5.1. Decomposition of Changes in CO2 Emission Intensity

To analyse the source of annual changes of CO

2 emission intensity from the reference year, the changes in the CO

2 emission intensity were decomposed into two parts, namely, the structural change effect and the intensity change effect. The structural change effect refers to the change of production composition among subsectors with different levels of CO

2 emission intensity. The intensity change effect denotes the change of CO

2 emission intensity of individual subsectors. If the change is negative, it means individual subsectors are able to decrease their CO

2 emission intensity. In our study we follow Ang [

14,

15] and use the logarithmic mean Divisia decomposition index in both additive and multiplicative forms to analyse the source of annual changes in CO

2 emission intensity in Thailand’s manufacturing industry during 2000–2018. The method was also used in Chontanawat et al. [

52].

The aggregated industrial CO

2 emission intensity can be defined as follows:

where

CI = CO2 emission intensity (kton/billion Baht)

C = CO2 emissions from manufacturing industry (kton)

Y = Value added of manufacturing output at constant 2002 prices (billion Baht).

The change in the CO

2 emission intensity mentioned above is decomposed into two main parts, namely, the structural changes effect and the intensity change effect. The expression of each effect, including the definitions of terms in each expression, is presented in the equations below.

where

Dtot is the total change in CO2 emission intensity in year t relative to the baseline

Dstr is the change in total CO2 emission intensity due to the structural change effect

Dint is the change in total CO2 emission intensity due to the intensity change effect

Si is the ratio of production of the i-th subsector to aggregate manufacturing production.

In our study of the decomposition of the changes of CO

2 emission intensity of the Thai manufacturing industries we use the CO

2 emissions data from DEDE [

47] and the production data from NESDB [

48]. The CO

2 emissions data are yearly and available only for 2000 to 2018, precisely the period we focus on in our decomposition study. The computed results are illustrated in

Figure 2 and the findings are discussed below.

