Energy Efficiency Comparison of Hydraulic Accumulators and Ultracapacitors

Abstract

1. Introduction

2. Relevance of This Work

3. Test Bench Description

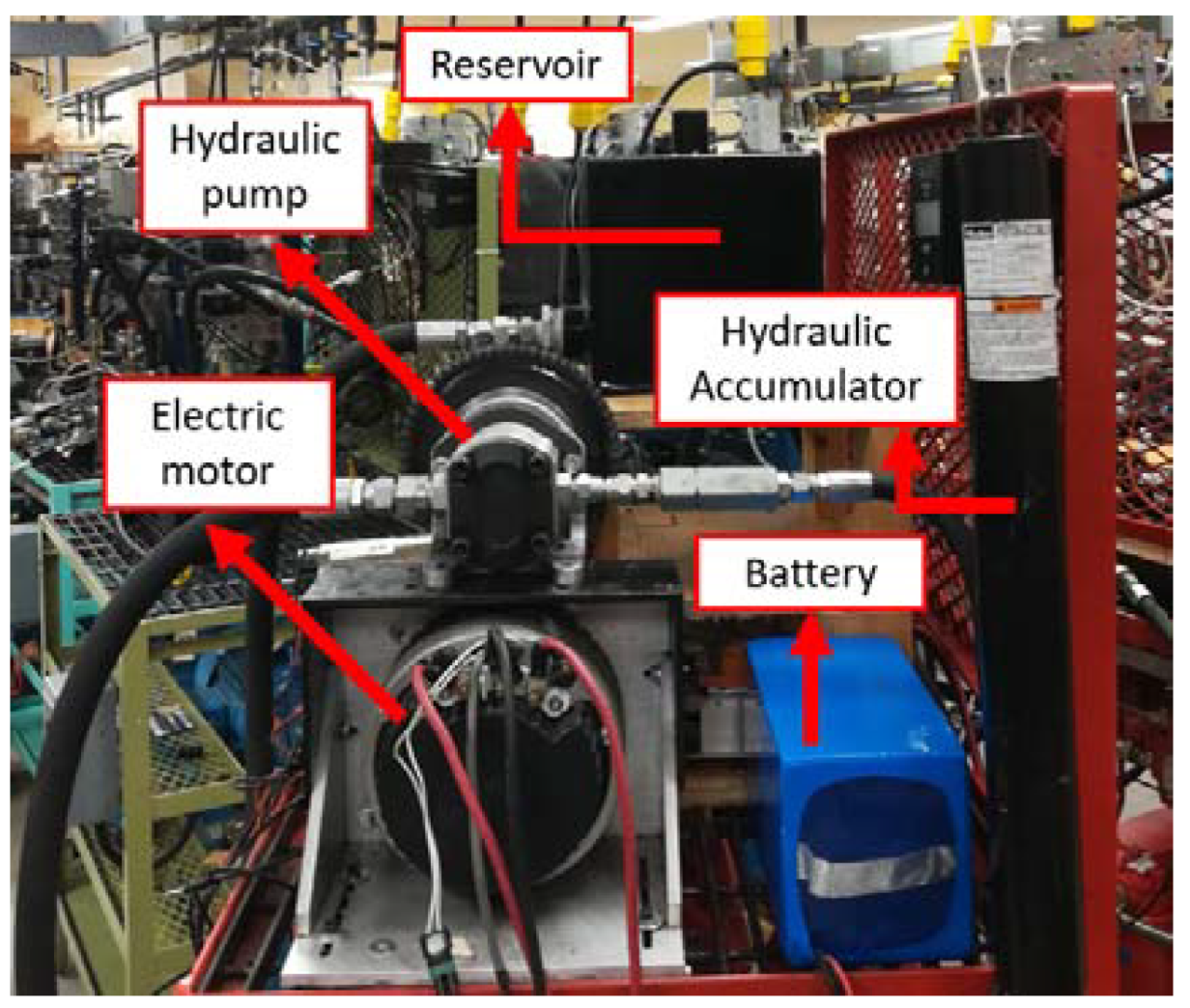

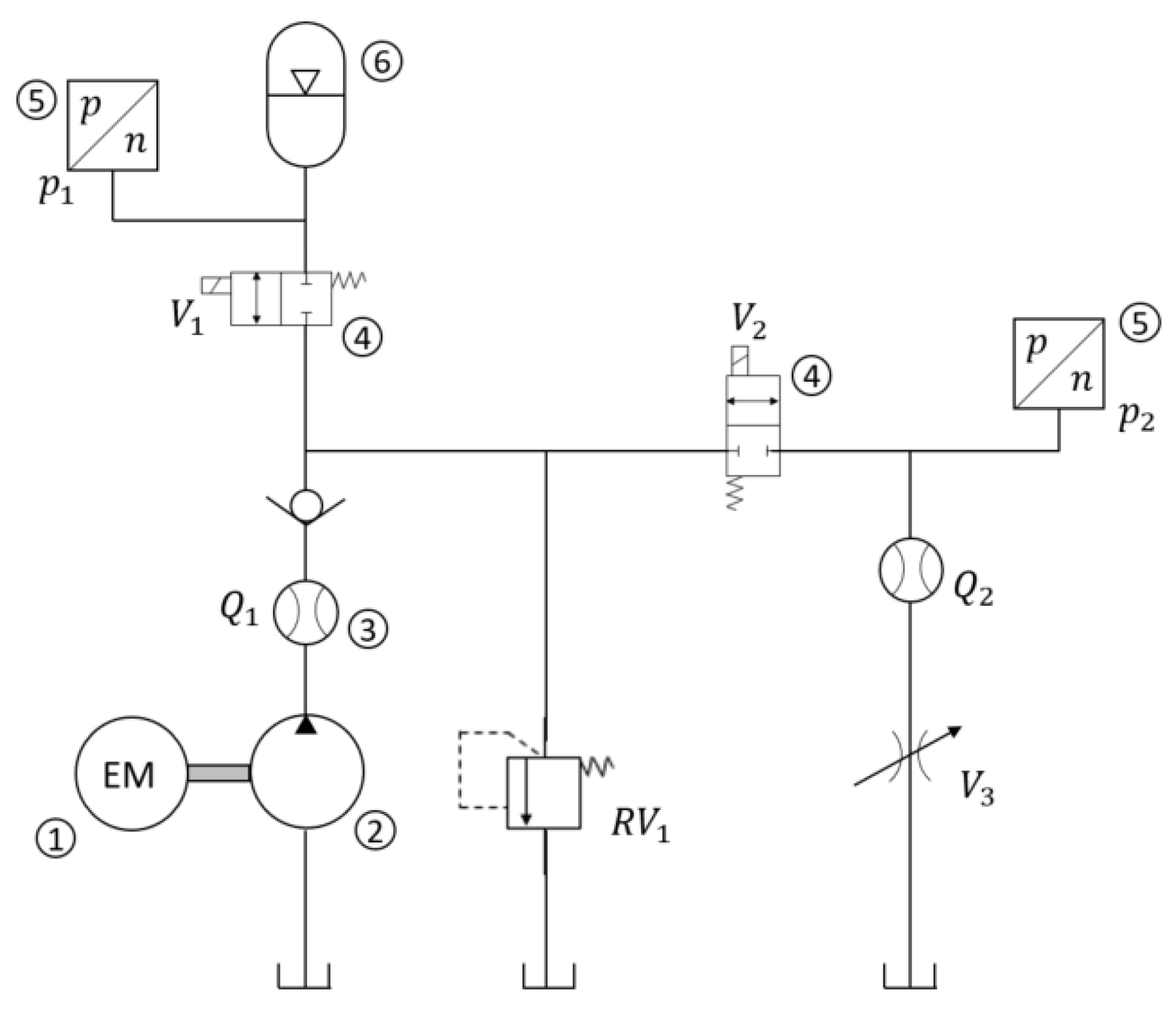

