Multi-Objective Optimization of Steel Off-Gas in Cogeneration Using the ε-Constraint Method: A Combined Coke Oven and Converter Gas Case Study

Abstract

1. Introduction

2. State of the Art

3. Materials and Methods

- First, the system was defined and structured. The different processes that make up the system were established and formulated mathematically.

- Second, taking into account the appropriate restrictions, the model was built, and the corresponding optimization tool was used.

- Third, a mono-objective model for maximizing profit was developed. In this study, the software CPLEX was used to solve the MILP problem.

- Fourth, the mono-objective problem was extended to a bi-objective problem (profit and CO2) through the application of the ε-constraint method.

- Fifth, the model was tested and verified by means of the case study, and the results were evaluated and discussed.

- Sixth, a sensitivity analysis was presented, varying CO2 price and comparing it with CO2 constraint parameters and its impact on the profitability of the process.

4. Case Study

5. Problem Formulation

5.1. Objective Functions

5.1.1. Emissions

5.1.2. Profit

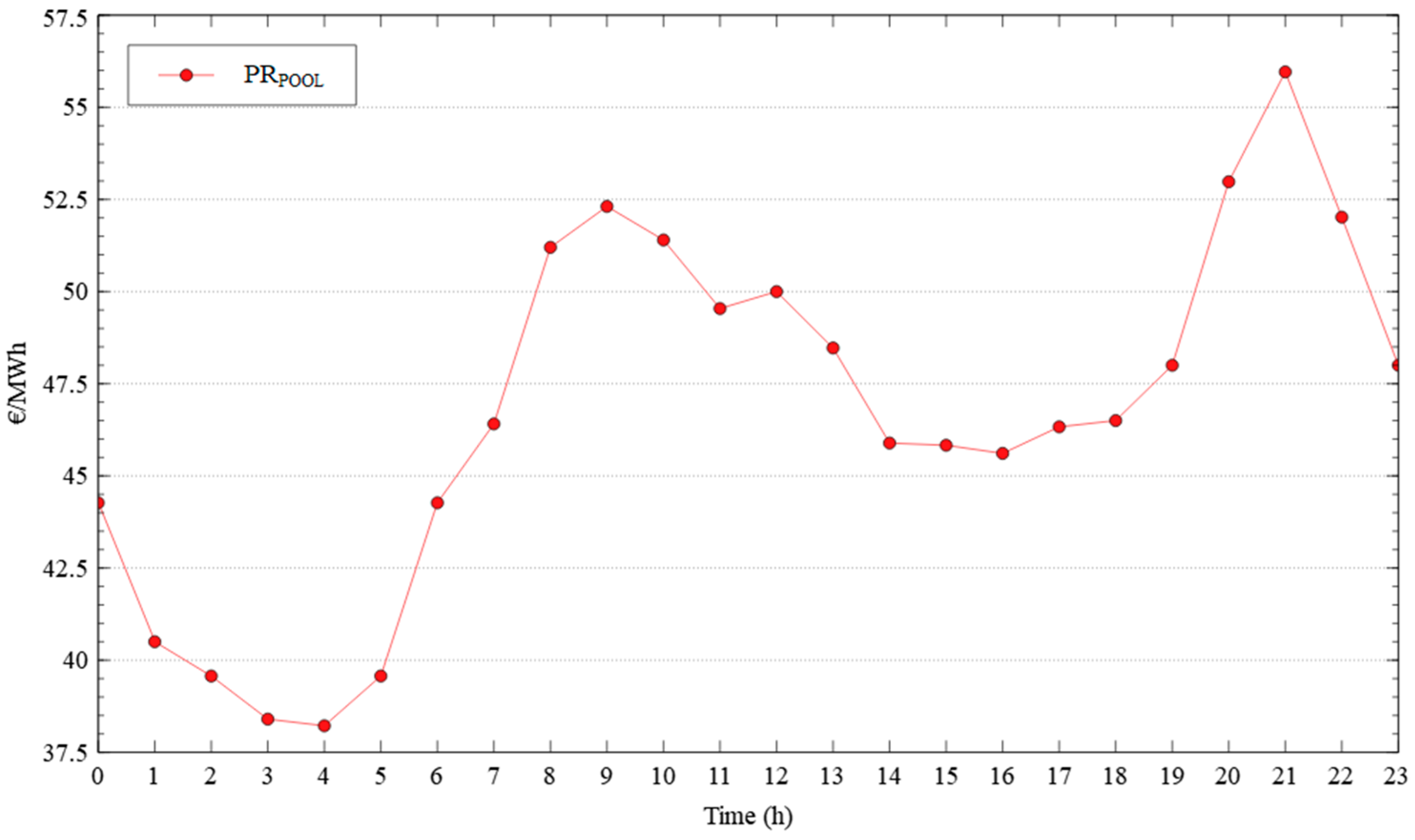

- Reward obtained for electric power (REE): the electric production is multiplied by the market price of the electricity, PPOOL[t]. The price is determined by the day-ahead market that aims to carry out electrical energy transactions for the twenty-four hours of the following day.

- Reward obtained for thermal energy (RTE): corresponds to the production of thermal energy multiplied by the price agreed between the cogeneration and the steel factory (PTE).

