Analyzing the Validity of Brazilian Testing Using Digital Image Correlation and Numerical Simulation Techniques

Abstract

1. Introduction

2. Laboratory Tests on Rocks

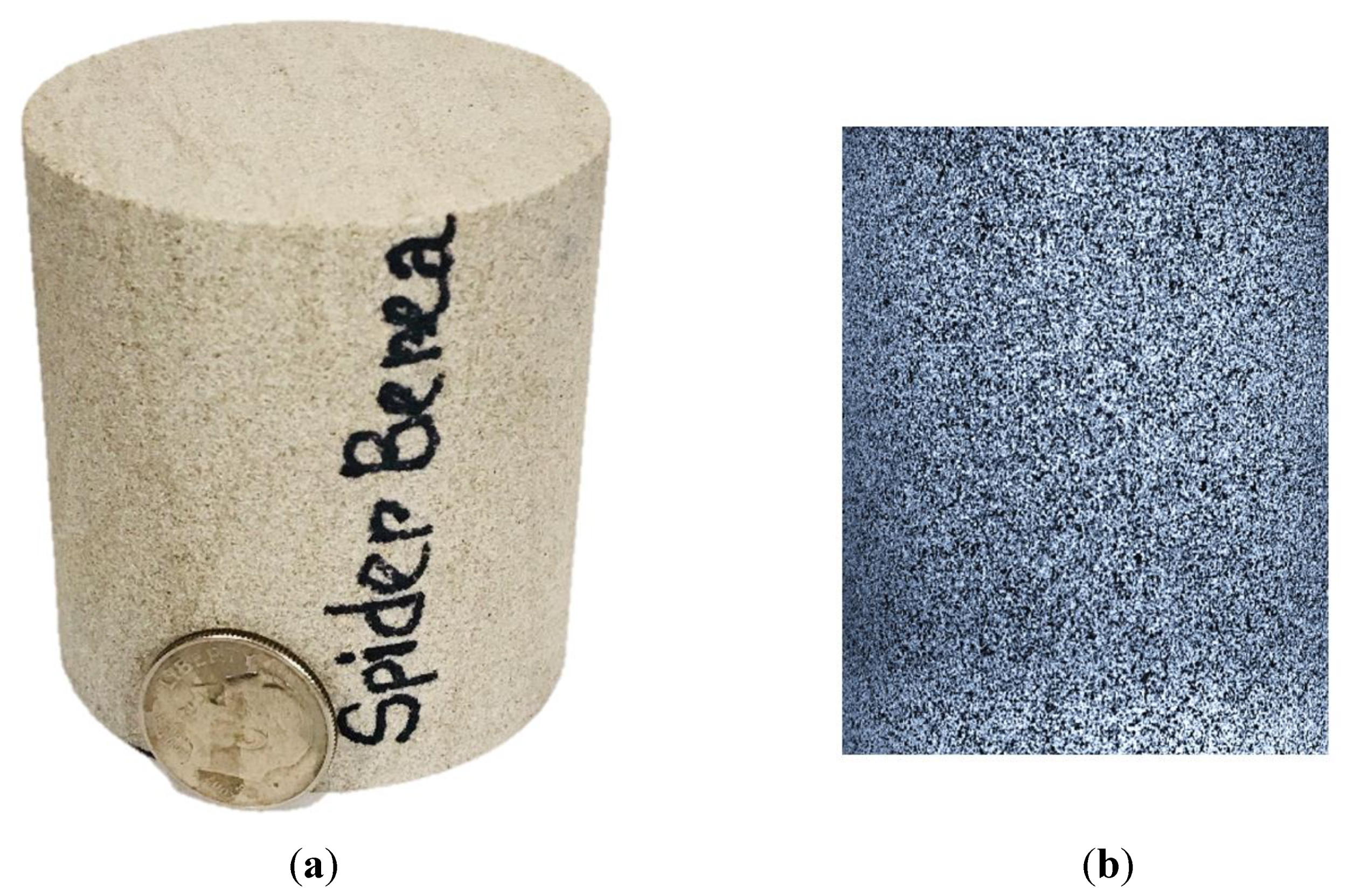

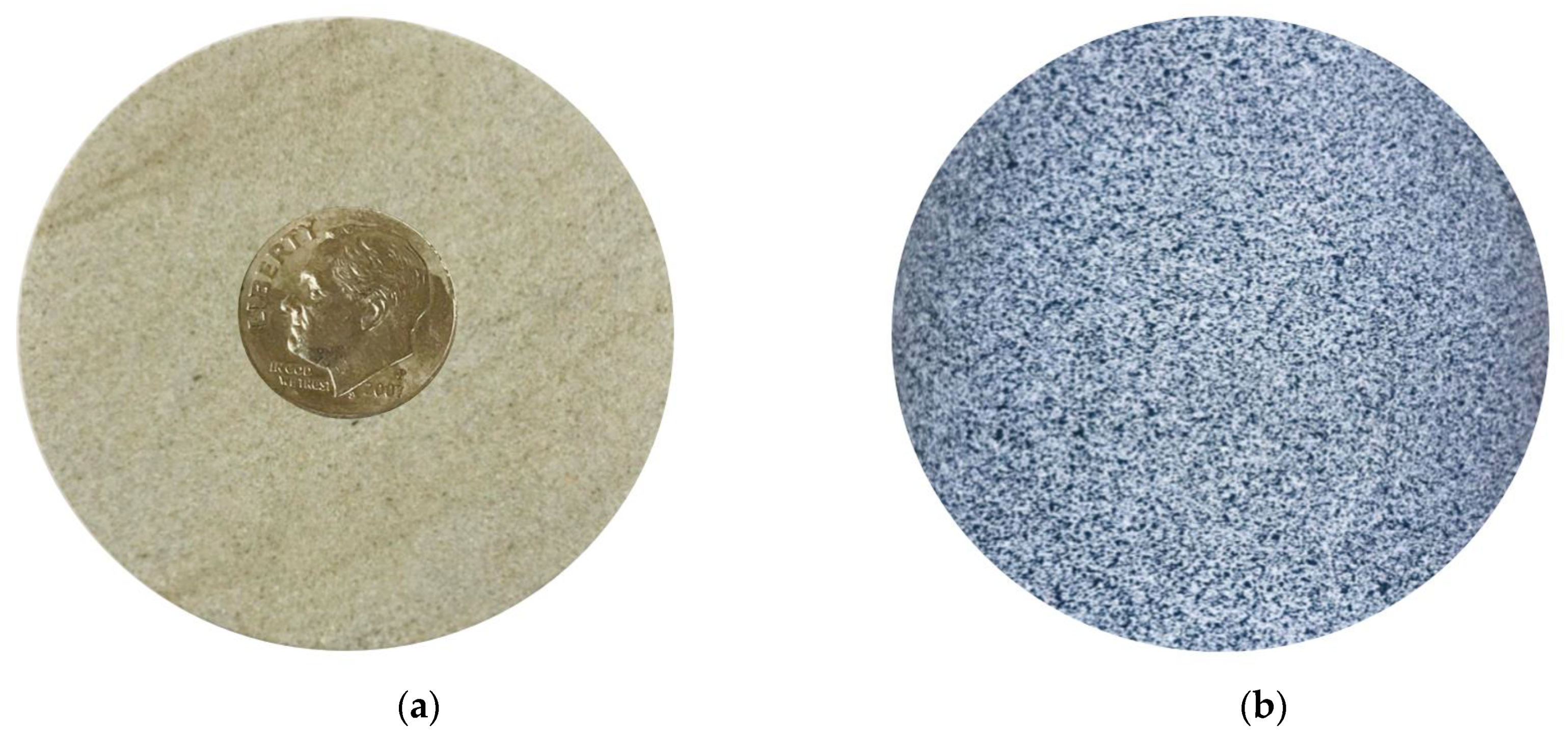

2.1. Sample Preparation

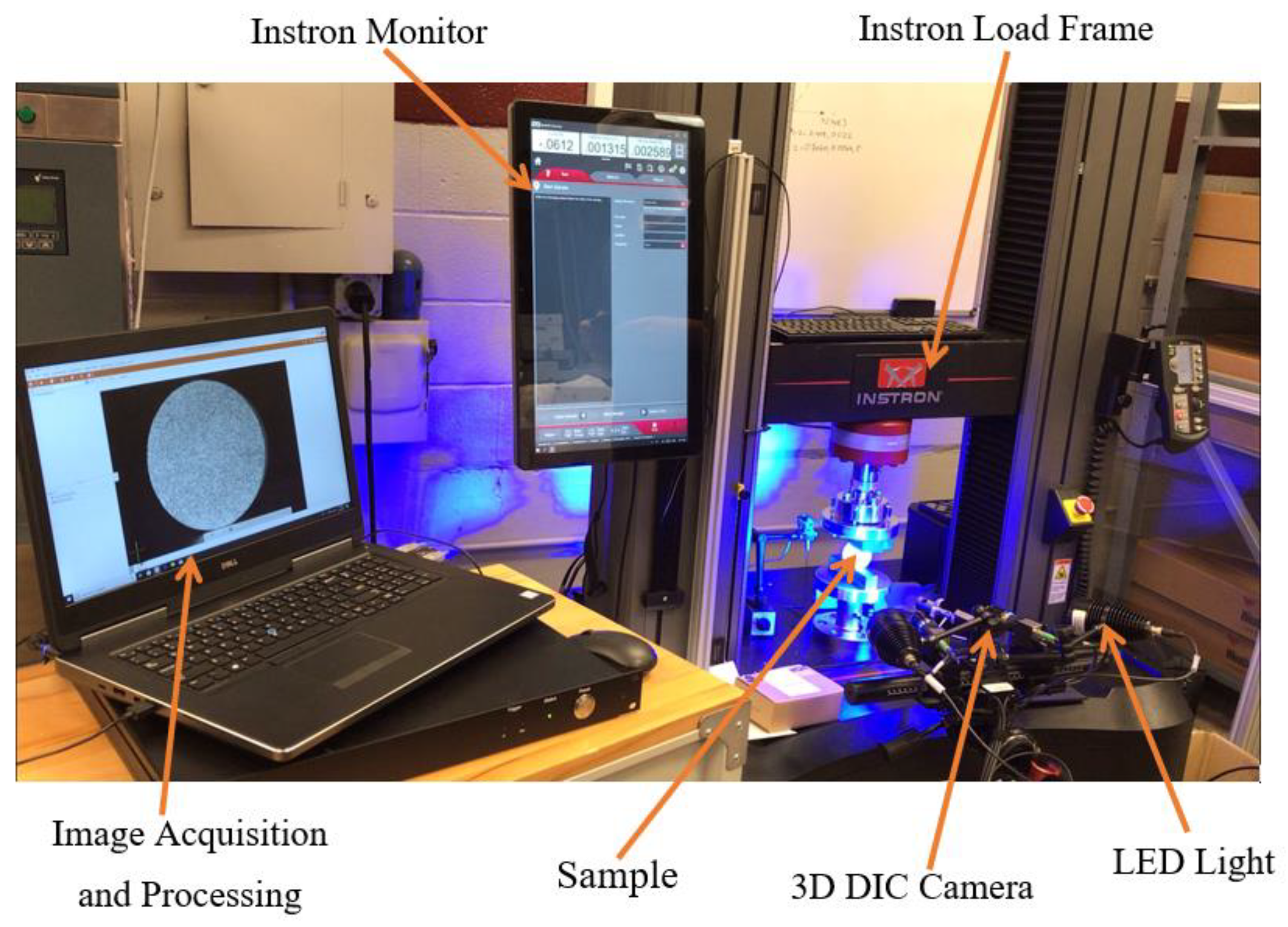

2.2. Deformation Measurement Using a Digital Image Correlation Method (DIC)

2.3. Experimental Procedure

3. Numerical Modeling Methodology

