Experimental Verification of Self-Adapting Data-Driven Controllers in Active Distribution Grids

Abstract

1. Introduction and Related Work

- First, we propose a self-adapting algorithm for the data-driven controls to improve performance when the operating conditions are not as in the training dataset.

- Second, we perform the first, to the best of our knowledge, experimental verification of data-driven local control schemes in inverter-based DGs to assess the performance of Artificial Intelligence (AI)-based controllers and identify hidden problems considering the whole system’s response, and not just individual components. Such an experimental verification in the power system society using control schemes that are allowed already today in grid codes i.e., volt/var schemes, can foster real-life field implementation.

2. Data-Driven Control Design

2.1. OPF Formulation

2.2. Control Design

3. Online Controller Self-Adapting Algorithm

| Algorithm 1 Real-time adjustment of the data-driven volt/var control scheme for the overvoltage case at |

|

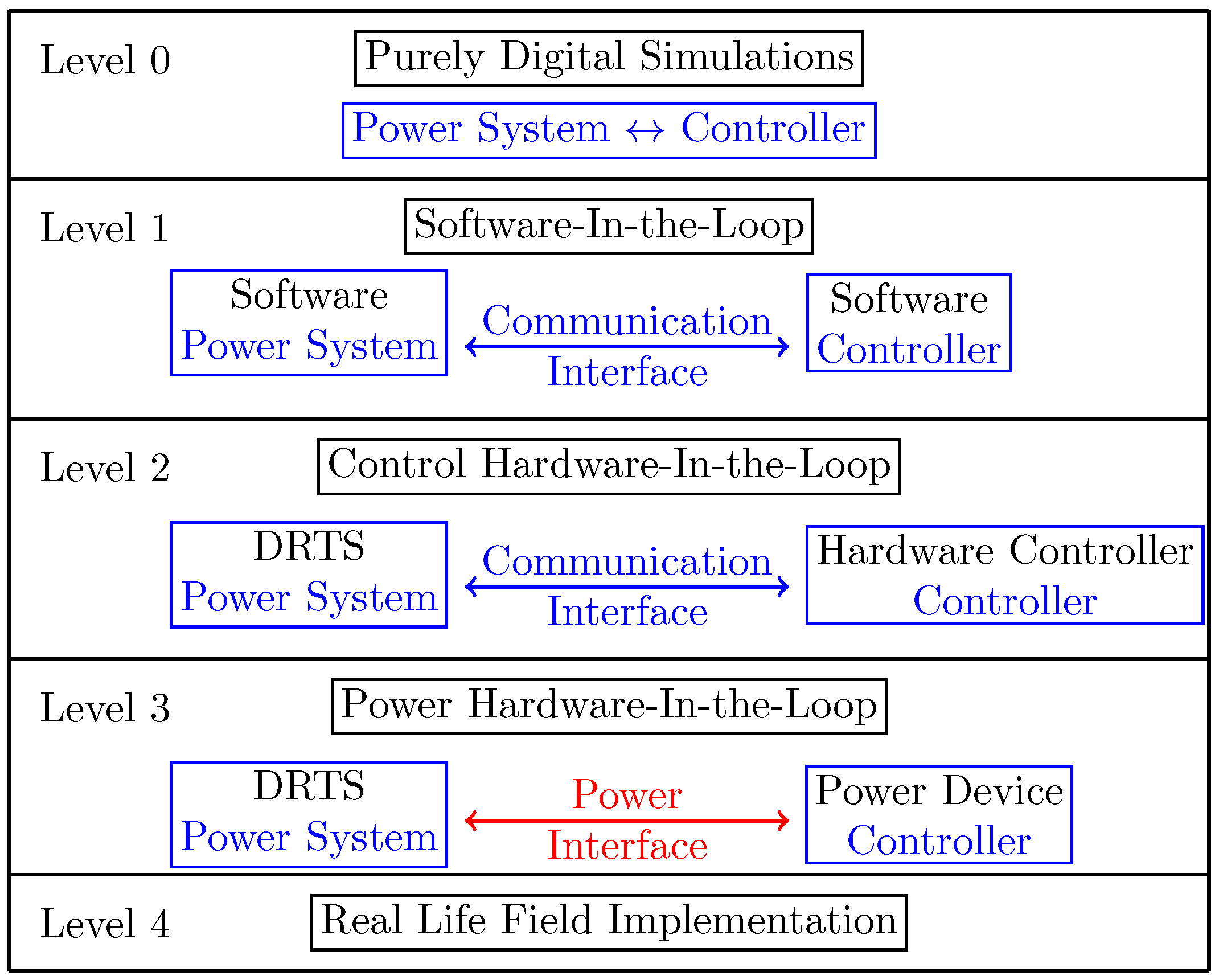

4. Types of Controller Testing

4.1. Purely Digital Simulations (PDS)

4.2. Software-in-the-Loop Simulations (SIL)

4.3. Control Hardware-in-the-Loop (CHIL) Simulations

4.4. Power Hardware-in-the-Loop (PHIL) Simulations

4.5. Real-Life Field Testing

5. Experimental Results

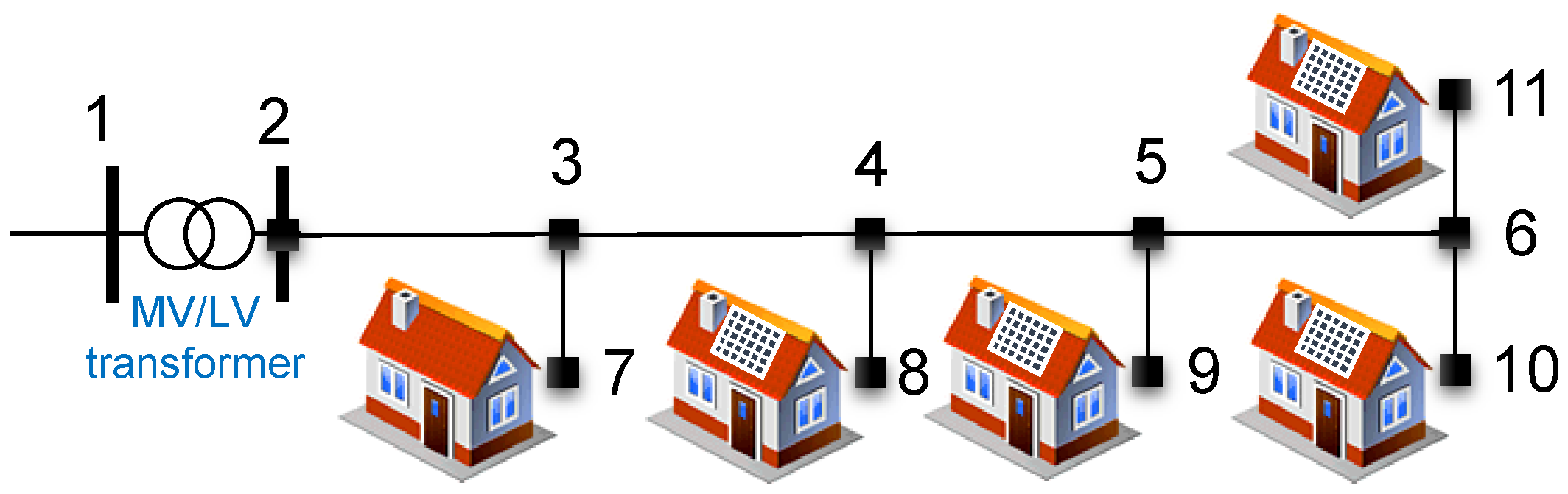

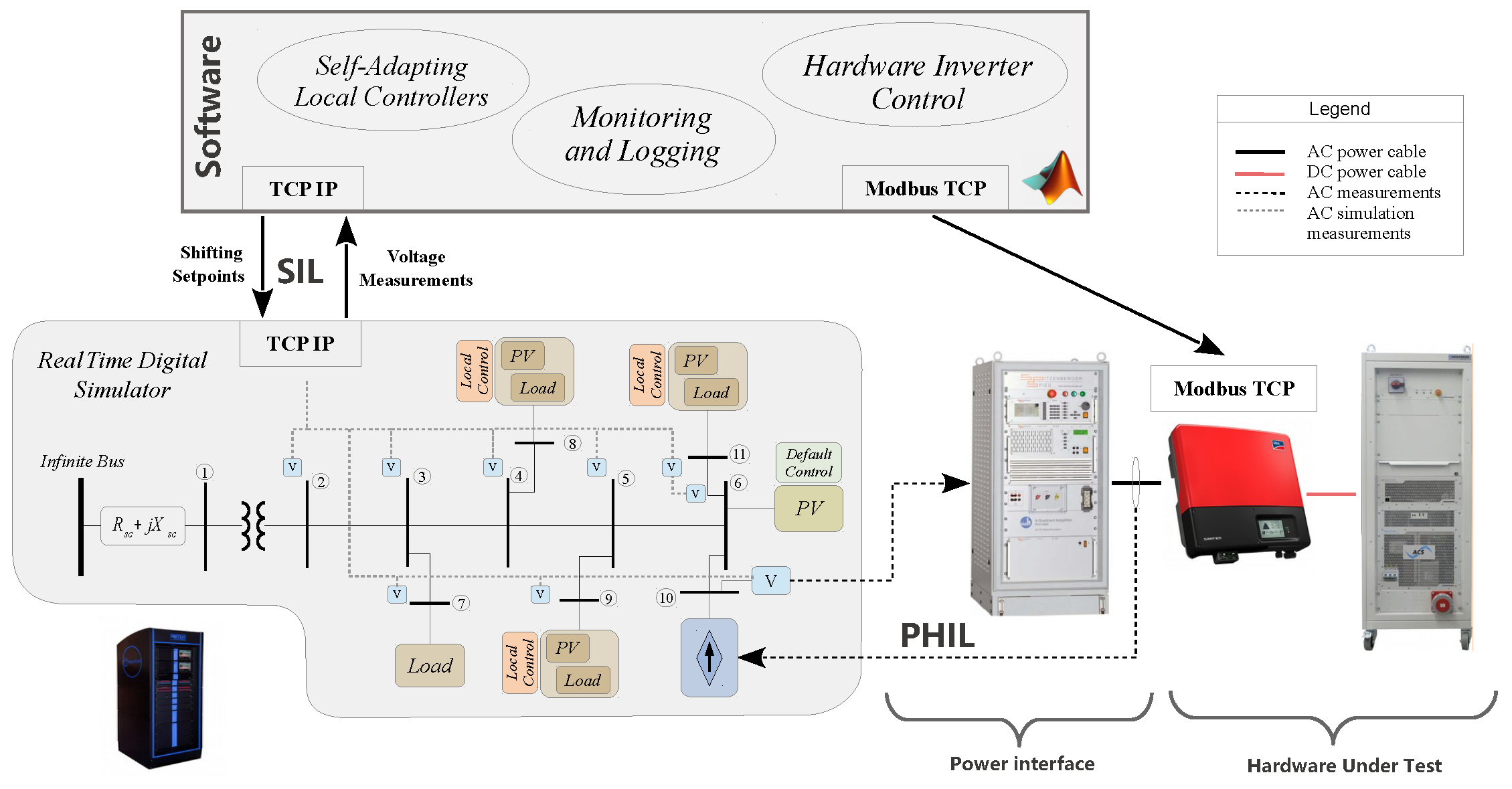

5.1. Laboratory Infrastructure

5.2. Experimental Setup

5.2.1. SIL Implementation

5.2.2. SIL-PHIL Implementation

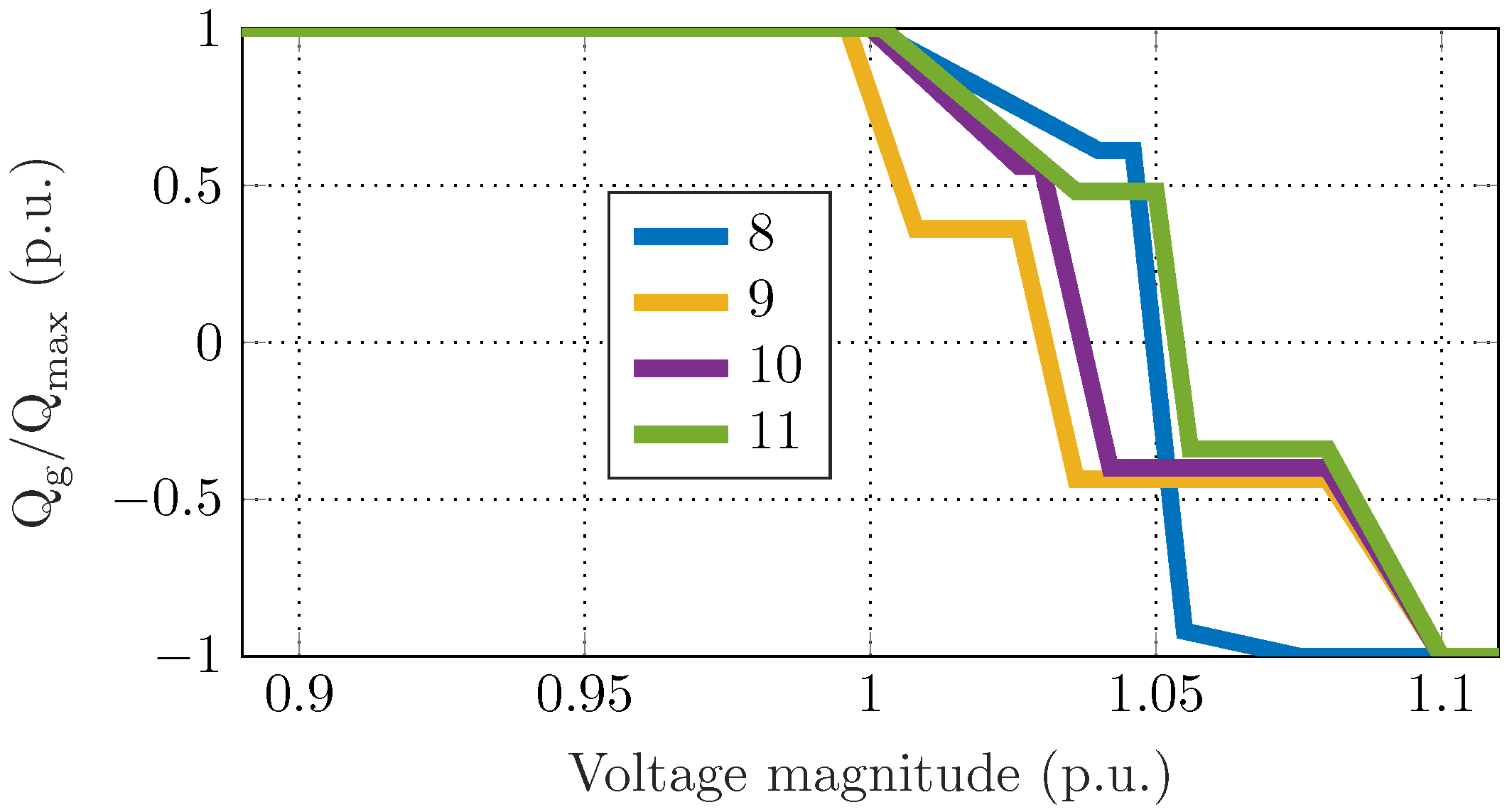

5.3. Individual Data-Driven Local Control Schemes

5.4. Experimental Results

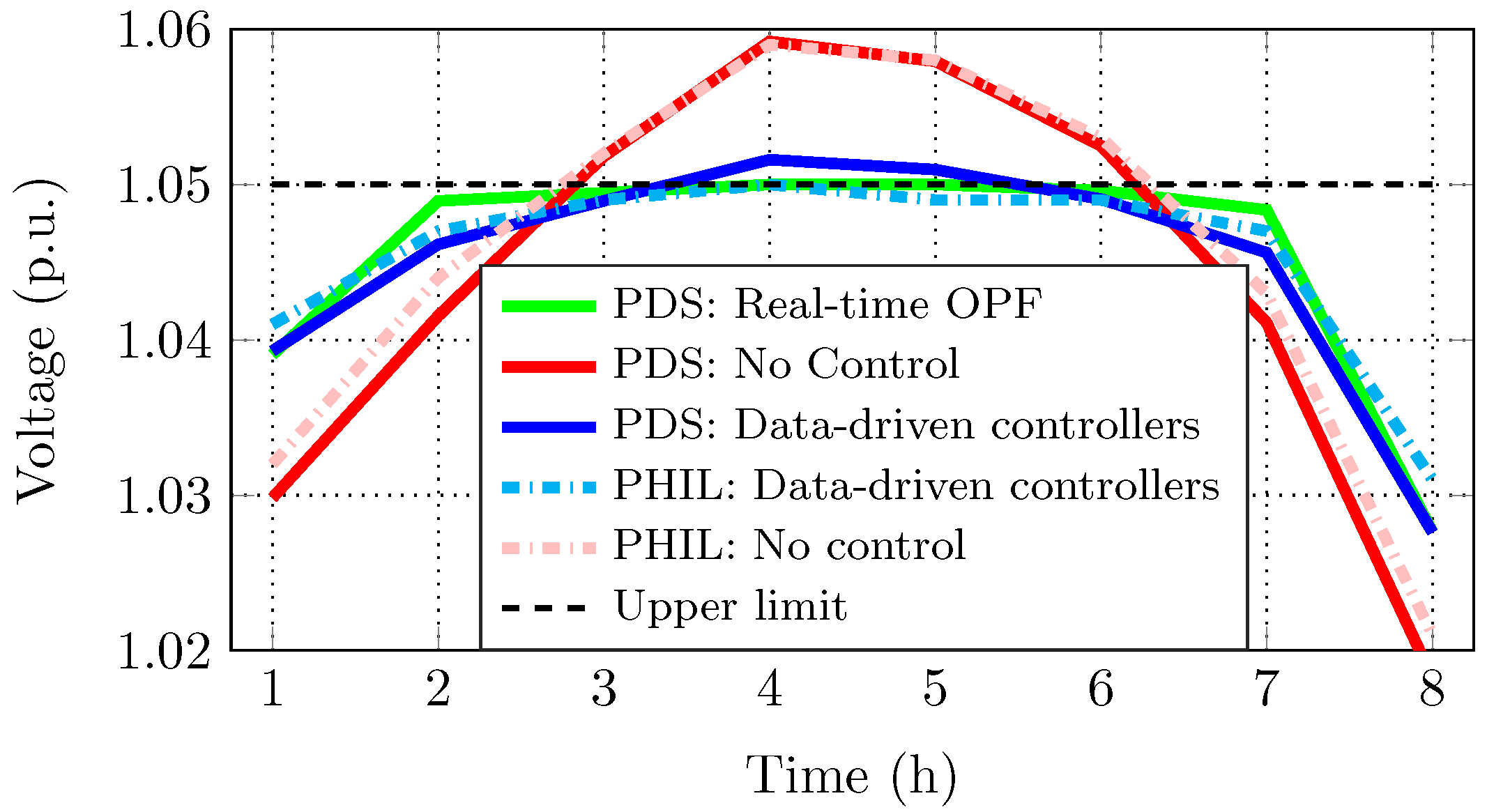

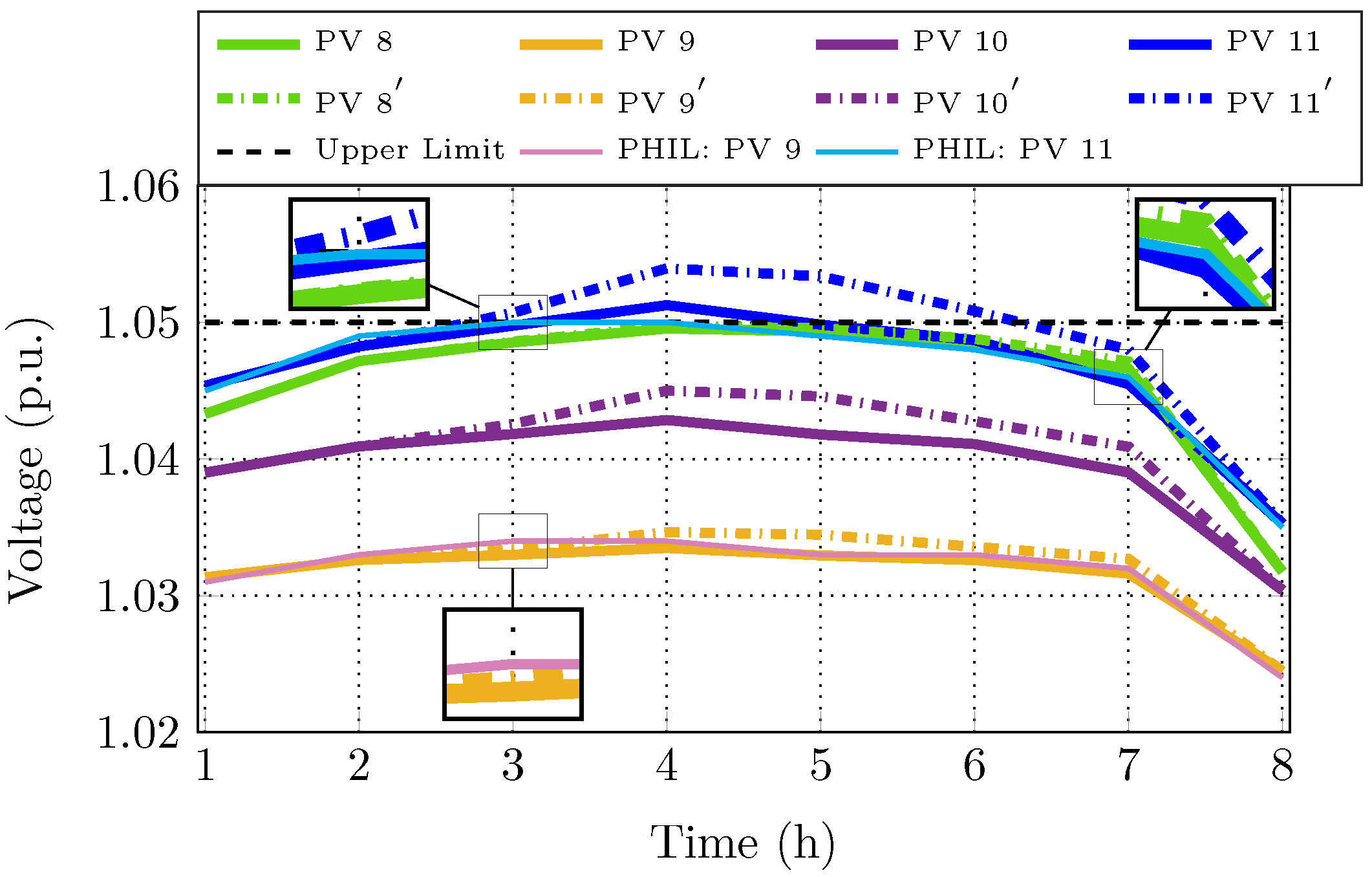

5.4.1. Expected Conditions

5.4.2. Online Self-Adapting Algorithm

5.4.3. Comparative Evaluation of Optimal, Adaptive and Non-Adaptive Schemes

- Method 0: PVs inject the maximum active power at unity power factor. This scheme shows the real-time behaviour when no control measures are taken.

