1. Introduction

In light of the climate objective in the Paris Agreement of limiting global mean temperature increase to well below 2 °C and pursuing efforts to limit it further to 1.5 °C [

1], governments worldwide have spared no effort in reducing carbon emissions. Over the past years, electricity consumption across Europe has increased significantly and accounts for around 21% of final energy demand, and the domestic sector alone accounts for almost 25% of final energy consumption and almost 30% of electrical energy demand. One key drive for increasing electrical demand in Europe is the rapid increasing number of household appliances with RAC (room air conditioner) as a major component [

2]. In Japan, from 1990 to 2005, the total emissions of CO

2 derived from RAC increased by 1.47 Mt-CO

2, which corresponds to an increase of 16.5% relative to the 1990 level of emissions [

3]. As the third largest market of RAC in the world, the demand in Japan reached 8.35 million units with a 3.1% increase [

4], and its residential electricity consumption in 2014 was up to 986 PJ [

5]. In the U.S., 1410 billion kW/h of electricity was used by the residential sector in 2016, of which 18% of annual household electricity use was for air conditioning. Residential electricity consumption seasonally rises and falls substantially more than commercial or industrial consumption, largely due to air conditioning use in the summer [

6].

As the world’s largest manufacturer and consumer of RACs, the total household electricity consumption in China in 2015 was up to 756.5 billion kW·h; meanwhile, the production output of RACs (room air conditioners) has maintained a high growth rate since 1992, and up to 2015, it reached 142 million units [

7]. In 2025, the total baseline electricity consumption of RACs will reach 753 billion kW·h [

8]. Furthermore, the electricity consumption of RACs is estimated to account for 30% of the peak summer load in some large and medium-sized cities [

9]. It can be expected that the potential of energy saving and greenhouse gas emissions reduction in RACs was much greater than in any other household electrical appliances in China [

10]. Among the methods in effect, the standards and regulations issued by governmental or regional administration bureaus play a significant role in guiding and regulating the carbon emissions reduction expectation for RACs.

Besides the fundamental index of EER, more comprehensive and extensive methods for energy conservation have been introduced in RAC energy efficiency evaluation. The effect of the main external factors including room air temperature, defrosting behavior, and user interactions are analyzed on the energy consumption of existing refrigerating appliances in the home for more in depth analysis and a better understanding of the energy consumption of household refrigerators in different regions [

11]. Thermodynamic perfectibility has been proposed as a consistent evaluation for the performance of RACs [

12,

13,

14,

15]. Life cycle cost analysis is widely applied to assess the impact of standard implementation to energy saving and emissions reduction in Europe [

16]. By analyzing the relationship between life cycle reduction and energy efficiency improvement, the significance of energy efficiency evaluation is illustrated [

17,

18]. The rebound effect was added to find a rise in energy consumption after the implementation of the energy efficiency standard in China [

19]. Recently, more scientists have recognized that the occupants’ behavior has a significant effect on the energy consumption of their air-conditioner, and that thermal conditions also affect an occupant’s behavior by influencing their expectation of thermal comfort [

20,

21,

22]. Fundamental studies on the RAC performance national standard have mainly focused on the effectiveness of measurements in the test procedure [

23,

24] and methods of lowering the uncertainty in theory [

25,

26,

27].

To help the standards and regulations work more efficiently, researchers have carried out great work by applying these methods in standard revision. Additionally, many investigations have found that the stipulation and revision of RAC standards have been proven effective in reducing energy consumption and emissions. A scenario analysis focusing on residential RACs in Japan during 1972–2013 showed that for a reduction of an average lifetime of one year, if the air conditioner energy efficiency limit could be improved by 1.4% from the estimated current efficiency level, CO

2 emissions could be reduced by approximately the same amount as for an extension of the average product lifetime of one year [

28]. In Europe, the implementation of a minimum energy performance standard based on least life cycle costs could save up to 49 TWh and 20 MtCO

2-eq in 2020. In the U.S., standards for RAC at efficiency level 3 revised by using common improvements found were more efficient and would save close to one quad of energy over 30 years and have a consumer NPV (net present value) between 0.14 billion and 1.82 billion dollars [

29]. From 2005 to 2025, the energy efficiency standards for RACs in China could help save 1430–2540 billion kW·h of electricity and reduce 908.3–1610.1 Mt CO

2 emissions in different scenarios.

