Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge

Abstract

1. Introduction

2. Experiment Description and Modeling Method

2.1. Experiment Overview and Substrates Characterization

2.2. Analytical Methods

2.3. Prediction Model for Flexible Biogas Production

3. Experimental Results and Discussion

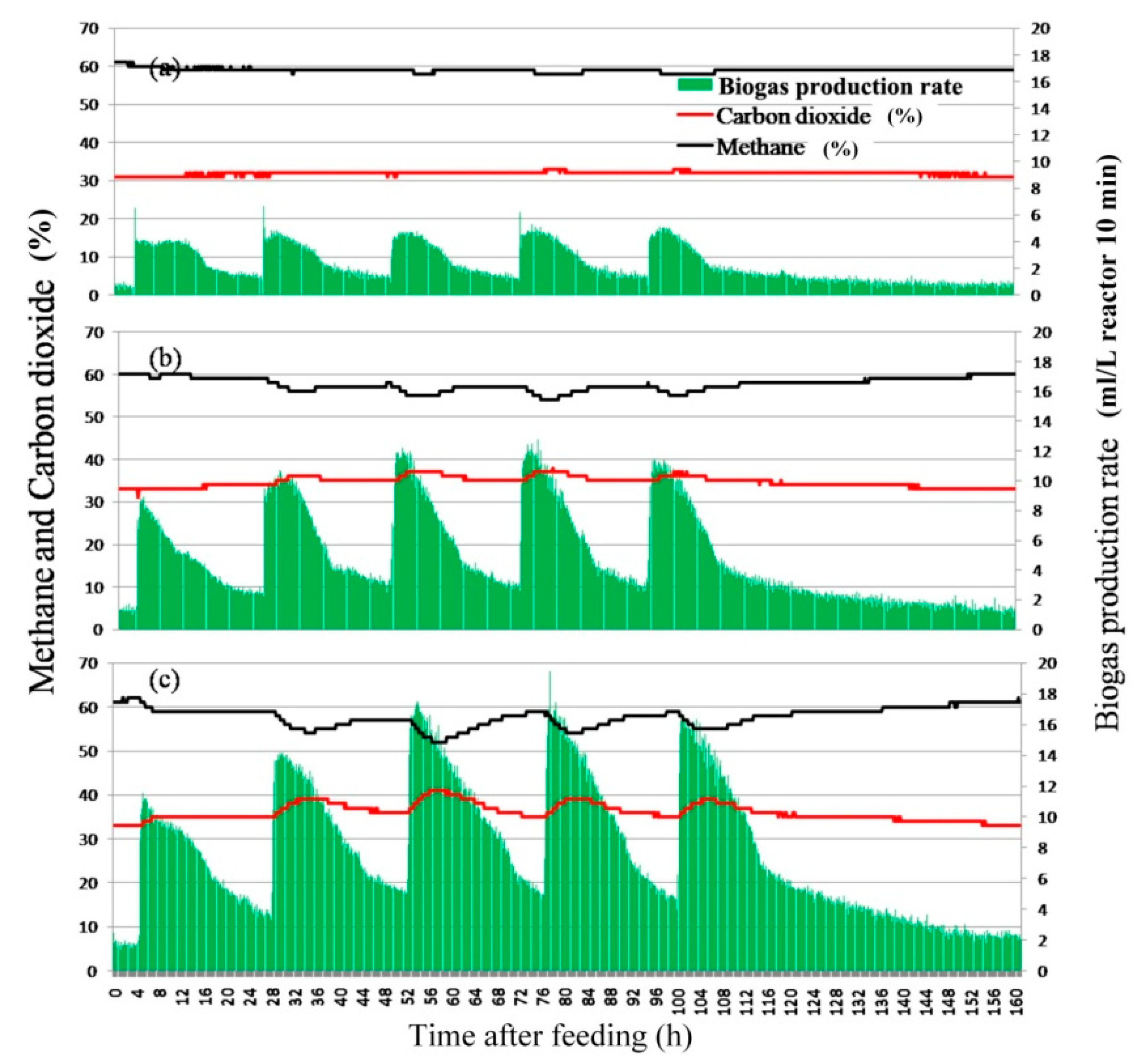

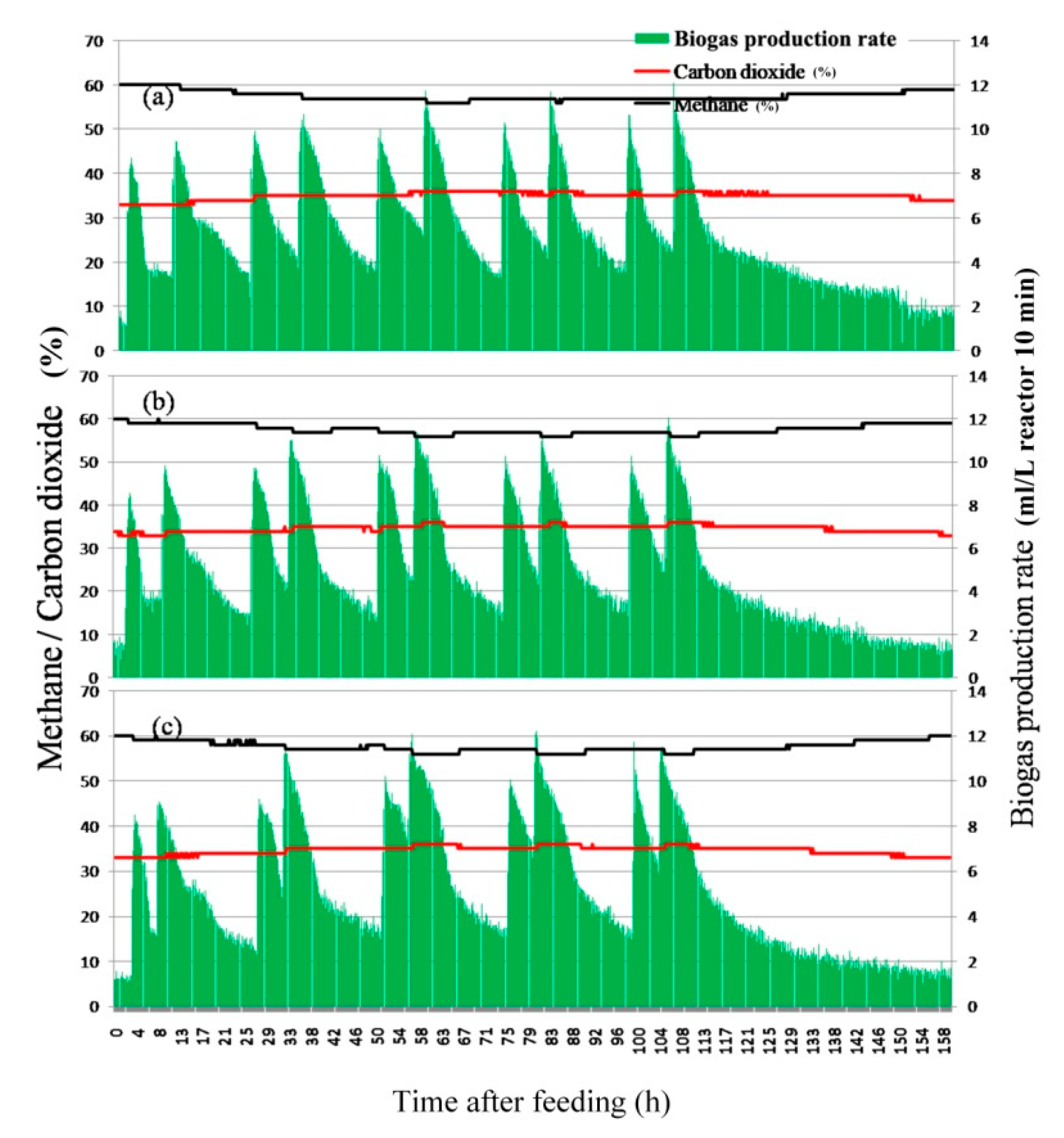

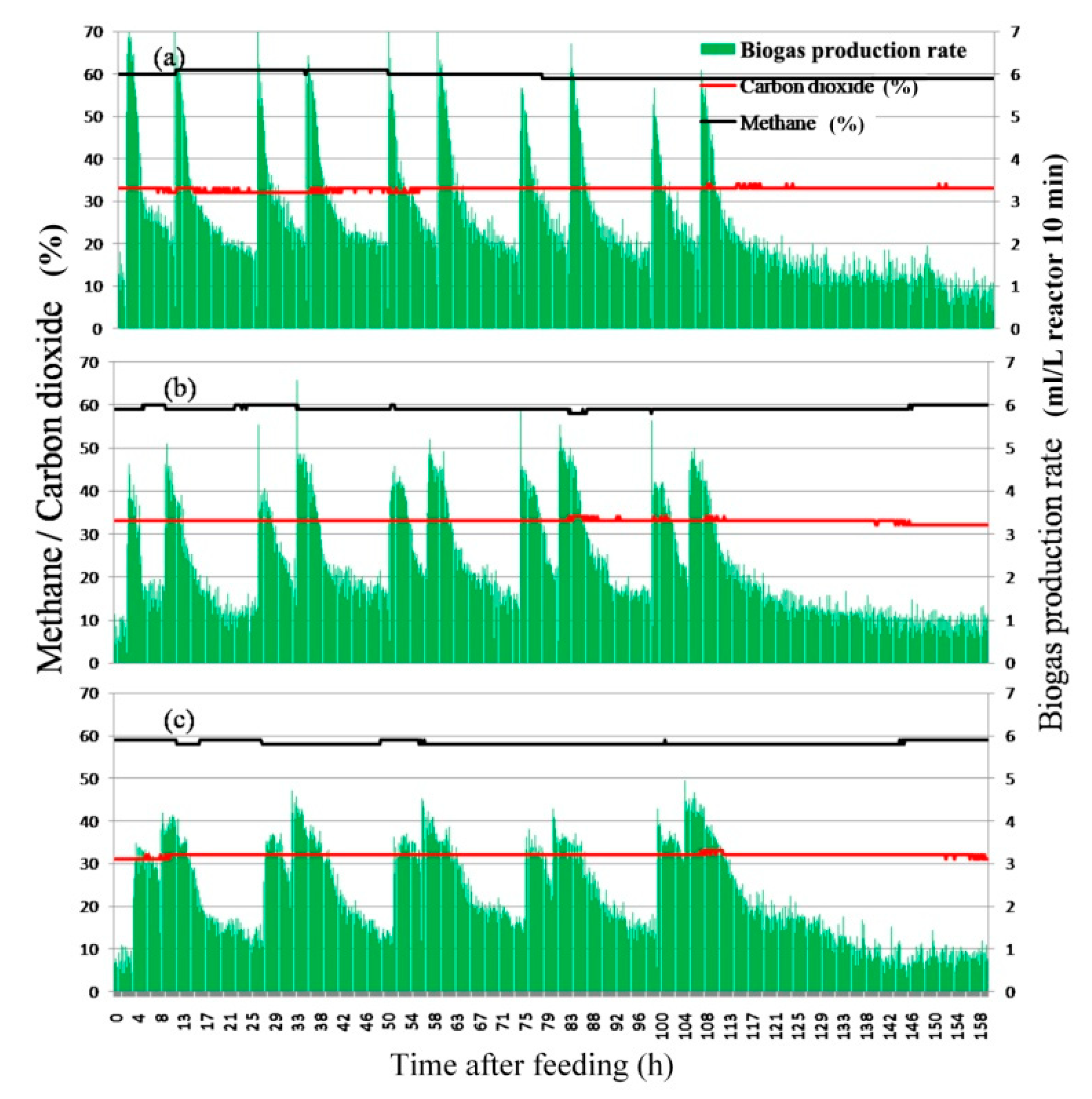

3.1. Effects of Targeted Variation of Feeding Scheme on Biogas and Methane Production

