Sustainability Evaluation of Non-Toxic Jatropha curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment

Abstract

1. Introduction

State of the Art of Sustainability of Jatropha curcas for Obtaining Biodiesel

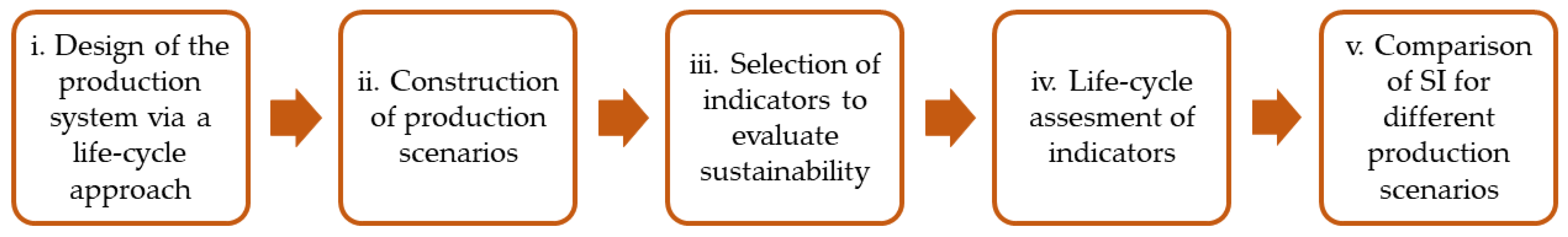

2. Materials and Methods

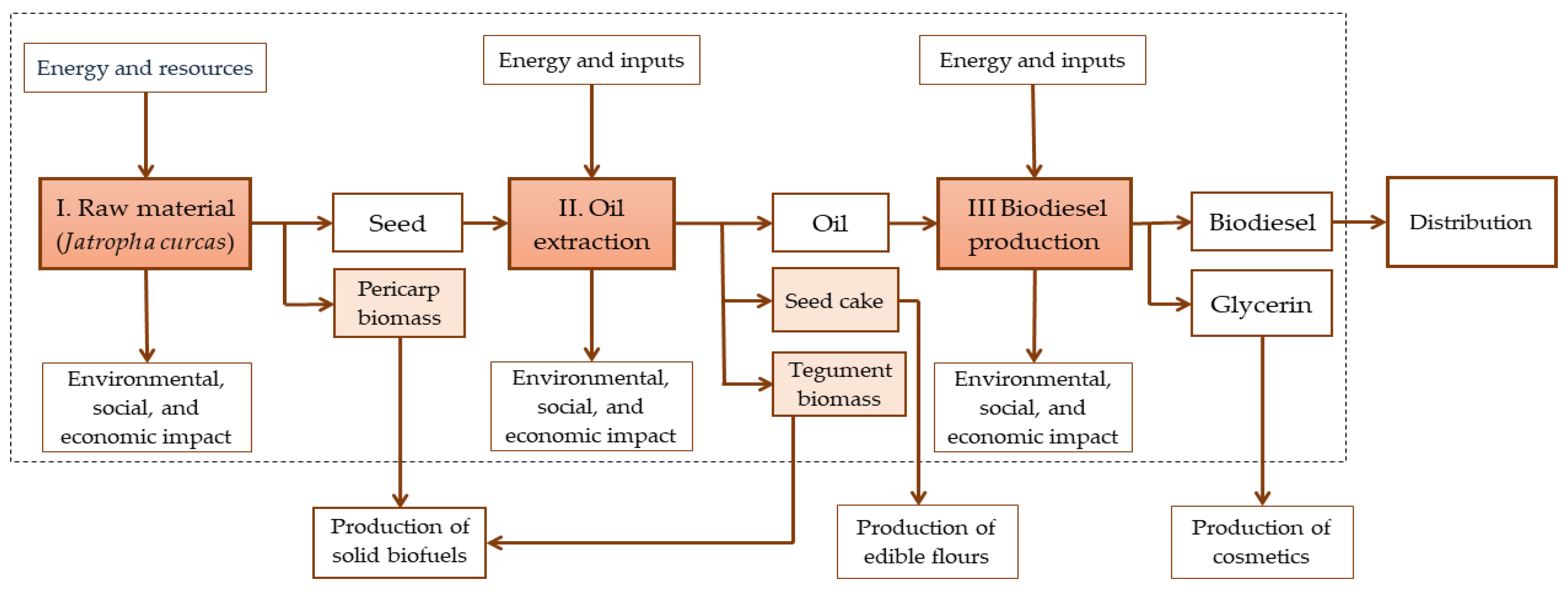

2.1. Design and Definition of Production System via a Life-Cycle Approach

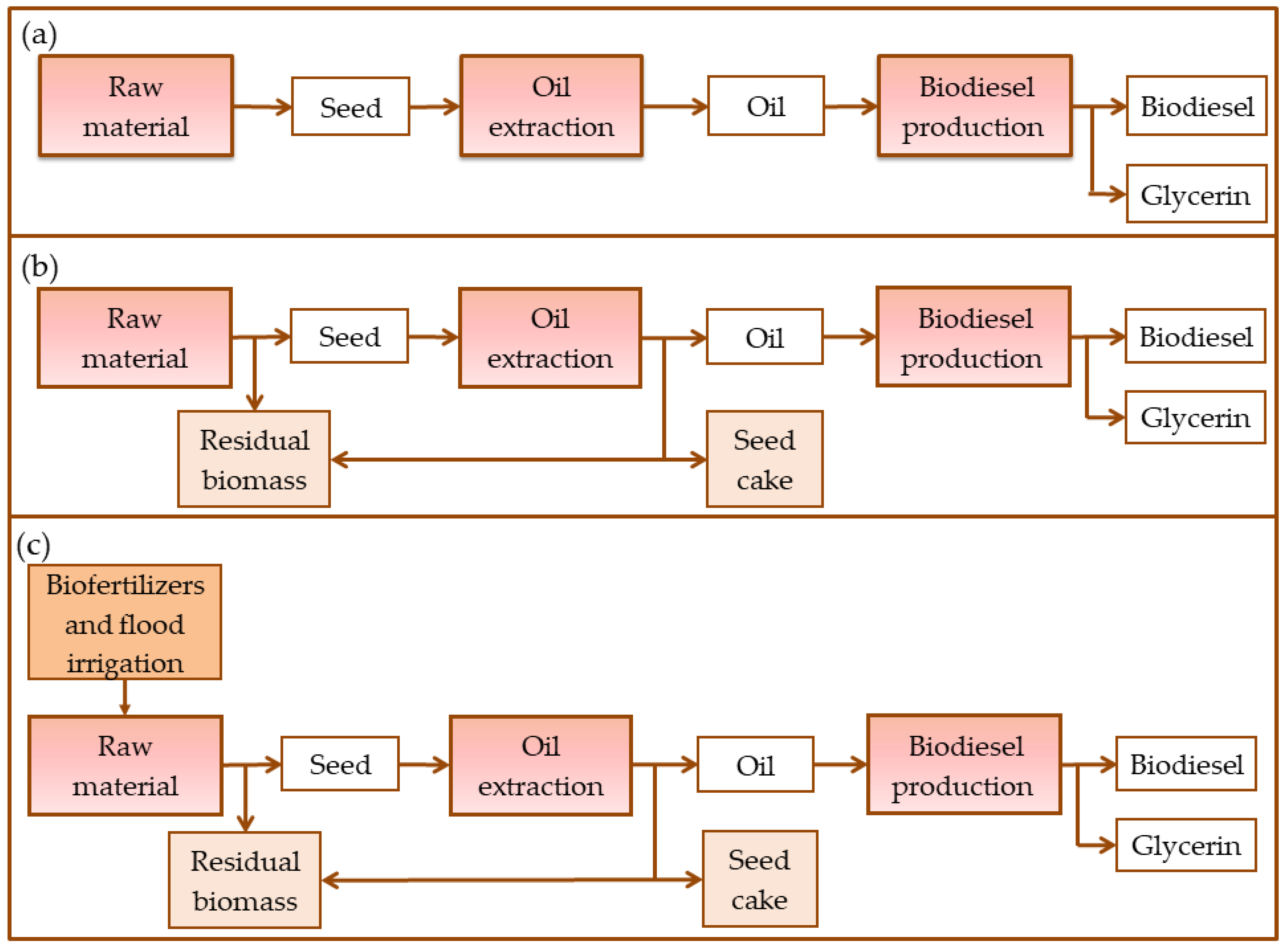

2.2. Construction of Production Scenarios

2.2.1. Scenario 1. MR (Minimal Resources)

