Study on Global Industrialization and Industry Emission to Achieve the 2 °C Goal Based on MESSAGE Model and LMDI Approach

Abstract

1. Introduction

2. Method and Data

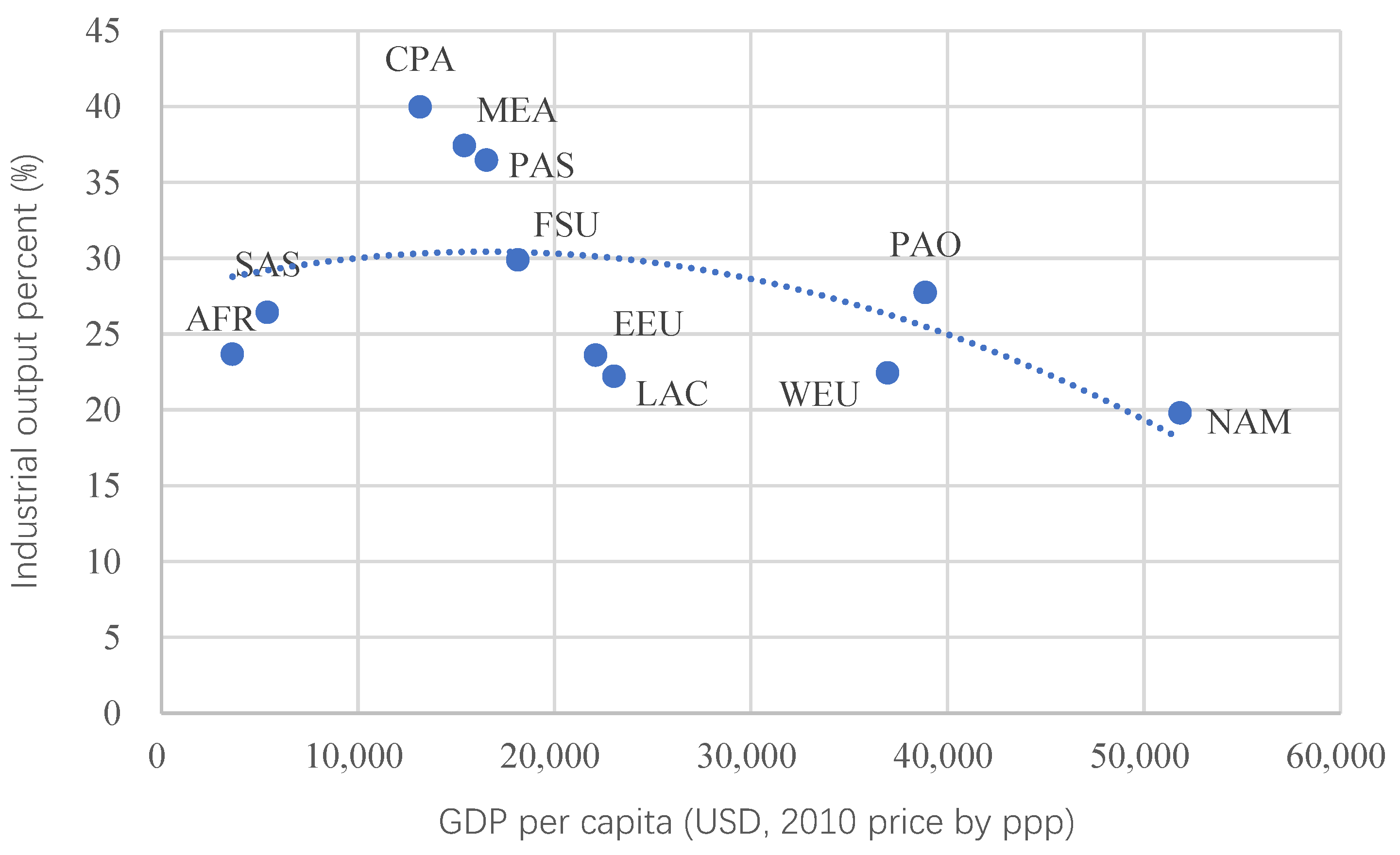

2.1. Industrialization Projection Method

2.2. Industrial Energy Demand Projection Method