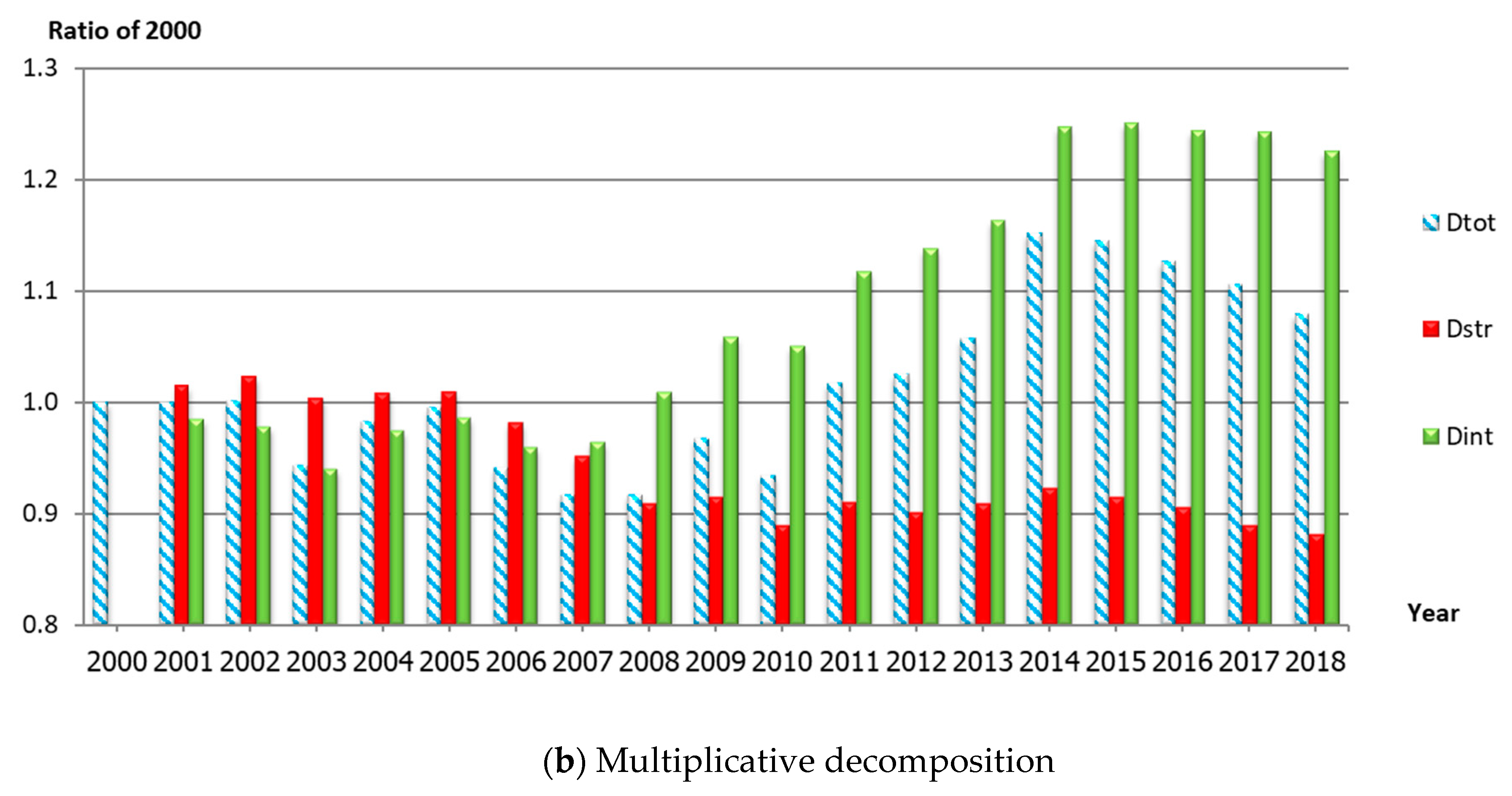

Figure 2 shows that the CO

2 emission intensity of Thailand’s manufacturing sector has become a matter of concern in the past decade. Although during 2000–2010 it decreased yearly relative to the base year of 2000, it increased every year from 2011 to 2018. The emission intensity decreased insignificantly, on average by about 1.6% each year from 2000 to 2005, but the reduction became larger (about 6.4%) during 2006 to 2010. From 2011 to 2018, the CO

2 emission intensity increased yearly as follows: 2011 (1.7%), 2012 (2.5%), 2013 (5.7%), 2014 (15.1%), 2015 (14.4%), 2016 (12.6%), 2017 (10.5%) and 2018 (7.8%). For the entire period between 2000 and 2018, the CO

2 emission intensity rose on average 1.7% per year. The sources of the emissions changes can be identified as follows.

During 2001 to 2005, the decline of the CO2 emission intensity, albeit small, was augmented by the subsectoral CO2 emission intensity effect. During 2006 to 2008, the greater reduction in the CO2 emission intensity was due to the combined contribution of the structural change and the subsectoral CO2 emission intensity effects. We noted that, from 2006 to 2018, while the structural change effect contributed to the decline in CO2 emission intensity for the entire period, the subsectoral intensity effect was changing—from decreasing in the first few years of the period to increasing the CO2 emission intensity for the rest of the period. As a result, during 2008 to 2010 the structural change effect helped reduce the CO2 emission intensity of the sector, whereas the intensity effect (measuring the change in CO2 emission intensity of individual industries) had the opposite result. However, since the structural change effect was stronger than the intensity effect, the CO2 emission intensity of the sector decreased. After 2010, the positive contribution of the structural change effect was not strong enough to offset the negative intensity effect. Thus, the CO2 emission intensity of the sector increased each year from 2011 to 2018. This implies that, if only individual industries were able to reduce their CO2 emission intensity, it would be possible for the intensity effect to strengthen the beneficial structural change effect so that both could provide a combined effect of reducing the CO2 emission intensity of the overall manufacturing sector. The structural change effect that led to the decline in the CO2 emission intensity in all years from 2006 to 2018 came from the declined shares in total manufacturing production of high CO2 emission intensity industries, namely nonmetal mineral products, basic metal products and paper and paper products industries. On the contrary, the industries with low CO2 emission intensity, which were machinery and equipment, and chemical and chemical products, showed increased shares in total production. In other words, from 2006 to 2018, Thailand’s industries with low CO2 emission intensity expanded but the ones with high CO2 emission intensity either grew slowly or had negative growth.