2.2.2. Scenario 2. MRUS (Minimal Resources and Utilization of Sub-Products)

2.2.3. Scenario 3. UBIS (Utilization of Biofertilizers, Flood Irrigation and Sub-Products)

2.3. Selection of Sustainability Indicators

2.4. Development of Indicators within the Context of the Life Cycle Assessment

2.5. Obtaining of Sustainability Index (SI)

3. Results and Discussion

3.1. Results of Sustainability Indicators

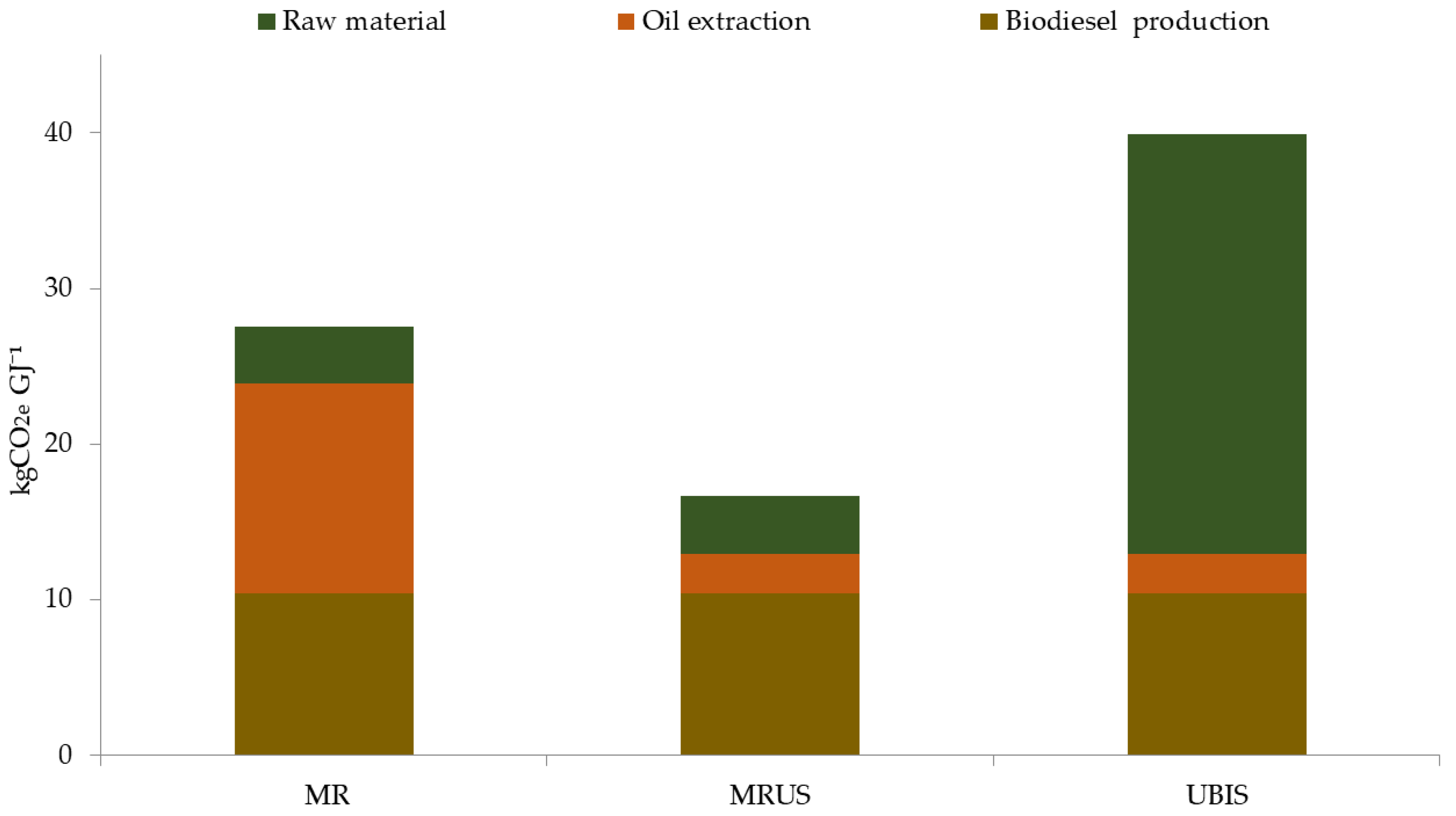

3.1.1. Indicator 1. Greenhouse Gas Emissions

3.1.2. Indicator 2. Land Use

