1. Introduction

Helicopters have been developed for widespread applications due to their versatile characteristics, such as vertical takeoff and landing, hovering, and flexibility. Airborne particle deposition poses a great challenge to the turboshaft engine, a form of gas turbine which is primarily used in the helicopter, in that helicopters always land on or takeoff from unprepared sites. Large concentrations of foreign particles would be ingested into the engine, particularly when the helicopter operates low over deserts or beaches. The particles would impact on the compressor blades and be further pulverized into smaller ones between 1 and 20 μm [

1] in diameter by rotor blades when passing through the compressor. Upon entering the primary combustion zone at a temperature above 2400K, parts of the particles become molten and subsequently adhere to the turbine guide blade, while some particles might impinge on and rebound against it. Once particles accrete on the surface, deposition occurs [

2]. Particle deposition is the result of multiphase flow, phase transition, and heat transfer, which affects the aerodynamic and thermodynamic performance [

3,

4].

With turbine inlet temperature rising, the modern gas turbine employs film-cooling configurations to decrease the thermal loading and protect the guide blades. However, particle deposition results in the partial blockage of film-cooling holes, degradation of film-cooling effectiveness, and failure of turbine blades [

5]. Apart from turboshaft engines, other gas turbines are also exposed to the particle-laden environments [

6,

7]. Ingested particles are detrimental to engine performance and life, even resulting in flight failure. Therefore, it is important to investigate the deposition behaviors in engine representative conditions.

In recent years, particle deposition has been investigated both experimentally and numerically. Kim et al. [

8] investigated the deposition behaviors of two volcanic materials and found that even dust could block cooling holes and cause turbine vane failure. Wammack et al. [

9] reported that particle deposition, together with thermal cycling, caused extensive thermal barrier coating spallation in their study of the test models after different kinds of surface treatments. Wenglarz and Fox [

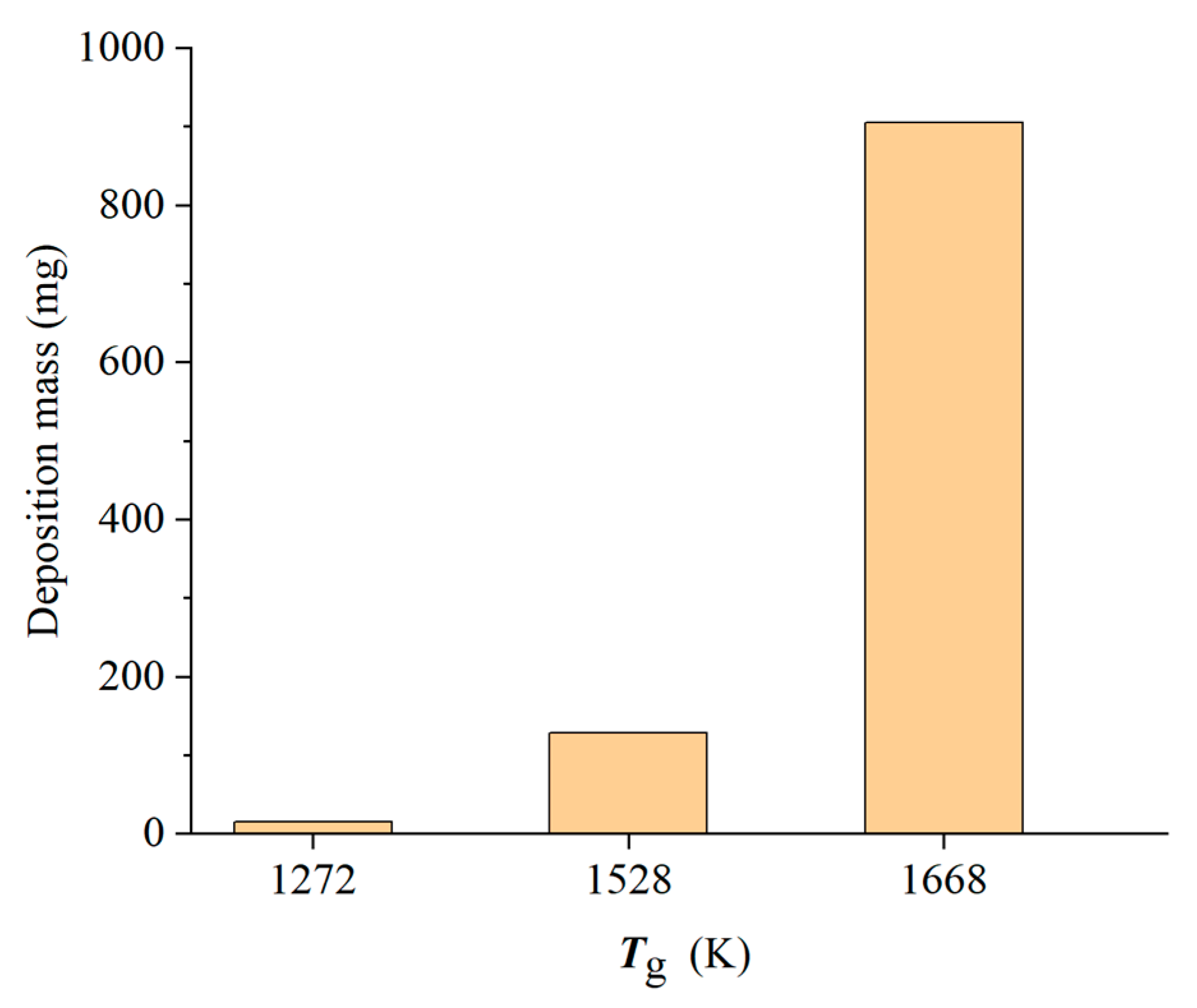

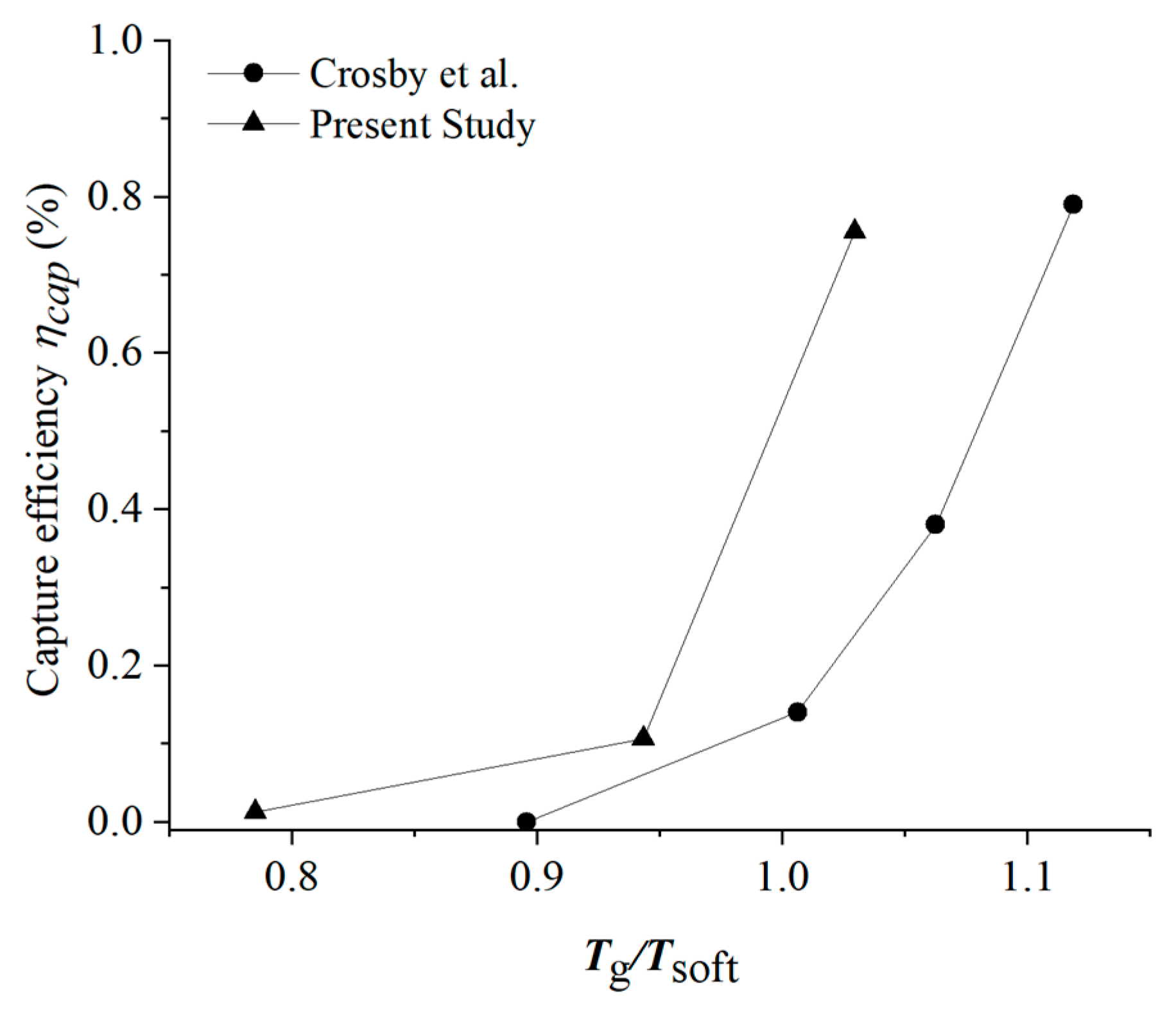

10] conducted deposition tests using three kinds of coal-water fuels. They noted that deposition mass was proportional to the gas temperature, varying from 1253 to 1373 K. Crosby et al. [

11] used a flat plate to study the independent effect of particle size and gas temperature on ash deposition. It was found that the deposition rate increased with increasing gas temperature and particle size. Ai et al. [

12] explored the effects of particle size on deposition by using a flat plate with film-cooling holes angled at 45°. Bonilla et al. [

13] further explored the particle size effect on the CFM56-5B nozzle guide vane. Lundgreen et al. [

14] designed a new turbine cascade to study deposition on the nozzle guide vane surface at inlet temperatures of 1090, 1265, and 1350 °C. It was found that the amount of deposition on the pressure surface increased as the inlet temperature increased. Due to harsh test conditions and high cost, the deposition test at temperatures representative of the actual engines was simulated by those at an ambient temperature, based on similarity laws. Albert et al. [

15,

16] simulated particle deposition at the turbine vane leading edge and on the pressure surface in a low-speed wind tunnel facility by matching the Stokes numbers and thermal scaling parameter (TSP). Zhang et al. [

17,

18] carried out deposition tests at different mainstream temperatures and velocities with wax particles and found deposition mass increased initially and then decreased with the mainstream temperature or velocity. Zhang et al. [

19] also investigated the effect of the angle of attack and particle concentration on the wax deposition behavior.

The numerical model was another strategy for predicting particle deposition behavior. Brach and Dunn [

20] proposed the critical velocity model, and they assumed that deposition would occur when particle velocity is below a certain threshold. Bons et al. [

21] improved the critical model and simulated the particle deposition on the turbine blade surface numerically. Sreedharan and Tafti [

22] modeled the ash particle deposition on a flat plate angled at 45° based on the critical viscosity method. They predicted an exponential increase in the deposition rate with mainstream temperature, which was consistent with the experimental results. Considering the effect of particle deposition on the geometry structure, Liu et al. [

23] developed a numerical model for simulating particle deposition with the dynamic mesh morphing technique. The increase in deposition mass was noted, with particle size increasing. Connolly et al. [

24] also utilized the dynamic mesh method to simulate particle deposition and found that the flow field was affected dramatically by deposition buildup.

Complex chemical and physical processes were involved in the particle deposition, including multiphase flow and heat transfer. It is difficult to predict the deposition formation accurately only by numerical models. Experimental study is a necessary part in the exploration of a complex process. However, turbine inlet temperatures have increased considerably with advances in gas turbine technology. This creates a demand for advances in material and blade-cooling techniques. Most deposition tests are still performed at turbine inlet temperatures around 1500 K. Hence, deposition tests at higher temperature could be beneficial to obtain more accurate results. To the best of our knowledge, there are few examples of any deposition test that runs at higher temperatures than those in the present work. The effect of the angle of attack was also explored using the turbine guide blade at changeable angles of attack.

In this work, we designed a turbine blade-fixing device by which the angle of attack can be adjusted to a desired angle manually. The objectives are to investigate the independent effects of gas temperature and angle of attack on particle deposition on a turbine blade with six rows of film-cooling holes, in a deposition facility equipped with an internally staged single-tube combustor with a single module, by adjusting the fuel–air ratio and the installation angle of the fixing device, respectively.