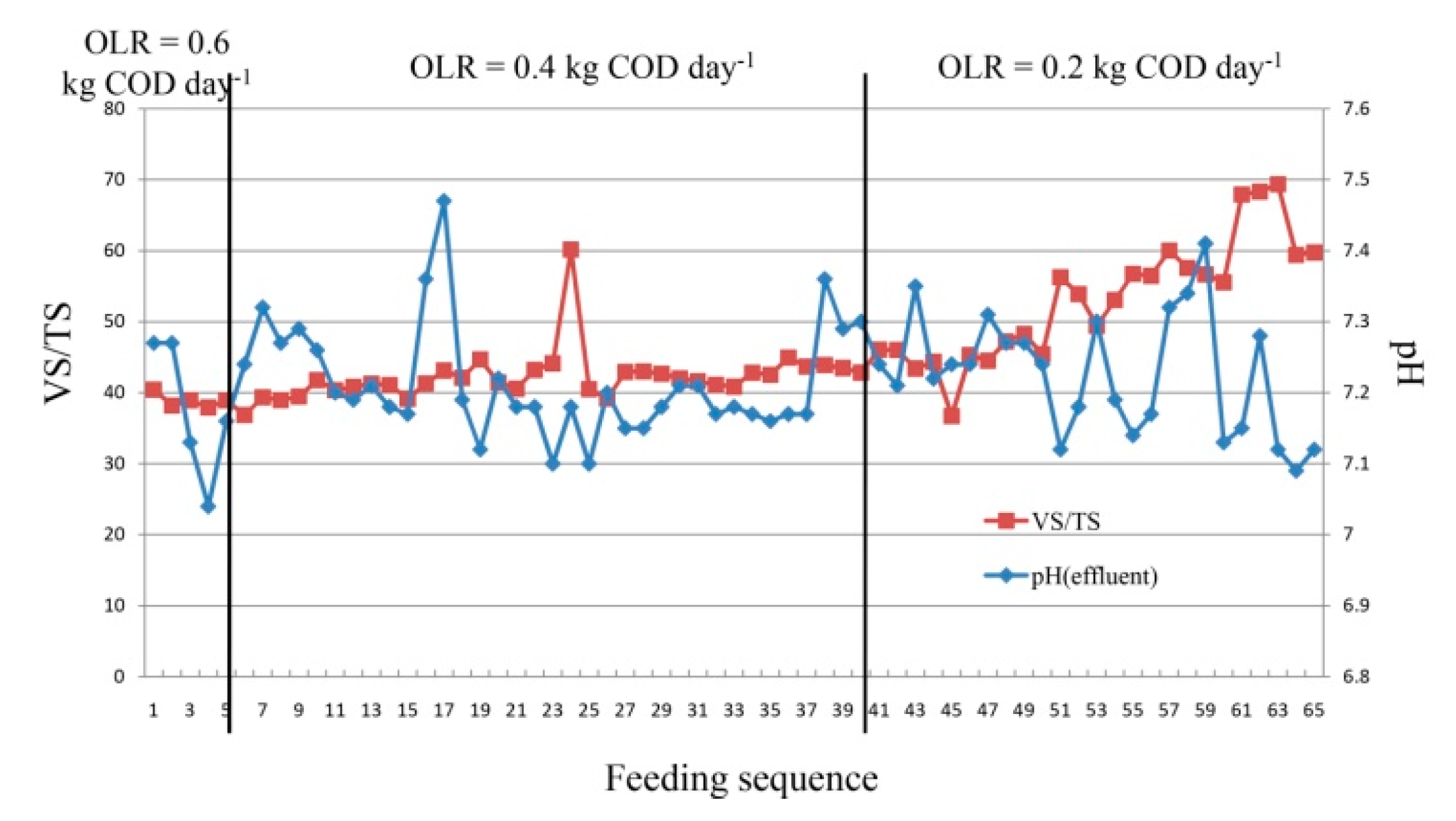

3.2. Process Stability

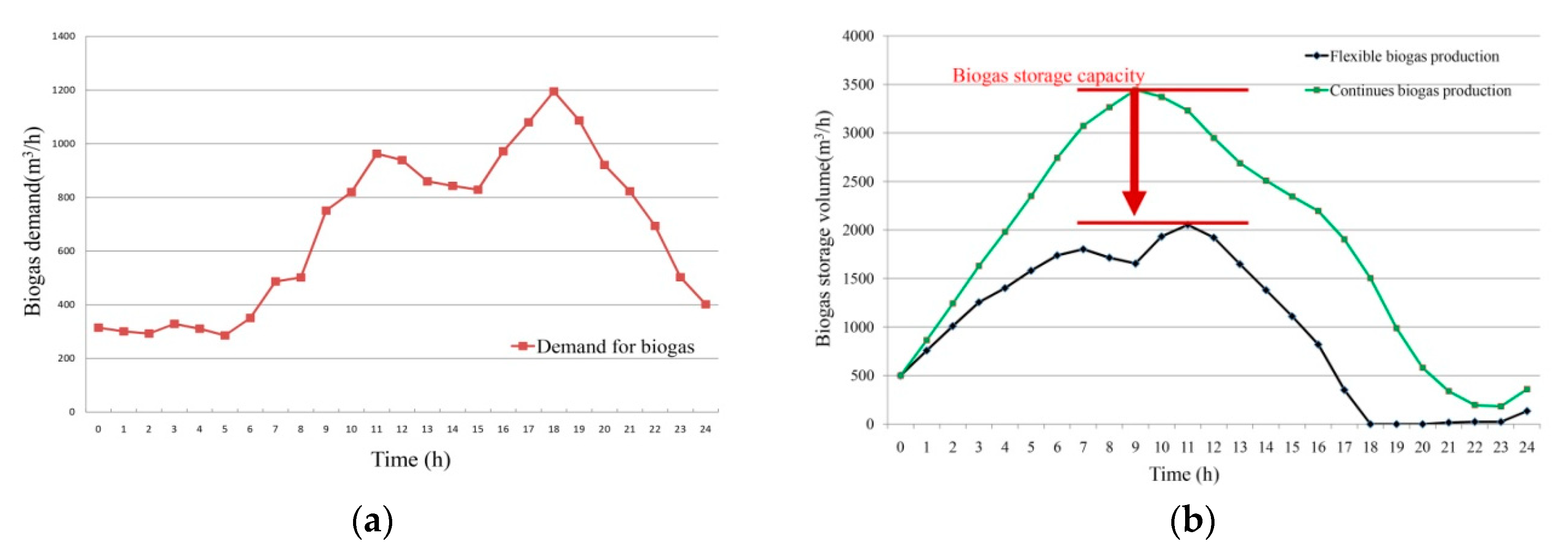

4. Evaluation of the Flexibilization

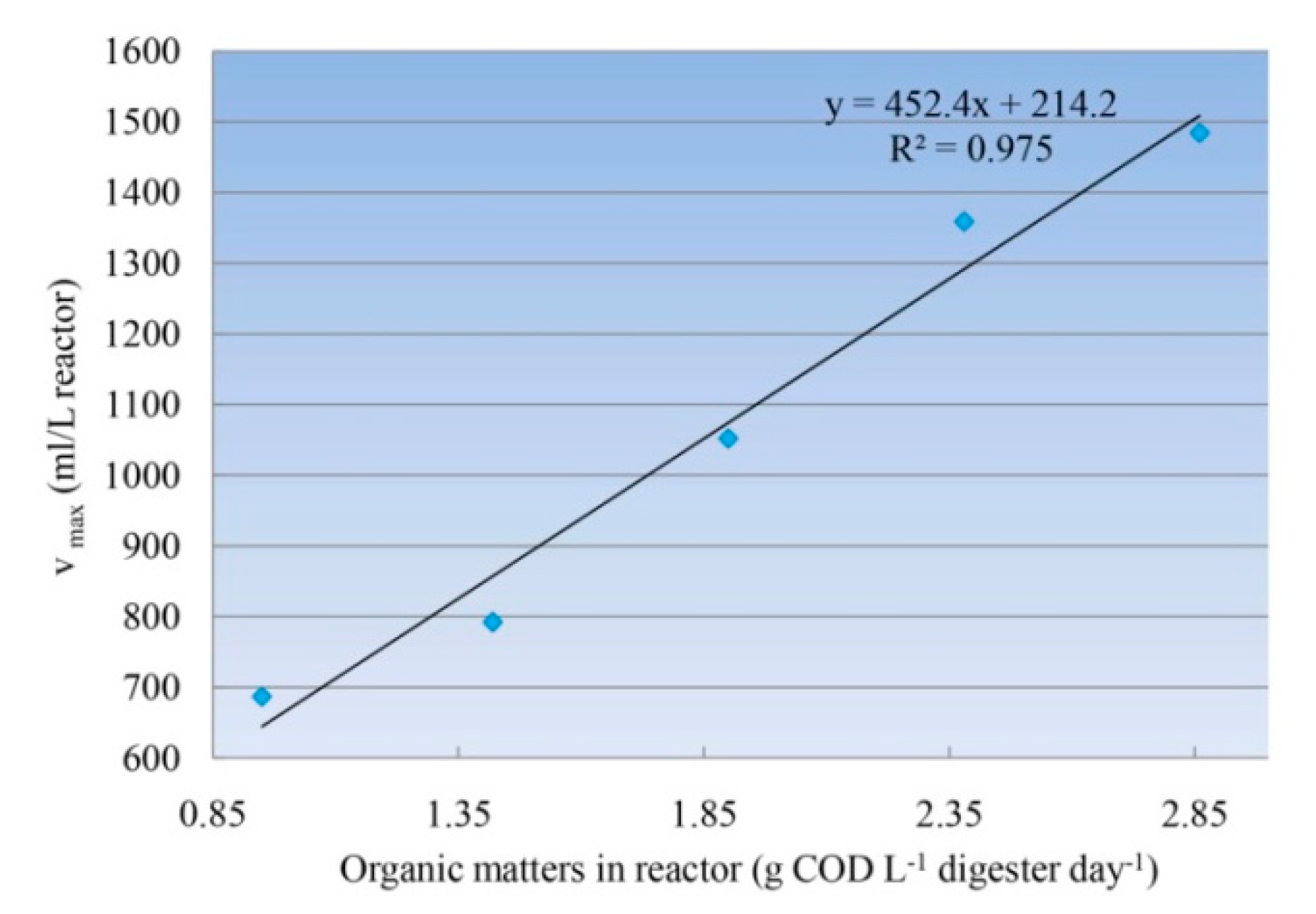

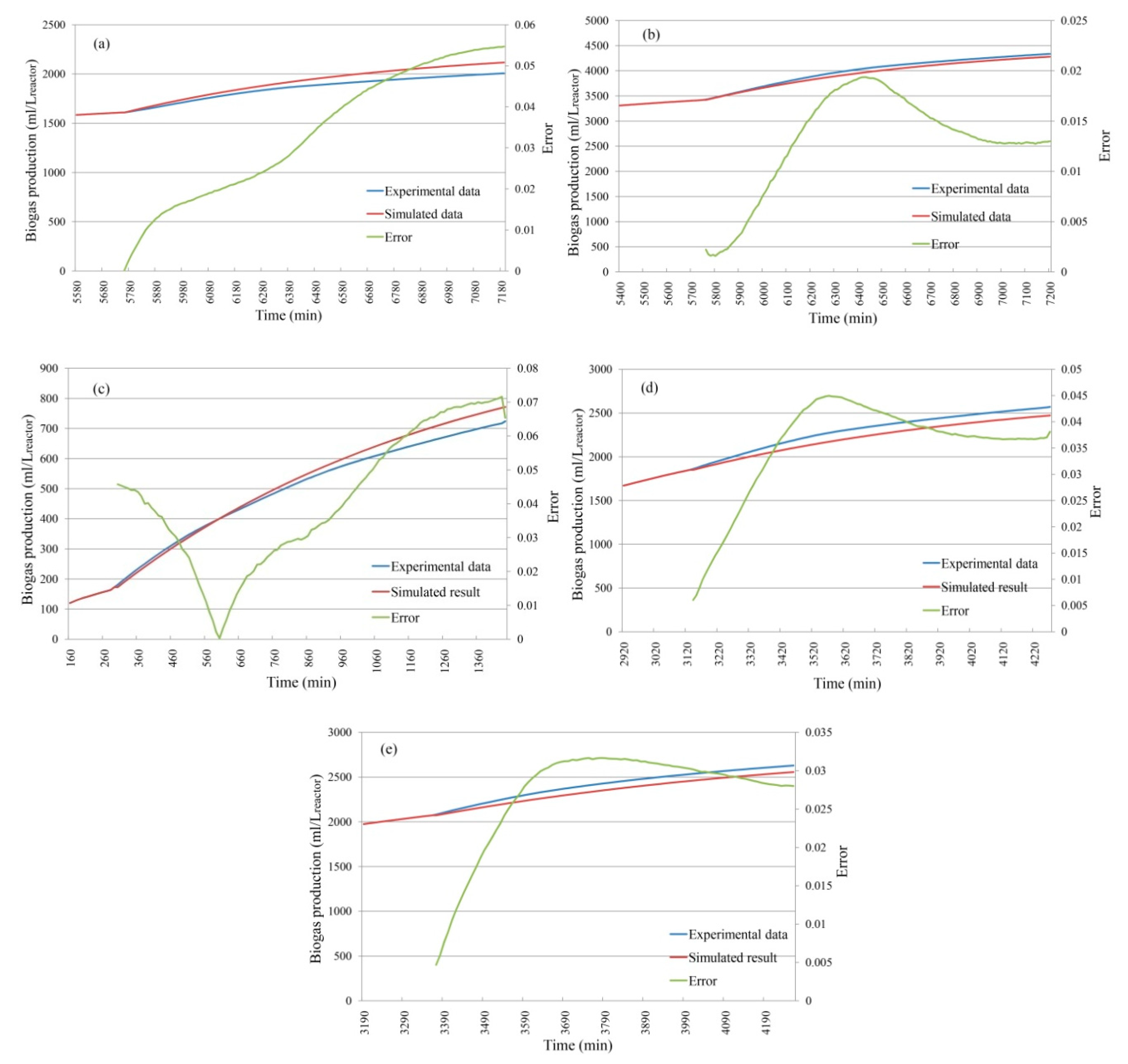

5. Validation of the Proposed Biogas Prediction Model

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Noodles (g) | Soy Flour (g) | Oil (g) | Salt (g) | |

|---|---|---|---|---|