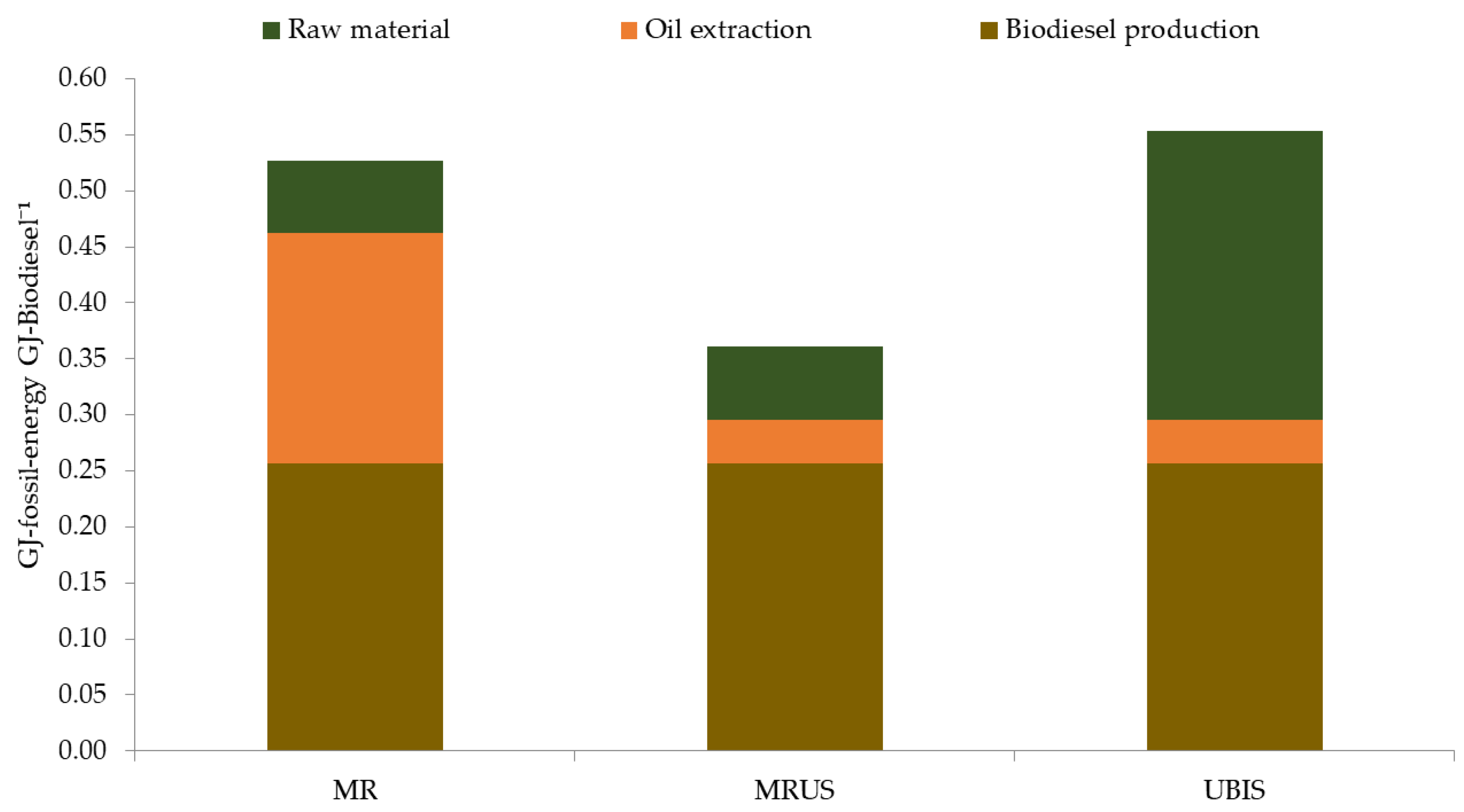

3.1.3. Indicator 3. Energy Balance

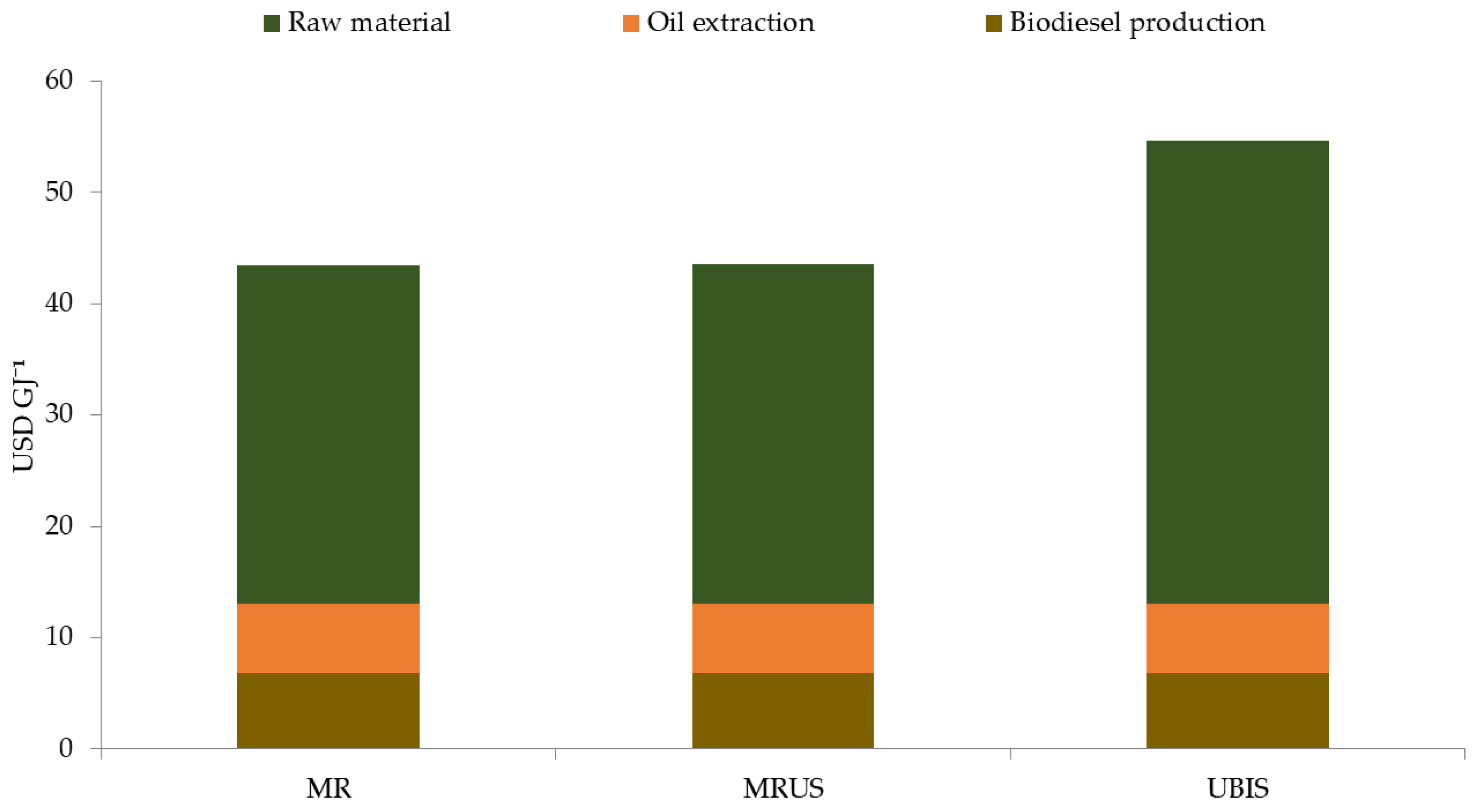

3.1.4. Indicator 4. Production Costs

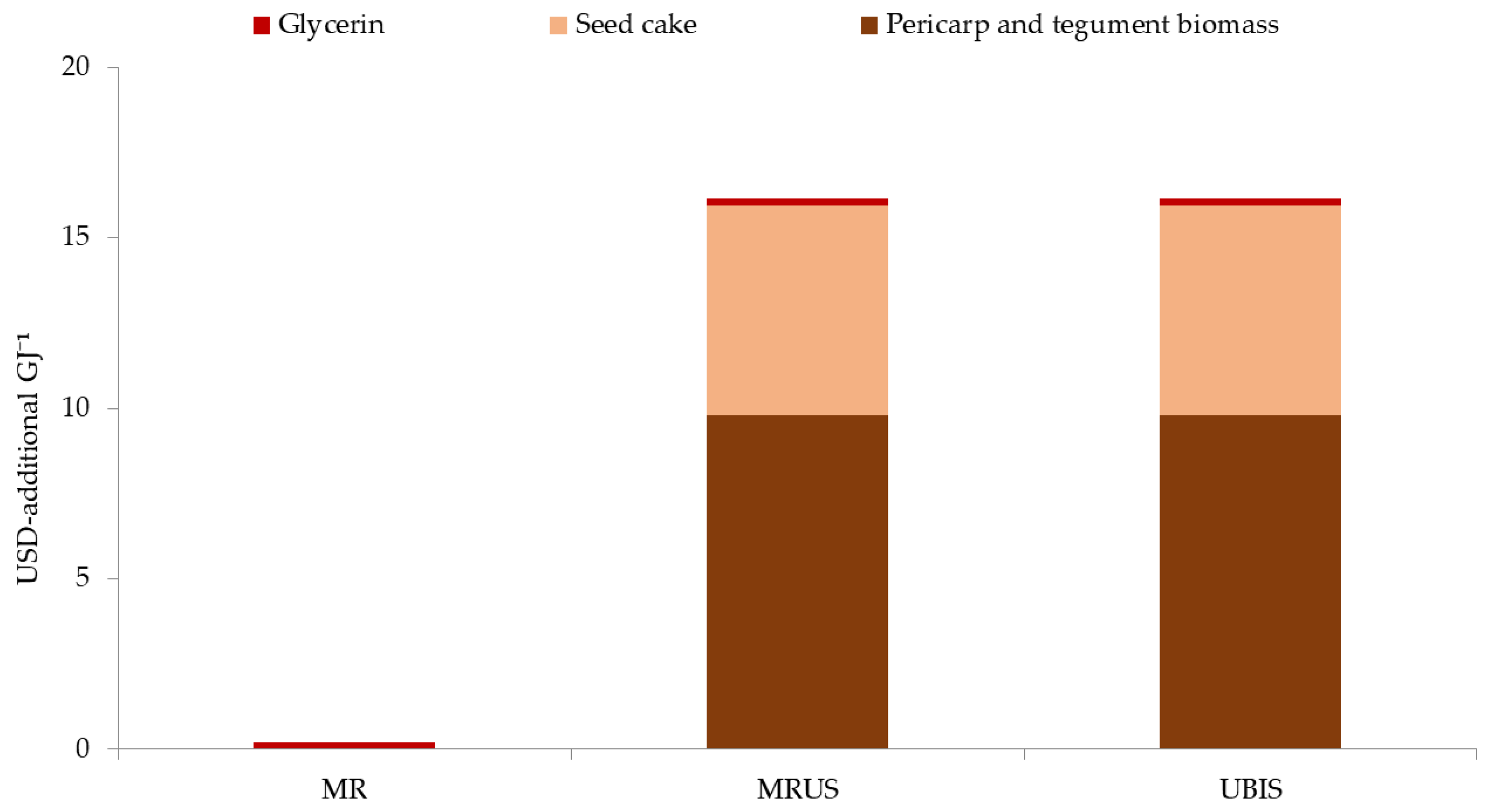

3.1.5. Indicator 5. Added Value

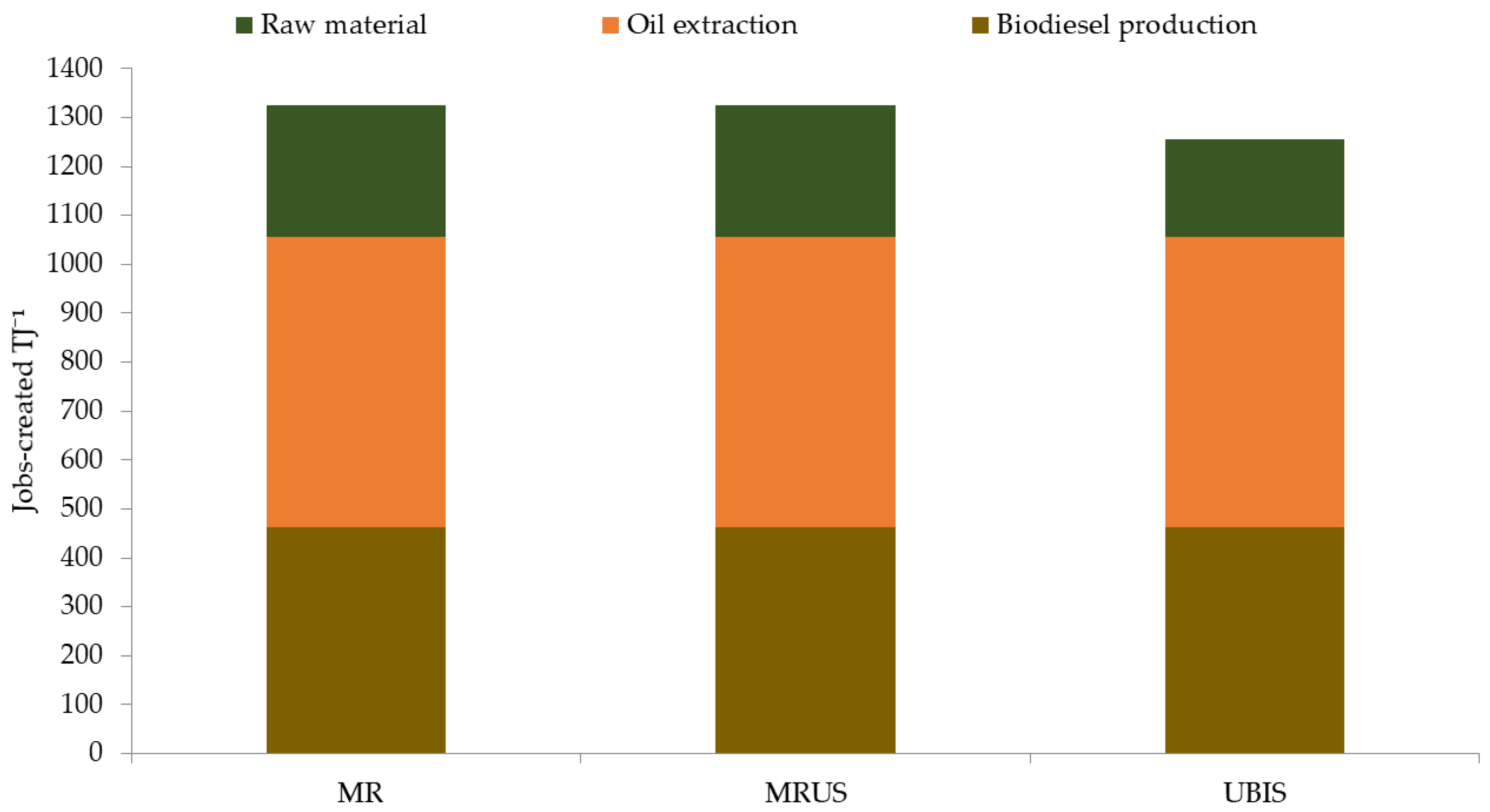

3.1.6. Indicator 6. Employment

3.2. Comparison of Scenarios in Terms of Sustainability Index

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | Greenhouse Gas |

| GBEP | Global Bioenergy Partnership |

| IESEP | Index of Environmental Sustainability in Energy Products |

| LCA | Life-Cycle Assessment |

| MR | Minimal Resources |

| MRUS | Minimal Resources and Utilization of Sub-products |

| NTJC | Non-toxic Jatropha curcas |

| RSB | Roundtable of Sustainable Biomaterials |

| SI | Sustainability Index |

| UBIS | Utilization of Biofertilizers, Flood Irrigation, and Sub-products |

References

- Muscat, A.; de Olde, E.M.; de Boer, I.J.M.; Ripoll-Bosch, R. The Battle for Biomass: A Systematic Review of Food-Feed-Fuel Competition. Glob. Food Sec. 2020, 25. [Google Scholar] [CrossRef]

