent and Connected Vehicles (ICV 2016), Chongqing, China, 22–23 September 2016. [Google Scholar]

- Ambuhl, D.; Guzzella, L. Predictive reference signal generator for hybrid electric vehicles. IEEE Trans. Veh. Technol. 2009, 58, 4730–4740. [Google Scholar] [CrossRef]

- Gaikwad, T.; Asher, Z.; Liu, K.; Huang, M.; Kolmanovsky, I. Vehicle Velocity Prediction and Energy Management Strategy Part 2: Integration of Machine Learning Vehicle Velocity Prediction with Optimal Energy Management to Improve Fuel Economy. SAE Tech. Pap. 2019, 2019-01-1212. [Google Scholar]

- Taghavipour, A.; Moghadasi, S. A Real-Time Nonlinear CRPE Predictive PHEV Energy Management System Design and HIL Evaluation. IEEE Trans. Veh. Technol. 2021, 70, 49–58. [Google Scholar] [CrossRef]

- Sun, C.; Moura, S.J.; Hu, X.; Hedrick, J.K.; Sun, F. Dynamic Traffic Feedback Data Enabled Energy Management in Plug-in Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2015, 23, 1075–1086. [Google Scholar]

- Bouwman, K.R.; Pham, T.H.; Wilkins, S.; Hofman, T. Predictive Energy Management Strategy Including Traffic Flow Data for Hybrid Electric Vehicles. IFAC-PapersOnLine 2017, 50, 10046–10051. [Google Scholar] [CrossRef]

- Soldo, J.; Škugor, B.; Deur, J. Optimal energy management and shift scheduling control of a parallel plug-in hybrid electric vehicle. Int. J. Powertrains 2020, 9, 240–264. [Google Scholar] [CrossRef]

- Volvo 7900 Electric Hybrid Specifications. Available online: https://www.volvobuses.co.uk/en-gb/our-offering/buses/volvo-7900-electric-hybrid/specifications.html (accessed on 17 March 2021).

- Paganelli, G.; Delprat, S.; Guerra, T.M.; Rimaux, J.; Santin, J.J. Equivalent consumption minimization strategy for parallel hybrid powertrains. Proc. IEEE Veh. Technol. Conf. 2002, 4, 2076–2081. [Google Scholar]

- Škugor, B.; Deur, J.; Cipek, M.; Pavković, D. Design of a power-split hybrid electric vehicle control system utilizing a rule-based controller and an equivalent consumption minimization strategy. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 631–648. [Google Scholar] [CrossRef]

- Škugor, B.; Hrgetić, M.; Deur, J. GPS measurement-based road grade reconstruction with application to electric vehicle simulation and analysis. In Proceedings of the 11th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES 2015), Dubrovnik, Croatia, 27 September–2 October 2015. [Google Scholar]

- Bellman, R.E.; Dreyfus, S.E. Applied Dynamic Programming; Princeton University Press: Princeton, NJ, USA, 1962. [Google Scholar]

- Cipek, M.; Škugor, B.; Čorić, M.; Kasać, J.; Deur, J. Control variable optimisation for an extended range electric vehicle. Int. J. Powertrains 2016, 5, 30. [Google Scholar] [CrossRef]

- Škugor, B.; Soldo, J.; Deur, J. Analysis of Optimal Battery State-of-Charge Trajectory for Blended Regime of Plug-in Hybrid Electric Vehicle. World Electr. Veh. J. 2019, 10, 75. [Google Scholar] [CrossRef]