| 2.86 g COD L−1 digester day−1 | 220 | 200 | 63 | 20 |

| 1.90 g COD L−1 digester day−1 | 136 | 127 | 39 | 12.87 |

| 0.95 g COD L−1 digester day−1 | 49 | 46 | 14 | 4.62 |

References

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Cupiał, M.; Klimas, A. Utilization of Post-Ferment from Co-Fermentation Methane for Energy Purposes. Ecol. Chem. Eng. A 2016, 23, 227–238. [Google Scholar]

- Szarka, N.; Scholwin, F.; Trommler, M.; Fabian Jacobi, H.; Eichhorn, M.; Ortwein, A.; Thrän, D. A novel rolefor bioenergy: A flexible, demand-oriented power supply. Energy 2013, 61, 18–26. [Google Scholar] [CrossRef]

- Budzianowski, W.M. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Markard, J. The next phase of the energy transition and its implications for research and policy. Nat. Energy 2018, 3, 628–633. [Google Scholar] [CrossRef]

- Hahn, H.; Krautkremer, B.; Hartmann, K.; Wachendorf, M. Review of concepts for a demand-driven biogassupply for flexible power generation. Renew. Sustain. Energy Rev. 2014, 29, 383–393. [Google Scholar] [CrossRef]

- Lemmer, A.; Krümpel, J. Demand-driven biogas production in anaerobic filters. Appl. Energy 2017, 185, 885–894. [Google Scholar] [CrossRef]

- Mauky, E.; Weinrich, S.; Jacobi, H.F.; Nägele, H.J.; Liebetrau, J.; Nelles, M. Demand-driven biogas production by flexible feeding in full-scale–Process stability and flexibility potentials. Anaerobe 2017, 46, 86–95. [Google Scholar] [CrossRef]

- Saracevic, E.; Frühauf, S.; Miltner, A.; Karnpakdee, K.; Munk, B.; Lebuhn, M.; Wlcek, B.; Leber, J.; Lizasoain, J.; Friedl, A.; et al. Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities. Energies 2019, 12, 2678. [Google Scholar] [CrossRef]

- Ertem, F.; Martínez-Blanco, J.; Finkbeiner, M.; Neubauer, P.; Junne, S. Life cycle assessment of flexibly fed biogas processes for an improved demand-oriented biogas supply. Bioresour. Technol. 2016, 219, 536–544. [Google Scholar] [CrossRef]

