Effect of Heat Demand on Integration of Urban Large-Scale Renewable Schemes—Case of Helsinki City (60 °N)

Abstract

1. Introduction

2. Methods

2.1. Input Data for Helsinki

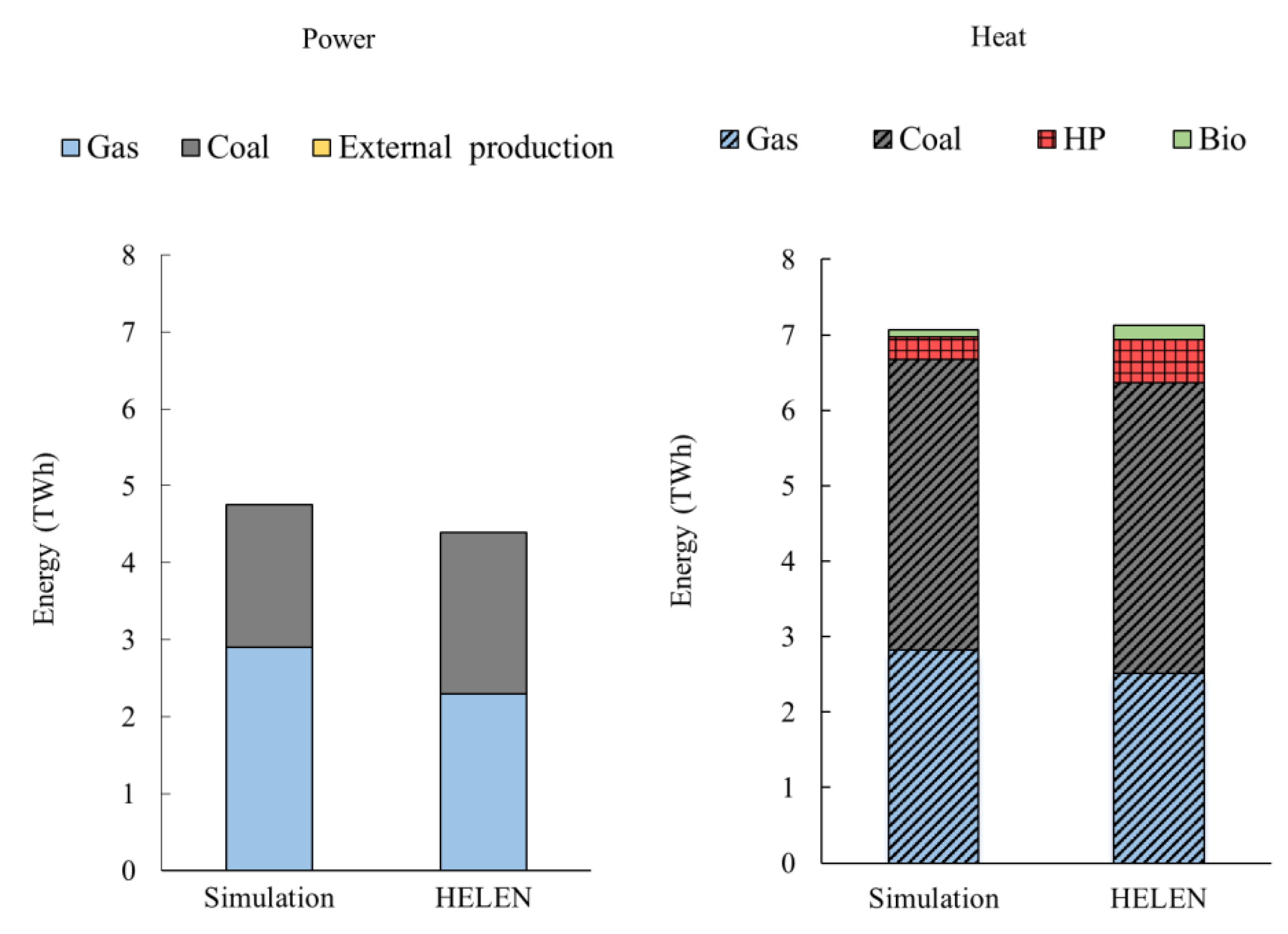

2.2. Energy System Modeling

2.3. Decarbonization Strategies

- Year 2018 heating demand (PRESENT): The annual heat demand is 6.8 TWh and the peak heat demand is 2360 MW.

- Year 2050 business-as-usual heating demand (BAU): The heat demand would follow a business-as-usual trend. The demand is affected by the rising ambient temperature and the increasing population. No major building energy efficiency measures are applied. The annual heat demand would then be 8.26 TWh (+21% from 2018 level) and the peak demand 2550 MW (+8% from 2018 level).

- Year 2050 heating demand with efficiency measures (EFF). In addition to the BAU, the demand is also affected by building energy efficiency measures according to EU policies (−1.5%/yr). The annual heat demand is 5.87 TWh (−12% from 2018 level) and the peak demand is 1932 MW (−21% from 2018 level).