Among the electric appliances, China first issued the national standard on energy efficiency grades for RAC in 1989 [

30]. With this initial edition, the Chinese national standard on RAC energy efficiency grades experienced three revisions in 2000 [

31], 2004 [

32], and 2010 [

33] after learning from similar regulations made in the USA, European Union, and Japan [

34,

35,

36,

37]. Revisions in 2000 and 2004 both focused on upgrading energy efficiency threshold values, while the latest revision (2010) was upgraded by adjusting the previous five-class energy efficiency grading into a three-class energy efficiency grading for both constant and variable speed RACs. This new standard, which is currently in effect, obsoletes RACs with high energy consumption, therefore, it expects to meet the requirements for a global low-carbon city and the energy saving and emissions reduction policy in China [

38,

39].

However, in the case of the Chinese national standards, RAC energy efficiency evaluation has its roots in the Chinese national RAC performance standard [

40]. In the RAC performance test, when D&WBTs (dry-bulb and wet-bulb temperatures) change within their tolerances, respectively or simultaneously, the measured values of both CC (cooling capacity) and EER (energy efficiency ratio) of the unit are affected directly. For a particular unit, when values of CC measured in the performance test with different D&WBTs happened to fall in two ranges of CC classified in the national standard, the values of the EER measured will label this unit with different energy efficiency classes (

Table 1 as a reference). Concerning the fact that with the higher precision and accuracy of measurement instruments, D&WBTs in the operation of the RAC performance test can now be kept much more stable than what they were 13 years ago, when the Chinese national RAC performance standard was put into effect and never revised thereafter. The lag in revising the D&WBT tolerances set in the national RAC performance standard forms a sharp contrast to the continual revisions of the national RAC energy efficiency standard and calls for an effective method to reduce the uncertainty in obtaining true values of CC and EER of the test unit.

In the Chinese national standard of RAC performance, D&WBT tolerances refer to the maximum permissible deviations of specified D&WBTs readings in RAC performance tests. For all other tests with the exception of the CC/heat pump test (e.g., defrosting test), the stipulated tolerances for both indoor and outdoor D&WBTs are ±1/±0.5 °C; for instantaneous readings in the CC/heat pump test, they are ±0.5/±0.3 °C; for average readings in the CC/heat pump test, they are ±0.3/±0.2 °C. Since the test results of CC and EER are the basis of energy efficiency evaluation, and changes of both indoor and outdoor D&WBTs directly affect the test results of CC and EER, the method of tightening D&WBT tolerances has been studied from various aspects. A formula for computing the wet-bulb temperature inversely from the relative humidity (or dewpoint temperature) and the air temperature has been proposed [

41]. A method of non-linear classification of D&WBT tolerances [

42] and an algorithm for correcting D&WBT tolerances using regression equations and analytic hierarchy process (AHP) [

43] have also been proposed. In the successive study of weight analysis by using the core area and span ratio analysis [

44] for tolerance correction, it was found that both indoor and outdoor D&WBT tolerances should be studied respectively with due consideration.

2. Principles of Tightening Instantaneous Indoor and Outdoor Dry-Bulb and Wet-Bulb Temperature Tolerances

In GB/T 7725-2004 (Chinese national standard for room air conditioners) and GB/T 17758-2010 (Chinese national standard for unitary air conditioners), indoor and outdoor D&WBT tolerances are specified specifically for each nominal working condition of constant and variable speed RAC. In particular, for variable speed RAC, nominal working conditions are more specifically defined with different running hours and operation load. For a precise energy efficiency evaluation, either indoor or outdoor D&WBT tolerances are expected to be listed corresponding to each working condition.

The mathematical method proposed in this investigation can be applied to tighten indoor and outdoor D&WBT tolerances for each working condition of both constant and variable speed RAC in regular performance tests. This process consists of RAC unit performance tests, data collection, mathematical calculation, and uncertainty evaluation. First, CC and PI (power input) are measured with indoor and outdoor D&WBTs changing within the stipulated tolerances of ±1/±0.5 °C, since even when D&WBTs change within the tolerances, different working conditions of a RAC unit in testing results in different EER, and consequently leads to a discrepancy in energy efficiency evaluation. By using the air enthalpy method in RAC performance testing, finite discrete experimental data of CC and EER under specific working conditions can be obtained when indoor/outdoor D&WBTs remain constant and outdoor/indoor D&WBTs change within ±1/±0.5 °C.