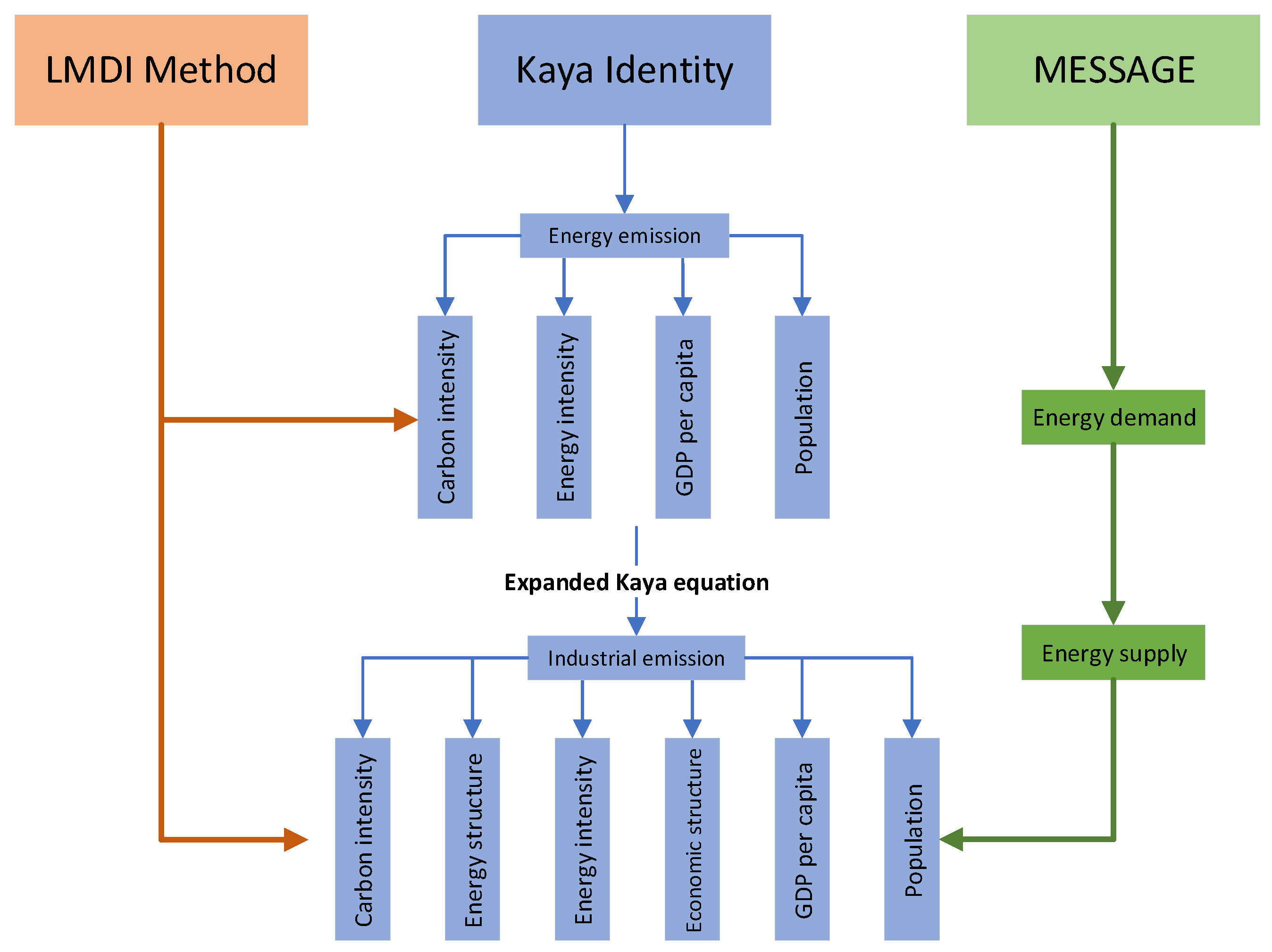

2.3. Expanded Kaya Equation and Contribution Decomposition

2.3.1. Expanded Kaya Equation

2.3.2. Contribution Analysis Based on LMDI Approach

3. Results and Discussion

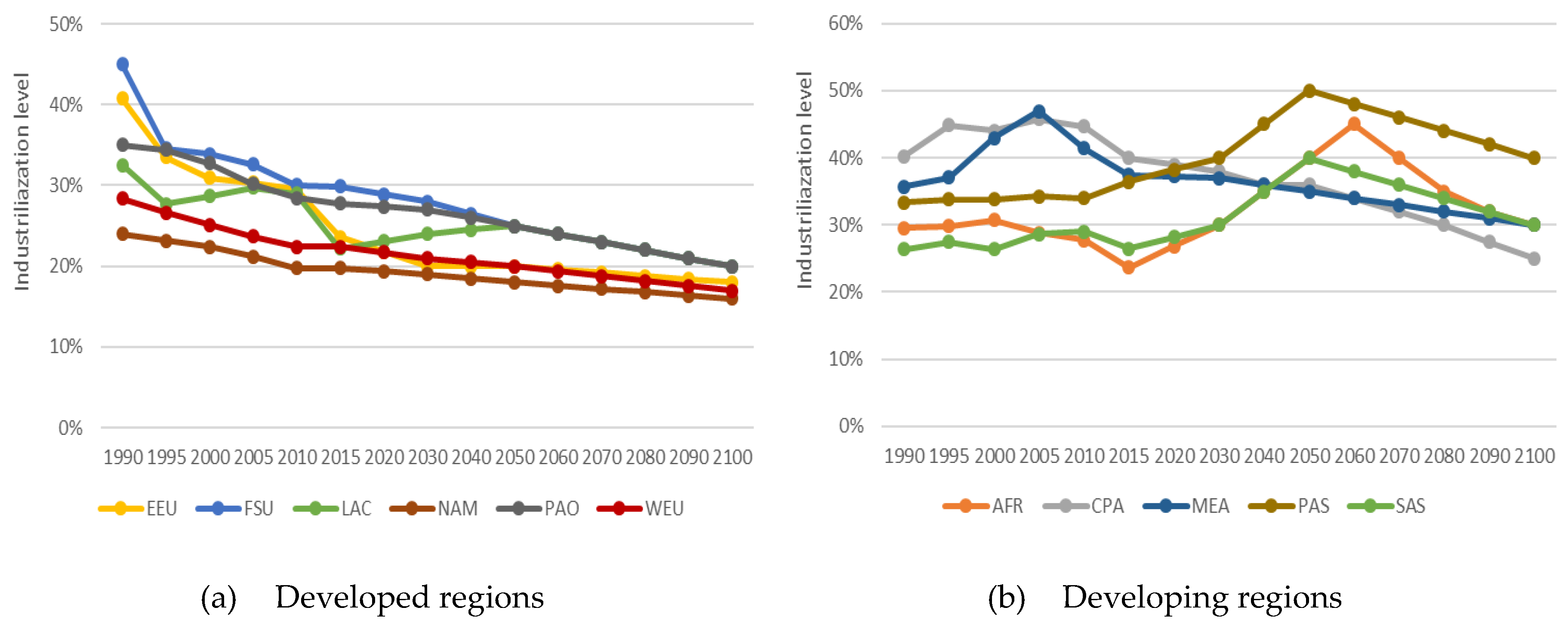