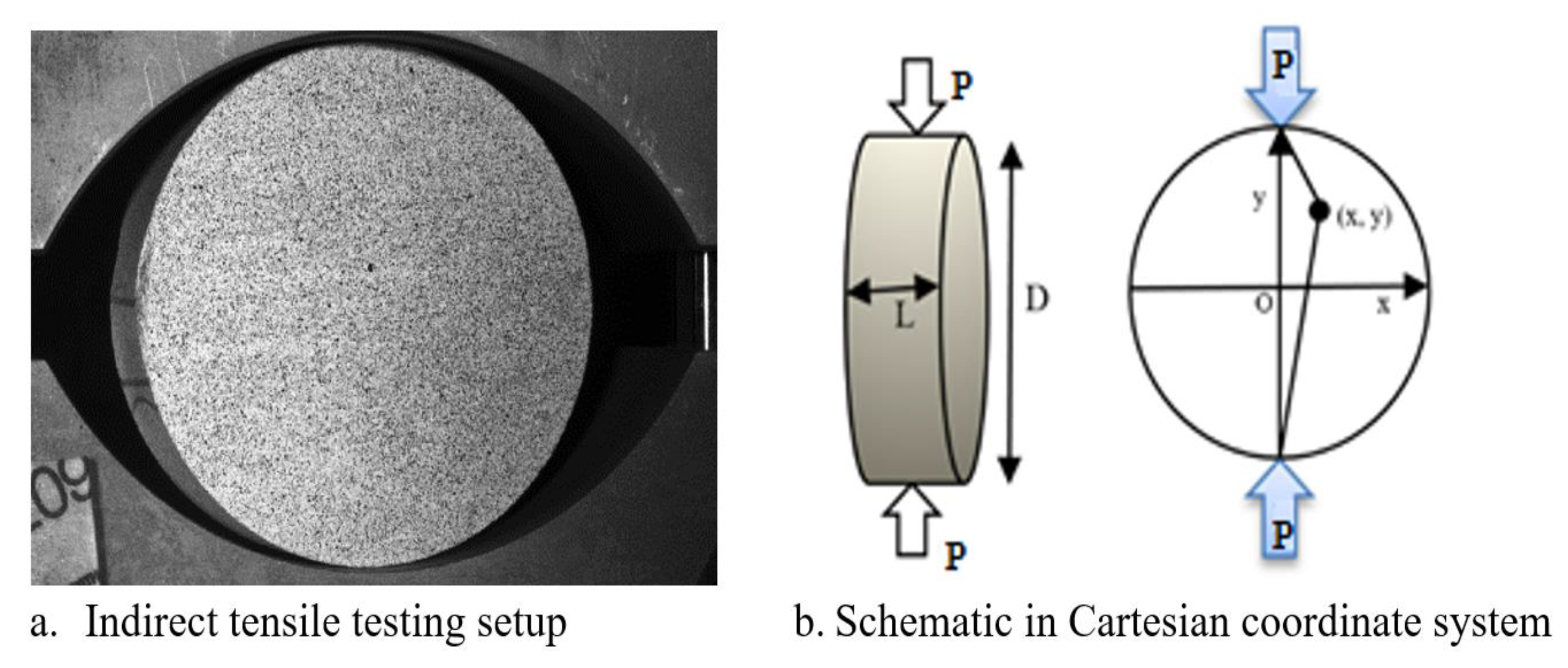

3.1. Brazilian Testing

3.2. Model Assumptions

- The Brazilian disc is loaded by diametrically opposed uniform pressure at both ends of its diameter over a small strip of the perimeter;

- The stress magnitude caused by the internal frictional force between the specimen and loading platens is neglected;

- The material is assumed as isotropic, homogeneous, and remains in a linearly elastic zone before causing the brittle failure.