In contrast to the positive role of the structural change effect in reducing the CO2 emission intensity, the intensity effect in almost all years after 2007 increased the CO2 emission intensity of the overall industries. This is because some industries, particularly ones with high CO2 emission intensity, were not able to reduce their CO2 emission intensity over time. It is true that there were some industries with declining CO2 emission intensity; most of them were the ones with low CO2 emission intensity, namely machinery and equipment. However, there were other industries with high CO2 emission intensity, namely nonmetal mineral products and basic metal products, the CO2 emission intensity of which was growing almost every year. Since the decline of the CO2 emission intensity of the industries with low CO2 emission intensity was not strong enough to offset the high growth of CO2 emission intensity of the industries with high CO2 emission intensity, the intensity effect in most years was hindering instead of helping the structural change effect to reduce the overall CO2 emission intensity of industry.

In summary, from 2001 to 2005 the CO2 emission intensity of Thailand’s manufacturing sector changed little; from 2006 to 2010, it decreased steadily relative to the base year of 2000. However, in each year from 2011 to 2018, it increased at an average rate of 8.8%. In all years from 2001 to 2007 the subsectoral CO2 emission intensity effect was the single factor that helped reduce the CO2 emission intensity of the whole manufacturing sector. However, from 2006 to 2018 the structural change effect either combined with the subsectoral CO2 emission intensity of the sector or was the single factor that contributed to the sector’s CO2 emissions reduction. In 2006 to 2007, both the structural change and intensity effects reduced the CO2 emission intensity. From 2010 to 2018, the intensity effect began to contribute negatively to the CO2 emission intensity reduction of the sector. Moreover, its negative contribution was so strong that it outweighed the positive contribution of the structural change effect; as a result, the CO2 emission intensity of the total manufacturing sector rose from the base level. In aiming to decrease the CO2 emission intensity of the sector, attempts should be made by individual industries, especially ones with high CO2 emission intensity, to reduce their CO2 emission intensity (intensity change effect). In the next section we will use the decomposition method to separate the sources of the change in the CO2 emissions level in order to detect factors accounting for the increased CO2 emission intensity of individual manufacturers. The computed results will enable us to find out more about how to turn the intensity effect from a negative to a positive contribution and strengthen the positive contribution of the structural change effect so as to reduce both the CO2 emission level and intensity.

5.2. Decomposition of Changes in the Amount of CO2 Emitted by the Manufacturing Industry

To further analyse the source of the change of CO

2 emission intensity of the manufacturing sector, we studied the source of the change of the amount of CO

2 emissions in the sector by using another version of the decomposition approach. The computed results will be useful for further identifying the origin of the difficulty of reducing the CO

2 emission intensity of individual industries. The decomposition method will follow Ang [

15]. The method has also been used by Chontanawat et al. [

52].

C = Amount of CO2 emissions in manufacturing industry (kton)

E = Energy consumption (kton)

Y = Manufacturing output at constant 2002 prices (billion Baht)

Q = Total industrial production level (billion Baht)

Si = Ratio of production of the i-th subsector to total production

I = Energy intensity (kton/billion Baht)

Mij = Fuel mix

Uij = CO2 emission factor (kton/kton)

The change in the amount of CO

2 emissions can be decomposed into changes of five elements, namely, total production in the manufacturing sector (activity effect), composition of subsectoral production (structural change effect), subsectoral energy intensity (energy intensity effect), subsectoral energy composition (fuel-mix effect), and CO

2 emission factor (emission factor effect). The expression of each effect in the CO

2 emissions decomposition analysis is presented in the equations below.

where

Dtot = Total change of CO2 emissions in year t relative to the base year

Dact = Change in total CO2 emissions due to activity effect

Dstr = Change in total CO2 emissions due to structural change effect

Dint = Change in total CO2 emissions due to energy intensity change effect

Dmix = Change in total CO2 emissions due to fuel mix effect

Demf = Change in total CO2 emissions due to emission factor effect.