- Ravindranath, N.H.; Sita Lakshmi, C.; Manuvie, R.; Balachandra, P. Biofuel Production and Implications for Land Use, Food Production and Environment in India. Energy Policy 2011, 39, 5737–5745. [Google Scholar] [CrossRef]

- Harvey, M.; Pilgrim, S. The New Competition for Land: Food, Energy, and Climate Change. Food Policy 2011, 36 (Suppl. 1), 40–51. [Google Scholar] [CrossRef]

- Francis, G.; Oliver, J.; Sujatha, M. Non-Toxic Jatropha Plants as a Potential Multipurpose Multi-Use Oilseed Crop. Ind. Crops Prod. 2013, 42, 397–401. [Google Scholar] [CrossRef]

- Basili, M.; Fontini, F. Biofuel from Jatropha Curcas: Environmental Sustainability and Option Value. Ecol. Econ. 2012, 1–8. [Google Scholar] [CrossRef]

- CastroGonzáles, N.F. International Experiences with the Cultivation of Jatropha Curcas for Biodiesel Production. Energy 2016, 112, 1245–1258. [Google Scholar] [CrossRef]

- Wang, Z.; Calderon, M.M.; Lu, Y. Lifecycle Assessment of the Economic, Environmental and Energy Performance of Jatropha Curcas L. Biodiesel in China. Biomass Bioenergy 2011, 35, 2893–2902. [Google Scholar] [CrossRef]

- Eshton, B.; Katima, J.H.Y.; Kituyi, E. Greenhouse Gas Emissions and Energy Balances of Jatropha Biodiesel as an Alternative Fuel in Tanzania. Biomass Bioenergy 2013, 58, 95–103. [Google Scholar] [CrossRef]

- Fuentes, A.; García, C.; Hennecke, A.; Masera, O. Life Cycle Assessment of Jatropha Curcas Biodiesel Production: A Case Study in Mexico. Clean Technol. Environ. Policy 2018, 20, 1721–1733. [Google Scholar] [CrossRef]

- Liang, S.; Xu, M.; Zhang, T. Life Cycle Assessment of Biodiesel Production in China. Bioresour. Technol. 2013, 129, 72–77. [Google Scholar] [CrossRef]

- Rivero, J.C.S.; Eastmond-Spencer, A.; García, J.B.; Navarro-Pineda, F.S. A Three-Dimensional Sustainability Evaluation of Jatropha Plantations in Yucatan, Mexico. Sustainability 2016, 8, 1316. [Google Scholar] [CrossRef]

- Kalinda, C.; Moses, Z.; Lackson, C.; Chisala, L.A.; Donald, Z.; Darius, P.; Exildah, C.K. Economic Impact and Challenges of Jatropha Curcas L. Projects in North-Western Province, Zambia: A Case of Solwezi District. Sustainability 2015, 7, 9907–9923. [Google Scholar] [CrossRef]

- Van Eijck, J.; Romijn, H.; Balkema, A.; Faaij, A. Global Experience with Jatropha Cultivation for Bioenergy: An Assessment of Socio-Economic and Environmental Aspects. Renew. Sustain. Energy Rev. 2014, 32, 869–889. [Google Scholar] [CrossRef]

- Baral, N.R.; Neupane, P.; Ale, B.B.; Quiroz-Arita, C.; Manandhar, S.; Bradley, T.H. Stochastic Economic and Environmental Footprints of Biodiesel Production from Jatropha Curcas Linnaeus in the Different Federal States of Nepal. Renew. Sustain. Energy Rev. 2020, 120. [Google Scholar] [CrossRef]

- Achten, W.M.J.; Almeida, J.; Fobelets, V.; Bolle, E.; Mathijs, E.; Singh, V.P.; Tewari, D.N.; Verchot, L.V.; Muys, B. Life Cycle Assessment of Jatropha Biodiesel as Transportation Fuel in Rural India. Appl. Energy 2010. [Google Scholar] [CrossRef]

- Ishimoto, Y.; Yabuta, S.; Kgokong, S.; Motsepe, M.; Tominaga, J.; Teramoto, S.; Konaka, T.; Mmopelwa, G.; Kawamitsu, Y.; Akashi, K.; et al. Environmental Evaluation with Greenhouse Gas Emissions and Absorption Based on Life Cycle Assessment for a Jatropha Cultivation System in Frost- and Drought-Prone Regions of Botswana. Biomass Bioenergy 2018, 33–40. [Google Scholar] [CrossRef]

- Somorin, T.O.; Di Lorenzo, G.; Kolios, A.J. Life-Cycle Assessment of Self-Generated Electricity in Nigeria and Jatropha Biodiesel as an Alternative Power Fuel. Renew Energy. 2017, 966–979. [Google Scholar] [CrossRef]

- Navarro-Pineda, F.S.; Baz-Rodríguez, S.A.; Handler, R.; Sacramento-Rivero, J.C. Advances on the Processing of Jatropha Curcas towards a Whole-Crop Biorefinery. Renew Sustain. Energy Rev. 2016, 54, 247–269. [Google Scholar] [CrossRef]

- Giraldi-Díaz, M.R.; De Medina-Salas, L.; Castillo-González, E.; De la Cruz-Benavides, M. Environmental Impact Associated with the Supply Chain and Production of Biodiesel from Jatropha Curcas L. through Life Cycle Analysis. Sustainability 2018, 10, 1451. [Google Scholar] [CrossRef]

- Rocha, M.H.; Capaz, R.S.; Lora, E.E.S.; Nogueira, L.A.H.; Leme, M.M.V.; Renó, M.L.G.; Del Olmo, O.A. Life Cycle Assessment (LCA) for Biofuels in Brazilian Conditions: A Meta-Analysis. Renew. Sustain. Energy Rev. 2014, 37, 435–459. [Google Scholar] [CrossRef]

- Maftuchah; Zainudin, A.; Ikhwan, A.; Winaya, A.; Purmana, A.; Surdarmo, H. The Potential of Physic Nut (Jatropha Curcas Linn) Hibrid Plant as Source of Biodiesel at Different Planting Location for Dry Land Utilization. Energy Rep. 2020, 921–926. [Google Scholar] [CrossRef]