Second, based on the performance data, a series of mathematical calculation methods can be employed to tighten the instantaneous D&WBT tolerances. Characteristics of the changes of CC and EER as the D&WBTs change within the tolerances have been found. When analyzing and processing the discrete experimental data collected in a limited sample number, the AIC (Akaike information criterion) has frequently been applied in curve fitting and data prediction [

45]. As a comprehensive index, the AIC evaluates the equations fitted by processing the sample size (n), the number of parameters (K), and the RSS (residual sum of squares), as is worked in Equation (1). The minimum AIC score is considered as the best evaluation criteria. When the finite sample size is comparatively small (n/K << 40), the AICc score (the corrected AIC score) can be employed, as in Equation (2) [

46]. AICc has been widely applied in fitting curves of petrol price vs. macro-economy, energy consumption vs. year to their experimental data and CO

2 emissions vs. energy consumption [

47,

48,

49] and proves effective, but is not yet popular in processing experimental data in RAC unit tests. In this investigation, AICc was employed to achieve the best curve fitting and data prediction for CC and EER, respectively.

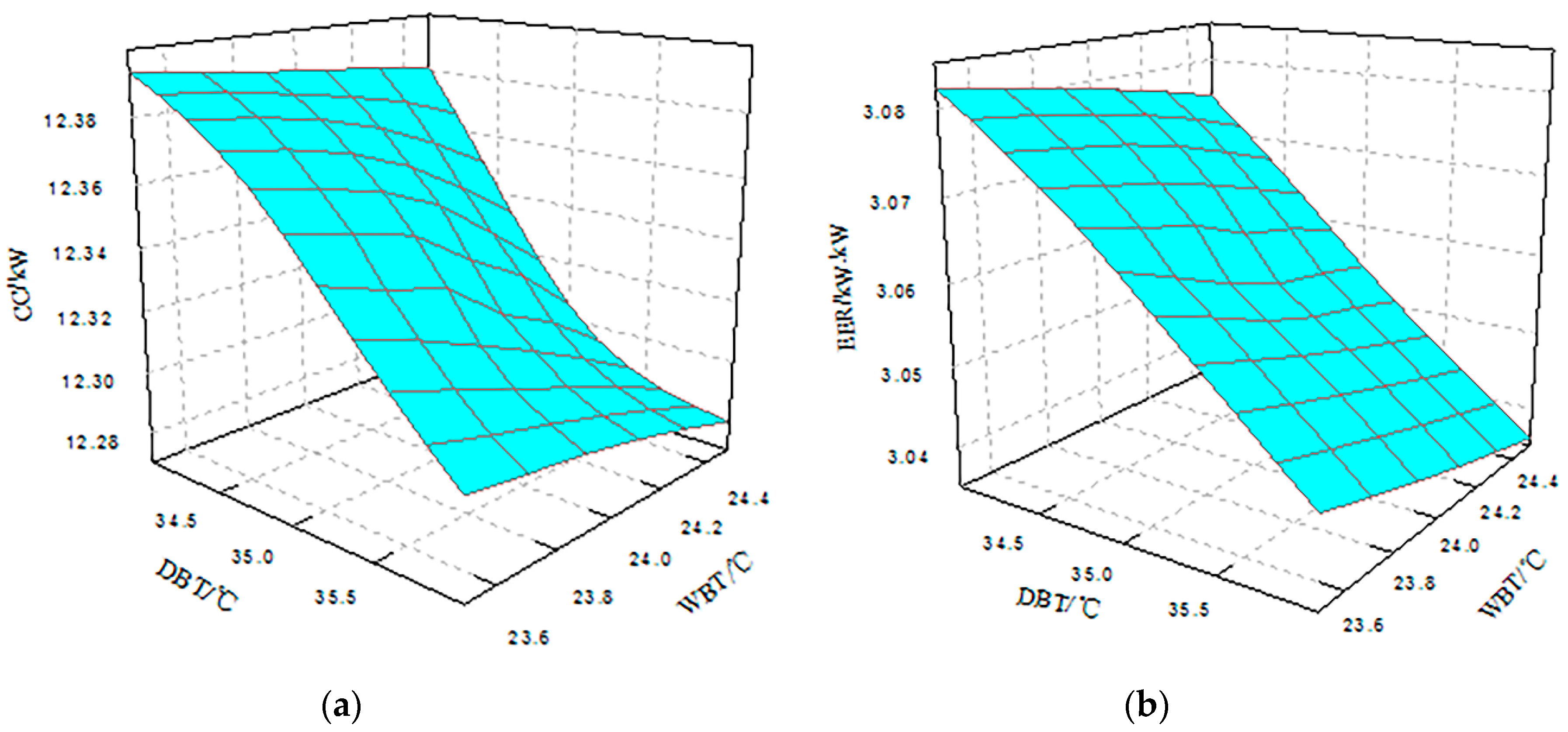

Subsequently, considering the fact that the two independent variables of dry-bulb temperature and wet-bulb temperatures affect CC and EER simultaneously, 3D surfaces, instead of curves, that indicate the changes of CC and EER can be fitted respectively. Proper equation models can be chosen on the basis of the changing characteristics of CC and EER and applied in surface fitting. Typical models and their properties are listed in

Appendix A. Using AICc, the best suitable equations are thus determined. Since non-uniform variation occurs in both CC and EER changing with indoor/outdoor D&WBTs [

50], the magnitudes of variation gradients of both CC and EER can be worked out in these most suitable equations. Furthermore, the narrowest intervals of CC and EER covering all extremal magnitudes of CC and EER gradients can be worked out, respectively, and are named as extremal intervals. In these two extremal intervals, the variation rates of CC and EER reach the maximum, respectively. Considering the compound effect of CC and EER on tightening the D&WBT tolerances, the union of D&WBTs where both CC and EER have the maximum variation rates can be considered the tightened tolerances. When the D&WBTs change within the tightened tolerances, CC and EER both fall in the intervals of gradient extrema. These tightened tolerances can make the measured CC and EER reflect their true values more convincingly, and eventually, a more accurate evaluation of energy efficiency can be realized.

According to the theory proposed above, constant speed RACs, for example, indoor and outdoor D&WBT tolerances under refrigerating and heating working conditions, can be classified in 12 conditions, as shown in

Figure 1, which presents in detail the tightening instantaneous indoor and outdoor D&WBT tolerances of the sample unit (7100 W < CC ≤ 14,000 W) under the refrigerating working condition.

