Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems

Abstract

1. Introduction

1.1. Motivation

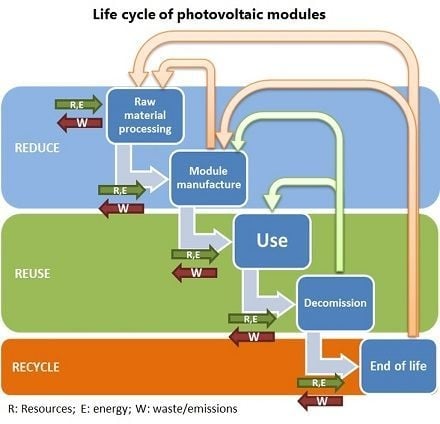

1.2. LCA of Waste Management for PV Systems

2. Materials and Methods

2.1. Product Systems Description

- Life expectancyModules: 30 years (for any type)Inverters: 15 yearsMounting structure: 30 years (for any type of module)Cabling: 30 yearsManufacturing plant: 30 years (for any type of module)Recycling plant: 30 years (for any type of module)

- Performance Ratio: Standard value of 0.75

- Degradation rate: Standard linear degradation rate of 0.7% per year

- Conversion efficiency from primary energy to electricity: ηG = 30%

- Irradiation: Conditions in Germany: 1.055 kWh/m2 [23]