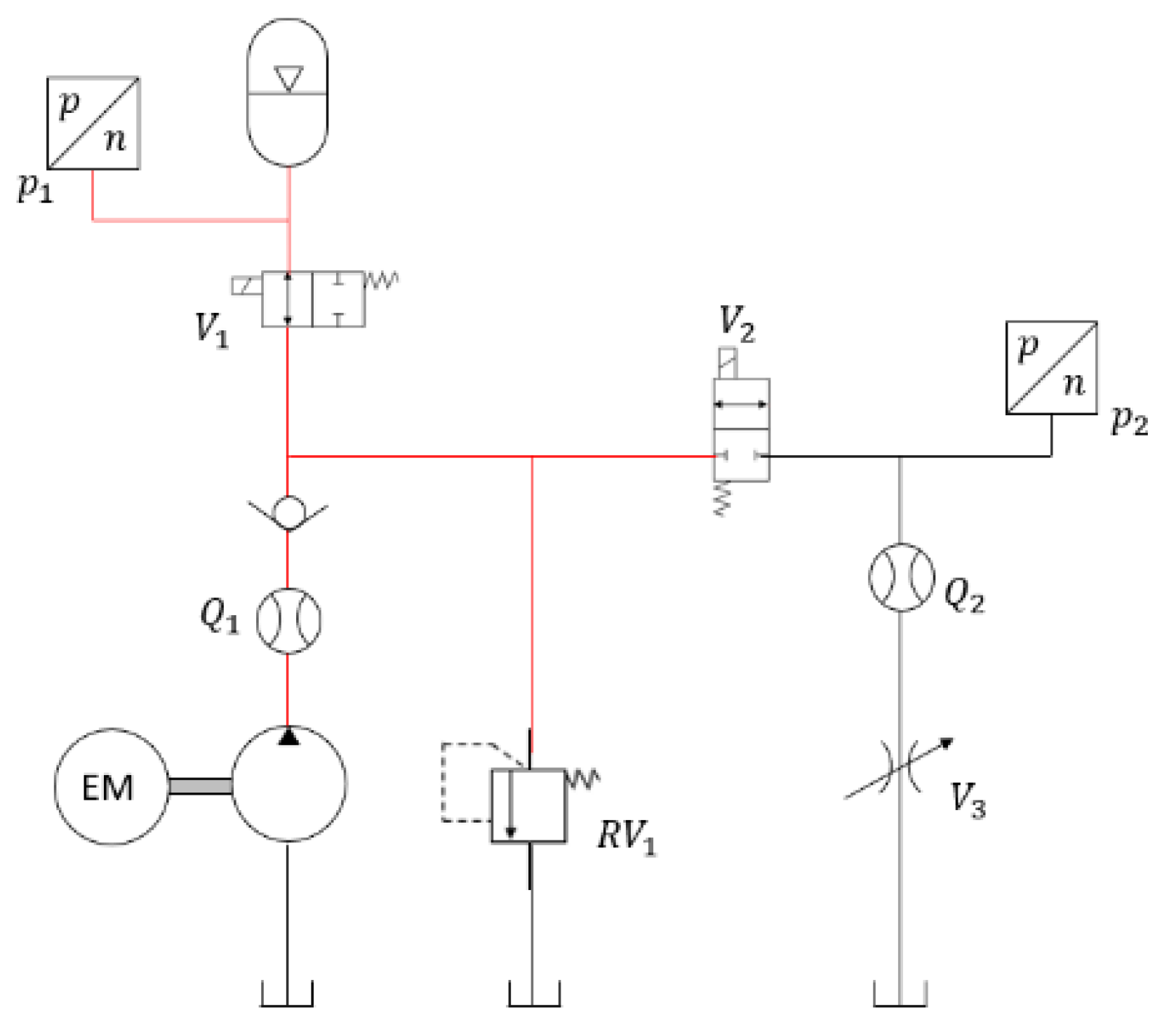

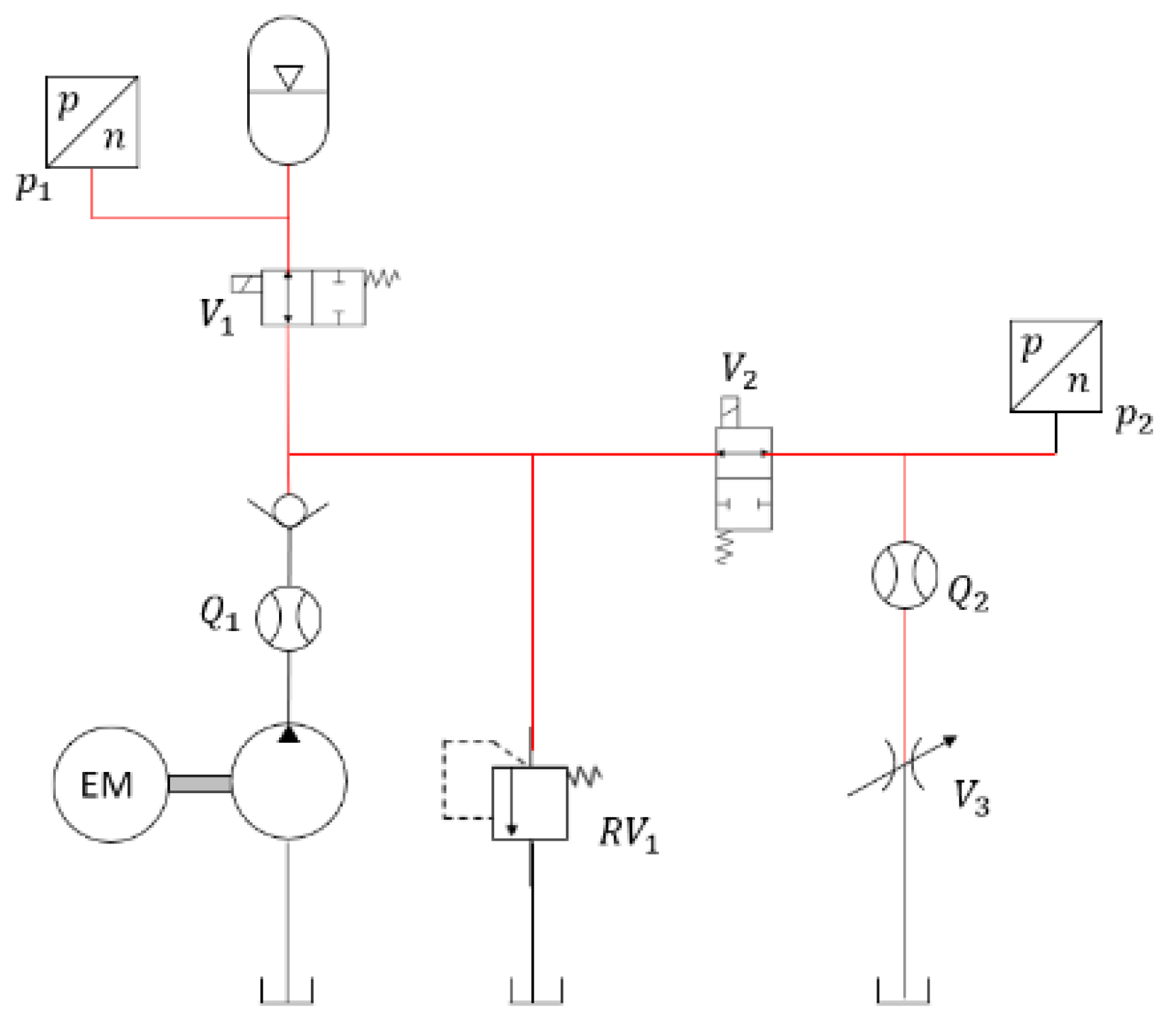

3.1. Hydraulic Test Bench

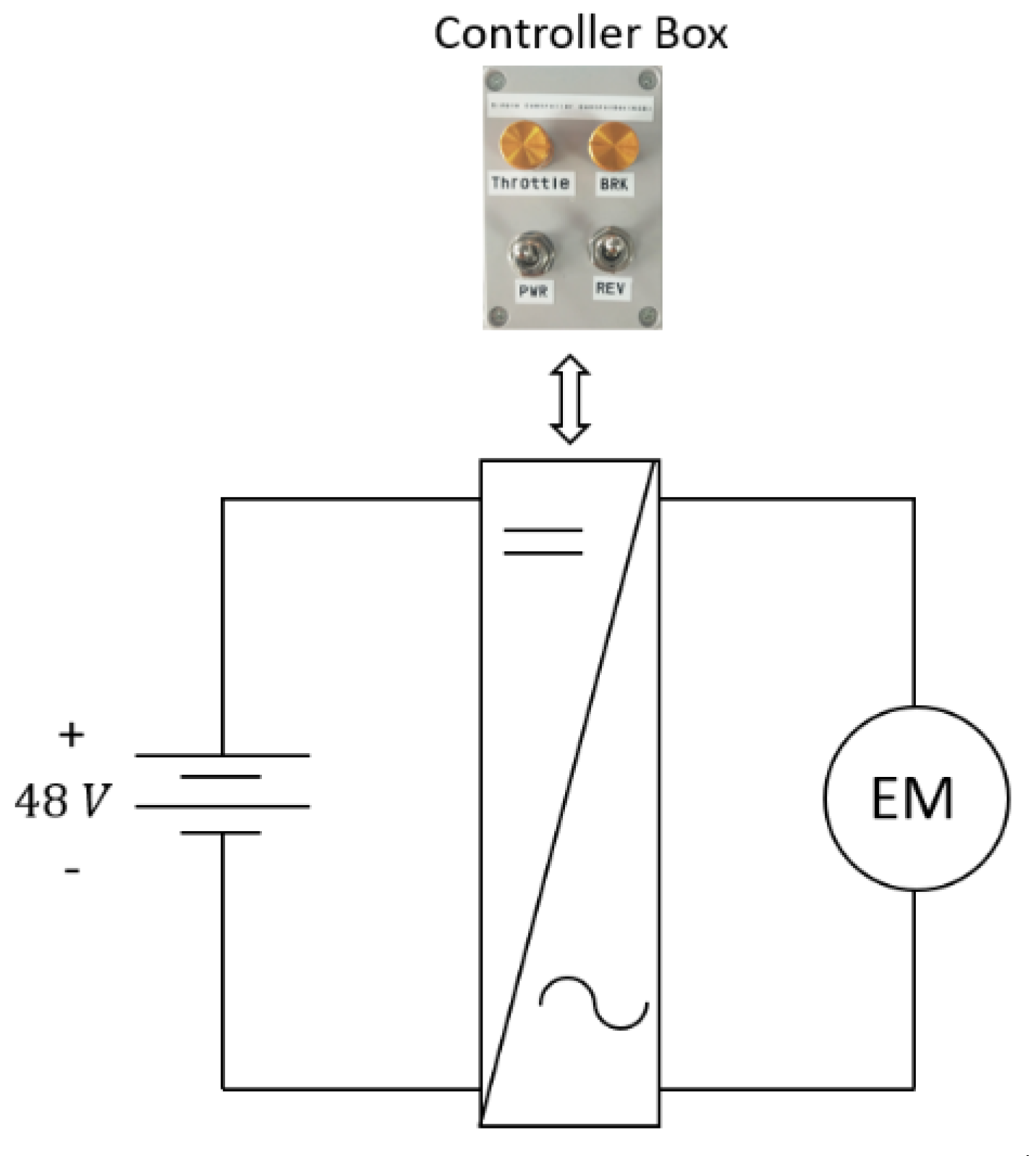

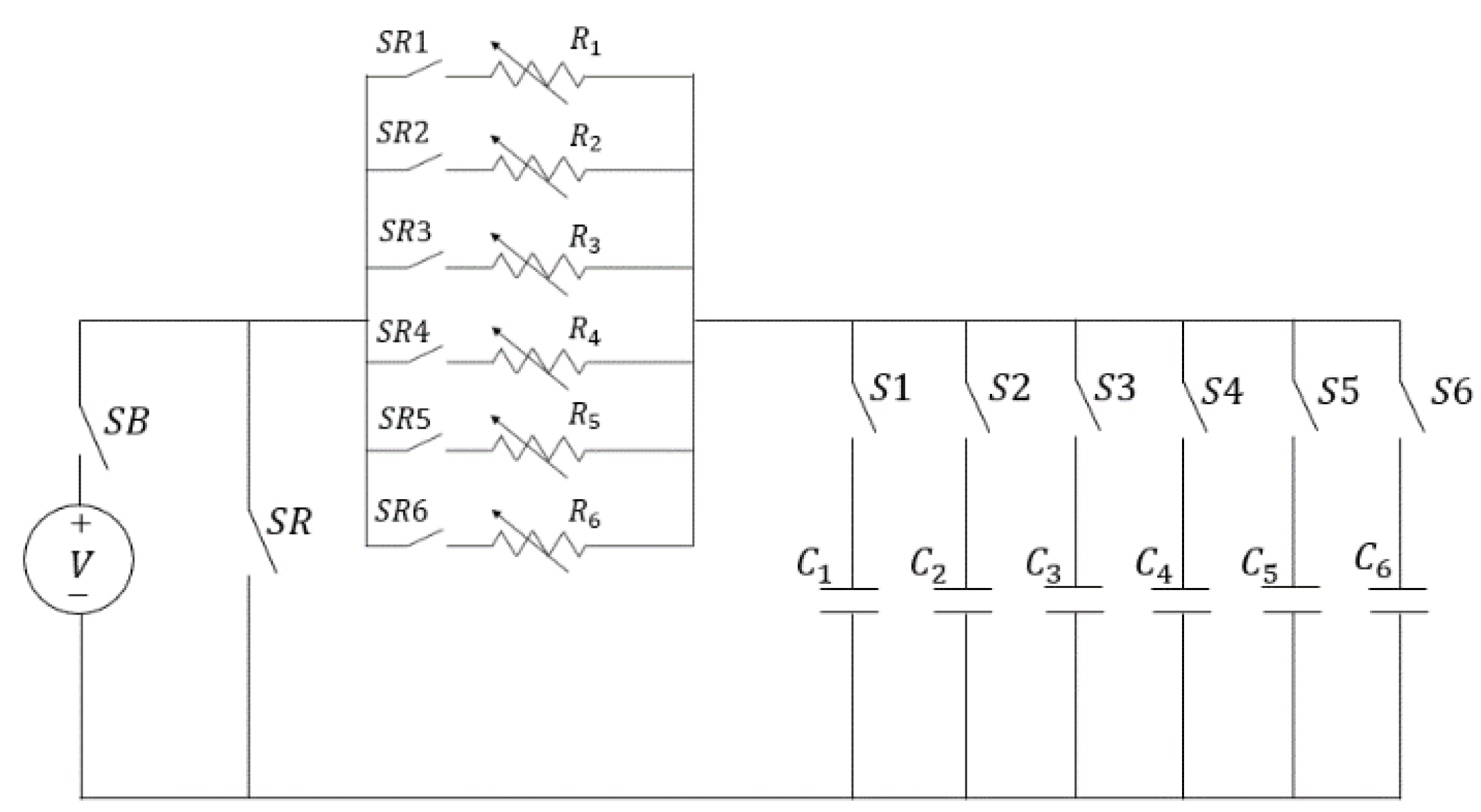

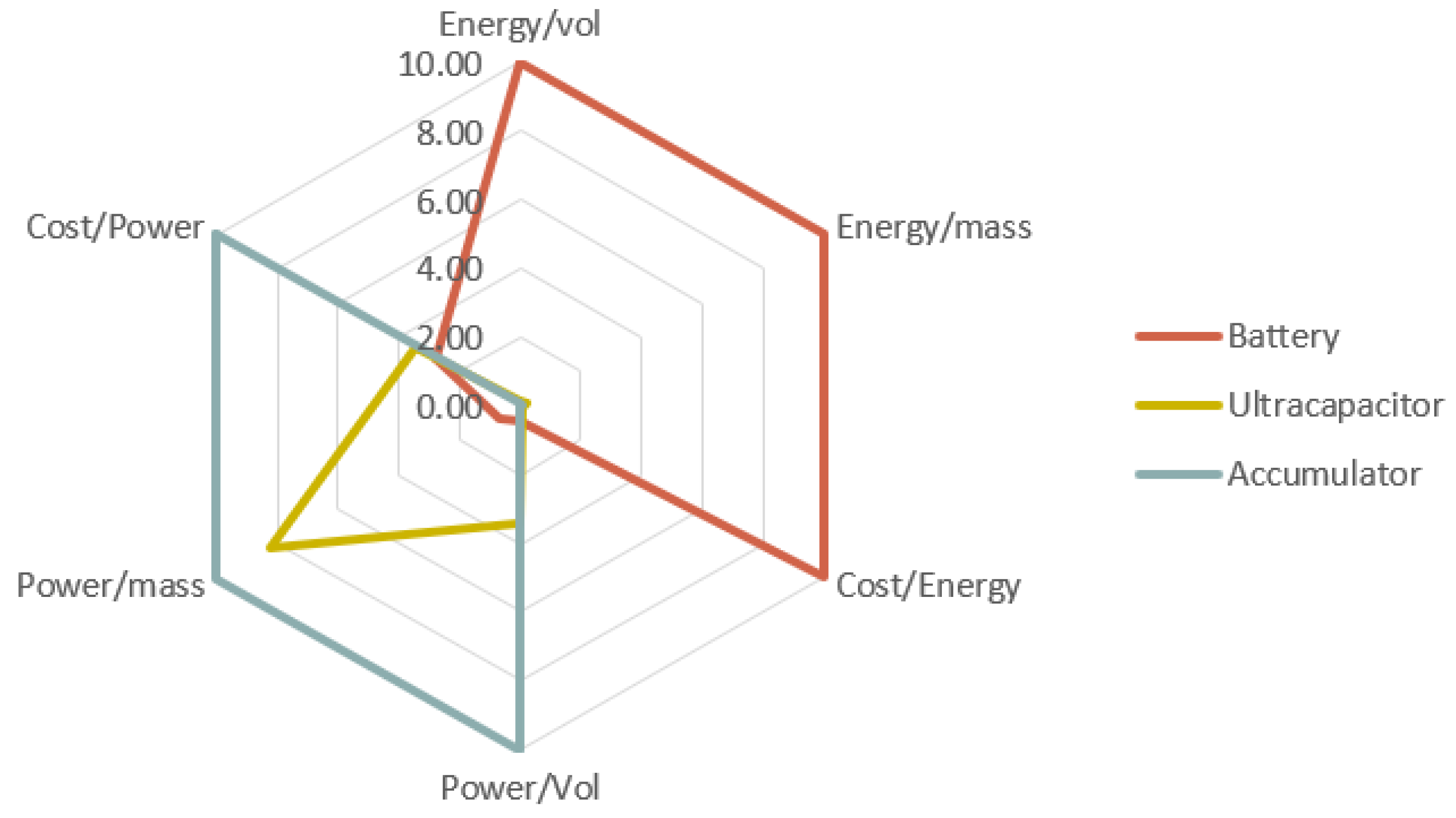

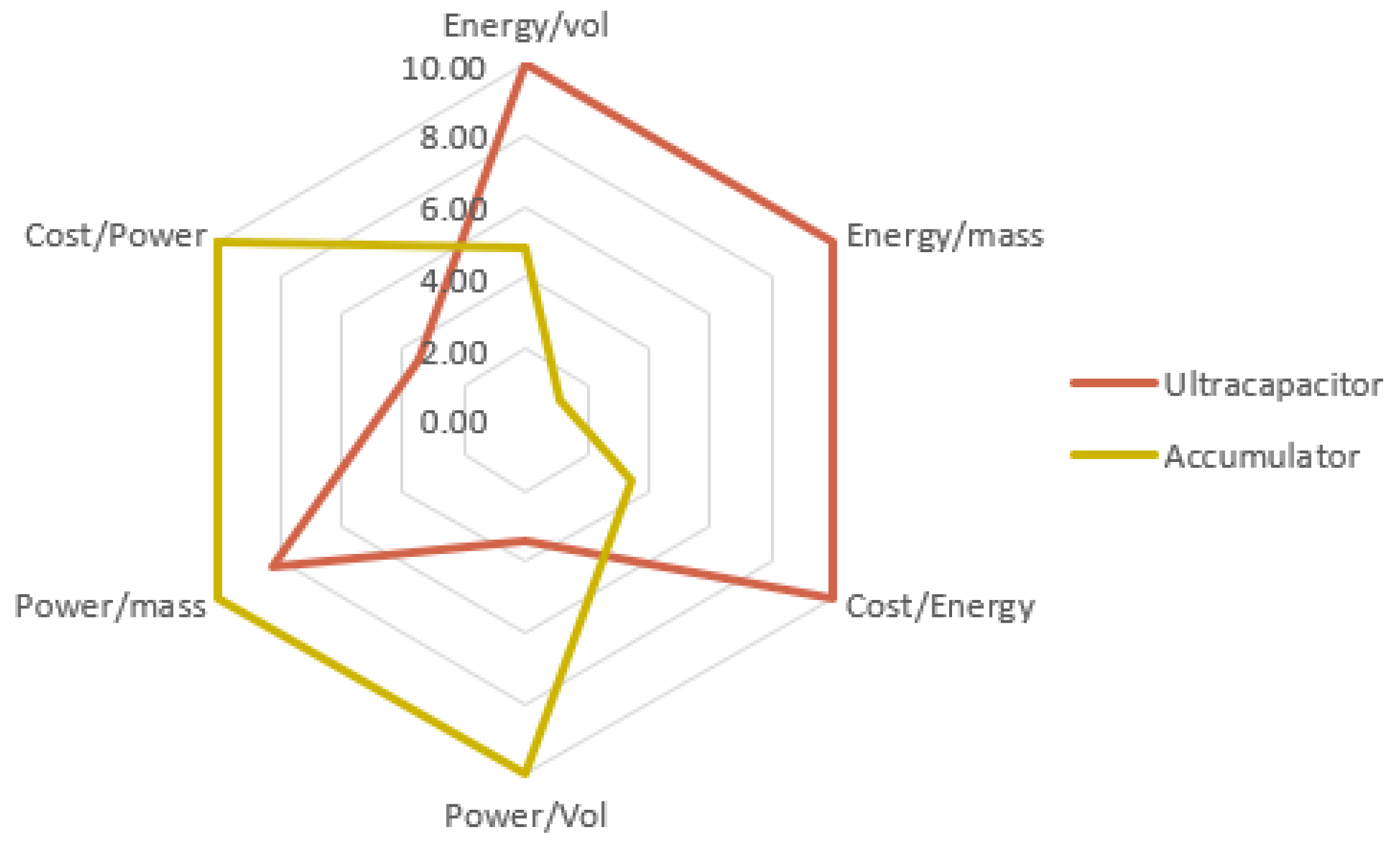