2. Experimental Facility and Method

2.1. Experimental Facility and Test Model

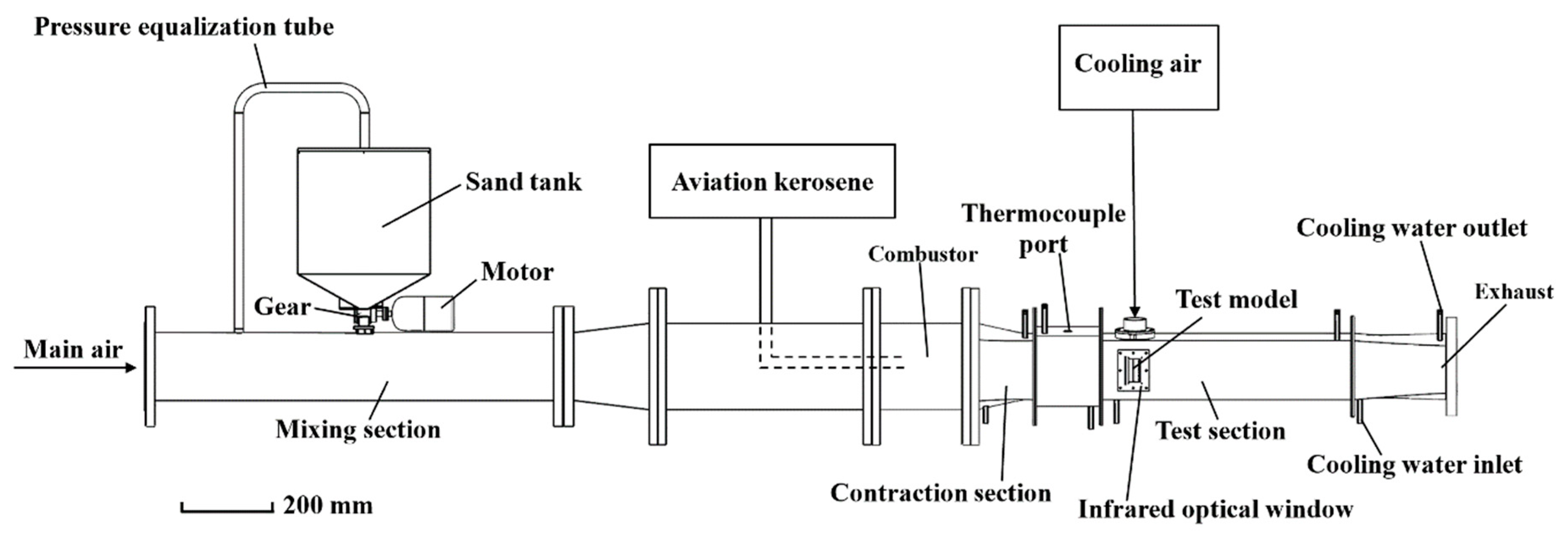

Experiments were performed in a turbine deposition facility equipped with an internally staged single-tube combustor with a single module, seeded with sand particles to replicate the particle deposition on the turbine blade. The experimental system consists of the mixing section, combustor, test section and other components (

Figure 1).

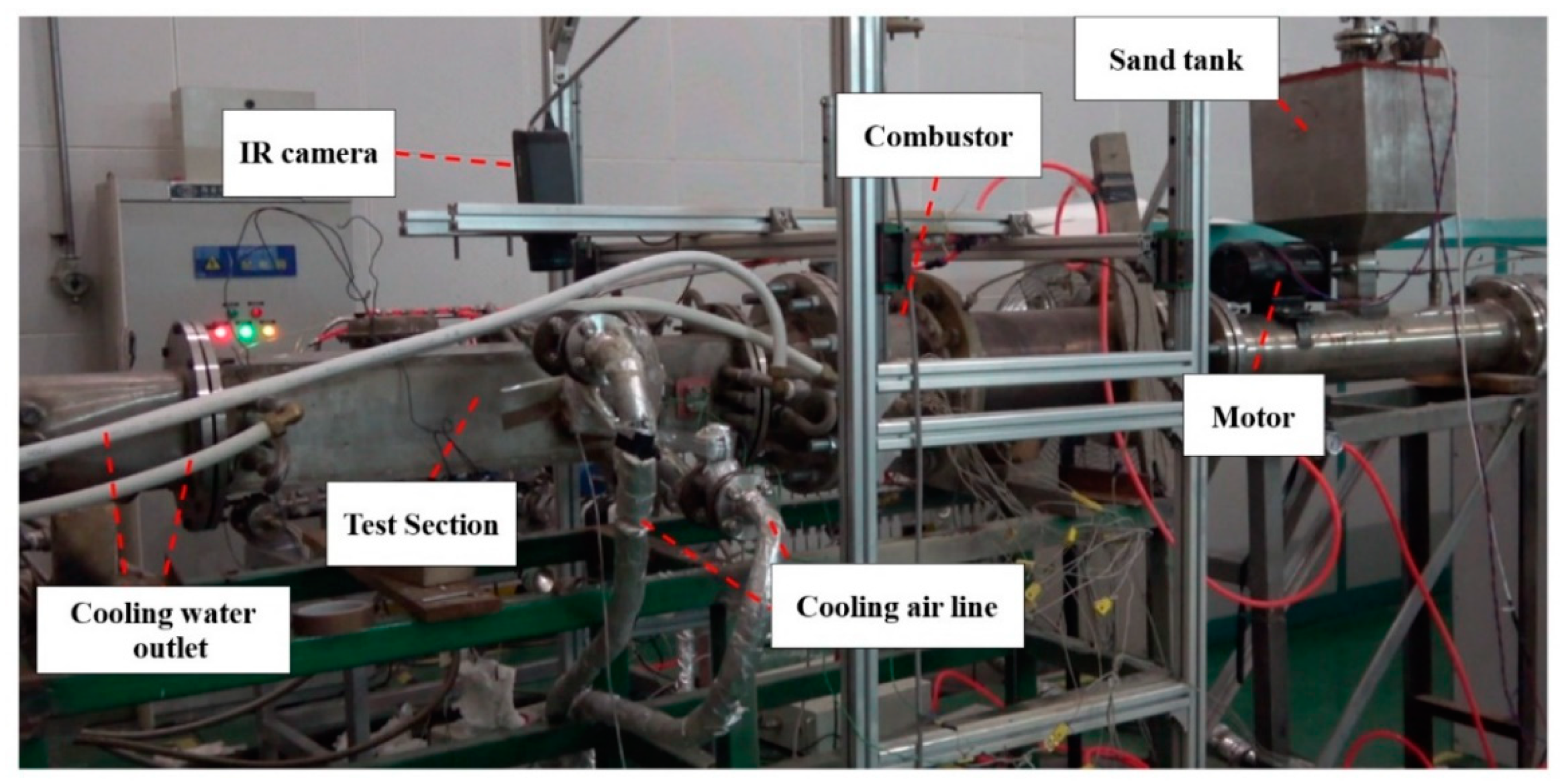

Figure 2 shows the photograph of the deposition facility with the single-tube combustor. Mainstream inlet was supplied from a high-pressure storage tank at a pressure around 0.6 MPa to achieve the mass flow rate range from 0 to 0.6 kg/s. It was preheated using a 550 kW electric heater with an upper limit of 773 K. The inlet temperature was adjusted by controlling the fuel–air ratio and measured using three S-type platinum–rhodium thermocouples located at the entrance to the test section, just upstream of the test model. The thermocouple has a relative uncertainty of 0.25%. Sand particles were injected into the mixing section from the sand tank, driven by a 15-tooth gear and an electric motor. The pressure equilibration tube connected the sand tank to the mixing section, aimed at achieving a balance between them. The gear was accelerated by the motor, producing a mass flow rate between 0 and 3 g/s, depending on the motor rotation speed. The uncertainty of the mass flow rate was 4.02%. Sand particles from the sand tank were entrained into the mainstream flow and entered the combustor. When heated by the hot gas, some sand particles became molten. Parts of particles might be deposited on the test model with film-cooling holes fixed by a holder in the test section. RP-3 aviation kerosene was pumped out of an underground fuel tank through a solenoid valve on the way to the combustor. Fuel mass flow rate was measured by the gear flow meter (STAUFF VC 0.4, Germany) with a relative uncertainty of 0.3%.

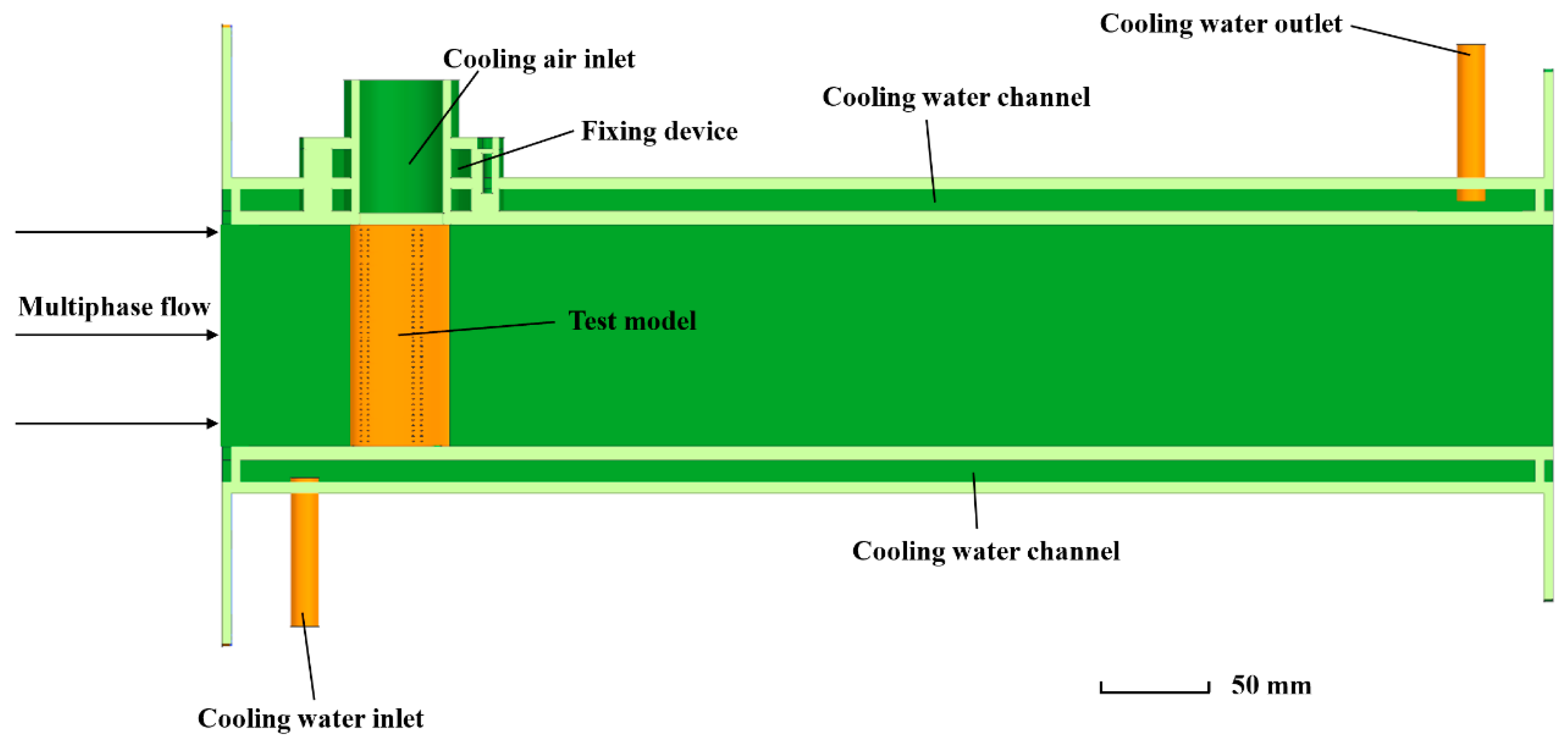

Figure 3 shows the structure of the test section. It was 1.2 m in length. The cross-section was a 0.1 × 0.1 m square. The inner wall of the test section employed water-cooling schemes to help protect the materials from heat generated during high temperature operations. Cooling water was supplied from three tubes upstream of the test model and one downstream of the test model on the exterior wall.

