Safe and Efficient Coal Mining Below the Goaf: A Case Study

Abstract

:1. Introduction

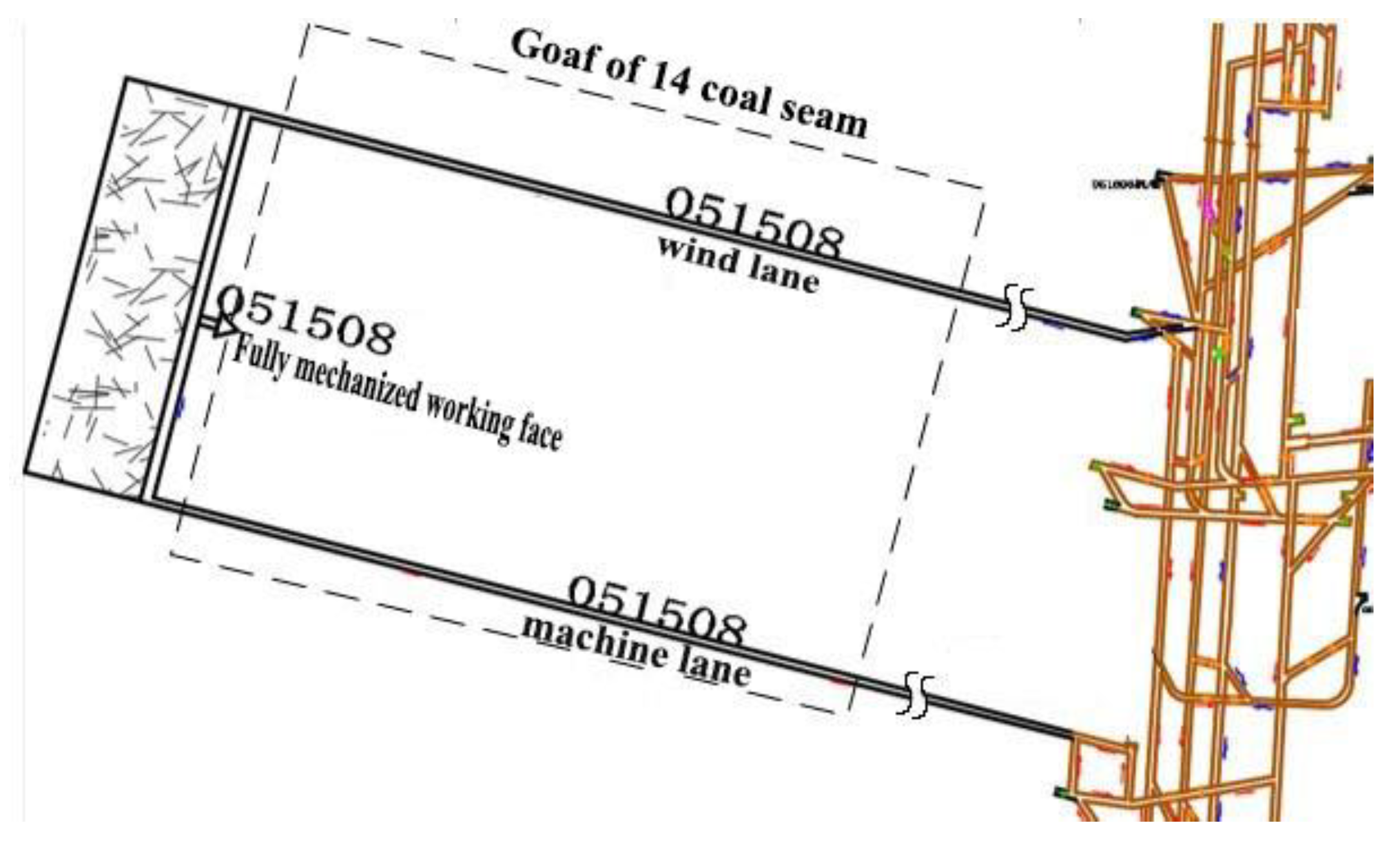

2. Overview of the Working Face

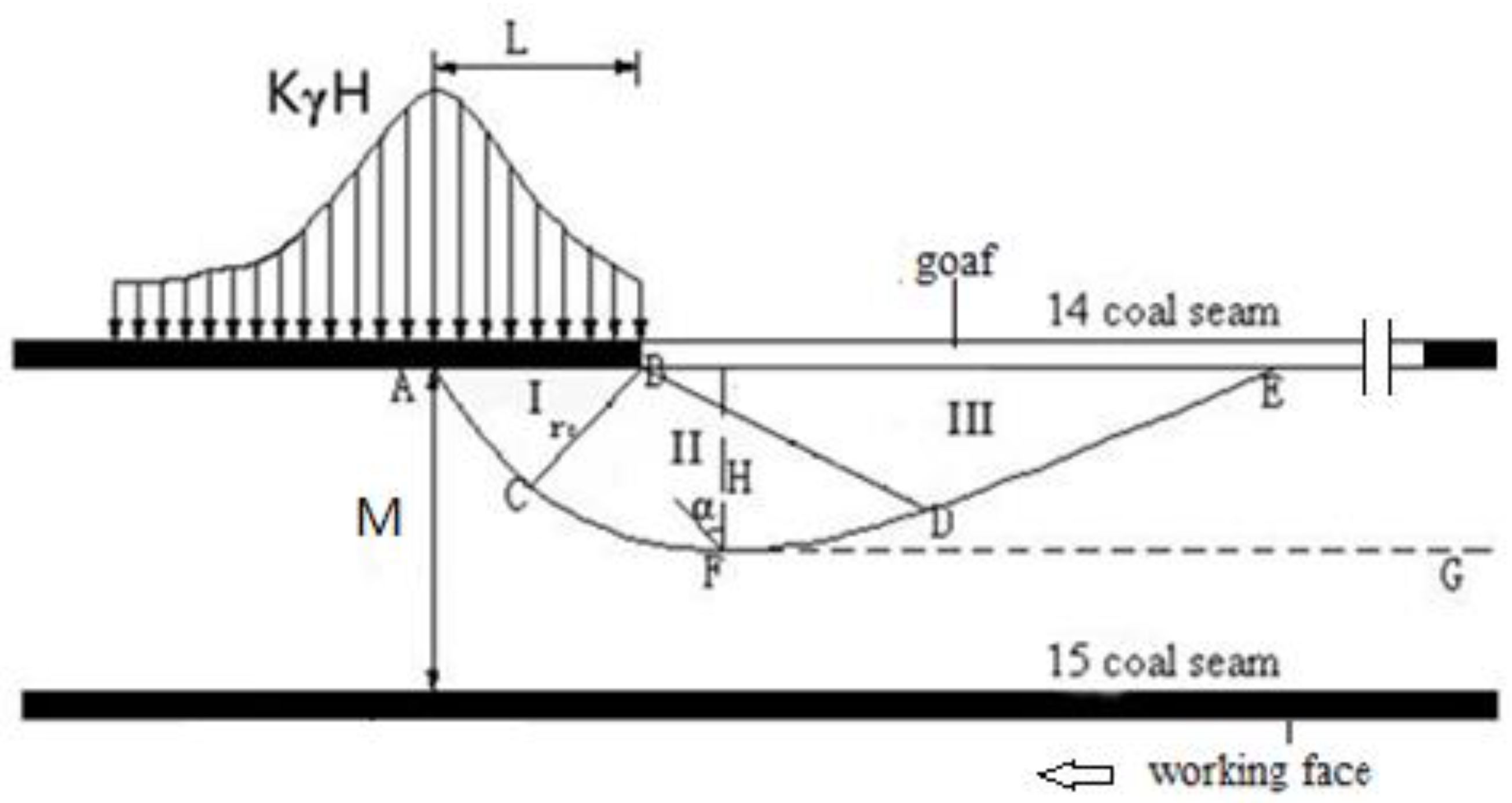

3. Analysis of Roof Weighting Law

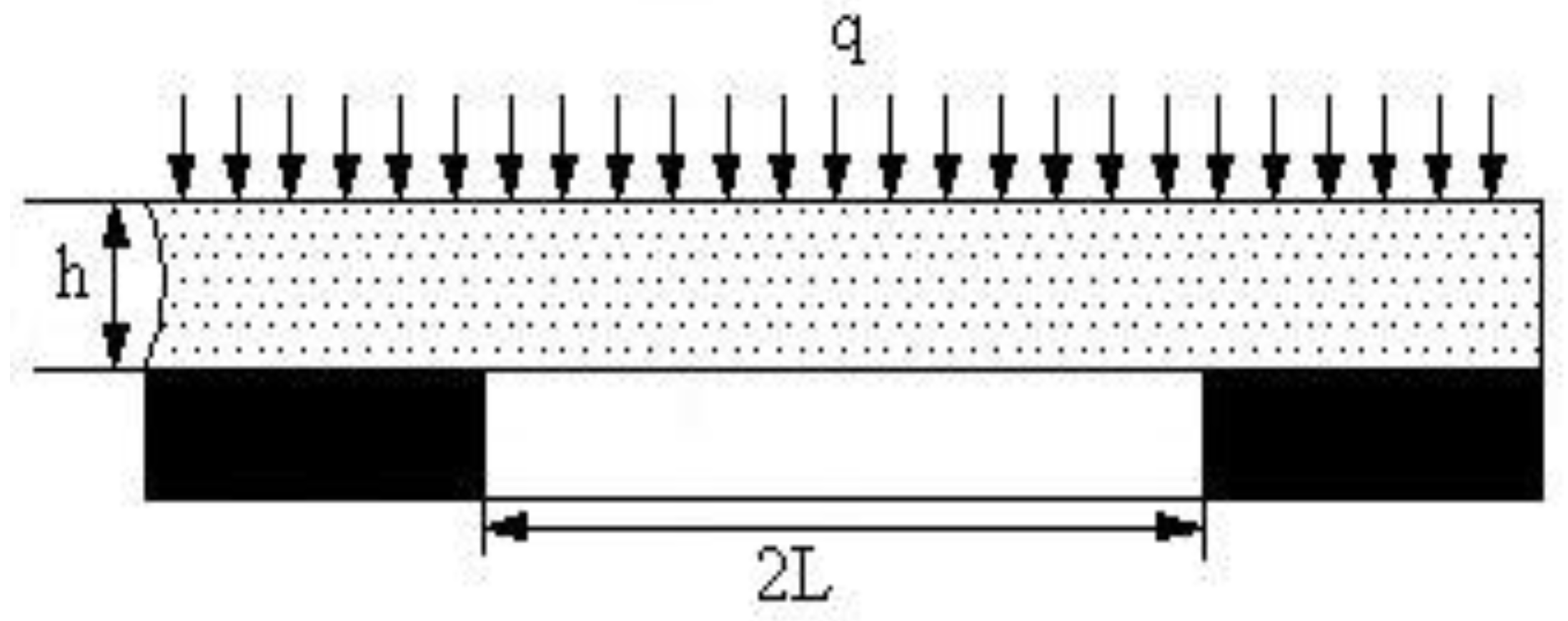

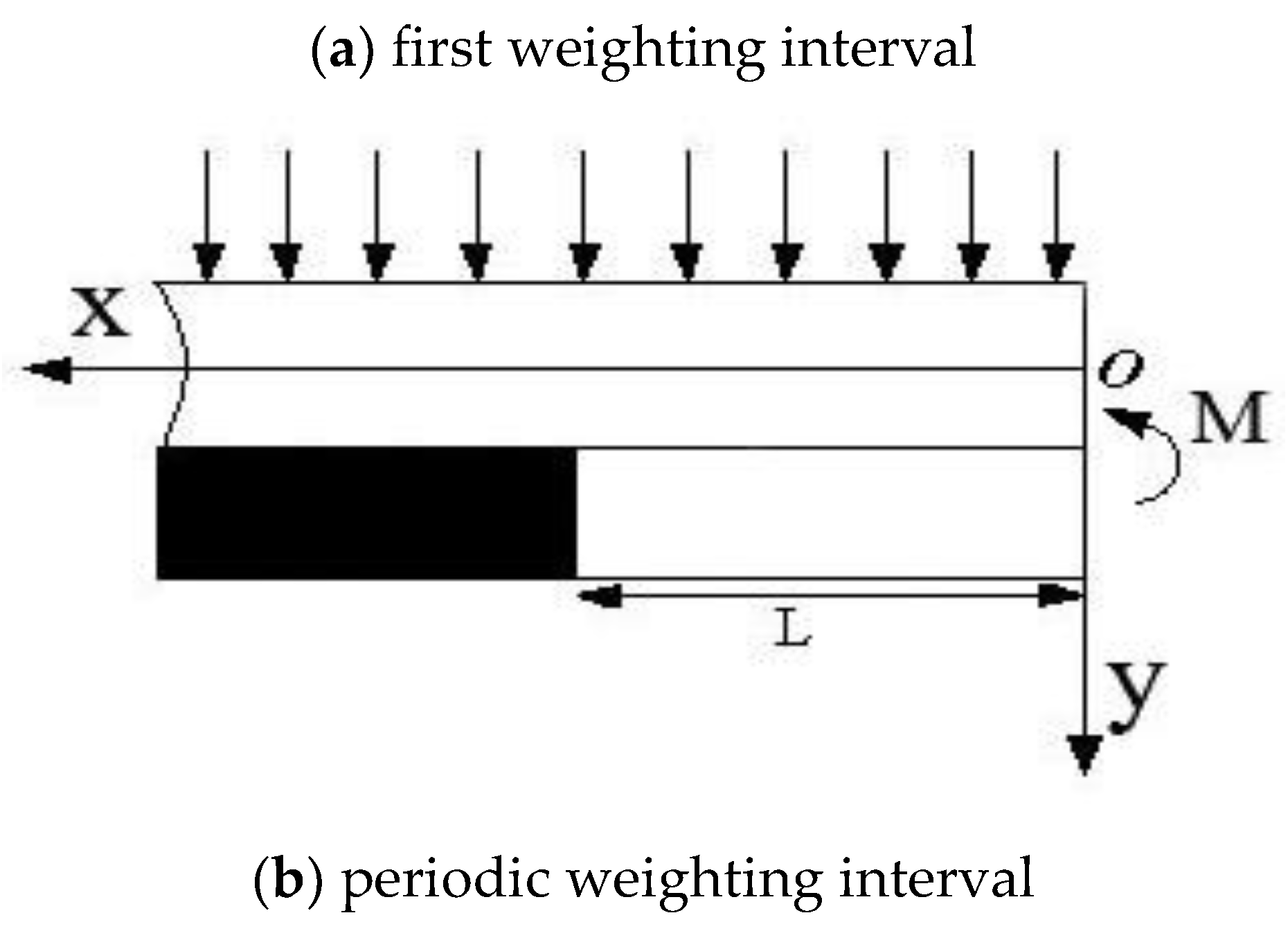

3.1. Analysis of the Weighting Interval below the Non-Goaf

3.2. Analysis of the Weighting Interval below the Goaf

