Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes

Abstract

1. Introduction

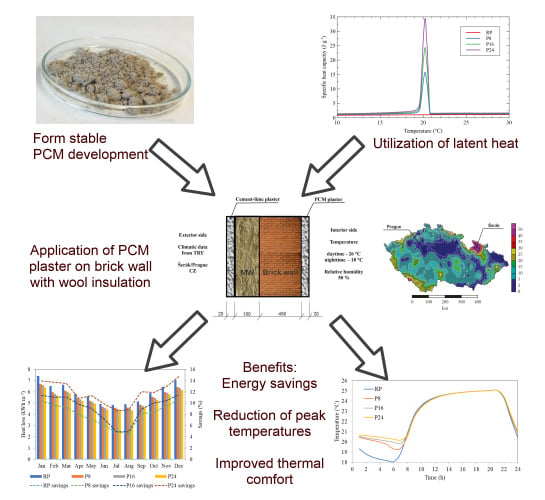

2. System Description

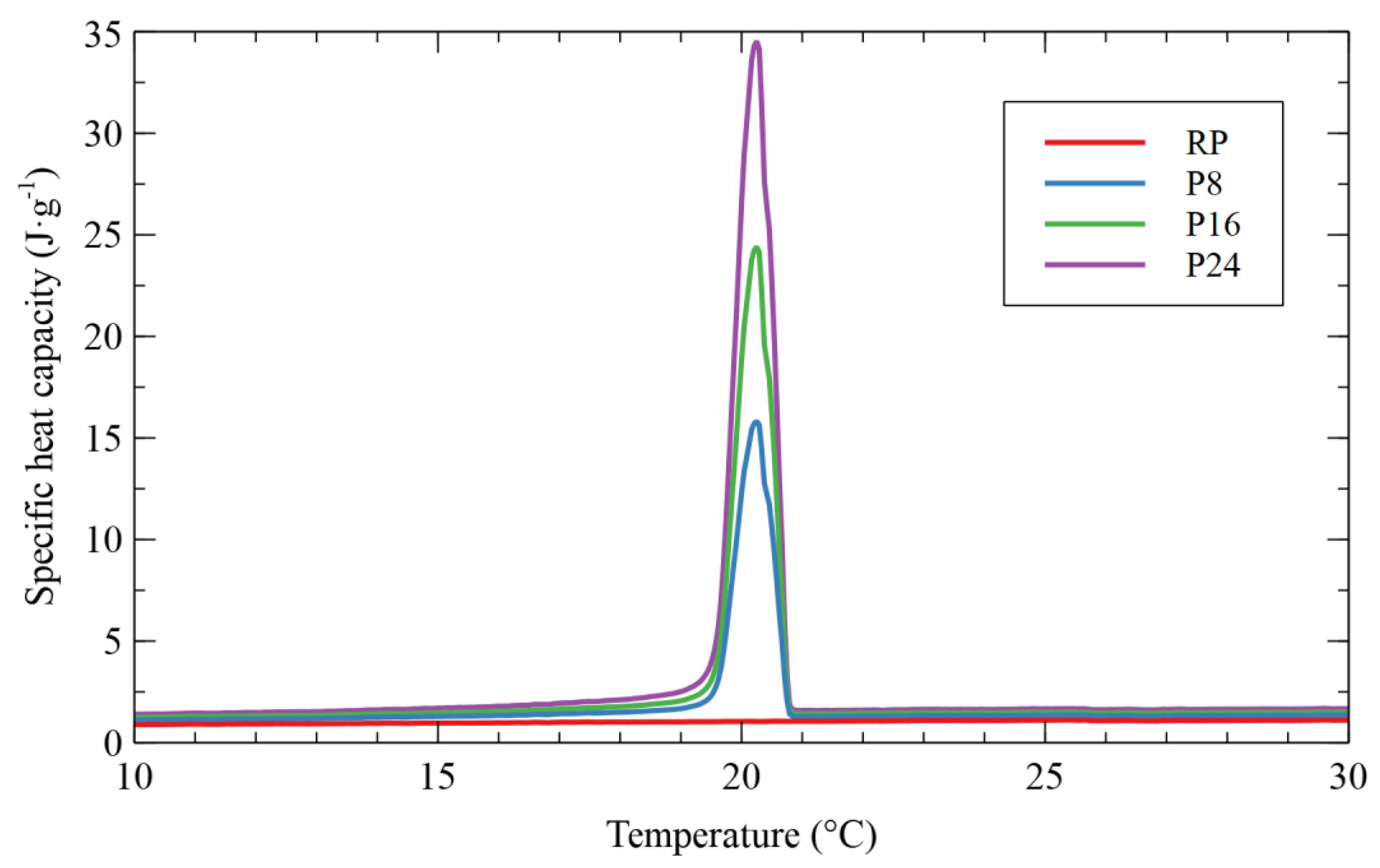

2.1. Materials

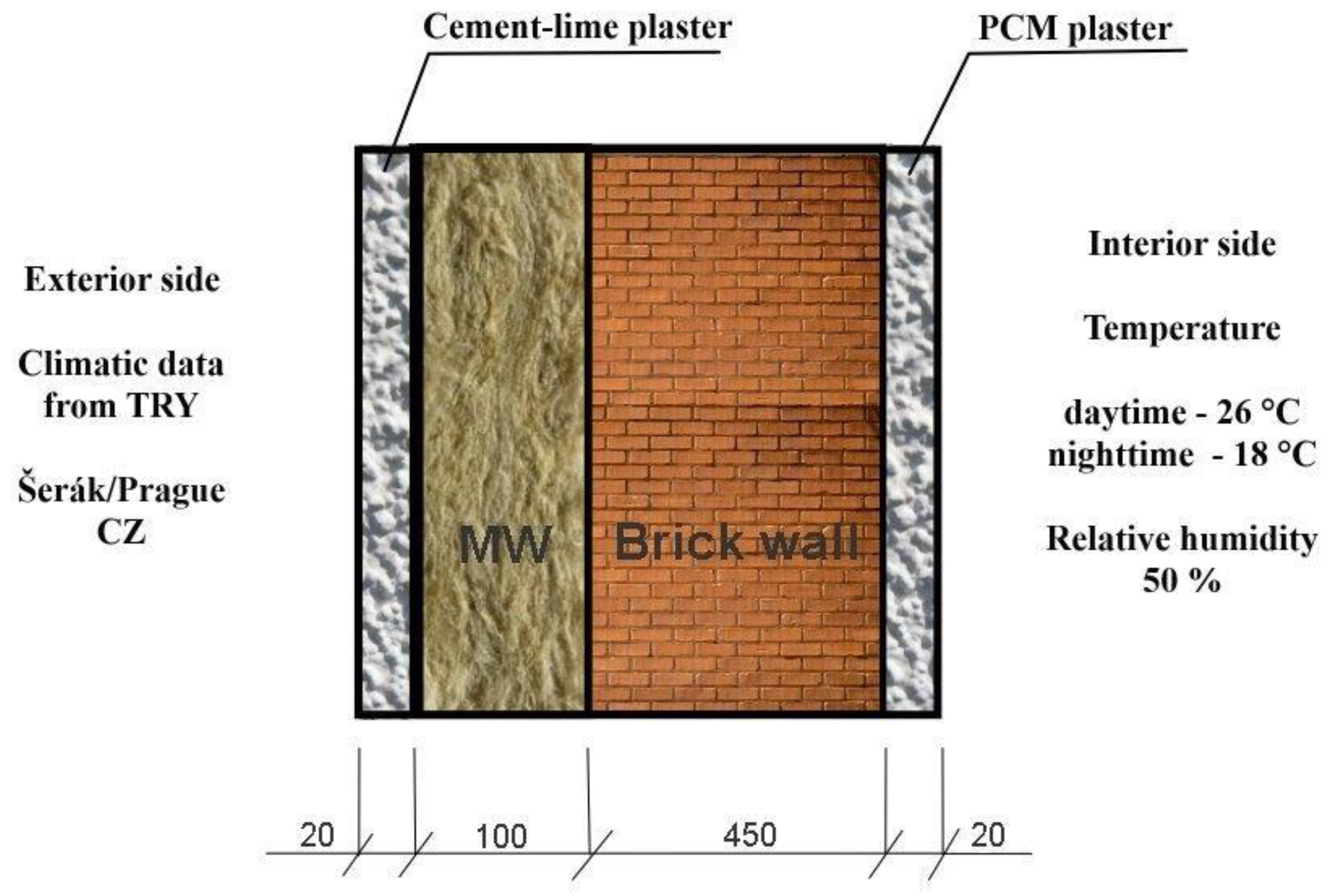

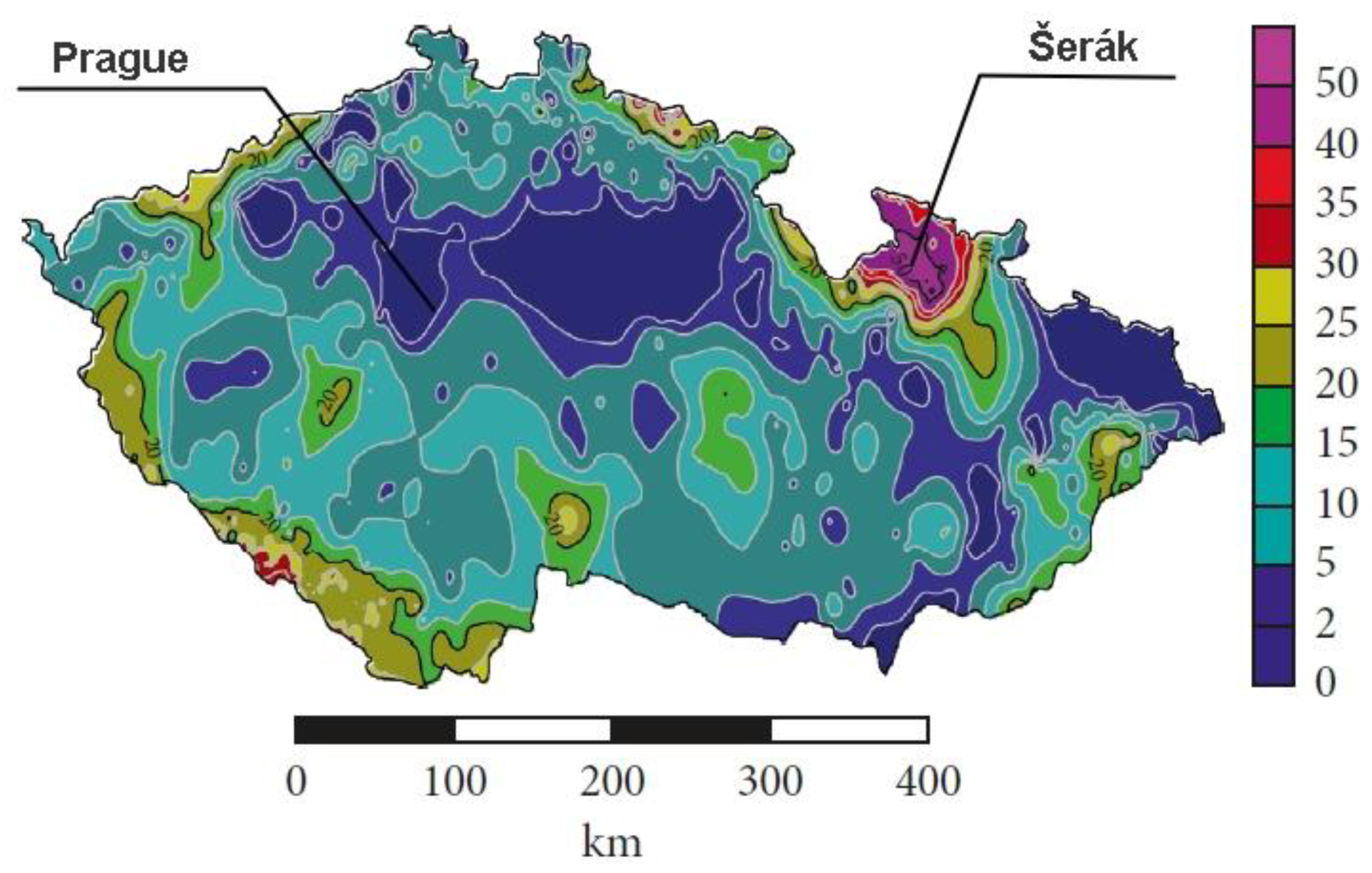

2.2. Boundary Conditions

2.3. Computational Analysis

Computational Model

3. Results