- Linke, B.; Rodríguez-Abalde, Á.; Jost, C.; Krieg, A. Performance of a novel two-phase continuously fed leach bed reactor for demand-based biogas production from maize silage. Bioresour. Technol. 2015, 177, 34–40. [Google Scholar] [CrossRef]

- Lauer, M.; Thrän, D. Flexible biogas in future energy systems—Sleeping beauty for a cheaper power generation. Energies 2018, 11, 761. [Google Scholar] [CrossRef]

- Mulat, D.G.; Fabian Jacobi, H.; Feilberg, A.; Adamsen, A.P.S.; Richnow, H.H.; Nikolausz, M. Changing feedingregimes to demonstrate flexible biogas production: Effects on process performance, microbial communitystructure, and methanogenesis pathways. Appl. Environ. Microbiol. 2016, 82, 438–449. [Google Scholar] [CrossRef] [PubMed]

- Zealand, A.M.; Roskilly, A.P.; Graham, D.W. Effect of feeding frequency and organic loading rate on biomethane production in the anaerobic digestion of rice straw. Appl. Energy 2017, 207, 156–165. [Google Scholar] [CrossRef]

- Ahmed, S.; Kazda, M. Characteristics of on-demand biogas production by using sugar beet silage. Anaerobe 2017, 46, 114–121. [Google Scholar] [CrossRef]

- Barchmann, T.; Mauky, E.; Dotzauer, M.; Stur, M.; Weinrich, S.; Jakobi, H.F.; Liebetrau, J.; Nelles, M. Expanding the flexibility of Biogas plants—Substrate management, schedule synthesis and economicassessment. Landtechnik 2016, 71, 233–251. [Google Scholar]

- Laperrière, W.; Barry, B.; Torrijos, M.; Pechiné, B.; Bernet, N.; Steyer, J.P. Optimal conditions for flexible methane production in a demand-based operation of biogas plants. Bioresour. Technol. 2017, 245, 698–705. [Google Scholar] [CrossRef]

- Nghiem, L.D.; Nguyen, T.T.; Manassa, P.; Fitzgerald, S.K.; Dawson, M.; Vierboom, S. Co-digestion of sewage sludge and crude glycerol for on-demand biogas production. Int. Biodeterior. Biodegrad. 2014, 95, 160–166. [Google Scholar] [CrossRef]

- Feng, L.; Ward, A.J.; Guixé, P.G.; Moset, V.; Møller, H.B. Flexible biogas production by pulse feeding maize silage or briquetted meadow grass into continuous stirred tank reactors. Biosyst. Eng. 2018, 174, 239–248. [Google Scholar] [CrossRef]

- Olech, E.; Sikora, J.; Kuboń, M. The potential for biogas production using selected substrates of the agri-food industry. Agric. For. Eng. 2016, 68, 81–86. [Google Scholar]

- Qin, Y.; Wu, J.; Xiao, B.; Hojo, T.; Li, Y.Y. Biogas recovery from two-phase anaerobic digestion of food waste and paper waste: Optimization of paper waste addition. Sci. Total Environ. 2018, 634, 1222–1230. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste–Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Meng, Y.; Li, S.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Chufo, A.; Jaffar, M.; Li, X. Evaluating biomethane production from anaerobic mono-and co-digestion of food waste and floatable oil (FO) skimmed from food waste. Bioresour. Technol. 2015, 185, 7–13. [Google Scholar] [CrossRef]

- Li, X.; Huang, J.; Liu, Y.; Huang, T.; Maurer, C.; Kranert, M. Effects of Salt on Anaerobic Digestion of Food Waste with Different Component Characteristics and Fermentation Concentrations. Energies 2019, 12, 3571. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef]

- Marañón, E.; Castrillón, L.; Quiroga, G.; Fernández-Nava, Y.; Gómez, L.; García, M.M. Co-digestion of cattle manure with food waste and sludge to increase biogas production. Waste Manag. 2012, 32, 1821–1825. [Google Scholar] [CrossRef]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- Lauven, L.P.; Geldermann, J.; Desideri, U. Estimating the revenue potential of flexible biogas plants in the power sector. Energy Policy 2019, 128, 402–410. [Google Scholar] [CrossRef]

- Vavilin, V.A.; Vasiliev, V.B.; Ponomarev, A.V.; Rytow, S.V. Simulation model ‘methane’ as a tool for effective biogas production during anaerobic conversion of complex organic matter. Bioresour. Technol. 1994, 48, 1–8. [Google Scholar] [CrossRef]

- Mauky, E.; Weinrich, S.; Nägele, H.J.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Model Predictive Control for Demand—Driven Biogas Production in Full Scale. Chem. Eng. Technol. 2016, 39, 652–664. [Google Scholar] [CrossRef]

- Löffler, D. Entwicklung Einer Regelungsstrategie für den Anaerob prozess am Beispiel Landwirtschaftlicher Biogasanlagen. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2012. [Google Scholar]