4. Numerical Simulation Analysis

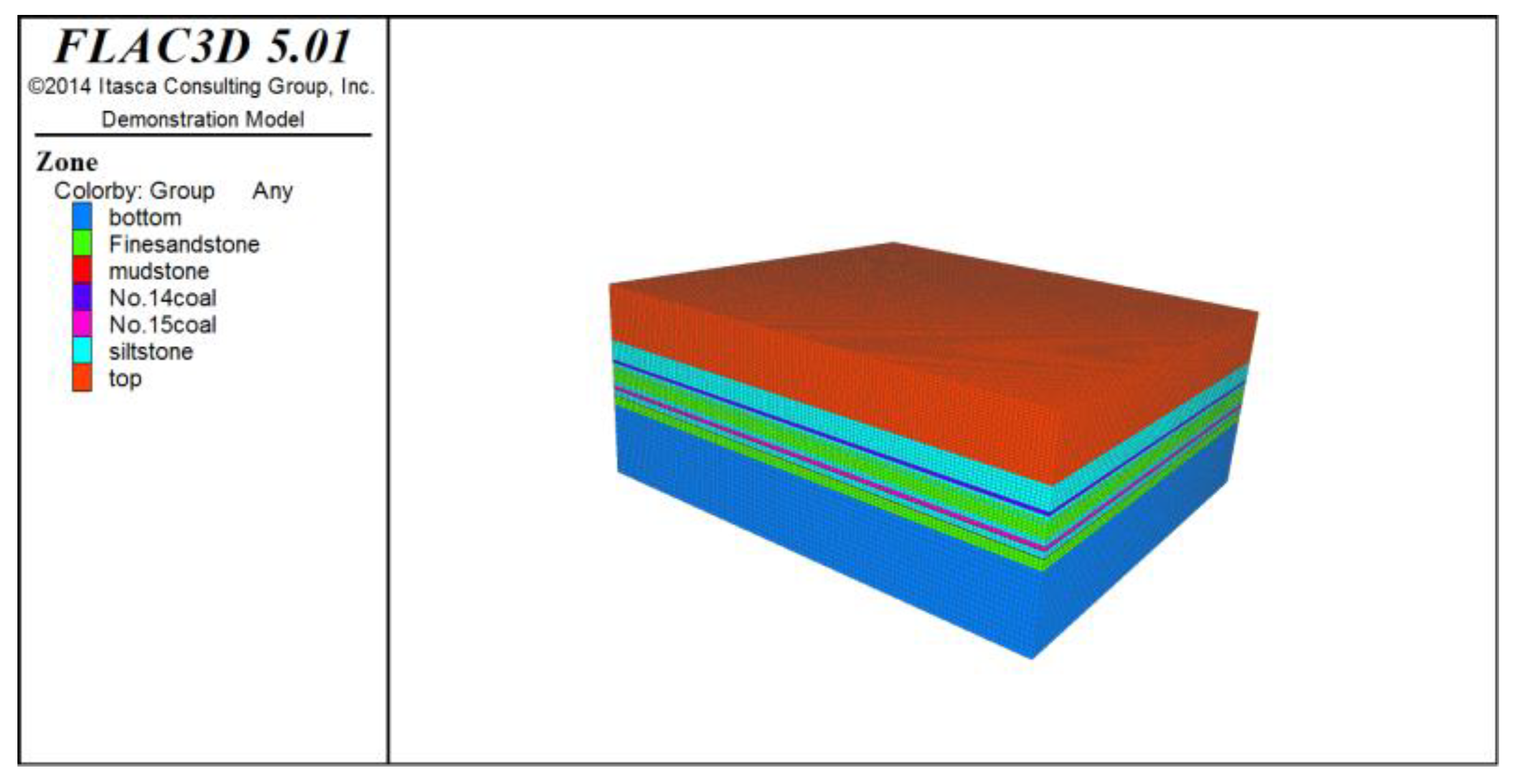

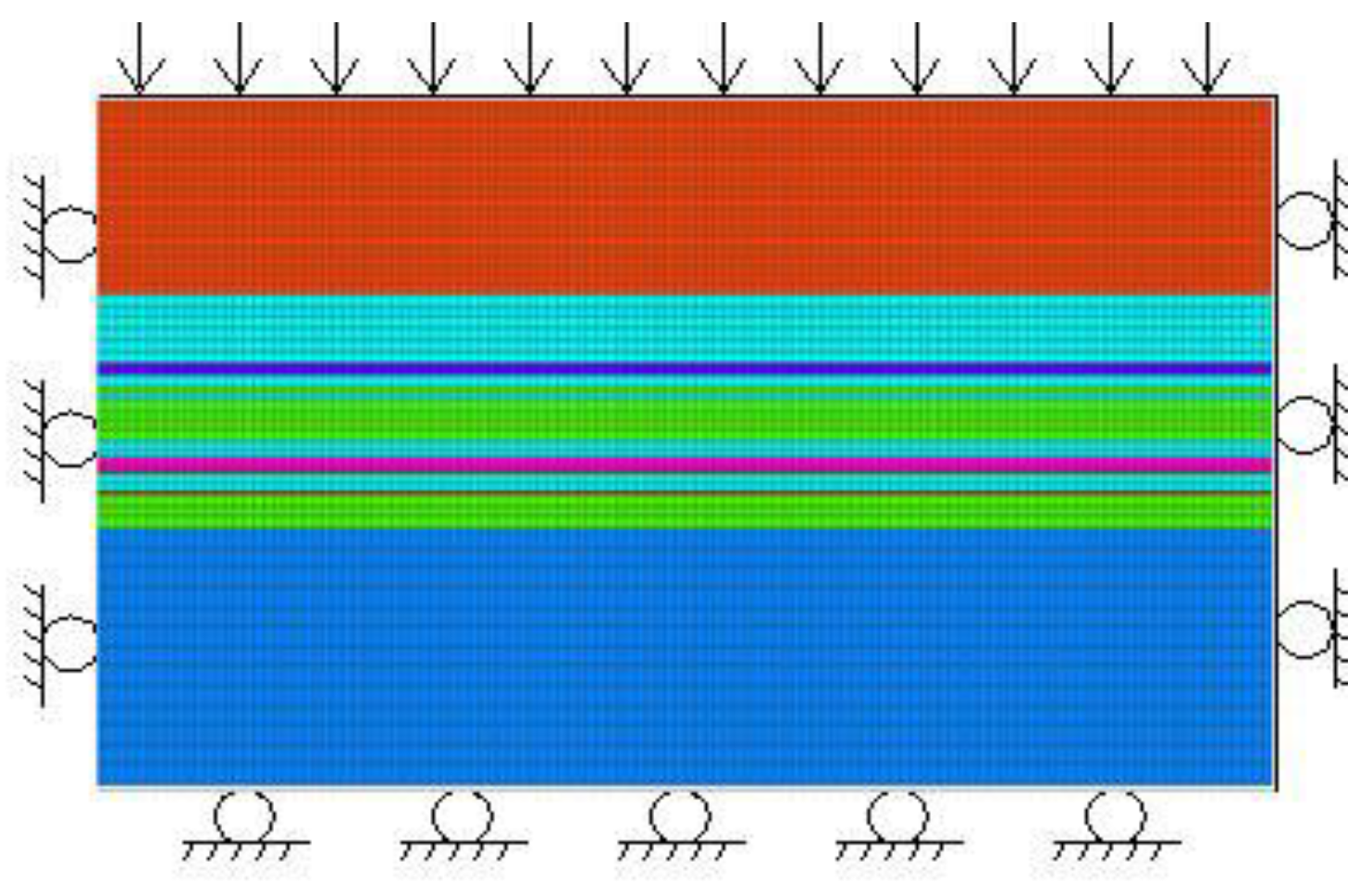

4.1. Model Establishment

4.2. Analysis of Simulation Results

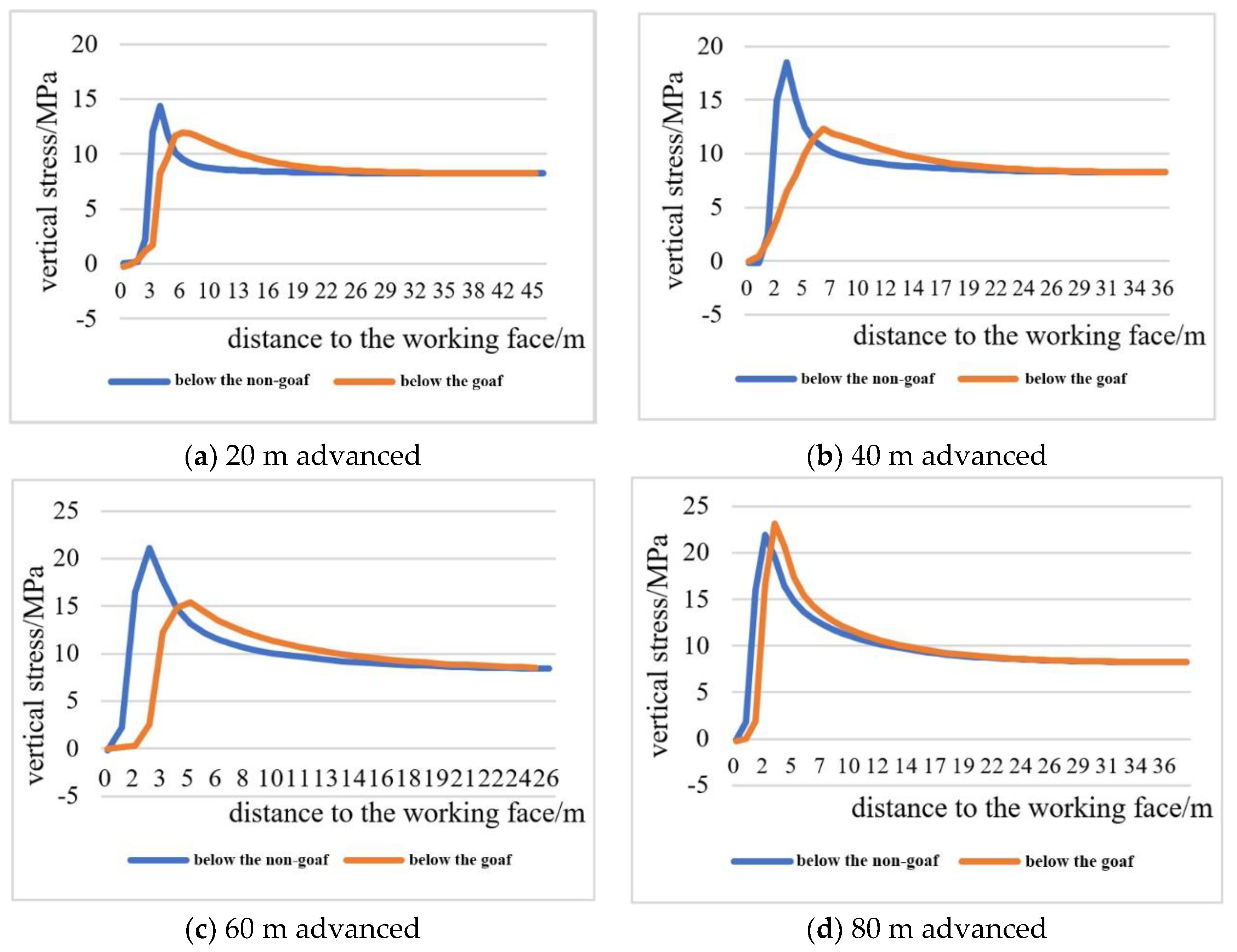

4.2.1. Vertical Stress Distribution in Front of the Working Face under Different Mining Conditions

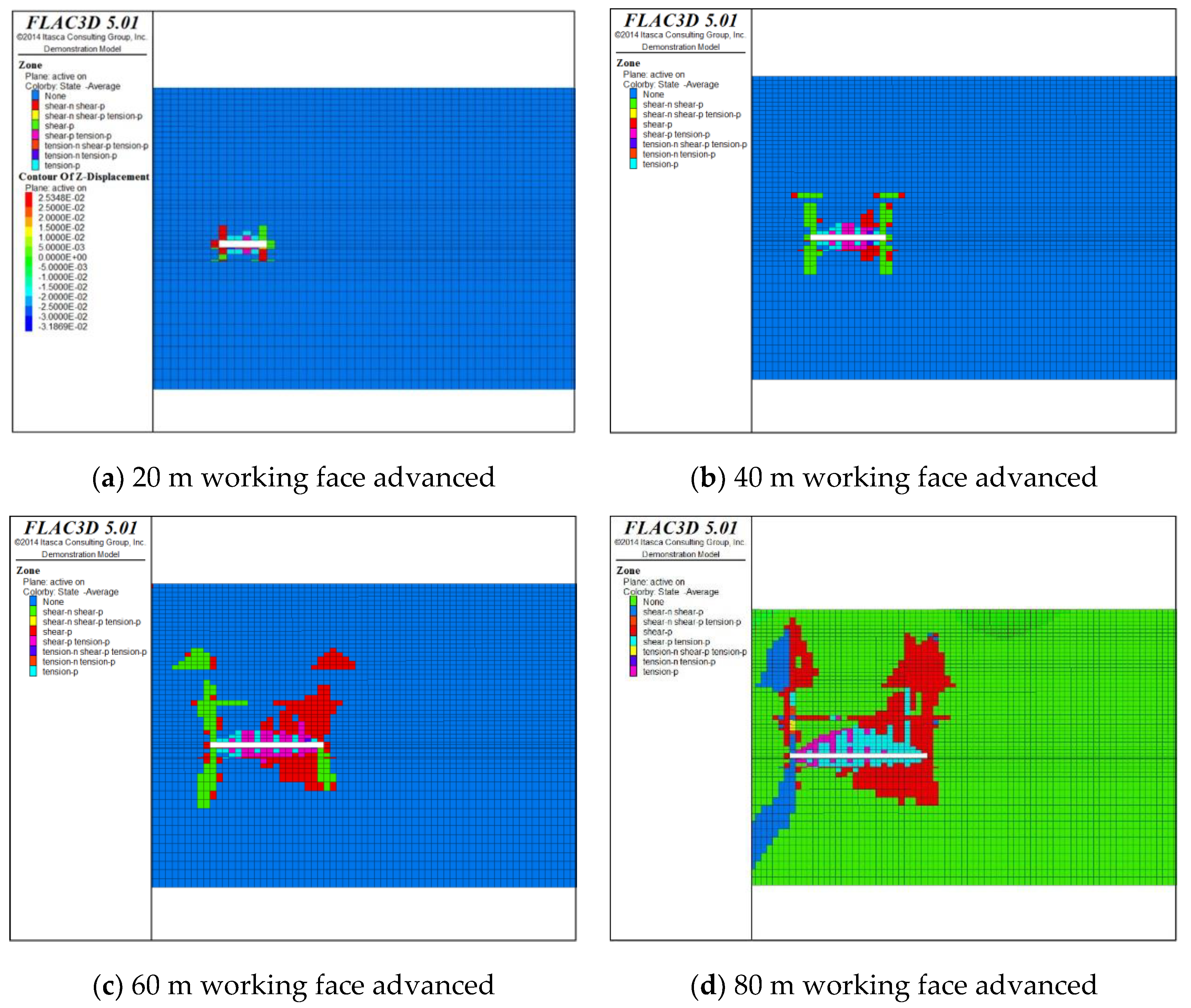

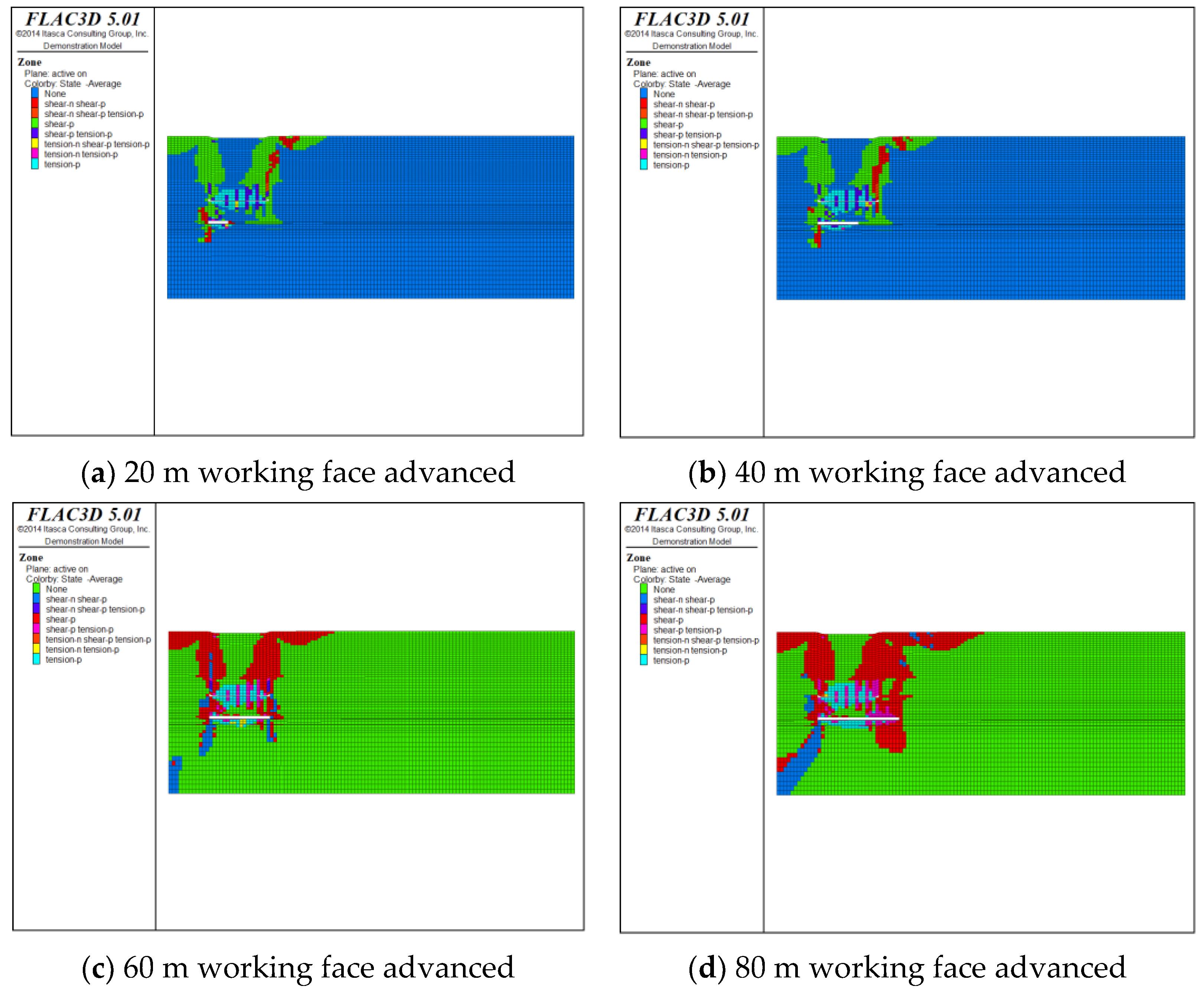

4.2.2. Distribution of Plastic Zones of the Working Face under Different Mining Conditions