- Moseki, O.; Murray-Hudson, M.; Kashe, K. Crop Water and Irrigation Requirements of Jatropha Curcas L. in Semi-Arid Conditions of Botswana: Applying the CROPWAT Model. Agric. Water Manag. 2019. [Google Scholar] [CrossRef]

- Mazumdar, P.; Singh, P.; Babu, S.; Siva, R.; Harikrishna, J.A. An Update on Biological Advancement of Jatropha Curcas L.: New Insight and Challenges. Renew. Sustain. Energy Rev. 2018, 903–917. [Google Scholar] [CrossRef]

- Nindita, A.; Dewi, I.S.; Purwoko, B.S.; Setyobudi, R.H. Genetic Improvement and Biotechnology Research of Jatropha Curcas Linn. Review: Future Research Opportunity and Sustainability Challenges in Indonesia. Energy Procedia 2015, 3–7. [Google Scholar] [CrossRef][Green Version]

- León-Villanueva, A.; Huerta-Ocampo, J.A.; Barrera-Pacheco, A.; Medina-Godoy, S.; Barba de la Rosa, A.P. Proteomic Analysis of Non-Toxic Jatropha Curcas Byproduct Cake: Fractionation and Identification of the Major Components. Ind. Crops Prod. 2018, 111, 694–704. [Google Scholar] [CrossRef]

- Oliveira, P.B.; Lima, P.M.T.; Campeche, A.; Mendonça, S.; Laviola, B.G.; McManus, C.; Louvandini, H. Growth and Carcass Characteristics of Santa Inês Lambs Fed Diet Supplemented with Physic Nut Meal Free of Phorbol Ester. Small Rumin. Res. 2013, 114, 20–25. [Google Scholar] [CrossRef]

- Makkar, H.P.S.; Becker, K. Jatropha Curcas, a Promising Crop for the Generation of Biodiesel and Value-Added Coproducts. Eur. J. Lipid Sci. Technol. 2009, 773–787. [Google Scholar] [CrossRef]

- Sánchez-Arreola, E.; Martin-Torres, G.; Lozada-Ramírez, J.D.; Hernández, L.R.; Bandala-González, E.R.; Bach, H. Biodiesel Production and De-Oiled Seed Cake Nutritional Values of a Mexican Edible Jatropha Curcas. Renew. Energy 2015, 76, 143–147. [Google Scholar] [CrossRef]

- He, W.; King, A.J.; Khan, M.A.; Cuevas, J.A.; Ramiaramanana, D.; Graham, I.A. Analysis of Seed Phorbol-Ester and Curcin Content Together with Genetic Diversity in Multiple Provenances of Jatropha Curcas L. from Madagascar and Mexico. Plant Physiol. Biochem. 2011, 49, 1183–1190. [Google Scholar] [CrossRef]

- Martínez-Díaz, Y.; González-Rodríguez, A.; Delgado-Lamas, G.; Espinosa-García, F.J. Geographic Structure of Chemical Variation in Wild Populations of the Fuel Crop Jatropha Curcas L. in Mexico. Ind. Crops Prod. 2015, 74, 63–68. [Google Scholar] [CrossRef]

- Kumar, V.; Makkar, H.P.S.; Amselgruber, W.; Becker, K. Physiological, Haematological and Histopathological Responses in Common Carp (Cyprinus Carpio L.) Fingerlings Fed with Differently Detoxified Jatropha Curcas Kernel Meal. Food Chem. Toxicol. 2010, 48, 2063–2072. [Google Scholar] [CrossRef] [PubMed]

- SENER. Prospectiva De Energias Renovables 2015–2029; SENER: Getxo, Spain, 2015. [Google Scholar]

- Pecina-Quintero, V.; Anaya-López, J.L.; Zamarripa-Colmenero, A.; Núñez-Colín, C.A.; Montes-García, N.; Solís-Bonilla, J.L.; Jiménez-Becerril, M.F. Genetic Structure of Jatropha Curcas L. in Mexico and Probable Centre of Origin. Biomass Bioenergy 2014, 60, 147–155. [Google Scholar] [CrossRef]

- Makkar, H.P.S.; Becker, K.; Schmook, B. Edible Provenances of Jatropha Curcas from Quintana Roo State of Mexico and Effect of Roasting on Antinutrient and Toxic Factors in Seeds. Plant Foods Hum. Nutr. 1998, 52, 31–36. [Google Scholar] [CrossRef]

- Martínez-Herrera, J.; Martíne Ayala, A.; Makkar, H.; Francis, G.; Becker, K. Agroclimatic Conditions, Chemical and Nutritional Characterization of Different Provenances of Jatropha Curcas L. from Mexico. Eur. J. Sci. Res. 2010, 39, 396–407. [Google Scholar]

- Pérez, G.; Islas, J.; Guevara, M.; Suárez, R. The Sustainable Cultivation of Mexican Nontoxic Jatropha Curcas to Produce Biodiesel and Food in Marginal Rural Lands. Sustainability 2019, 11, 5823. [Google Scholar] [CrossRef]

- European Commission--Joint Research Centre--Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook--General Guide for Life Cycle Assessment--Detailed Guidance; Springer: Berlin, Germany, 2010. [Google Scholar] [CrossRef]

- Manzini, F.; Islas, J.; Macías, P. Model for Evaluating the Environmental Sustainability of Energy Projects. Technol. Forecast. Soc. Chang. 2011, 78, 931–944. [Google Scholar] [CrossRef]

- Lim, B.Y.; Shamsudin, R.; Baharudin, B.T.H.T.; Yunus, R. A Review of Processing and Machinery for Jatropha Curcas L. Fruits and Seeds in Biodiesel Production: Harvesting, Shelling, Pretreatment and Storage. Renew. Sustain. Energy Rev. 2015, 52, 991–1002. [Google Scholar] [CrossRef]

- Kamel, D.A.; Farag, H.A.; Amin, N.K.; Zatout, A.A.; Ali, R.M. Smart Utilization of Jatropha (Jatropha Curcas Linnaeus) Seeds for Biodiesel Production: Optimization and Mechanism. Ind. Crops Prod. 2018, 111, 407–413. [Google Scholar] [CrossRef]

- Walmsley, D.C.; Bailis, R.; Klein, A.-M. A Global Synthesis of Jatropha Cultivation: Insights into Land Use Change and Management Practices. Environ. Sci. Technol. 2016, 8993–9002. [Google Scholar] [CrossRef]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha Bio-Diesel Production and Use. Biomass Bioenergy 2008, 1063–1084. [Google Scholar] [CrossRef]

- Pandey, V.C.; Singh, K.; Singh, J.S.; Kumar, A.; Singh, B.; Singh, R.P. Jatropha Curcas: A Potential Biofuel Plant for Sustainable Environmental Development. Renew. Sustain. Energy Rev. 2012, 2870–2883. [Google Scholar] [CrossRef]

- RSB. Compliance Indicators to the RSB Principles & Criteria. Rsbservices Org. 2011, 1, 1–81. [Google Scholar]

- Morese, M.M.; Rossi, A.; Colangeli, M. The Global Bioenergy Partnership Sustainability Indicator for Bioenergy; FAO: Rome, Italy, 2017; Volume 2017. [Google Scholar]