3.1. Industrialization and Its Projection

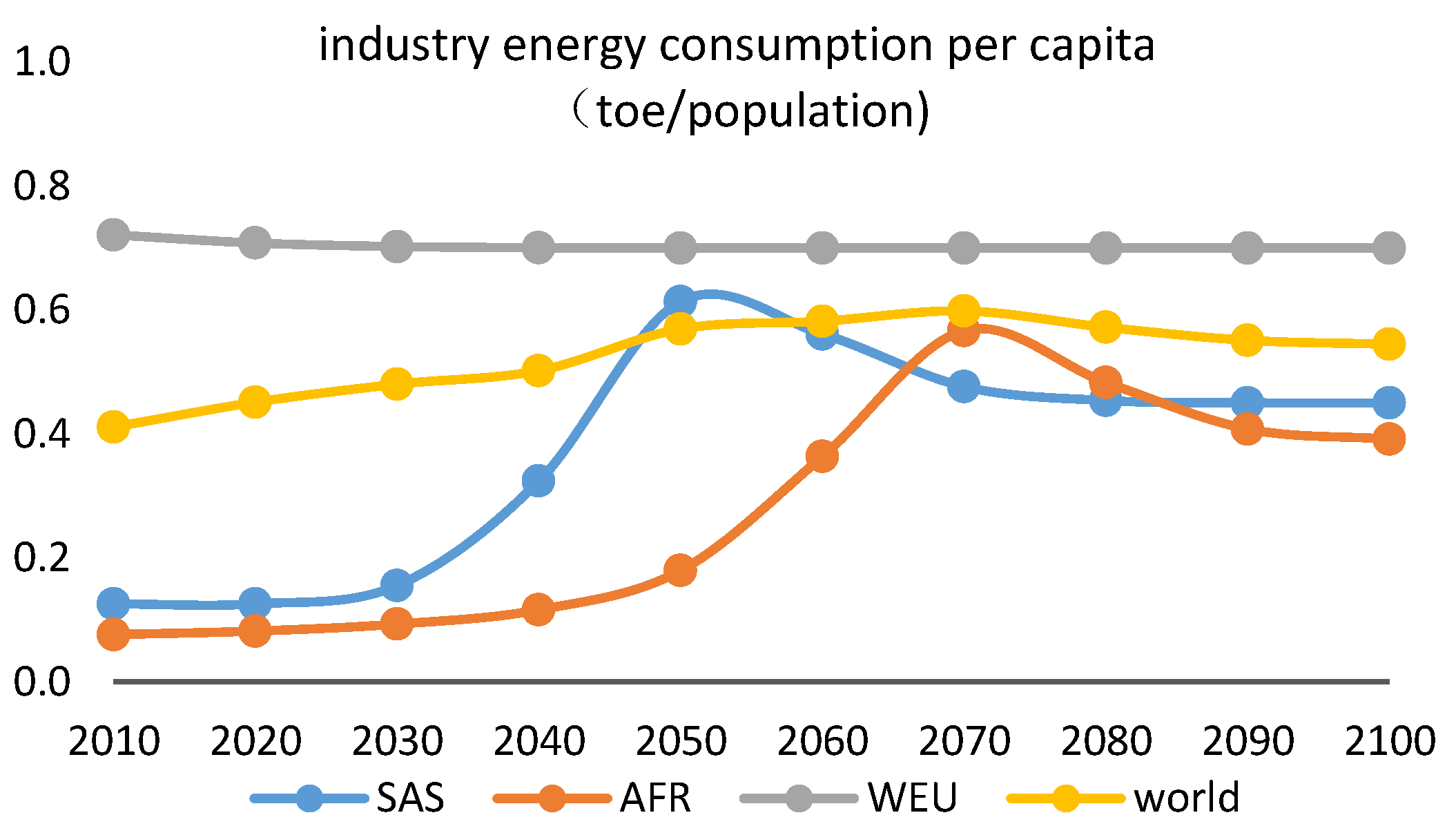

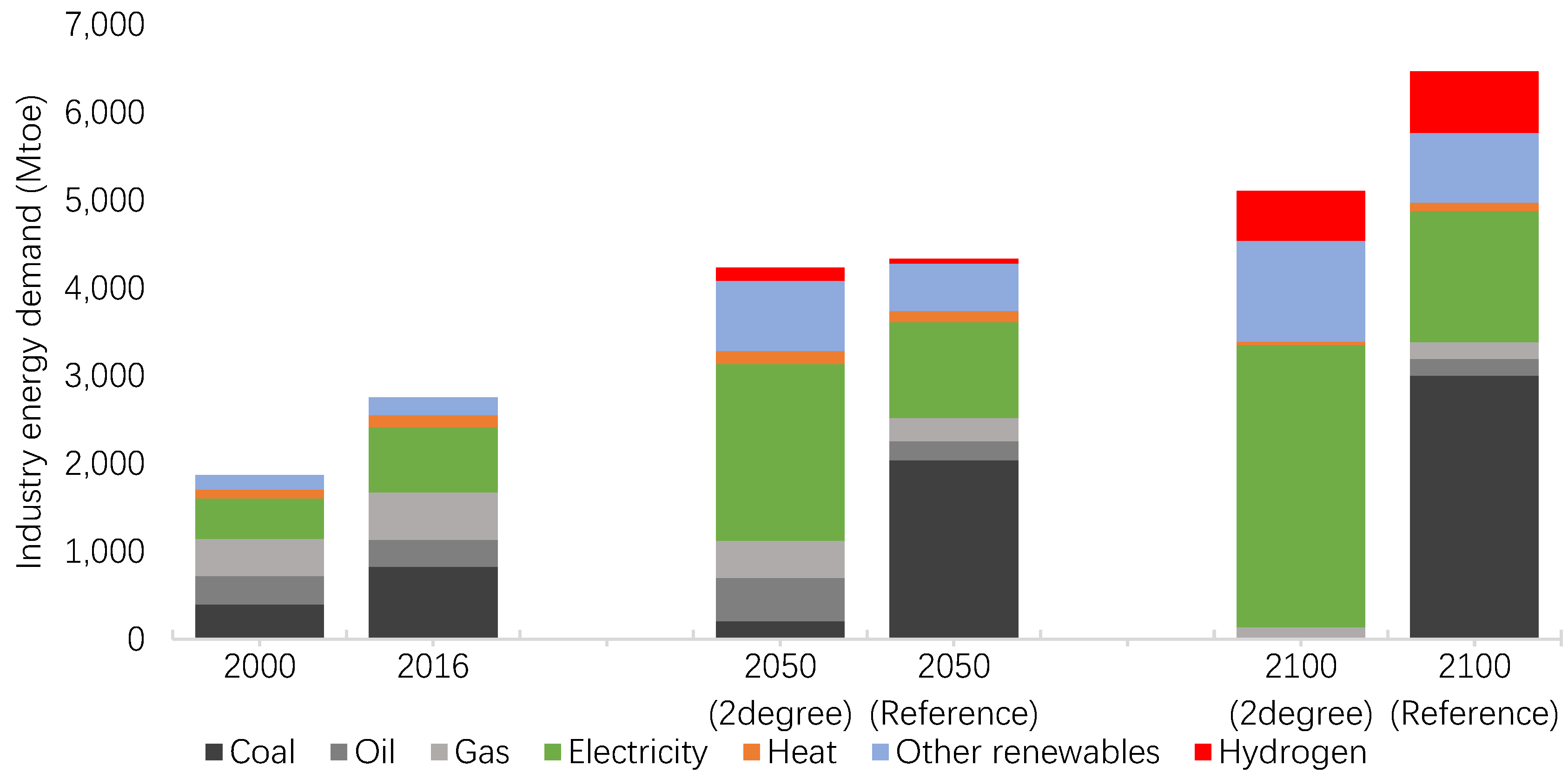

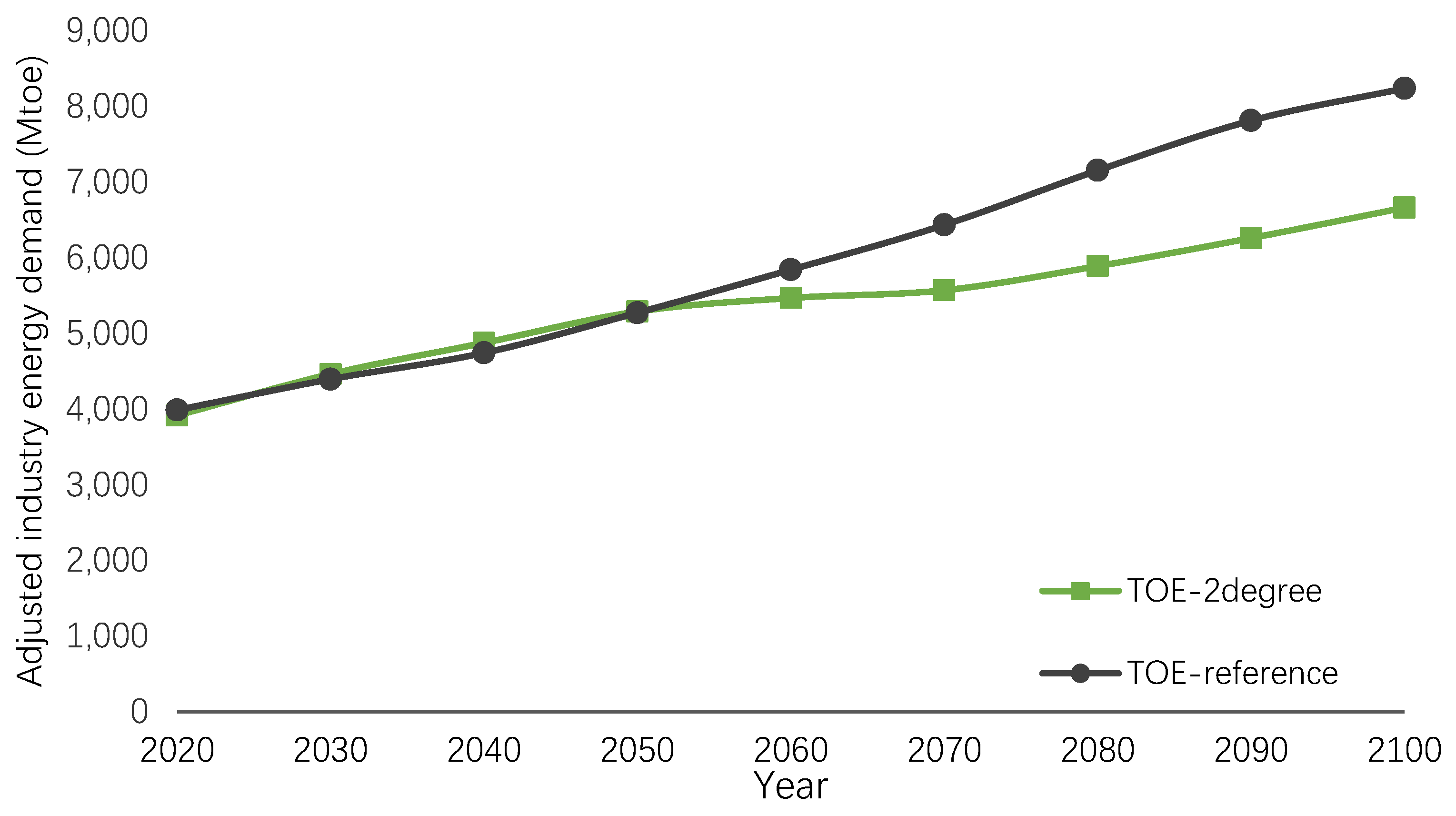

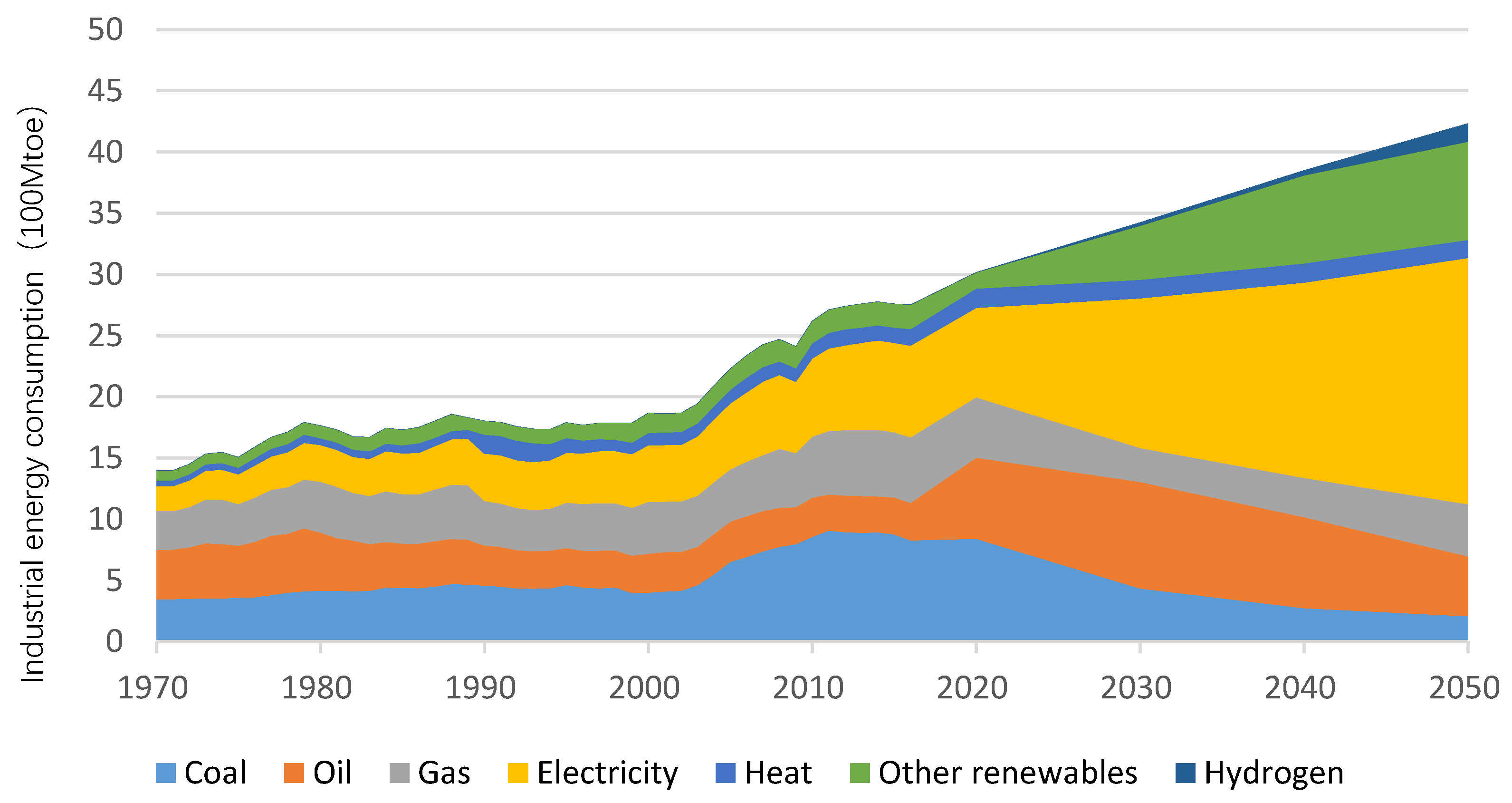

3.2. Industrial Energy Consumption and Demand

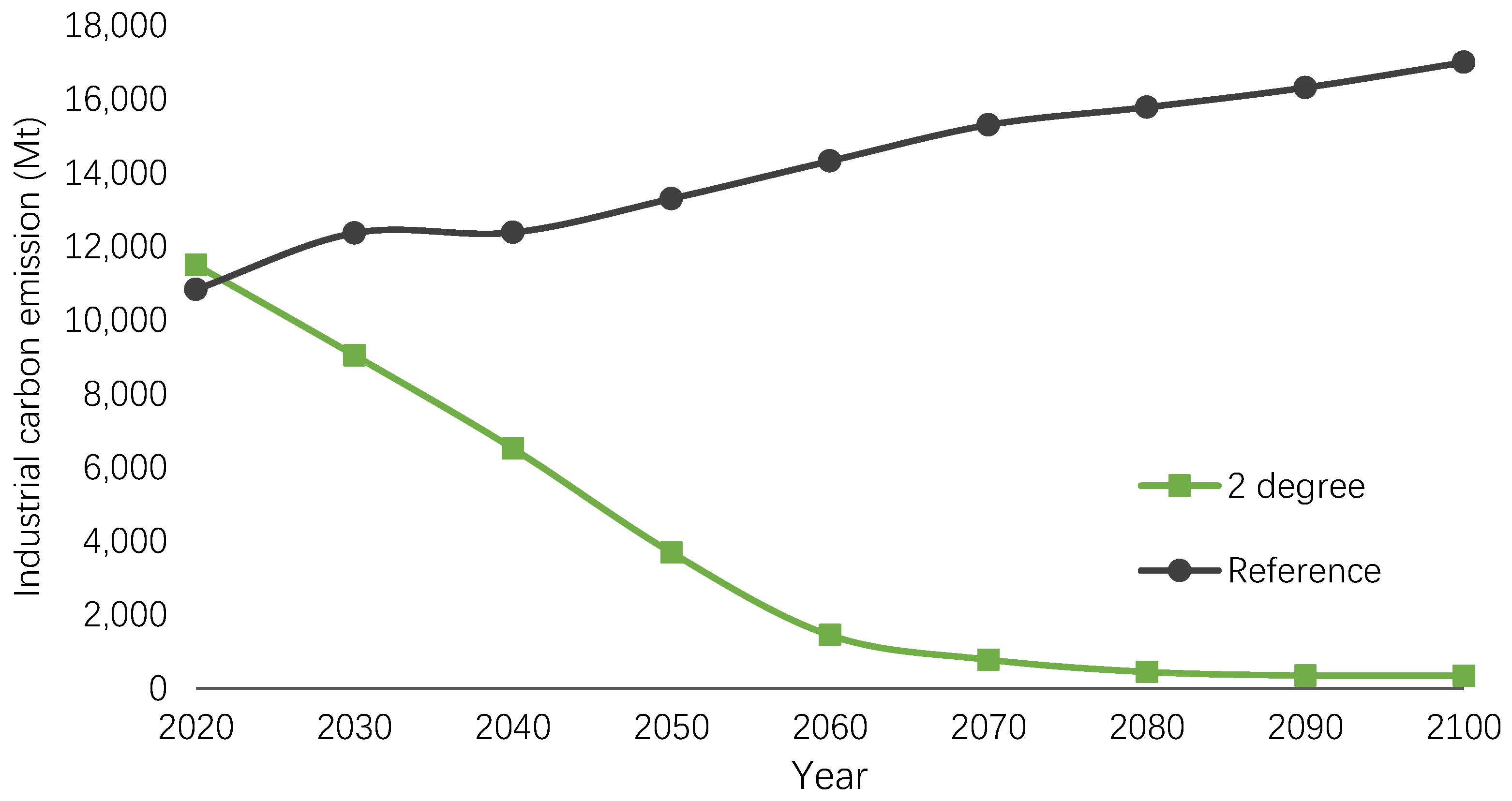