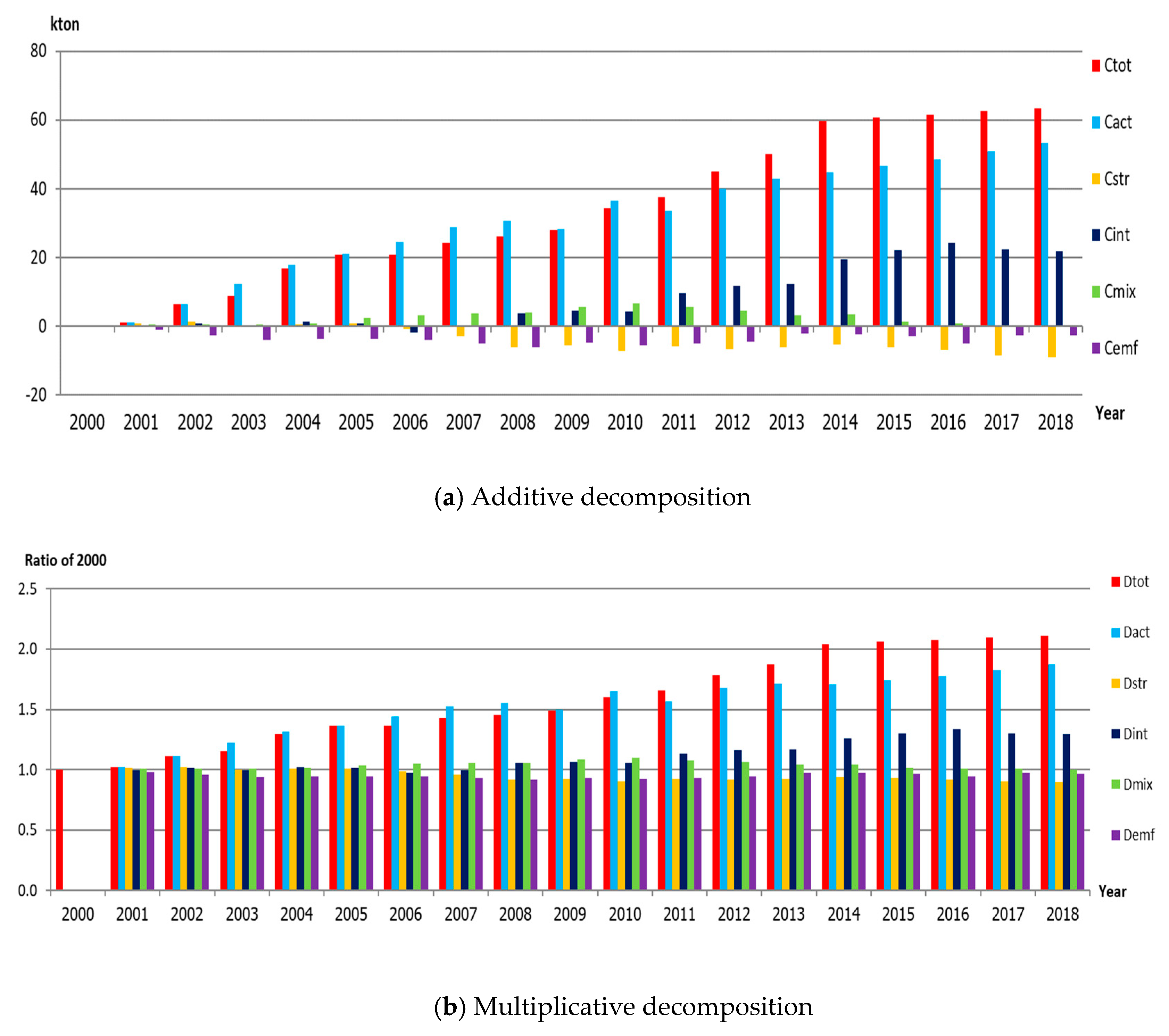

We see from

Figure 2 that from 2000 to 2018 there were periods of increase and decrease of the CO

2 emission intensity of Thailand’s manufacturing sector. However, in terms of the CO