- Method 1: PVs operate according to the same standardised volt/var curves from the IEEE grid-codes [26]. The maximum acceptable voltage is set to p.u. We use this scheme as the benchmark for the current industrial practice without the possibility for online adjustments.

- Method 2: PVs operate according to the German grid-code [14]. DGs become inductive when injecting more than 50% of their installed capacity. The power factor decreases linearly from 1 to or based on the DG capacity. This scheme is also used as the current open-loop industrial practice without online adjustments.

- Method 3: PVs are controlled with a centralised OPF algorithm summarised in Section 2. This scheme is used as the benchmark for the best achievable performance.

- Method 4: The offline training methodology is repeated considering the addition of the PV unit. The PV inverters implement the updated volt/var curves which refer to the new conditions, and the self-adapting algorithm in case of unexpected overvoltage issues.

- Method 5: The PV units are operating according to the initial local data-driven schemes without re-training, i.e., the PV unit at node 6 is not considered in the design stage. Potential overvoltages are tackled by the online algorithm proposed in Section 3.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| (A) Indices & functions | |

| j | Index of nodes. |

| i | Index of branches. |

| l | Index of lines. |

| t | Index of time. |

| Index for the current iteration of the segmented regression problem. | |

| Superscript indicating the complex conjugate. | |

| (B) Parameters | |

| The indicator function which becomes one when the statement inside is true. | |

| Total number of network nodes (−). | |

| Total number of network branches (−). | |

| Power factor of the load (−). | |

| Length of a time interval within the optimization horizon (h). | |

| Maximum available active power of the DER connected at node j, at time t (kW). | |

| Fixed cost of curtailing active power (). | |

| Fixed cost of providing reactive power support (DER opportunity cost or contractual agreement) (). | |

| Voltage magnitude at node j, and time t; the bar indicates that the known value from the previous Backward/Forward Sweep iteration is used (p.u.). | |

