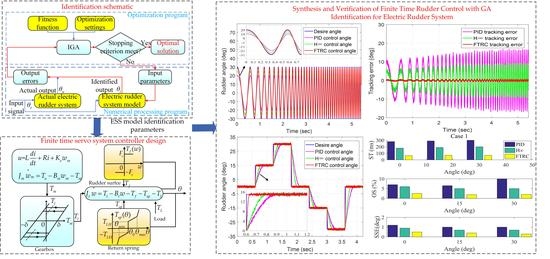

Synthesis and Verification of Finite-Time Rudder Control with GA Identification for Electric Rudder System

Abstract

1. Introduction

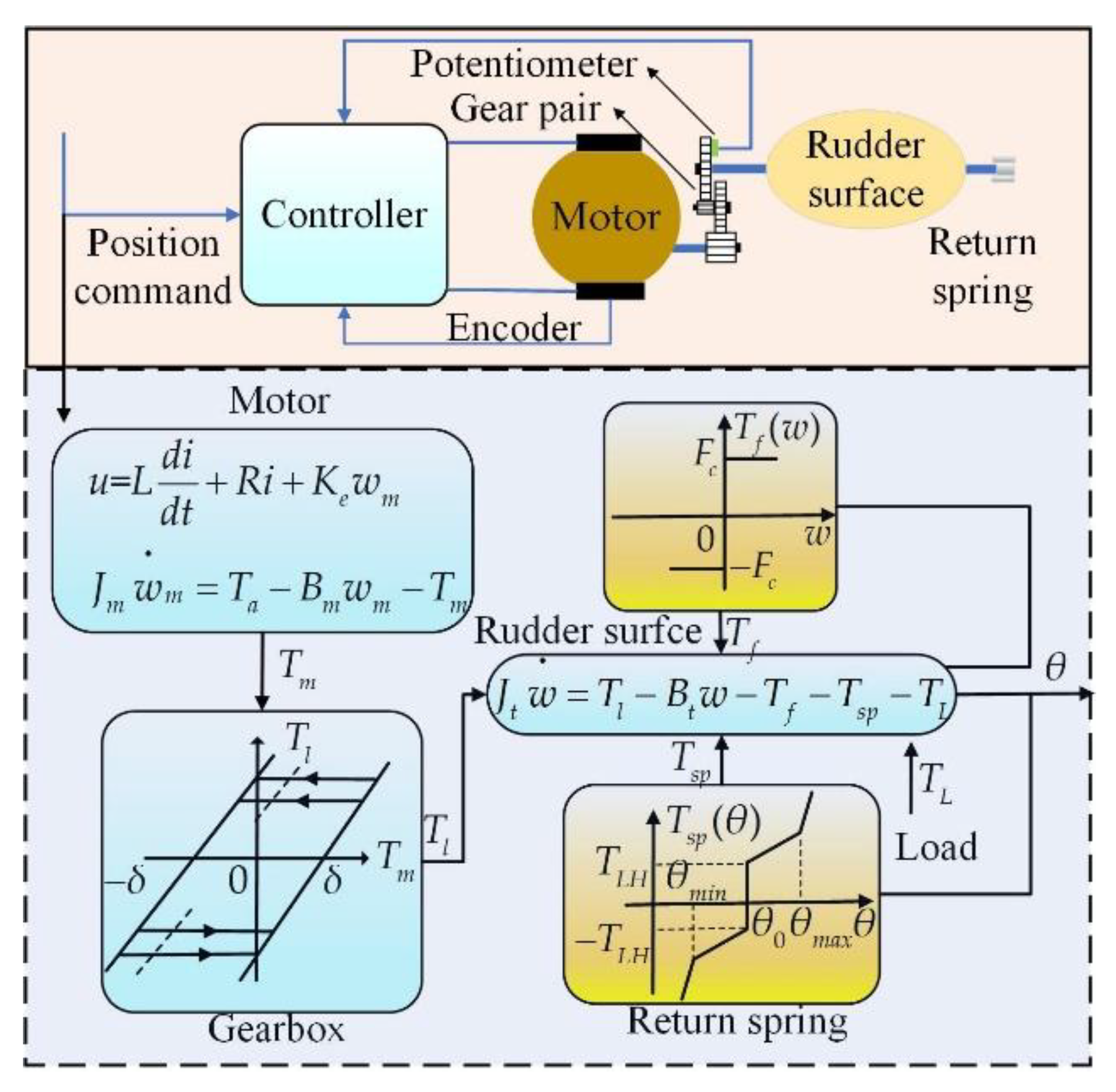