- Utilizing the existing gas CHP with climate-neutral biogas or bio-SNG.

- Employing more intensively the Nordpool electricity market.

- Adding heat pumps for heating and biomass boilers (typically for peak demand).

- No gas: electricity is fully handled exogenously through the electricity market, heating is handled by the heat pumps and bio-boilers.

- Gas boilers: as in the “No gas” case, but existing gas boilers are used for heating.

- Gas CHP: as in the “No gas” case, but the existing gas CHP is used.

- Gas boilers and gas CHP: as in “No gas” case, but existing gas boilers and gas CHP are used.

3. Results and Discussion

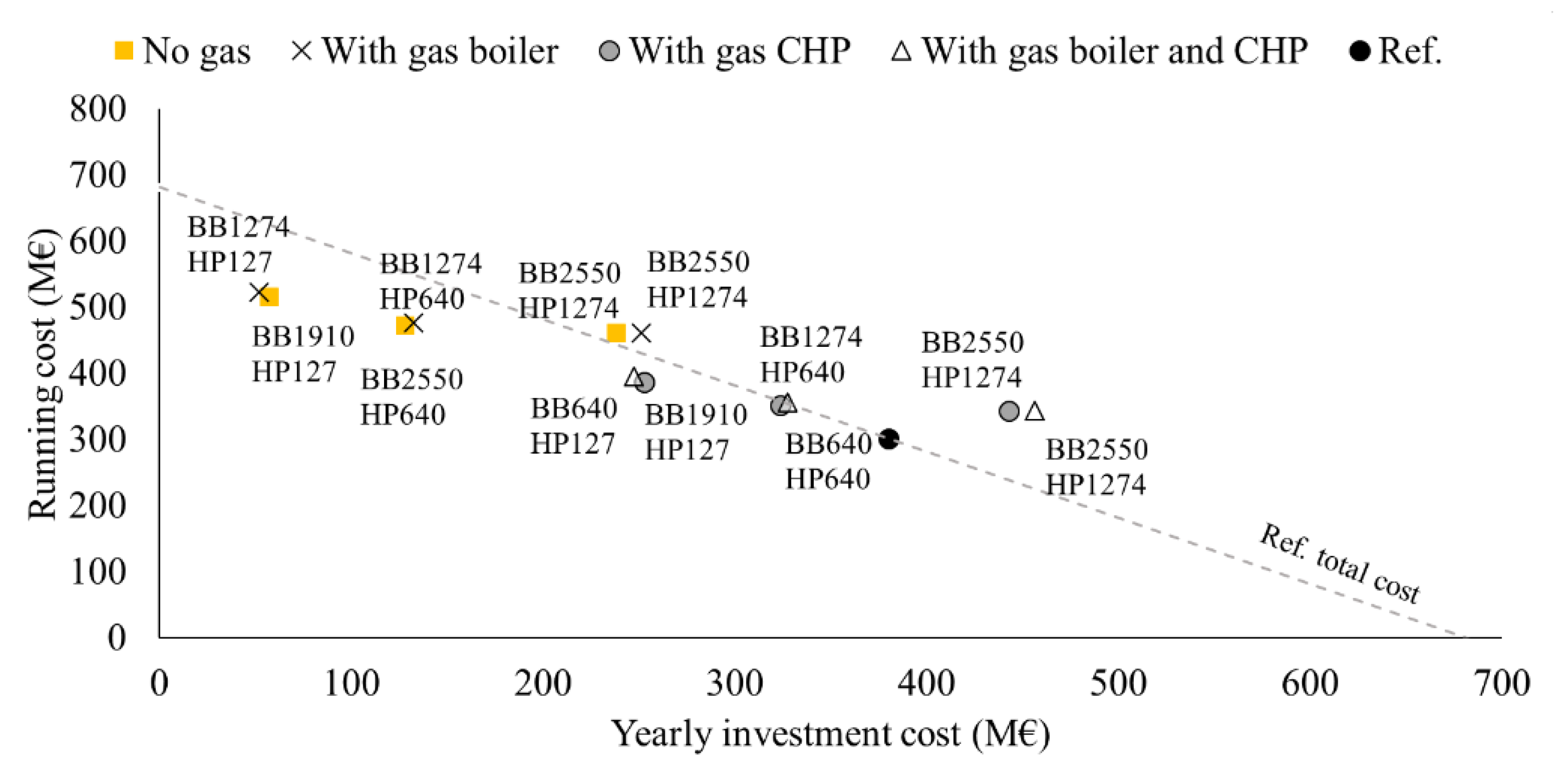

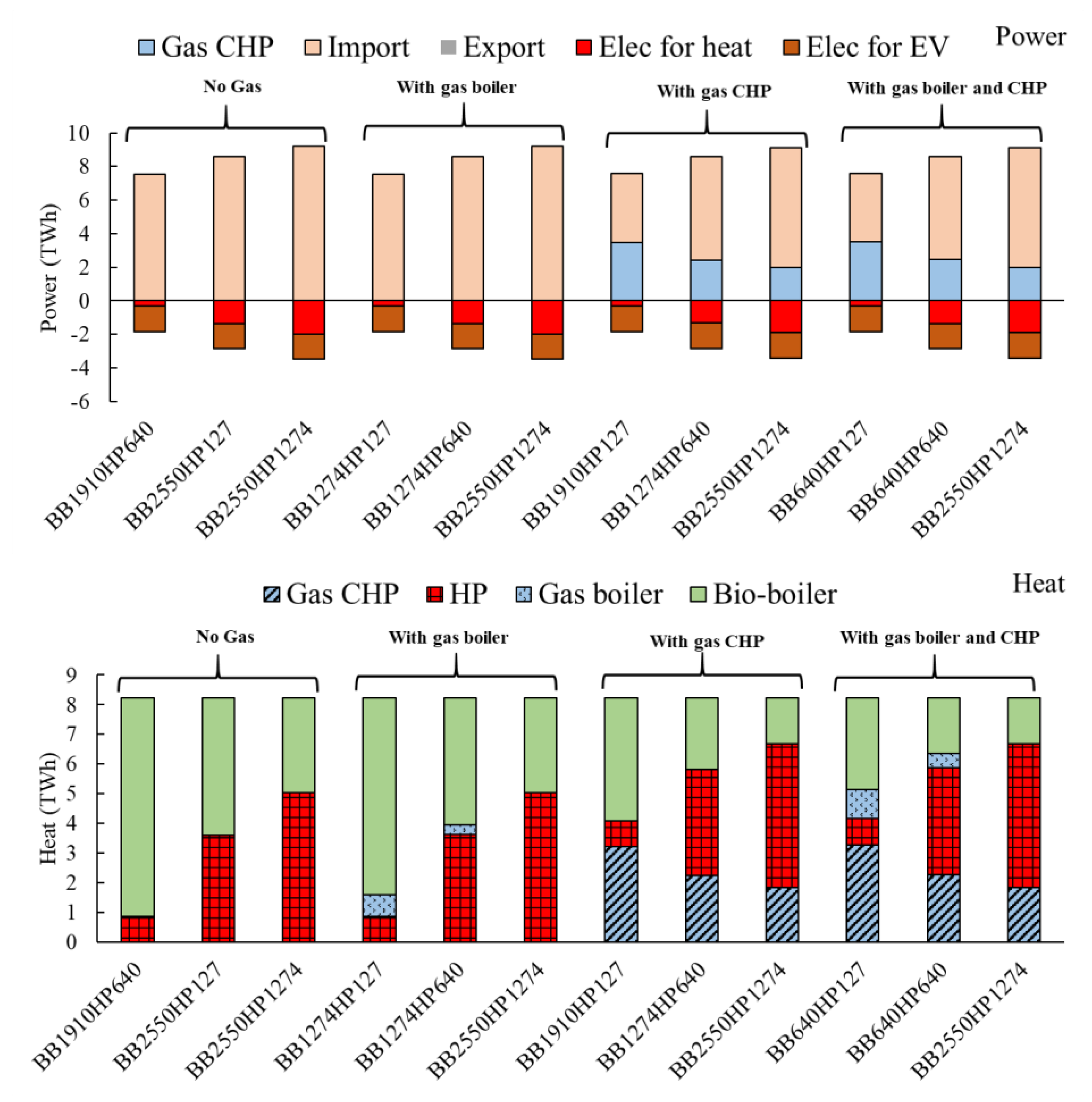

3.1. Existing Infrastructure Scenario (BIO-GAS)

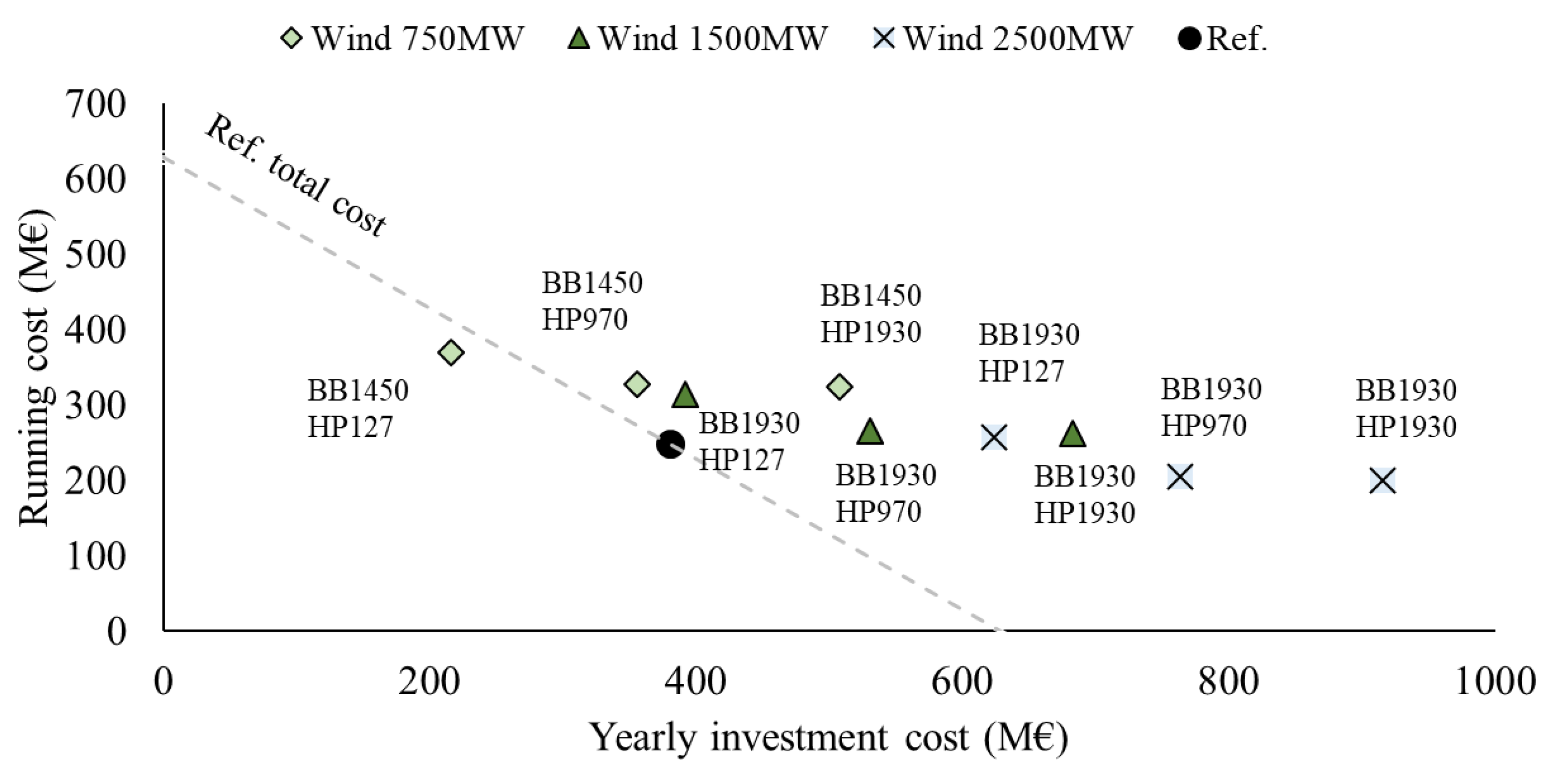

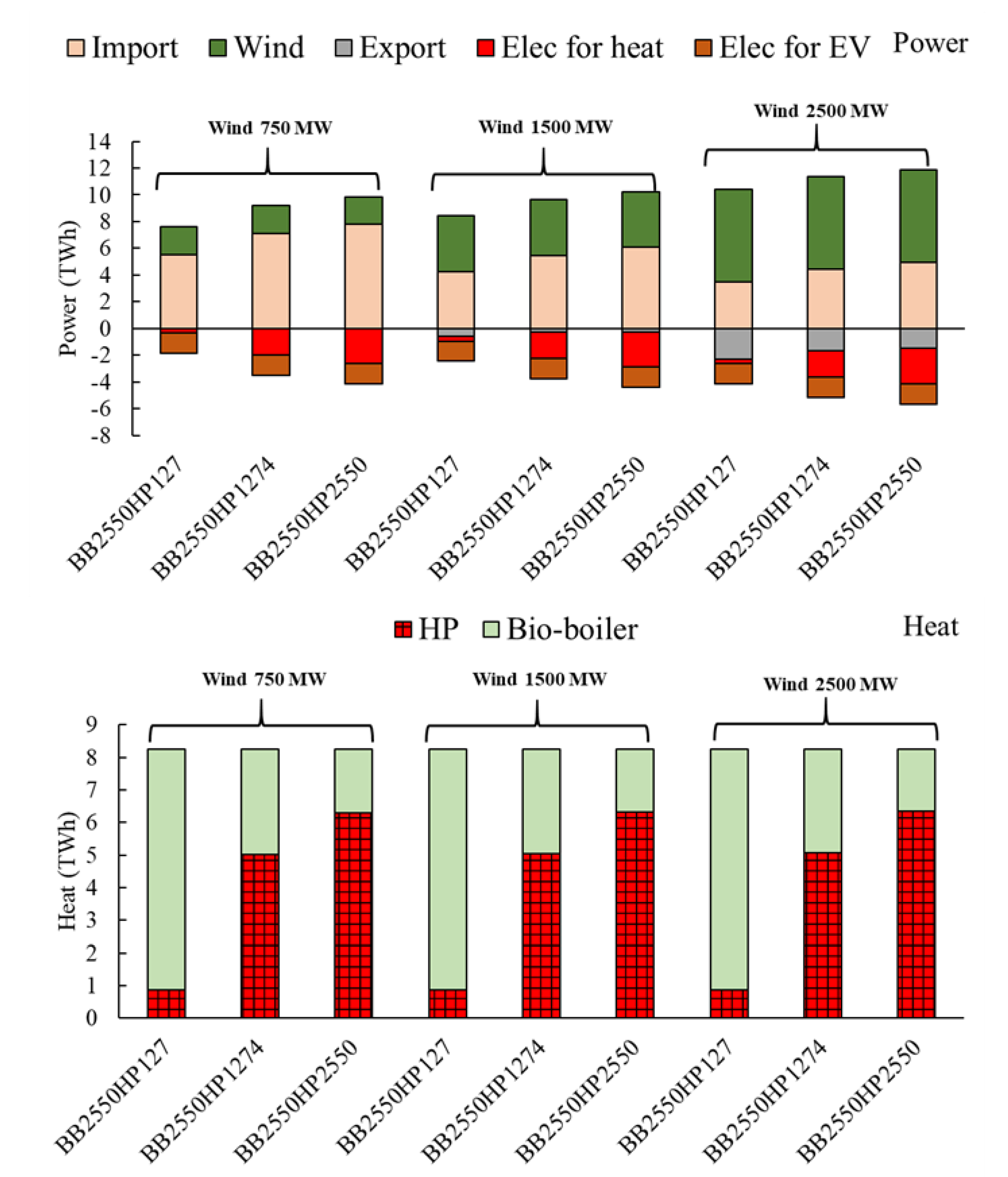