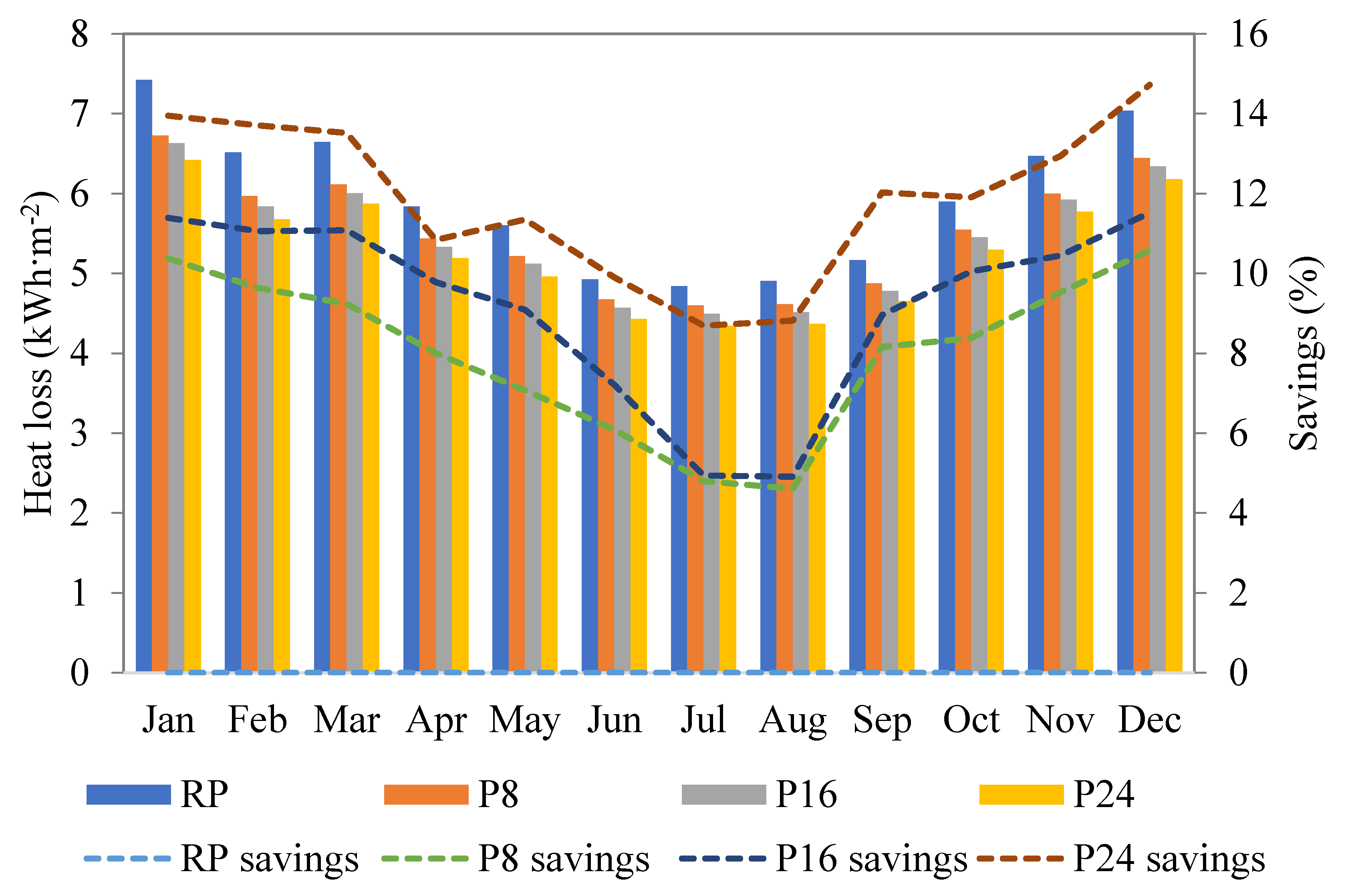

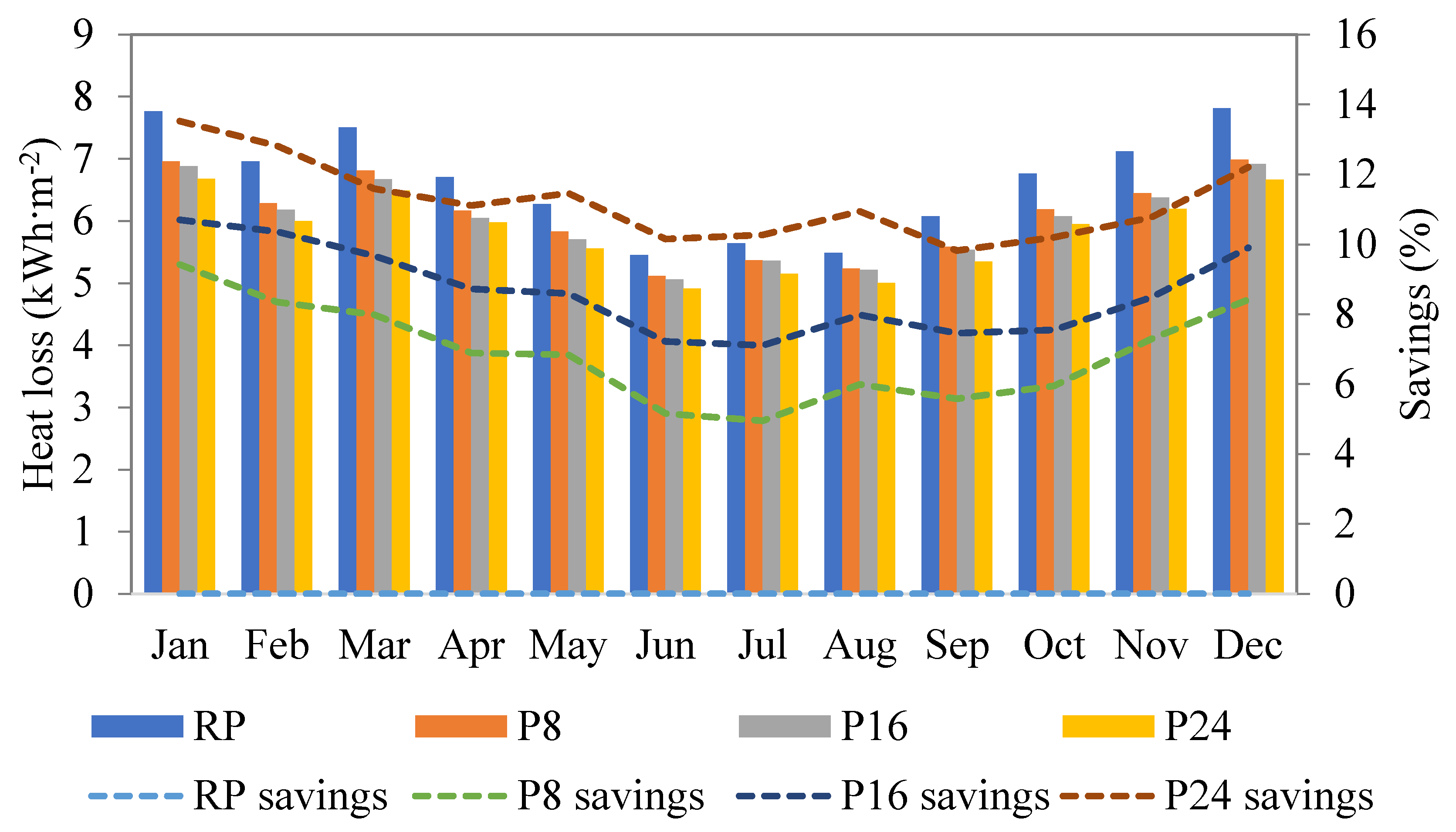

3.1. Energy Simulation Analysis

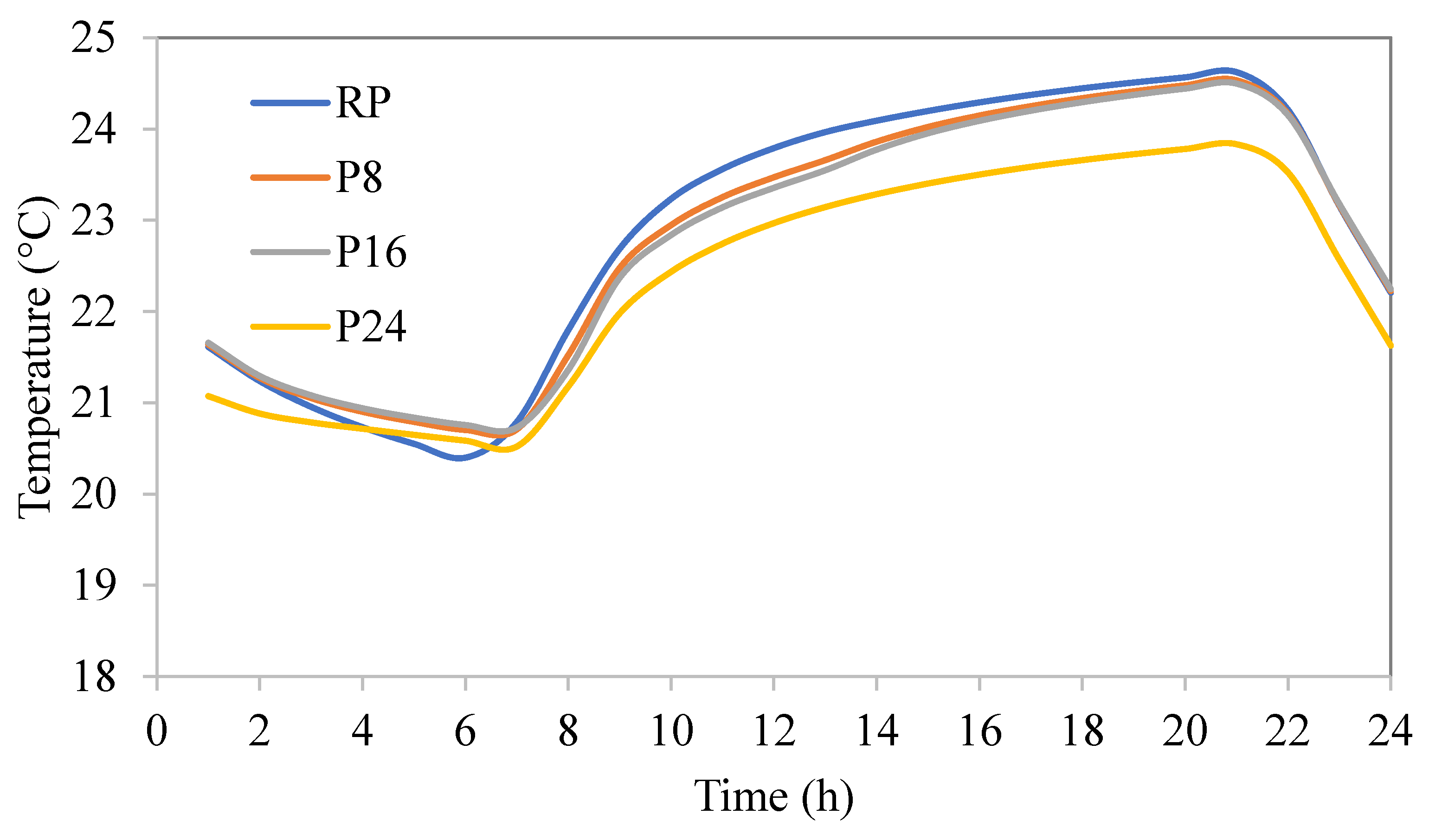

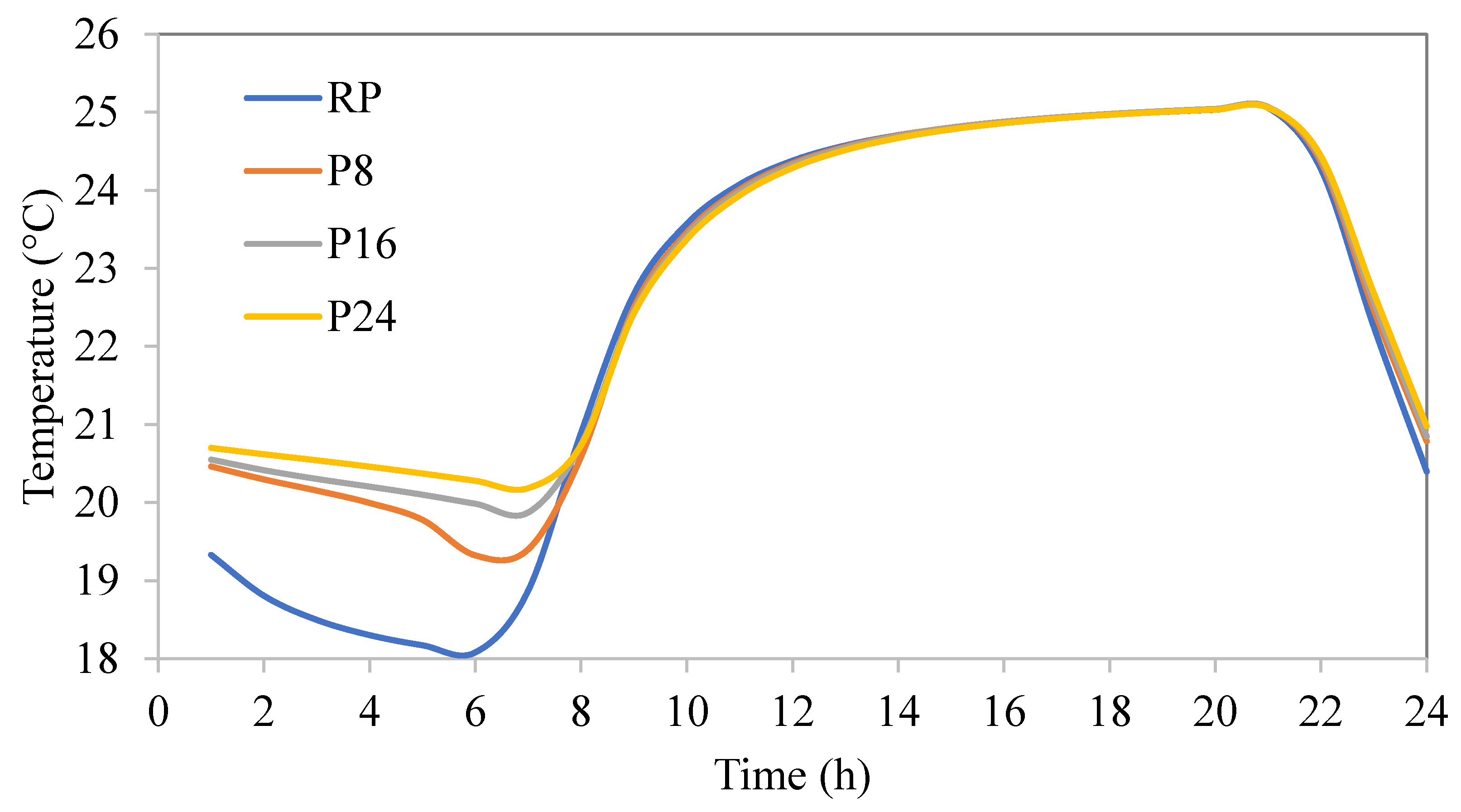

3.2. Diurnal Surface Temperature Fluctuation

4. Discussion

5. Conclusions

- Computational modeling revealed that case walls with applied modified plaster decelerated interior temperature changes during charging and discharging periods. As a result of the application of developed plaster, annual energy savings were identified in ranges from 6% to 12%, dependent on the selected location.

- Obtained results within this study clearly highlighted the contrasts between common building envelopes in terms of energy savings. Therefore, the investigation of PCMs needs to be well-specified due to a variety of influencing factors such as humidity, masonry type or applied insulation.

- Even small differences in outdoor climate conditions have a significant effect on the resulting thermal energy performance of applied PCMs. The complete overpassing of the phase change temperature poses an important criterion assessing the potential and viability of PCMs usage.

- The utilization of FSPCM plaster can significantly enhance the ability of the wall to recuperate the interior heat that would normally be lost when non-PCM plasters are applied. The amount of recuperated heat depends on the material of a load-bearing structure and can range up to 10 kWh m−2 a month, which presents an improvement of about 20% when compared to the non-PCM plaster.