- Diaz-Balteiro, L.; González-Pachón, J.; Romero, C. Measuring Systems Sustainability with Multi-Criteria Methods: A Critical Review. Eur. J. Oper. Res. 2017, 258, 607–616. [Google Scholar] [CrossRef]

- Ndong, R.; Montrejaud-Vignoles, M.; Saint Girons, O.; Gabrielle, B.; Pirot, R.; Domergue, M.; Sablayrolles, C. Life Cycle Assessment of Biofuels from Jatropha Curcas in West Africa: A Field Study. GCB Bioenergy 2009, 1, 197–210. [Google Scholar] [CrossRef]

- Kaewcharoensombat, U.; Prommetta, K.; Srinophakun, T. Life Cycle Assessment of Biodiesel Production from Jatropha. J. Taiwan Inst. Chem. Eng. 2011, 42, 454–462. [Google Scholar] [CrossRef]

- Prueksakorn, K.; Gheewala, S.H. Energy and Greenhouse Gas Implications of Biodiesel Production from Jatropha Curcas L. Renew. Energy 2006, 53, 3–8. [Google Scholar]

- Baumert, S.; Khamzina, A.; Vlek, P.L.G. Greenhouse Gas and Energy Balance of Jatropha Biofuel Production Systems of Burkina Faso. Energy Sustain. Dev. 2018, 42, 14–23. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, J.; Nanoti, S.M.; Garg, M.O. A Comprehensive Life Cycle Assessment (LCA) of Jatropha Biodiesel Production in India. Bioresour. Technol. 2012, 110, 723–729. [Google Scholar] [CrossRef] [PubMed]

- Beaver, A.; Castaño, A.G.; Díaz, M.S. Life Cycle Analysis of Jatropha Curcas as a Sustainable Biodiesel Feedstock in Argentina. Chem. Eng. Trans. 2016, 50, 433–438. [Google Scholar] [CrossRef]

- ISO. 14040: Environmental Management–Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. ISO 14044:2006 + A1:2018 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Ahmed, W.; Nazar, M.F.; Ali, S.D.; Rana, U.A.; Khan, S.U.D. Detailed Investigation of Optimized Alkali Catalyzed Transesterification of Jatropha Oil for Biodiesel Production. J. Energy Chem. 2015, 24, 331–336. [Google Scholar] [CrossRef]

- Heller, J. Physic Nut. Jatropha Curcas L. Promoting the Conservation and Use of Underutilized and Neglected Crops. 1; Gatersleben/International Plant Genetic Resources Institute: Roma, Italy, 1996. [Google Scholar]

- Pierobon, F.; Zanetti, M.; Grigolato, S.; Sgarbossa, A.; Anfodillo, T.; Cavalli, R. Life Cycle Environmental Impact of Firewood Production—A Case Study in Italy. Appl. Energy 2015, 150, 185–195. [Google Scholar] [CrossRef]

- Marquez-Reynoso, M.I.; Ramírez-Marcial, N.; Cortina-Villar, S.; Ochoa-Gaona, S. Purpose, Preferences and Fuel Value Index of Trees Used for Firewood in El Ocote Biosphere Reserve, Chiapas, Mexico. Biomass Bioenergy 2017, 1–9. [Google Scholar] [CrossRef]

- Singh, B.; Singh, K.; Rejeshwar Rao, G.; Chikara, J.; Kumar, D.; Mishra, D.K.; Saikia, S.P.; Pathre, U.V.; Raghuvanshi, N.; Rahi, T.S.; et al. Agro-Technology of Jatropha Curcas for Diverse Environmental Conditions in India. Biomass Bioenergy 2013, 48, 191–202. [Google Scholar] [CrossRef]

- Phiwngam, A.; Anusontpornperm, S.; Thanachit, S.; Wisawapipat, W. Effects of Soil Moisture Conservation Practice, Irrigation and Fertilization on Jatropha Curcas. Agric. Nat. Resour. 2016, 50, 454–459. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008 Report I: Characterisation. Natl. Inst. Public Health Environ. 2013. Available online: https://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 11 May 2021).

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.D.; Hollander, M.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.1 A Harmonized Life Cycle Impcat Assessment Method at Midpoint and Endpoint Level; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2017; Volume 22, p. 201. [Google Scholar]

- Anyang Best Complete Machinery Engineering Co., L. Precios de Equipos de Extracción de Aceite. Available online: www.oilmillplant.com (accessed on 13 June 2018).

- Alibaba. Precios Filtro de Aceite. Available online: https://spanish.alibaba.com/product-detail/low-price-multi-functional-jatropha-niger-seed-oil-filter-machine-60726518648.html (accessed on 18 June 2018).

- Comisión Federal de Electricidad. Tarifas Eléctricas. Available online: https://app.cfe.mx/Aplicaciones/CCFE/Tarifas/TarifasCREIndustria/Tarifas/GranDemandaMTO.aspx (accessed on 3 August 2019).

- Distribuidor Nacional. Precios de Equipos de Almacenamiento. Available online: https://distribuidornacional.com/Categoria/Rotoplas-Tolvas?gclid=EAIaIQobChMIsfuQj9zs5QIVNSCtBh3x7QxMEAAYAyAAEgIMGvD_BwE (accessed on 24 August 2019).

- Solben. Precios de Planta de Biodiesel. Available online: http://www.solben.org.mx/ (accessed on 27 June 2019).

- Mercado Libre. Precios de Methanol. Available online: https://articulo.mercadolibre.com.mx/MLM-706097873-metanol-9997-de-pureza-precio-por-litro-_JM?quantity=1#position=1&type=item&tracking_id=0227bd55-6a7c-4081-b5e0-a0be3b64c846 (accessed on 15 February 2019).

- Mercado Libre. Precios de Hidroxido de Sodio. Available online: https://articulo.mercadolibre.com.mx/MLM-716684947-hidroxido-de-sodio-sosa-en-escamas-saco-25-kg-_JM?matt_tool=18293428&matt_word&gclid=EAIaIQobChMImK-AguWm5QIVi8VkCh2g4QGTEAYYAyABEgI2R_D_BwE&quantity=1 (accessed on 15 February 2019).

- Consejo para el Desarrollo Económico de Sinaloa. Compendio de Paquetes Tecnológicos Para El Establecimiento de La Cadena Agroindustrial de Jatropha Curcas En El Noroeste de México. Available online: https://docplayer.es/39654923-Compendio-de-paquetes-tecnologicos-para-el-establecimiento-de-la-cadena-agroindustrial-de-jatropha-curcas-en-el-noroeste-de-mexico.html (accessed on 11 May 2021).

- Vazquez Perales, R. La Producción Sustentable de Energía Mediante Una Plantación Energética: El Caso Cuentepec, 2009. Ph.D. Thesis, Universidad Nacional Autónoma de México, Mexico City, Mexico, 2009. [Google Scholar]

- Mercado Libre. Precios de Glicerina Cruda. Available online: https://articulo.mercadolibre.com.mx/MLM-666235830-glicerina-cruda-_JM?quantity=1#position=1&type=item&tracking_id=6c1febdb-070a-4b2d-a048-ddfb4636a247 (accessed on 15 February 2019).