| Complex voltage at the slack bus (here assumed to be (p.u.). | |

| / | Minimum/Maximum acceptable voltage magnitude (here assumed to be / (p.u.). |

| Maximum thermal limit for the i-th branch (p.u.). | |

| / | Upper and lower limits for the active DER power at node j, and time t (kW). |

| Number of breakpoints for the segmented regression problem (−). | |

| Known breakpoints used for the fitting of the segmented regression problem at the current iteration (−). | |

| Number of the voltage series in terms of the reactive characteristic curves (−). | |

| (C) Variables | |

| Active power injection of the DER connected at node j, at time t (kW). | |

| Curtailed active power of the DER connected at node j, at time t (kW). | |

| Active power losses at branch i, at time t (kW). | |

| / | Active and reactive demand of constant power type at node j, at time t (kW). |

| Reactive power injection (positive) or absorption (negative) of the DER connected at node j, phase z, at time t (kVAr). | |

| Current flowing at the i-th branch, at time t (p.u.) | |

| Model for the reactive power control based on the segmented regression problem with unknown breakpoints (−). | |

| / | Left slope and difference-in-slopes values of the fitting problem (−). |

| The model intercept (p.u.). | |

| Parameter which updates the location of the breakpoints towards the optimal one in the regression problem (−). | |

| (D) Vectors and Matrices | |

| u | Vector of the available active control measures. |

| Vector of bus injections for all nodes. | |

| Vector of branch flow currents for all branches. | |

| Vector of the maximum branch current for all branches. | |

| Matrix with ones and zeros, capturing the radial topology of the network. | |

| Matrix with the complex impedances of the lines as elements. | |

| Feature matrix containing the optimal setpoints which refer to the local measurements (features) that are used for the design of the local controllers. | |

| Vector containing the voltage series in terms of the active or reactive characteristic curves. | |