3.2. Electric Test Bench

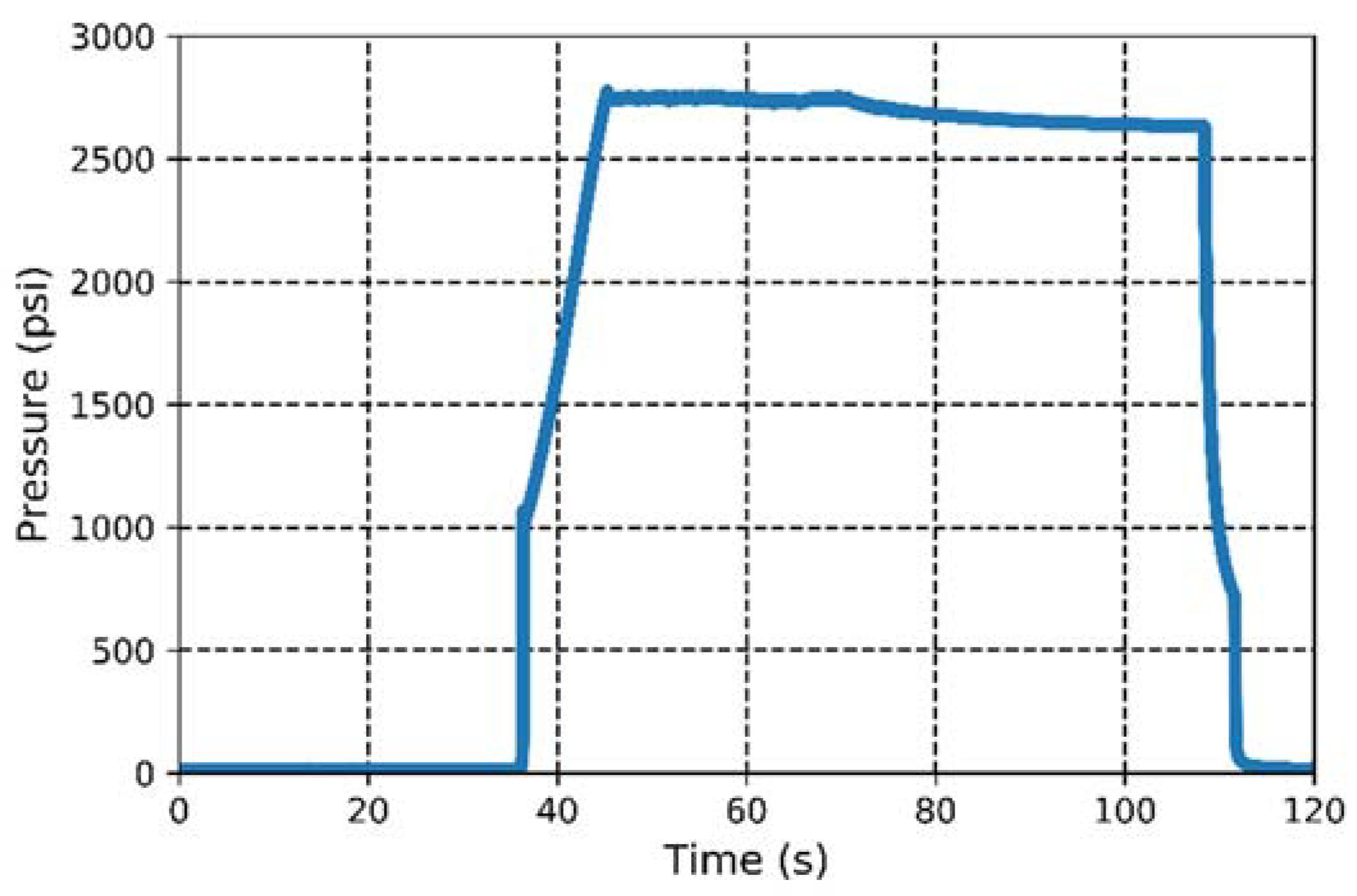

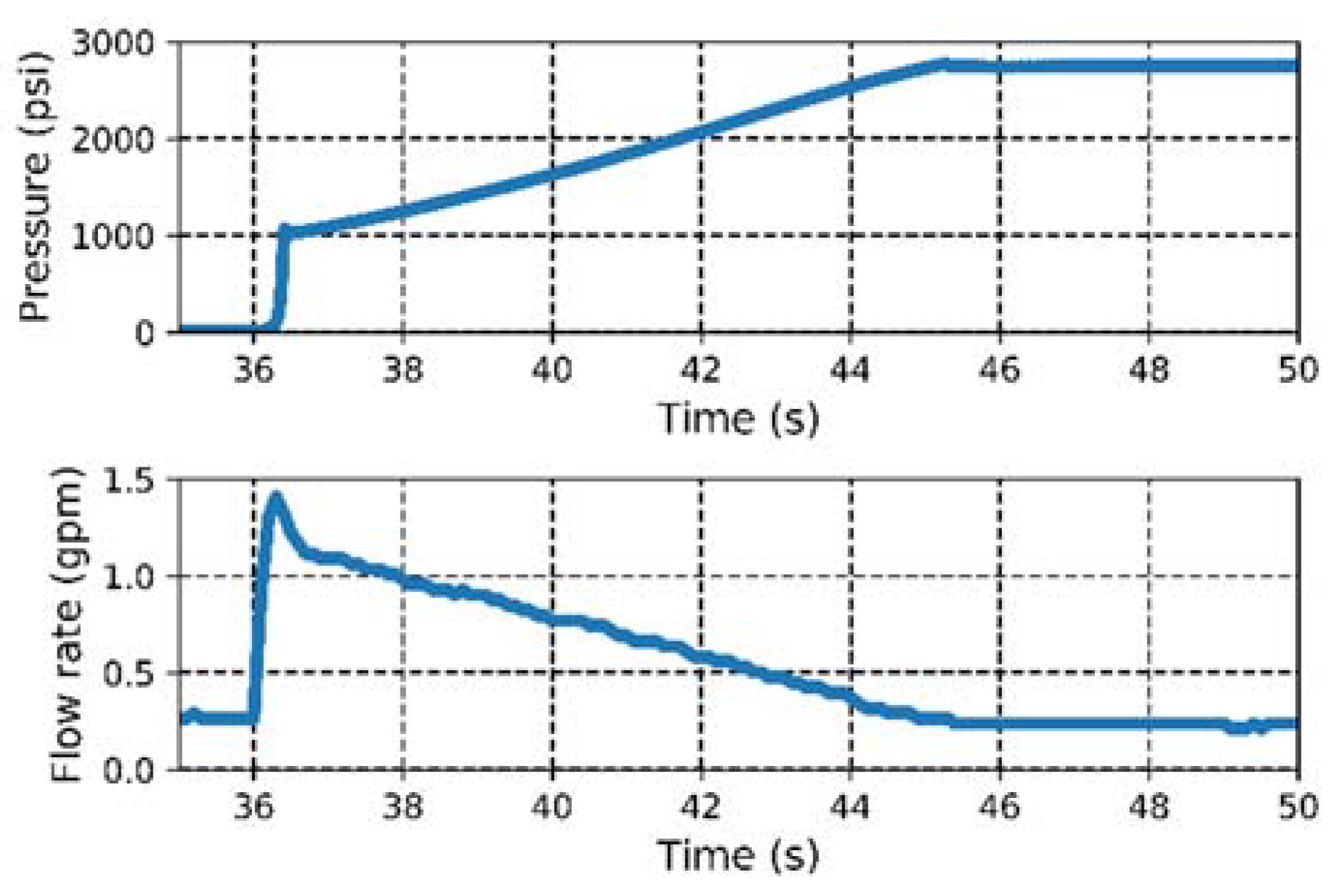

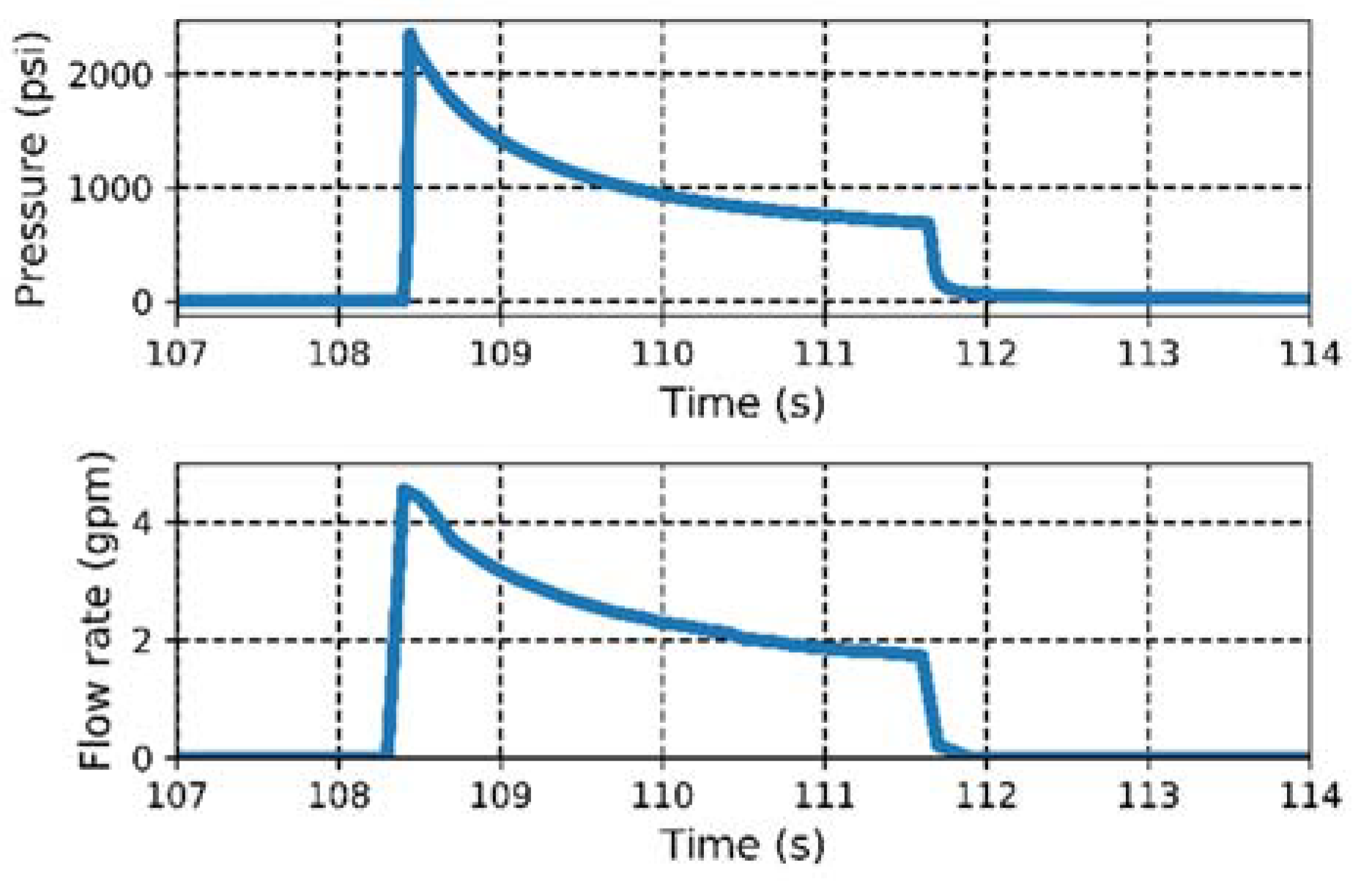

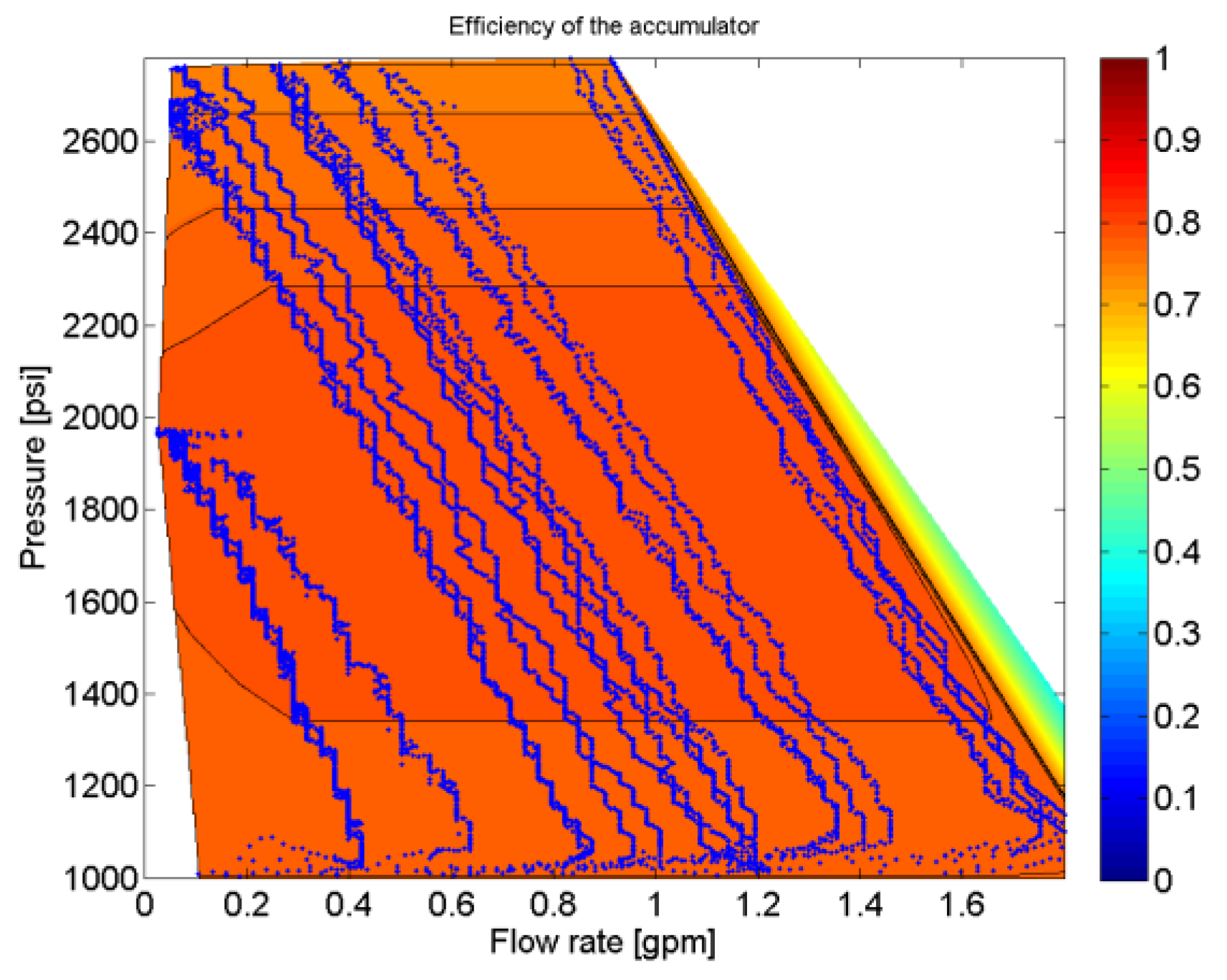

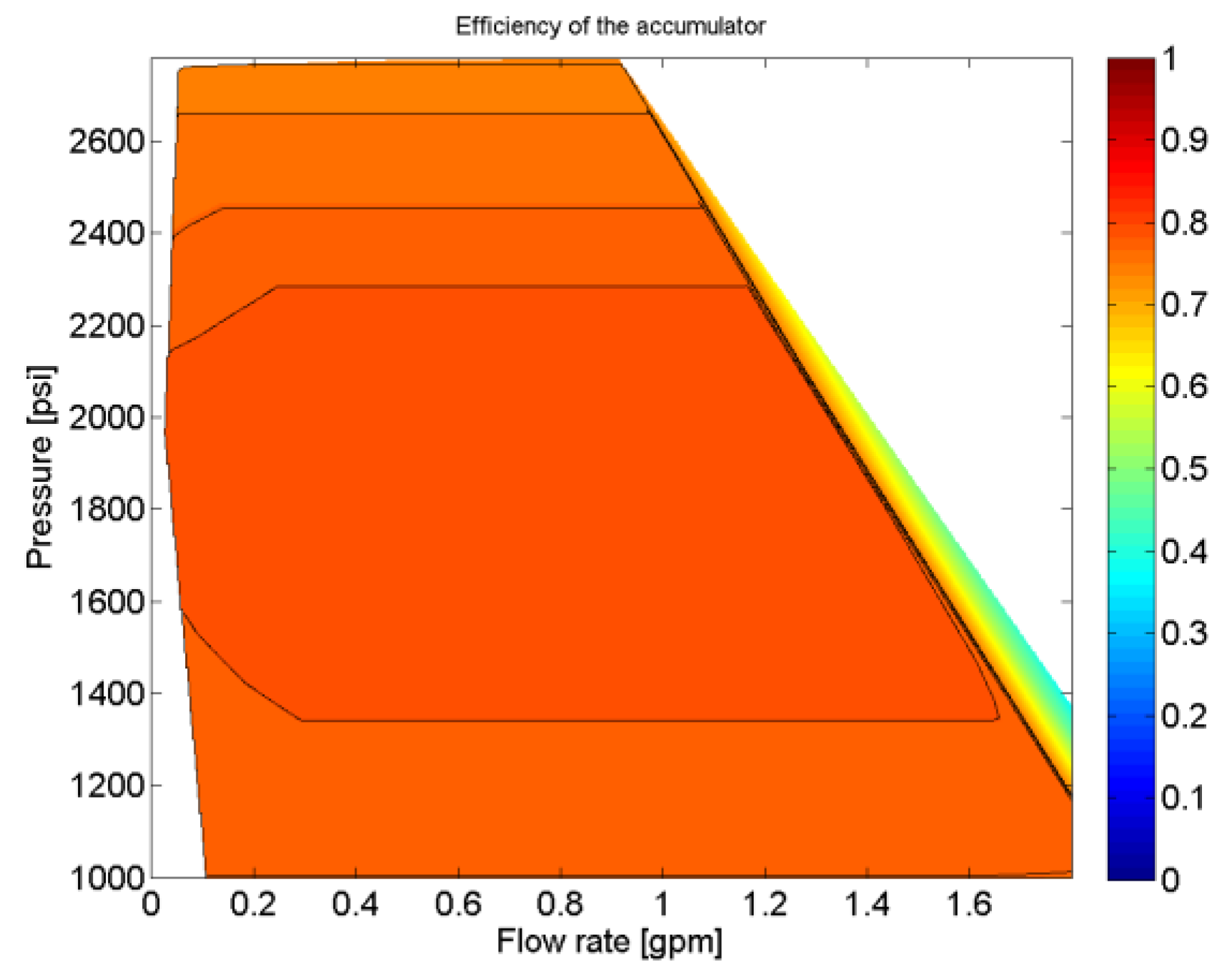

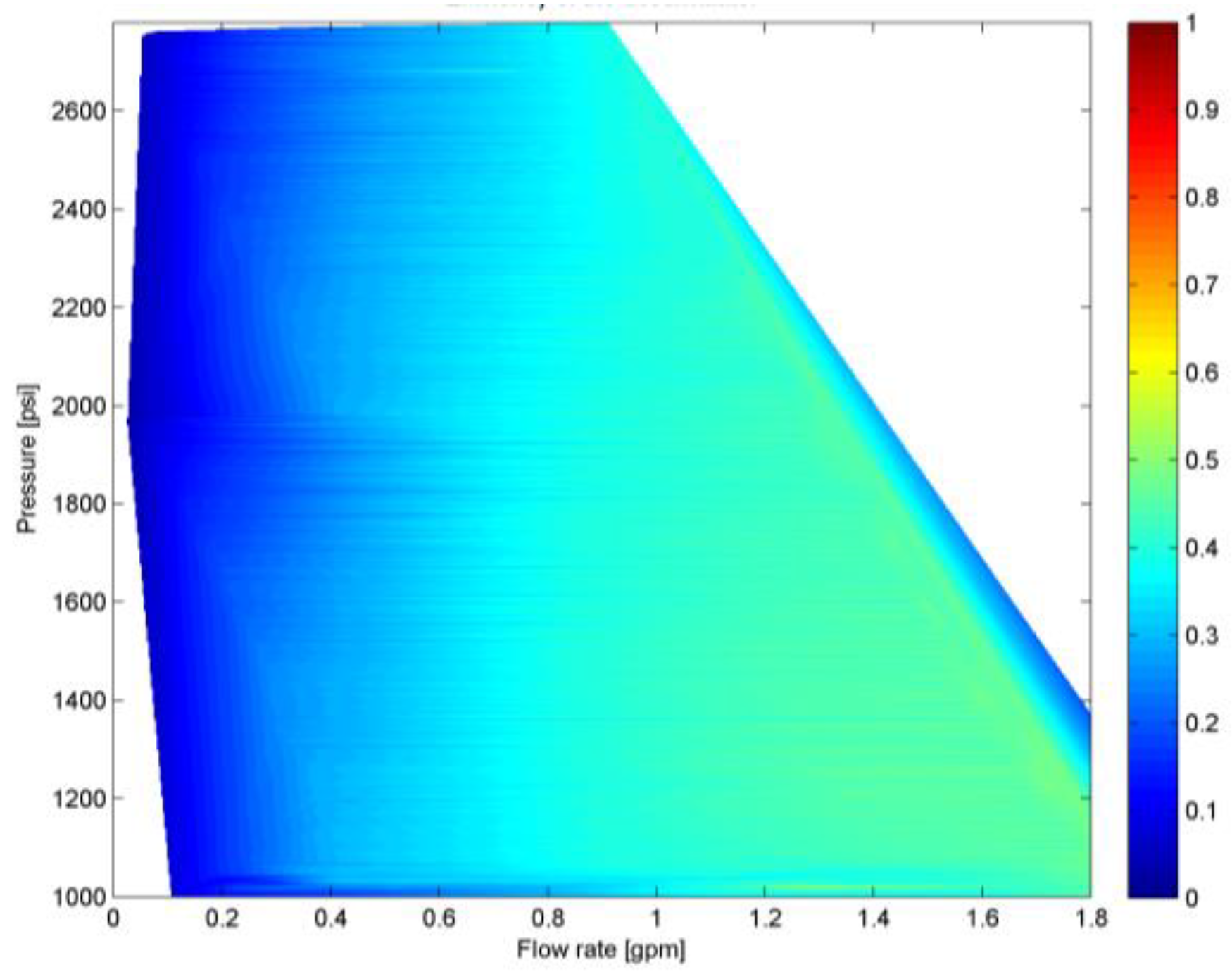