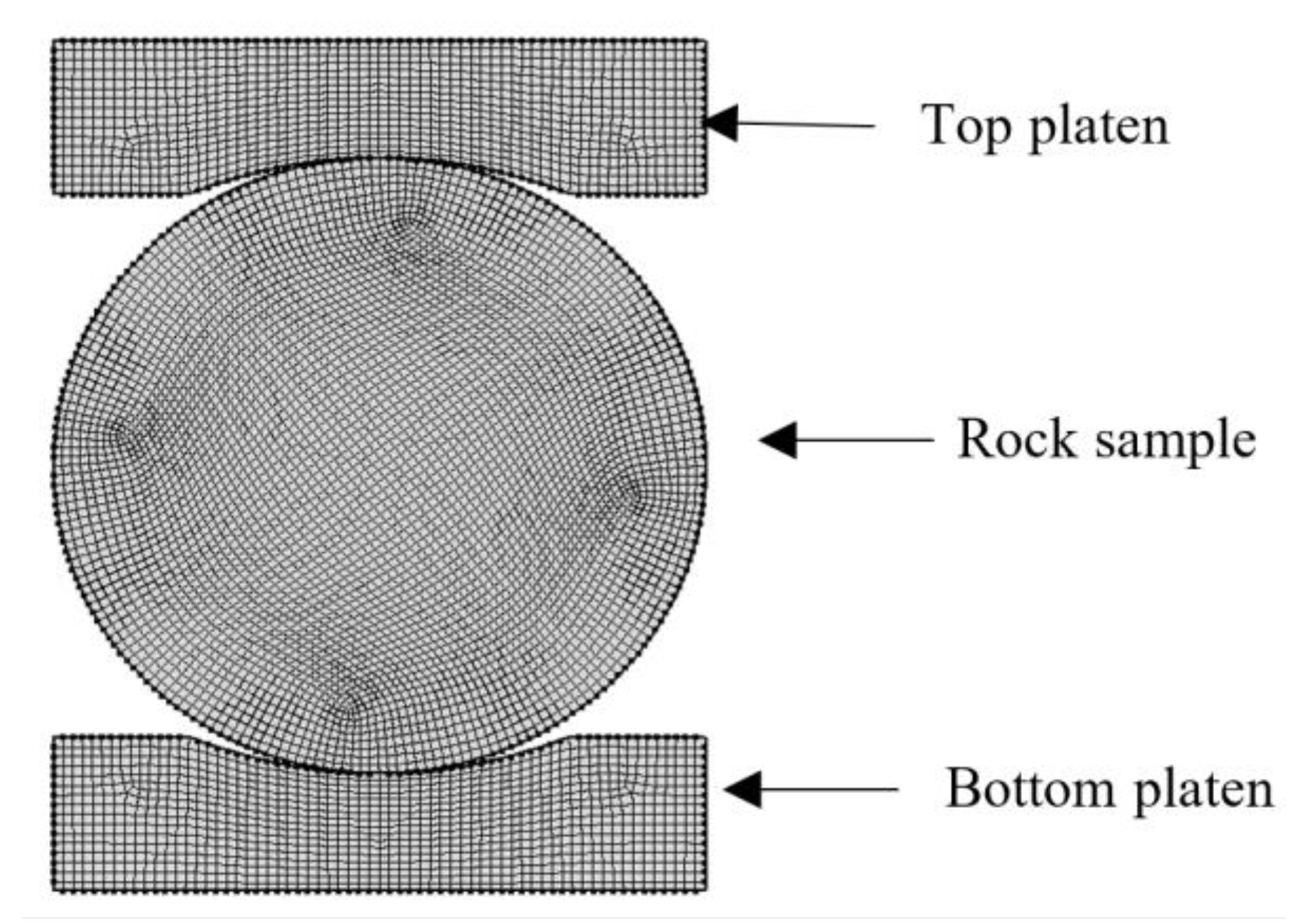

3.3. Model Set-up and Inputs

4. Results and Discussions

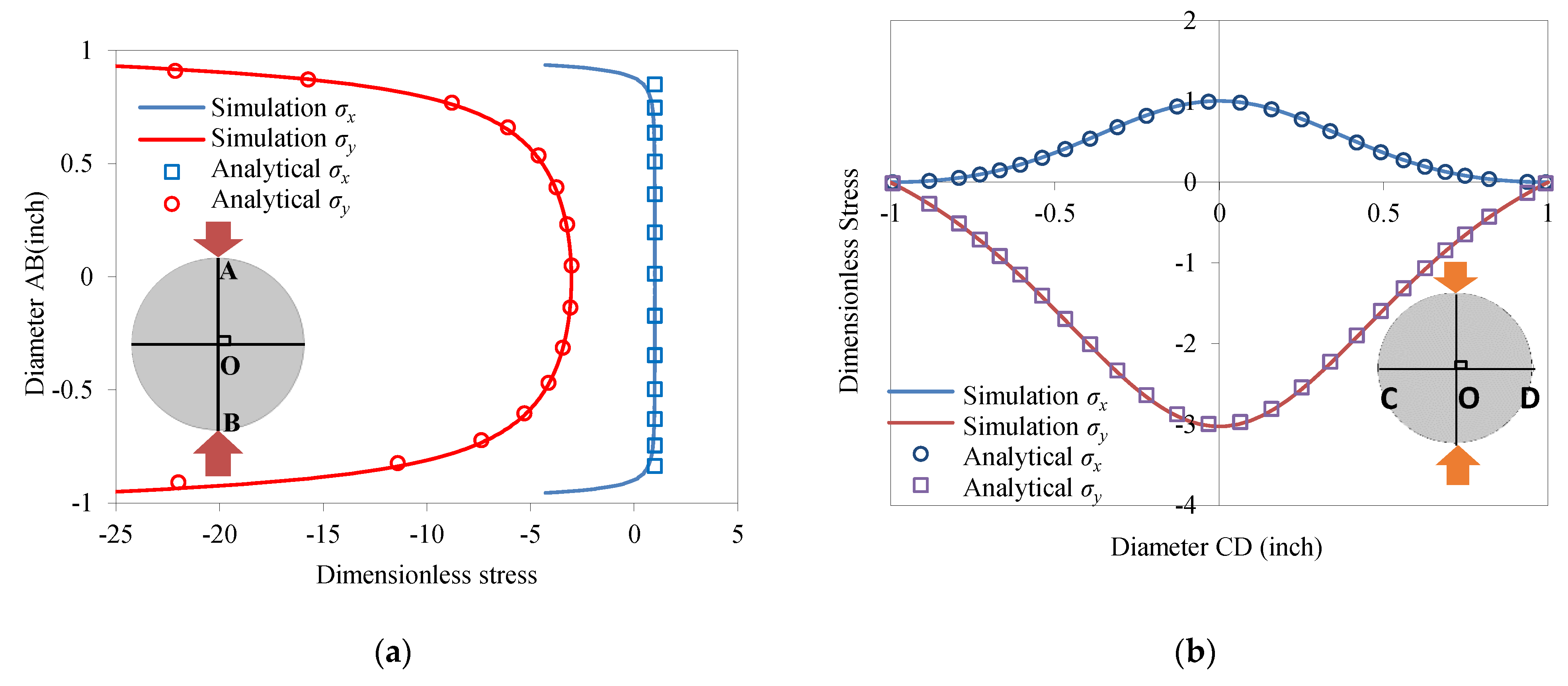

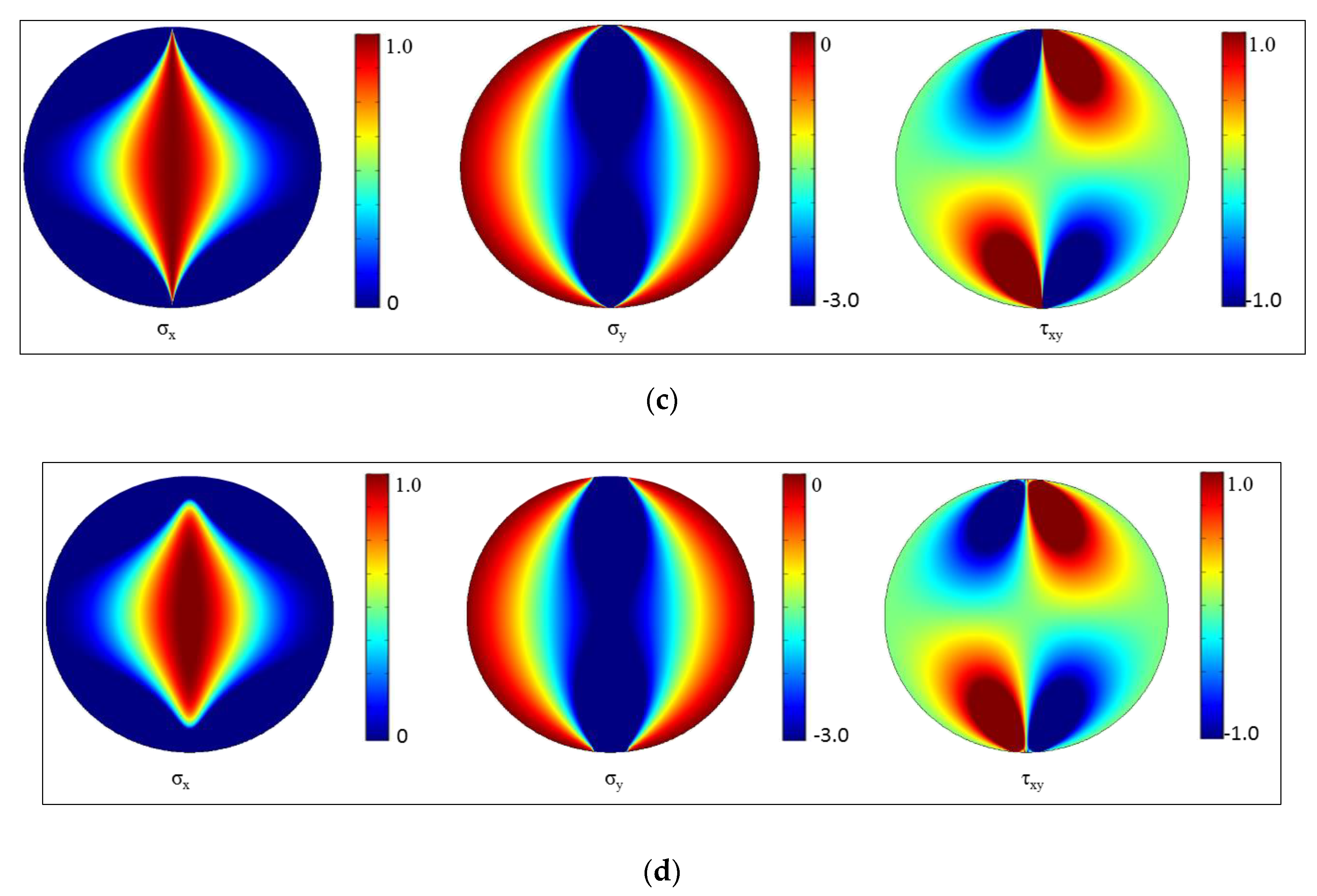

4.1. Numerical vs. Analytical Solutions for Stress Distribution

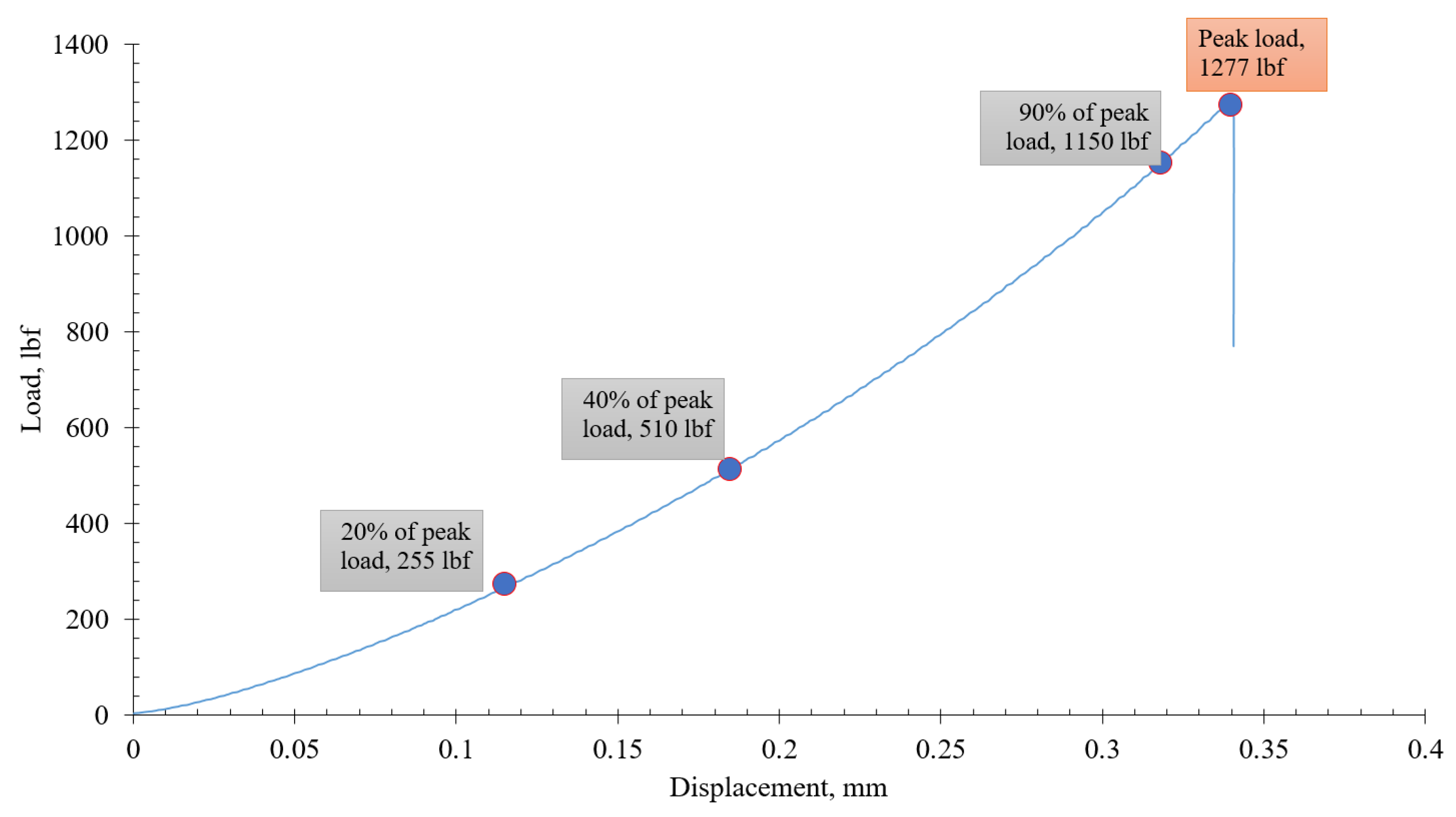

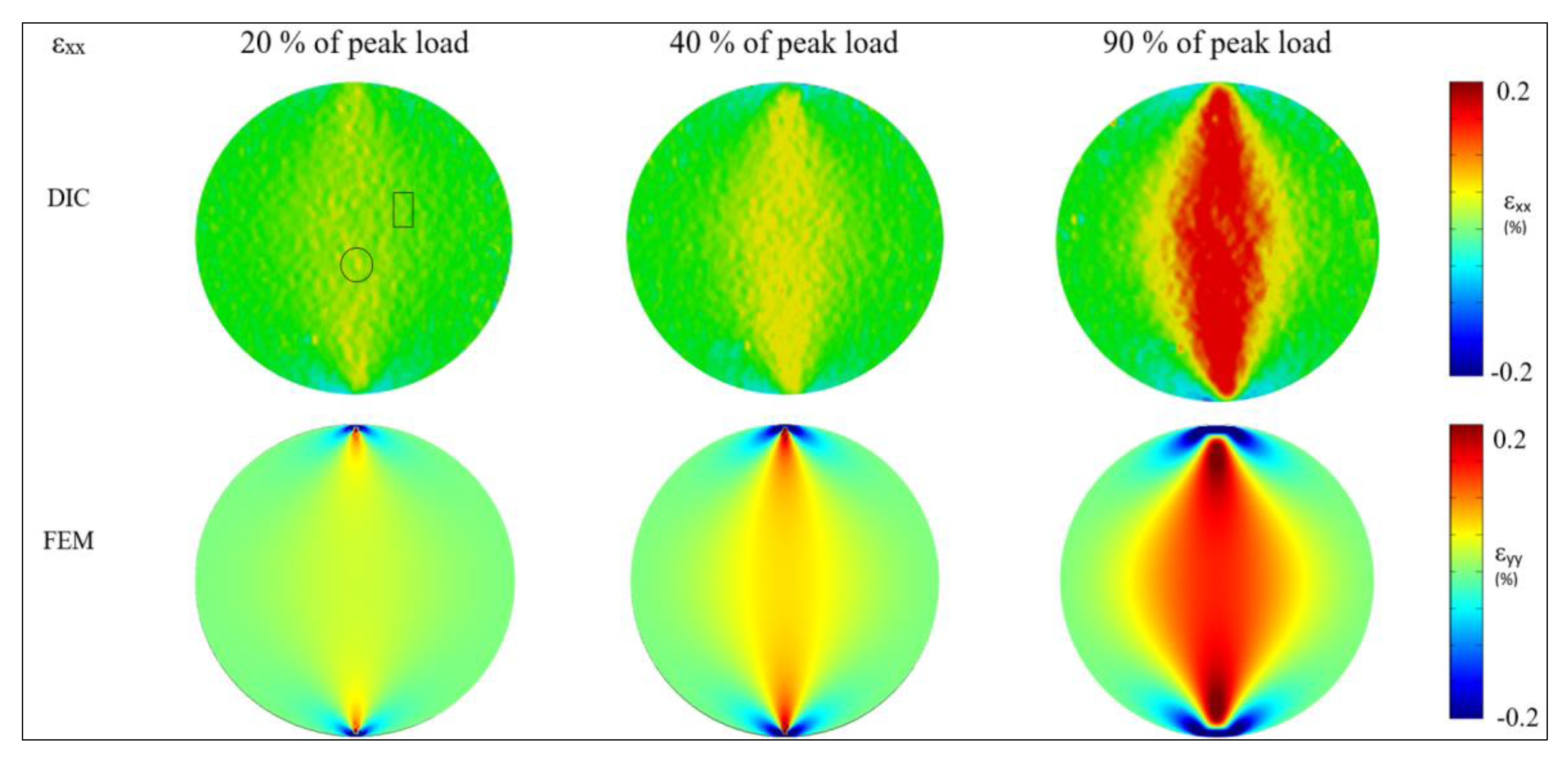

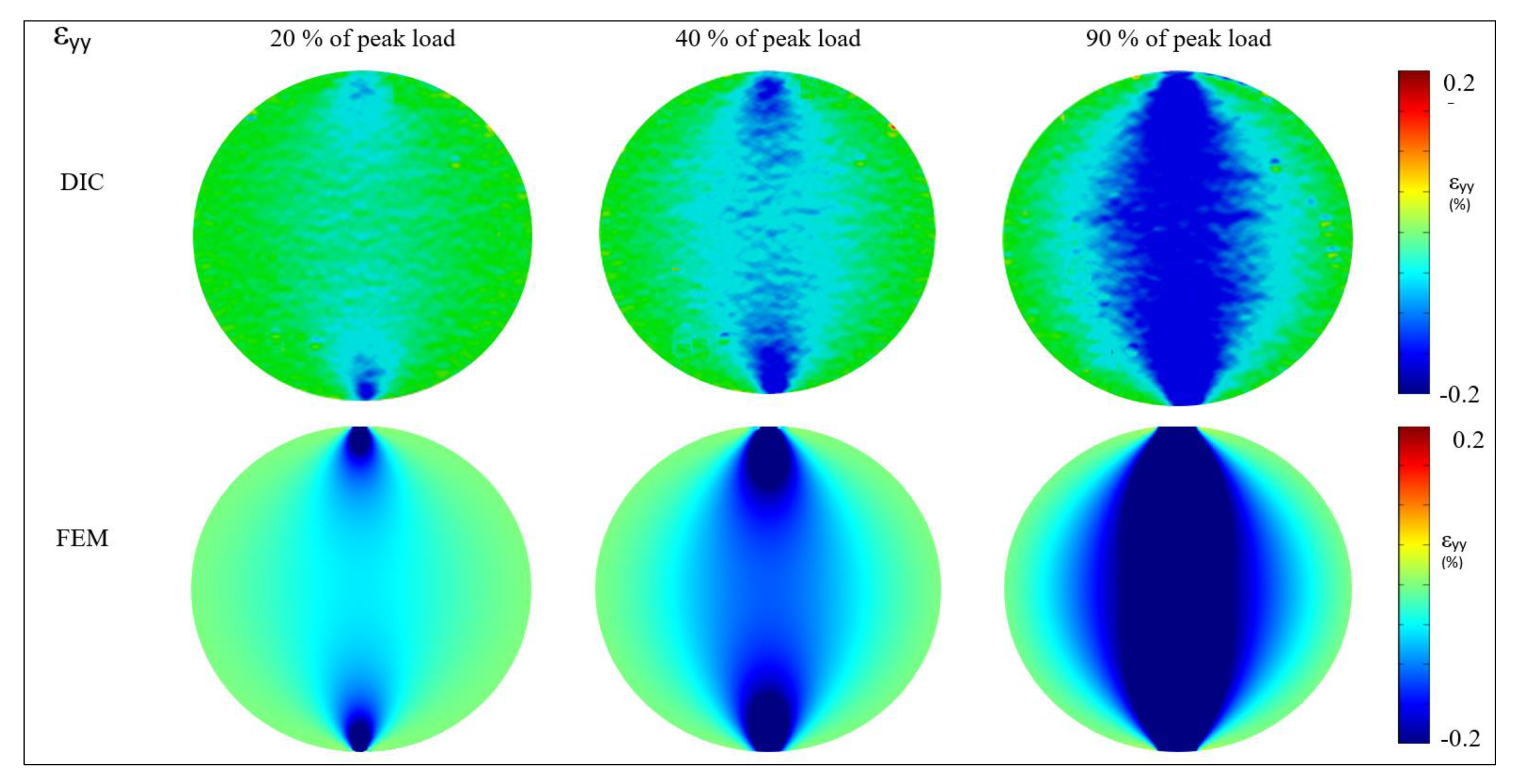

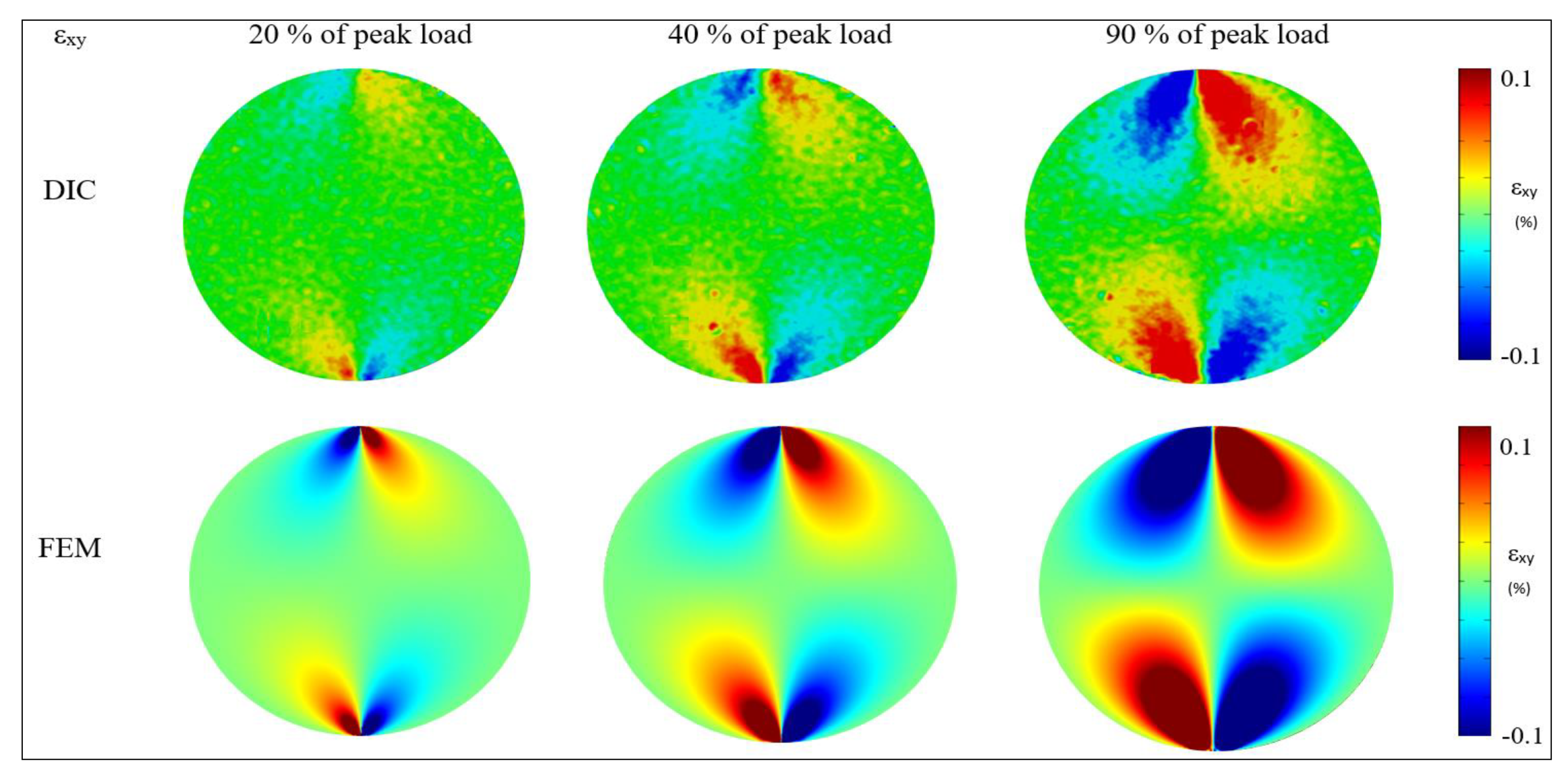

4.2. Strain Distribution in Homogeneous Rocks from FEM vs. DIC Results

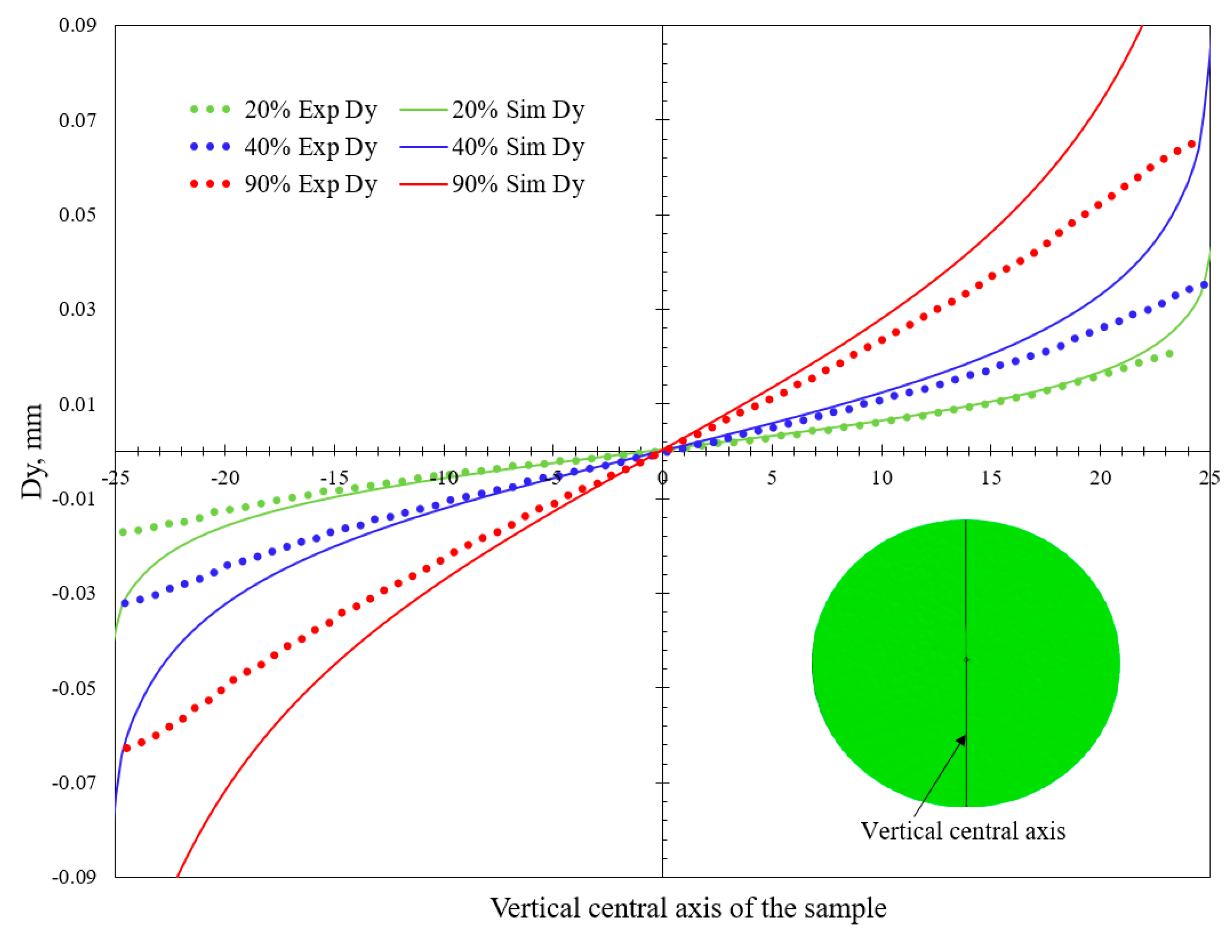

4.3. Vertical Displacement from Numerical Model vs. DIC Results

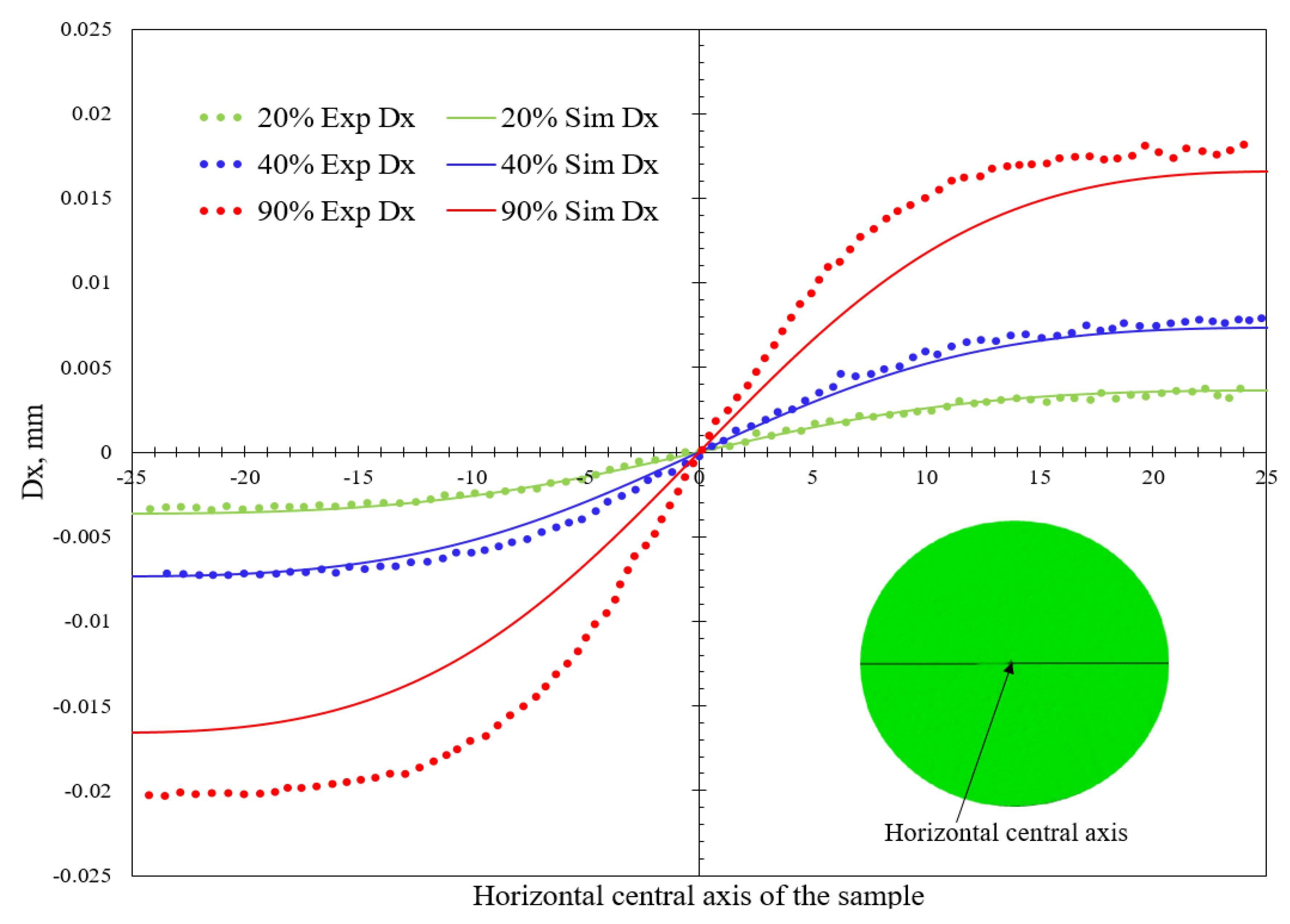

4.4. Horizontal Displacements from the Numerical Model vs. DIC Results

5. Conclusions

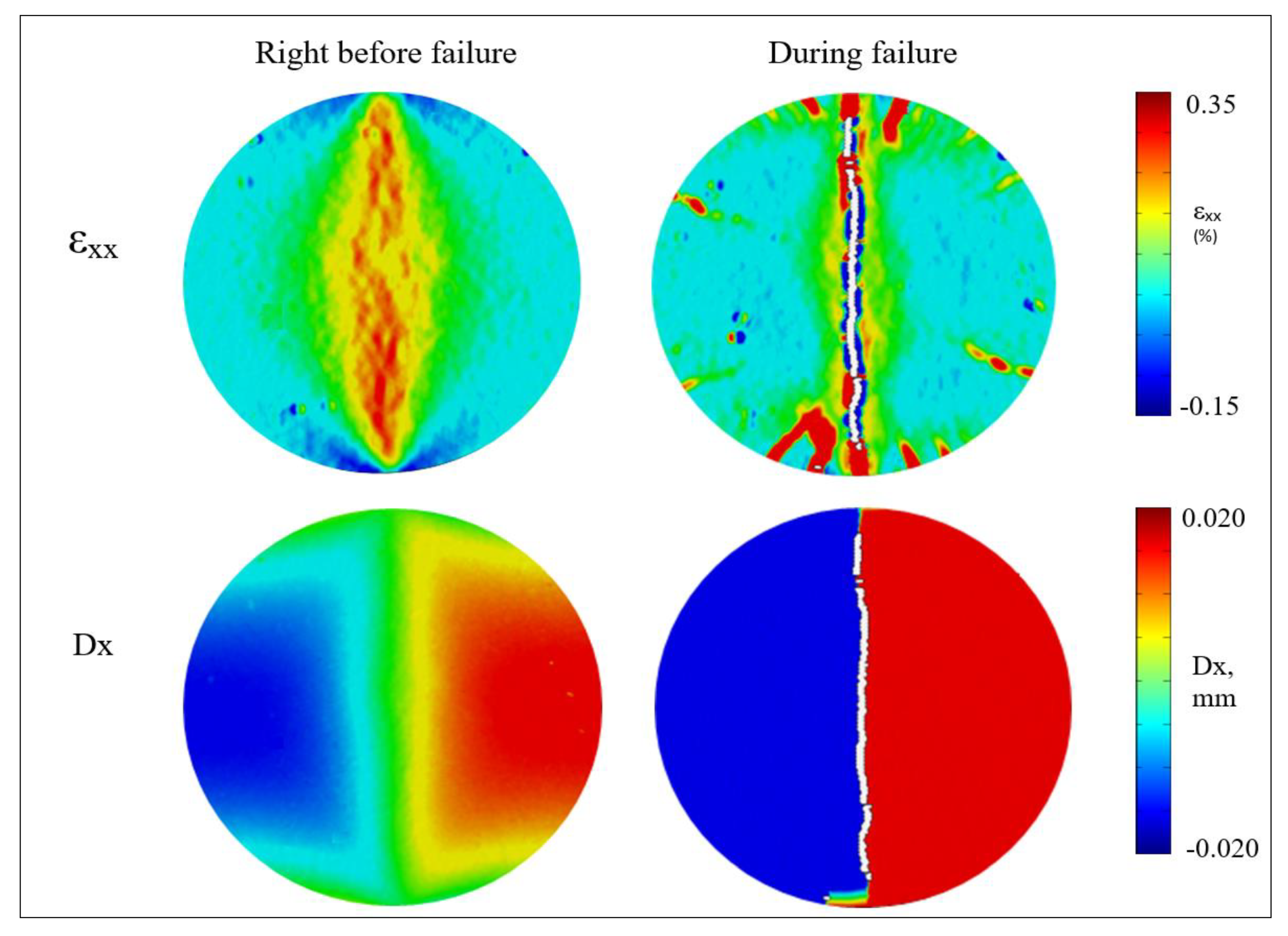

- The highest tensile strain investigated along the vertical centerline in the Spider Berea sandstone sample; with load, the tension on the centerline increases until it is causing a vertical, and central fracture;

- Linear elastic quasi-static numerical results of Brazilian testing reasonably match the analytical solutions. The MAPEs of σx and σy on the vertical diameter are 10.95% and 14.59%, respectively;