2 emissions level,

Figure 3 shows that the amount of emissions increased every year compared to the base year of 2000 (the database used to analyse the source of the changes of CO

2 emissions level in the manufacturing industrial sector comes from the same source as the one used for studying the change in CO

2 emission intensity). The increase was small before 2010 but grew during 2011 to 2014 before stabilizing at a high level in 2018. The increase in the amount of CO

2 emissions arose from five sources, namely, activity (production effect), structural effect, energy intensity effect, subsectoral fuel mix effect, and emission factor effect. Among the above sources, the annual increase in CO

2 emissions mostly came from the growth of manufacturing production, followed by the energy intensity effect and the fuel mix effect. In comparison, the structural change effect helped reduce the CO

2 emissions in the manufacturing sector most years, whereas the emission factor effects had little influence on the change in the CO

2 emissions of the manufacturing industries in Thailand.

It is quite common for the production growth to be the main source of a rise in CO

2 emissions in the manufacturing sector. This is because the production of manufactured goods requires energy as an input and CO

2 emissions result from the use of fossil fuels as the source of energy.

Figure 3 shows that the effect of the growth of manufacturing production on increasing the CO

2 emissions level in the industrial sector was very strong during the early period of 2000 to 2010 when the production growth was relatively high, but weakened during 2011 to 2018 when the production growth declined. For the early period of 2000 to 2007, the energy intensity effect slightly increased the amount of CO

2 emissions in almost all years. The negative effect of increasing the emissions intensified from 2008 to 2018 when energy prices decreased and the energy intensity of the manufacturing sector increased. The fuel mix effect, albeit small relative to the industrial production and energy intensity effects, increased the CO

2 emission level. Furthermore, the effect became pronounced during 2005–2014, when there was an increase in the use of coal in the production of industrial goods and electricity. The structural change effect had little effect on increasing the CO

2 emissions level before 2006, but helped reduce the CO

2 emissions in all years from 2006 to 2018. Finally, the emissions factor effect, however small, contributed to the CO

2 emissions reduction because there was not much change in the CO

2 emission coefficients.

In summary, although increased industrial production was the main factor increasing the amount of CO2 emissions released by the manufacturing sector, particularly during the strong growth period before 2006, the effect increased at a slower rate than the growth of the energy intensity and the fuel mix effects from 2006 to 2018. In contrast to the energy intensity effect, the structural change effect contributed to a reduction in the amount of CO2 emissions in all years after 2006. The emission factor effect was small but helped toward the CO2 emissions reduction. On the whole, since the findings show that the CO2 emissions rose as the manufacturing sector expanded, it would be beneficial if each industry could decrease its CO2 emissions per unit of production (CO2 emission intensity).

In the previous section we showed that, conceptually, the CO

2 emission intensity of the manufacturing sector can be reduced through either the structural change effect or the CO

2 emission intensity effect, or both. In the case of Thailand, while the structural change effect mostly contributed to the reduction of the CO

2 emission intensity, the intensity effect was not able to help it. Based on the decomposition analysis in the present section, we will be able to understand more clearly why the CO

2 emission intensity effect was not helpful at reducing the CO

2 emissions in Thailand. However, before analysing the negative contribution of the intensity effect, let us first find out what

Figure 3 tells us about the structural change effect based on the present method.

Figure 2 in the previous section has already shown that the structural change effect helped reduce the CO

2 emission intensity after 2005.

Figure 3 in this section confirms the positive role of the structural change effect by showing that it helps reduce the amount of CO

2 emissions as well. We have shown in the last section that from 2005 to 2018 the composition of the manufacturing production changed in such a way that the share of output of industries with low CO

2 emissions in total manufacturing output increased, while the share of output of industries with high CO

2 emissions declined. In other words, the structural change was helpful for decreasing CO

2 emissions simply because less energy-intensive industries with low CO

2 emission intensity such as machinery and equipment and food and beverages grew faster than highly energy-intensive industries with high CO

2 emission intensity such as nonmetal mineral products and basic metal products.