3.2. Wind Power and P2H Scenario (WIND)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Details on Helsinki Energy System and Input Parameter Values

| Fuel | Cost (€/GJ) 2018 | Cost (€/GJ) 2050 |

|---|---|---|

| Oil | 9.7 | 9.8 |

| Coal | 3.8 | 4.2 |

| Natural gas | 8.3 | 9.7 |

| Wood pellets | 5.6 | 7.7 |

| Technology | Cost (€/MWh) 2018 | Cost (€/MWh) 2050 |

|---|---|---|

| Oil boiler | 1.1 | 1.32 |

| Coal boiler | 1.1 | 1.32 |

| Gas boiler | 1.1 | 1.32 |

| Bio-boiler | 1.1 | 1.32 |

| Coal CHP | 4.5 | 5.40 |

| Gas CHP | 4.5 | 5.40 |

| Fuel | Emissions (tCO2/TJ) |

|---|---|

| Oil | 79 |

| Coal | 93 |

| Gas | 55 |

References

- International Renewable Energy Agency. Demand-Side Flexibility for Power Sector Transformation; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; ISBN 9789292601591. [Google Scholar]

- Cao, K.K.; Nitto, A.N.; Sperber, E.; Thess, A. Expanding the horizons of power-to-heat: Cost assessment for new space heating concepts with wind powered thermal energy systems. Energy 2018, 164, 925–936. [Google Scholar] [CrossRef]