5. Conclusions

Theoretically speaking, when the D&WBT tolerances are narrowed, the variation rates of CC and EER in the performance tests can be effectively decreased, and the reliability of the energy efficiency class determination can be more convincing. To accommodate the development of a global low-carbon economy, the continuous upgrading of the threshold values of RAC energy efficiency grades raise the requirements in RAC performance. Correspondingly, RAC performance test reliability is in need of improvement to avoid possible mis-evaluation of energy efficiency caused by measurements as much as possible.

Technically speaking, the instantaneous indoor and outdoor D&WBT tolerances proposed herein aim at avoiding “bad money drives out goo” in the RAC market in China. Current tolerances leave a generous range for CC and EER measurement. With the measuring instruments of greatly improved accuracy and precision than a decade ago, when the currently enacted national RAC performance standard was put into effect, the D&WBTs in performance test operation can be manipulated to fall into the energy efficiency class expected. For instance, by controlling the D&WBTs or experimental coincident, a RAC unit that actually fails to reach Class 3 can be labeled as Class 3, and a unit actually qualified for Class 3 can be determined as unqualified. Out of financial concern, products of the quality “in the margin” may gradually drive out those truly qualified units, and units of higher energy-consuming may gradually drive out those comparatively energy-saving units. RAC of energy efficiency Class 3 is of more significance in energy-saving in China because RAC units of low energy efficiency, currently being more popular in the household RAC market, have turned out to be massive energy-consuming object. When “bad money drives out good” in the household RAC market, this will end up with a massive energy waste. A responsible revision of the current Chinese national RAC performance standard will noticeably contribute to preventing unhealthy and unfair evaluations from happening.

Additionally, it has to be mentioned that the tightened D&WBT tolerances worked out in this investigation were only the calculation results for one particular RAC unit with a certain rated cooling capacity. Determination of D&WBT tolerances for this type of RAC can be achieved on the basis of greater performance test data and further data analysis. Furthermore, the determination of indoor and outdoor D&WBT tolerances for average readings in cooling capacity and heat pump tests under different working conditions of both constant and variable speed RAC units with different rated cooling capacity requires further theoretical research and much greater experimental analysis.

Furthermore, consumers can expect more reliable energy efficiency and electricity savings of energy appliance products with a revised energy efficiency evaluation using precise D&WBT tolerances. With the expected sales of RAC in China between 2009 and 2020 being about 500 million units [

53], the energy saving and reduction in carbon emissions can be noticeably large, especially in summer when the energy demand amounts normally peak during the year.