2.2. Characterization of Modules and Input Waste

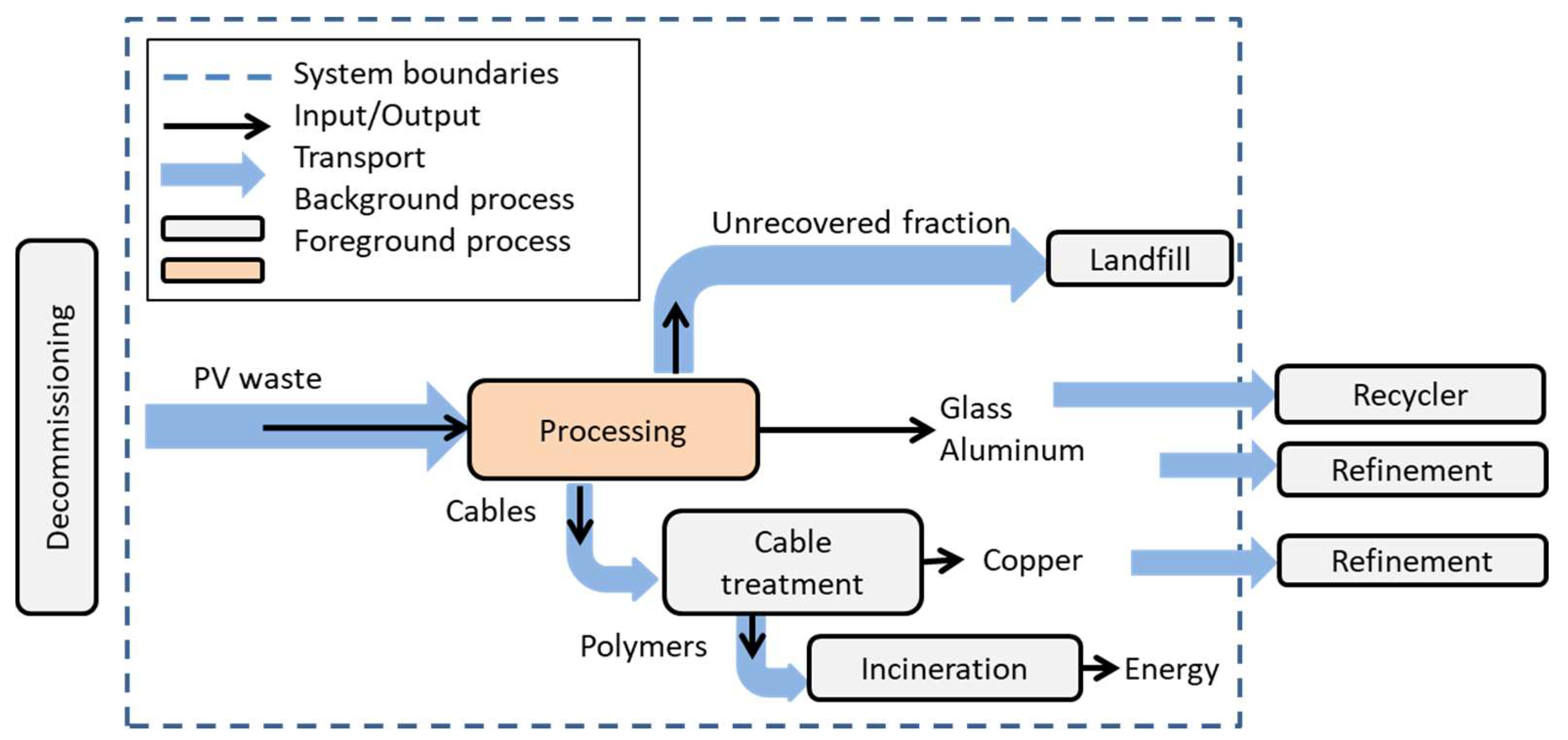

2.3. Description of the EoL Approaches

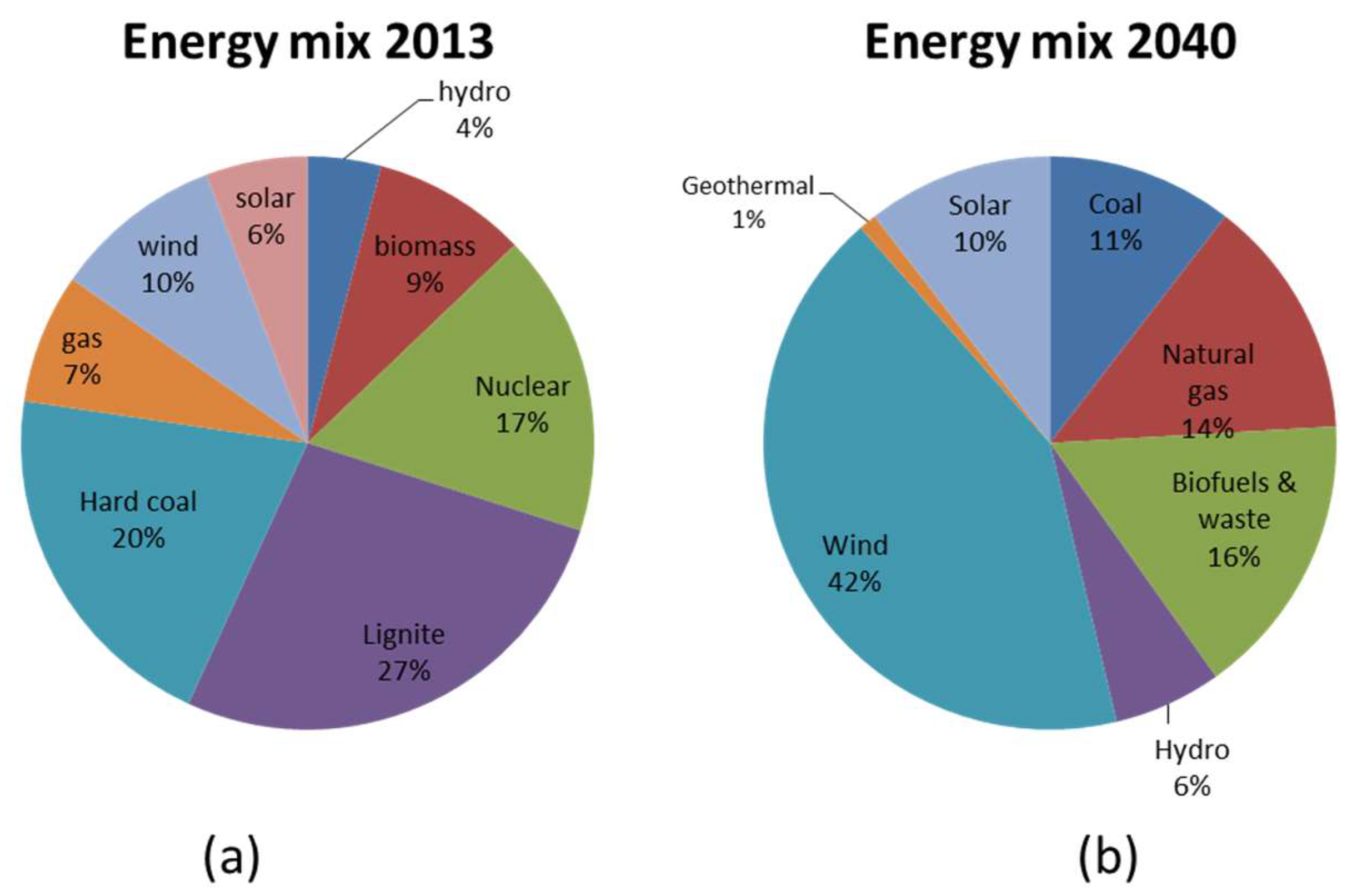

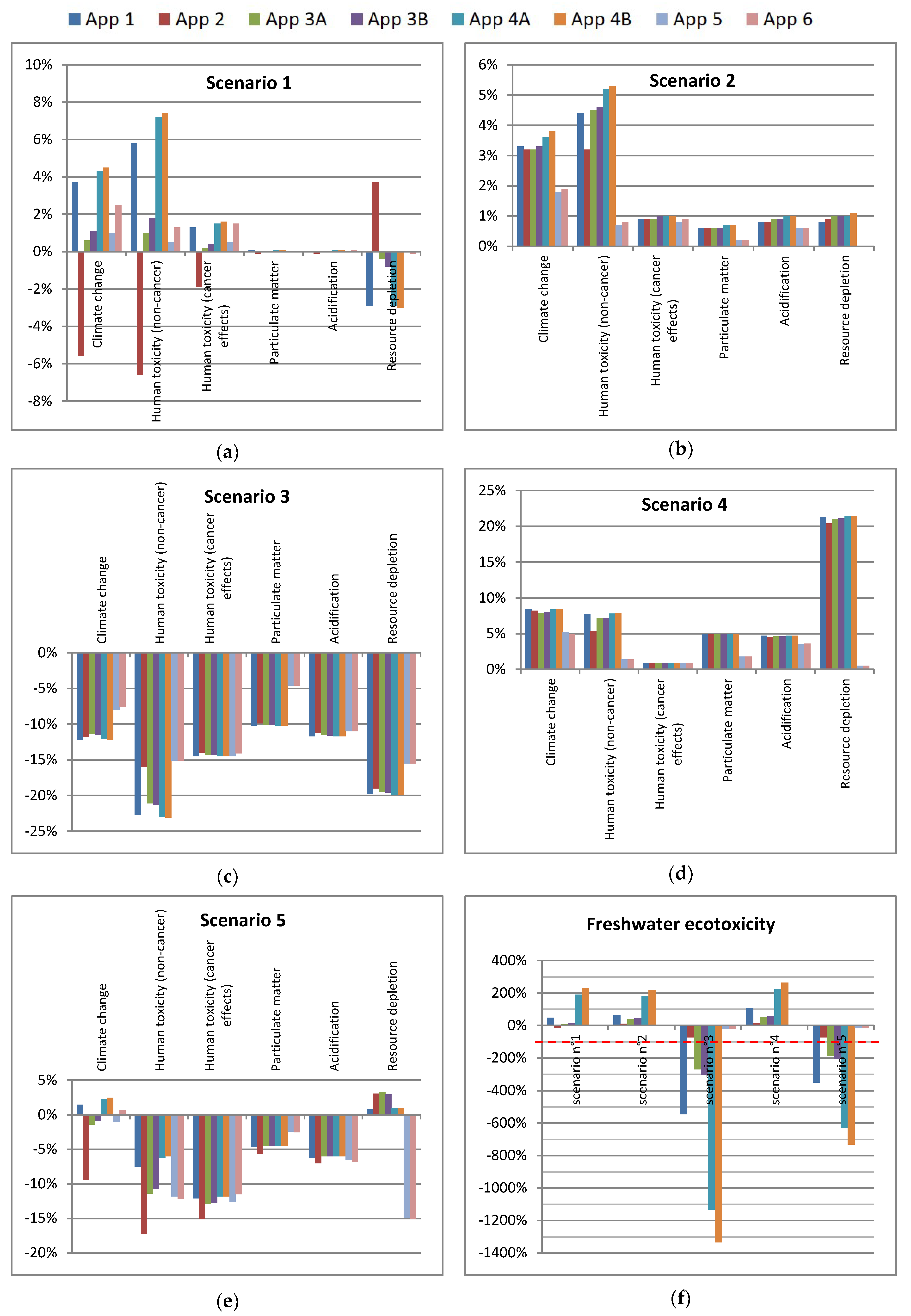

2.4. Sensitivity Analysis

- Scenario n°2: Changing recycling efficiency due to enhanced processes or bigger flows of material. An energy demand of 60% of the value in the baseline scenario is assumed.

- Scenario n°3: Changing primary material content due to increased recycled fraction. Usually, environmental credits are given for the primary material content existing in the market at the moment the recycling is performed. However, since recycling is assumed to take place after 30 years of installment of the modules, its environmental performance would be better described if the calculations contained estimates of the primary material content in 2040. For the baseline scenario, these values are 48%, 56% and 77%, while for 2040, these are assumed to be 41%, 48% and 65% for aluminum, copper and silver respectively [26,27].

- Scenario n°4: Reduced transportation due to an efficient collection network. It will be assumed that the waste management network is optimized in a way that transportation demands are reduced 50% of the initial estimate.