3.3. Industrial Emissions and Its Projection

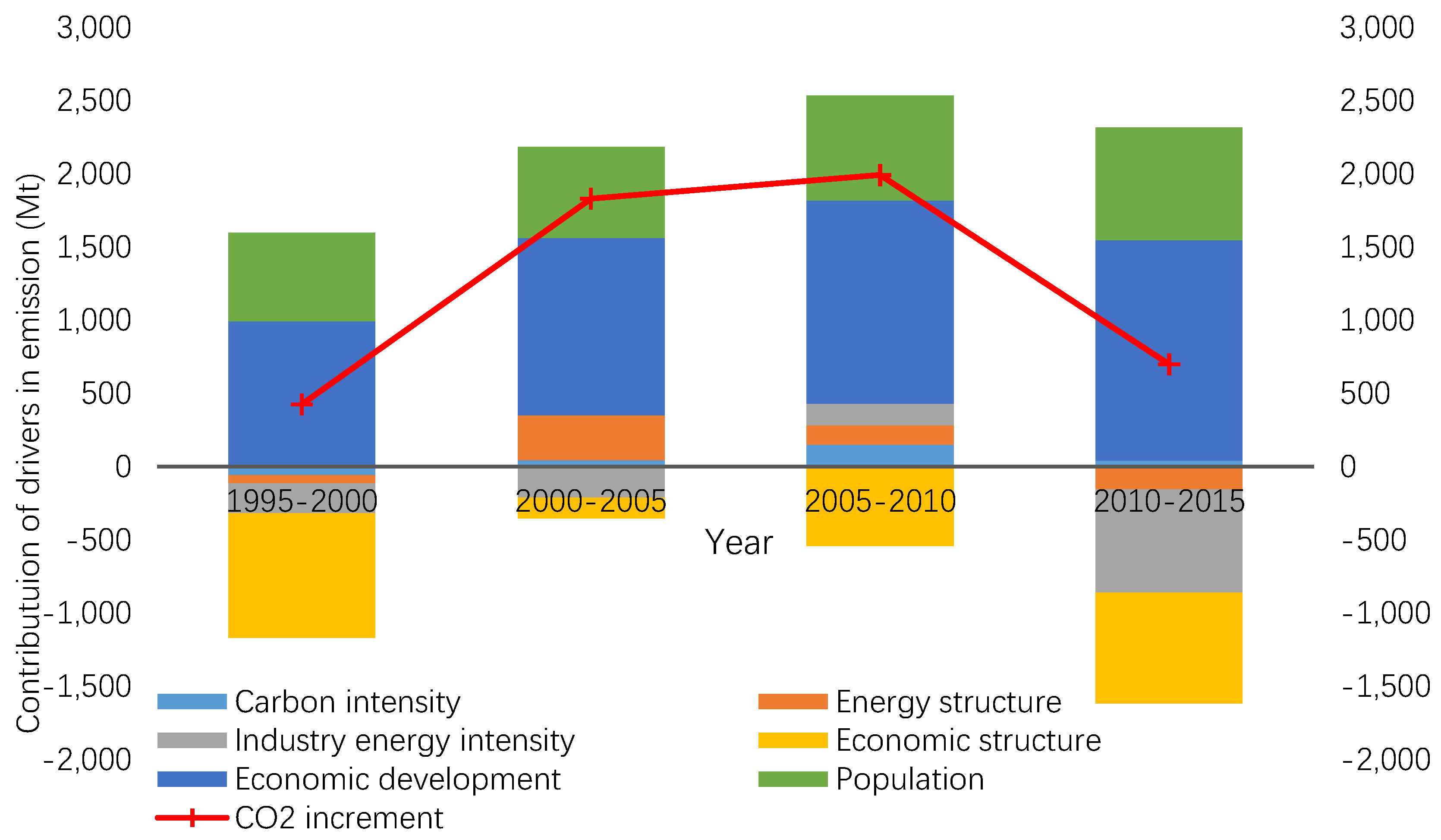

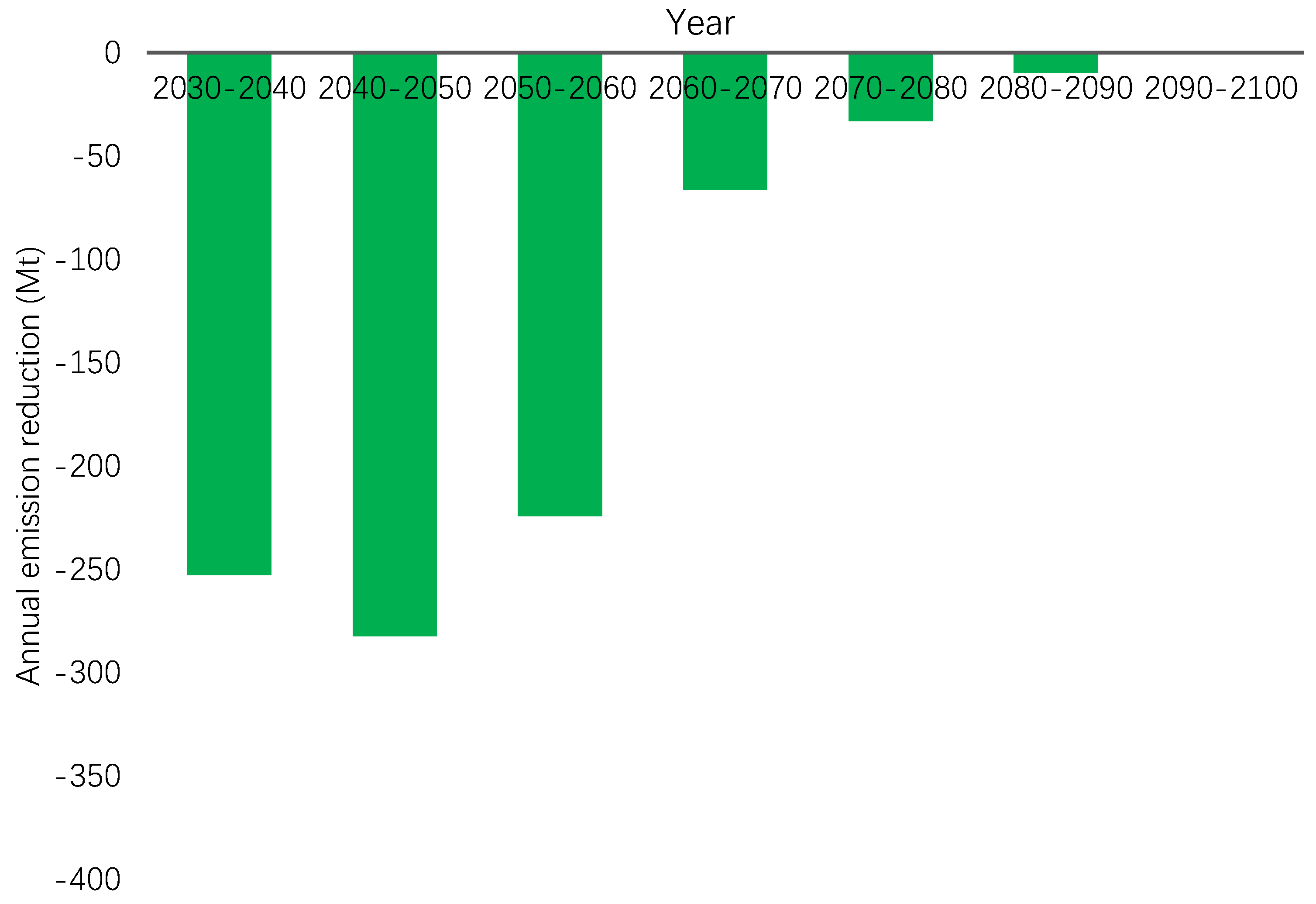

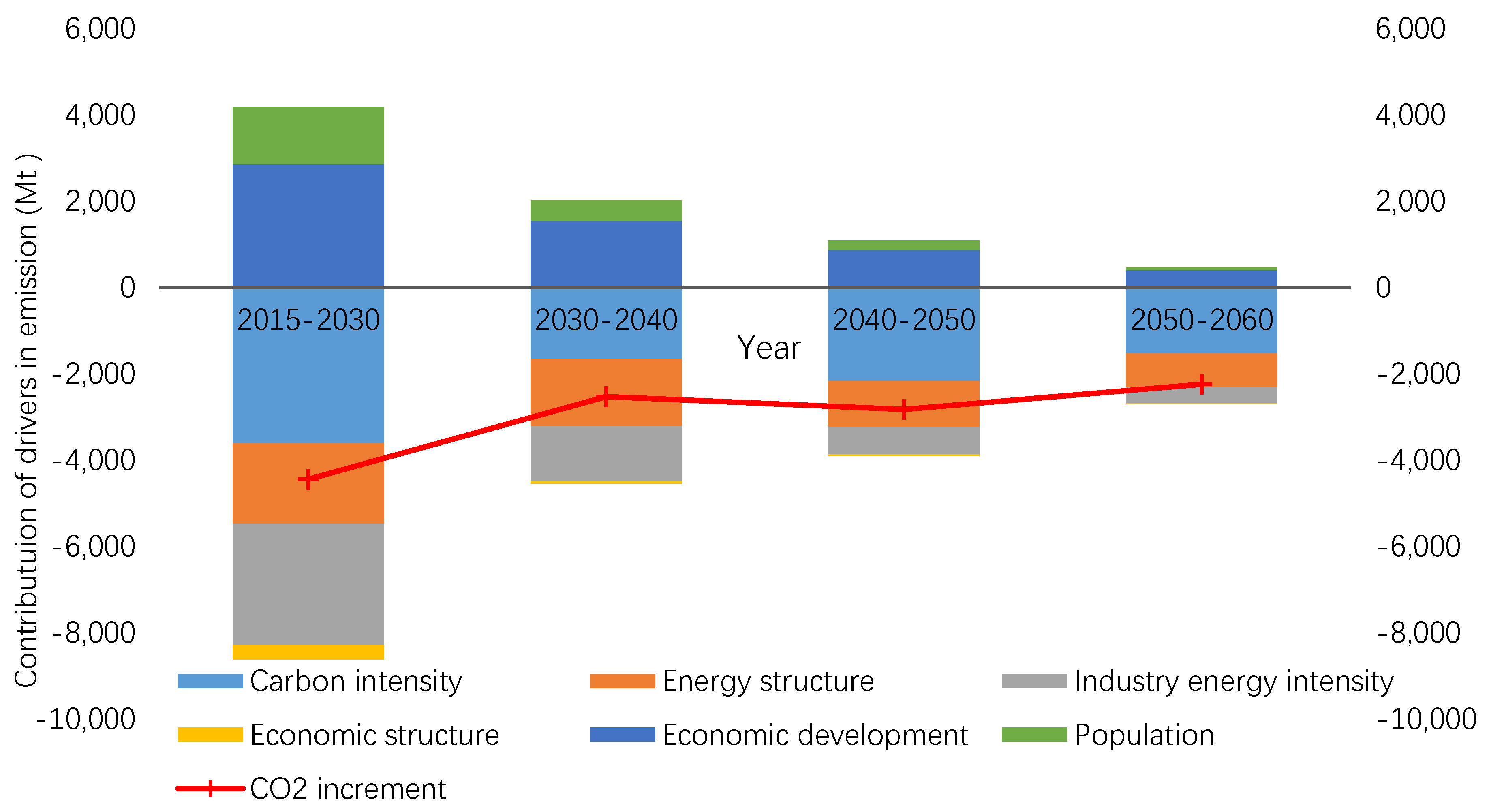

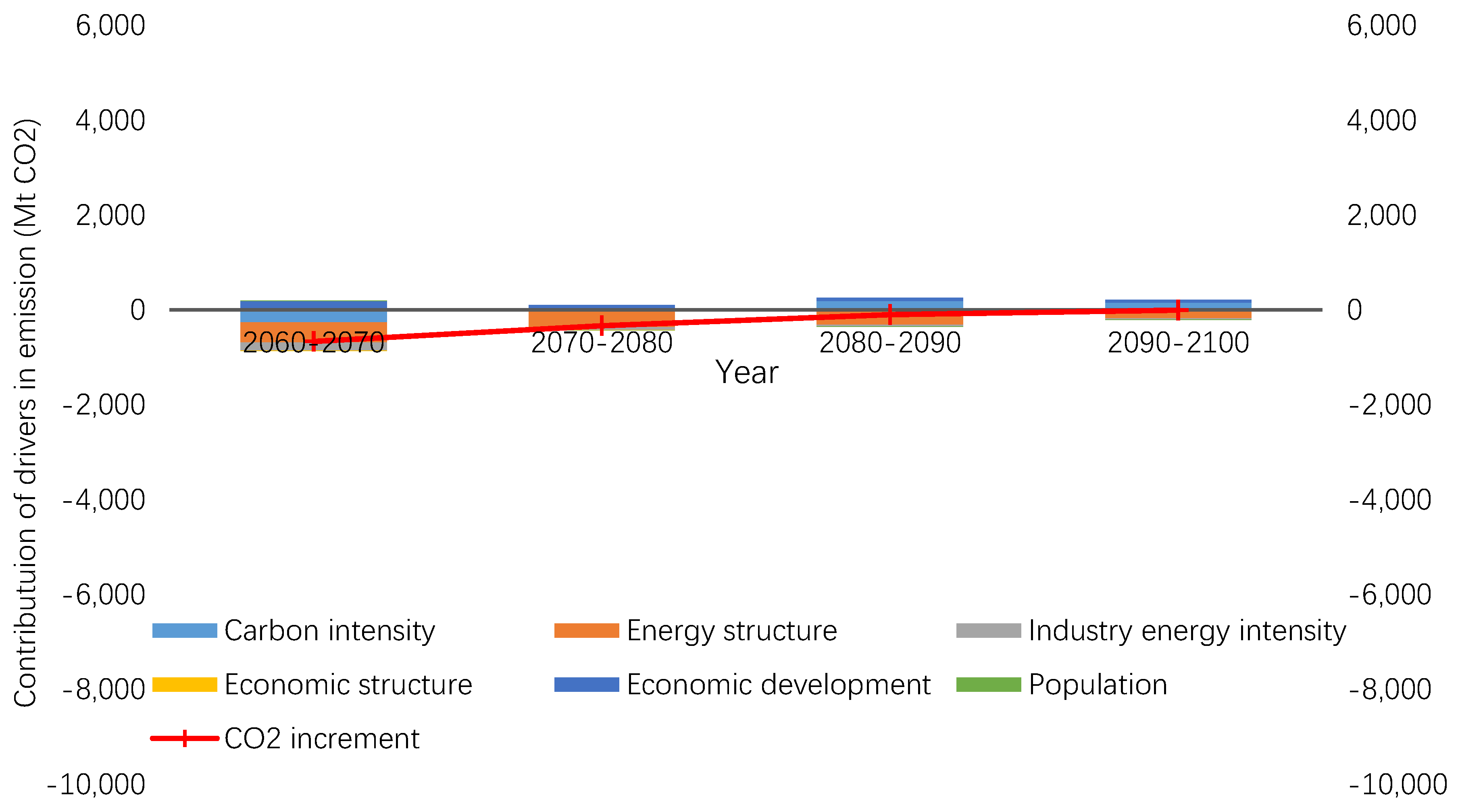

3.4. Decomposition Analysis of Industrial Carbon Emission