5.2. Constraints

5.2.1. Gas Availability

5.2.2. Gasometer Constraints

5.2.3. Steam Demand Satisfaction Constraint

5.2.4. Boiler Constraints

5.2.5. Engine Constraints

5.3. Scenario Description

6. Results and Discussion

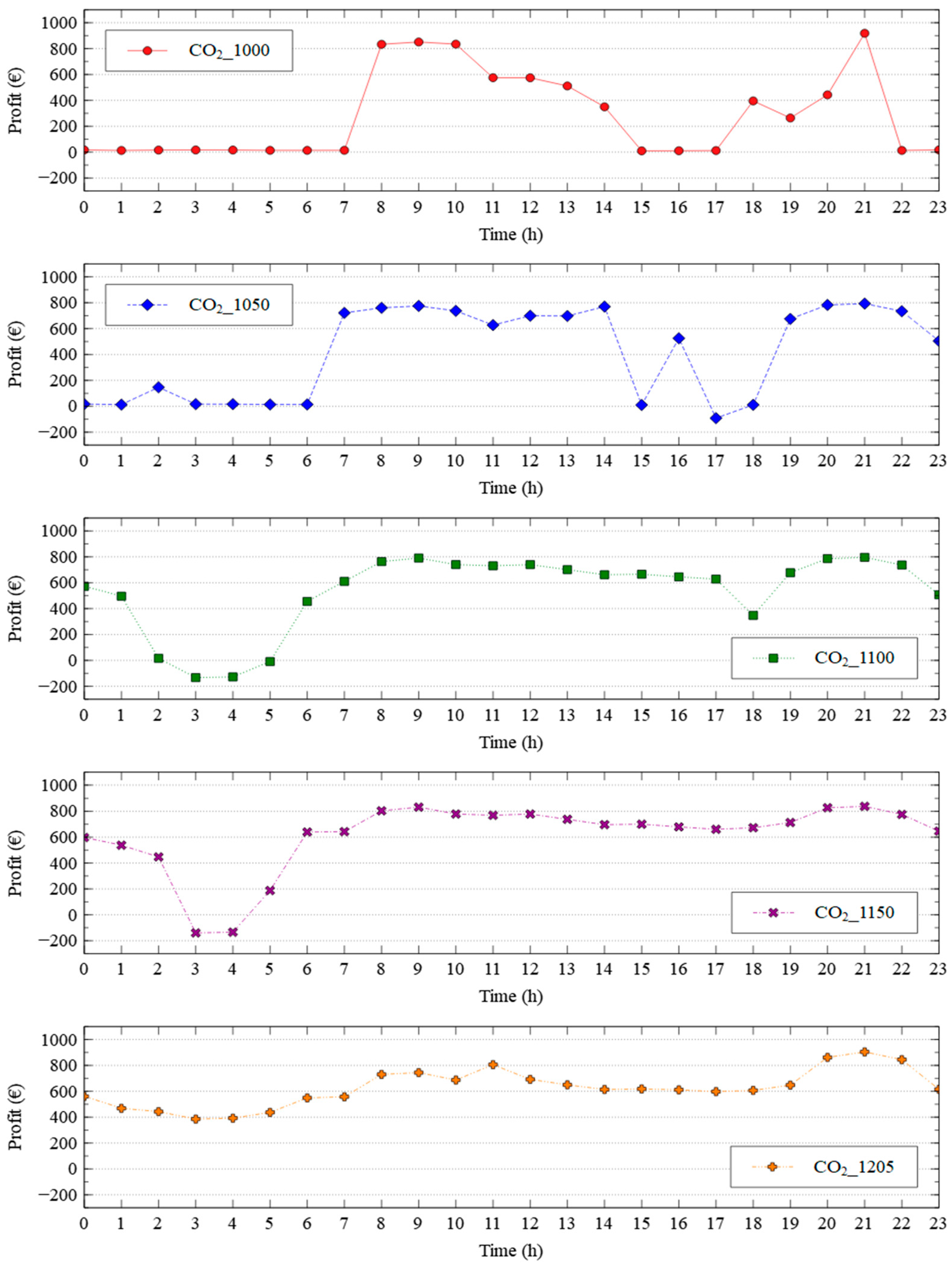

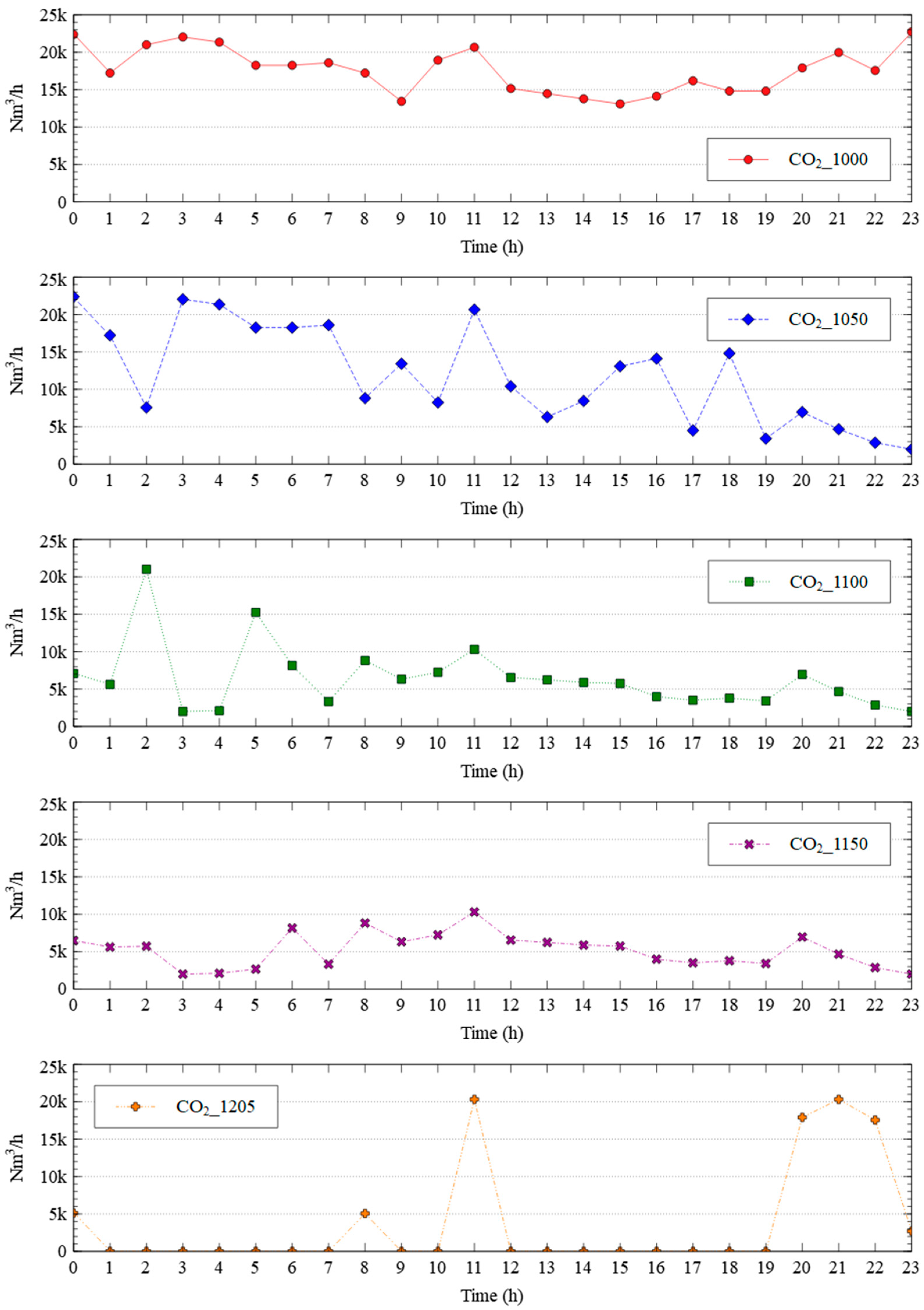

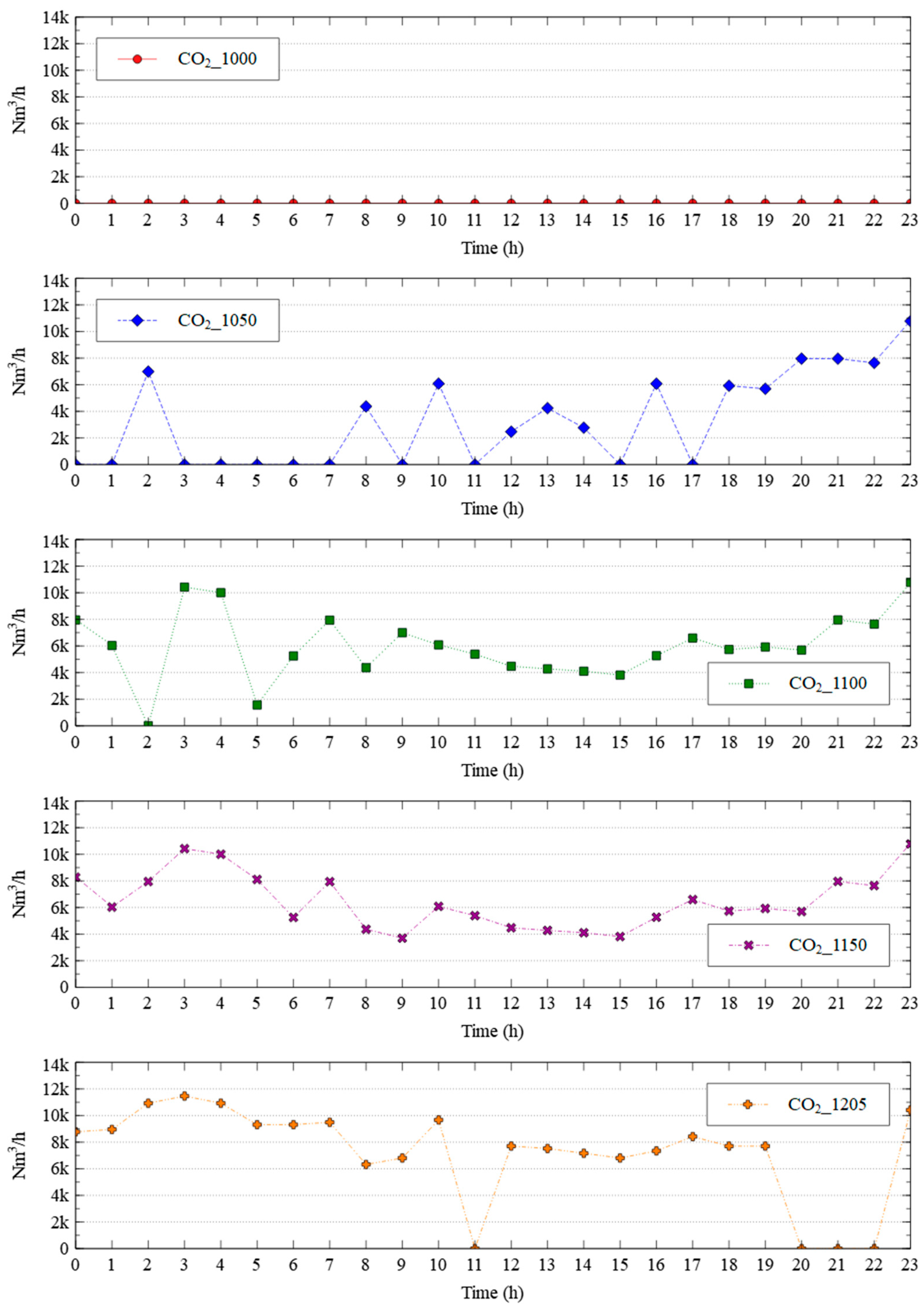

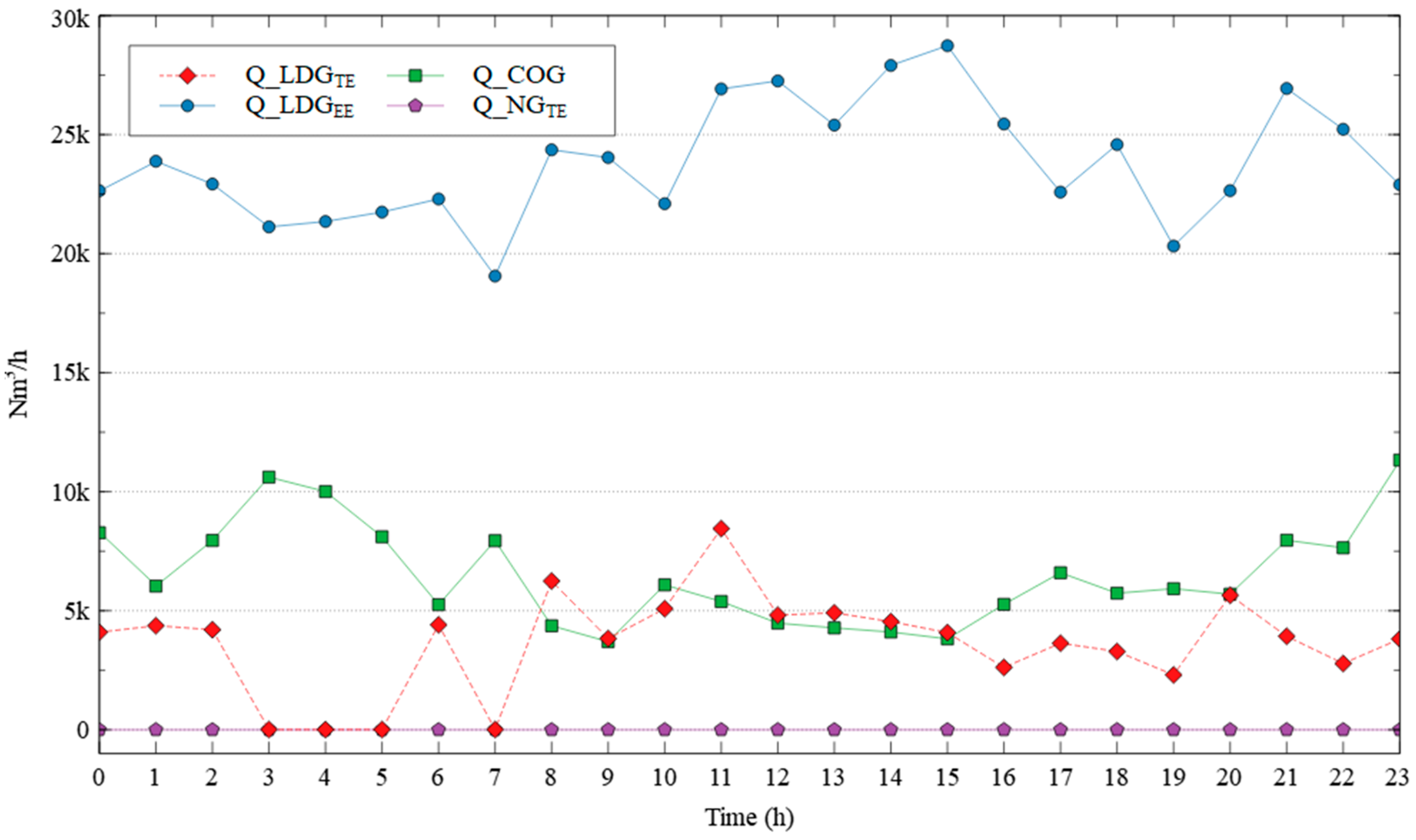

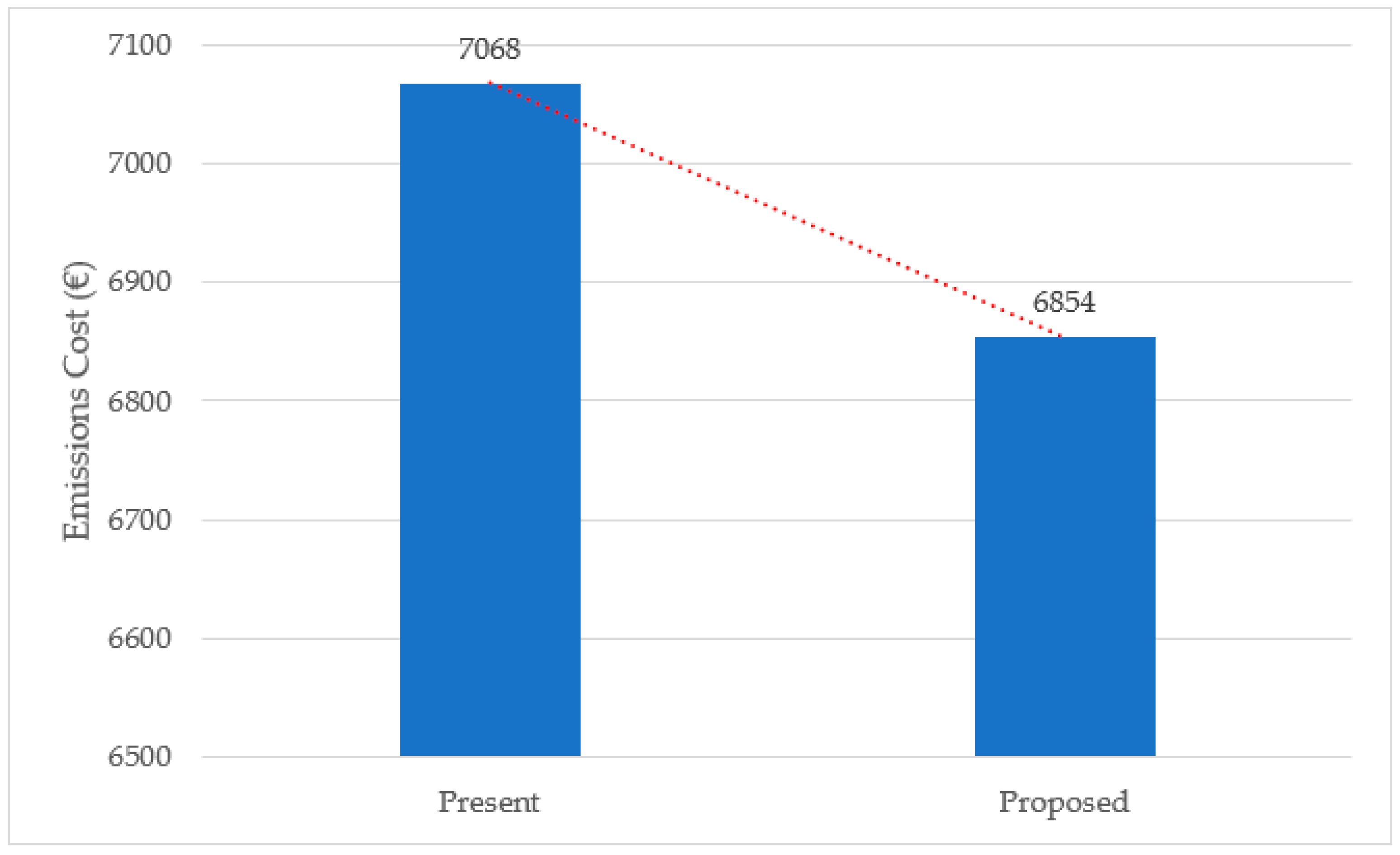

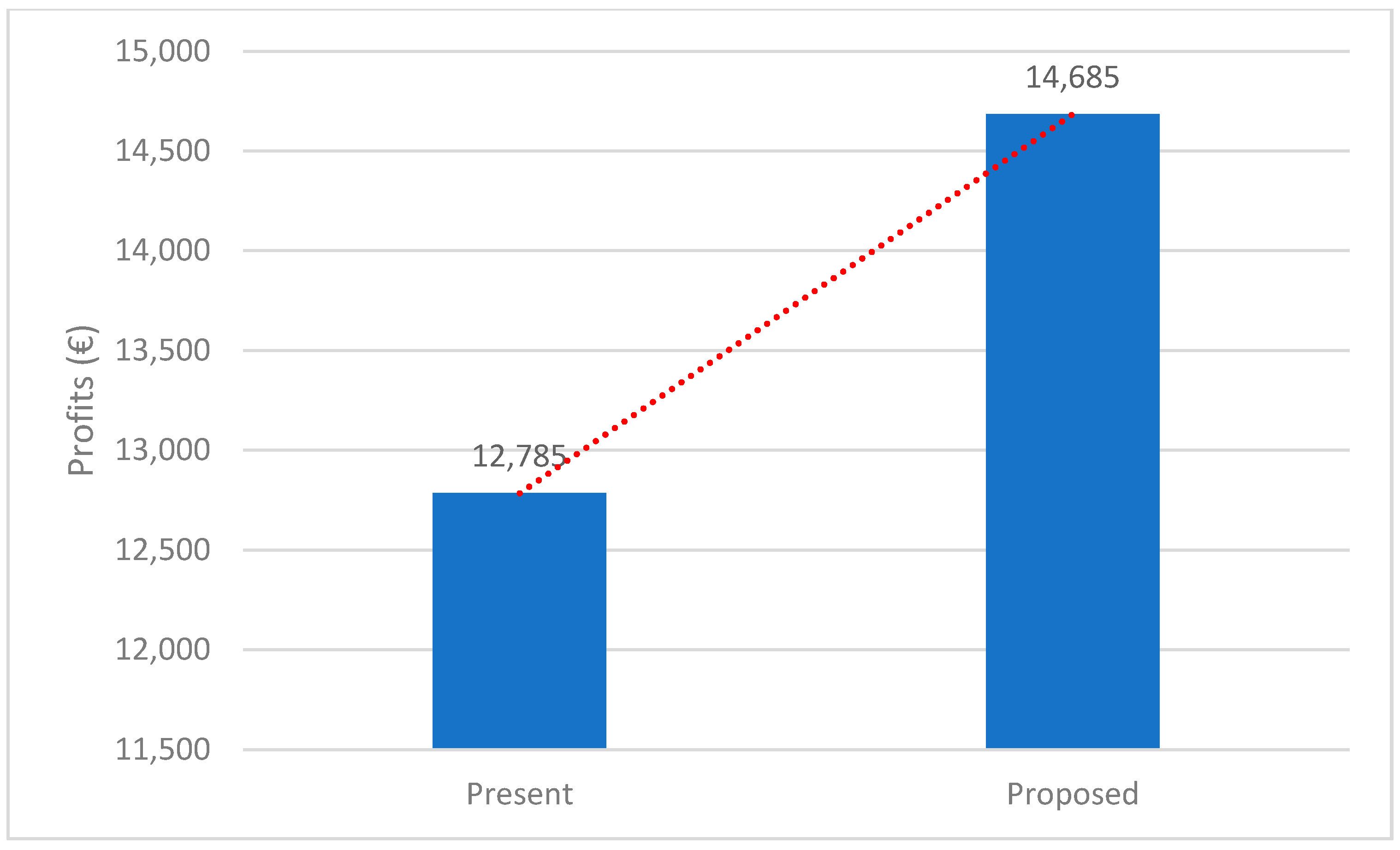

Sensitivity Analysis of the CO2 Price and CO2 Constraints

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CFUELS | Fuel costs (€) |

| CCO2 | Emissions CO2 costs (€) |

| DTE | Demanded thermic energy (t) |

| FLDG | LDG flow (Nm3/h) |

| HLDG | Heat value of LDG (kJ/Nm3) |

| HCOG | Heat value of COG (kJ/Nm3) |

| HNG | Heat value of NG (kJ/Nm3) |

| LLDG | Gasometer level (Nm3) |