- Scenario n°5: Year 2040, combined conditions. It is fair to assume that future conditions would be better represented by the combination of the previously described scenarios. To obtain a more accurate perspective of the overall impact in the future the assumptions in the previous scenarios have been taken into account in one single analysis. This scenario is shown for illustrative purposes and entails a high level of uncertainty.

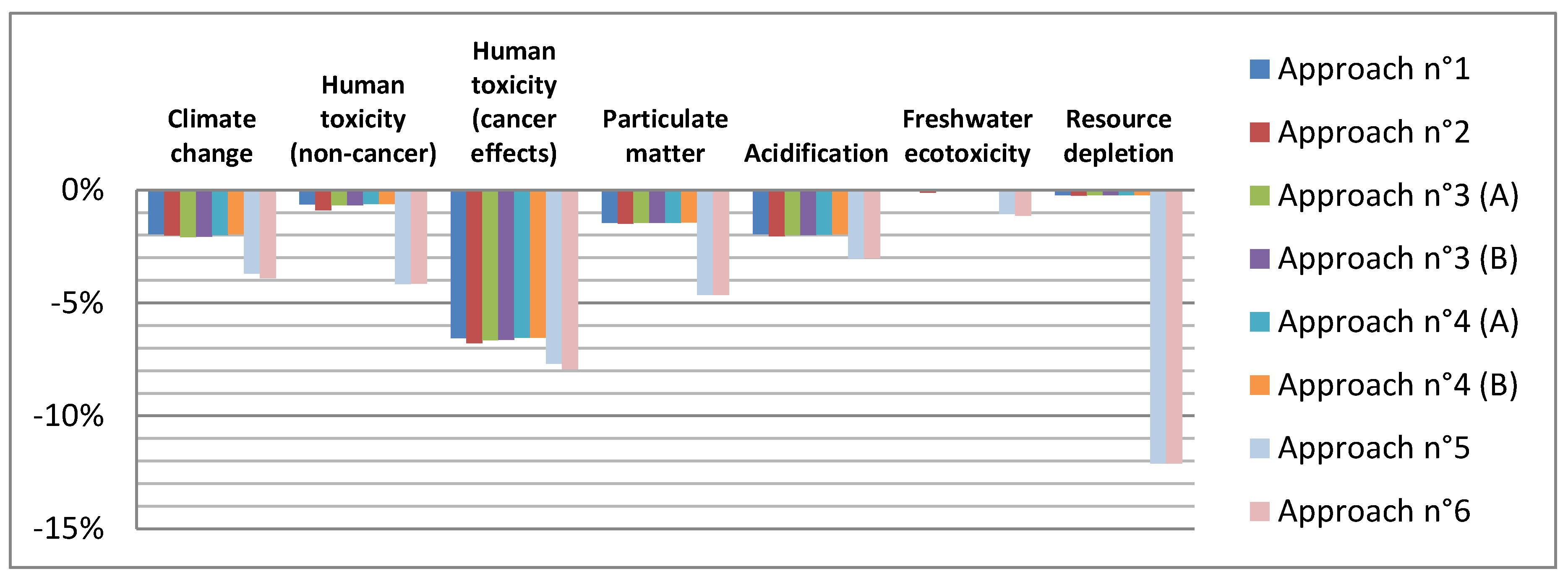

3. Results

3.1. Electricity Production

3.2. Sensitivity Analysis

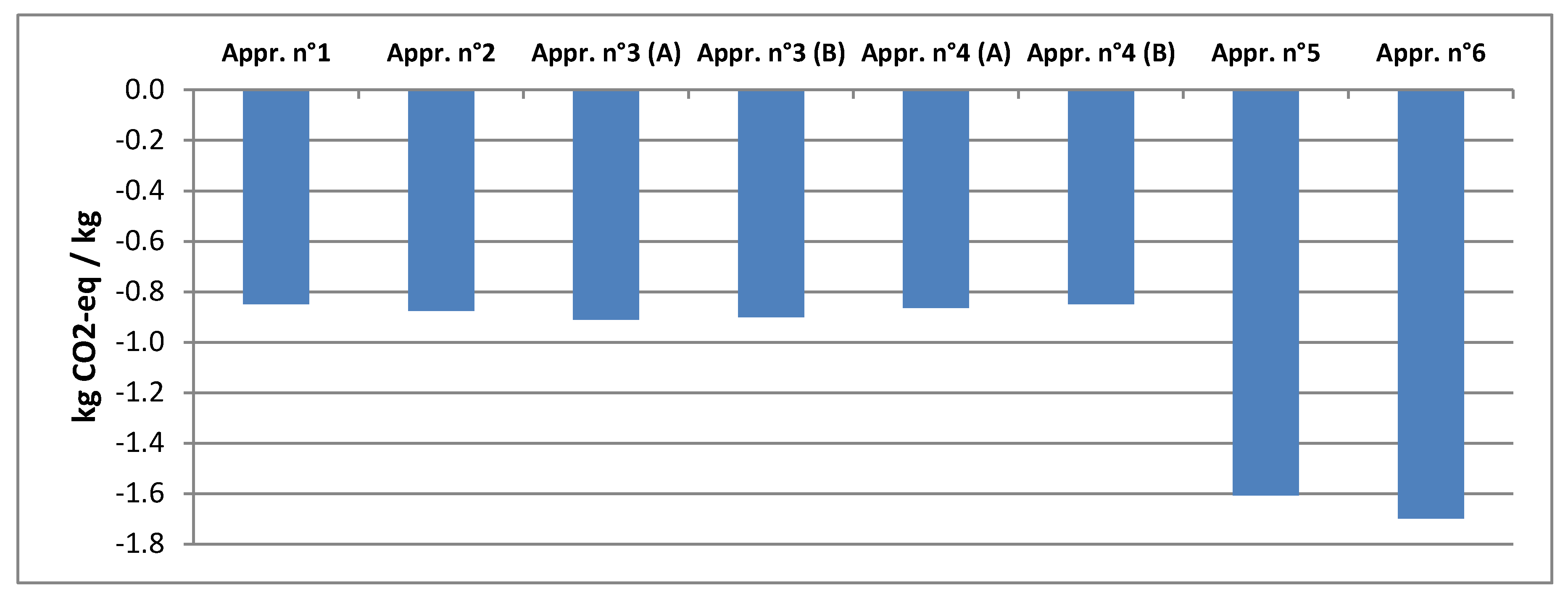

3.3. Greenhouse Gas Emissions

3.4. Energy Payback Time

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

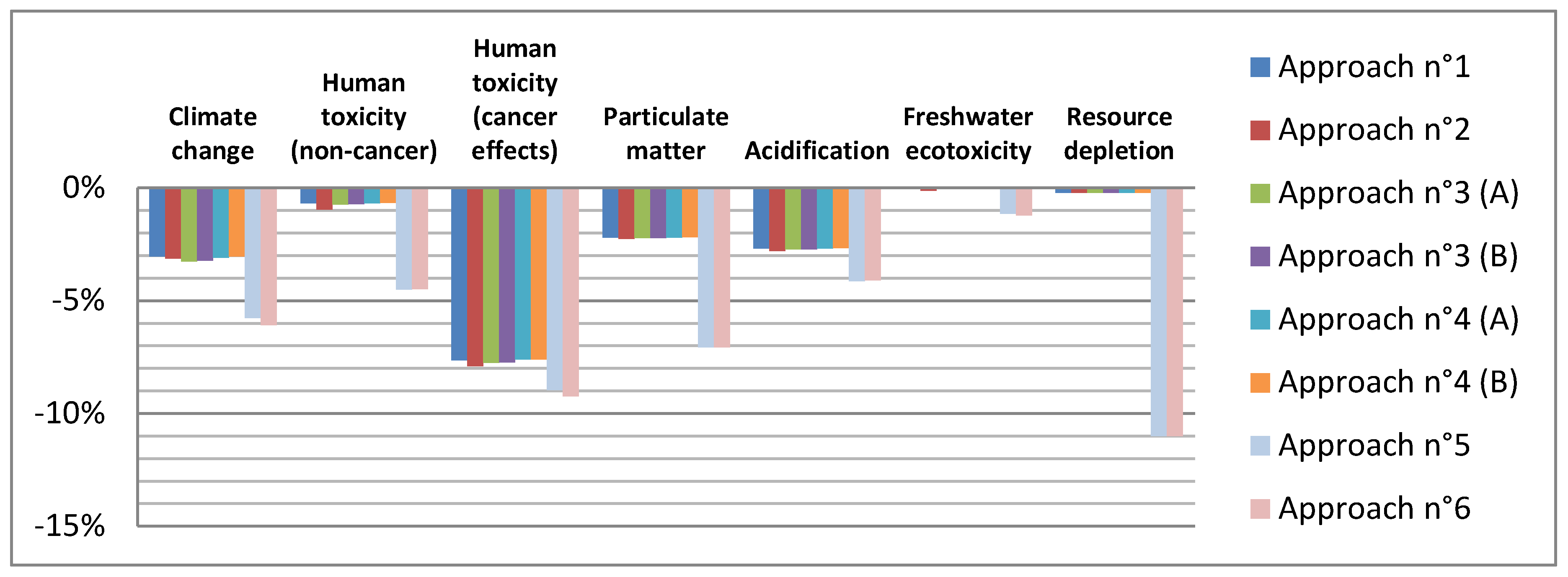

| Climate Change | Human Toxicity (Non-Cancer) | Human Toxicity (Cancer Effects) | Particulate Matter | Acidification | Freshwater Ecotoxicity | Resource Depletion | |