- Soldo, J.; Škugor, B.; Deur, J. Analysis of Patterns of Optimal Battery State-of-Charge Trajectories for Blended Regime of a Parallel Plug-in Hybrid Electric Vehicle and a Wide Range of Driving Conditions. In Proceedings of the 15th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES 2020), Cologne, Germany, 1–5 September 2020. [Google Scholar]

| Assumed Road Grade Profile | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rec. Grade | MF Grade | HF Grade | |||||||||

| Vf (L) | Vf,comp1 (%) | SoCf (%) | Vf (L) | Vf,comp1 (%) | SoCf (%) | Vf (L) | Vf,comp1 (%) | SoCf (%) | |||

| Driving cycle and actual/applied road grade profile | 6 × DUB w/Rec. grade | Offline | 8.23 | +2.11 | 35.48 | 8.23 | +4.23 | 30.88 | 8.12 | +2.42 | 31.79 |

| Online | 8.29 | +1.94 | 37.47 | 7.80 | +2.31 | 23.36 | 8.20 | +2.05 | 34.90 | ||

| 4 × DUB w/MF grade | Offline | 4.35 | +4.89 | 46.23 | 3.64 | +1.84 | 30.91 | 4.32 | +4.70 | 45.67 | |

| Online | 3.75 | +1.84 | 33.86 | 3.63 | +1.51 | 30.87 | 3.70 | +1.62 | 32.61 | ||

| 4 × DUB w/HF grade | Offline | 3.97 | +3.36 | 39.35 | 3.60 | +4.84 | 28.67 | 3.62 | +2.29 | 31.45 | |

| Online | 3.67 | +2.43 | 33.32 | 3.24 | +2.62 | 21.69 | 3.63 | +2.17 | 31.83 | ||

| Assumed Driving Cycle Characteristics | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Actual | Actual Ones Increased by 50% | Characteristics of Characteristics of WHVC Driving Cycle Used | |||||||||

| Vf (L) | Vf,comp 1 (%) | SoCf (%) | Vf (L) | Vf,comp 1 (%) | SoCf (%) | Vf (L) | Vf,comp 1 (%) | SoCf (%) | |||

| Driving cycle and actual driving cycle characteristics | 6 × DUB w/Rec. grade | Offline | 8.23 | +2.11 | 35.48 | 8.22 | +2.13 | 35.50 | 8.23 | +1.99 | 35.86 |

| Online | 8.29 | +1.94 | 37.47 | 8.24 | +1.93 | 36.19 | 8.56 | +2.10 | 44.60 | ||

| 4 × DUB w/MF grade | Offline | 3.64 | +1.84 | 30.91 | 3.64 | +1.84 | 30.91 | 3.78 | +2.20 | 34.40 | |

| Online | 3.63 | +1.51 | 30.87 | 3.62 | +1.49 | 30.76 | 3.72 | +1.60 | 33.31 | ||

| 4 × DUB w/HF grade | Offline | 3.62 | +2.29 | 31.45 | 3.62 | +2.30 | 31.42 | 3.68 | +2.33 | 32.96 | |

| Online | 3.63 | +2.17 | 31.83 | 3.63 | +2.16 | 31.78 | 3.76 | +2.13 | 35.31 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soldo, J.; Škugor, B.; Deur, J. Online Synthesis of an Optimal Battery State-of-Charge Reference Trajectory for a Plug-in Hybrid Electric City Bus. Energies 2021, 14, 3168. https://doi.org/10.3390/en14113168

Soldo J, Škugor B, Deur J. Online Synthesis of an Optimal Battery State-of-Charge Reference Trajectory for a Plug-in Hybrid Electric City Bus. Energies. 2021; 14(11):3168. https://doi.org/10.3390/en14113168

Chicago/Turabian StyleSoldo, Jure, Branimir Škugor, and Joško Deur. 2021. "Online Synthesis of an Optimal Battery State-of-Charge Reference Trajectory for a Plug-in Hybrid Electric City Bus" Energies 14, no. 11: 3168. https://doi.org/10.3390/en14113168

APA StyleSoldo, J., Škugor, B., & Deur, J. (2021). Online Synthesis of an Optimal Battery State-of-Charge Reference Trajectory for a Plug-in Hybrid Electric City Bus. Energies, 14(11), 3168. https://doi.org/10.3390/en14113168