- Kirkerud, J.G.; Bolkesjø, T.F.; Trømborg, E. Power-to-heat as a flexibility measure for integration of renewable energy. Energy 2017, 128, 776–784. [Google Scholar] [CrossRef]

- Hedegaard, K.; Mathiesen, B.V.; Lund, H.; Heiselberg, P. Wind power integration using individual heat pumps—Analysis of different heat storage options. Energy 2012, 47, 284–293. [Google Scholar] [CrossRef]

- Askeland, K.; Bozhkova, K.N.; Sorknæs, P. Balancing Europe: Can district heating affect the flexibility potential of Norwegian hydropower resources? Renew. Energy 2019, 141, 646–656. [Google Scholar] [CrossRef]

- Helin, K.; Syri, S.; Zakeri, B. Improving district heat sustainability and competitiveness with heat pumps in the future Nordic energy system. Energy Procedia 2018, 149, 455–464. [Google Scholar] [CrossRef]

- Ikäheimo, J. Power-to-gas plants in a future Nordic district heating system. Energy Procedia 2017, 135, 172–182. [Google Scholar] [CrossRef]

- Sandberg, E.; Sneum, D.M.; Trømborg, E. Framework conditions for Nordic district heating—Similarities and differences, and why Norway sticks out. Energy 2018, 149, 105–119. [Google Scholar] [CrossRef]

- Sovacool, B.K. Contestation, contingency, and justice in the Nordic low-carbon energy transition. Energy Policy 2017, 102, 569–582. [Google Scholar] [CrossRef]

- Helen Helen Annual Report 2018. Available online: https://www.helen.fi/en/annual-report/annual-report-2018 (accessed on 17 April 2020).

- District Heating Statistics. Available online: https://energia.fi/en/news_and_publications/publications/district_heating_statistics.html (accessed on 10 December 2019).

- The Carbon-Neutral Helsinki 2035 Action Plan; City of Helsinki: Helsinki, Finland, 2019; ISBN 9789523314856.