- Mendes, C.; Esquerre, K.; Queiroz, L.M. Application of Anaerobic Digestion Model No. 1 for simulating anaerobic mesophilic sludge digestion. Waste Manag. 2015, 35, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Nordlander, E.; Thorin, E.; Yan, J. Investigating the possibility of applying an ADM1 based model to a full-scale co-digestion plant. Biochem. Eng. J. 2017, 120, 73–83. [Google Scholar] [CrossRef]

- Rajendran, K.; Kankanala, H.R.; Lundin, M.; Taherzadeh, M.J. A novel process simulation model (PSM) for anaerobic digestion using Aspen Plus. Bioresour. Technol. 2014, 168, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Rieke, C.; Stollenwerk, D.; Dahmen, M.; Pieper, M. Modeling and optimization of a biogas plant for a demand-driven energy supply. Energy 2017, 145, 657–664. [Google Scholar] [CrossRef]

- Hien, S.; Hansen, J.; Drewes, J.E.; Koch, K. BioTOOL—A Readily and Flexible Biogas Rate Prediction Tool for End-users. Environ. Model. Assess. 2019, 24, 87–94. [Google Scholar] [CrossRef]

- Yang, J. Study on the Medium Temperature Anaerobic Experiment of Meat Waste with Pig Manure as Inoculum. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2012. [Google Scholar]

- Rao, M.S.; Singh, S.P. Bioenergy conversion studies of organic fraction of MSW: Kinetic studies and gas yield–organic loading relationships for process optimisation. Bioresour. Technol. 2004, 95, 173–185. [Google Scholar] [CrossRef]

- Xie, S.; Hai, F.I.; Zhan, X.; Guo, W.; Ngo, H.H.; Price, W.E.; Nghiem, L.D. Anaerobic co-digestion: A critical review of mathematical modelling for performance optimization. Bioresour. Technol. 2016, 222, 498–512. [Google Scholar] [CrossRef]

- Whitmore, T.; Lloyd, D.; Jones, G.; Williams, T. Hydrogen-dependent control of the continuous anaerobic digestion process. Appl. Microbiol. Biotechnol. 1987, 26, 383–388. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Lo, H.M.; Kurniawan, T.A.; Sillanpää, M.E.T.; Pai, T.Y.; Chiang, C.F.; Chao, K.P.; Liu, M.H.; Chuang, S.H.; Banks, C.J.; Wang, S.C.; et al. Modeling biogas production from organic fraction of MSW co-digested with MSWI ashes in anaerobic bioreactors. Bioresour. Technol. 2010, 101, 6329–6335. [Google Scholar] [CrossRef]

| Parameters | Substrates | |||

|---|---|---|---|---|

| Noodle | Soybean | Oil | Excess Sludge | |

| TS (%) | 88.5 | 88 | - | 0.84 |

| VS (%) | 99 | 93.3 | 99.9 | 69.1 |

| VS (g/kg fresh substance) | 876.2 | 821.04 | 999 | 5.8 |

| COD (gL−1) | 283.5 | 1053.7 | 2384.2 | 8.77 |

| (gL−1) | 0.93 | 0.8 | 0.91 | 1 |

| Protein (%) | 12 | 58.6 | - | - |

| Fat (%) | 1.2 | 2.1 | 100 | - |

| Carbohydrate (%) | 71 | 21.3 | - | - |

| Parameters | |||

|---|---|---|---|

| Feeding COD (g COD L−1 Digester day−1) | (mL BiogasL−1 Digester) | (1 day−1) | Adjusted R2 |

| 0.95 | 686.799 | 0.001 | 0.993 |

| 1.42 | 792.004 | 0.001 | 0.997 |

| 1.90 | 1052.010 | 0.001 | 0.995 |

| 2.38 | 1358.809 | 0.00045 | 0.997 |

| 2.86 | 1484.287 | 0.001 | 0.997 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Huang, T.; Li, X.; Huang, J.; Peng, D.; Maurer, C.; Kranert, M. Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge. Energies 2020, 13, 818. https://doi.org/10.3390/en13040818

Liu Y, Huang T, Li X, Huang J, Peng D, Maurer C, Kranert M. Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge. Energies. 2020; 13(4):818. https://doi.org/10.3390/en13040818

Chicago/Turabian StyleLiu, Yiyun, Tao Huang, Xiaofeng Li, Jingjing Huang, Daoping Peng, Claudia Maurer, and Martin Kranert. 2020. "Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge" Energies 13, no. 4: 818. https://doi.org/10.3390/en13040818

APA StyleLiu, Y., Huang, T., Li, X., Huang, J., Peng, D., Maurer, C., & Kranert, M. (2020). Experiments and Modeling for Flexible Biogas Production by Co-Digestion of Food Waste and Sewage Sludge. Energies, 13(4), 818. https://doi.org/10.3390/en13040818