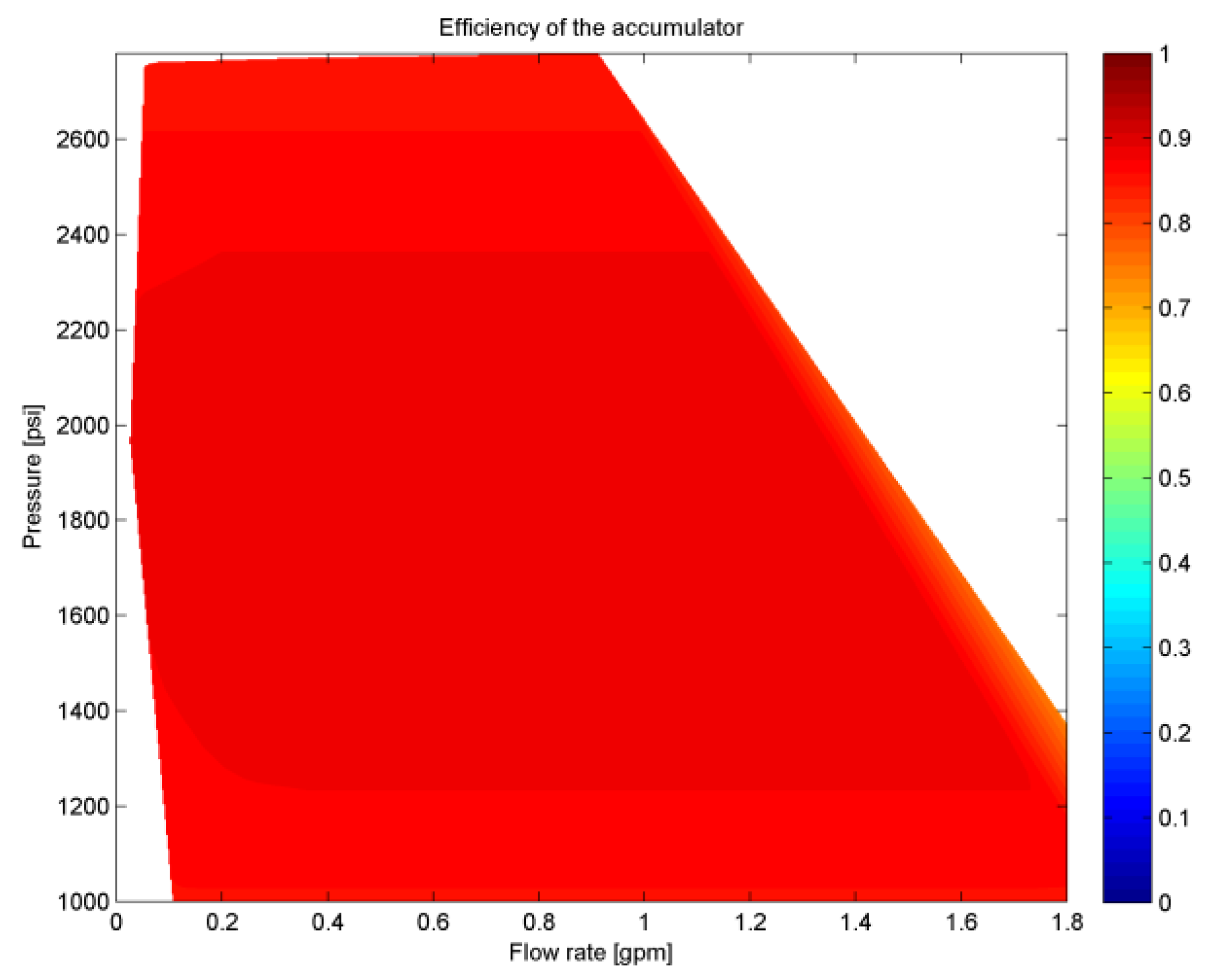

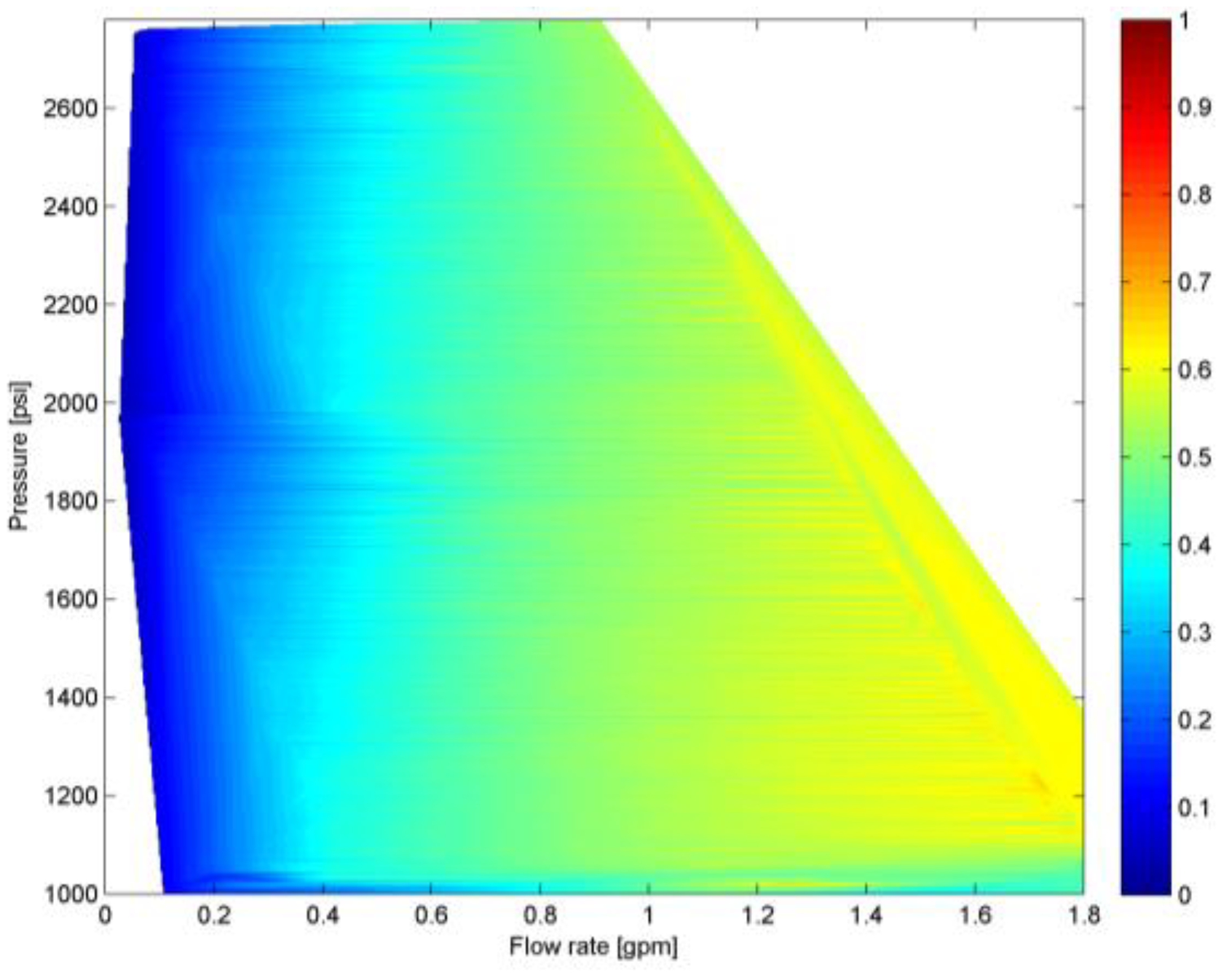

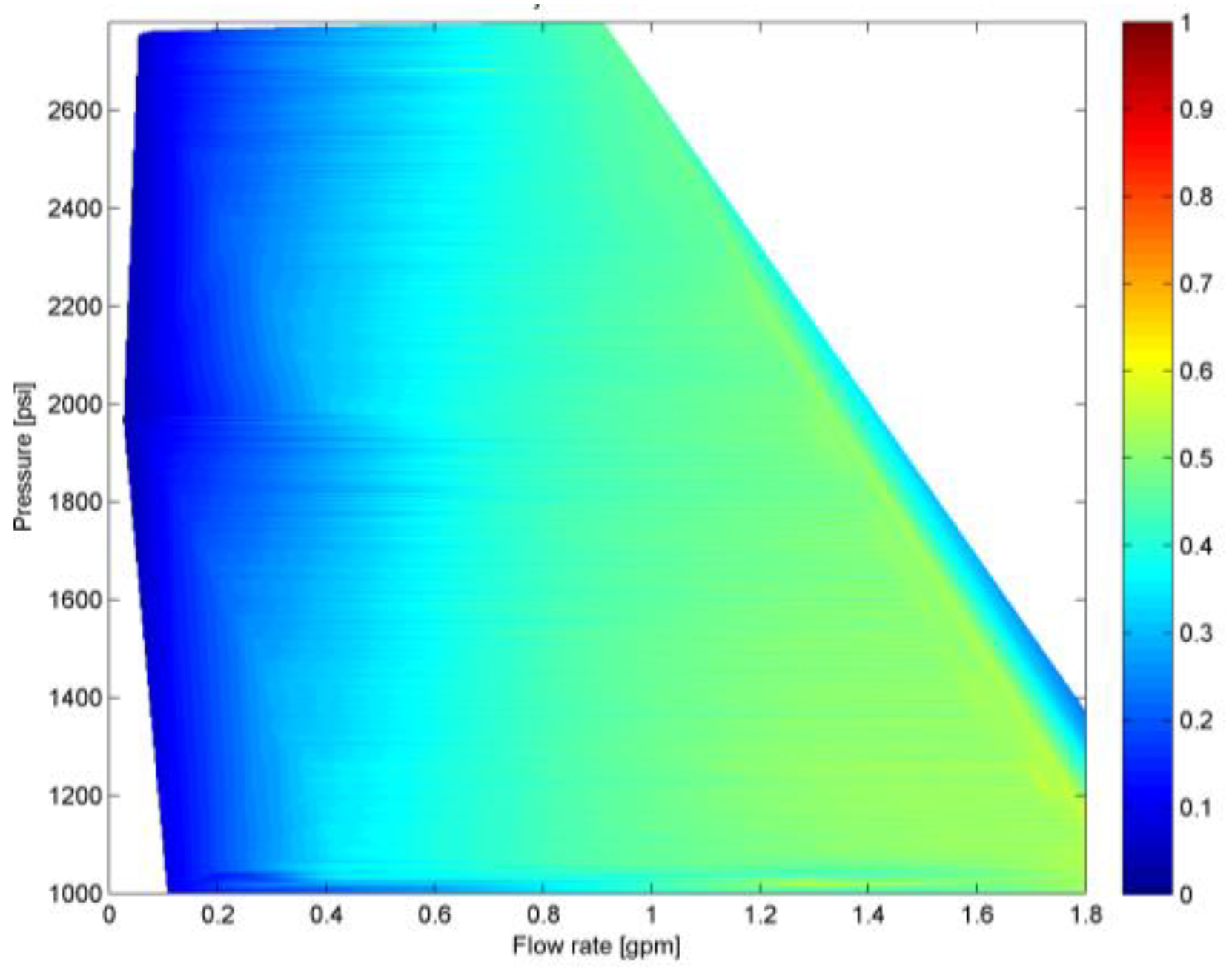

4. Results for the Hydraulic Accumulator

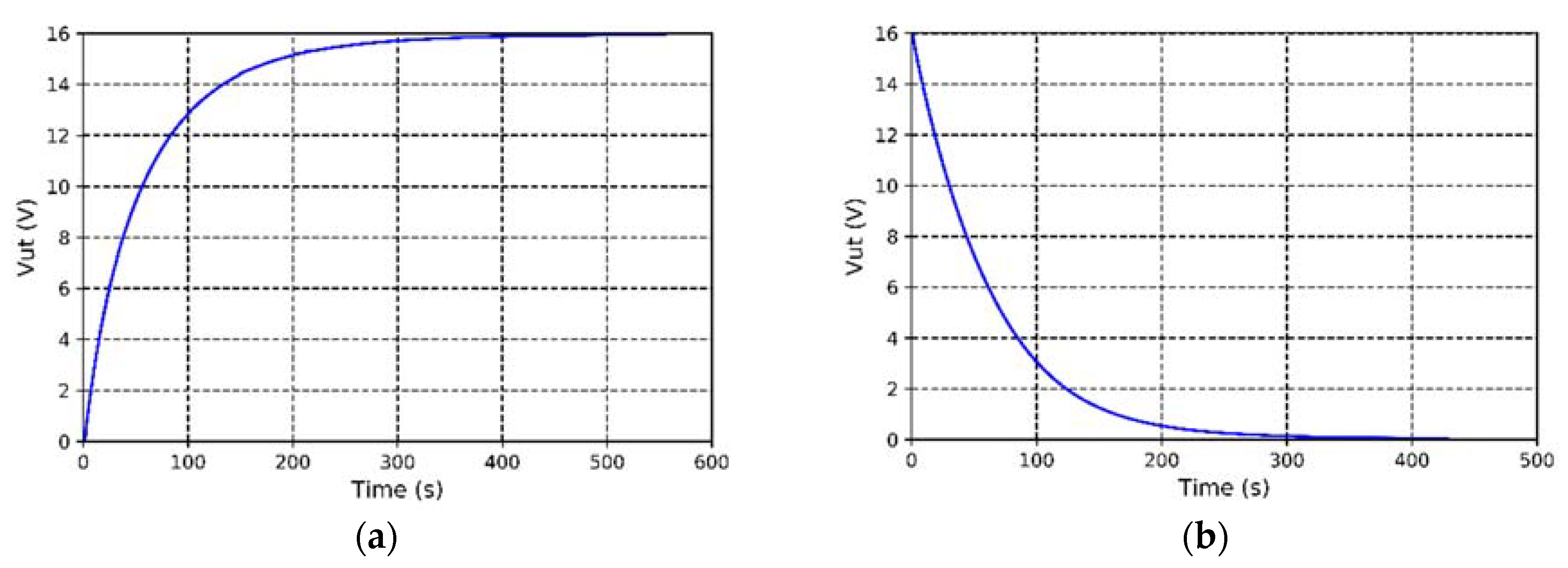

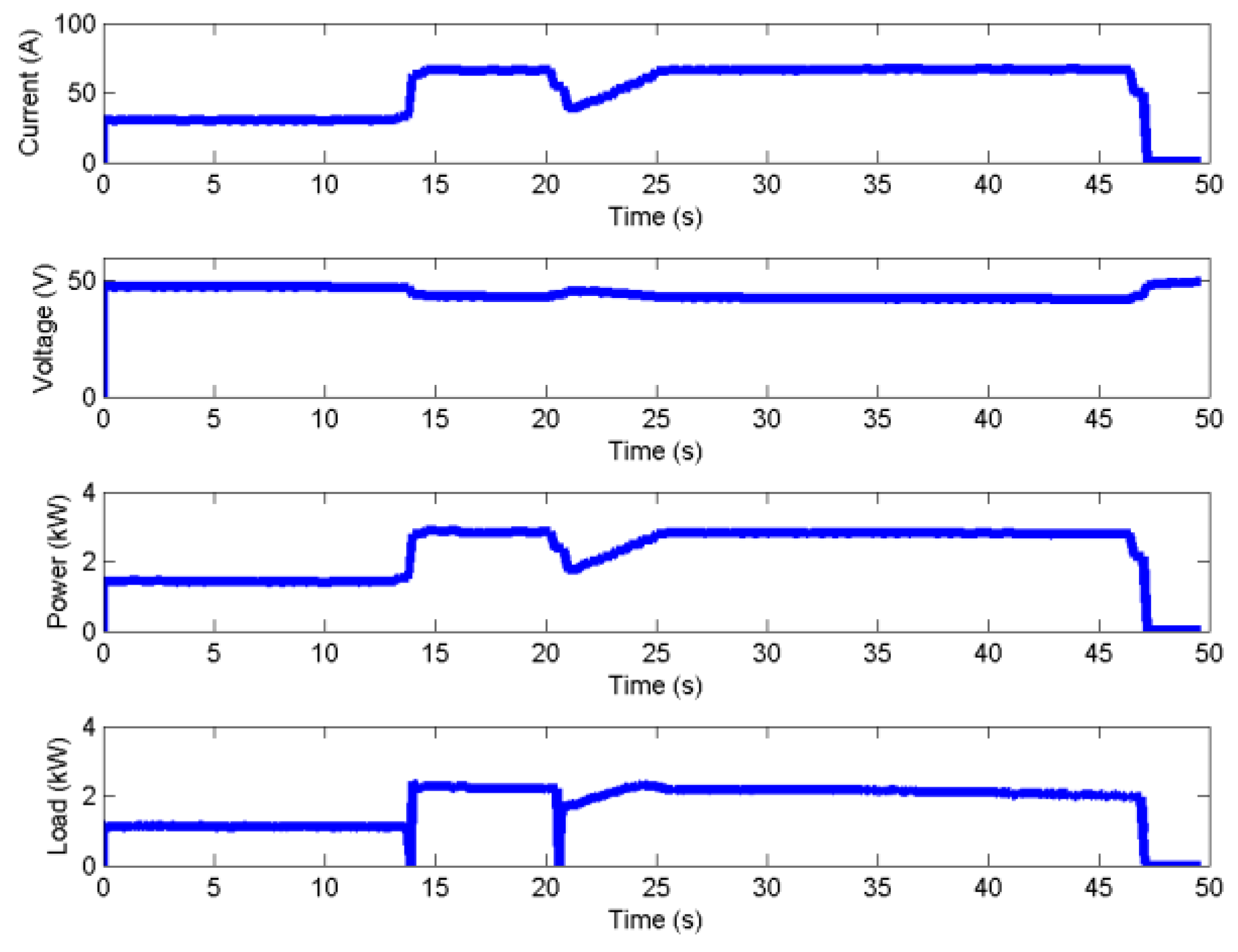