In

Figure 2 and

Section 5.1, we have also already showed that, in contrast to the positive contribution of the structural change effect to the CO

2 emissions reduction in the manufacturing sector, the CO

2 emission intensity effect led to the opposite result. Below we list the factors that hinder the intensity effect to reduce the CO

2 emissions by dividing the source of the CO

2 emission intensity effect into three separate components. They are (1) the energy intensity effect, (2) the subsectoral fuel mix effect and (3) the emission factor effect. From

Figure 3 we see that, from 2008 to 2018, the energy intensity effect was the major source of the increased CO

2 emissions of the manufacturing sector compared to the base year of 2000. Similar findings on the negative contribution of the energy intensity effect on the change of CO

2 emissions were also found in several other countries [

30,

39,

40,

41,

42,

46]. The subsectoral fuel mix effect resulting from the increased use of coal increased the CO

2 emissions level during 2005–2012, whereas the emission factor effect had little impact on the emissions in most years.

The negative impact of the energy intensity effect on the amount of CO

2 emissions was due to the yearly increases in the energy intensity of individual industries (the findings are from our computed results of decomposing the source of changes of energy intensity of the manufacturing sector (not shown). We found that the energy intensity of the sector increased steadily from 2008 to 2018, and the increase was due to the positive subsectoral energy intensity effect (negative contribution to energy intensity) outweighing the negative structural change effect (positive contribution). Our computed results are available upon request. While coal, which had a rather high emission factor, remained heavily used in CO

2 emission-intensive industries such as nonmetal mineral products and basic metal products, electricity is also increasingly used in almost all industries, resulting in a rise in the direct and indirect use of fossil fuels in all manufacturing industries. In Thailand, although the production of electricity has shifted from the use of imported crude oil to natural gas since the early 1980s, the CO

2 emission factor (CO

2 emissions per energy consumption) of electricity is still higher than that of fossil fuels. Thus, there is room for further reduction of the emission factor of electricity in order to increase its contribution to the CO

2 emissions mitigation effort by industry. There are many studies in Asian countries that show that a decrease in the emission factor of electricity, achieved by increasing the use of non-fossil fuels and renewable energy in electricity generation, can lower the CO

2 emissions in the manufacturing industry. For instance, Ang [

39] found that, from 1982 to 1992, South Korea and Taiwan used nuclear power and hydropower in their electricity generation and the CO

2 emissions of the manufacturing sector was reduced. Yan and Fang [

40] used a scenario analysis to project the CO

2 emissions and mitigation potential of the Chinese manufacturing sector and concluded that the CO

2 emissions of the sector can be reduced by optimizing the use of coal-fire power and increasing the use of hydro, wind and solar energy and other renewable resources in electricity generation. Finally, Jeong and Kim [

38] studied the GHG emissions in South Korea’s manufacturing industry during 1991–2009 and found that the use of natural gas in combination with nuclear power and renewable energy in electricity generation could reduce both its CO

2 emission factor and the amount of CO

2 emissions of the industries. Today nuclear power is used in a limited number of countries. There are many other alternative non-fossil fuels and renewable energy resources that countries can choose to use in their electricity generation.

On the whole,

Figure 3 shows that, from 2001 to 2018, the CO

2 emissions of the manufacturing sector in Thailand increased every year compared to the base year of 2000. The increase was almost entirely due to manufacturing production growth during 2000 to 2010. From 2008 to 2018, the structural change effect helped reduce the CO

2 emissions. However, the positive effects could not compensate for the adverse effects of the energy intensity effect, which came from the increased use of coal in some industries and electricity in almost all industries. As a result, the amount of CO

2 emissions increased when the manufacturing production increased. These findings are consistent with the conclusions of most CO

2 emissions studies in emerging markets and developing countries found in

Section 2. Thus, the case of Thailand confirms the studies in the literature in that the increased use of fossil fuels, particularly coal, in the production of manufactured goods and electricity hindered the effort to reduce CO

2 emissions. Without a reduction in the energy intensity of individual industries by changing the fuel mix from coal to natural gas or non-fossil fuels in manufacturing goods production and electricity generation, it will be difficult to balance the benefits of industrial growth with the social costs of environmental deterioration in the future.