|---|---|---|---|---|---|---|---|

| Appr. n°1 | −2.0% | −0.6% | −6.6% | −1.4% | −2.0% | 0.0% | −0.2% |

| Appr. n°2 | −2.0% | −0.9% | −6.8% | −1.5% | −2.0% | −0.1% | −0.2% |

| Appr. n°3 (A) | −2.1% | −0.7% | −6.7% | −1.5% | −2.0% | 0.0% | −0.2% |

| Appr. n°3 (B) | −2.1% | −0.7% | −6.6% | −1.5% | −2.0% | 0.0% | −0.2% |

| Appr. n°4 (A) | −2.0% | −0.6% | −6.5% | −1.4% | −2.0% | 0.0% | −0.2% |

| Appr. n°4 (B) | −2.0% | −0.6% | −6.5% | −1.4% | −2.0% | 0.0% | −0.2% |

| Appr. n°5 | −3.7% | −4.2% | −7.7% | −4.6% | −3.0% | −1.1% | −12.1% |

| Appr. n°6 | −3.9% | −4.1% | −7.9% | −4.6% | −3.0% | −1.1% | −12.1% |

| Climate Change | Human Toxicity (Non-Cancer) | Human Toxicity (Cancer Effects) | Particulate Matter | Acidification | Freshwater Ecotoxicity | Resource Depletion | |

|---|---|---|---|---|---|---|---|

| Appr. n°1 | −3.0% | −0.7% | −7.6% | −2.2% | −2.7% | 0.0% | −0.2% |

| Appr. n°2 | −3.1% | −1.0% | −7.9% | −2.3% | −2.8% | −0.1% | −0.2% |

| Appr. n°3 (A) | −3.3% | −0.7% | −7.8% | −2.2% | −2.7% | 0.0% | −0.2% |

| Appr. n°3 (B) | −3.2% | −0.7% | −7.7% | −2.2% | −2.7% | 0.0% | −0.2% |

| Appr. n°4 (A) | −3.1% | −0.7% | −7.6% | −2.2% | −2.7% | 0.0% | −0.2% |

| Appr. n°4 (B) | −3.0% | −0.7% | −7.6% | −2.2% | −2.7% | 0.0% | −0.2% |

| Appr. n°5 | −5.8% | −4.5% | −9.0% | −7.1% | −4.1% | −1.2% | −11.0% |

| Appr. n°6 | −6.1% | −4.5% | −9.2% | −7.1% | −4.1% | −1.2% | −11.0% |

References

- Choi, J.-K.; Fthenakis, V. Crystalline silicon photovoltaic recycling planning. Macro and micro perspectives. J. Clean. Prod. 2014, 66, 443–449. [Google Scholar] [CrossRef]

- McDonald, N.C.; Pearce, J.M. Producer responsibility and recycling solar photovoltaic modules. Energy Policy 2010, 38, 7041–7047. [Google Scholar] [CrossRef]

- D’Adamo, I.; Miliacca, M. Rosa, Paolo Economic Feasibility for Recycling of Waste Crystalline Silicon Photovoltaic Modules. Int. J. Photoenergy 2017, 2017, 1–6. [Google Scholar] [CrossRef]

- Heinemann, D.; Jürgens, W.; Knecht, R.; Parisi, J. A historical module: The TSG MQ 36/0 solar panel. Einblicke 2011, 54, 6–11. [Google Scholar]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates—An Analytical Review. Prog. Photovolt. Res. Appl. 2013, 21. [Google Scholar] [CrossRef]

- Virtuani, A.; Caccivio, M.; Annigoni, E.; Friesen, G.; Chianese, D.; Ballif, C.; Sample, T. 35 years of photovoltaics: Analysis of the TISO-10-kW solar plant, lessons learnt in safety and performance—Part 1. Prog. Photovolt. Res. Appl. 2019, 328–339. [Google Scholar] [CrossRef]

- Wambach, K. Life Cycle Inventory of Current Photovoltaic Module Recycling Processes in Europe; IEA PVPS Task12, Subtask 2, LCA Report IEA-PVPS T12-12:2017; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017. [Google Scholar]

- Held, M. LCA screening of a recycling process for silicon based PV modules. In Proceedings of the Symposium conducted at PV Cycle Conference, Rome, Italy, 12–13 February 2018. [Google Scholar]

- Giacchetta, G.; Leporini, M.; Marchetti, B. Evaluation of the environmental benefits of new high value process for the management of the end of life of thin film photovoltaic modules. J. Clean. Prod. 2013, 51, 214–224. [Google Scholar] [CrossRef]