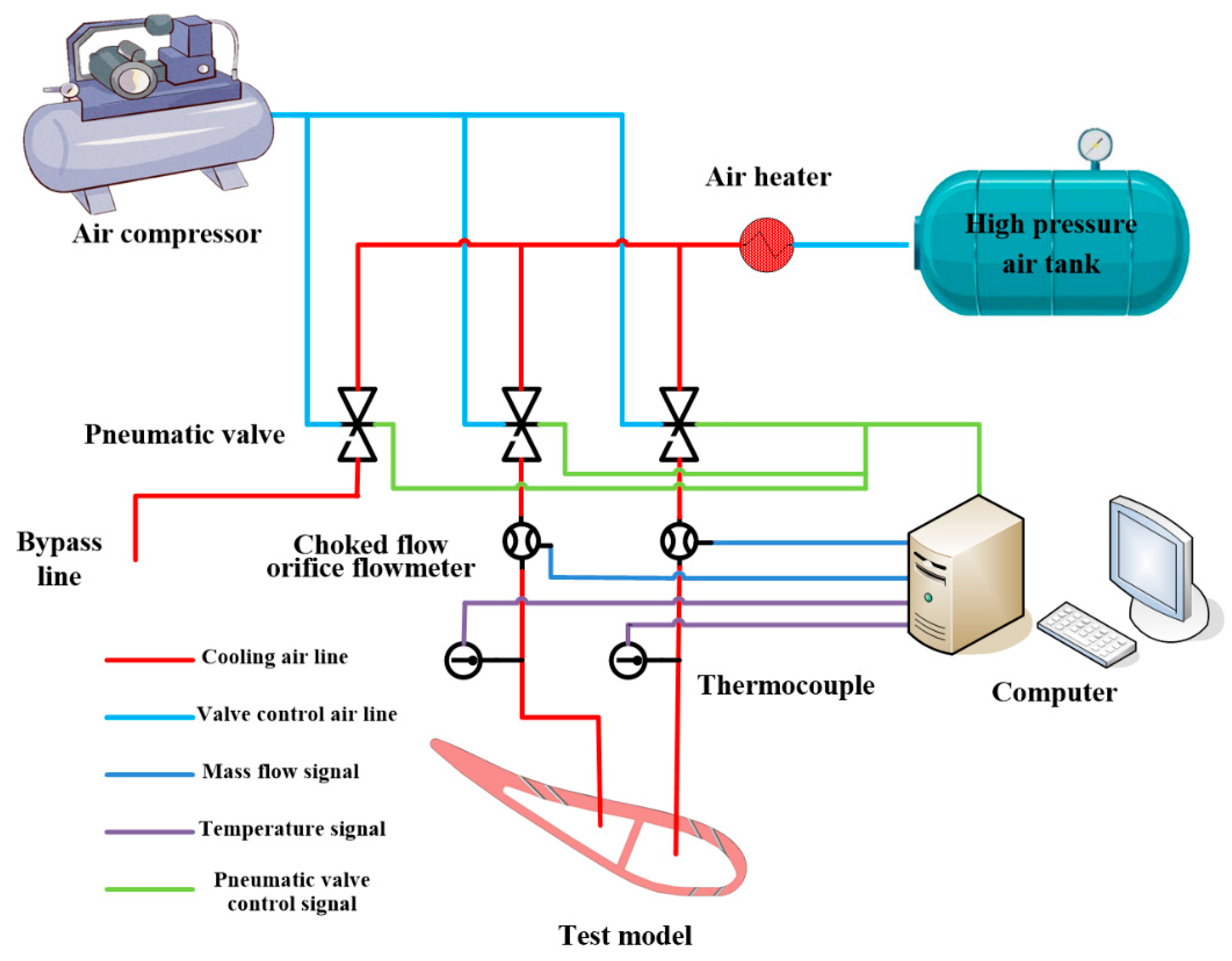

The schematics of the cooling air system is presented in

Figure 4. The cooling air was supplied by a high-pressure air tank and then heated by an electrical heater. The heated cooling air was divided into three parts: two for blade cooling (cooling air lines) and one for residue air emission and heater protection (bypass line). The cooling air flow rate was measured by an orifice flowmeter with a maximum capacity of 10 g/s and a relative uncertainty of 0.6%. It could be controlled by three pneumatic valves installed on three cooling air lines, respectively. The cooling air temperature was detected using two resistance thermometers with a maximum capacity of 573 K and an uncertainty of ±0.5 K.

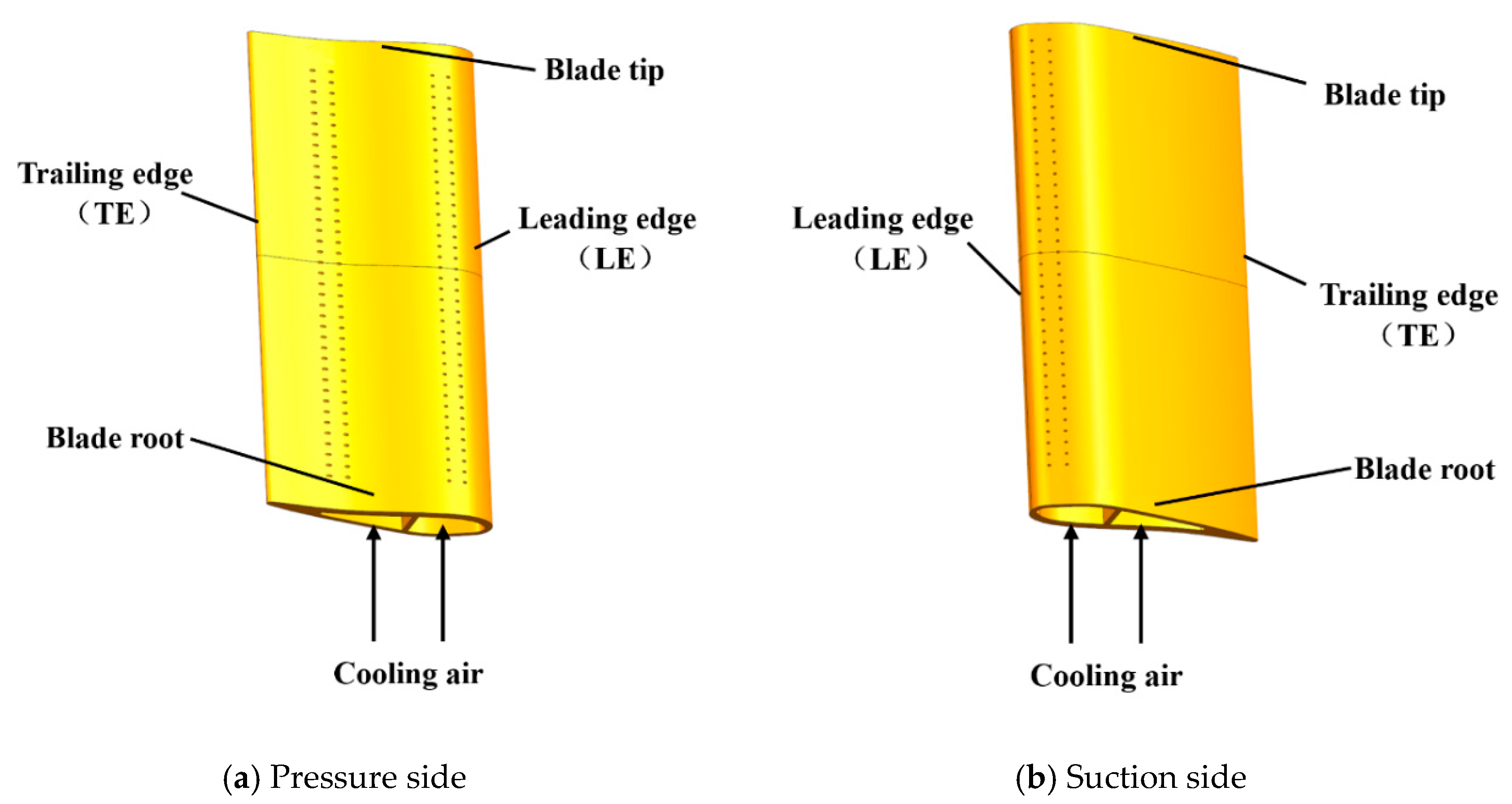

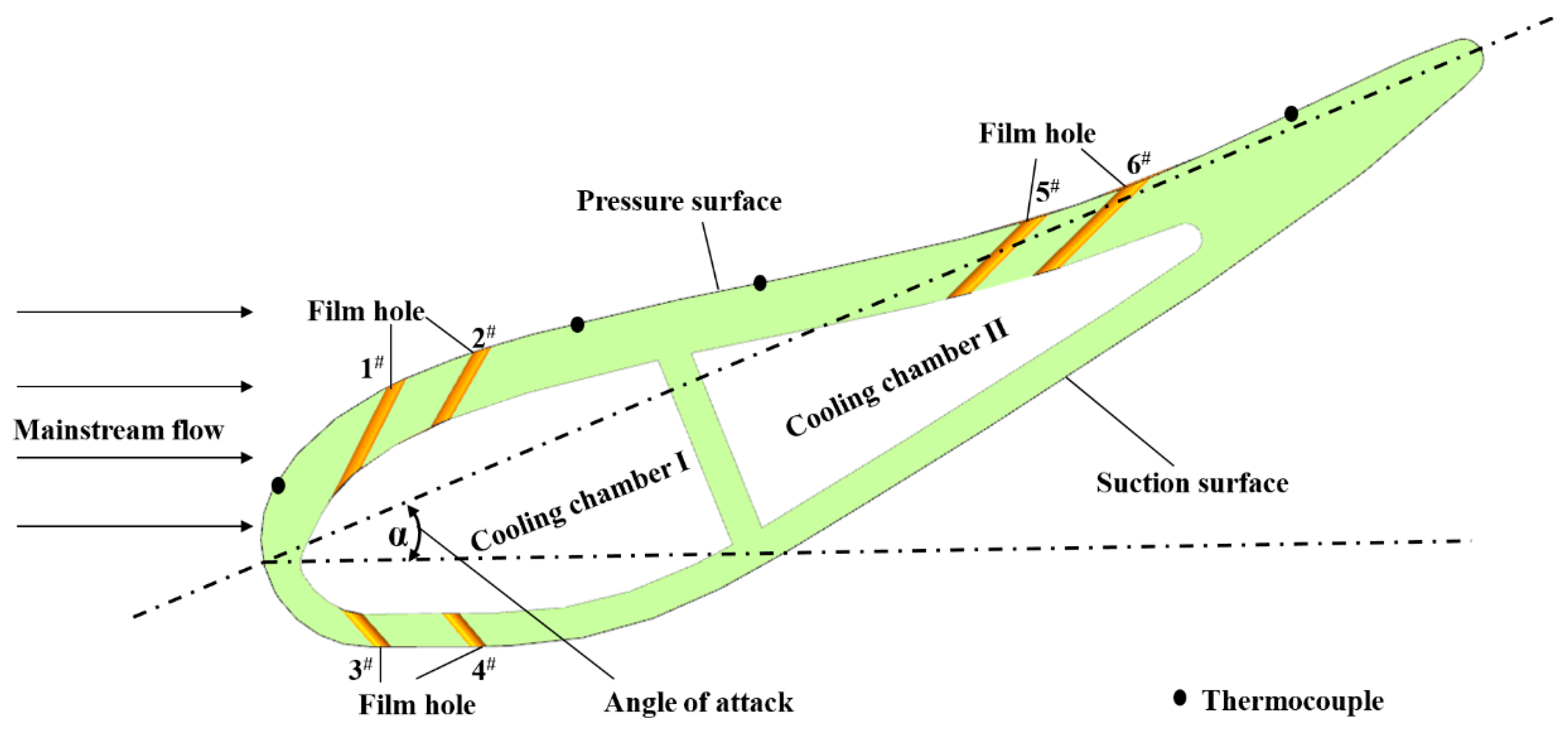

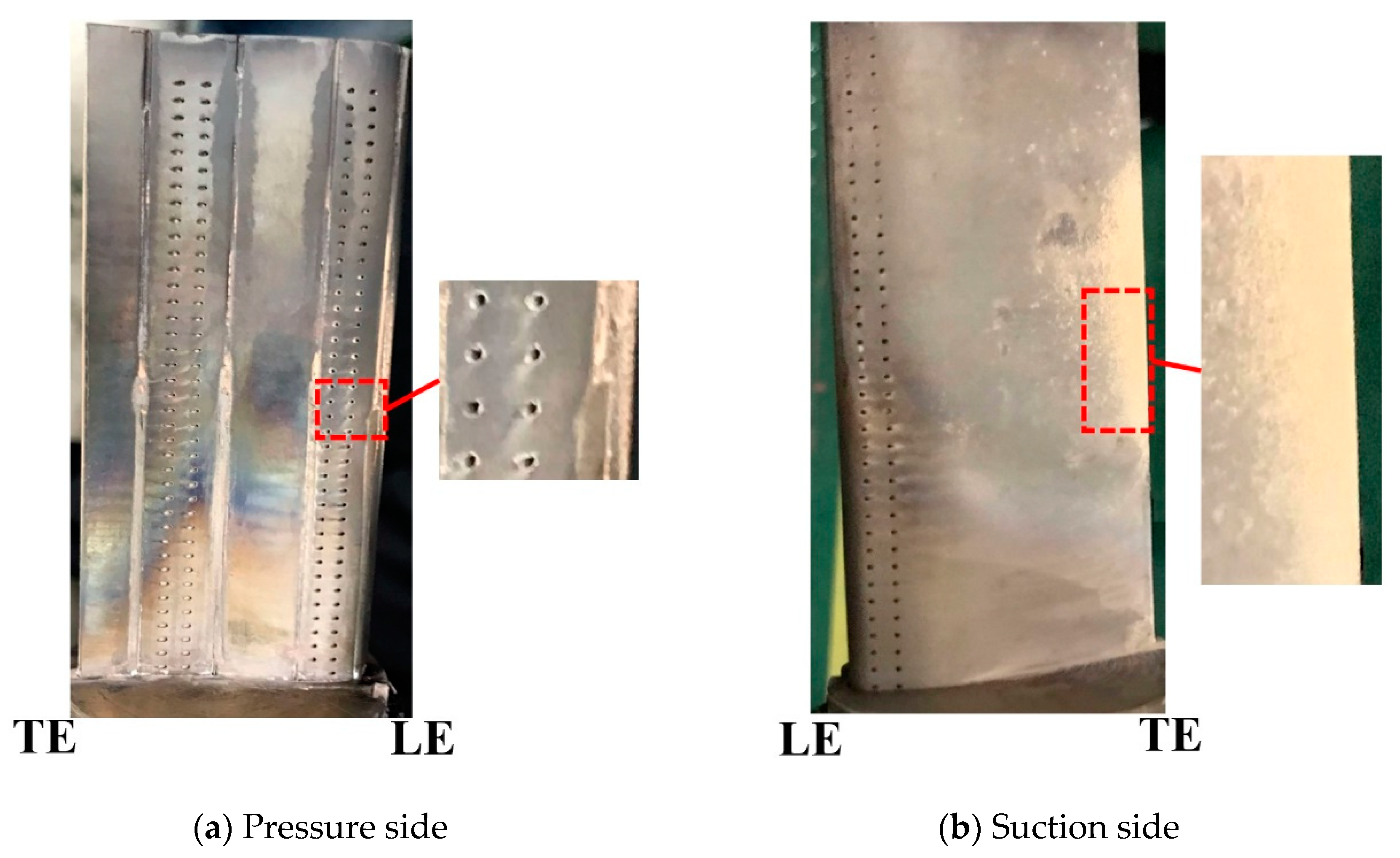

A turbine guide blade was designed as the test model in this study, made of the nickel-based superalloy GH4169 processed by additive manufacturing technology. The test model can be set at an angle of attack ranging from 10° to 40° by adjusting the rotation angle of the test model fixing device. As is shown in

Figure 5, the chord length of the test model is 50 mm, half of the blade height. Forty film-cooling holes are arranged on each row along the spanwise direction of the model. The film-cooling holes are cylindrical with a diameter of 0.5 mm and the hole spacing is 1.88 mm. In total, 240 film-cooling holes were distributed across six rows: four rows on the pressure surface of the blade and the other rows on the suction surface. The inner cooling cavity was separated into two by a central partition with a thickness of 1.2 mm (

Figure 6). Four rows on the suction and pressure surfaces were connected to cooling cavity I near the leading edge, while two rows on the pressure surface were connected to cooling cavity II near the trailing edge. Cooling air was supplied from the blade root to inner cooling cavities I and II through two cooling air lines. The exhausted air was emitted from the inner cavity through film-cooling holes.