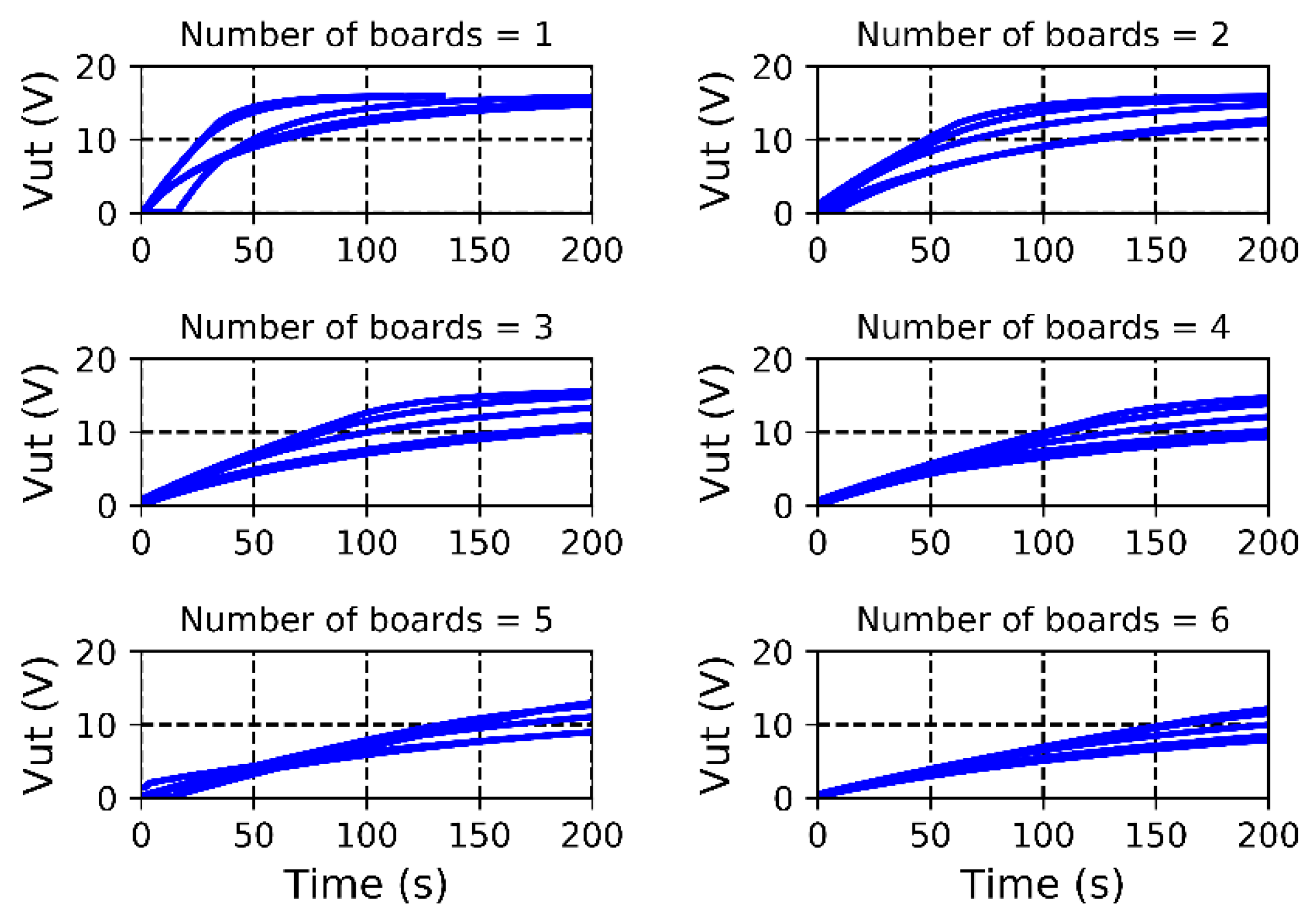

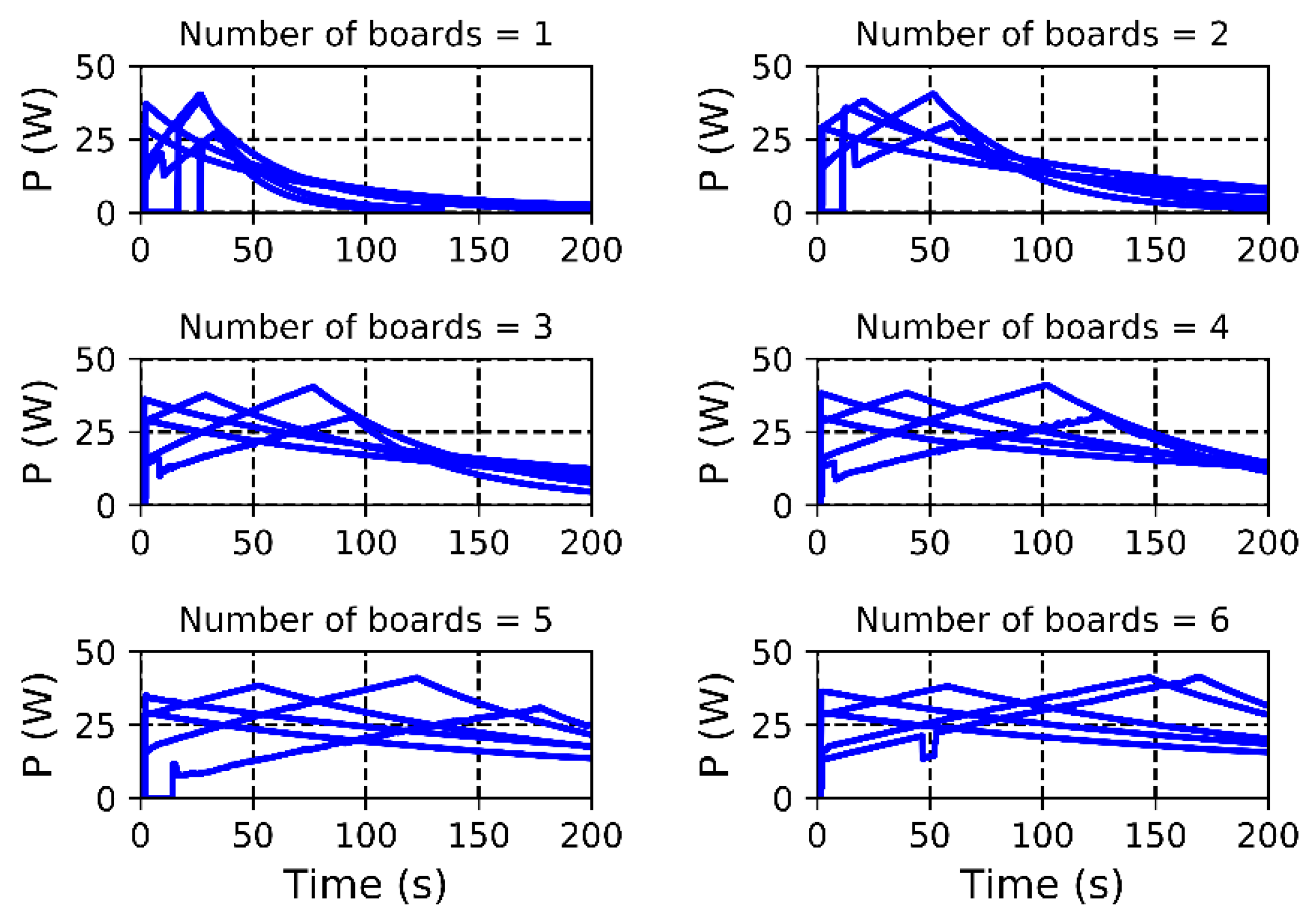

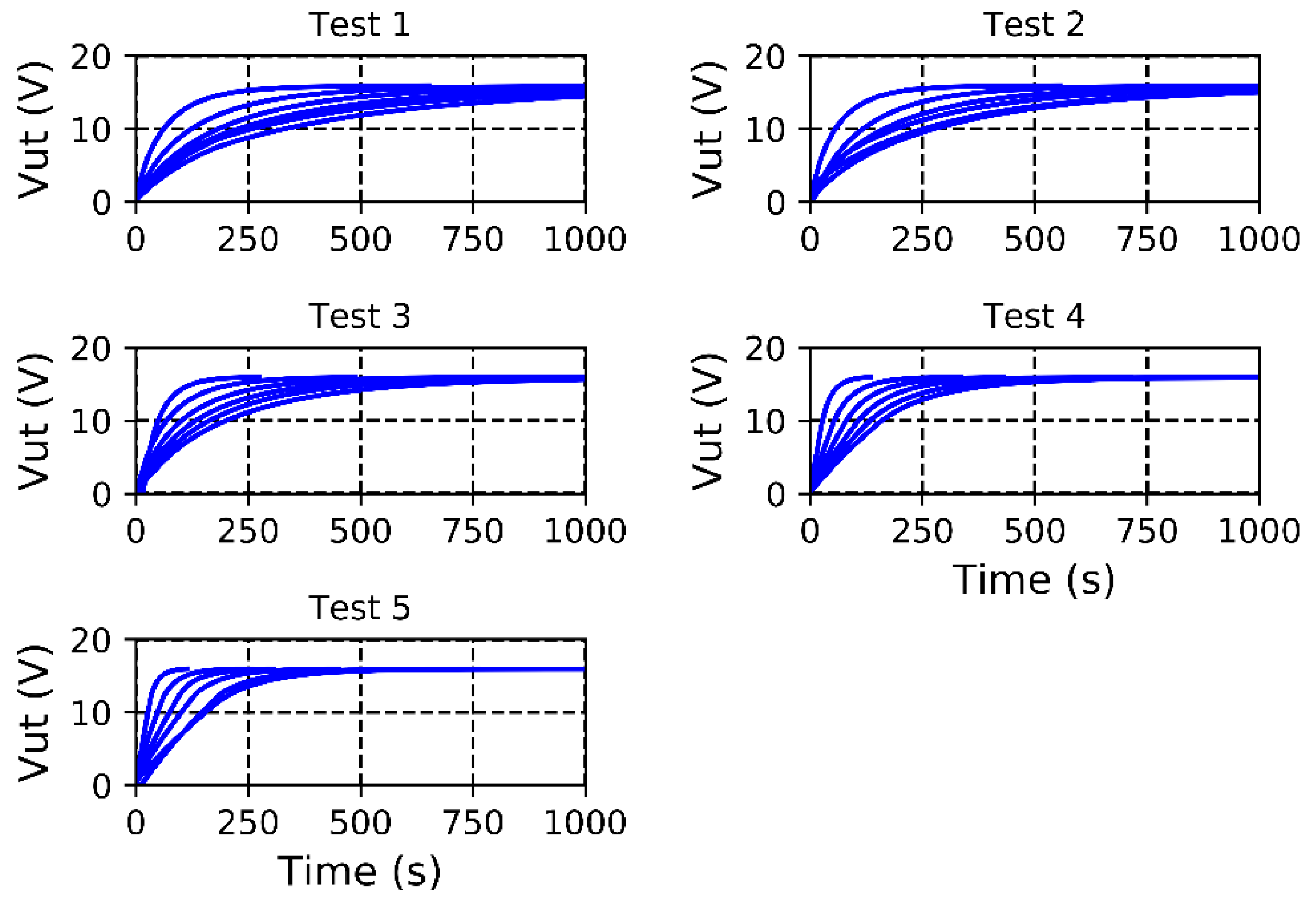

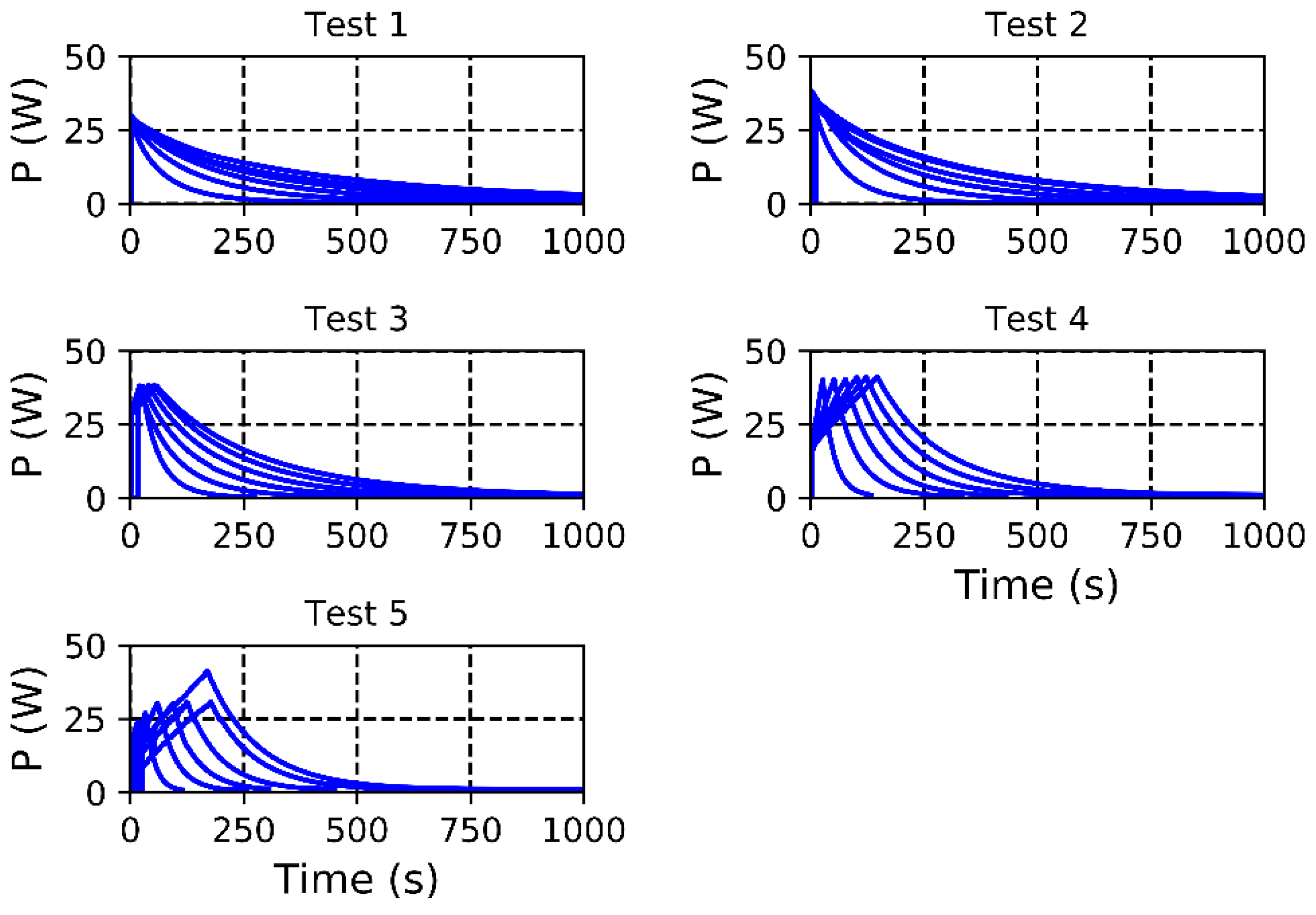

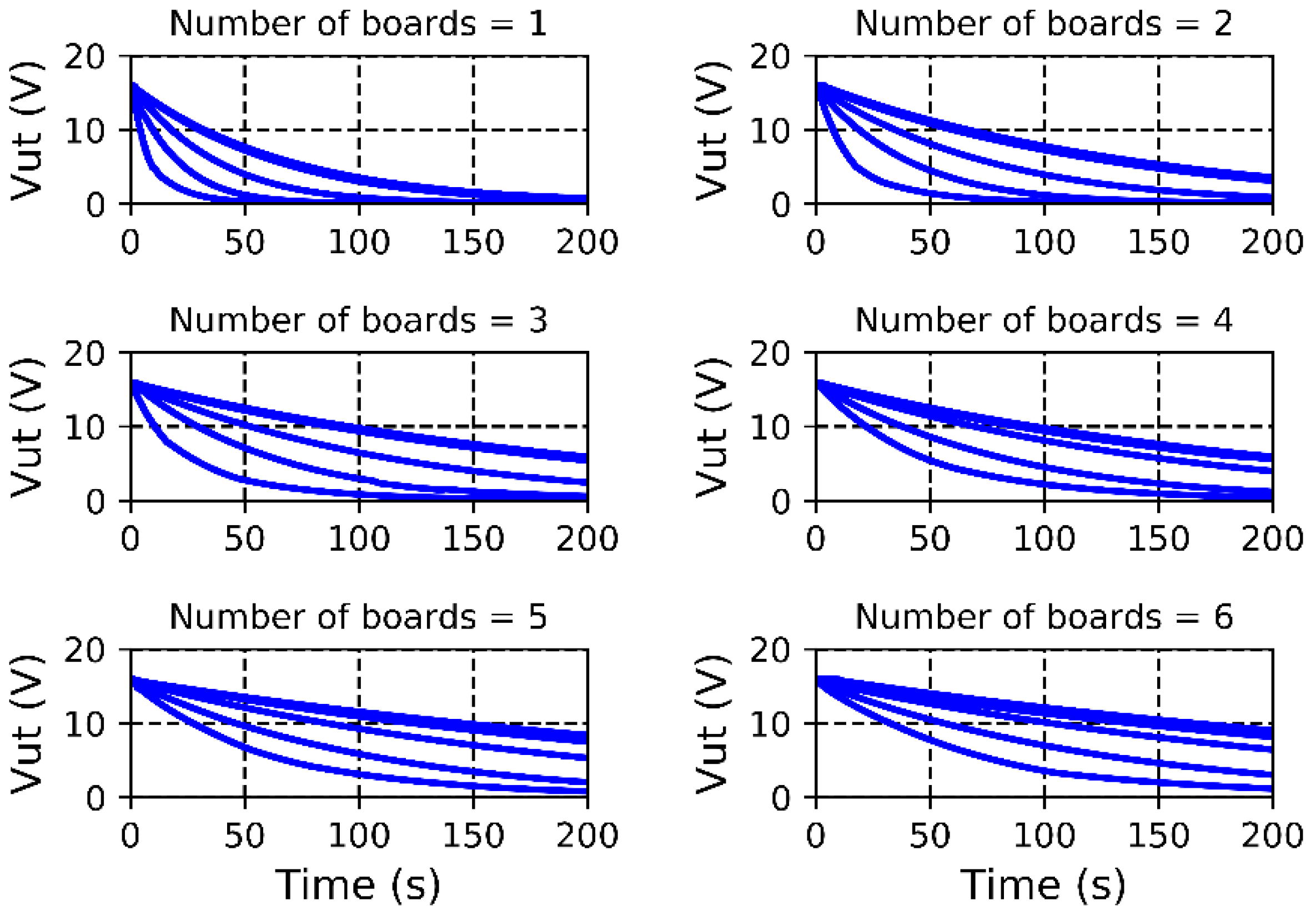

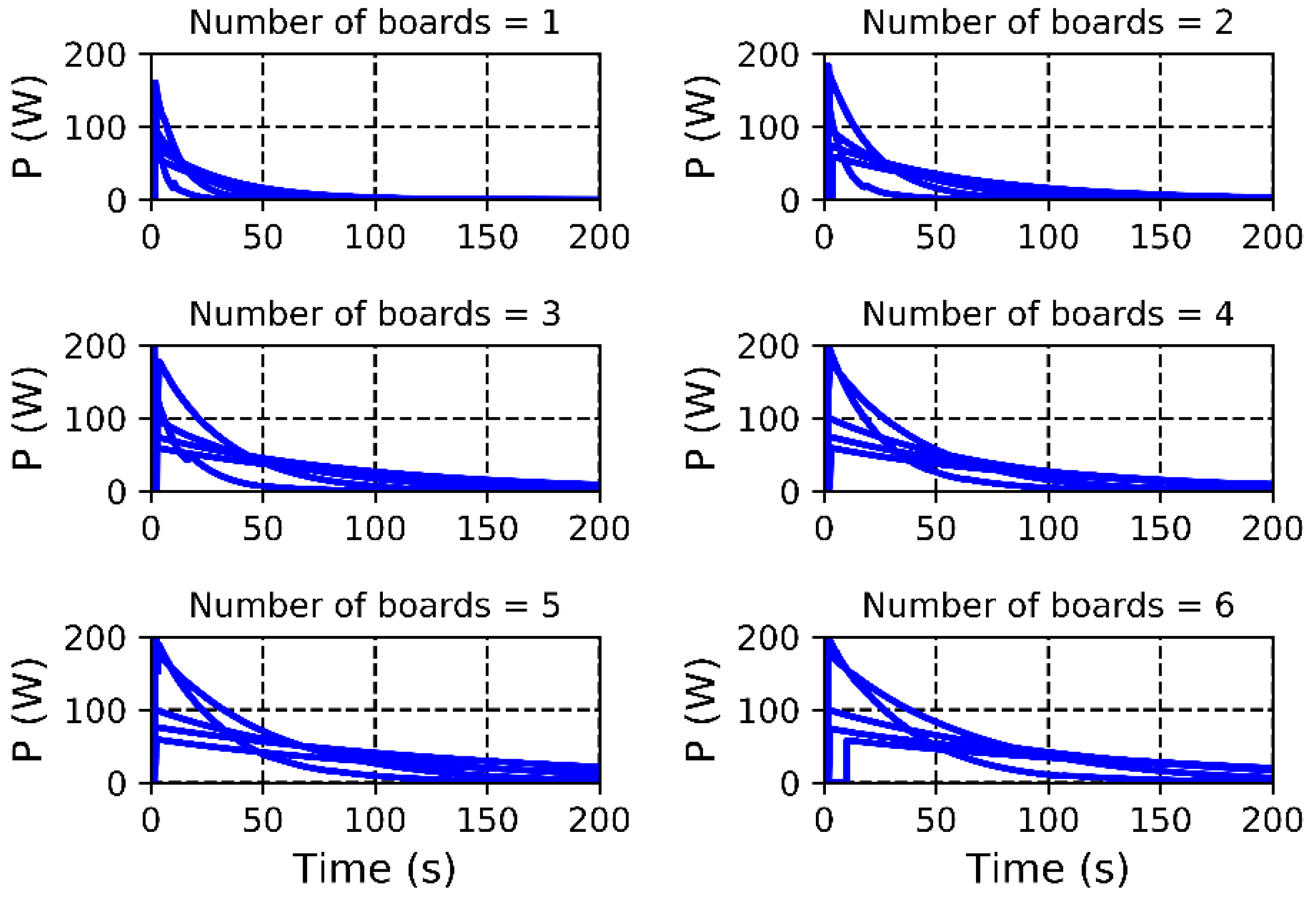