- Duflou, J.; Peeters, J.; Altamirano, D.; Bracquene, E.; Dewulf, W. Demanufacturing photovoltaic panels: Comparison of end-of-life treatment strategies for improved resource recovery. CIRP Ann. Manuf. Technol. 2018, 67, 29–32. [Google Scholar] [CrossRef]

- Latunussa, C.E.L.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Latunussa, C.; Mancini, L.; Blengini, G.; Ardente, F.; Pennington, D. Analysis of Material Recovery from Photovoltaic Panels; EUR 27797; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar] [CrossRef]

- Ardente, F.; Latunussa, C.; Blengini, G. Resource efficient recovery of critical and precious metals from waste silicon PV panel recycling. Waste Manag. 2019, 91, 156–167. [Google Scholar] [CrossRef] [PubMed]

- Aryan, V.; Danz, P.; Maga, D.; Brucart, M.F. End-of-Life Pathways for PV Backsheets; Final Report; Fraunhofer UMSICHT: Oberhausen, Germany, 2017. [Google Scholar]

- Komoto, K.; Lee, J.-S. End-of-Life Management of Photovoltaic Panels: Trends in PV Module Recycling Technologies; IEA PVPS Task12, Subtask 1, Recycling Report IEA-PVPS T12-10:2018; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [Google Scholar]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE. Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef] [PubMed]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H.; Bernardes, A.M. Recycling WEEE. Extraction and concentration of silver from waste crystalline silicon photovoltaic modules. Waste Manag. 2016, 57, 220–225. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.-H.; Shin, W.J.; Wang, L.; Sun, W.-C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar] [CrossRef]

- Wade, A.; Stolz, P.; Frischknecht, R.; Heath, G.; Sinha, P. The Product Environmental Footprint (PEF) of photovoltaic modules-Lessons learned from the environmental footprint pilot phase on the way to a single market for green products in the European Union. Prog. Photovolt. Res. Appl. 2018, 26, 553–564. [Google Scholar] [CrossRef]

- JRC European Commission. Recommendations Fir Life Cycle Impact Assessment in the European Context. ILCD Handbook; JRC European Commission: Ispra, Italy, 2011; ISBN 978-92-79-17451-3. [Google Scholar]

- Jungbluth, N.; Stucki, M.; Büsser, S.; Flury, K.; Frischknecht, R. Life Cycle Inventories of Photovoltaics; ESU-Services Ltd.: Uster, Switzerland, 2012. [Google Scholar]

- Frischknecht, R.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M.; Fthenakis, V.; Kim, H.C.; Alsema, E.; Held, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity, 3rd ed.; IEA PVPS Task 12, International Energy Agency Photovoltaic Power Systems Programme; Report IEA-PVPS T12-06:2016; IEA: Paris, France, 2016; ISBN 978-3-906042-38-1. [Google Scholar]

- Philipps, S.; Warmuth, W. Photovoltaics Report. Fraunhofer Institute for Solar Energy Systems ISE. Available online: https://www.ise.fraunhofer.de/en/publications/studies/photovoltaics-report.html (accessed on 9 March 2020).

- Fraunhofer ISE Energy Charts. Fraunhofer Institute for Solar Energy Systems ISE. Available online: https://www.energy-charts.de (accessed on 9 March 2020).

- International Energy Agency. Energy Policies of IEA Countries; 2013 Review: OECD; IEA: Paris, France, 2013; ISBN 978-92-64-19076-4. [Google Scholar]

- Stolz, P.; Frischknecht, R.; Wambach, K.; Sinha, P.; Heath, G. Life Cycle Assessment of Current Photovoltaic Module Recycling; IEA PVPS Task 12; International Energy Agency Power Systems Programme; Report IEA-PVPS T12-13:2018; IEA: Paris, France, 2017. [Google Scholar]

- O’Connell, R.; Alexander, C.; Alway, B.; Litosh, S.; Nambiath, S.; Wiebe, J.; Yao, W.; Norton, K.; Li, S.; Aranda, D.; et al. World Silver Survey 2018; Produced for The Silver Institute by the GFMS team at Thomson Reuters; The Silver Institute: Washington, DC, USA, 2018; ISBN 978-1-880936-31-3. [Google Scholar]

- IRENA and IEA-PVPS. End-of-Life Management: Solar Photovoltaic Panels; International Renewable Energy Agency and International Energy Agency Photovoltaic Power Systems; IEA: Paris, France, 2016; ISBN 978-92-95111-99-8. [Google Scholar]

- The World Bank. CO2 Emissions (Metric Tons Per Capita) 2018. Available online: https://data.worldbank.org/indicator/EN.ATM.CO2E.PC?end=2014&start=1960 (accessed on 9 March 2020).