- Arabzadeh, V.; Mikkola, J.; Jasiūnas, J.; Lund, P.D. Deep decarbonization of urban energy systems through renewable energy and sector-coupling flexibility strategies. J. Environ. Manag. 2020, 260, 110090. [Google Scholar] [CrossRef]

- Pilpola, S.; Arabzadeh, V.; Lund, P.D. Energy system impact of wind power with curtailment: National- and city-scale analysis. Int. J. Low Carbon Technol. 2019, 14, 277–285. [Google Scholar] [CrossRef]

- Pilpola, S.; Arabzadeh, V.; Mikkola, J.; Lund, P.D. Analyzing national and local pathways to carbon-neutrality from technology, emissions, and resilience perspectives—Case of Finland. Energies 2019, 12, 949. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Pilpola, S.; Lund, P.D. Coupling variable renewable electricity production to the heating sector through curtailment and power-to- heat Strategies for Accelerated Emission Reduction. Futur. Cities Environ. 2019, 5, 1–10. [Google Scholar] [CrossRef]

- Arnaudo, M.; Topel, M.; Puerto, P.; Widl, E.; Laumert, B. Heat demand peak shaving in urban integrated energy systems by demand side management—A techno-economic and environmental approach. Energy 2019. [Google Scholar] [CrossRef]

- Zhou, C.; Zheng, J.; Liu, S.; Liu, Y.; Mei, F.; Pan, Y.; Shi, T.; Wu, J. Operation optimization of multi-district integrated energy system considering flexible demand response of electric and thermal loads. Energies 2019, 12, 3831. [Google Scholar] [CrossRef]

- Finck, C.; Li, R.; Kramer, R.; Zeiler, W. Quantifying demand flexibility of power-to-heat and thermal energy storage in the control of building heating systems. Appl. Energy 2018, 209, 409–425. [Google Scholar] [CrossRef]

- Lundström, L.; Wallin, F. Heat demand profiles of energy conservation measures in buildings and their impact on a district heating system. Appl. Energy 2016, 161, 290–299. [Google Scholar] [CrossRef]

- Pedersen, L.; Stang, J.; Ulseth, R. Load prediction method for heat and electricity demand in buildings for the purpose of planning for mixed energy distribution systems. Energy Build. 2008, 40, 1124–1134. [Google Scholar] [CrossRef]

- Ma, Z.; Li, H.; Sun, Q.; Wang, C.; Yan, A.; Starfelt, F. Statistical analysis of energy consumption patterns on the heat demand of buildings in district heating systems. Energy Build. 2014. [Google Scholar] [CrossRef]

- Li, Z.; Friedrich, D.; Harrison, G.P. Demand forecasting for a mixed-use building using agent-schedule information with a data-driven model. Energies 2020, 13, 780. [Google Scholar] [CrossRef]

- Michalski, J.; Poltrum, M.; Bünger, U. The role of renewable fuel supply in the transport sector in a future decarbonized energy system. Int. J. Hydrog. Energy 2019, 44, 12554–12565. [Google Scholar] [CrossRef]

- Grübler, A.; Nakićenović, N. Decarbonizing the global energy system. Technol. Forecast. Soc. Chang. 1996, 53, 97–110. [Google Scholar] [CrossRef]

- Morvaj, B.; Evins, R.; Carmeliet, J. Decarbonizing the electricity grid: The impact on urban energy systems, distribution grids and district heating potential. Appl. Energy 2017, 191, 125–140. [Google Scholar] [CrossRef]

- Rinne, S.; Syri, S. The possibilities of combined heat and power production balancing large amounts of wind power in Finland. Energy 2015, 82, 1034–1046. [Google Scholar] [CrossRef]

- Pilpola, S.; Lund, P.D. Different flexibility options for better system integration of wind power. Energy Strateg. Rev. 2019, 26, 100368. [Google Scholar] [CrossRef]

- Hellström, J.; Lundgren, J.; Yu, H. Why do electricity prices jump? Empirical evidence from the Nordic electricity market. Energy Econ. 2012, 34, 1774–1781. [Google Scholar] [CrossRef]

- Amundsen, E.S.; Bergman, L. Why has the Nordic electricity market worked so well? Util. Policy 2006, 14, 148–157. [Google Scholar] [CrossRef]

- Paiho, S.; Saastamoinen, H.; Hakkarainen, E.; Similä, L.; Pasonen, R.; Ikäheimo, J.; Rämä, M.; Tuovinen, M.; Horsmanheimo, S. Increasing flexibility of Finnish energy systems—A review of potential technologies and means. Sustain. Cities Soc. 2018, 43, 509–523. [Google Scholar] [CrossRef]

- Pilpola, S.; Lund, P.D. Effect of major policy disruptions in energy system transition: Case Finland. Energy Policy 2018, 116, 323–336. [Google Scholar] [CrossRef]

- Fang, T.; Lahdelma, R. State estimation of district heating network based on customer measurements. Appl. Therm. Eng. 2014, 73, 1211–1221. [Google Scholar] [CrossRef]

- Fang, T.; Lahdelma, R. Genetic optimization of multi-plant heat production in district heating networks. Appl. Energy 2015, 159, 610–619. [Google Scholar] [CrossRef]