4. Modes for Industrial Emission Mitigation

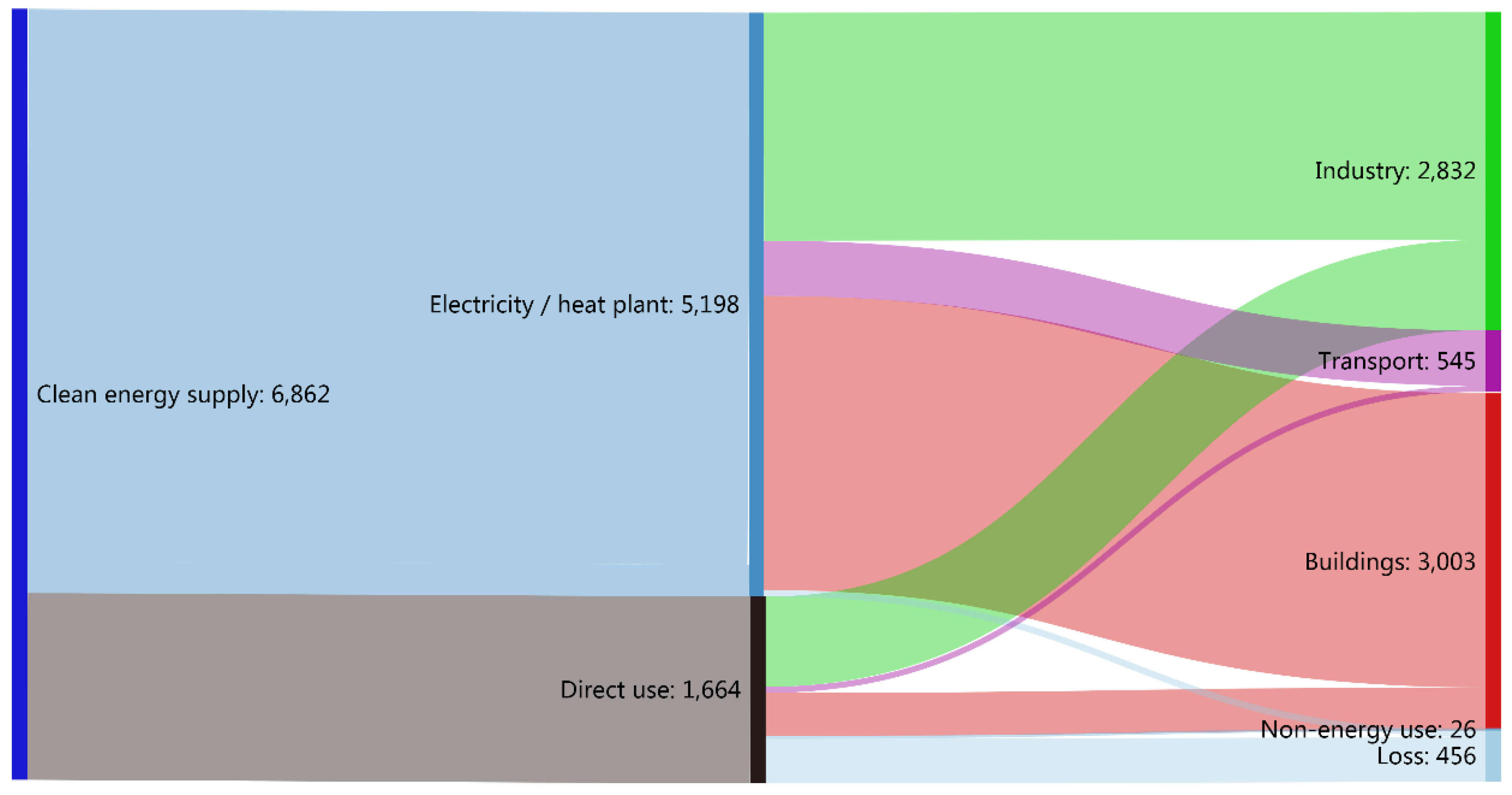

4.1. Mode 1: Clean Supply-Driven Mode

4.2. Mode 2: Electricity Consumption-Driven Mode

4.3. Mode 3: Energy Efficiency-Driven Mode

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fischedick, M.; Roy, J.; Acquaye, A.; Allwood, J.; Ceron, J.P.; Geng, Y.; Kheshgi, H.; Lanza, A.; Perczyk, D.; Price, L.; et al. Industry, in Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- IEA. IEA Data and Statistics. 2017. Available online: http://data.iea.org (accessed on 1 December 2019).