An infrared inspection window, designed to allow infrared radiation to transmit to the outside environment, was installed above the upper surface of the test model to collect infrared temperature data for an infrared camera (FLIR A655sc, relative certainty: 2%). The K-type thermocouple with an uncertainty of 2 K serves as the method used for IR camera calibration. It had four data collection points on the blade pressure surface. The resulting deposition mass was measured by the analytical balance (METTLER TOLEDO XPR 3003S, Switzerland, precision grade: 1 mg). Pre-test and post-test blade profiles were obtained by a 3D scanner with a precision up to 5 μm (Tianyuan OKIO-5M-100, China). The differences in geometry were acquired to provide the deposition thickness.

2.2. Sand Preparation and Characterization

Gas turbine engines operate in different environments that feature various kinds of airborne particles, such as volcanic ash, coal dust, sand particles and others. The distribution and composition varies among those foreign particles. However, the physical and chemical properties of the ingested particles would exert direct effects on the deposition behaviors [

25], which further affect the engine performance. The test sand in the sand tank, adopted for the deposition tests, is prepared according to the USA military standard (MIL-STD-3033) [

26] to simulate the effects on the engine blade through environments that contain sand particles.

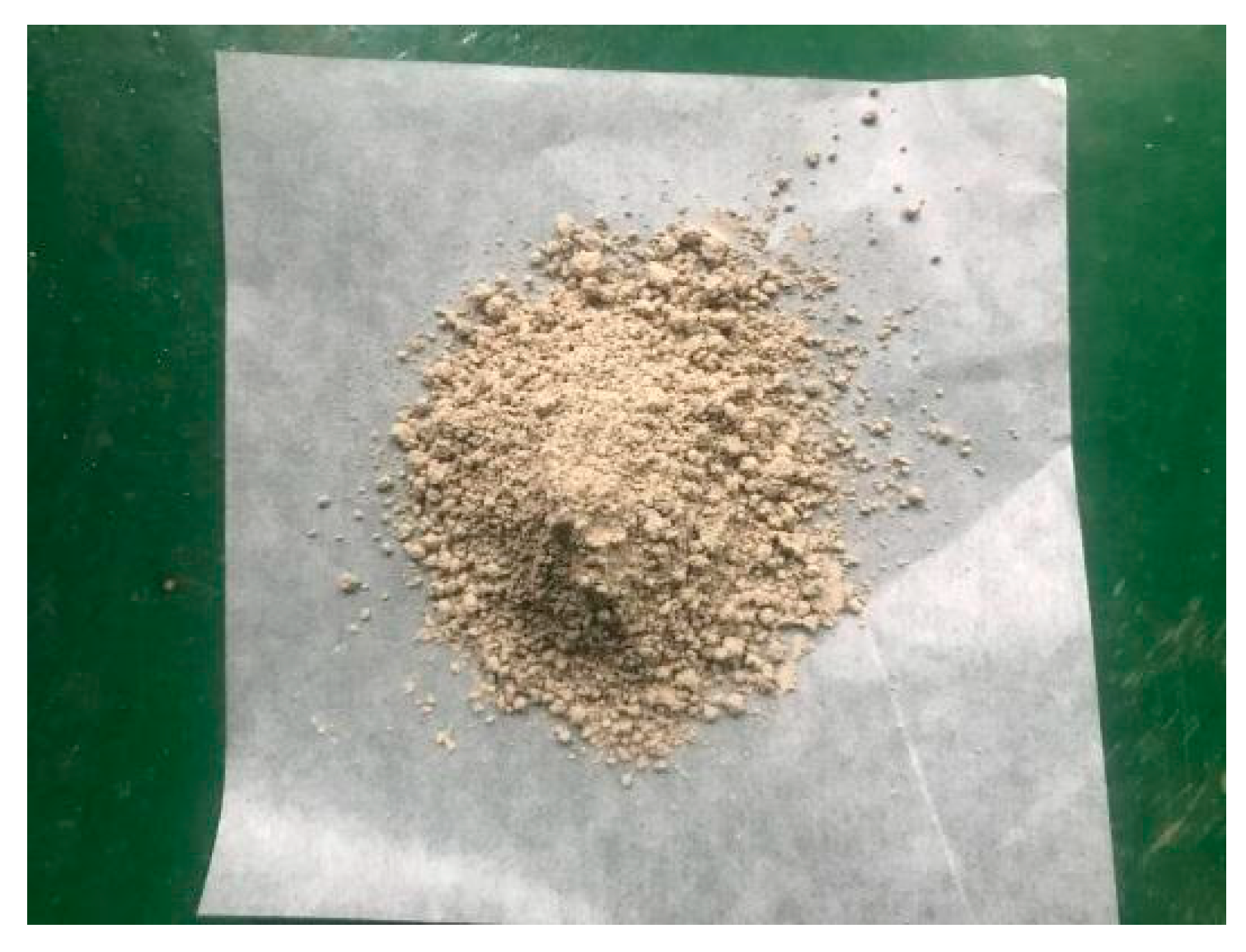

The test sand was a light brown powder (

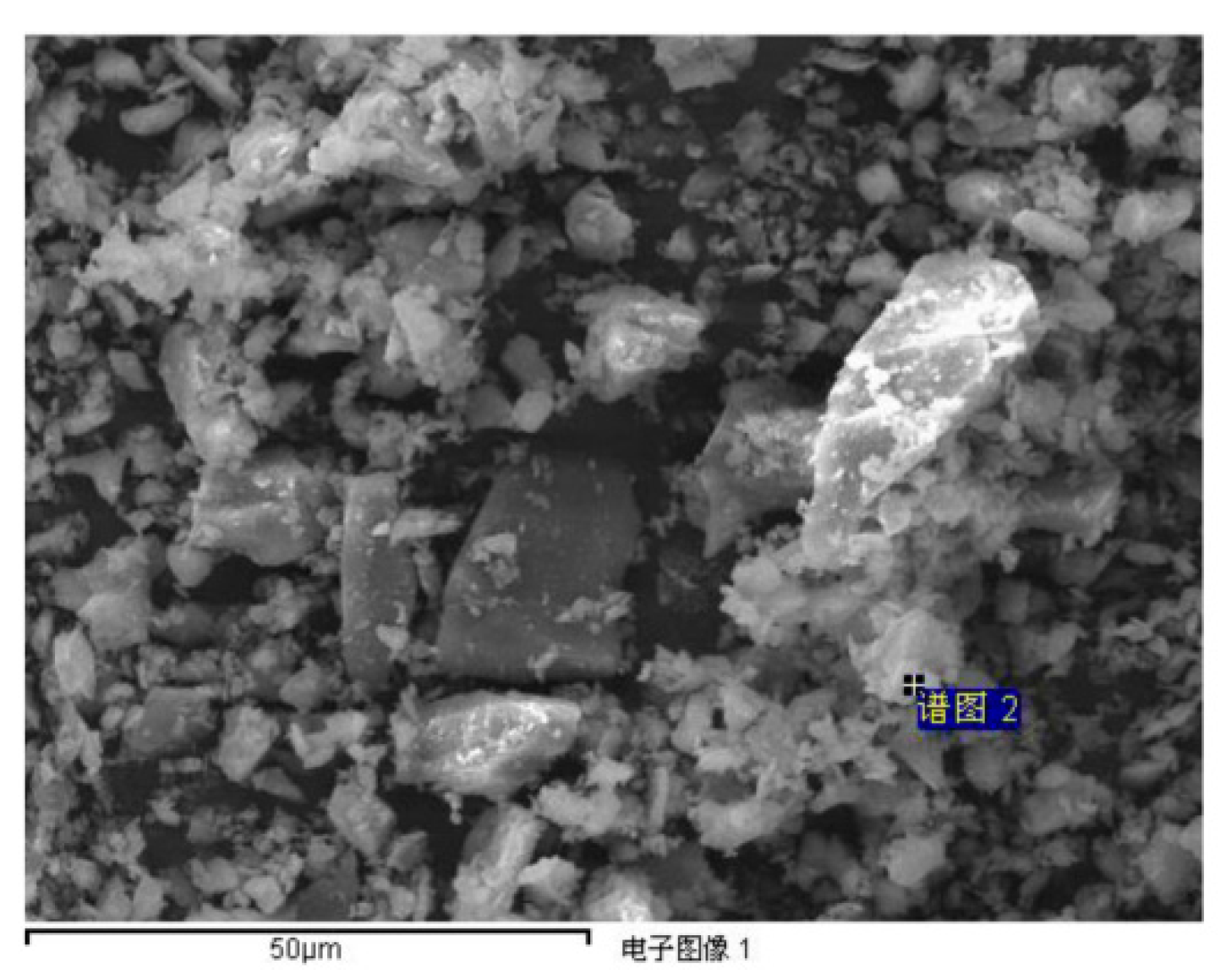

Figure 7) that can hardly be dissolved in water. Its density is roughly 2.65 times that of water. The morphology of the test sand was characterized by a scanning electron microscope (SEM, Hitachi model S-4800, Japan). The sand particle size distribution was determined on a laser particle size analyzer (LPSA, Malvern Mastersizer 2000, UK). SEM imaging reveals that the sand sample is primarily composed of angular, discrete particles of different sizes, which have edges and corners with bump surface (

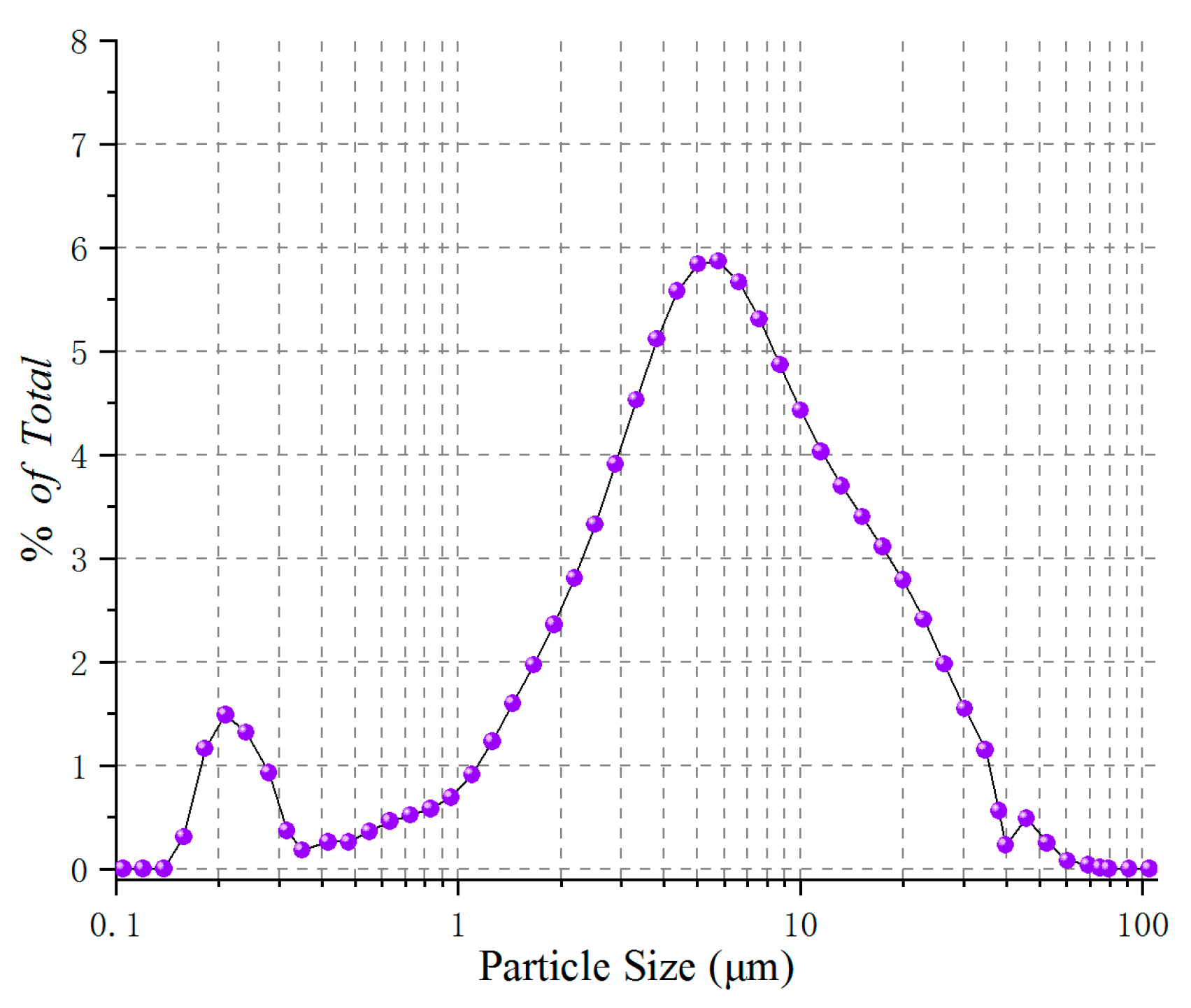

Figure 8). Slight agglomerates of fine particles are observed on the large sand particle surface. The mean particle sizes are mainly distributed between 1 and 10 μm, confirmed by laser particle size analysis (