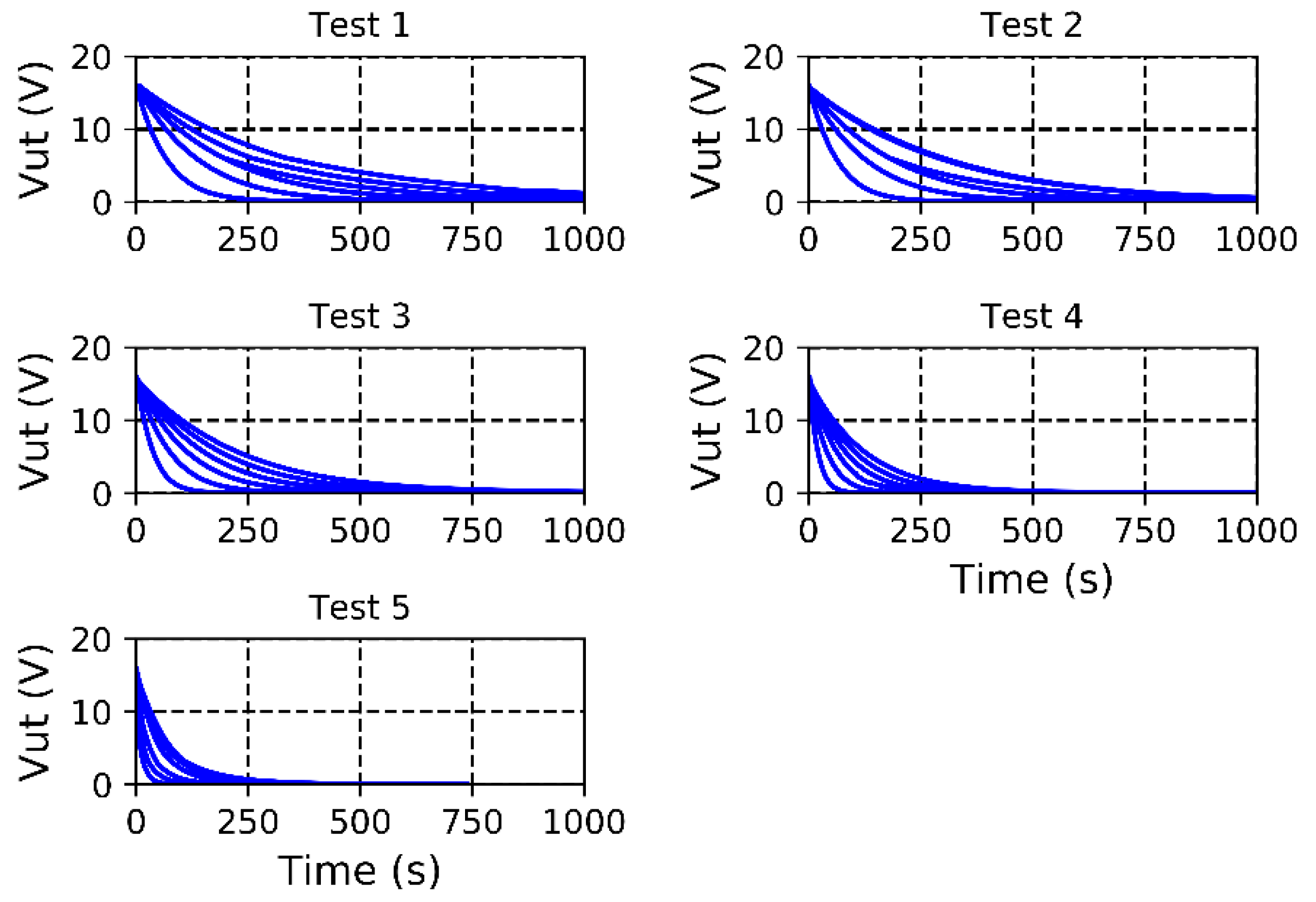

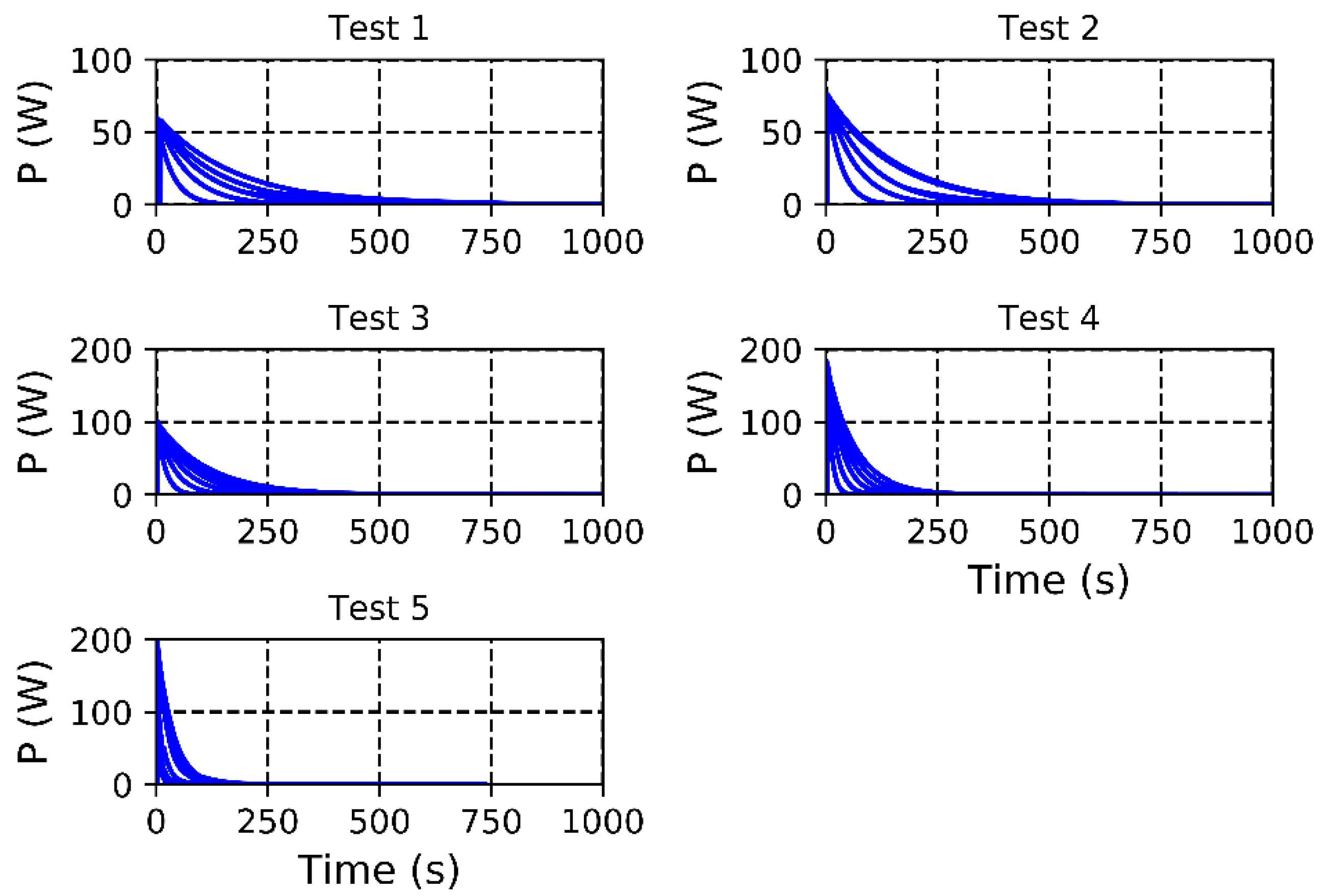

5. Results for the Ultracapacitors

6. Comparative Evaluation

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Energy Information Administration. Monthly Energy Review; U.S. Energy Information Administration: Washington, DC, USA, 2019. [Google Scholar]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Development of hybrid powered hydraulic construction machinery. Autom. Constr. 2010, 19, 11–19. [Google Scholar] [CrossRef]