Author Contributions

Funding

Conflicts of Interest

References

- Fan, Y.L.; Xia, X.H. Energy-efficiency building retrofit planning for green building compliance. Build. Environ. 2018, 136, 312–321. [Google Scholar] [CrossRef]

- Levy, J.I.; Woo, M.K.; Tambouret, Y. Energy savings and emissions reductions associated with increased insulation for new homes in the United States. Build. Environ. 2016, 96, 72–79. [Google Scholar] [CrossRef]

- Cai, S.S.; Zhang, B.X.; Cremaschi, L. Review of moisture behavior and thermal performance of polystyrene insulation in building applications. Build. Environ. 2017, 123, 50–65. [Google Scholar] [CrossRef]

- Yun, B.Y.; Park, J.H.; Yang, S.; Wi, S.; Kim, S. Integrated analysis of the energy and economic efficiency of PCM as an indoor decoration element: Application to an apartment building. Sol. Energy 2020, 196, 437–447. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, Z. Standard effective temperature based adaptive-rational thermal comfort model. Appl. Energy 2020, 264, 114723. [Google Scholar] [CrossRef]

- McArthur, J.J.; Powell, C. Health and wellness in commercial buildings: Systematic review of sustainable building rating systems and alignment with contemporary research. Build. Environ. 2020, 171, 106635. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Q.; Zhang, Y.P.; Wang, X. Exploring buildings’ secrets: The ideal thermophysical properties of a building’s wall for energy conservation. Int. J. Heat Mass Transf. 2013, 65, 265–273. [Google Scholar] [CrossRef]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-mortar based construction materials for energy efficient buildings: A review on research trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Tao, Y.B.; He, Y.L. A review of phase change material and performance enhancement method for latent heat storage system. Renew. Sustain. Energy Rev. 2018, 93, 245–259. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Johra, H.; Heiselberg, P.; Le Dreau, J. Influence of envelope, structural thermal mass and indoor content on the building heating energy flexibility. Energy Build. 2019, 183, 325–339. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, J.; Wi, S.; Jeon, J.; Chang, S.J.; Chang, J.D.; Kim, S. Optimization of phase change materials to improve energy performance within thermal comfort range in the South Korean climate. Energy Build. 2019, 185, 12–25. [Google Scholar] [CrossRef]

- Li, C.E.; Yu, H.; Song, Y. Experimental investigation of thermal performance of microencapsulated PCM-contained wallboard by two measurement modes. Energy Build. 2019, 184, 34–43. [Google Scholar] [CrossRef]

- Oropeza-Perez, I.; Ostergaard, P.A. Active and passive cooling methods for dwellings: A review. Renew. Sustain. Energy Rev. 2018, 82, 531–544. [Google Scholar] [CrossRef]

- Reddy, K.S.; Mudgal, V.; Mallick, T.K. Thermal Performance Analysis of Multi-Phase Change Material Layer-Integrated Building Roofs for Energy Efficiency in Built-Environment. Energies 2017, 10, 1367. [Google Scholar] [CrossRef]

- Firlag, S.; Zawada, B. Impacts of airflows, internal heat and moisture gains on accuracy of modeling energy consumption and indoor parameters in passive building. Energy Build. 2013, 64, 372–383. [Google Scholar] [CrossRef]

- Kasaeian, A.; Bahrami, L.; Pourfayaz, F.; Khodabandeh, E.; Yan, W.M. Experimental studies on the applications of PCMs and nano-PCMs in buildings: A critical review. Energy Build. 2017, 154, 96–112. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L.; Goia, F.; Serra, V. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (SWOT) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef]

- Navarro, L.; Sole, A.; Martin, M.; Barreneche, C.; Olivieri, L.; Tenorio, J.A.; Cabeza, L.F. Benchmarking of useful phase change materials for a building application. Energy Build. 2019, 182, 45–50. [Google Scholar] [CrossRef]

- Solgi, E.; Hamedani, Z.; Fernando, R.; Kari, B.M. A parametric study of phase change material characteristics when coupled with thermal insulation for different Australian climatic zones. Build. Environ. 2019, 163, 106317. [Google Scholar] [CrossRef]

- Jeong, S.G.; Wi, S.; Chang, S.J.; Lee, J.; Kim, S. An experimental study on applying organic PCMs to gypsum-cement board for improving thermal performance of buildings in different climates. Energy Build. 2019, 190, 183–194. [Google Scholar] [CrossRef]

- Sinka, M.; Bajare, D.; Jakovics, A.; Ratnieks, J.; Gendelis, S.; Tihana, J. Experimental testing of phase change materials in a warm-summer humid continental climate. Energy Build. 2019, 195, 205–215. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, X.J.; Zhao, Y.; Zhang, X.B. A Novel Passive Method for Regulating Both Air Temperature and Relative Humidity of the Microenvironment in Museum Display Cases. Energies 2019, 12, 3768. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Economic impact of integrating PCM as passive system in buildings using Fanger comfort model. Energy Build. 2016, 112, 159–172. [Google Scholar] [CrossRef]

- Mi, X.M.; Liu, R.; Cui, H.Z.; Memon, S.A.; Xing, F.; Lo, Y. Energy and economic analysis of building integrated with PCM in different cities of China. Appl. Energy 2016, 175, 324–336. [Google Scholar] [CrossRef]

- Zuhaib, S.; Manton, R.; Griffin, C.; Hajdukiewicz, M.; Keane, M.M.; Goggins, J. An Indoor Environmental Quality (IEQ) assessment of a partially-retrofitted university building. Build. Environ. 2018, 139, 69–85. [Google Scholar] [CrossRef]

- Mlakar, J.; Strancar, J. Temperature and humidity profiles in passive-house building blocks. Build. Environ. 2013, 60, 185–193. [Google Scholar] [CrossRef]

- Salthammer, T.; Schieweck, A.; Gu, J.W.; Ameri, S.; Uhde, E. Future trends in ambient air pollution and climate in Germany—Implications for the indoor environment. Build. Environ. 2018, 143, 661–670. [Google Scholar] [CrossRef]

- Chen, W.J.; Chan, M.Y.; Deng, S.M.; Yan, H.X.; Weng, W.B. A direct expansion based enhanced dehumidification air conditioning system for improved year-round indoor humidity control in hot and humid climates. Build. Environ. 2018, 139, 95–109. [Google Scholar] [CrossRef]

- Sun, Y.X.; Hou, J.; Kong, X.R.; Zhang, Q.N.; Wang, P.; Weschler, L.B.; Sundell, J. "Dampness" and "Dryness": What is important for children’s allergies? A cross-sectional study of 7366 children in northeast Chinese homes. Build. Environ. 2018, 139, 38–45. [Google Scholar] [CrossRef]