Figure 9). Particle size is one of the major factors in determining the particle flow and deposition behavior. Deposition on the blade is a result of inertial particle transport. However, the particle trajectory is influenced by aerodynamic forces acting upon the ingested particles when they are carried with gas through the combustor. The aerodynamic forces are highly dependent on particle size. For example, friction is proportional to the square of the particle diameter. The mean particle size at the turbine inlet is found to be mainly below 50 μm from previous studies. Thus, the sand sample adopted herein is representative of that ingested by the turbine.

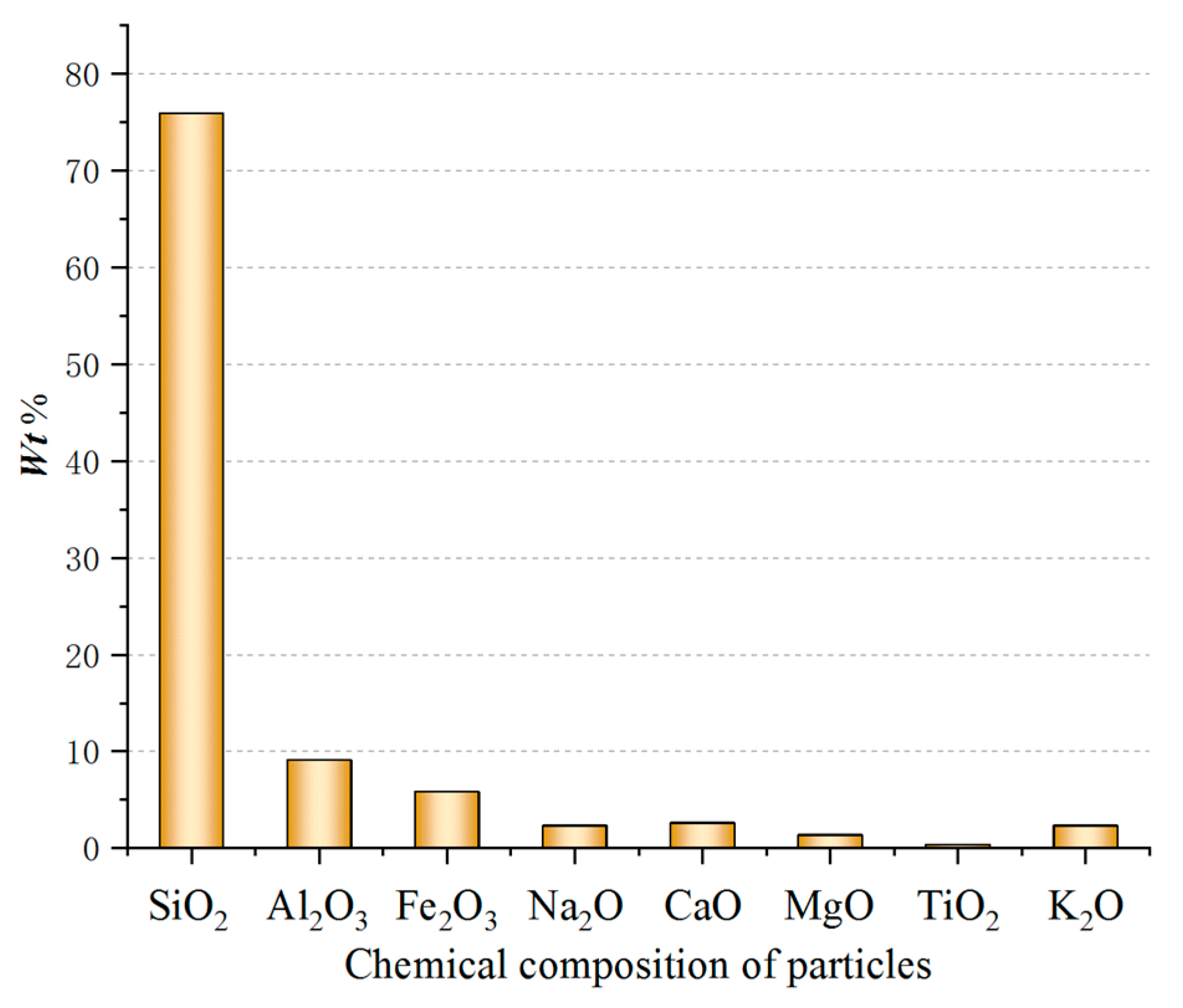

The elemental composition was provided using a ThermoFisher Scientific X-ray photoelectron spectrometer (XPS, ESCALAB 250Xi, USA). The XPS survey spectra confirms the existence of oxygen (O), silicon (Si), aluminium (Al), iron (Fe), potassium (K), solium (Na), calcium (Ca), magnesium (Mg) and titanium (Ti) in the test sand. Apart from oxygen, Si was the most abundant element, indicating that silicon dioxide was the major phase in the sand, amounting to more than 70% of the test sand (

Figure 10). The rest of the constituents were metal oxides.

2.3. Experimental Parameters

The main operating parameters of the deposition test facility are listed in

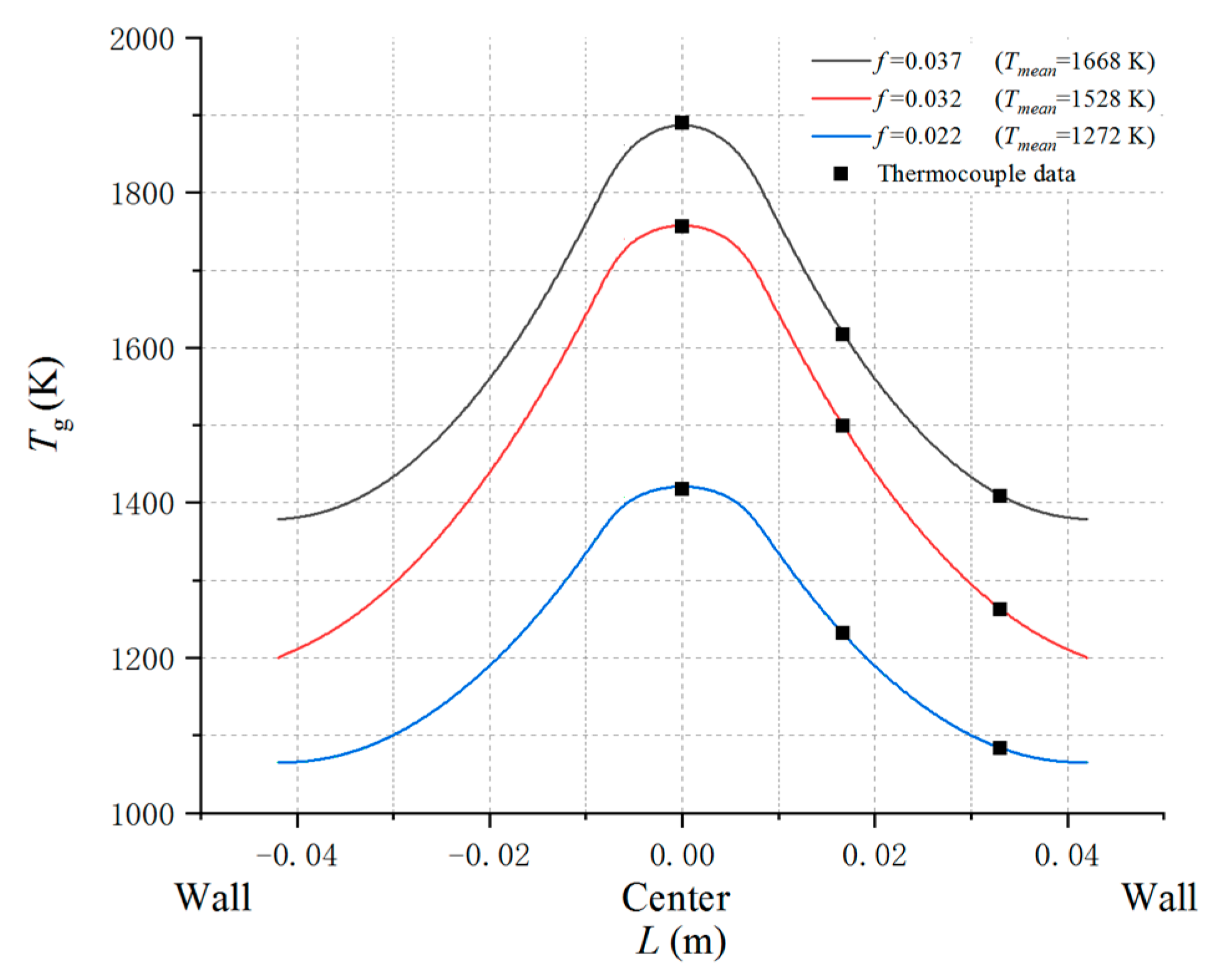

Table 1. The outlet temperatures of modern gas turbine combustors vary from 1200 to 2100 K depending on the engine purposes. For the combustor utilized herein, the upper limit of the fuel–air ratio was 0.037, with a maximum temperature rise of 1300 K. The combustor outlet temperature was controlled by adjusting fuel–air ratio and holding inlet temperature constant. It was measured by three thermocouples, located at the center of the cross-section of the test section. The field temperature was symmetrically distributed along the axis of the fuel nozzle based on the characteristics of the internally staged single-tube combustor [

27]. The temperature reached the highest level in the center and the lowest level near the wall, as shown in the fitted quadratic curve of gas temperature data at the outlet cross-section of the combustor (

Figure 11). At the fuel–air ratio of 0.037, the temperature peak at the outlet section is approximately 1890 K, while it decreases to 1400 K near the wall. The mean temperature at the test section inlet was determined using definite integrals. It decreased as the fuel–air ratio decreased. The average values were calculated to be 1668, 1528 and 1272 K, corresponding to the fuel–air ratios of 0.037, 0.032, and 0.022, respectively. The main variables of the deposition tests are listed in

Table 2. The mainstream inlet flow is a fully developed turbulent flow at Reynolds number Re ≈ 1.01 × 10

5 based on the mainstream velocity and cross-sectional width upstream of the test model.

2.4. Test Procedures

The deposition test procedure is listed below:

(1) The test model was carefully cleared before three-dimensional (3D) shape and weight measurements. The test model geometric profile was obtained by a 3D scanner. The initial mass of the test model was measured by the analytical balance, recorded as the pre-test mass;

(2) After the geometric and weight data of the test model were acquired, it was mounted in the fixing device at a specified angle of attack. The positions were marked to make sure the model was always located at the same place and orientation before the test restarted. Then, the test device status was checked, such as the air heater and IR camera;

(3) The cooling air system was turned on and then the cooling air flow rate was adjusted and stabilized. Subsequently, the online temperature measurement system was switched on, including the infrared thermometer and thermocouples;

(4) The air heater was opened to preheat the mainstream flow;

(5) The fuel feed pump was started to add the fuel. With fuel and air being supplied, the combustor burned the mix after ignition. The fuel–air ratio was adjusted to the specified value to control the inlet temperature at the test section;

(6) The temperature at the combustor exit was monitored by thermocouples. The temperatures of mainstream flow and test model surface were both allowed to reach steady state. Once the deposition facility reached the steady state, the variable speed motor, which controlled the sand seeding system, was driven. The sand mass flow rate was set at the specified value for different test cases. The test model temperature data were recorded by the IR camera;

(7) At the end of the deposition test, the fuel pump and cooling air system were turned off in sequence. The test model was removed when it cooled down to room temperature;

(8) The test model was reweighed by the analytical balance, recorded as the post-test mass and the deposition mass was calculated by subtracting the pre-test mass from the post-test mass. The 3D scanning was utilized again to acquire the geometric shape of the test model. The deposition thickness was obtained by comparing the 3D geometric profile data of the test model, and then the test model with particle deposition on.