- Chen, Z.; Liu, C.; Qu, S. China’s Industrialization and the Pathway of Industrial CO2 Emissions. Chin. J. Urban Environ. Stud. 2005, 3, 1550019. [Google Scholar] [CrossRef]

- Chenery, H.B. Patterns of Industrial Growth. Am. Econ. Rev. 1960, 4, 624–654. [Google Scholar]

- Chen, J.; Huang, Q.; Lv, T.; Li, X. The Report on Chinese Industrialization (1995–2010); Social Sciences Academic Press: Beijing, China, 2012. [Google Scholar]

- UNIDO. Industrial Development Report 2016. The Role of Technology and Innovation in Inclusive and Sustainable Industrial Development; United Nations Industrial Development Organization: Vienna, Austria, 2015. [Google Scholar]

- UNIDO. Industrial Development Report 2018. Demand for Manufacturing: Driving Inclusive and Sustainable Industrial Development; United Nations Industrial Development Organization: Vienna, Austria, 2017. [Google Scholar]

- Caraiani, C.A.; Lungu, C.I.; Dasc Lu, C. Energy consumption and GDP causality: A Three-Step Analysis for Emerging European Countries. Renew. Sustain. Energy Rev. 2015, 44, 198–210. [Google Scholar] [CrossRef]

- Ntanos, S.; Skordoulis, M.; Kyriakopoulos, G.; Arabatzis, G.; Chalikias, M.; Galatsidas, S.; Batzios, A.; Katsarou, A. Renewable Energy and Economic Growth: Evidence from European Countries. Sustainability 2018, 8, 2626. [Google Scholar] [CrossRef]

- Taeyoung, J.; Jinsoo, K. Coal Consumption and Economic Growth: Panel Cointegration and Causality Evidence from OECD and Non-OECD Countries. Sustainability 2018, 3, 660. [Google Scholar] [CrossRef]

- Wang, H.; Chen, W. Modelling Deep Decarbonization of Industrial Energy Consumption under 2-Degree Target: Comparing China, India and Western Europe. Appl. Energy 2019, 1563–1572. [Google Scholar] [CrossRef]

- Van Ruijven, B.J.; Van Vuuren, D.P.; Boskaljon, W.; Neelis, M.L.; Saygin, D.; Patel, M.K. Long-Term Model-Based Projections of Energy Use and CO2 Emissions from the Global Steel and Cement Industries. Resour. Conserv. Recycl. 2016, 112, 15–36. [Google Scholar] [CrossRef]

- IEA. Tracking Industrial Energy Efficiency and CO2 Emissions; International Energy Agency: Paris, France, 2007. [Google Scholar]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios; Intergovernmental Panel on Climate Change (IPCC)/Response Strategies Working Group: Geneva, Switzerland, 1990. [Google Scholar]

- Gabriel Blanco, R.G.S.S. Drivers, Trends and Mitigation. In Climate Change 2014: Mitigation of Climate Change; Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- IEA. CO2 Emissions from Fuel Combustion; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Ang, B.W.; Liu, F.; Chew, E. Perfect Decomposition Techniques in Energy and Environmental Analysis. Energy Policy 2003, 31, 1561–1566. [Google Scholar] [CrossRef]

- Ang, B.W. The LMDI Approach to Decomposition Analysis: A Practical Guide. Energy Policy 2005, 7, 867–871. [Google Scholar] [CrossRef]

- Freitas, L.C.; Kaneko, S. Decomposition of CO2 Emissions Change from Energy Consumption in Brazil: Challenges and Policy Implications. Energy Policy 2011, 3, 1495–1504. [Google Scholar] [CrossRef]

- Fatima, T.; Xia, E.; Cao, Z.; Khan, D.; Fan, J. Decomposition Analysis of Energy-Related CO2 Emission in the Industrial Sector of China: Evidence from the LMDI Approach. Environ. Sci. Pollut. Res. 2019, 21, 21736–21749. [Google Scholar] [CrossRef]

- Khan, A.; Jamil, F.; Khan, N.H. Decomposition Analysis of Carbon Dioxide emissions in Pakistan. SN Appl. Sci. 2019, 1, 1012. [Google Scholar] [CrossRef]

- Ouyang, X.; Lin, B. An Analysis of the Driving Forces of Energy-Related Carbon Dioxide Emissions in China’s Industrial Sector. Renew. Sustain. Energy Rev. 2015, 45, 838–849. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Zheng, W. Decomposition Analysis of Energy-Related CO2 Emissions and Decoupling Status in China’s Logistics Industry. Sustainability 2018, 5, 1340. [Google Scholar] [CrossRef]

- Mousavi, B.; Lopez, N.S.A.; Biona, J.B.M.; Chiu, A.S.; Blesl, M. Driving Forces of Iran’s CO2 Emissions from Energy Consumption: An LMDI Decomposition Approach. Appl. Energy 2017, 206, 804–814. [Google Scholar] [CrossRef]

- Sumabat, A.K.; Lopez, N.S.; Yu, K.D.; Hao, H.; Li, R.; Geng, Y.; Chiu, A.S. Decomposition Analysis of Philippine CO2 Emissions from Fuel Combustion and Electricity Generation. Appl. Energy 2016, 164, 795–804. [Google Scholar] [CrossRef]

- Cansino, J.M.; Sánchez-Braza, A.; Rodríguez-Arévalo, M.L. Driving Forces of Spain’s CO2 Emissions: A LMDI Decomposition Approach. Renew. Sustain. Energy Rev. 2015, 48, 749–759. [Google Scholar] [CrossRef]

- Alves, M.R.; Moutinho, V. Decomposition analysis for energy-related CO2 emissions intensity over 1996–2009 in Portuguese Industrial Sectors; CEF AGE-UE Working Paper; Center for Advanced Studies in Management and Economics: Evora, Portugal, 2013. [Google Scholar]

- Hosseini Nasab, E.; Aalami, R.; Foroughi Dahr, S.; Sadeghzadeh, M.A. An Analysis of Energy Consumption in Transportation and Industrial Sectors- a Multiplicative LMDI Approach with Application to Iran. Iran. Econ. Rev. 2012, 16, 1–17. [Google Scholar]

- Akbostancı, E.; Tunç, G.İ.; Türüt-Aşık, S. CO2 Emissions of Turkish Manufacturing Industry: A Decomposition Analysis. Appl. Energy 2011, 6, 2273–2278. [Google Scholar] [CrossRef]

- Hatzigeorgiou, E.; Polatidis, H.; Haralambopoulos, D. CO2 Emissions in Greece for 1990–2002: A Decomposition Analysis and Comparison of Results Using the Arithmetic Mean Divisia Index and Logarithmic Mean Divisia Index Techniques. Energy 2008, 3, 492–499. [Google Scholar] [CrossRef]

- Moutinho, V.; Moreira, A.C.; Silva, P.M. The Driving Forces of Change in Energy-Related CO2 Emissions in Eastern, Western, Northern and Southern Europe: The LMDI Approach to Decomposition Analysis. Renew. Sustain. Energy Rev. 2015, 1485–1499. [Google Scholar] [CrossRef]

- IIASA. MESSAGE Model Regions. 2013. Available online: http://www.iiasa.ac.at/web/home/research/researchPrograms/Energy/MESSAGE-model-regions.en.html (accessed on 22 July 2013).

- World Bank Database. Available online: https://databank.worldbank.org/databases (accessed on 20 December 2019).