- The horizontal (εxx), vertical (εyy) and shear strain (εxy) were investigated for 20%, 40% and 90% of the peak load obtained from the experimental investigation. The simulation results obtained from the numerical model matched reasonably with DIC generated strain maps except for the proximity of the boundary as DIC maps are in limitations encountering the boundary effect. Therefore, a validated simulation model can be used to predict the boundary effect in Brazilian testing with a different condition for which experimental validation is critical;

- Changes in vertical (Dy) and horizontal (Dx) displacement in the along centerline was investigated. The numerical results obtained were repetitive and closely match the experimental DIC value. Dx comparison was better matching than Dy due to non-linearity arising from the bedding plane compression, which could not be captured by the linear elastic model;

- Simulation results of 20% and 40% of the peak loads for vertical (Dy) and horizontal (Dx) displacement are in very good agreement till the load increased near to the failure (90% of the peak load) the DIC value deviates more from simulation value. These observations revealed that changes in both vertical and horizontal displacement are very little in the elastic limit.

- DIC technique is capable of producing a strain map across the rock surface and can capture the effects of porosity variation, soft lamination, and other non-homogeneity.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DIC | Digital Image Correlation |

| UCS | Uniaxial Compressive Strength |

| BTS | Brazilian Tensile Strength |

| BDT | Brazilian Disc Test |

| MAPE | Mean Absolute Percentage of Error |

| FEM | Finite Element Model |

| FPS | Frame Per Second |

| ROI | Region of Interest |

| σx | Stress in the x-direction |

| σy | Stress in the y-direction |

| τxy | Shear stress |

| εxx | Strain in the x-direction |

| εyy | Strain in the y-direction |

| εxy | Shear strain |

| Dx | Horizontal strain along the centerline |

| Dy | Vertical strain along the centerline |

References

- Mokhtari, M.; Tutuncu, A.N. Impact of Laminations and Natural Fractures on Rock Failure in Brazilian Experiments: A Case Study on Green River and Niobrara Formations. J. Nat. Gas Sci. Eng. 2016, 36, 79–86. [Google Scholar] [CrossRef]

- Hagström, E.L.; Adams, J.M. Hydraulic fracturing: Identifying and managing the risks. Environ. Claims J. 2012, 24, 93–115. [Google Scholar] [CrossRef]

- Gu, H.; Siebrits, E.; Sabourov, A. Hydraulic fracture modeling with bedding plane interfacial slip. In SPE Eastern Regional/AAPG Eastern Section Joint Meeting; Society of Petroleum Engineers: London, UK, 2008. [Google Scholar]

- Aadnoy, B.S.; Ong, S. Introduction to Special Issue on Borehole Stability. J. Pet. Sci. Eng. 2003, 38, 79–82. [Google Scholar] [CrossRef]