| teti | Thermal energy boiler I at time t (t) |

| PPOOL | Electricity market price (€/MW) |

| PTE | Thermal energy price (€/t) |

| PLDG | LDG price (€/Nm3) |

| PCOG | GOG price (€/Nm3) |

| PNG | NG price (€/Nm3) |

| PCO2 | CO2 price (€/t) |

| PREE | Electric power production (MW) |

| PRTE | Thermal energy production (t) |

| QCOG | Allocated amount of COG (Nm3/h) |

| QLDG | Allocated amount of LDG (Nm3/h) |

| QNG | Allocated amount of NG (Nm3/h) |

| R | Revenue (€) |

| REE | Electric power revenue (€) |

| RTE | Thermal energy revenue (€) |

| stockLDG | Stocked LDG in the gasometer |

| μLDG | Emission factor LDG (t/Nm3) |

| μCOG | Emission factor COG (t/Nm3) |

| μNG | Emission factor NG (t/Nm3) |

| VLDG_MIN | Min. LDG gasometer threshold (Nm3) |

| VLDG_MAX | Max. LDG gasometer threshold (Nm3) |

| Subscript | |

| NG | Natural gas |

| LDG | Linz-Donawitz gas |

| COG | Coke oven gas |

| GEN | Generate |

| PLANT | Steel Cogeneration Plant |

| POOL | Daily electricity market |

| STEAM | Steam |

| EE | Electric energy |

| TE | Thermal energy |

References

- Ren, L.; Zhou, S.; Peng, T.; Ou, X. A Review of CO2 Emissions Reduction Technologies and Low-Carbon Development in the Iron and Steel Industry Focusing on China. Renew. Sustain. Energy Rev. 2021, 143, 110846. [Google Scholar] [CrossRef]

- De Ras, K.; Van de Vijver, R.; Galvita, V.V.; Marin, G.B.; Van Geem, K.M. Carbon Capture and Utilization in the Steel Industry: Challenges and Opportunities for Chemical Engineering. Curr. Opin. Chem. Eng. 2019, 26, 81–87. [Google Scholar] [CrossRef]

- Allwood, J.M.; Cullen, J.M.; Milford, R.L. Options for Achieving a 50% Cut in Industrial Carbon Emissions by 2050; ACS Publications: Washington, DC, USA, 2010; ISBN 0013-936X. [Google Scholar]