- Fricko, O.; Havlik, P.; Rogelj, J.; Klimont, Z.; Gusti, M.; Johnson, N.; Kolp, P.; Strubegger, M.; Valin, H.; Amann, M.; et al. The Marker Quantification of the Shared Socioeconomic Pathway 2: A Middle-of-the-Road Scenario for the 21st Century. Glob. Environ. Chang. 2017, 42, 251–267. [Google Scholar] [CrossRef]

- Liu, G. Research on the Model and Application of Sector Final Energy Consumption: Based on the Industry and Transportation Sector; China University of Geosciences: Beijing, China, 2016; p. 133. [Google Scholar]

- Schrattenholzer, L. The Energy Supply Model MESSAGE; International Institute for Applied Systems Analysis: Laxenburg, Austria, 1981. [Google Scholar]

- Hou, F.; Zhang, S.; Zhao, Z.; Chen, X.; Tan, X.; Huang, H.; Yang, F.; Tan, F. Global Energy Interconnection Scenario Outlook and Analysis in the Context of Achieving the Paris Agreement Goals. J. Glob. Energy Interconnect. 2020, 3, 34–43. [Google Scholar]

- Zhou, Y.; Chen, X.; Tan, X.; Liu, C.; Zhang, S.; Yang, F.; Zhou, W.; Huang, H. Mechanism of CO2 Emission Reduction by Global Energy Interconnection. J. Glob. Energy Interconnect. 2018, 1, 409–419. [Google Scholar]

- IEA. Energy Efficiency Indicators Database; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Tan, X.; Liu, C.; Chen, X.; Zhang, S.; Yang, F.; Wei, C. Carbon Flow and Mitigation Benefits Based on Grid Interconnection: A Case Study on Africa Energy Interconnection. J. Glob. Energy Interconnect. 2019, 3, 291–298. [Google Scholar]

- Zhang, Q.; Zhang, W.; Wang, Y.; Xu, J.; Cao, X. Potential of Energy Saving and Emission Reduction and Energy Efficiency Improvement of China’s Steel Industry. Iron Steel. 2019, 54, 7–14. [Google Scholar]

- Jiang, K.; He, C.; Xu, X.; Jiang, W.; Xiang, P.; Li, H.; Liu, J. Transition Scenarios of Power Generation in China under Global 2 °C and 1.5 °C Targets. J. Glob. Energy Interconnect. 2018, 4, 79–88. [Google Scholar]

- Wang, M.; Kang, W.; Chen, Z.; Zhang, Y.; Liu, C.; Yang, F. Global Energy Interconnection: An Innovative Solution for Implementing the Paris Agreement—The Significance and Pathway of Integrating GEI into Global Climate Governance. J. Glob. Energy Interconnect. 2018, 4, 69–78. [Google Scholar]

| Criterions | Pre-Industrialization (I) | Industrialization Stages | Post-Industrialization Stage (V) | ||

|---|---|---|---|---|---|

| Early Stage of Industrialization (II) | Intermediate Stage of Industrialization (III) | Late Stage of Industrialization (IV) | |||

| (1) GDP per capita (2015 USD, in PPP) | <1000 | 1000~5000 | 5000~18,000 | 18,000~30,000 | >30,000 |

| (2) Economic structure | A > I | A > 20% and A > I | A < 20% and A > S | A < 10% and I > S | A < 10% and I < S |

| (3) Urbanization rate by population | Below 30% | 30~50% | 50~60% | 60~75% | Above 75% |

| Type | Take-Off Point | Gi and Ei at Turning Point | Gi and Ei at Zero Growth Point | Representative Countries |

|---|---|---|---|---|

| High “S” type | 2500~3000 | 10,000~12,000 | 15,000~17,000 | U.S., Canada |

| 1.6~1.8 | 2~2.5 | |||

| Mid “S” type | 10,000~12,000 | 15,000~17,000 | Sweden, Belgium | |

| 1.4~1.5 | 1.7~1.8 | |||

| Low “S” type | 7000~9000 | 10,000~12,000 | England, France, Germany, Japan, Italy, etc. | |

| 0.6~0.8 | 0.7~1.2 |

| Items | Description | |

|---|---|---|

| Model related | Socio-economic | SSP2 |

| Industry energy demand | S-Curve | |

| Resource potential | Resource curves for each region | |

| Solve | Global optimization | |

| Scenario related | 2 °C target | Carbon budget for 2018–2100: 1280 Gt CO2 [1] |

| Reference scenario | No carbon limit, NPi_v4 from IIASA | |

| Technology | Exogenous technological progress |

| Regions | Constant | a | b | c | Adj-R2 | F-stat | p-Value for F |

|---|---|---|---|---|---|---|---|

| CPA | 38 *** | 2.22 × 10−3 *** | −1.63 × 10−7 *** | / | 0.78 | 48.2 | 2.64 × 10−9 |

| EEU | 98.04 *** | −1.46 × 10−2 ** | 1.02 × 10−6 ** | −2.34 × 10−11 ** | 0.39 | 5.07 | 0.012 |

| FSU | 119 *** | −1.42 × 10−2 ** | 7.53 × 10−7 ** | −1.32 × 10−11 ** | 0.58 | 9.57 | 7.4 × 10−4 |

| LAC | 847.4 *** | −0.2 *** | 1.615 × 10−5 *** | −4.34 × 10−10 *** | 0.526 | 11 | 9.74 × 10−5 |

| MEA | 368.2 * | −0.12 * | 1.42 × 10−5 ** | −5.34 × 10−10 ** | 0.69 | 21 | 6.78 × 10−7 |

| NAM | 31.2 *** | −2.12 × 10−4 *** | / | / | 0.75 | 82 | 1.54 × 10−9 |

| PAS | 66.3 *** | −9.05 × 10−3 ** | 8.08 × 10−7 ** | −2.33 × 10−11 ** | 0.55 | 12.2 | 4.84 × 10−5 |

| PAO | 66.4 *** | 1.02 × 10−3 *** | / | / | 0.68 | 57.4 | 3.83 × 10−8 |

| SAS | 16.4 *** | 6.24 × 10−3 *** | −8 × 10−7 *** | / | 0.62 | 23.2 | 1.99 × 10−6 |

| AFR | 4.47 | 2.48 × 10−2 ** | −4.61 × 10−6 ** | / | 0.45 | 12 | 2.22 × 10−4 |

| WEU | 39.8 *** | −4.93 × 10−4 *** | / | / | 0.91 | 282 | 1.78 × 10−15 |

| Regions | “S” Type | Ei | A | α1 | α2 | α3 | Gi |

|---|---|---|---|---|---|---|---|

| (toe/p) | ($/capita) | (1/$) | (1/$) | (1/$) | ($/capita) | ||

| CPA | Low | 0.75 | 0.7 | 0.00002 | 0.00025 | 0.00009 | 9000 |

| EEU | Mid | 0.55 | 1 | 0.000015 | 0.00025 | 0.00009 | 7000 |

| FSU | Mid | 0.75 | 1.2 | 0.000015 | 0.00025 | 0.00009 | 6000 |

| LAC | Mid | 0.6 | 1 | 0.000015 | 0.00025 | 0.00009 | 10,000 |

| MEA | High | 0.55 | 1 | 0.00001 | 0.00035 | 0.0001 | 7000 |

| NAM | High | 0.75 | 1 | 0.000015 | 0.00025 | 0.00009 | 15,000 |

| PAS | Low | 0.55 | 1 | 0.000015 | 0.00025 | 0.00009 | 10,000 |

| PAO | Low | 0.7 | 1 | 0.000015 | 0.00025 | 0.00009 | 9000 |

| SAS | Low | 0.45 | 1 | 0.00002 | 0.00019 | 0.00011 | 10,000 |

| AFR | Low | 0.39 | 1 | 0.00002 | 0.00019 | 0.00011 | 7300 |

| WEU | Mid | 0.7 | 1 | 0.000015 | 0.00025 | 0.00009 | 10,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yang, F.; Liu, C.; Chen, X.; Tan, X.; Zhou, Y.; Guo, F.; Jiang, W. Study on Global Industrialization and Industry Emission to Achieve the 2 °C Goal Based on MESSAGE Model and LMDI Approach. Energies 2020, 13, 825. https://doi.org/10.3390/en13040825

Zhang S, Yang F, Liu C, Chen X, Tan X, Zhou Y, Guo F, Jiang W. Study on Global Industrialization and Industry Emission to Achieve the 2 °C Goal Based on MESSAGE Model and LMDI Approach. Energies. 2020; 13(4):825. https://doi.org/10.3390/en13040825

Chicago/Turabian StyleZhang, Shining, Fang Yang, Changyi Liu, Xing Chen, Xin Tan, Yuanbing Zhou, Fei Guo, and Weiyi Jiang. 2020. "Study on Global Industrialization and Industry Emission to Achieve the 2 °C Goal Based on MESSAGE Model and LMDI Approach" Energies 13, no. 4: 825. https://doi.org/10.3390/en13040825

APA StyleZhang, S., Yang, F., Liu, C., Chen, X., Tan, X., Zhou, Y., Guo, F., & Jiang, W. (2020). Study on Global Industrialization and Industry Emission to Achieve the 2 °C Goal Based on MESSAGE Model and LMDI Approach. Energies, 13(4), 825. https://doi.org/10.3390/en13040825