| (E) Acronyms | |

| BFS | Backward Forward Sweep |

| BIBC | Bus Injection to Branch Current |

| BCBV | Branch Current to Bus Voltage |

| CHIL | Controller-Hardware-in-the-loop |

| DER | Distributed Energy Resource |

| DRTS | Digital Real-Time Simulator |

| DG | Distributed Generator |

| DN | Distribution Network |

| HIL | Hardware-in-the-loop |

| HuT | Hardware-under-Test |

| LV | Low Voltage |

| OPF | Optimal Power Flow |

| PV | Photovoltaic |

| PDS | Purely Digital Simulations |

| PHIL | Power-Hardware-in-the-loop |

| RTDS | Real Time Digital Simulator |

| RSS | Residual Sum-of-Squares |

| RSSV | Root-Sum-of-Squares Value |

| SIL | Software-in-the-Loop |

References

- Karagiannopoulos, S.; Aristidou, P.; Hug, G. Data-driven Local Control Design for Active Distribution Grids using off-line Optimal Power Flow and Machine Learning Techniques. IEEE Trans. Smart Grid 2019, 10, 6461–6471. [Google Scholar] [CrossRef]

- Dobbe, R.; Sondermeijer, O.; Fridovich-Keil, D.; Arnold, D.; Callaway, D.; Tomlin, C. Towards Distributed Energy Services: Decentralizing Optimal Power Flow with Machine Learning. arXiv 2018, arXiv:1806.06790. [Google Scholar] [CrossRef]

- Karagiannopoulos, S.; Dobbe, R.; Aristidou, P.; Callaway, D.; Hug, G. Data-driven Control Design Schemes in Active Distribution Grids: Capabilities and Challenges. In Proceedings of the 2019 IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019. [Google Scholar]

- Garg, A.; Jalali, M.; Kekatos, V.; Gatsis, N. Kernel-Based Learning for Smart Inverter Control. arXiv 2018, arXiv:1807.03769. [Google Scholar]

- Eggli, A.; Karagiannopoulos, S.; Bolognani, S.; Hug, G. Stability Analysis and Design of Local Control Schemes in Active Distribution Grids. IEEE Trans. Power Syst. 2019, 36, 1900–1909. [Google Scholar]

- Kotsampopoulos, P.; Hatziargyriou, N.; Bletterie, B.; Lauss, G.; Strasser, T. Introduction of advanced testing procedures including PHIL for DG providing ancillary services. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 5398–5404. [Google Scholar]

- Maniatopoulos, M.; Lagos, D.; Kotsampopoulos, P.; Hatziargyriou, N. Combined control and power hardware in-the-loop simulation for testing smart grid control algorithms. IET Gener. Transm. Distrib. 2017, 11, 3009–3018. [Google Scholar] [CrossRef]

- Kotsampopoulos, P.C.; Lehfuss, F.; Lauss, G.F.; Bletterie, B.; Hatziargyriou, N.D. The limitations of digital simulation and the advantages of PHIL testing in studying distributed generation provision of ancillary services. IEEE Trans. Ind. Electron. 2015, 62, 5502–5515. [Google Scholar] [CrossRef]

- Kotsampopoulos, P.C.; Kleftakis, V.A.; Hatziargyriou, N.D. Laboratory education of modern power systems using PHIL simulation. IEEE Trans. Power Syst. 2016, 32, 3992–4001. [Google Scholar] [CrossRef]

- Bolognani, S. Grid Topology Identification via Distributed Statistical Hypothesis Testing. In Big Data Application in Power Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 281–301. [Google Scholar]

- Olivier, F.; Sutera, A.; Geurts, P.; Fonteneau, R.; Ernst, D. Phase identification of smart meters by clustering voltage measurements. In Proceedings of the 2018 Power Systems Computation Conference (PSCC), Dublin, Ireland, 11–15 June 2018; pp. 1–8. [Google Scholar]

- Fortenbacher, P.; Zellner, M.; Andersson, G. Optimal sizing and placement of distributed storage in low voltage networks. In Proceedings of the 19th Power Systems Computation Conference, Genova, Italy, 20–24 June 2016. [Google Scholar] [CrossRef]

- Karagiannopoulos, S.; Aristidou, P.; Roald, L.; Hug, G. Operational Planning of Active Distribution Grids under Uncertainty. In Proceedings of the X Bulk Power Systems Dynamics and Control Symposium, Espinho, Portugal, 27 August–1 September 2017. [Google Scholar]

- VDE-AR-N 4105. Generators Connected to the LV Distribution Network-Technical Requirements for the Connection to and Parallel Operation with Low-Voltage Distribution Networks; Technical Report for VDE FNN: Berlin, Germany, 2011. [Google Scholar]