- World Steel Association World Steel in Figures. 2019. Available online: https://www.worldsteel.org/en/dam/jcr:96d7a585-e6b2-4d63-b943-4cd9ab621a91/World%2520Steel%2520in%2520Figures%25202019.pdf (accessed on 1 February 2021).

- Fu, J.; Tang, G.; Zhao, R.; Hwang, W. Carbon Reduction Programs and Key Technologies in Global Steel Industry. J. Iron Steel Res. Int. 2014, 21, 275–281. [Google Scholar] [CrossRef]

- European Commission. Ultra-Low CO2 Steelmaking.|ULCOS Project|FP6|CORDIS.|. Available online: https://cordis.europa.eu/project/id/515960 (accessed on 29 April 2021).

- SALCOS. Available online: https://salcos.salzgitter-ag.com/en/index.html (accessed on 29 April 2021).

- Course 50 Project|Challenge Zero. Available online: https://www.challenge-zero.jp/en/casestudy/549 (accessed on 29 April 2021).

- Rootzén, J.; Johnsson, F. Exploring the Limits for CO2 Emission Abatement in the EU Power and Industry Sectors—Awaiting a Breakthrough. Energy Policy 2013, 59, 443–458. [Google Scholar] [CrossRef]

- Otto, A.; Robinius, M.; Grube, T.; Schiebahn, S.; Praktiknjo, A.; Stolten, D. Power-to-Steel: Reducing CO2 through the Integration of Renewable Energy and Hydrogen into the German Steel Industry. Energies 2017, 10, 451. [Google Scholar] [CrossRef]

- Bhaskar, A.; Assadi, M.; Somehsaraei, H.N. Can Methane Pyrolysis Based Hydrogen Production Lead to the Decarbonisation of Iron and Steel Industry? Energy Convers. Manag. X 2021, 10, 100079. [Google Scholar] [CrossRef]

- Williams, R.; Jack, C.; Gamboa, D.; Shackley, S. Decarbonising Steel Production Using CO2 Capture and Storage (CCS): Results of Focus Group Discussions in a Welsh Steel-Making Community. Int. J. Greenh. Gas Control 2021, 104. [Google Scholar] [CrossRef]