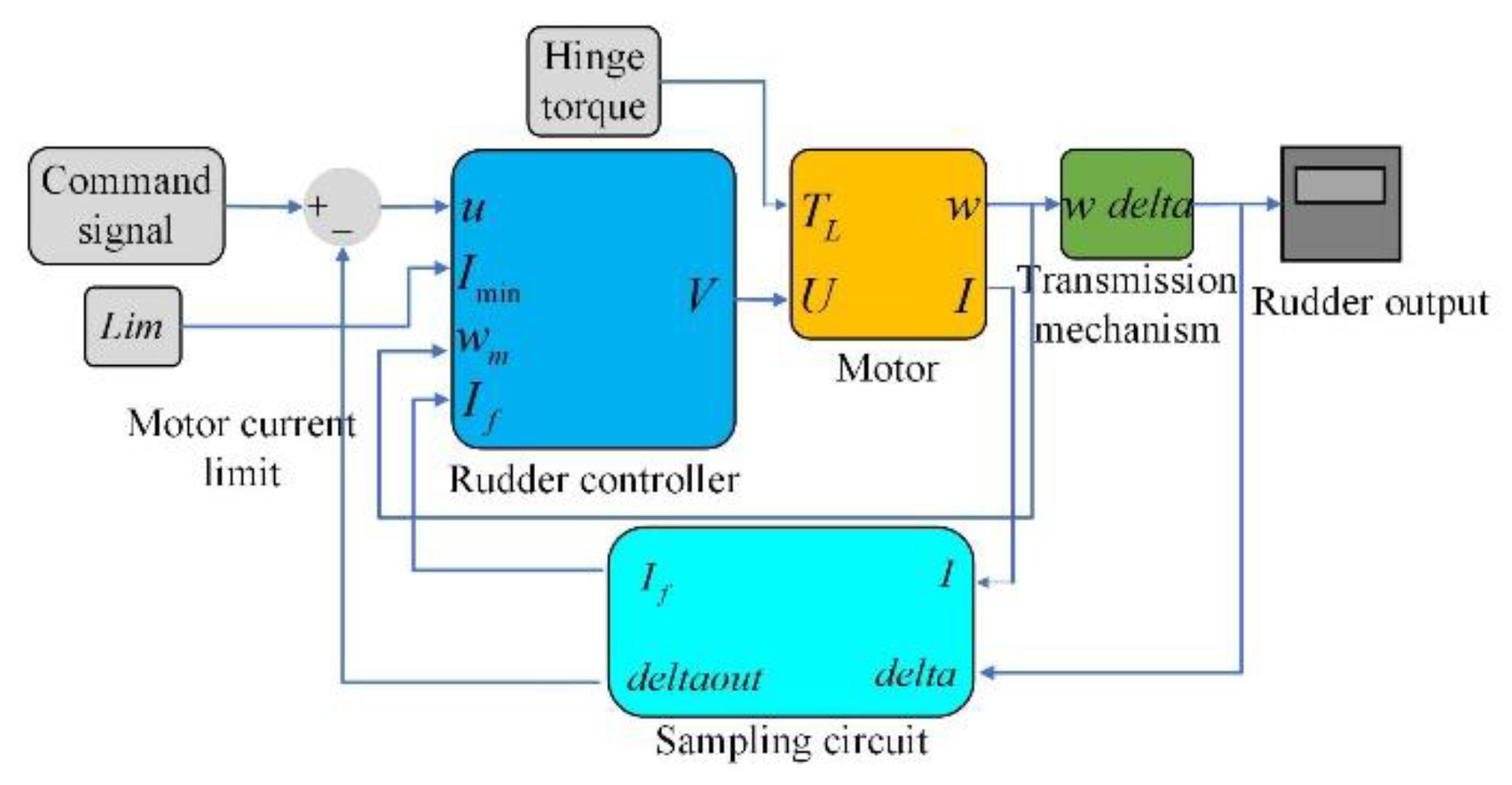

2. Model of Electric Rudder System

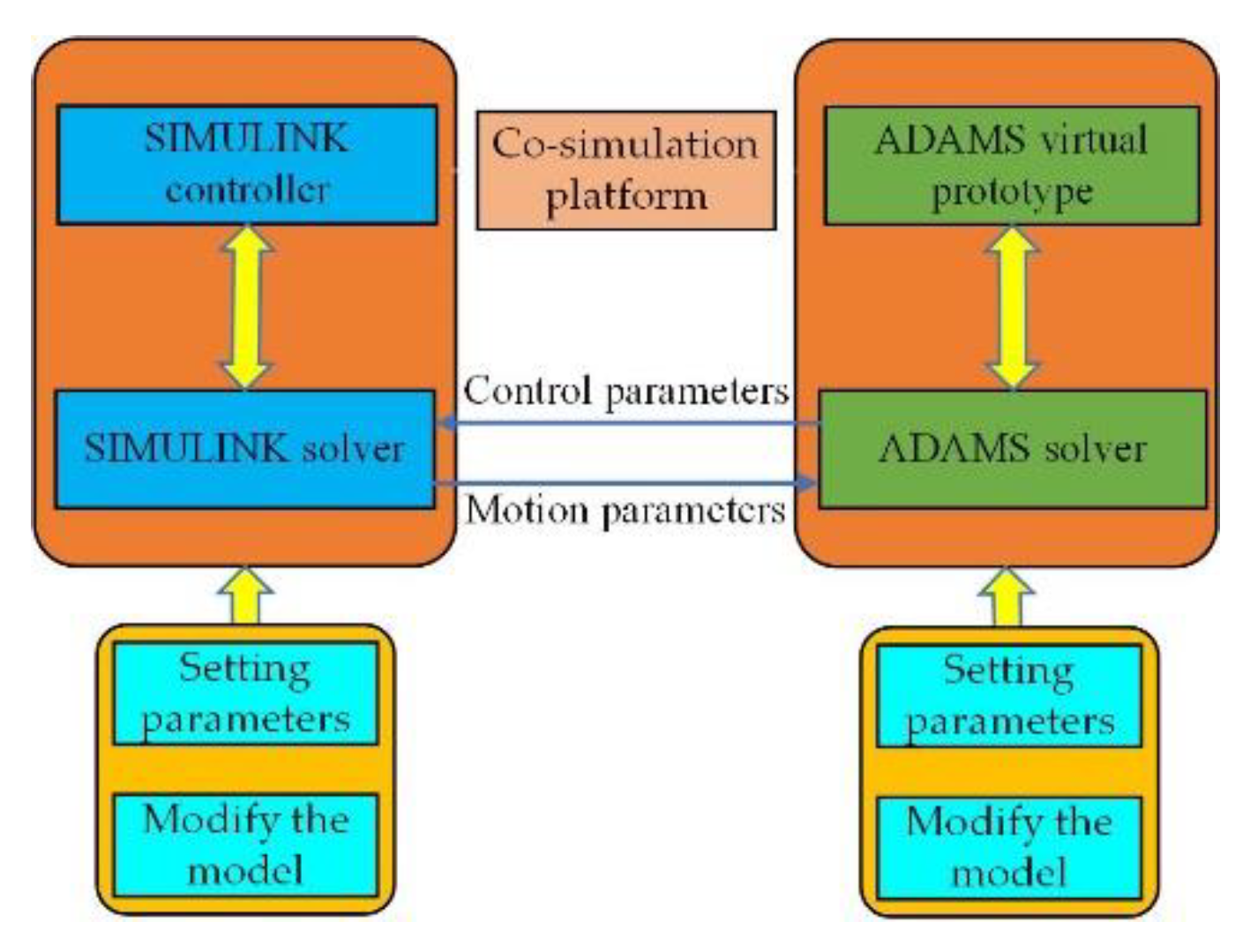

2.1. System Description

2.2. Fundamental Lemma

- (1)

- V: .