- Senff, L.; Ascensao, G.; Ferreira, V.M.; Seabra, M.P.; Labrincha, J.A. Development of multifunctional plaster using nano-TiO2 and distinct particle size cellulose fibers. Energy Build. 2018, 158, 721–735. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Vieira, N.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. The influence of porogene additives on the properties of mortars used to control the ambient moisture. Energy Build. 2014, 74, 61–68. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, S.D.; Cao, J.Z. An energy-efficient composite by using expanded graphite stabilized paraffin as phase change material. Compos. Part. A-Appl. Sci. Manuf. 2018, 107, 83–93. [Google Scholar] [CrossRef]

- Wen, R.L.; Zhang, X.G.; Huang, Y.T.; Yin, Z.Y.; Huang, Z.H.; Fang, M.H.; Liu, Y.G.; Wu, X.W. Preparation and properties of fatty acid eutectics/expanded perlite and expanded vermiculite shape-stabilized materials for thermal energy storage in buildings. Energy Build. 2017, 139, 197–204. [Google Scholar] [CrossRef]

- Li, X.Q.; Wei, H.T.; Lin, X.S.; Xie, X.Z. Preparation of stearic acid/modified expanded vermiculite composite phase change material with simultaneously enhanced thermal conductivity and latent heat. Sol. Energy Mater. Sol. Cells 2016, 155, 9–13. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Zheng, S.L.; Zhu, S.Q.; Ma, J.N.; Sun, Z.M.; Farid, M. Evaluation of paraffin infiltrated in various porous silica matrices as shape-stabilized phase change materials for thermal energy storage. Energy Convers. Manag. 2018, 171, 361–370. [Google Scholar] [CrossRef]

- Fort, J.; Trnik, A.; Pavlikova, M.; Pavlik, Z.; Cerny, R. Fabrication of Dodecanol/Diatomite Shape-Stabilized PCM and Its Utilization in Interior Plaster. Int. J. Thermophys. 2018, 39, 11. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjoniksen, A.L. Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications. Sol. Energy 2019, 178, 295–307. [Google Scholar] [CrossRef]

- Fort, J.; Novotny, R.; Trnik, A.; Cerny, R. Preparation and Characterization of Novel Plaster with Improved Thermal Energy Storage Performance. Energies 2019, 12, 3318. [Google Scholar] [CrossRef]

- Pavlik, Z.; Jerman, M.; Fort, J.; Cerny, R. Monitoring Thermal Performance of Hollow Bricks with Different Cavity Fillers in Difference Climate Conditions. Int. J. Thermophys. 2015, 36, 557–568. [Google Scholar] [CrossRef]

- Jerman, M.; Keppert, M.; Vyborny, J.; Cerny, R. Hygric, thermal and durability properties of autoclaved aerated concrete. Constr. Build. Mater. 2013, 41, 352–359. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Koppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Madera, J.; Koci, J.; Koci, V.; Kruis, J. Parallel modeling of hygrothermal performance of external wall made of highly perforated bricks. Adv. Eng. Softw. 2017, 113, 47–53. [Google Scholar] [CrossRef]

- Lewis, R.W.; Ravindren, K. Finite element simulation of metal casting. Int. J. Numer. Methods Eng. 2000, 47, 29–59. [Google Scholar] [CrossRef]

- Kruis, J.; Koudelka, T.; Krejci, T. Efficient computer implementation of coupled hydro-thermo-mechanical analysis. Math. Comput. Simul. 2010, 80, 1578–1588. [Google Scholar] [CrossRef]

- Koci, V.; Koci, J.; Madera, J.; Pavlik, Z.; Gu, X.L.; Zhang, W.P.; Cerny, R. Thermal and hygric assessment of an inside-insulated brick wall: 2D critical experiment and computational analysis. J. Build. Phys. 2018, 41, 497–520. [Google Scholar] [CrossRef]

- Tuncbilek, E.; Arici, M.; Bouadila, S.; Wonorahardjo, S. Seasonal and annual performance analysis of PCM-integrated building brick under the climatic conditions of Marmara region. J. Ther. Anal. Calorim. 2020, 1–12. [Google Scholar] [CrossRef]

- Wang, H.; Lu, W.; Wu, Z.G.; Zhang, G.H. Parametric analysis of applying PCM wallboards for energy saving in high-rise lightweight buildings in Shanghai. Renew. Energy 2020, 145, 52–64. [Google Scholar] [CrossRef]

- Wang, C.X.; Huang, X.; Deng, S.M.; Long, E.S.; Niu, J.L. An experimental study on applying PCMs to disaster-relief prefabricated temporary houses for improving internal thermal environment in summer. Energy Build. 2018, 179, 301–310. [Google Scholar] [CrossRef]

- Liu, C.Y.; Zhang, G.J.; Arici, M.; Bian, J.; Li, D. Thermal performance of non-ventilated multilayer glazing facades filled with phase change material. Sol. Energy 2019, 177, 464–470. [Google Scholar] [CrossRef]

- Wu, Z.M.; Qin, M.H.; Zhang, M.J. Phase change change humidity control material and its impact on building energy consumption. Energy Build. 2018, 174, 254–261. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.B.; Castro-Gomes, J. Experimental and numerical studies of hybrid PCM embedded in plastering mortar for enhanced thermal behaviour of buildings. Energy 2016, 94, 250–261. [Google Scholar] [CrossRef]

- Sari, A.; Sharma, R.K.; Hekimoglu, G.; Tyagi, V.V. Preparation, characterization, thermal energy storage properties and temperature control performance of form-stabilized sepiolite based composite phase change materials. Energy Build. 2019, 188, 111–119. [Google Scholar] [CrossRef]

- Kusama, Y.; Ishidoya, Y. Thermal effects of a novel phase change material (PCM) plaster under different insulation and heating scenarios. Energy Build. 2017, 141, 226–237. [Google Scholar] [CrossRef]

- Li, Z.X.; Al-Rashed, A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S. Energy conservative air conditioning system using silver nano-based PCM thermal storage for modern buildings. Energy Build. 2014, 69, 202–212. [Google Scholar] [CrossRef]