- Kwon, T.S.; Lee, S.W.; Sul, S.K.; Park, C.G.; Kim, N.I.; Kang, B.I.; Hong, M.S. Power Control Algorithm for Hybrid Excavator with Supercapacitor. IEEE Trans. Ind. Appl. 2010, 46, 1447–1455. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, Q.; Zhang, Y. Control strategies of power system in hybrid hydraulic excavator—ScienceDirect. Autom. Constr. 2018, 17, 361–367. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q.; Lin, T. Improvement of boom control performance for hybrid hydraulic excavator with potential energy recovery—ScienceDirect. Autom. Constr. 2013, 30, 161–169. [Google Scholar] [CrossRef]

- Lin, T.; Chen, Q.; Ren, H.; Huang, W.; Chen, Q.; Fu, S. Review of boom potential energy regeneration technology for hydraulic construction machinery. Renew. Sustain. Energy Rev. 2017, 79, 358–371. [Google Scholar] [CrossRef]

- Lin, T.; Huang, W.; Ren, H.; Fu, S.; Liu, Q. New compound energy regeneration system and control strategy for hybrid hydraulic excavators. Autom. Constr. 2016, 68, 11–20. [Google Scholar] [CrossRef]

- Tan, Y.; Ciufo, P.; Meegahapola, L.; Muttaqi, K.M. Enhanced Frequency Response Strategy for a PMSG-Based Wind Energy Conversion System Using Ultracapacitor in Remote Area Power Supply Systems. IEEE Trans. Ind. Appl. 2016, 53, 549–558. [Google Scholar] [CrossRef]

- Kim, S.M.; Sul, S.K. Control of Rubber Tyred Gantry Crane with Energy Storage Based on Supercapacitor Bank. IEEE Trans. Power Electron. 2006, 21, 1420–1427. [Google Scholar] [CrossRef]

- Pandey, A.; Allos, F.; Hu, A.P.; Budgett, D. Integration of supercapacitors into wirelessly charged biomedical sensors. In Proceedings of the 2011 6th IEEE Conference on Industrial Electronics and Applications, Beijing, China, 21–23 June 2011; pp. 56–61. [Google Scholar] [CrossRef]

- Lin, T.; Zhou, S.; Chen, Q.; Fu, S. A Novel Control Strategy for an Energy Saving Hydraulic System With Near-Zero Overflowing Energy-Loss. IEEE Access 2018, 6, 33810–33818. [Google Scholar] [CrossRef]

- Wang, B. High Speed On-Off Valve Self-adapting Clamping System. J. Appl. Sci. 2014, 14, 279–284. [Google Scholar] [CrossRef]

- Andruch, J.; Lumkes, J.H. Regenerative Hydraulic Topographies using High Speed Valves. SAE Tech. Pap. Ser. 2009. [Google Scholar] [CrossRef]

- Fouda, M.; Elwakil, A.S.; Radwan, A.G.; Allagui, A. Power and energy analysis of fractional-order electrical energy storage devices. Energy 2016, 111, 785–792. [Google Scholar] [CrossRef]

- Hartley, T.T.; Veillette, R.J.; Adams, J.L.; Lorenzo, C.F. Energy storage and loss in fractional-order circuit elements. IET Circuits Devices Syst. 2015, 9, 227–235. [Google Scholar] [CrossRef]

- Allagui, A.; Freeborn, T.J.; Elwakil, A.S.; Maundy, B.J. Reevaluation of Performance of Electric Double-layer Capacitors from Constant-current Charge/Discharge and Cyclic Voltammetry. Sci. Rep. 2016, 6, 38568. [Google Scholar] [CrossRef] [PubMed]

- Freeborn, T.J. Estimating supercapacitor performance for embedded applications using fractional-order models. Electron. Lett. 2016, 52, 1478–1480. [Google Scholar] [CrossRef]

- Hui, S.; Lifu, Y.; Junqing, J.; Yanling, L. Control strategy of hydraulic/electric synergy system in heavy hybrid vehicles. Energy Convers. Manag. 2011, 52, 668–674. [Google Scholar] [CrossRef]

- Wang, F. Comparison between Hydraulic Hybrid and Electric Hybrid Passenger Vehicles using ADVISOR 2004. In Proceedings of the 52nd National Conference on Fluid Power, Las Vegas, NV, USA, 23–25 March 2011; pp. 31–40. [Google Scholar]

- Rabie, M.G. Fluid Power Engineering; McGraw-Hill: New York, NY, USA, 2009; Volume 28. [Google Scholar]

- Interpolate 2-D or 3-D Scattered Data—MATLAB Griddata. Available online: https://www.mathworks.com/help/matlab/ref/griddata.html (accessed on 15 January 2020).

| Hydraulic Accumulator | |

|---|---|

| Manufacturer | Parker Hannifin |

| Reference | A2N0058D1K |

| Mass (kg) | 4.53 |

| Vol. Capacity () | 950 |

| Max. Pressure (Bar) | 207 |

| Ultracapacitor | |

|---|---|

| Manufacturer | Maxwell Technologies |

| Reference | BCAP0050 P270 S01 |

| Mass (g) | 12.2 |

| Energy Capacity (mWh) | 50.6 |

| Max. Voltage (V) | 2.7 |

| Max. Current (A) | 6.1 |

| Index | Device | Reference | Characteristics |

|---|---|---|---|

| 1 | Electric motor | Motenergy 0907 | Max. Speed: 5000 rpm Peak torque: 38 Nm |

| 2 | Hydraulic pump | GP-F20-12-P-A | Disp: Max. Flow: 40 L/min Max. Pressure: 252 Bar |

| 3 | Flow meter | FlowTech FSC 375 | Max. Pressure: 6 kpsi Max. Flow: 26.45 L/min |

| 4 | V1 and V2 | Hydraforce 12 V DC NC solenoid valve | Max. Flow: 56.7 L/min Max. Pressure: 3 kpsi |

| 5 | Pressure gage | Wika A-10 | Max. Pressure: 5 kpsi Signal output: 4 to 20 mA |

| 6 | Hydraulic accumulator | Parker A2N0058D1K | Capacity: Max. Pressure: 3 kpsi Precharge pressure: 1 kpsi |

| Device | Reference | Characteristics |

|---|---|---|

| Electric motor | Motenergy 0907 | Max. Speed: 5000 rpm Peak torque: 38 Nm Continuous current of 80 Amps AC Inductance phase to phase: 0.1 millihenry |

| Inverter | KEB48600 | Max. Power: 6 kW Max. voltage: 48 V Max. Current: 125 A |

| Battery | SUN-CYCLE LiFePO4 48 V 24 Ah | Max. Voltage: 48 V Max. discharge current: 60 A Weight: 9.8 kg |

| Variable | Description |

|---|---|

| (W) | Power charging the accumulator |

| (W) | Power discharging the accumulator |

| (gal/min) | Volumetric flow charging the accumulator |

| (gal/min) | Volumetric flow discharging the accumulator |

| (psi) | Pressure charging the accumulator |

| (psi) | Pressure discharging the accumulator |

| Efficiency of the accumulator |

| Orifice Area While Charging | Orifice Area While Discharging | Orifice Area While Charging | Orifice Area While Discharging |

|---|---|---|---|

| 3.1% | 3.1% | 12.5% | 3.1% |

| 6.2% | 6.2% | ||

| 9.4% | 9.4% | ||

| 12.5% | 12.5% | ||

| 25.0% | 25.0% | ||

| 100.0% | 100.0% | ||

| 6.2% | 3.1% | 25.0% | 3.1% |

| 6.2% | 6.2% | ||

| 9.4% | 9.4% | ||

| 12.5% | 12.5% | ||

| 25.0% | 25.0% | ||

| 100.0% | 100.0% | ||

| 9.4% | 3.1% | 100.0% | 3.1% |

| 6.2% | 6.2% | ||

| 9.4% | 9.4% | ||

| 12.5% | 12.5% | ||

| 25.0% | 25.0% | ||

| 100.0% | 100.0% |

| Variable | Value |

|---|---|

| (psi) | 1000 |

| (psi) | 3000 |

| 1.4 | |

| (liter) | 1 |

| (Wh) | 1.77 |

| Variable | Value |

|---|---|

| 50 | |

| 2.7 | |

| 6 | |

| 6 | |

| 1.82 |

| Number of Boards Connected | C (F) | R (Ω) | Number of Boards Connected | C (F) | R (Ω) |

|---|---|---|---|---|---|

| 1 | 8.33 | 7.7 | 4 | 33.32 | 7.7 |

| 6 | 6 | ||||

| 4.3 | 4.3 | ||||

| 2.1 | 2.1 | ||||

| 1.6 | 1.6 | ||||

| 2 | 16.66 | 7.7 | 5 | 41.65 | 7.7 |

| 6 | 6 | ||||

| 4.3 | 4.3 | ||||

| 2.1 | 2.1 | ||||

| 1.6 | 1.6 | ||||

| 3 | 24.99 | 7.7 | 6 | 50 | 7.7 |

| 6 | 6 | ||||

| 4.3 | 4.3 | ||||

| 2.1 | 2.1 | ||||

| 1.6 | 1.6 |

| Variable | Value |

|---|---|

| Total Energy Stored While Charging | |

| Total energy released while discharging | |

| Energy cycle efficiency |

| Test Number | Resistance Value |

|---|---|

| Test 1 | |

| Test 2 | |

| Test 3 | |

| Test 4 | |

| Test 5 |

| Variable | Number of Boards Connected in Parallel | |||||

| 1 | 2 | 3 | ||||

| Value | Error | Value | Error | Value | Error | |

| Energy stored while charging (Wh) | 0.31 | 0.01 | 0.63 | 0.02 | 0.92 | 0.03 |

| Energy stored while discharging (Wh) | 0.25 | 0.01 | 0.50 | 0.01 | 0.76 | 0.02 |

| Energy efficiency | 77.46 | 2.33 | 77.2 | 2.7 | 80.75 | 3.3 |

| Variable | Number of Boards Connected in Parallel | |||||

| 4 | 5 | 6 | ||||

| Value | Error | Value | Error | Value | Error | |

| Energy saved while charging (Wh) | 1.24 | 0.04 | 1.61 | 0.05 | 1.89 | 0.06 |

| Energy stored while discharging (Wh) | 0.97 | 0.03 | 1.29 | 0.04 | 1.47 | 0.05 |

| Energy efficiency | 78.99 | 3.91 | 80.4 | 4.73 | 77.74 | 5.42 |

| Energy Storage System | Energy/Vol (Wh/m3) | Energy/Mass (Wh/kg) | Cost/Energy (US$/Wh) |

| Battery | 195144 | 115.2 | 0.45 |

| Ultracapacitor | 2539.7 | 2.72 | 138.67 |

| Accumulator | 1227 | 0.29 | 404.68 |

| Energy Storage System | Power/Vol (kW/m3) | Power/Mass (kW/kg) | Cost/Power (US$/kW) |

| Battery | 325.24 | 0.192 | 270.83 |

| Ultracapacitor | 2588 | 2.21 | 217 |

| Accumulator | 7548 | 2.69 | 75 |

| Energy Storage System | Cost |

|---|---|

| Battery | 390 USD |

| Ultracapacitors | 210 USD |

| Hydraulic accumulator | 391 USD |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon-Quiroga, J.; Newell, B.; Krishnamurthy, M.; Gonzalez-Mancera, A.; Garcia-Bravo, J. Energy Efficiency Comparison of Hydraulic Accumulators and Ultracapacitors. Energies 2020, 13, 1632. https://doi.org/10.3390/en13071632

Leon-Quiroga J, Newell B, Krishnamurthy M, Gonzalez-Mancera A, Garcia-Bravo J. Energy Efficiency Comparison of Hydraulic Accumulators and Ultracapacitors. Energies. 2020; 13(7):1632. https://doi.org/10.3390/en13071632

Chicago/Turabian StyleLeon-Quiroga, Jorge, Brittany Newell, Mahesh Krishnamurthy, Andres Gonzalez-Mancera, and Jose Garcia-Bravo. 2020. "Energy Efficiency Comparison of Hydraulic Accumulators and Ultracapacitors" Energies 13, no. 7: 1632. https://doi.org/10.3390/en13071632

APA StyleLeon-Quiroga, J., Newell, B., Krishnamurthy, M., Gonzalez-Mancera, A., & Garcia-Bravo, J. (2020). Energy Efficiency Comparison of Hydraulic Accumulators and Ultracapacitors. Energies, 13(7), 1632. https://doi.org/10.3390/en13071632