- Amitrano, D. Rupture by Damage Accumulation in Rocks. Int. J. Fract. 2006, 139, 369–381. [Google Scholar] [CrossRef]

- Li, D.; Wong, L.N.Y. The Brazilian Disc Test for Rock Mechanics Applications: Review and New Insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- Standard Test Method for Uniaxial Compressive Strength of Intact Rock Core Specimens; ASTM D 2938; ASTM International: West Conshohocken, PA, USA, 2008.

- Carneiro, F.L.L.B. A new method to determine the tensile strength of concrete. In Proceedings of the 5th Meeting of the Brazilian Association for Technical Rules, Sao Paulo, Brazil, 16 September 1943; Volume 16, pp. 126–129. [Google Scholar]

- Akazawa, T. New test method for evaluating internal stress due to compression of concrete: The splitting tension test. J. Jpn. Soc. Civ. Eng. 1943, 29, 777–787. [Google Scholar]

- Tavallali, A.; Vervoort, A. Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 313–322. [Google Scholar] [CrossRef]

- Frash, L.P.; Gutierrez, M.; Tutuncu, A.; Hood, J.; Mokhtari, M. True-triaxial hydraulic fracturing of Niobrara carbonate rock as an analogue for complex oil and gas reservoir stimulation. In Proceedings of the 49th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015. [Google Scholar]

- Li, H.; Lai, B.; Liu, H.-H.; Zhang, J.; Georgi, D. Experimental Investigation on Brazilian Tensile Strength of Organic-Rich Gas Shale. SPE J. 2017, 22, 148–161. [Google Scholar] [CrossRef]