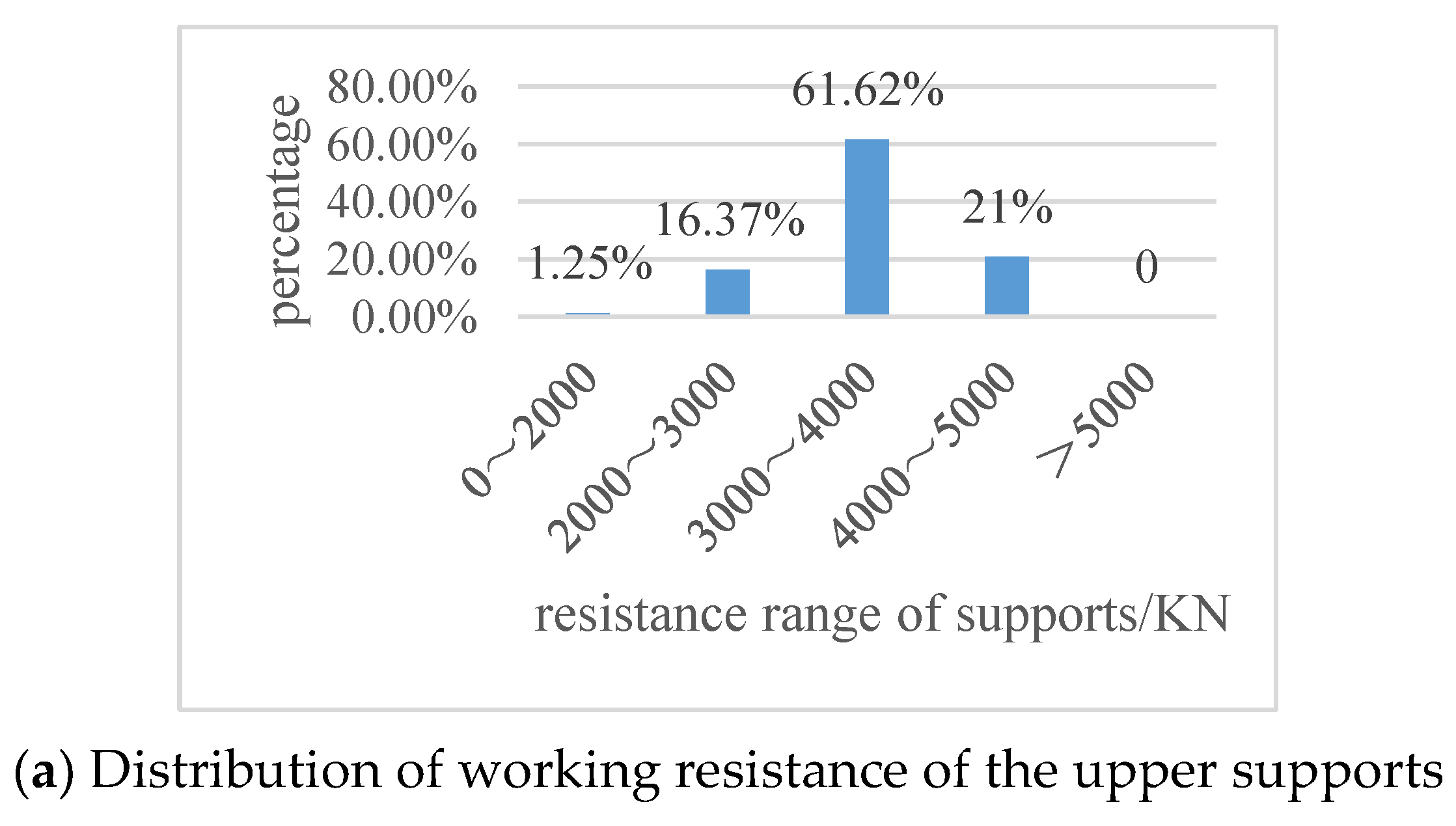

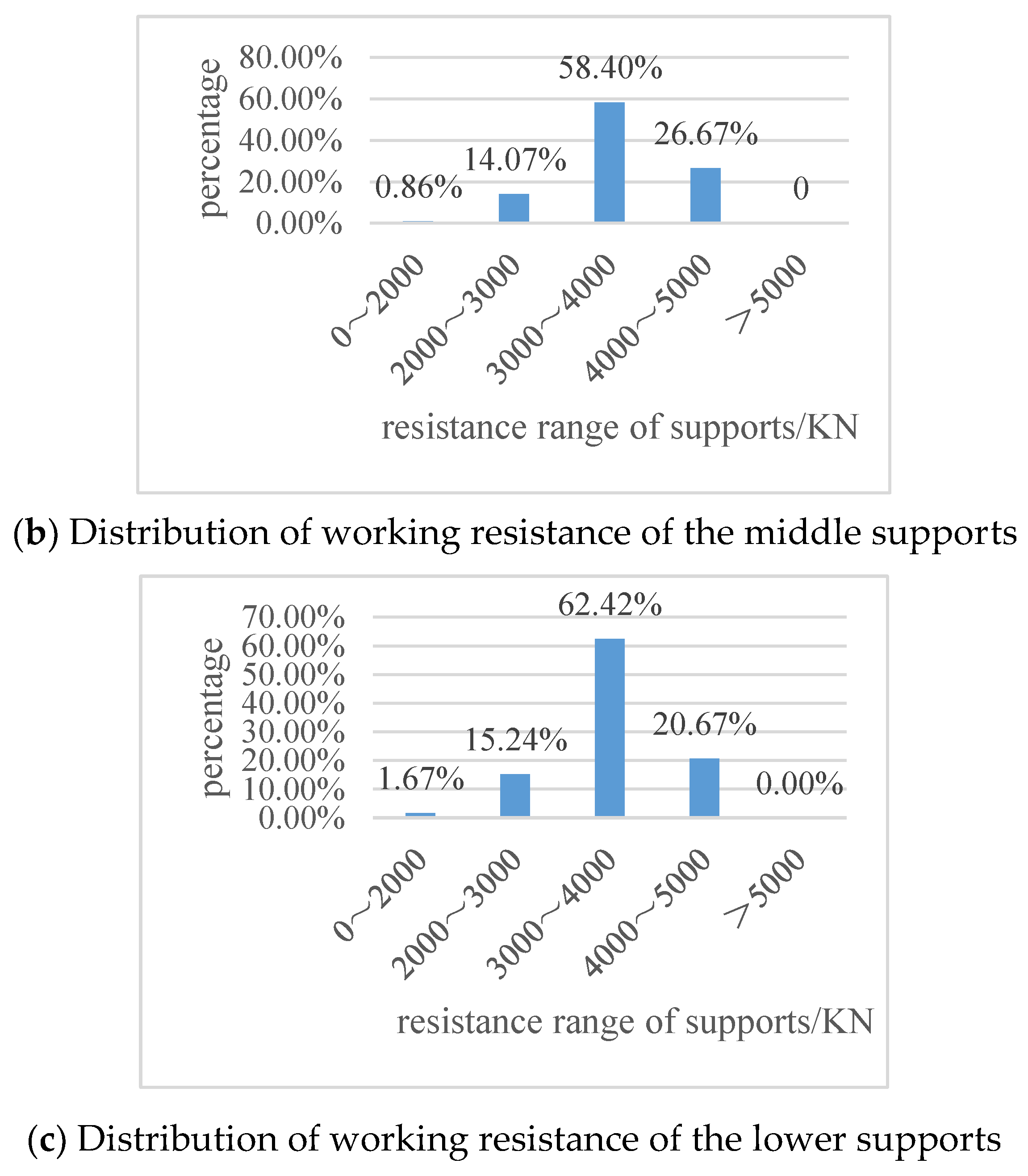

5. Working Resistance of Supports and its Distribution

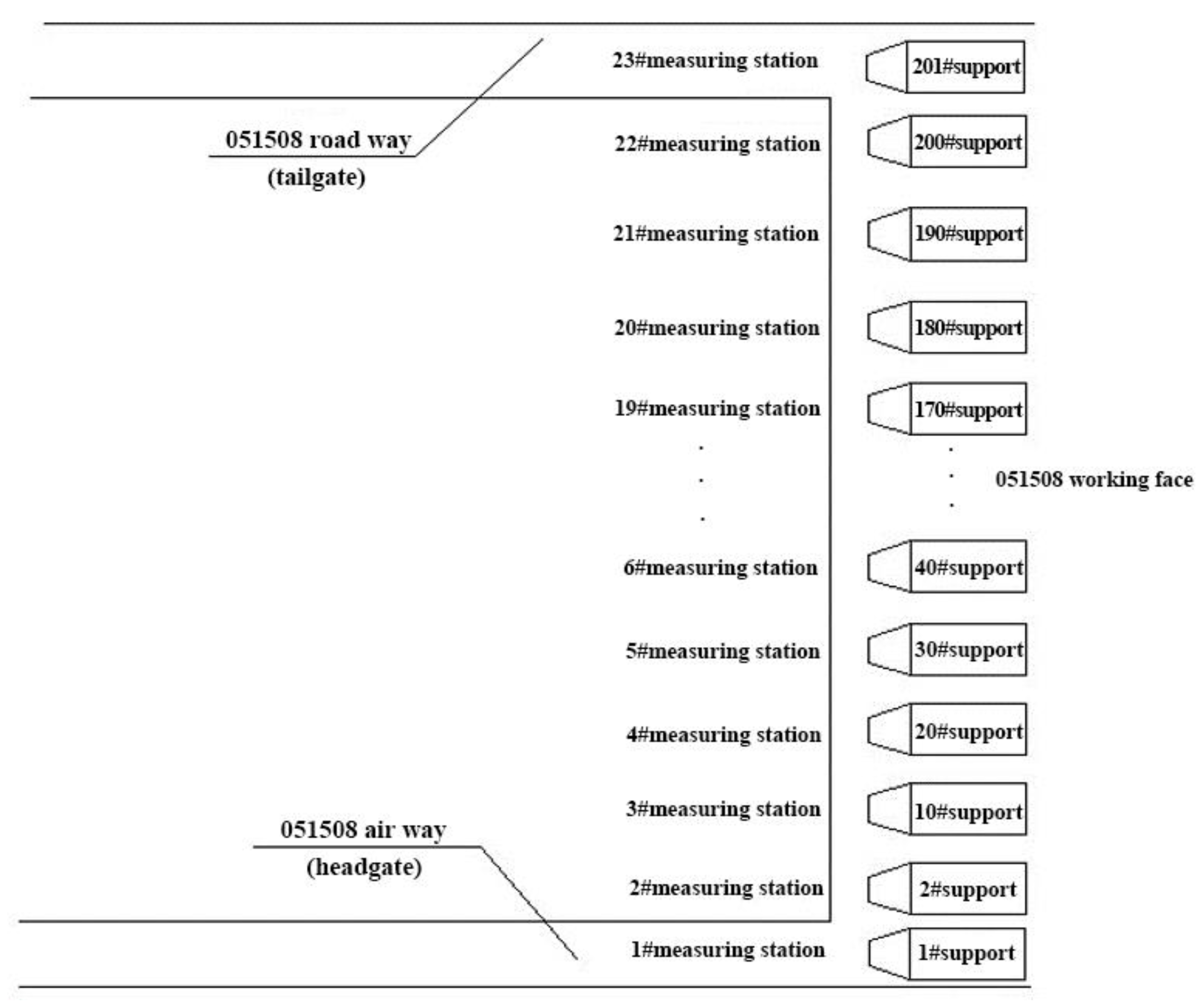

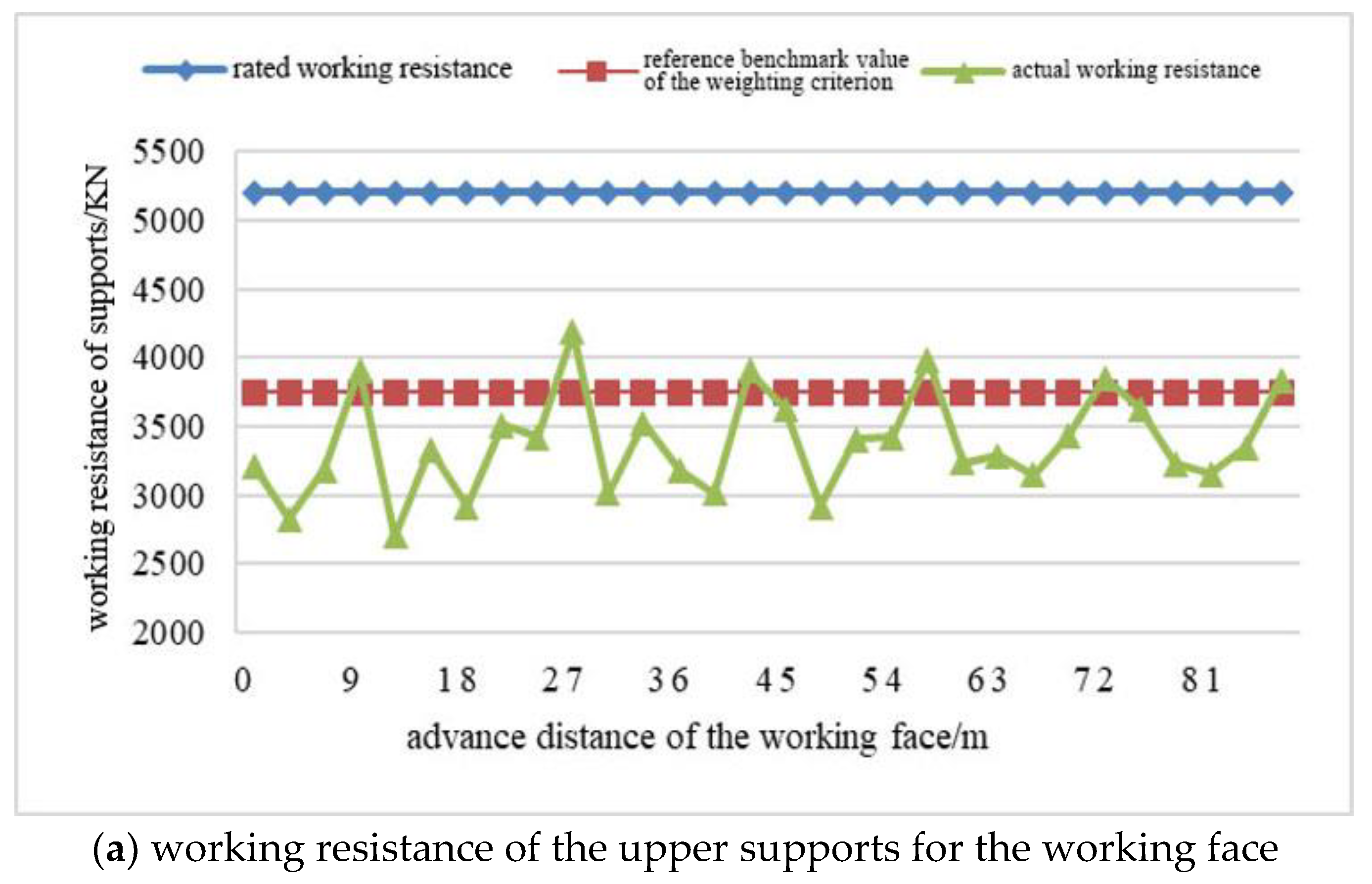

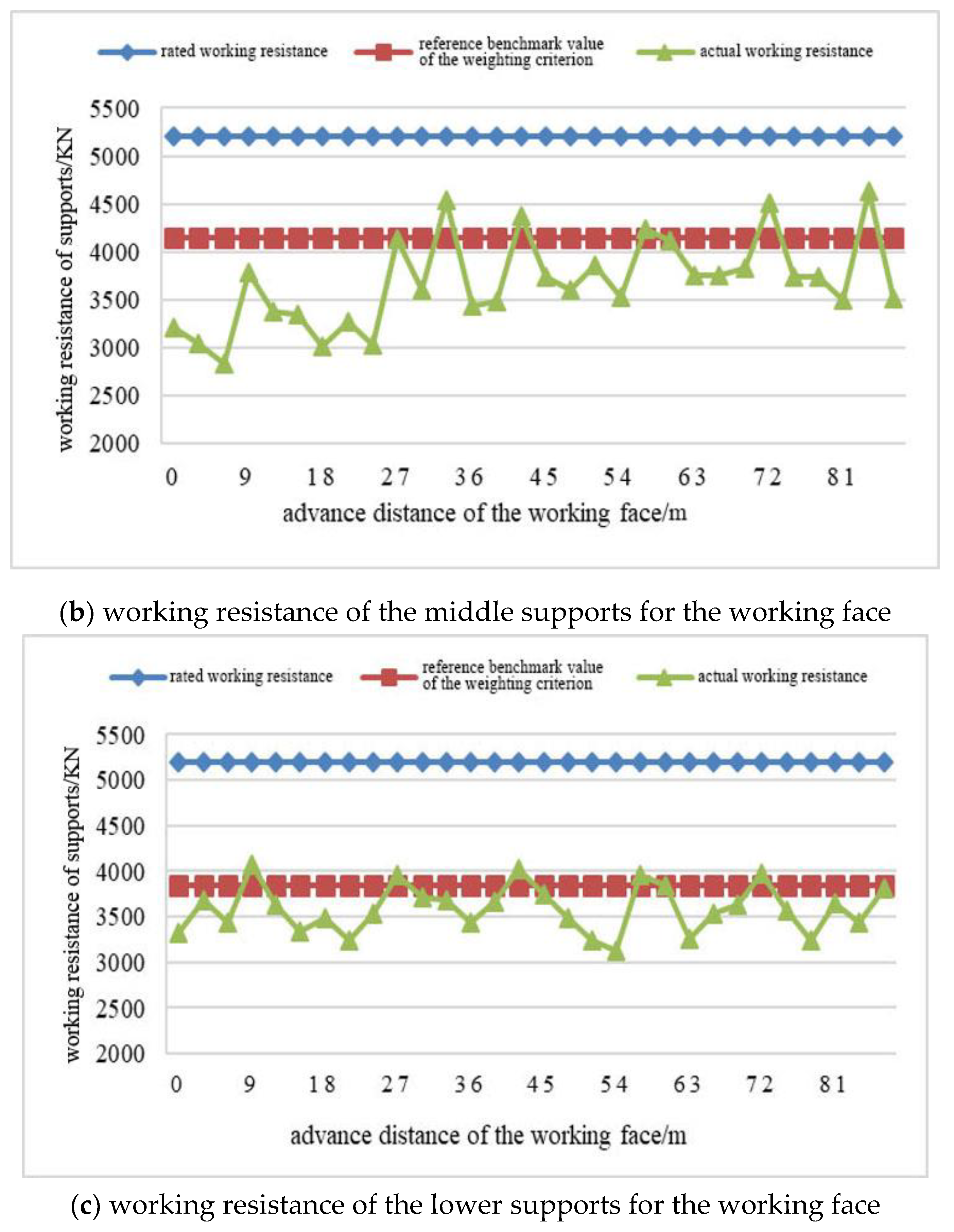

5.1. Observation and Analysis of the Pressure of Supports for the Working Face

5.2. Distribution of Working Resistance of Supports