- (2)

- There exist real numbers c > 0, a∈(0,1) and an open neighborhood containing the origin, so that the following conditions are true

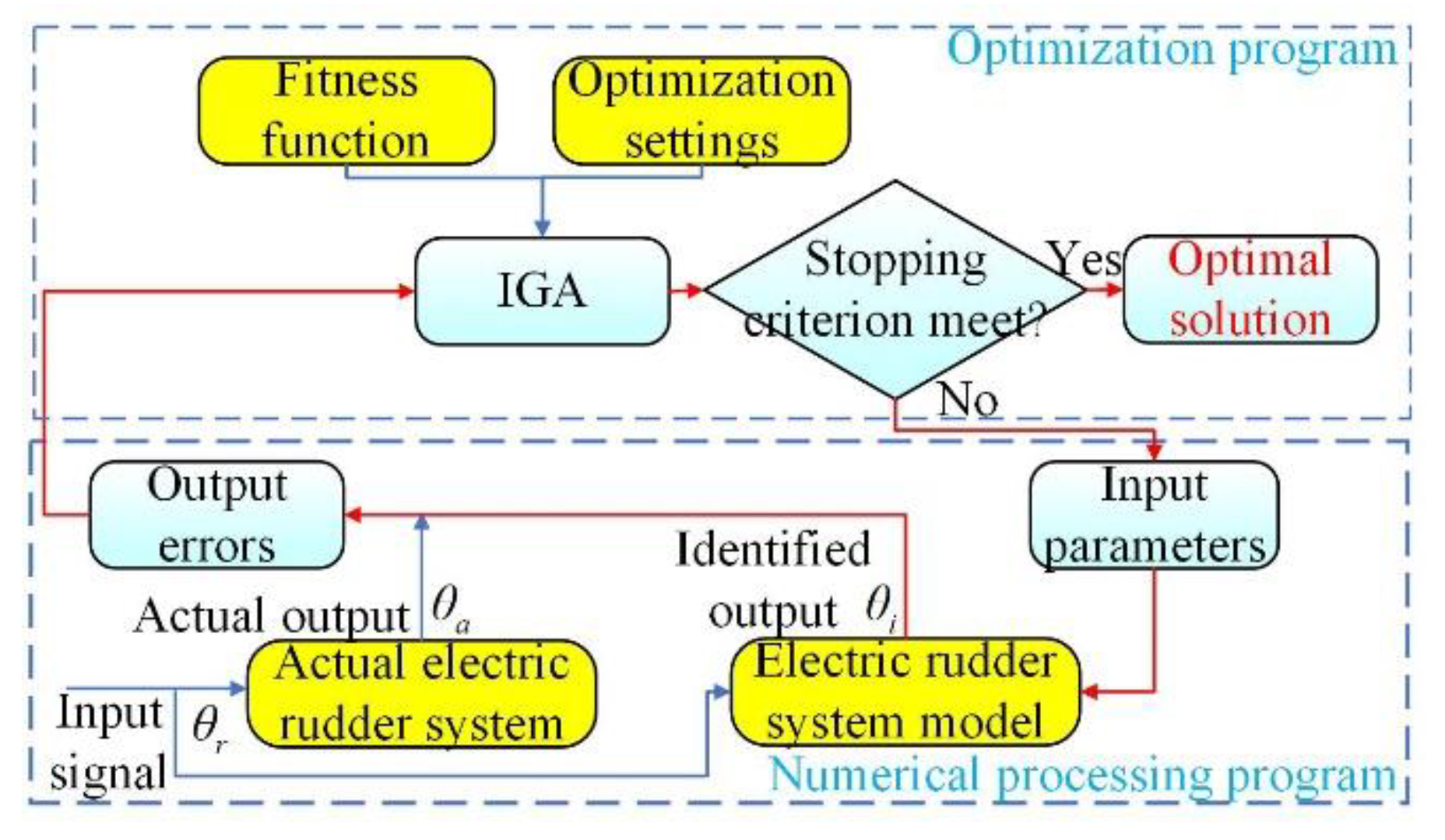

3. Strategy Based on GA Identification

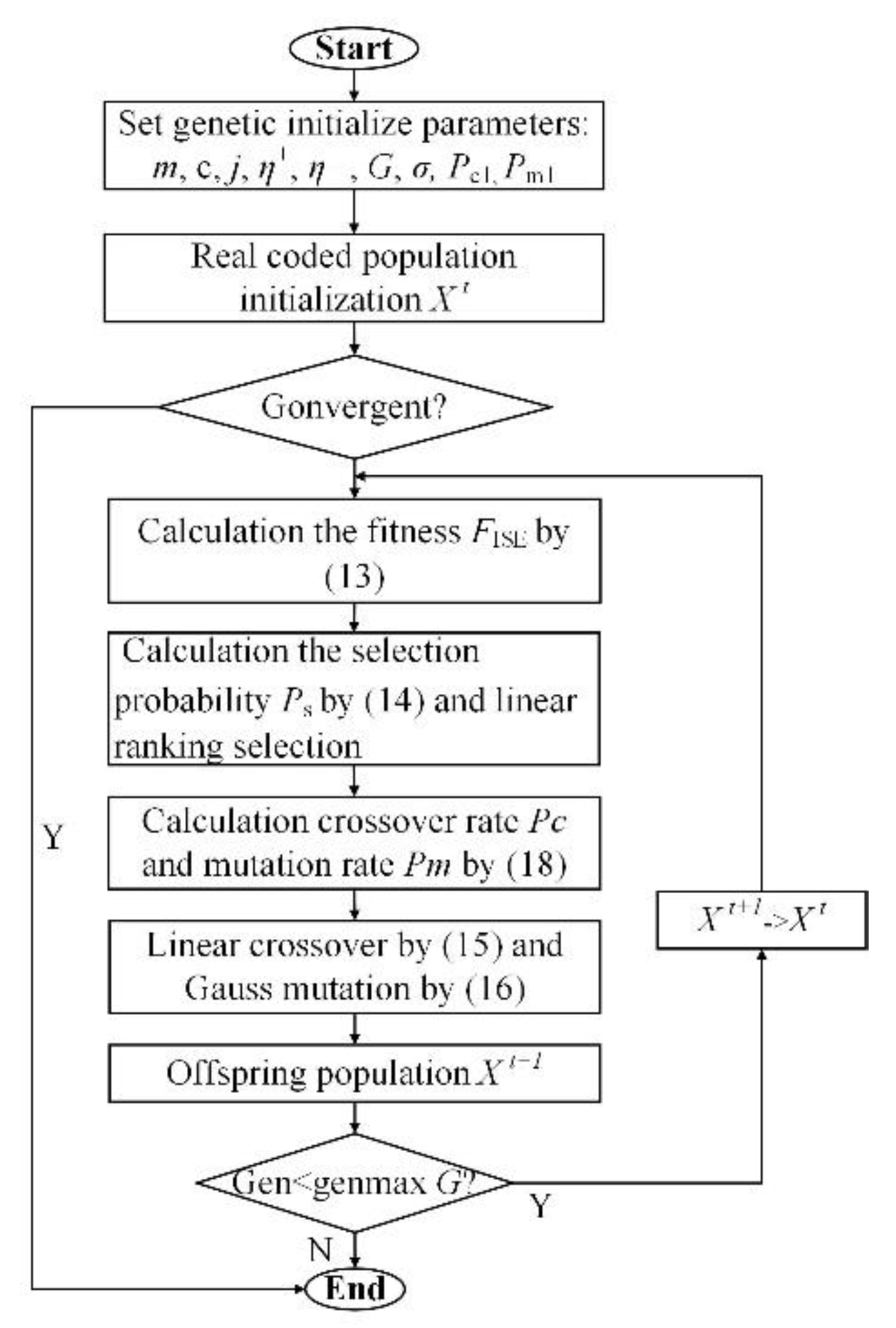

3.1. GA-Based Parameter Identification

3.2. Improvement on GA

3.2.1. Genetic Operators

3.2.2. Adaptive Crossover and Mutation Probability

3.3. Controller Based on Finite Time

- (1)

- q is chosen as a fraction satisfying q ∈ (2/3, 1) with the odd numerator and denominator; generally, it may be more likely to close to 1.

- (2)

- This paper chooses L ∈ (0, 1) by determining (32), so as to reduce the influence of uncertain parameters on the convergence rate. Therefore, on the premise of satisfying the convergence rate, the parameter should be as small as possible.

- (3)

- The choice of k1, k2, and k3 is mainly based on guaranteeing the positiveness of m1, m2, and m3; that is, inequality (33)–(35) holds. Note the interrelations and constraints between k1, k2, and k3 in (33)–(35). Their selection follows the following guidelines: first, k1 is selected by guaranteeing inequality (33). Then, choose k2 to be greater than k1 according to (34). After that, select k3 to be greater than k1 and k2 according to (35). It should be noted that a larger k3 will increase the burden on the control input u from (31).

- (4)

- γi (i = 1, …, 7) are just for guaranteeing the positiveness of m1, m2, and m3.