- Fang, T.; Lahdelma, R. Evaluation of a multiple linear regression model and SARIMA model in forecasting heat demand for district heating system. Appl. Energy 2016, 179, 544–552. [Google Scholar] [CrossRef]

- Sandberg, A.; Wallin, F.; Li, H.; Azaza, M. An analyze of long-term hourly district heat demand forecasting of a commercial building using neural networks. Energy Procedia 2017, 105, 3784–3790. [Google Scholar] [CrossRef]

- Kwak, Y.; Seo, D.; Jang, C.; Huh, J.H. Feasibility study on a novel methodology for short-term real-time energy demand prediction using weather forecasting data. Energy Build. 2013, 57, 250–260. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Alimohammadisagvand, B.; Jokisalo, J.; Siren, K. A novel cost-optimizing demand response control for a heat pump heated residential building. Build. Simul. 2018, 11, 533–547. [Google Scholar] [CrossRef]

- Xue, G.; Pan, Y.; Lin, T.; Song, J.; Qi, C.; Wang, Z. Forecasting stock prices with a feature fusion LSTM-CNN model using different representations of the same data. PLoS ONE 2019, 14, e212320. [Google Scholar] [CrossRef]

- An, J.; Yan, D.; Hong, T.; Sun, K. A novel stochastic modeling method to simulate cooling loads in residential districts. Appl. Energy 2017, 206, 134–149. [Google Scholar] [CrossRef]

- Nigitz, T.; Gölles, M. A generally applicable, simple and adaptive forecasting method for the short-term heat load of consumers. Appl. Energy 2019, 241, 73–81. [Google Scholar] [CrossRef]

- Johansson, C.; Bergkvist, M.; Geysen, D.; De Somer, O.; Lavesson, N.; Vanhoudt, D. Operational demand forecasting in district heating systems using ensembles of online machine learning algorithms. Energy Procedia 2017, 116, 208–216. [Google Scholar] [CrossRef]

- Yong, S.G.; Kim, J.H.; Gim, Y.; Kim, J.; Cho, J.; Hong, H.; Baik, Y.J.; Koo, J. Impacts of building envelope design factors upon energy loads and their optimization in US standard climate zones using experimental design. Energy Build. 2017, 141, 1–15. [Google Scholar] [CrossRef]

- Geysen, D.; De Somer, O.; Johansson, C.; Brage, J.; Vanhoudt, D. Operational thermal load forecasting in district heating networks using machine learning and expert advice. Energy Build. 2018, 162, 144–153. [Google Scholar] [CrossRef]

- Danov, S.; Carbonell, J.; Cipriano, J.; Martí-Herrero, J. Approaches to evaluate building energy performance from daily consumption data considering dynamic and solar gain effects. Energy Build. 2013, 57, 110–118. [Google Scholar] [CrossRef]

- Sjögren, J.U.; Andersson, S.; Olofsson, T. Sensitivity of the total heat loss coefficient determined by the energy signature approach to different time periods and gained energy. Energy Build. 2009, 41, 801–808. [Google Scholar] [CrossRef]

- Dotzauer, E. Simple model for prediction of loads in district—Heating systems. Appl. Energy 2002, 37, 277–284. [Google Scholar] [CrossRef]

- Calikus, E.; Nowaczyk, S.; Sant’Anna, A.; Gadd, H.; Werner, S. A data-driven approach for discovering heat load patterns in district heating. Appl. Energy 2019, 252, 113–409. [Google Scholar] [CrossRef]

- Helen Co Report 2018. Available online: https://www.helen.fi/en/annual-report/annual-report-2018/year-2018/business-year (accessed on 5 December 2019).

- Finnish Energy District Heating in Finland 2018; Energiateollisuus: Helsinki, Finland, 2019.

- Helsinki. Available online: https://www.hel.fi/helsinki/en/housing/construction/construction-urban/efficiency/renewable/ (accessed on 14 January 2019).

- Mikkola, J.; Lund, P.D. Modeling flexibility and optimal use of existing power plants with large-scale variable renewable power schemes. Energy 2016, 112, 364–375. [Google Scholar] [CrossRef]

- Bolwig, S.; Bazbauers, G.; Klitkou, A.; Lund, P.D.; Blumberga, A.; Blumberga, D.; Gravelsins, A.; Blumberga, D. Review of modelling energy transitions pathways with application to energy system flexibility. Renew. Sustain. Energy Rev. 2019, 101, 1–23. [Google Scholar] [CrossRef]

- Xing, L.; Xue, M.; Hu, M. Dynamic simulation and assessment of the coupling coordination degree of the economy–resource–environment system: Case of Wuhan City in China. J. Environ. Manag. 2019, 230, 474–487. [Google Scholar] [CrossRef]

- Statistic Finland. Available online: https://www.stat.fi/index_en.html (accessed on 10 January 2019).