- Mokhtari, M.; Bui, B.T.; Tutuncu, A.N. Tensile Failure of Shales: Impacts of Layering and Natural Fractures. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Wang, Q.Z.; Jia, X.M.; Kou, S.Q.; Zhang, Z.X.; Lindqvist, P.A. The flattened Brazilian disc specimen used for testing elastic modulus, tensile strength and fracture toughness of brittle rocks: Analytical and numerical results. Int. J. Rock Mech. Min. Sci. 2004, 41, 245–253. [Google Scholar] [CrossRef]

- Chen, S.; Yue, Z.Q.; Tham, L.G.; Lee, P.K.K. Modeling of the indirect tensile test for inhomogeneous granite using a digital image-based numerical method. Int. J. Rock Mech. Min. Sci. 2004, 41 (Suppl. 1), 466–471. [Google Scholar] [CrossRef]

- Yanagidani, T.; Sano, O.; Terada, M.; Ito, I. The observation of cracks propagating in diametrically compressed rock discs. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 225–235. [Google Scholar] [CrossRef]

- Hudson, J.A.; Brown, E.T.; Rummel, F. The controlled failure of rock discs and rings loaded in diametral compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 241–248. [Google Scholar] [CrossRef]

- Hooper, J.A. The failure of glass cylinders in diametral compression. J. Mech. Phys. Solids 1971, 19, 179–200. [Google Scholar] [CrossRef]