- Muggeo, V.M.R. Estimating regression models with unknown break-points. Stat. Med. 2003, 22, 3055–3071. [Google Scholar] [CrossRef] [PubMed]

- Dobbe, R.; Hidalgo-Gonzalez, P.; Karagiannopoulos, S.; Henriquez-Auba, R.; Hug, G.; Callaway, D.; Tomlin, C. Learning to control in power systems: Design and analysis guidelines for concrete safety problems. Electr. Power Syst. Res. 2020, 189, 106615. [Google Scholar] [CrossRef]

- Werner, S.; Masing, L.; Lesniak, F.; Becker, J. Software-in-the-loop simulation of embedded control applications based on virtual platforms. In Proceedings of the 25th International Conference on Field Programmable Logic and Applications (FPL), London, UK, 2–4 September 2015. [Google Scholar]

- Muresan, M.; Pitica, D. Software in the loop environment reliability for testing embedded code. In Proceedings of the IEEE 18th International Symposium for Design and Technology in Electronic Packaging, Alba Iulia, Romania, 25–28 October 2012. [Google Scholar]

- Faruque, M.O.; Strasser, T.; Lauss, G.; Jalili-Marandi, V.; Forsyth, P.; Dufour, C.; Dinavahi, V.; Monti, A.; Kotsampopoulos, P.; Martinez, J.A.; et al. Real-time simulation technologies for power systems design, testing, and analysis. IEEE Power Energy Technol. Syst. J. 2015, 2, 63–73. [Google Scholar] [CrossRef]

- Ren, W.; Steurer, M.; Baldwin, T.L. Improve the stability and the accuracy of power hardware-in-the-loop simulation by selecting appropriate interface algorithms. IEEE Trans. Ind. Appl. 2008, 44, 1286–1294. [Google Scholar] [CrossRef]

- Löfberg, J. YALMIP: A Toolbox for Modeling and Optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 2–4 September 2004. [Google Scholar]

- Gurobi Optimization, Inc. Gurobi Optimizer Reference Manual; Gurobi Optimization, Inc.: Beaverton, OR, USA, 2016. [Google Scholar]

- RTDS Technology Inc. Real-Time Simulation. Winnipeg, MB, Canada. Available online: http://www.rtds.com (accessed on 5 October 2019).

- Strunz, K.; Abbasi, E.; Abbey, C.; Andrieu, C.; Gao, F.; Gaunt, T.; Gole, A.; Hatziargyriou, N.; Iravani, R. Benchmark Systems for Network Integration of Renewable and Distributed Energy Resources; CIGRE, Task Force C6.04: Paris, France, 2014; pp. 4–6. [Google Scholar]

- SMA Solar Technology AG. Sunny Boy 3000TL/3600TL/4000TL/5000TL with Reactive Power Control; SMA: Niestetal, Germany, 2015; Available online: http://files.sma.de/dl/15330/SB30-50TL-21-BE-en-11.pdf (accessed on 5 October 2019).

- IEEE 1547-2018. Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces; Standard; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

| Method | 0 | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|

| Losses (%) | 5.74 | 5.78 | 6.47 | 5.11 | 5.18 | 5.17 |

| (p.u.) | 1.071 | 1.054 | 1.053 | 1.05 | 1.051 | 1.052 |

| → (17) | 0 | 9.18 | 30.55 | 67.29 | 62.38 | 59.39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karagiannopoulos, S.; Vasilakis, A.; Kotsampopoulos, P.; Hatziargyriou, N.; Aristidou, P.; Hug, G. Experimental Verification of Self-Adapting Data-Driven Controllers in Active Distribution Grids. Energies 2021, 14, 2837. https://doi.org/10.3390/en14102837

Karagiannopoulos S, Vasilakis A, Kotsampopoulos P, Hatziargyriou N, Aristidou P, Hug G. Experimental Verification of Self-Adapting Data-Driven Controllers in Active Distribution Grids. Energies. 2021; 14(10):2837. https://doi.org/10.3390/en14102837

Chicago/Turabian StyleKaragiannopoulos, Stavros, Athanasios Vasilakis, Panos Kotsampopoulos, Nikos Hatziargyriou, Petros Aristidou, and Gabriela Hug. 2021. "Experimental Verification of Self-Adapting Data-Driven Controllers in Active Distribution Grids" Energies 14, no. 10: 2837. https://doi.org/10.3390/en14102837

APA StyleKaragiannopoulos, S., Vasilakis, A., Kotsampopoulos, P., Hatziargyriou, N., Aristidou, P., & Hug, G. (2021). Experimental Verification of Self-Adapting Data-Driven Controllers in Active Distribution Grids. Energies, 14(10), 2837. https://doi.org/10.3390/en14102837