6. Conclusions

- According to theoretical calculations, the roof is weakened to a certain degree during mining below the goaf, and the weighting interval becomes smaller, which is conducive to the control of the wall rock in the stope.

- Numerical simulation results show that when the working face is mined below the goaf, there is a certain stress reduction zone attributed to the pressure relief effect. The bearing pressure in advance below the goaf is lower than that below non-goaf. When the working face is pushed beyond the boundary of the goaf, the distribution of the bearing pressure returns to normal.

- By combining theoretical analysis with field measurements, analyzing the adaptability of hydraulic supports, and making recommendations and targeted improvements, the safe and efficient mining of coal seams under the goaf can be achieved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yuan, Z.; Zhen, C.; Lei, W.; Gao, W. The green behavioral effect of clean coal technology on China’s power generation industry. Sci. Total Environ. 2019, 675, 286–294. [Google Scholar]

- Yan, L.; Jie, G.; Changyou, L.; Liqiang, M.; Yechang, W. Study on Optimal Layout of Same Mining Roadway in Close Coal Seams. J. Min. Saf. Eng. 2012, 29, 797–801. [Google Scholar]

- Yong, Y.; Shi-hao, T.; Lian-ning, L.; Xiao-tao, M.; Jie, G. Unconventional staggered distance simultaneous mining theory in extremely close and thin coal seams and its application. Procedia Earth Planet. Sci. 2009, 1, 288–293. [Google Scholar] [CrossRef] [Green Version]

- Chekan, G.J.; Matetic, R.J.; Galek, J.A. Strata Interactions in Multiple-Seam Mining—Two Case Studies in Pennsylvania Bumines RI 9056; Centers for Disease Control and Prevention: Atlanta, GA, USA, 1986; Volume 17, pp. 1–17. [Google Scholar]