- Observatorio Laboral. Estadísticas de Carreras Profesionales por Área. Available online: http://www.observatoriolaboral.gob.mx/static/estudios-publicaciones/Ingenierias.html (accessed on 26 July 2019).

- Neuvoo. Salarios de Técnico Operador. Available online: http://neuvoo.com.mx/salario/?job=Operador Técnico (accessed on 26 September 2019).

- Indeed. Salarios de Ayudante General. Available online: https://www.indeed.com.mx/salaries/ayudante-de-producción-Salaries (accessed on 26 September 2019).

- Observatorio Laboral. Estadísticas de Carreras Profesionales Administrativos. Available online: http://www.observatoriolaboral.gob.mx/static/estudios-publicaciones/Administrativo.html (accessed on 26 July 2019).

| Scenario | Stage | Inputs | Quantity | Unit | Outputs | Quantity | Unit |

|---|---|---|---|---|---|---|---|

| (a) MR | 1. Obtaining of raw material | Soil | 1351.9 | m2 | Jatropha curcas fruits | 139 | Kg |

| Irrigation water | 506.9 | L | |||||

| Diesel fuel for tractor | 0.215 | kg | |||||

| Transport of fruit | 5.304 | tkm | |||||

| 2. Oil extraction | Electricity for cracking | 16.9 | kWh | Oil | 25.6 | Kg | |

| Electricity for pressing | 3.8 | kWh | Biomass and seed cake | 111.5 | Kg | ||

| Electricity for filtering | 0.2 | kWh | |||||

| 3. Production of biodiesel fuel | Electricity for reactor | 4.6 | kWh | Biodiesel | 24.6 | Kg | |

| Methanol | 5.64 | kg | Glycerin | 1.03 | Kg | ||

| Sodium hydroxide | 0.23 | kg | |||||

| (b) MRUS | 2. Oil extraction | Electricity for cracking | 16.9 | kWh | Oil | 25.6 | kg |

| Electricity for pressing | 3.8 | kWh | Biomass pericarp and tegument | 82.3 | kg | ||

| Electricity for filtering | 0.2 | kWh | Seed cake | 29.5 | kg | ||

| (c) UBIS | Stage 1. Obtaining of raw material | Soil | 995.5 | m2 | Jatropha curcas fruits | 136.9 | Kg |

| Irrigation water | 8959.1 | L | |||||

| Biofertilizers | 622.2 | kg | |||||

| Diesel for tractor | 0.1 | kg | |||||

| Transport of fruit | 5.3 | tkm |

| Stage costs | Description | Annual Cost (USD 2018) | References | ||

|---|---|---|---|---|---|

| MR | MRUS | UBIS | |||

| (a) Obtaining raw material for 1 ha | Investment cost—including cost of seedlings, clearing the land, and planting the seedlings | $1305.14 | Field data from the experimental plantation for E2M NTJC | ||

| Operation and maintenance costs—including manual labor for the clearing of the land, harvesting of fruit, and transportation—years 1 and 2 | $124.75 | $530.22 * | |||

| Operation and maintenance costs—including manual labor for the clearing of the land, harvesting of fruit, and transportation—beginning in year 3 | $343.08 | $748.54 * | |||

| Costs for tools and materials | $363.87 | ||||

| (b) Oil extraction | Investment cost—including machine and equipment cost | $36,287.37 | [63,64] | ||

| Operation and maintenance costs—including manual labor and electricity costs | $95,591.98 | [65] | |||

| Storage costs | $263.53 ** | $692.16 *** | [66] | ||

| (c) Biodiesel production | Investment cost—including equipment costs | $25,111.14 | [67] | ||

| Operation and maintenance costs—including manual labor and electricity costs | $62,787.39 | [65] | |||

| Costs for input flow, i.e., methanol and sodium hydroxide | $30,320.20 | [68,69] | |||

| Costs for storage of biodiesel and glycerin | $315.51 | [66] | |||

| (a) Stage 1. Obtaining Raw Materials * | ||||||

| Activity | Unity | Quantity | Days Per Year for Each Scenario | Reference | ||

| MR | MRUS | UBIS | ||||

| Manual labor for preparation of land. | Workers /ha | 2 | 17 | Field data from the experimental plantation for the E2M NTJC | ||

| Manual labor for planting seedlings. | Workers /ha | 2 | 6 | |||

| Manual labor for applying flood irrigation during Year 1. | Workers /ha | 3 | 4 | - | ||

| Manual labor for application of flood irrigation. | Workers /ha | 2 | - | 5 | ||

| Manual labor: application of biofertilizers. | Workers /ha | 2 | - | 12 | ||

| Annual clearing of land | Workers /ha | 2 | 6 | |||

| Cutting of fruit | Workers /ha | 2 | 20 | |||

| (b) Stage 2. Oil Extraction | ||||||

| Activity | Profile | Quantity | Reference | |||

| MR | MRUS | UBIS | ||||

| Plant supervisor | Industrial engineer | 2 | [73] | |||

| Machine operator | Technical operator | 4 | [74] | |||

| General assistant | General assistant | 4 | [75] | |||

| Machine maintenance | Mechanical engineer | 1 | [73] | |||

| Administration of plant | Accountant | 1 | [76] | |||

| Sales | Degree in Marketing | 1 | [76] | |||

| (c) Stage 3. Biodiesel Production | ||||||

| Plant supervisor | Industrial engineer | 2 | [73] | |||

| Machine operator | Technical operator | 2 | [74] | |||

| General assistant | General assistant | 2 | [75] | |||

| Machine maintenance | Mechanical engineer | 1 | [73] | |||

| Administration of plant | Accountant | 1 | [76] | |||

| Sales | Degree in Marketing | 1 | [76] | |||

| Scenario | Normalized Values * | Weighted Value of Each Indicator | |||||

|---|---|---|---|---|---|---|---|

| GHG Emissions | Land Use | Energy Balance | Production Cost | Added Value | Employment | ||

| MR | 0.60 | 0.74 | 0.69 | 1 | 0.01 | 1 | 0.167 |

| MRUS | 1 | 0.74 | 1.0 | 1 | 1.00 | 1 | |

| UBIS | 0.42 | 1.0 | 0.65 | 0.8 | 1.00 | 0.95 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, G.; Islas-Samperio, J.M. Sustainability Evaluation of Non-Toxic Jatropha curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment. Energies 2021, 14, 2746. https://doi.org/10.3390/en14102746

Pérez G, Islas-Samperio JM. Sustainability Evaluation of Non-Toxic Jatropha curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment. Energies. 2021; 14(10):2746. https://doi.org/10.3390/en14102746

Chicago/Turabian StylePérez, Guadalupe, and Jorge M. Islas-Samperio. 2021. "Sustainability Evaluation of Non-Toxic Jatropha curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment" Energies 14, no. 10: 2746. https://doi.org/10.3390/en14102746

APA StylePérez, G., & Islas-Samperio, J. M. (2021). Sustainability Evaluation of Non-Toxic Jatropha curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment. Energies, 14(10), 2746. https://doi.org/10.3390/en14102746