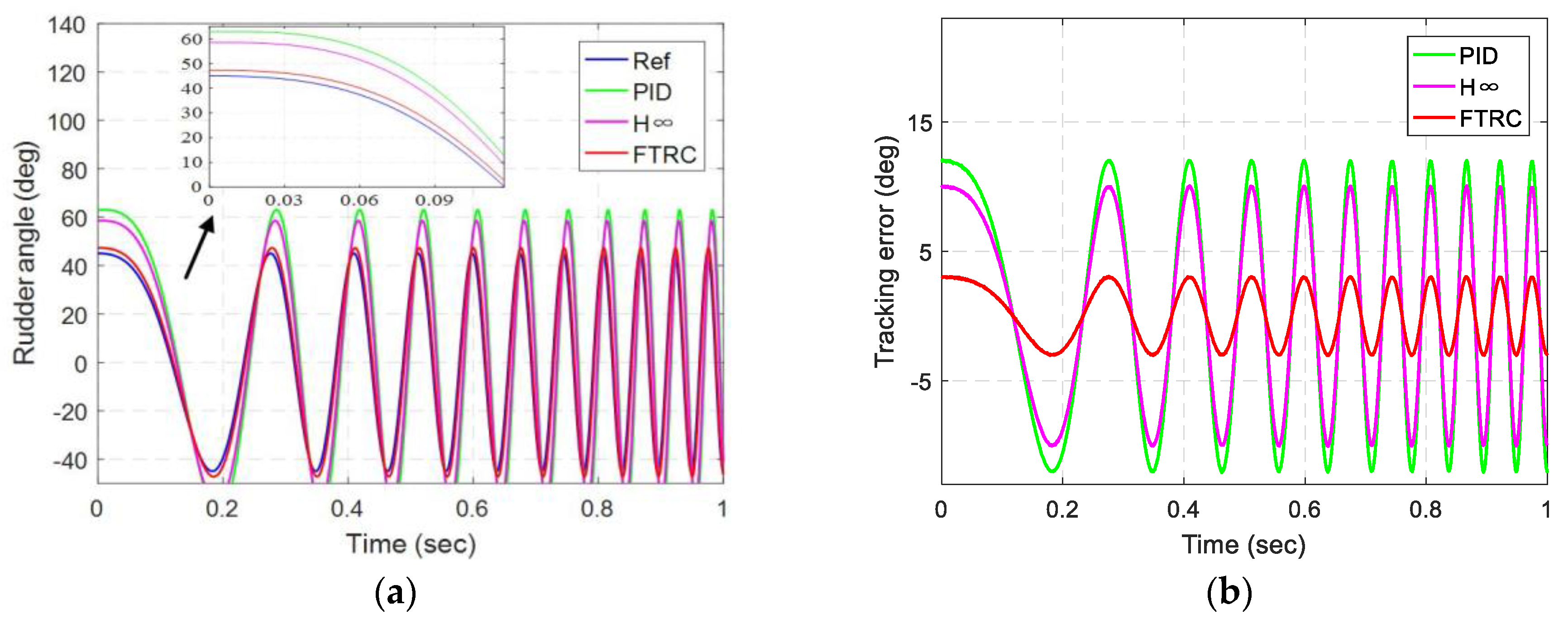

4. Simulation Comparison with Existing Strategies

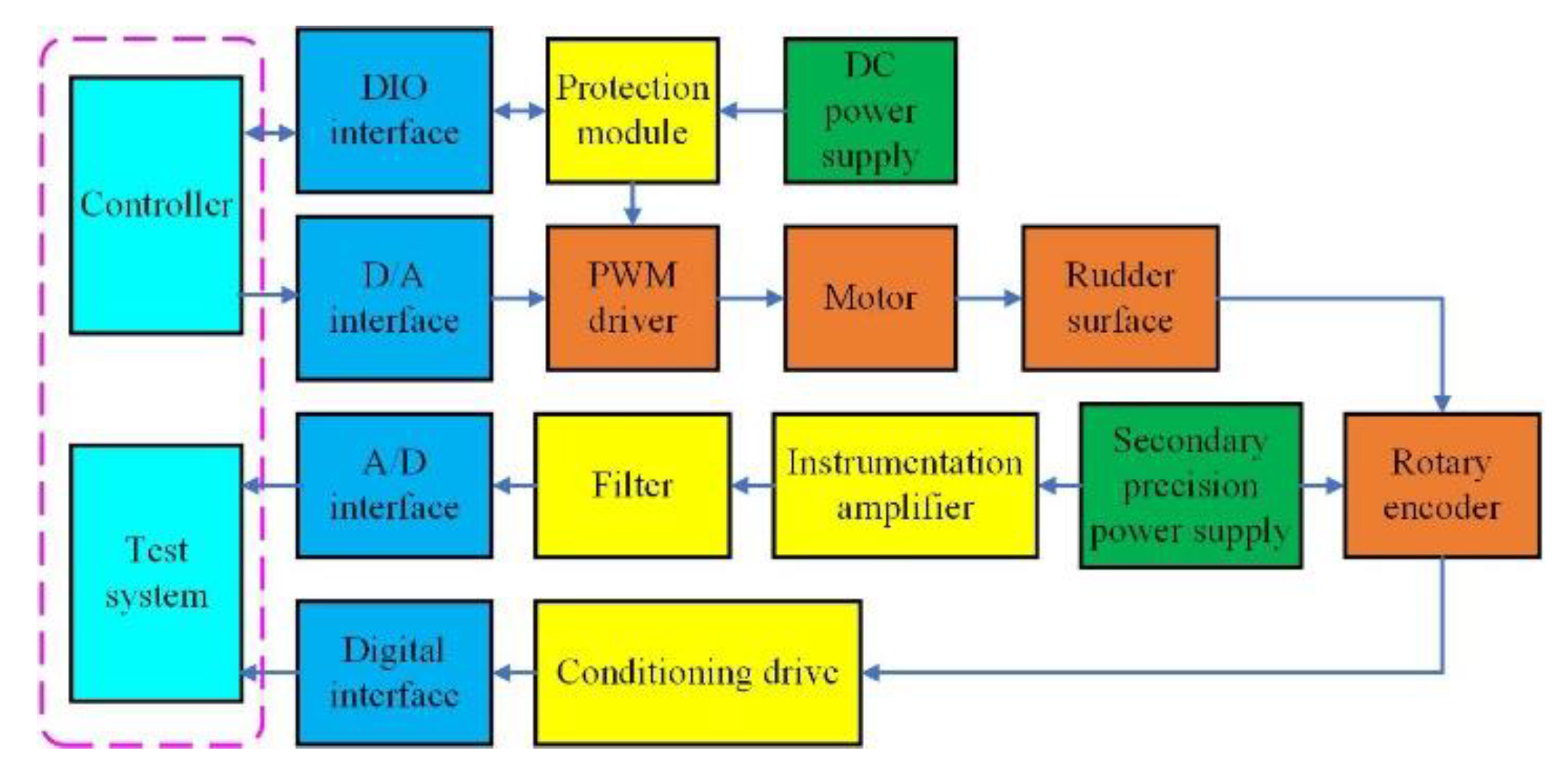

5. Experimental Application and Results Analysis

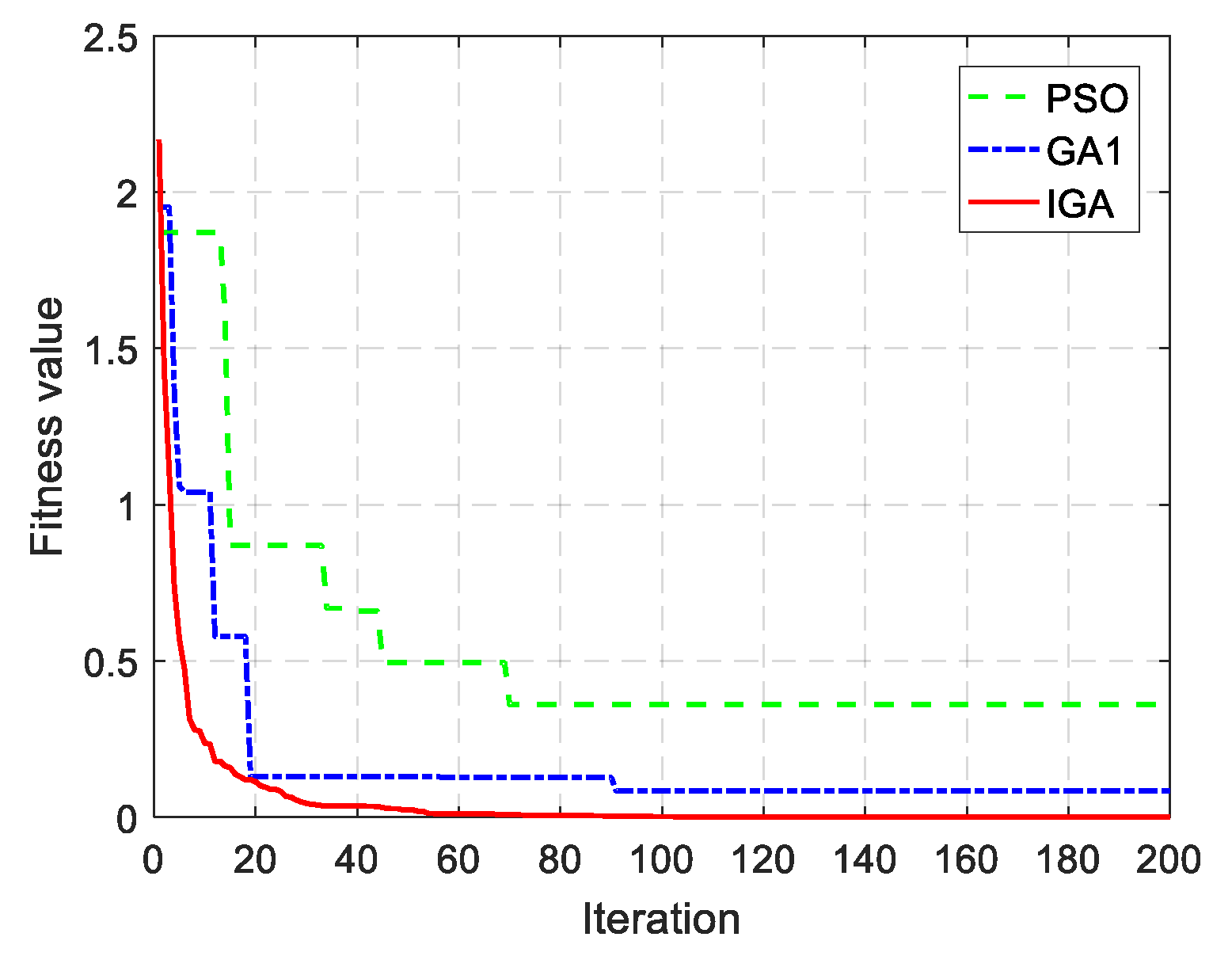

5.1. Parameter Identification Algorithm Verification

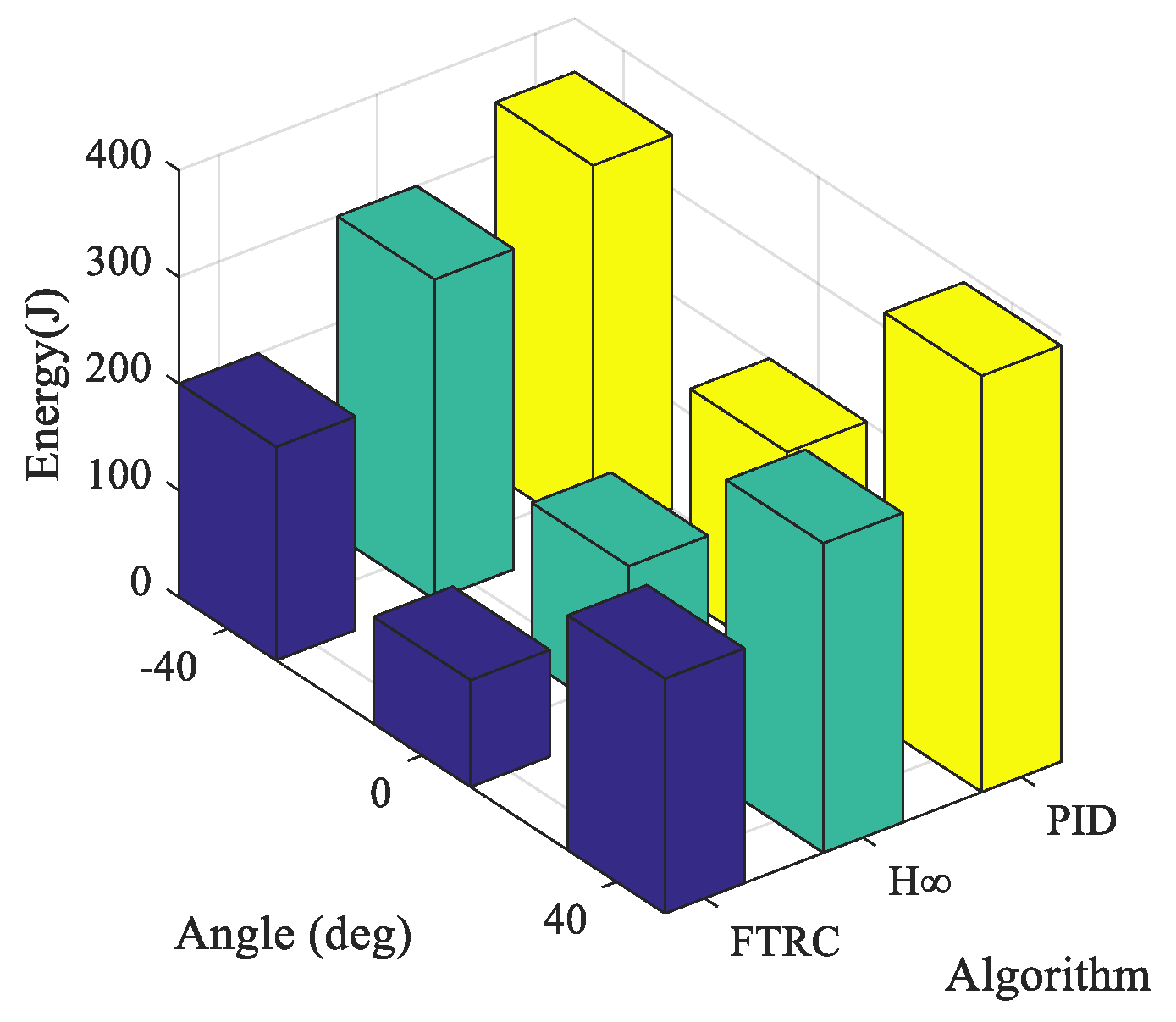

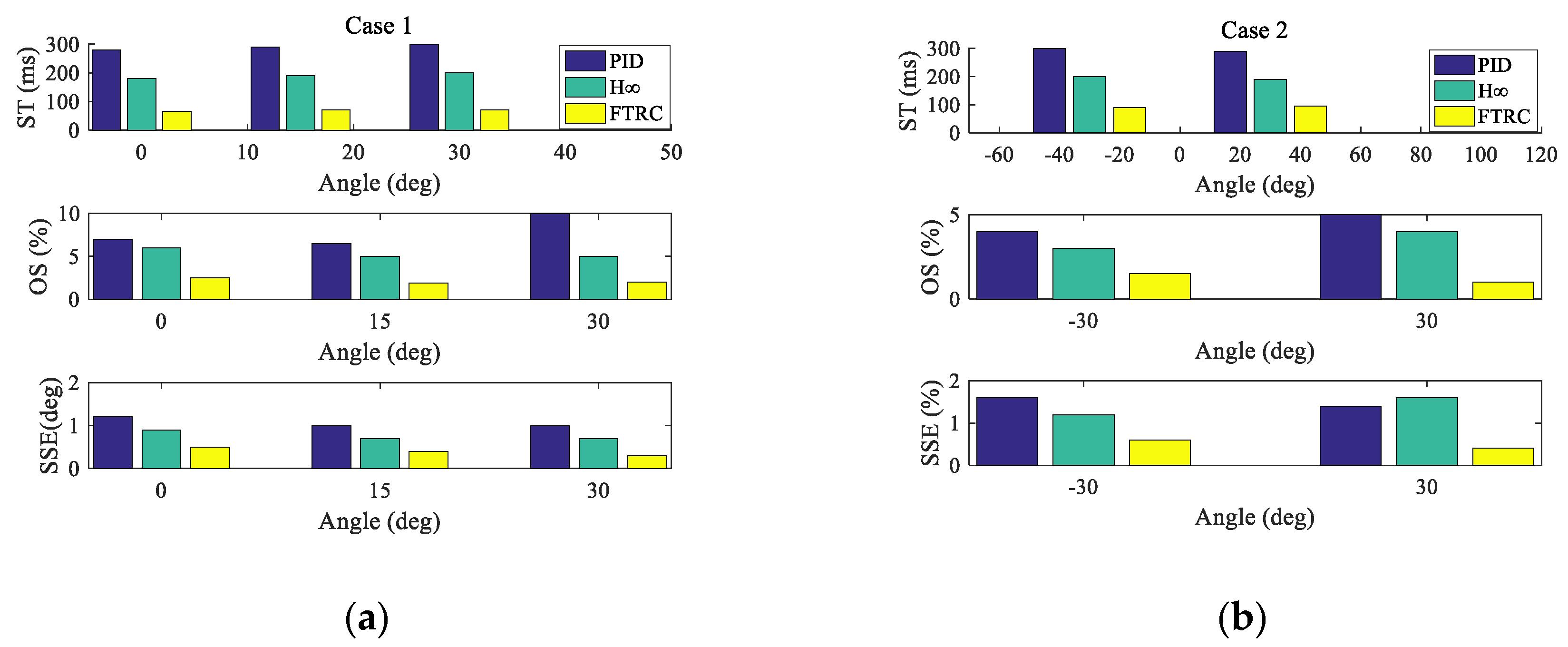

5.2. Controller Verification

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chang, J. Test Method and Model Identification of Flight Control Actuator Based on Video Acquisition. Master′s Thesis, Beijing Institute of Technology, Beijing, China, 2016. [Google Scholar]

- Shi, Z.; Wang, Z.; Ji, Z. A multi-Innovation recursive least squares algorithm with a forgetting factor for Hammerstein CAR systems with backlash. Circuits Syst. Signal Process. 2016, 35, 4271–4289. [Google Scholar] [CrossRef]

- Claes, M.; Graham, M. Frequency domain subspace identification of a tape servo system. Microsyst. Technol. 2007, 13, 1439–1447. [Google Scholar] [CrossRef]

- Liu, G.; Shen, G. Experimental evaluation of the parameter-Based closed-Loop transfer function identification for electro-Hydraulic servo systems. Adv. Mech. Eng. 2017, 9, 1–14. [Google Scholar] [CrossRef]

- Thomas, G.; Lingai, L.; Dominique. Identification of optimal parameters for a small-Scale compressed-Air energy storage system using real coded genetic algorithm. Energies 2019, 12, 377–408. [Google Scholar]

- Liu, H.; Lin, Z.; Xu, Y. Coverage uniformity with improved genetic simulated annealing algorithm for indoor Visible Light Communications. Opt. Commun. 2019, 439, 156–163. [Google Scholar] [CrossRef]