4. Conclusions

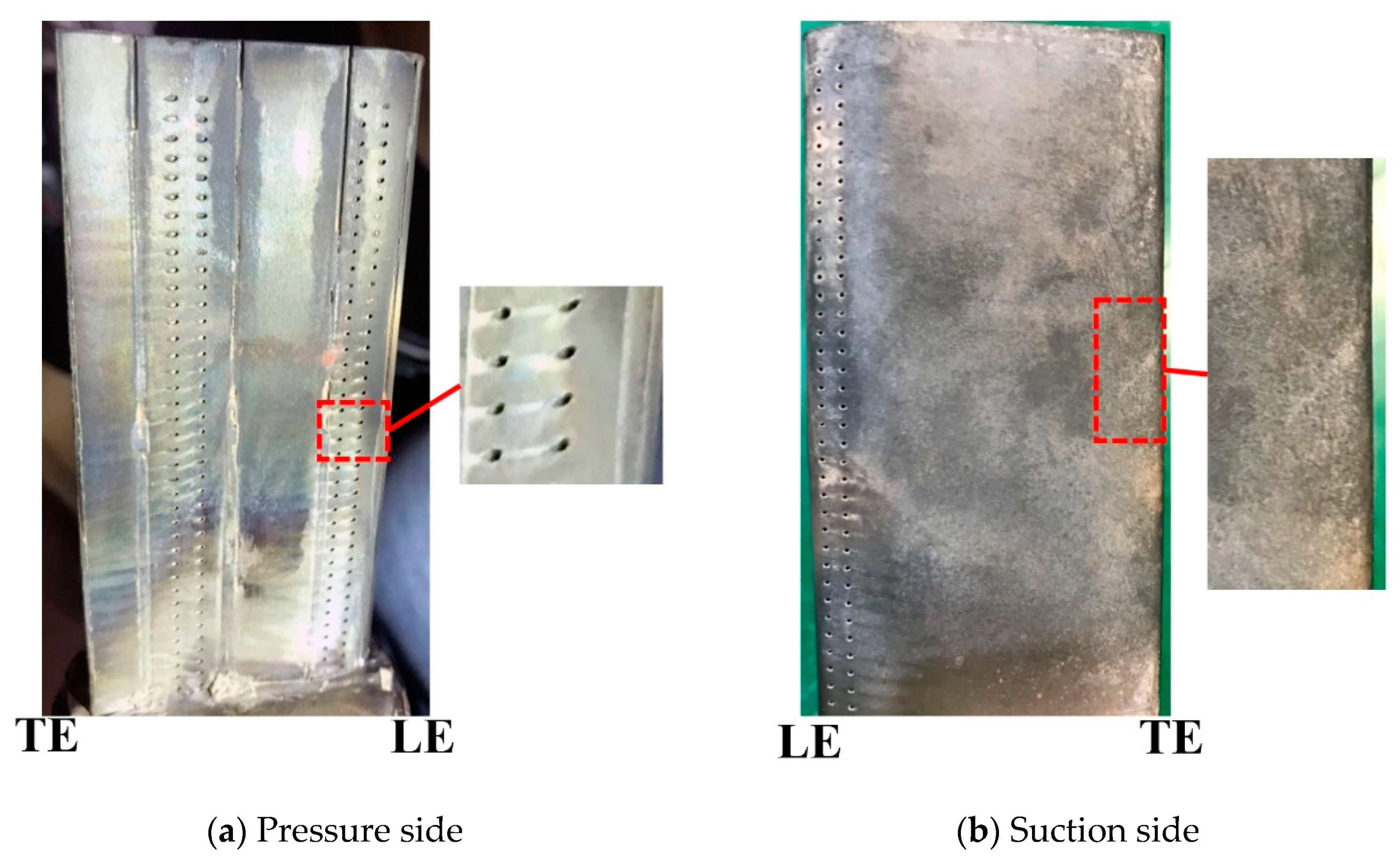

A deposition test facility equipped with an internally staged single-tube combustor with a single module was used to study the effect of the gas temperature and angle of attack on the deposition distribution, mass and thickness. All deposition tests were performed on a turbine blade with six rows of film-cooling holes at turbine representative temperatures (1272 to 1668 K) provided by the combustor with a maximum fuel–air ratio of 0.037. Test sand was prepared based on the MIL-STD-3033 standard sand and injected into the mainstream flow to simulate the effects on the turbine blade exposed to environments containing sand particles.