- VDMA Photovoltaic Equipment. International Technology Roadmap for Photovoltaic (ITRPV), 8th ed.; Results including Maturity Report; VDMA Photovoltaic Equipment: Frankfurt, Germany, 2017. [Google Scholar]

| Parameter | Mono-Si | Multi-Si | |

|---|---|---|---|

| Location of Manufacturing (Market Share) | China (CN) | 79.6% | |

| Europe (RER) | 14.5% | ||

| Asia Pacific (APAC) | 5.9% | ||

| Plant size (kWp) | 3 | 3 | |

| Module efficiency | 14% | 13.60% | |

| Panel capacity rate (Wp/m2) | 140 | 136 | |

| Module lifetime (Years) | 30 | 30 | |

| Module weight (kg/m2) | 10 | 10 | |

| Module Area (m2) | 1.6 | 1.6 | |

| Module Section | Material | Mass Fraction |

|---|---|---|

| Front glass | Glass | 70.00% |

| Frame | Aluminium | 18.00% |

| Junction box | Copper | 0.33% |

| Plastic junction box | 0.67% | |

| Encapsulant | EVA | 5.10% |

| Backsheet | PET | 1.50% |

| Solar cell | Silicon | 3.65% |

| Aluminium | 0.53% | |

| Copper | 0.11% | |

| Silver | 0.05% | |

| others | other metals (tin, lead) | 0.05% |

| Sealant, potting | 0.00% |

| Appr. | Materials Recovered | Unrecovered Fraction Disposal Method |

|---|---|---|

| n°1 | Glass, Aluminum, copper | Landfilling |

| n°2 | Glass, Aluminum, copper | Landfilling/Incineration |

| n°3 | Glass, Aluminum, copper | Landf *./Inciner **./Inciner. of Backsheet |

| n°4 | Glass, Aluminum, copper | Landf./Inciner./Pyrol. of Backsheet |

| n°5 | Glass, Aluminum, copper, MG-Si, Silver | Landfilling/Incineration |

| n°6 | Glass, Aluminum, copper, MG-Si, Silver | Landfilling/Pyrolysis |

| No EoL | Appr. | Appr. | Appr. 3 | Appr. 4 | Appr. | Appr. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | (A) Fluor- Free | (B) Fluor | (A) Fluor- Free | (B) Fluor | 5 | 6 | ||||

| Mono-Si | CED (GJ) | 127.3 | CED saving (GJ) | −3.00 | −3.70 | −3.24 | −3.20 | −3.05 | −3.05 | −5.93 | −5.69 |

| EPBT (Years) | 4.5 | EPBT incl. EoL (years) | 4.36 | 4.34 | 4.35 | 4.36 | 4.36 | 4.36 | 4.26 | 4.27 | |

| % Reduction | 2.4% | 2.9% | 2.5% | 2.5% | 2.4% | 2.4% | 4.7% | 4.5% | |||

| Multi-Si | CED (GJ) | 88.6 | CED saving (GJ) | −3.20 | −3.95 | −3.45 | −3.41 | −3.25 | −3.25 | −6.32 | −6.07 |

| EPBT (Years) | 3.1 | EPBT incl. EoL (years) | 3.00 | 2.97 | 2.99 | 2.99 | 3.00 | 3.00 | 2.89 | 2.90 | |

| % Reduction | 3.6% | 4.5% | 3.9% | 3.8% | 3.7% | 3.7% | 7.1% | 6.9% | |||

| Year | Area | PV Waste (Million Tons) | Cumulative Million Ton CO2-eq | |

|---|---|---|---|---|

| MIN | MAX | |||

| 2040 | Germany | 2.4 | 2.04 | 4.08 |

| Global | 23.5 | 19.95 | 39.90 | |

| 2050 | Germany | 4.3 | 3.65 | 7.30 |

| Global | 69 | 58.57 | 117.16 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herceg, S.; Pinto Bautista, S.; Weiß, K.-A. Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies 2020, 13, 2146. https://doi.org/10.3390/en13092146

Herceg S, Pinto Bautista S, Weiß K-A. Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies. 2020; 13(9):2146. https://doi.org/10.3390/en13092146

Chicago/Turabian StyleHerceg, Sina, Sebastián Pinto Bautista, and Karl-Anders Weiß. 2020. "Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems" Energies 13, no. 9: 2146. https://doi.org/10.3390/en13092146

APA StyleHerceg, S., Pinto Bautista, S., & Weiß, K.-A. (2020). Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies, 13(9), 2146. https://doi.org/10.3390/en13092146