- Nwachukwu, C.M.; Wang, C.; Wetterlund, E. Exploring the Role of Forest Biomass in Abating Fossil CO2 Emissions in the Iron and Steel Industry—The Case of Sweden. Appl. Energy 2021, 288, 116558. [Google Scholar] [CrossRef]

- Frey, A.; Goeke, V.; Voss, C. Steel Gases as Ancient and Modern Challenging Resource; Historical Review, Description of the Present, and a Daring Vision. Chem. Ing. Tech. 2018, 90, 1384–1391. [Google Scholar] [CrossRef]

- Zhao, J.; Sheng, C.; Wang, W.; Pedrycz, W.; Liu, Q. Data-Based Predictive Optimization for Byproduct Gas System in Steel Industry. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1761–1770. [Google Scholar] [CrossRef]

- Caillat, S. Burners in the Steel Industry: Utilization of by-Product Combustion Gases in Reheating Furnaces and Annealing Lines. Energy Procedia 2017, 120, 20–27. [Google Scholar] [CrossRef]

- Liu, J.; Chai, S.; Chang, Y. Economic Benefit between Autonomous Power and Purchasing Power from State Grid in Iron and Steel Enterprises. J. Northeast. Univ. Nat. Sci. 2015, 36, 980. [Google Scholar]

- Kong, H.; Qi, E.; Li, H.; Li, G.; Zhang, X. An MILP Model for Optimization of Byproduct Gases in the Integrated Iron and Steel Plant. Appl. Energy 2010, 87, 2156–2163. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, T.I.; Cai, J.; Tao, D.U.; Wang, A. Multi-Period Optimal Distribution Model of Energy Medium and Its Application. J. Iron Steel Res. Int. 2011, 18, 37–41. [Google Scholar] [CrossRef]

- Mavrotas, G. Generation of Efficient Solutions in Multiobjective Mathematical Programming Problems Using GAMS. Effective Implementation of the ε-Constraint Method; Lecturer, Laboratory of Industrial and Energy Economics, School of Chemical Engineering. National Technical University of Athens: Athens, Greece, 2007. [Google Scholar]

- García García, S.; Rodríguez Montequín, V.; Morán Palacios, H.; Mones Bayo, A. A Mixed Integer Linear Programming Model for the Optimization of Steel Waste Gases in Cogeneration: A Combined Coke Oven and Converter Gas Case Study. Energies 2020, 13, 3781. [Google Scholar] [CrossRef]

- Akimoto, K.; Sannomiya, N.; Nishikawa, Y.; Tsuda, T. An Optimal Gas Supply for a Power Plant Using a Mixed Integer Programming Model. Automatica 1991, 27, 513–518. [Google Scholar] [CrossRef]

- Wei, Z.; Zhai, X.; Zhang, Q.; Yang, G.; Du, T.; Wei, J. A MINLP Model for Multi-Period Optimization Considering Couple of Gas-Steam-Electricity and Time of Use Electricity Price in Steel Plant. Appl. Therm. Eng. 2020, 168, 114834. [Google Scholar] [CrossRef]

- Kim, J.H.; Yi, H.-S.; Han, C. A Novel MILP Model for Plantwide Multiperiod Optimization of Byproduct Gas Supply System in the Iron-and Steel-Making Process. Chem. Eng. Res. Des. 2003, 81, 1015–1025. [Google Scholar] [CrossRef]

- de Oliveira Junior, V.B.; Pena, J.G.C.; Salles, J.L.F. An Improved Plant-Wide Multiperiod Optimization Model of a Byproduct Gas Supply System in the Iron and Steel-Making Process. Appl. Energy 2016, 164, 462–474. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, W.; Qu, Q. Multi-Objective Optimization for Gas Distribution in Continuous Annealing Process. J. Adv. Comput. Intell. Intell. Inform. 2019, 23, 229–235. [Google Scholar] [CrossRef]

- Dettori, S.; Matino, I.; Colla, V.; Weber, V.; Salame, S. Neural Network-Based Modeling Methodologies for Energy Transformation Equipment in Integrated Steelworks Processes. Energy Procedia 2019, 158, 4061–4066. [Google Scholar] [CrossRef]

- Liang, Z.; Liang, X.; Yan, O.U. Energy Integrated Scheduling Based on Multi-Objective-Constrained Optimization Evolutionary Algorithm. Comput. Integr. Manuf. Syst. 2016, 22, 2668–2678. [Google Scholar]

- Maddaloni, A.; Porzio, G.F.; Nastasi, G.; Colla, V.; Branca, T.A. Multi-Objective Optimization Applied to Retrofit Analysis: A Case Study for the Iron and Steel Industry. Appl. Therm. Eng. 2015, 91, 638–646. [Google Scholar] [CrossRef]

- Porzio, G.F.; Colla, V.; Matarese, N.; Nastasi, G.; Branca, T.A.; Amato, A.; Fornai, B.; Vannucci, M.; Bergamasco, M. Process Integration in Energy and Carbon Intensive Industries: An Example of Exploitation of Optimization Techniques and Decision Support. Appl. Therm. Eng. 2014, 70, 1148–1155. [Google Scholar] [CrossRef]

- Porzio, G.F.; Nastasi, G.; Colla, V.; Vannucci, M.; Branca, T.A. Comparison of Multi-Objective Optimization Techniques Applied to off-Gas Management within an Integrated Steelwork. Appl. Energy 2014, 136, 1085–1097. [Google Scholar] [CrossRef]

- Zhang, Q.; Yao, T.; Cai, J.; Shen, F. On the Multi-Objective Optimal Model of Blast Furnace Iron-Making Process and Its Application. J. Northeastern. (Nature Sci.) Univ. Nat. Sci. 2011, 32, 270–273. [Google Scholar]