- Biswas, K.; Lu, J.; Soroushian, P.; Shrestha, S. Combined experimental and numerical evaluation of a prototype nano-PCM enhanced wallboard. Appl. Energy 2014, 131, 517–529. [Google Scholar] [CrossRef]

- Ahangari, M.; Maerefat, M. An innovative PCM system for thermal comfort improvement and energy demand reduction in building under different climate conditions. Sustain. Cities Soc. 2019, 44, 120–129. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Passive cooling techniques for building and their applicability in different climatic zones-The state of art. Energy Build. 2019, 198, 467–490. [Google Scholar] [CrossRef]

- Park, J.H.; Jeon, J.; Lee, J.; Wi, S.; Yun, B.Y.; Kim, S. Comparative analysis of the PCM application according to the building type as retrofit system. Build. Environ. 2019, 151, 291–302. [Google Scholar] [CrossRef]

- Zeinelabdein, R.; Omer, S.; Gan, G.H. Experimental performance of latent thermal energy storage for sustainable cooling of buildings in hot-arid regions. Energy Build. 2019, 186, 169–185. [Google Scholar] [CrossRef]

- Qiao, Y.H.; Yang, L.; Bao, J.Y.; Liu, Y.; Liu, J.P. Reduced-scale experiments on the thermal performance of phase change material wallboard in different climate conditions. Build. Environ. 2019, 160, 106191. [Google Scholar] [CrossRef]

- Zhu, N.; Li, S.S.; Hu, P.F.; Wei, S.; Deng, R.J.; Lei, F. A review on applications of shape-stabilized phase change materials embedded in building enclosure in recent ten years. Sustain. Cities Soc. 2018, 43, 251–264. [Google Scholar] [CrossRef]

- Entrop, A.G.; Brouwers, H.J.H.; Reinders, A. Experimental research on the use of micro-encapsulated Phase Change Materials to store solar energy in concrete floors and to save energy in Dutch houses. Sol. Energy 2011, 85, 1007–1020. [Google Scholar] [CrossRef]

- Erlbeck, L.; Schreiner, P.; Schlachter, K.; Dornhofer, P.; Fasel, F.; Methner, F.J.; Radle, M. Adjustment of thermal behavior by changing the shape of PCM inclusions in concrete blocks. Energy Convers. Manag. 2018, 158, 256–265. [Google Scholar] [CrossRef]

| Material | Phase Change Temperature (°C) | Latent Heat of Fusion/Freezing (J/g) | ||||

|---|---|---|---|---|---|---|

| Heating | Cooling | Heating | Cooling | |||

| Onset | Endset | Onset | Endset | |||

| RP | - | - | - | - | - | - |

| P8 | 22.46 | 24.68 | 20.68 | 18.63 | 4.63 | 4.89 |

| P16 | 22.13 | 24.91 | 20.81 | 18.98 | 10.11 | 10.28 |

| P24 | 22.68 | 25.86 | 20.75 | 19.66 | 15.20 | 15.38 |

| Material Parameter | Ceramic Brick | Mineral Wool |

|---|---|---|

| Bulk density (kg·m−3) | 1831 | 70 |

| Matrix density (kg·m−3) | 2581 | 2260 |

| Total open porosity (%) | 27.9 | 96.9 |

| Thermal conductivity (W·m−1·K−1) | 0.59 | 0.036 |

| Specific heat capacity (J·kg−1·K−1) | 825 | 810 |

| Water vapor diffusion resistance factor (-) | 22.1 | 2.62 |

| Location | January | February | March | April | May | June | July | August | September | October | November | December |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Prague–temp. (°C) | 1.83 | 2.53 | 4.83 | 9.33 | 15.19 | 18.03 | 19.61 | 19.09 | 15.02 | 8.94 | 5.62 | 1.56 |

| Šerák–temp. (°C) | −4.36 | −2.31 | −3.18 | 2.12 | 7.06 | 11.04 | 11.59 | 12.33 | 7.55 | 3.51 | −1.66 | −3.98 |

| Prague–RH (%) | 77.2 | 72.4 | 67.6 | 60 | 57.9 | 57.9 | 66.1 | 62.7 | 72.4 | 75.5 | 78.2 | 77.6 |

| Šerák–RH (%) | 82.8 | 86.4 | 82.7 | 77.9 | 73 | 76.1 | 82.6 | 83.7 | 83.1 | 87.9 | 93 | 87 |

| Location | Plaster | Heat Transmission per Unit Area of the Wall (kWh·m−2·a−1) | Savings on Heating (%) |

|---|---|---|---|

| Šerák | RP | 79.55 | - |

| P8 | 72.98 | 8.26 | |

| P16 | 72.04 | 9.45 | |

| P24 | 69.94 | 12.08 | |

| Prague | RP | 71.27 | - |

| P8 | 66.22 | 7.09 | |

| P16 | 65 | 8.8 | |

| P24 | 63.13 | 11.36 |

| Location | Plaster | Recuperation Heat per Unit Area of the Wall (kWh·m−2·a−1) | Improvement (%) |

|---|---|---|---|

| Šerák | RP | 52.16 | - |

| P8 | 59.1 | 13.3 | |

| P16 | 60.27 | 15.53 | |

| P24 | 62.13 | 19.09 | |

| Prague | RP | 57.39 | - |

| P8 | 62.33 | 8.61 | |

| P16 | 63.22 | 10.15 | |

| P24 | 64.97 | 13.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fořt, J.; Šál, J.; Kočí, J.; Černý, R. Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies 2020, 13, 2012. https://doi.org/10.3390/en13082012

Fořt J, Šál J, Kočí J, Černý R. Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies. 2020; 13(8):2012. https://doi.org/10.3390/en13082012

Chicago/Turabian StyleFořt, Jan, Jiří Šál, Jan Kočí, and Robert Černý. 2020. "Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes" Energies 13, no. 8: 2012. https://doi.org/10.3390/en13082012

APA StyleFořt, J., Šál, J., Kočí, J., & Černý, R. (2020). Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies, 13(8), 2012. https://doi.org/10.3390/en13082012