- Liao, J.; Luo, F.; Luo, Z. The parameter identification method of steam turbine nonlinear servo system based on artificial neural network. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–10. [Google Scholar] [CrossRef]

- Wang, J. Research on Parameter Optimization Method of Electric Rudder System. Master′s Thesis, North University of China, Taiyuan, China, 2016. [Google Scholar]

- Deur, J.; Pavkovic, D.; Peric, C. An electronic throttle control strategy including compensation of friction and limp-Home effects. IEEE Trans. Ind. Appl. 2003, 40, 821–834. [Google Scholar] [CrossRef]

- Wang, H.; Liu, L.; He, P. Robust adaptive position control of automotive electronic throttle valve using PID-Type sliding mode technique. Nonlinear Dyn. 2016, 85, 1331–1344. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, Y. A novel electronic-Throttle-Valve controller based on approximate model method. IEEE Trans. Ind. Electron. 2009, 56, 883–890. [Google Scholar] [CrossRef]

- Wang, C.H.; Huang, D.Y. A new intelligent fuzzy controller for nonlinear hysteretic electronic throttle in modern intelligent automobiles. IEEE Trans. Ind. Electron. 2013, 60, 2332–2345. [Google Scholar] [CrossRef]

- Bernardo, M.; Montanaro, A. Synthesis and experimental validation of the novel LQ-NEMCSI adaptive strategy on an electronic throttle valve. IEEE Trans. Control Syst. Technol. 2010, 18, 1325–1337. [Google Scholar] [CrossRef]

- Montanaro, U.; Gaeta, A.; Giglio, V. Robust discrete-Time MRAC with minimal controller synthesis of an electronic throttle body. IEEE-Asme Trans. Mechatron. 2014, 19, 524–537. [Google Scholar] [CrossRef]

- Jiao, X.; Zhang, J.; Shen, T. An adaptive servo control strategy for automotive electronic throttle and experimental validation. IEEE Trans. Ind. Electron. 2014, 61, 5275–6284. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, S.; Karimi, H. Robust finite-Time control of switched linear systems and application to a class of servomechanism systems. IEEE/ASME Trans. Mechatron. 2015, 20, 1–10. [Google Scholar] [CrossRef]

- Huang, J.; Wen, C.; Wang, C. Design of adaptive finite-Time controllers for nonlinear uncertain systems based on given transient specifications. Automatica 2016, 59, 395–404. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, R.; Guo, C.; Ge, S.; Chen, X. Analysis and Verification of Finite Time Servo System Control with PSO Identification for Electric Servo System. Energies 2019, 12, 3578. [Google Scholar] [CrossRef]

- Huang, X.; Lin, W.; Yang, B. Global finite-Time stabilization of a class of uncertain nonlinear systems. Automatica 2005, 41, 881–888. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agareal, S. A fast and elitist multi-Objective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Shieh, N.; Tung, P.; Lin, C. Robust output tracking control of a linear brushless DC motor with time-Varying disturbances. IEE Proc.-Electr. Power Appl. 2002, 149, 39–45. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| J | 0.0031 | kgm2 |

| B | 0.0098 | Nm s/rad |

| Kt | 0.0175 | Nm/A |

| Ke | 0.0295 | V s/rad |

| ks | 0.0877 | Nm/rad |

| TLH | 0.46 | Nm |

| Fc | 0.34 | Nm |

| R | 1.55 | Ω |

| L | 1.6 | mH |

| θ0 | 15 | ° |

| n | 22.26 | / |

| Parameters | Value | Mean Value of the Identification Parameter (30 Trials) | |||||

|---|---|---|---|---|---|---|---|

| PSO | GA | IGA | |||||

| EPE | EPE | EPE | |||||

| L | 0.003 | 0.002 | 0.33 | 0.004 | 0.33 | 0.0025 | 0.167 |

| R | 1.2 | 1.52 | 0.27 | 1.02 | 0.15 | 1.105 | 0.079 |

| ks | 0.08 | 0.06 | 0.25 | 0.05 | 0.375 | 0.071 | 0.113 |

| TLH | 0.4 | 0.55 | 0.375 | 0.25 | 0.375 | 0.32 | 0.2 |

| Fc | 0.2 | 0.31 | 0.55 | 0.15 | 0.25 | 0.17 | 0.15 |

| J | 0.001 | 0.0012 | 0.2 | 0.0008 | 0.2 | 0.0011 | 0.1 |

| B | 0.006 | 0.0039 | 0.35 | 0.0089 | 0.483 | 0.0069 | 0.15 |

| Kt | 0.5 | 0.31 | 0.38 | 0.38 | 0.24 | 0.42 | 0.16 |

| Ke | 0.6 | 0.88 | 0.47 | 0.45 | 0.25 | 0.69 | 0.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Yang, R.; Guo, C.; Ge, S.; Chen, X. Synthesis and Verification of Finite-Time Rudder Control with GA Identification for Electric Rudder System. Energies 2020, 13, 1379. https://doi.org/10.3390/en13061379

Wu Z, Yang R, Guo C, Ge S, Chen X. Synthesis and Verification of Finite-Time Rudder Control with GA Identification for Electric Rudder System. Energies. 2020; 13(6):1379. https://doi.org/10.3390/en13061379

Chicago/Turabian StyleWu, Zhihong, Ruifeng Yang, Chenxia Guo, Shuangchao Ge, and Xiaole Chen. 2020. "Synthesis and Verification of Finite-Time Rudder Control with GA Identification for Electric Rudder System" Energies 13, no. 6: 1379. https://doi.org/10.3390/en13061379

APA StyleWu, Z., Yang, R., Guo, C., Ge, S., & Chen, X. (2020). Synthesis and Verification of Finite-Time Rudder Control with GA Identification for Electric Rudder System. Energies, 13(6), 1379. https://doi.org/10.3390/en13061379