- Yingda, Z.; Baofu, L. The theory and practice of the wrong arrangement outside the mining roadway. J. Taiyuan Univ. Technol. 2006, 04, 420–433. [Google Scholar]

- Zhang, M.; Shimada, H.; Sasaoka, T.; Matsui, K.; Dou, L. Evolution and effect of the stress concertation and rock failure in the deep multi-seam coal mining. Environ. Earth Sci. 2014, 72, 629–643. [Google Scholar] [CrossRef]

- Cheng, W.; Nong, Z.; Guichen, L.; Nianchao, Z. De-stressed mining of multi-seams: Surrounding rock control during the mining of a roadway in the overlying protected seam. Min. Sci. Technol. 2011, 21, 159–164. [Google Scholar] [CrossRef]

- Jiangong, Z.; Xiexing, M.; Yanli, H.; Meng, L. Fracture mechanics model of fully mechanized top coal caving of shallow coal seams and its application. Int. J. Min. Sci. Technol. 2014, 24, 349–352. [Google Scholar]

- Singh, R.; Sheorey, P.R.; Singh, D.P. Stability of the parting between coal pillar workings in level contiguous seams. Int. J. Rock Mech. Min. Sci. 2002, 39, 9–39. [Google Scholar] [CrossRef]

- Gale, W.J. Strata control utilizing rock reinforcement techniques and stress control methods, in Australian coalmines. Min. Eng. 1991, 150, 247–253. [Google Scholar]

- Chekan, G.J.; Listak, J.M. Design Practice for Multiple-Seam Room-and-Pillar Mines; Technology News 443; Bureau of Mines, United States Department of the Interior: Washington, DC, USA, 1994; p. 2.

- Wei, X.-Q.; Bai, H.-B.; Rong, H.-R.; Jiao, Y.; Zhang, B.-Y. Research on mining fracture of overburden in close distance multi-seam. Procedia Earth Planet. Sci. 2011, 2, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Dongming, Z.Q.; Guangzhi, Y.; Binbin, Z. Coal and rock fissure evolution and distribution characteristics of multi-seam mining. Int. J. Min. Sci. Technol. 2013, 23, 835–840. [Google Scholar]

- Suchowerska, A.M.; Merifield, R.S.; Carter, J.P. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Shuangsuo, Y.; Lixun, K.; Minggao, Q. Study on the stability of immediate roof blocks at the end face. J. Coal Sci. Eng. 1999, 01, 30–32. [Google Scholar]

- Das, A.J.; Mandal, P.K.; Prakash, A.; Roy, L.B.; Tewari, S. Underground extraction methodology of contiguous coal seams ensuring the safety of the parting and the surface structures. Saf. Sci. 2020, 121, 215–230. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Kaiser, P.K. Stability of large excavations in laminated hard rock masses: The voussoir analogue revisited. Int. J. Rock Mech. Min. Sci. 1999, 36, 97–117. [Google Scholar] [CrossRef]

- Congliang, L.; Tan, Z.; Deng, K.; Li, P. Synergistic instability of coal pillar and roof system and filling method based on plate model. Int. J. Min. Sci. Technol. 2013, 23, 145–149. [Google Scholar] [CrossRef]

- Long, F.; Shimin, L. Evaluation of permeability damage for stressed coal with cyclic loading: An experimental study. Int. J. Coal Geol. 2019, 216. [Google Scholar] [CrossRef]

- Zhanbo, C.; Dezhong, K.; Jinghu, Y. Breakage characteristics of thick hard roof in fully mechanized caving face and determination of working resistance of support. Min. Sci. Technol. 2016, 1, 172–180. [Google Scholar]

- Weidong, P.; Xiaodong, N.; Xinyuan, L. Effect of Premining on Hard Roof Distress Behavior: A Case Study. Rock Mech. Rock Eng. 2019, 52, 1871–1885. [Google Scholar]

- Yi, L. Study on Ground Pressure Behavior Law of Fully Mechanized Mining Face under Goaf of Close Coal Seam. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

| Type of the Roof and Floor | Lithology | Height (m) | Description of Lithology | |

|---|---|---|---|---|

| conditions of the roof and floor of the coal seam | basic roof | 14 coal | 2.49 | A medium-thick coal seam, with a stable coal seam structure and small variation of thickness of the coal seam and with a dirt band. |

| siltstone | 2.92 | Gray, with a large number of root fossils and a hardness coefficient of 3.4. | ||

| fine sandstone | 1.05 | Light gray, composed of quartz mica feldspar, with a hardness coefficient of 3.6. | ||

| siltstone | 1.35 | Gray, with a large number of root fossils and a hardness coefficient of 3.4. | ||

| fine sandstone | 9.25 | Light gray coefficient, composed of quartz mica feldspar, with a hardness coefficient of 3.6. | ||

| siltstone | 3.85 | Gray, with a large number of root fossils and a hardness coefficient of 3.4. | ||

| immediate roof | mud stone | 0.3 | Gray, argillaceous cemented with siltstone bands. | |

| immediate floor | coal streak | 0.2 | Bright black, shiny briquette, lumpy, with a hardness coefficient of 2. | |

| siltstone | 4.48 | Gray, with a large number of root fossils and a hardness coefficient of 3.4. | ||

| mud stone | 0.68 | Gray, argillaceous cemented with siltstone bands. | ||

| basic floor | fine sandstone | 7.82 | Light gray, composed of quartz mica feldspar, with a hardness coefficient of 3.6. |

| Lithology | Density (Kg/m3) | Shear Modulus (GPa) | Volume Modulus (GPa) | Bulk Modulus (MPa) | Cohesion (MPa) | Internal Frictional Angle (°) |

|---|---|---|---|---|---|---|

| mud stone | 2540 | 2.17 | 3.16 | 1.1 | 2.1 | 26 |

| siltstone | 2470 | 2.71 | 3.93 | 1.9 | 3. 1 | 35 |

| 15 coal | 1290 | 1.39 | 2.33 | 0.74 | 1.6 | 25 |

| 14 coal | 1320 | 1.50 | 2.57 | 0.9 | 1.4 | 24 |

| fine sandstone | 2490 | 2.52 | 3.45 | 1.8 | 2.9 | 34 |

| Measurement Area | Average Resistance (KN) | Mean Square Error (KN) | Judgment Criteria for Weighting (KN) |

|---|---|---|---|

| upper | 3378 | 368 | 3746 |

| middle | 3683 | 471 | 4154 |

| lower | 3591 | 261 | 3852 |

| Working Face Area | Upper | Middle | Lower | Average | |

|---|---|---|---|---|---|

| first caving step of the immediate roof (m) | 9.4 | 10.6 | 9.0 | 9.7 | |

| first weighting interval of the basic roof (m) | 25.6 | 27.1 | 26.4 | 26.4 | |

| periodic weighting interval (m) | weighting 1 | 14.6 | 16.1 | 17.1 | 16.0 |

| weighting 2 | 13.5 | 15.0 | 15.3 | 14.6 | |

| weighting 3 | 16.6 | 13.5 | 15.0 | 15.1 | |

| weighting 4 | 13.5 | 11.5 | 16.0 | 13.7 | |

| average value of weighting (m) | 14.6 | 14.0 | 15.9 | 14.9 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, W.; Zhang, S.; Liu, Y. Safe and Efficient Coal Mining Below the Goaf: A Case Study. Energies 2020, 13, 864. https://doi.org/10.3390/en13040864

Pan W, Zhang S, Liu Y. Safe and Efficient Coal Mining Below the Goaf: A Case Study. Energies. 2020; 13(4):864. https://doi.org/10.3390/en13040864

Chicago/Turabian StylePan, Weidong, Shaopeng Zhang, and Yi Liu. 2020. "Safe and Efficient Coal Mining Below the Goaf: A Case Study" Energies 13, no. 4: 864. https://doi.org/10.3390/en13040864

APA StylePan, W., Zhang, S., & Liu, Y. (2020). Safe and Efficient Coal Mining Below the Goaf: A Case Study. Energies, 13(4), 864. https://doi.org/10.3390/en13040864