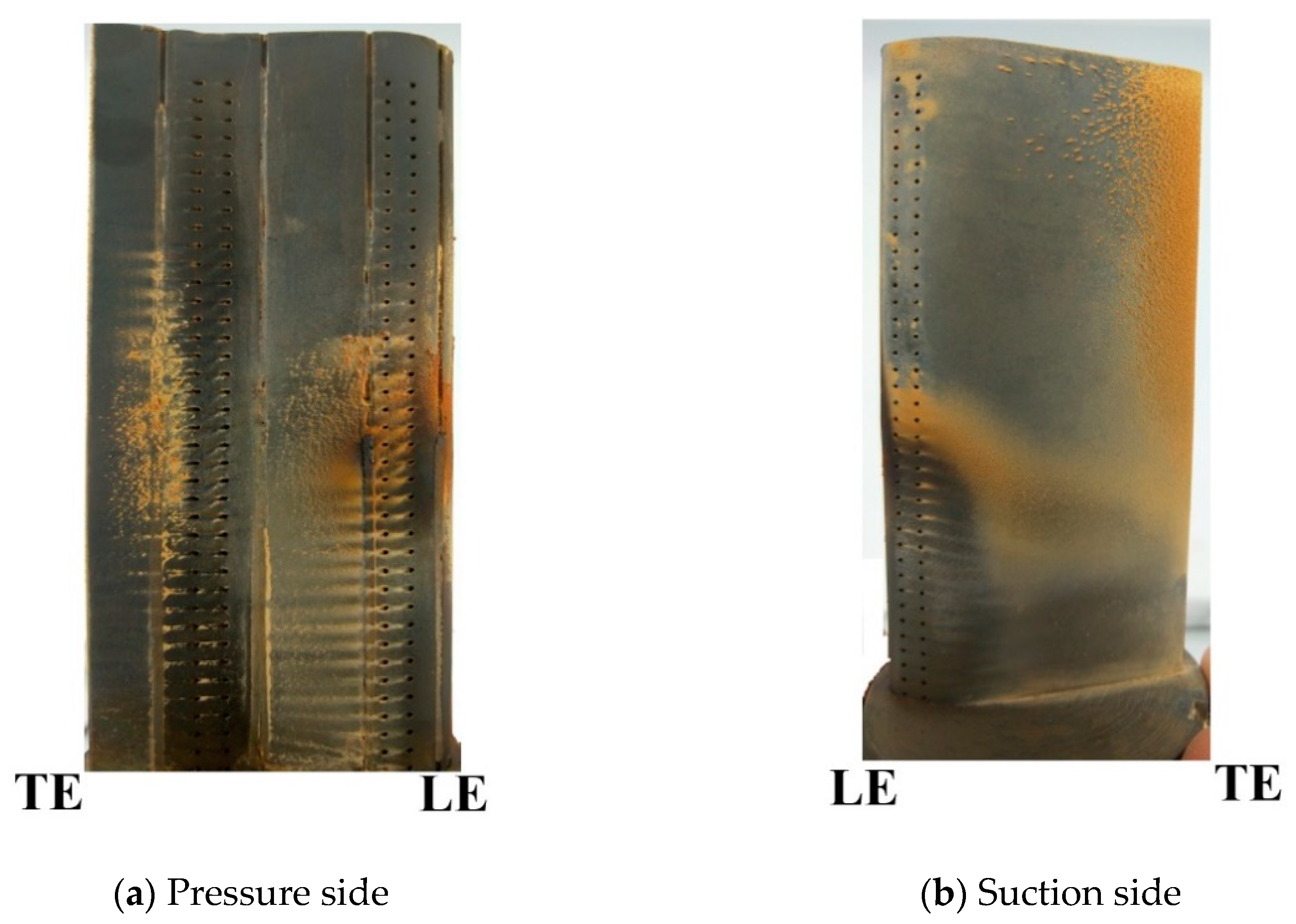

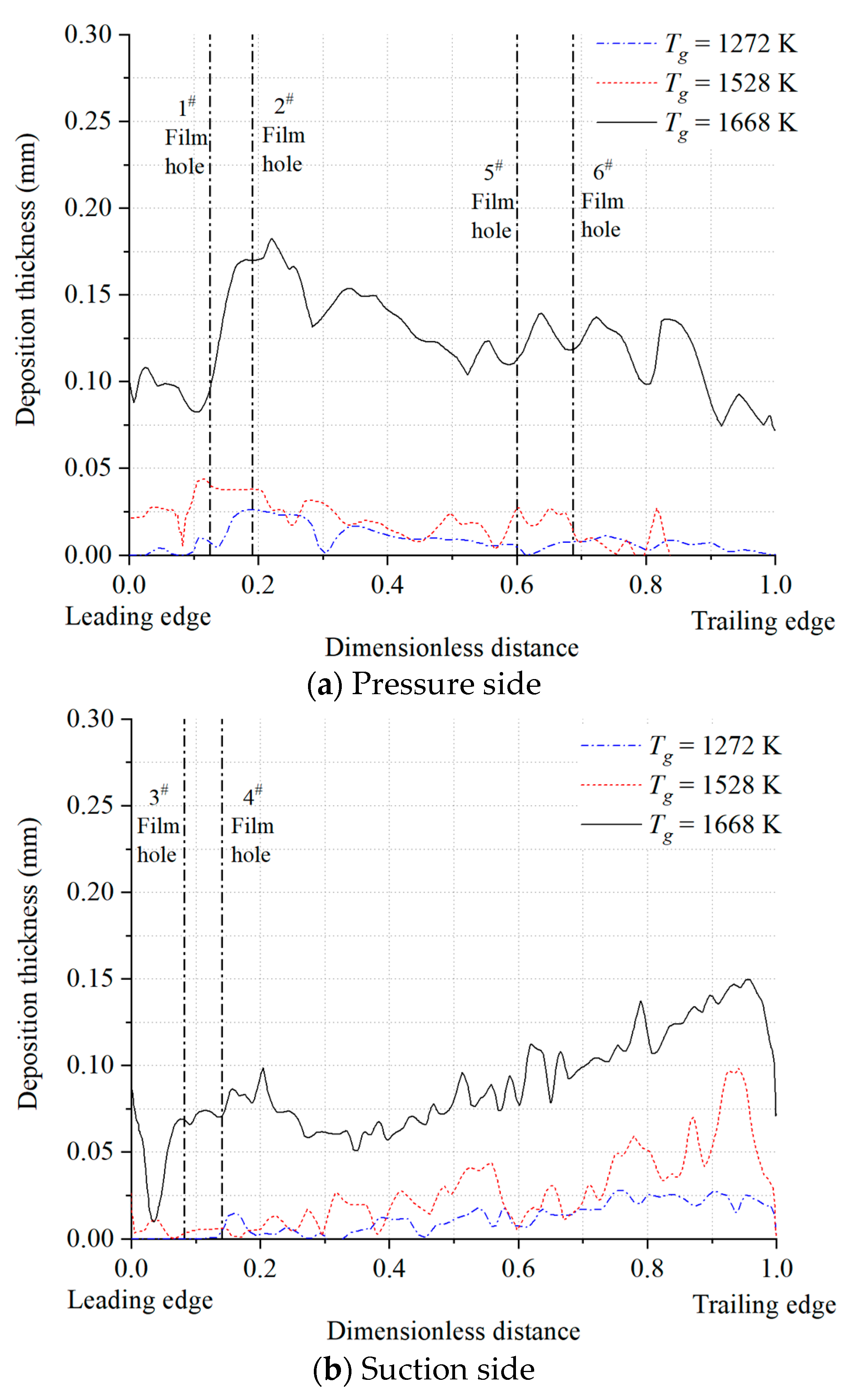

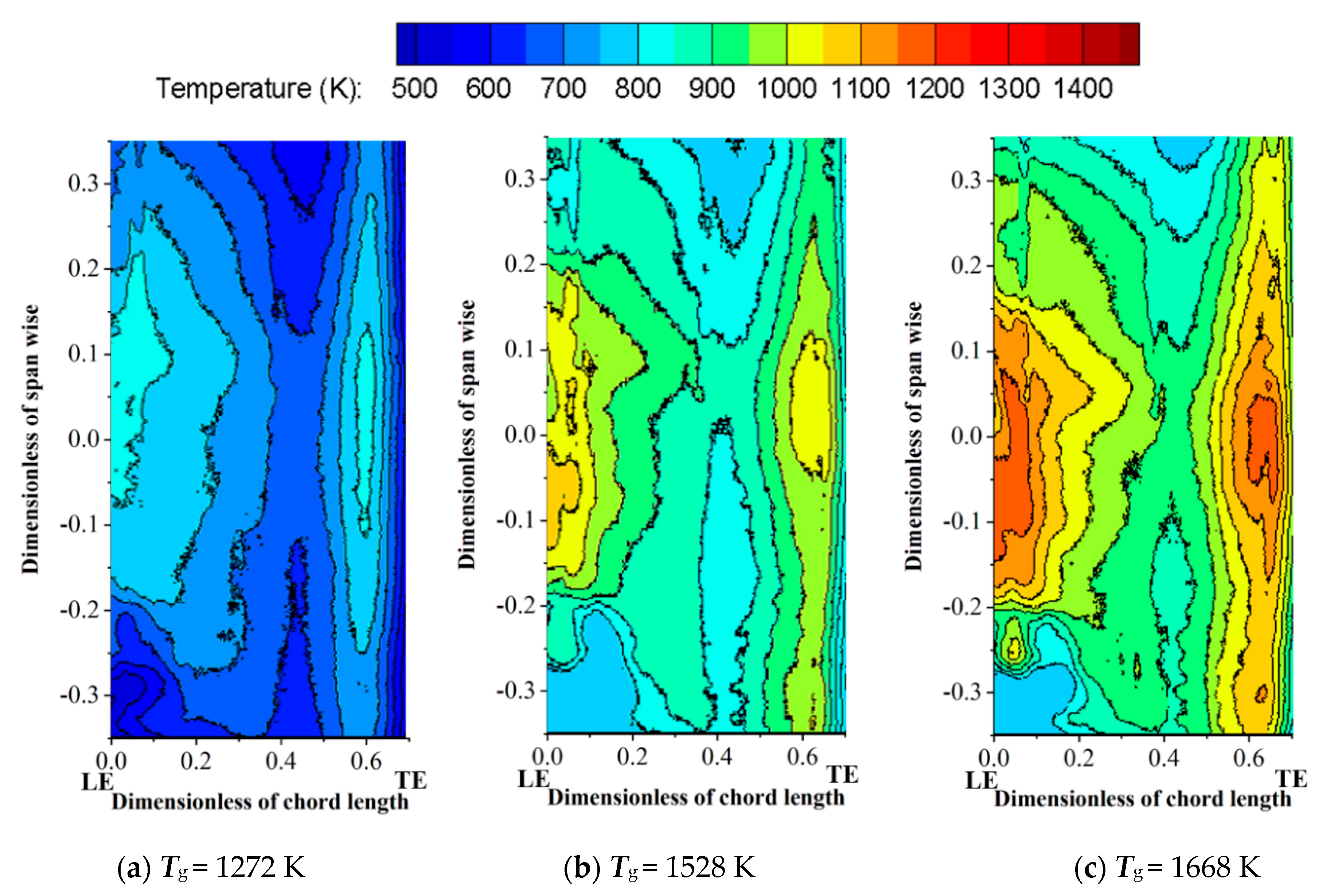

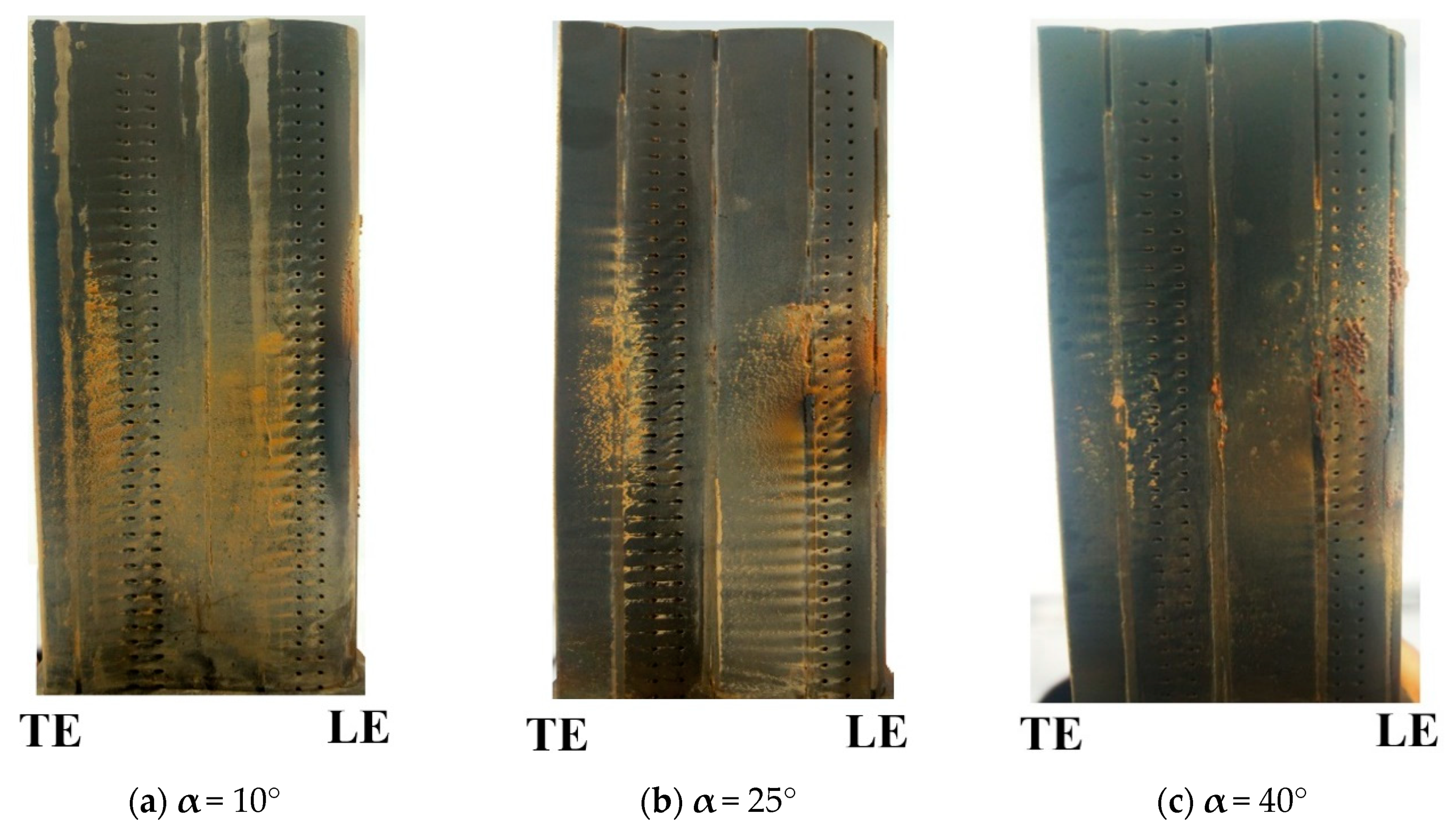

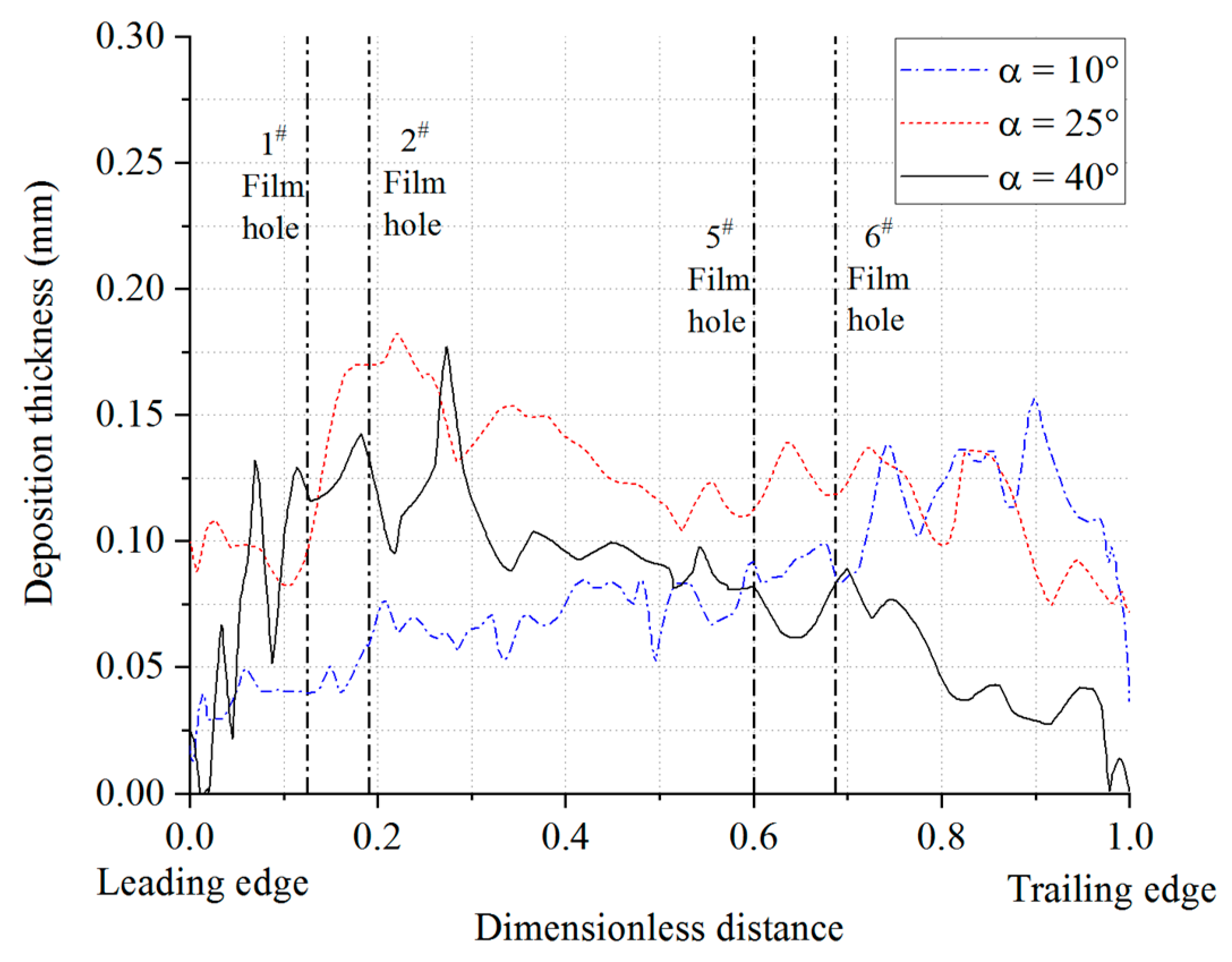

Gas temperature was assumed to have a marked effect on deposition as the gas temperature varied from 1272 to 1668 K with the adjustment of the fuel–air ratio. There exists a threshold temperature as a function of the particle chemical composition. Deposition accumulated on the blade surface faster when gas temperature was increased above it. Evident deposition at a gas temperature of 1668 K suggested that sand deposition mainly formed on the aft portion of the suction surface and downstream of the film-cooling holes on the pressure surface.