| Year | Energy Sector | Gas CHP | Coal CHP 1 | Coal CHP 2 | Gas Boiler | Oil Boiler | Coal Boiler | Bio- Boiler | Heat Pump | Storage MWh |

|---|---|---|---|---|---|---|---|---|---|---|

| (2018) | Power | 630 | 218 | 160 | --- | --- | --- | --- | --- | --- |

| Heat | 587 | 429 | 300 | 912 | 1010 | 190 | 92 | 127 | 5000 |

| System Variable | Energy Sector | Gas CHP | Gas Boiler | Bio- Boiler | Heat Pump |

|---|---|---|---|---|---|

| Alternatives for profile EFF (MW) | Power | 0; 630 | --- | --- | --- |

| Heat | 0; 587 | 0; 912 | 92; 480; 970; 1450; 1932 | 127; 483; 966 | |

| Alternatives for profile BAU (MW) | Power | 0; 630 | --- | --- | --- |

| Heat | 0; 587 | 0; 912 | 92; 640; 1274; 1910; 2550 | 92; 640; 1275 |

| System Variable | Energy Sector | Bio- Boiler | Heat Pump | Wind |

|---|---|---|---|---|

| Alternatives for profile EFF (MW) | Power | --- | --- | 750; 1500; 2500 |

| Heat | 92; 480; 970; 1450; 1932 | 127; 480; 970; 1450; 1932 | ||

| Alternatives for profile BAU (MW) | Power | --- | --- | 750; 1500; 2500 |

| Heat | 92; 640; 1275; 1910; 2550 | 127; 640; 1274; 1910; 2550 |

| Case No. | Gas Technology /Wind Power | System Composition Profile EFF * | Annual Total Cost for EFF (M€) | System Composition Profile BAU * | Annual Total Cost for BAU (M€) | Difference of Solutions (EFF-BAU %) |

|---|---|---|---|---|---|---|

| 1 | No gas | BB1450HP127 | 481 | BB2550HP127 | 574 | 19 |

| 2 | No gas | BB1450HP480 | 503 | BB1910HP640 | 601 | 20 |

| 3 | No gas | BB1932HP970 | 577 | BB2550HP1274 | 699 | 21 |

| 4 | With gas boiler | BB480HP127 | 494 | BB1274HP127 | 575 | 16 |

| 5 | With gas boiler | BB480HP480 | 509 | BB1274HP640 | 609 | 19 |

| 6 | With gas boiler | BB1932HP970 | 591 | BB2550HP1274 | 713 | 21 |

| 7 | With gas CHP | BB970HP127 | 551 | BB1274HP640 | 640 | 16 |

| 8 | With gas CHP | BB970HP480 | 581 | BB1910HP127 | 676 | 16 |

| 9 | With gas CHP | BB1932HP970 | 664 | BB2550HP1274 | 786 | 18 |

| 10 | With gas boiler and CHP | BB92HP127 | 562 | BB640HP127 | 643 | 14 |

| 11 | With gas boiler and CHP | BB92HP480 | 586 | BB640HP640 | 684 | 17 |

| 12 | With gas boiler and CHP | BB1932HP970 | 677 | BB2550HP1274 | 799 | 18 |

| 13 | 750MW | BB1450HP127 | 586 | BB2550HP127 | 679 | 16 |

| 14 | 750MW | BB1450HP970 | 682 | BB2550HP1274 | 804 | 18 |

| 15 | 750MW | BB1450HP1930 | 831 | BB2550HP2550 | 998 | 20 |

| 16 | 1500MW | BB1450HP127 | 706 | BB2550HP127 | 799 | 13 |

| 17 | 1500MW | BB1930HP970 | 796 | BB2550HP1274 | 918 | 15 |

| 18 | 1500MW | BB1930HP1930 | 944 | BB2550HP2550 | 1111 | 18 |

| 19 | 2500MW | BB1930HP127 | 882 | BB2550HP127 | 975 | 11 |

| 20 | 2500MW | BB1930HP970 | 968 | BB2550HP1274 | 1088 | 12 |

| 21 | 2500MW | BB1930HP1930 | 1115 | BB2550HP2550 | 1182 | 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arabzadeh, V.; Lund, P.D. Effect of Heat Demand on Integration of Urban Large-Scale Renewable Schemes—Case of Helsinki City (60 °N). Energies 2020, 13, 2164. https://doi.org/10.3390/en13092164

Arabzadeh V, Lund PD. Effect of Heat Demand on Integration of Urban Large-Scale Renewable Schemes—Case of Helsinki City (60 °N). Energies. 2020; 13(9):2164. https://doi.org/10.3390/en13092164

Chicago/Turabian StyleArabzadeh, Vahid, and Peter D. Lund. 2020. "Effect of Heat Demand on Integration of Urban Large-Scale Renewable Schemes—Case of Helsinki City (60 °N)" Energies 13, no. 9: 2164. https://doi.org/10.3390/en13092164

APA StyleArabzadeh, V., & Lund, P. D. (2020). Effect of Heat Demand on Integration of Urban Large-Scale Renewable Schemes—Case of Helsinki City (60 °N). Energies, 13(9), 2164. https://doi.org/10.3390/en13092164