- Zhao, X.; Bai, H.; Lu, X.; Shi, Q.; Han, J. A MILP Model Concerning the Optimisation of Penalty Factors for the Short-Term Distribution of Byproduct Gases Produced in the Iron and Steel Making Process. Appl. Energy 2015, 148, 142–158. [Google Scholar] [CrossRef]

- Zhao, X.; Bai, H.; Shi, Q.; Lu, X.; Zhang, Z. Optimal Scheduling of a Byproduct Gas System in a Steel Plant Considering Time-of-Use Electricity Pricing. Appl. Energy 2017, 195, 100–113. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. Survey of Multi-Objective Optimization Methods for Engineering. Struct. Multidiscip. Optim. 2004, 26, 369–395. [Google Scholar] [CrossRef]

- Figueira, J.; Greco, S.; Ehrgott, M. Multiple Criteria Decision Analysis: State of the Art Surveys; Springer: New York, NY, USA, 2005; Volume 78, pp. 859–890. [Google Scholar]

- Haimes, Y.Y.; Wismer, D.A. Integrated System Modeling and Optimization via Quasilinearization. J. Optim. Theory Appl. 1971, 8, 100–109. [Google Scholar] [CrossRef]

- Ehrgott, M.; Ruzika, S. Improved ε-Constraint Method for Multiobjective Programming. J. Optim. Theory Appl. 2008, 138, 375. [Google Scholar] [CrossRef]

- Carvalho, M.; Lozano, M.A.; Serra, L.M. Multicriteria Synthesis of Trigeneration Systems Considering Economic and Environmental Aspects. Appl. Energy 2012, 91, 245–254. [Google Scholar] [CrossRef]

- García, S.G.; Montequín, V.R.; Fernández, R.L.; Fernández, F.O. Evaluation of the Synergies in Cogeneration with Steel Waste Gases Based on Life Cycle Assessment: A Combined Coke Oven and Steelmaking Gas Case Study. J. Clean. Prod. 2019, 217, 576–583. [Google Scholar] [CrossRef]

- IBM Corp. IBM ILOG CPLEX Optimization Studio. CPLEX Users Manual. Available online: https://www.ibm.com/docs/en/SSSA5P_12.7.1/ilog.odms.studio.help/pdf/usrcplex.pdf (accessed on 1 February 2021).

| Gas | Heating Values (MJ/m3) | Factor Emission (kg CO2/GJ) |

|---|---|---|

| COG | 16.9 | 42.32 |

| LDG | 8.8 | 185.47 |

| NG | 36.1 | 55.83 |

| Units | COG | LDG | NG | |

|---|---|---|---|---|

| Cost for gas purchasing | (€/m3) | 0.0288 | 0 | 0.2574 |

| Revenue for steam production | (€/t) | 3.6 | 3.6 | 2.4 |

| Penalty | Values (€) |

|---|---|

| Mg CO2 Emissions | 5.96 |

| Fuel | i | Equipment | j | Constraints | |

|---|---|---|---|---|---|

| Bij | mij | ||||

| COG | 1 | Boiler | 3 | 5000 | 1200 |

| Plant | 1 | 15,000 | 1200 | ||

| LDG | 2 | Boiler | 3 | 15,000 | 2000 |

| Engine | 12 | 2000 | 1100 | ||

| Plant | 1 | 45,000 | 2000 | ||

| NG | 3 | Boiler | 3 | 4000 | 400 |

| Plant | 1 | 12,000 | 400 | ||

| LDG GH | 4 | Gasometer | 1 | 61,000 | 10,000 |

| Profit [€] | CO2 Price (€/t) | ||||||

|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | ||

| CO2 Constraint (t) | 1000 | 7597 | 2599 | −2400 | −7401 | −12,400 | −17,398 |

| 1050 | 10,947 | 5697 | 447 | −4802 | −10,052 | −15,302 | |

| 1100 | 13,749 | 8249 | 2749 | −2750 | −8250 | −13,750 | |

| 1150 | 14,952 | 9202 | 3452 | −2297 | −7976 | −13,529 | |

| 1200 | 15,555 | 9595 | 3650 | −2280 | −7976 | −13,529 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, S.G.; Montequín, V.R.; Piloñeta, M.D.; Lougedo, S.T. Multi-Objective Optimization of Steel Off-Gas in Cogeneration Using the ε-Constraint Method: A Combined Coke Oven and Converter Gas Case Study. Energies 2021, 14, 2741. https://doi.org/10.3390/en14102741

García SG, Montequín VR, Piloñeta MD, Lougedo ST. Multi-Objective Optimization of Steel Off-Gas in Cogeneration Using the ε-Constraint Method: A Combined Coke Oven and Converter Gas Case Study. Energies. 2021; 14(10):2741. https://doi.org/10.3390/en14102741

Chicago/Turabian StyleGarcía, Sergio García, Vicente Rodríguez Montequín, Marina Díaz Piloñeta, and Susana Torno Lougedo. 2021. "Multi-Objective Optimization of Steel Off-Gas in Cogeneration Using the ε-Constraint Method: A Combined Coke Oven and Converter Gas Case Study" Energies 14, no. 10: 2741. https://doi.org/10.3390/en14102741

APA StyleGarcía, S. G., Montequín, V. R., Piloñeta, M. D., & Lougedo, S. T. (2021). Multi-Objective Optimization of Steel Off-Gas in Cogeneration Using the ε-Constraint Method: A Combined Coke Oven and Converter Gas Case Study. Energies, 14(10), 2741. https://doi.org/10.3390/en14102741