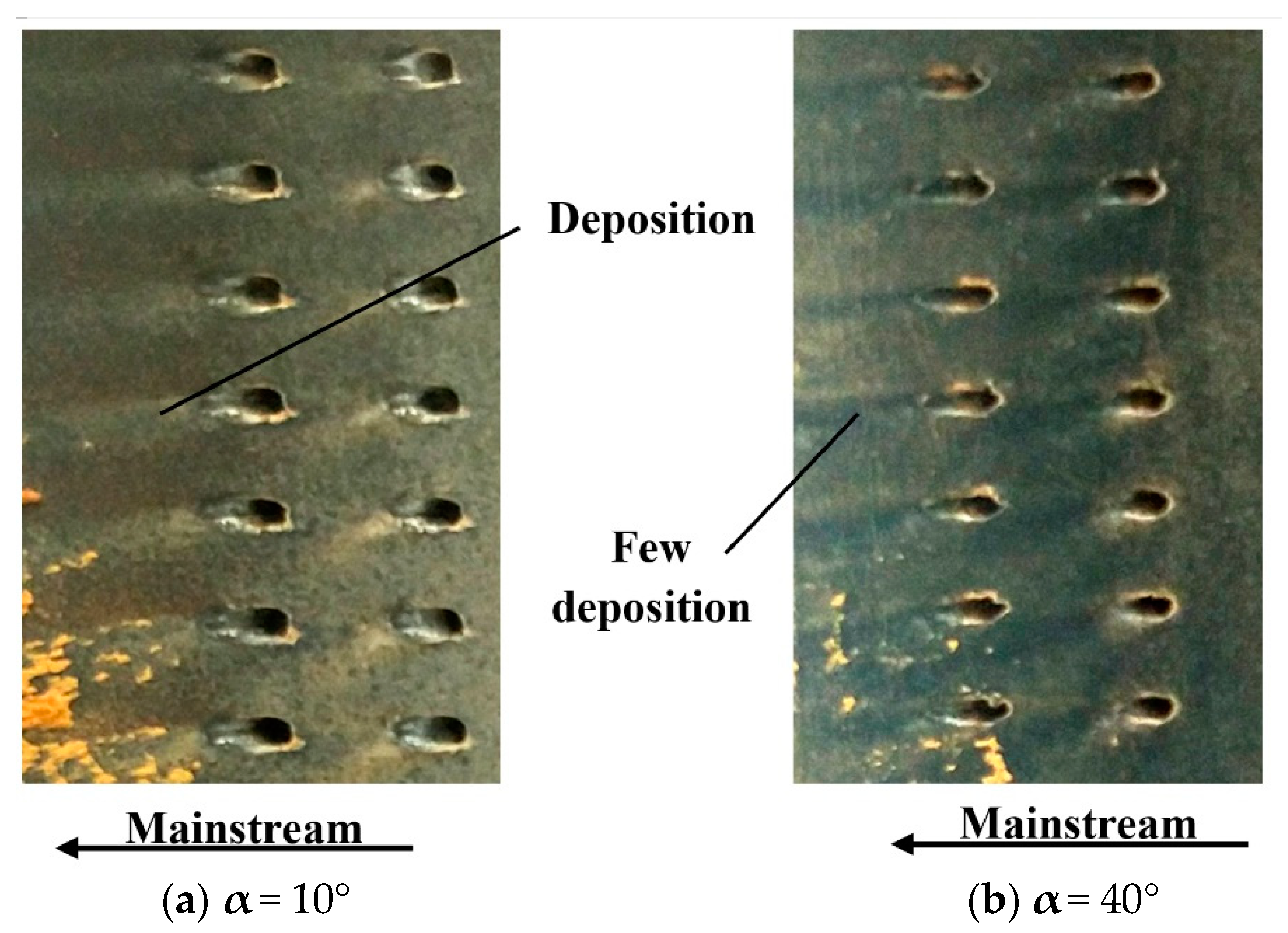

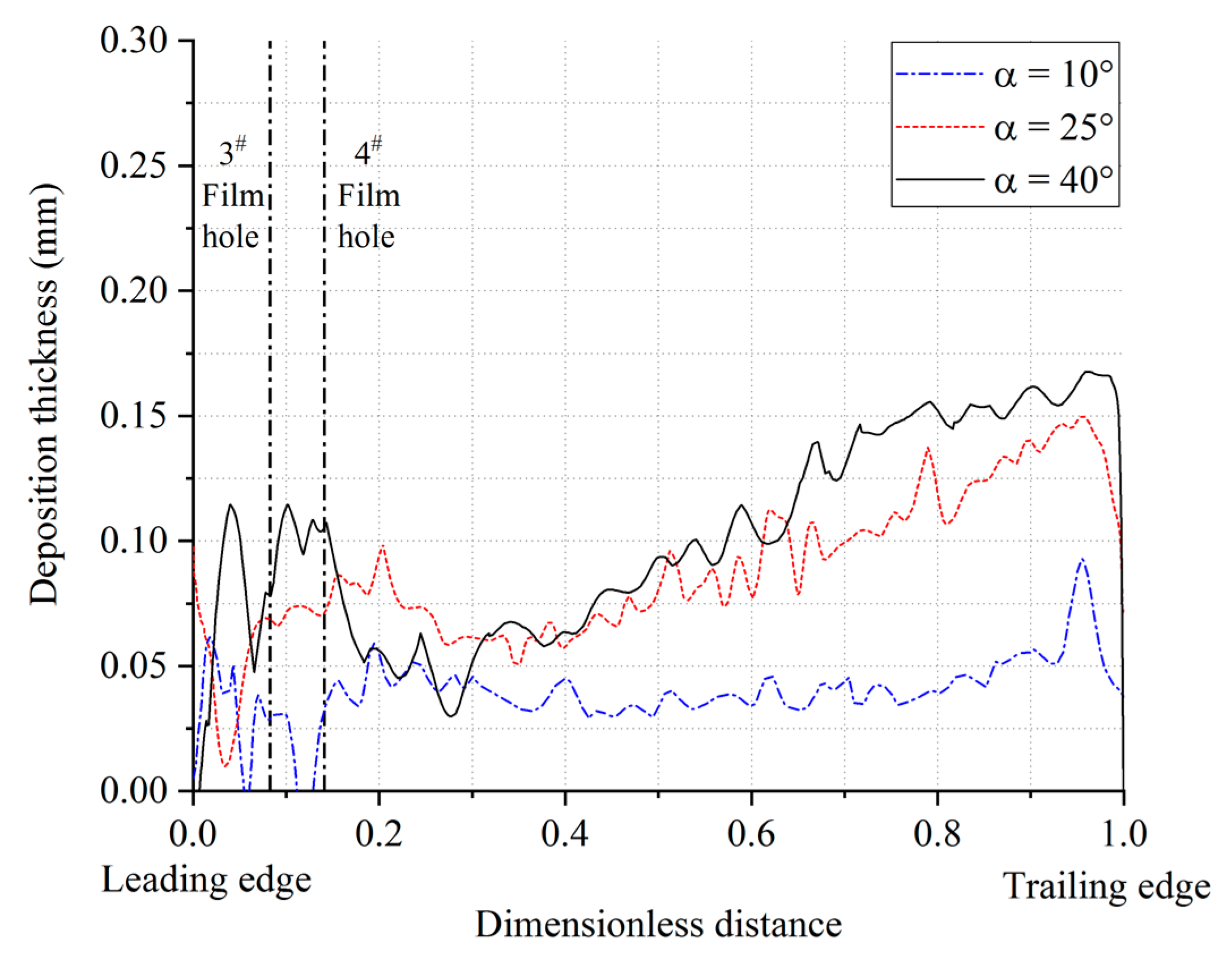

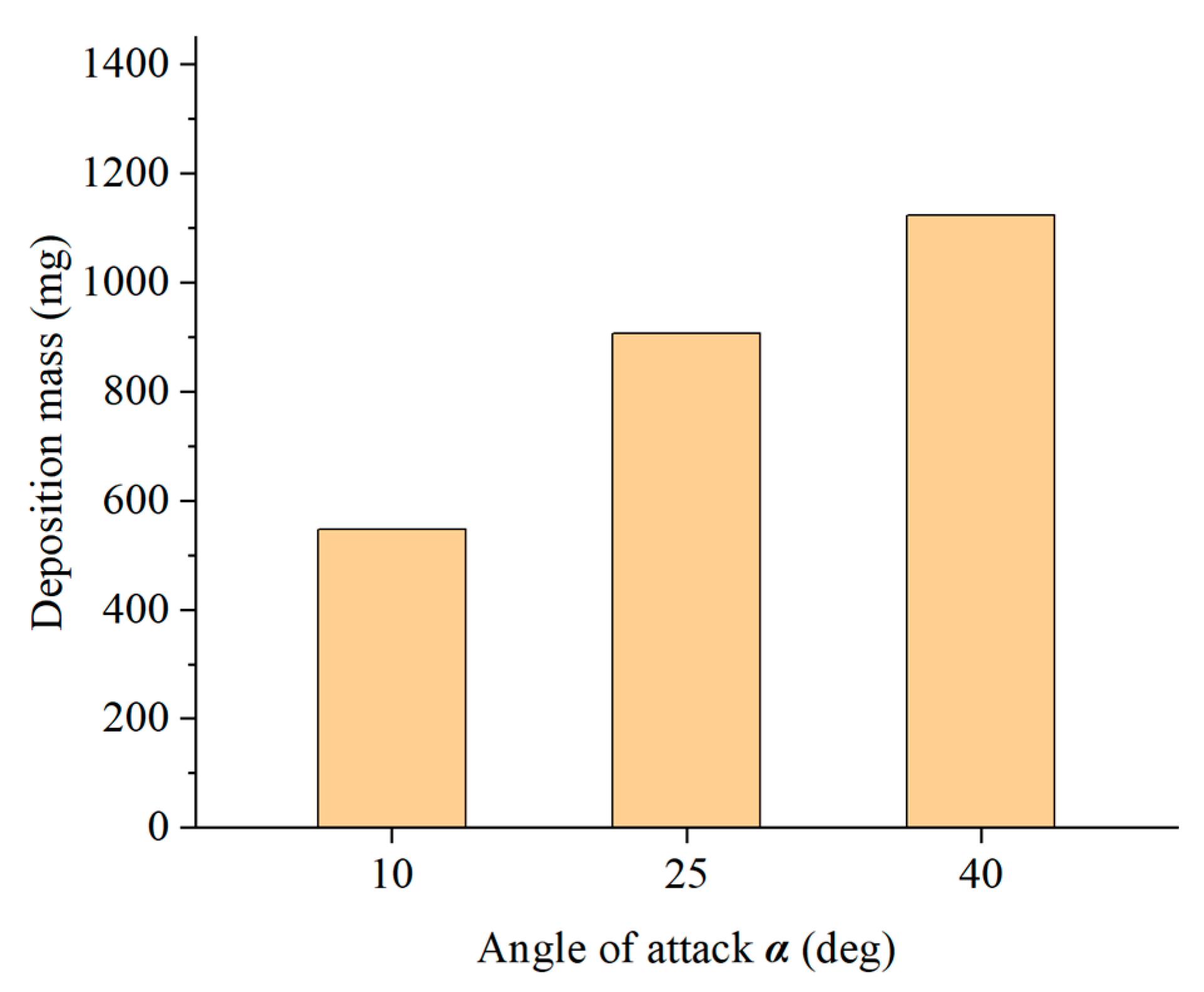

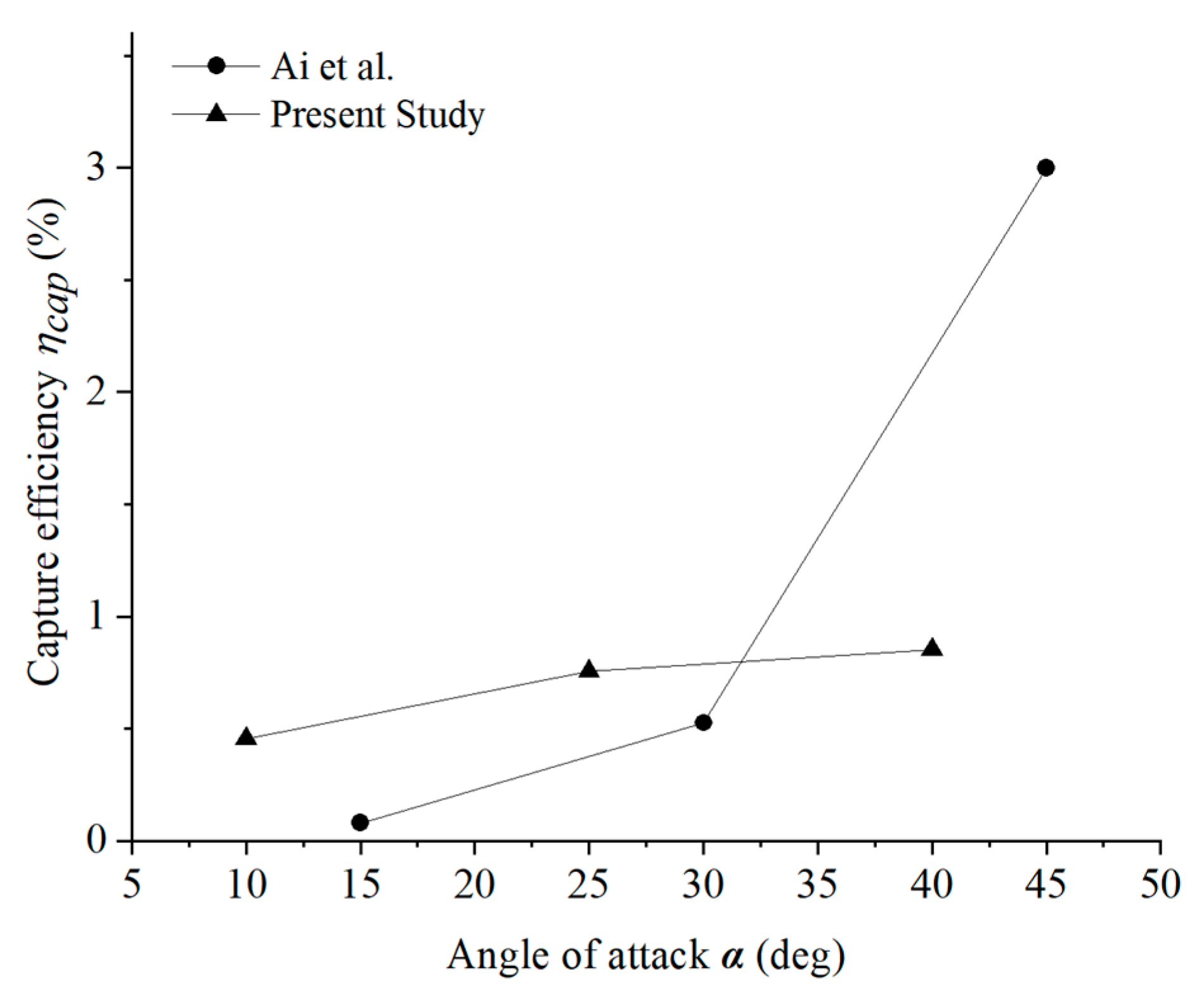

The second test series was run by varying the angle of attack from 10° to 40° at a gas temperature of 1668 K. The deposition mass increased with the angle of attack. The increase in capture efficiency slowed down as the angle of attack rose from 25° to 40° when compared with that the capture efficiency of the angle of attack that rose from 10° to 25°. The deposition distribution downstream of the film-cooling holes depends on angle of attack for the blade pressure surface. In the small angle of attack case, jet vortices formed under the interaction between the film-cooling jet and mainstream, further resulting in the particle deposition downstream of the cooling holes. For the large angle of attack case, the film-cooling jet flow would be fully suppressed by the mainstream flow. The cooling air flows close to the blade surface, accounting for less deposition downstream.