- Fairhurst, C. On the validity of the ‘Brazilian test for brittle materials. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1964, 4, 535–546. [Google Scholar] [CrossRef]

- Swab, J.J.; Yu, J.; Gamble, R.; Kilczewski, S. Analysis of the diametral compression method for determining the tensile strength of transparent magnesium aluminate spinel. Int. J. Fract. 2011, 172, 187–192. [Google Scholar] [CrossRef]

- Stirling, R.A.; Simpson, D.J.; Davie, C.T. The application of digital image correlation to Brazilian testing of sandstone. Int. J. Rock Mech. Min. Sci. 2013, 60, 1–11. [Google Scholar] [CrossRef]

- Mokhtari, M.; Hayatdavoudi, A.; Nizamutdinov, R.; Rizvi, H.; Nath, F. Characterization of complex fracture propagation in naturally fractured formations using Digital Image Correlation technique. In SPE Hydraulic Fracturing Technology Conference and Exhibition; Society of Petroleum Engineers: London, UK, 2017. [Google Scholar] [CrossRef]

- Nath, F.; Mokhtari, M. Optical visualization of strain development and fracture propagation in laminated rocks. J. Pet. Sci. Eng. 2018, 167, 354–365. [Google Scholar] [CrossRef]

- Pan, B.; Asundi, A.; Xie, H.; Gao, J. Digital image correlation using iterative least squares and pointwise least squares for displacement field and strain field measurements. Opt. Lasers Eng. 2009, 47, 865–874. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Berlin, Germany, 2009. [Google Scholar]

- Baqersad, J.; Poozesh, P.; Niezrecki, C.; Avitabile, P. Photogrammetry and optical methods in structural dynamics—A review. Mech. Syst. Signal Process. 2017, 86, 17–34. [Google Scholar] [CrossRef]

- Chu, T.; Ranson, W.; Sutton, M. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Reu, P. DIC: A Revolution in experimental mechanics. Exp. Tech. 2015, 39, 1–2. [Google Scholar] [CrossRef]

- Parshall, J.; Whitfield, S.; Jacobs, T. Digital Image Correlation: A New Way to Look at Hydraulic Fracturing. J. Pet Technol. 2017, 69, 2226. [Google Scholar] [CrossRef]

- Nath, F.; Salvati, P.E.; Mokhtari, M.; Seibi, A.; Hayatdavoudi, A. Laboratory Investigation of Dynamic Strain Development in Sandstone and Carbonate Rocks Under Diametrical Compression Using Digital-Image Correlation. Soc. Pet. Eng. 2019, 24, 254–273. [Google Scholar] [CrossRef]

- Chandler, M.R.; Fauchille, A.L.; Kim, H.K.; Ma, L.; Mecklenburgh, J.; Rizzo, R.; Mostafavi, M.; Marussi, S.; Atwood, R.; May, S.; et al. Correlative optical and X-ray imaging of strain evolution during double-torsion fracture toughness measurements in shale. J. Geophys. Res. Solid Earth 2018, 123, 10517–10533. [Google Scholar] [CrossRef]

- Mokhtari, M.; Nath, F.; Hayatdavoudi, A.; Nizamutdinov, R.; Jiang, S.; Rizvi, H. Complex deformation of naturally fractured rocks. J. Pet. Sci. Eng. 2019, 183, 106410. [Google Scholar] [CrossRef]

- Na, S.; Sun, W.; Ingraham, M.D.; Yoon, H. Effects of Spatial Heterogeneity and Material Anisotropy on the Fracture Pattern and Macroscopic Effective Toughness of Mancos Shale in Brazilian Tests. J. Geophys. Res. Solid Earth 2017, 122, 6202–6230. [Google Scholar] [CrossRef]

- Erarslan, N.; Williams, D.J. Experimental, numerical and analytical studies on tensile strength of rocks. Int. J. Rock Mech. Min. Sci. 2011, 49, 21–30. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Xing, L. Determination of fracture toughness KIC by using the flattened Brazilian disk specimen for rocks. Eng. Fract. Mech. 1999, 64, 193–201. [Google Scholar] [CrossRef]

- Tavallali, A.; Vervoort, A. Behavior of layered sandstone under Brazilian test conditions: Layer orientation and shape effects. J. Rock Mech. Geotech. Eng. 2013, 5, 366–377. [Google Scholar] [CrossRef]

- Zhu, W.C.; Tang, C.A. Numerical simulation of Brazilian disk rock failure under static and dynamic loading. Int. J. Rock Mech. Min. Sci. 2006, 43, 236–252. [Google Scholar] [CrossRef]

- Lanaro, F.; Sato, T.; Stephansson, O. Microcrack modeling of Brazilian tensile tests with the boundary element method. Int. J. Rock Mech. Min. Sci. 2009, 46, 450–461. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Q.B.; Chen, P.; Yang, C.; Zhao, J. Fracture pressure model for inclined wells in layered formations with anisotropic rock strengths. J. Pet. Sci. Eng. 2017, 149, 393–408. [Google Scholar] [CrossRef]

- Liao, J.J.; Yang, M.T.; Hsieh, H.Y. Direct tensile behavior of a transversely isotropic rock. Int. J. Rock Mech. Min. Sci. 1997, 34, 837–849. [Google Scholar] [CrossRef]

- Kocurek Inc. Details for Spider Berea Sandstone. 2019. Available online: https://kocurekindustries.com/index.php?page_name=Berea%20Spider&page_id=240&id=192 (accessed on 17 February 2020).

- ISRM. Suggested method for determining indirect tensile strength by Brazilian test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 102–103. [Google Scholar]

- Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens; ASTM D3967-08; ASTM International: West Conshohocken, PA, USA, 2008. [CrossRef]

- Knudsen, O.Ø.; Bjørgum, A.; Polanco-Loria, M.; Øyen, A.; Johnsen, R. Internal Stress and Mechanical Properties of Paint Films. In Proceedings of the CORROSION 2007, Nashville, TN, USA, 11–15 March 2007. [Google Scholar]

- Reu, P. Points on Paint. Exp. Tech. 2015, 39, 1–2. [Google Scholar] [CrossRef]

- ARAMIS. Standard Operating Manual of ARAMIS Professional. 2019. Available online: https://www.gom.com/3d-software/gom-system-software/aramis-professional.html (accessed on 18 March 2020).

- Jianhong, Y.; Wu, F.Q.; Sun, J.Z. Estimation of the Tensile Elastic Modulus Using Brazilian Disc by Applying Diametrically Opposed Concentrated Loads. Int. J. Rock Mech. Min. 2009, 46, 568–576. [Google Scholar] [CrossRef]

- Titkcov, V.V.; Panin, S.V. Measurement Affecting Errors in Digital Image Correlation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 511, 012018. [Google Scholar] [CrossRef]

| Rock Specimen | Formation | Permeability (md) | Porosity (%) |

|---|---|---|---|

| Spider Berea sandstone | Upper Devonian | 120–130 | 19–21 |

| Items | Dimensions | Young’s Modulus | Poisson’s Ratio |

|---|---|---|---|

| Rock Specimen | D = 2″, t = 0.6″ | 3.93 GPa | 0.20 |

| Platen Material | L = 4″, l = 0.5″, t = 1″ | 200 GPa | 0.33 |

| Load | Coefficient of Determination, R2 (%) | |

|---|---|---|

| Dx | Dy | |

| 20% of the peak load | 99.75 | 96.91 |

| 40% of the peak load | 98.98 | 94.92 |

| 90% of the peak load | 97.77 | 94.85 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Nath, F.; Parrikar, P.N.; Mokhtari, M. Analyzing the Validity of Brazilian Testing Using Digital Image Correlation and Numerical Simulation Techniques. Energies 2020, 13, 1441. https://doi.org/10.3390/en13061441

Zhang H, Nath F, Parrikar PN, Mokhtari M. Analyzing the Validity of Brazilian Testing Using Digital Image Correlation and Numerical Simulation Techniques. Energies. 2020; 13(6):1441. https://doi.org/10.3390/en13061441

Chicago/Turabian StyleZhang, He, Fatick Nath, Prathmesh Naik Parrikar, and Mehdi Mokhtari. 2020. "Analyzing the Validity of Brazilian Testing Using Digital Image Correlation and Numerical Simulation Techniques" Energies 13, no. 6: 1441. https://doi.org/10.3390/en13061441

APA StyleZhang, H., Nath, F., Parrikar, P. N., & Mokhtari, M. (2020). Analyzing the Validity of Brazilian Testing Using Digital Image Correlation and Numerical Simulation Techniques. Energies, 13(6), 1441. https://doi.org/10.3390/en13061441