Energy Performance Comparison between Two Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems

Abstract

1. Introduction

2. System Overview

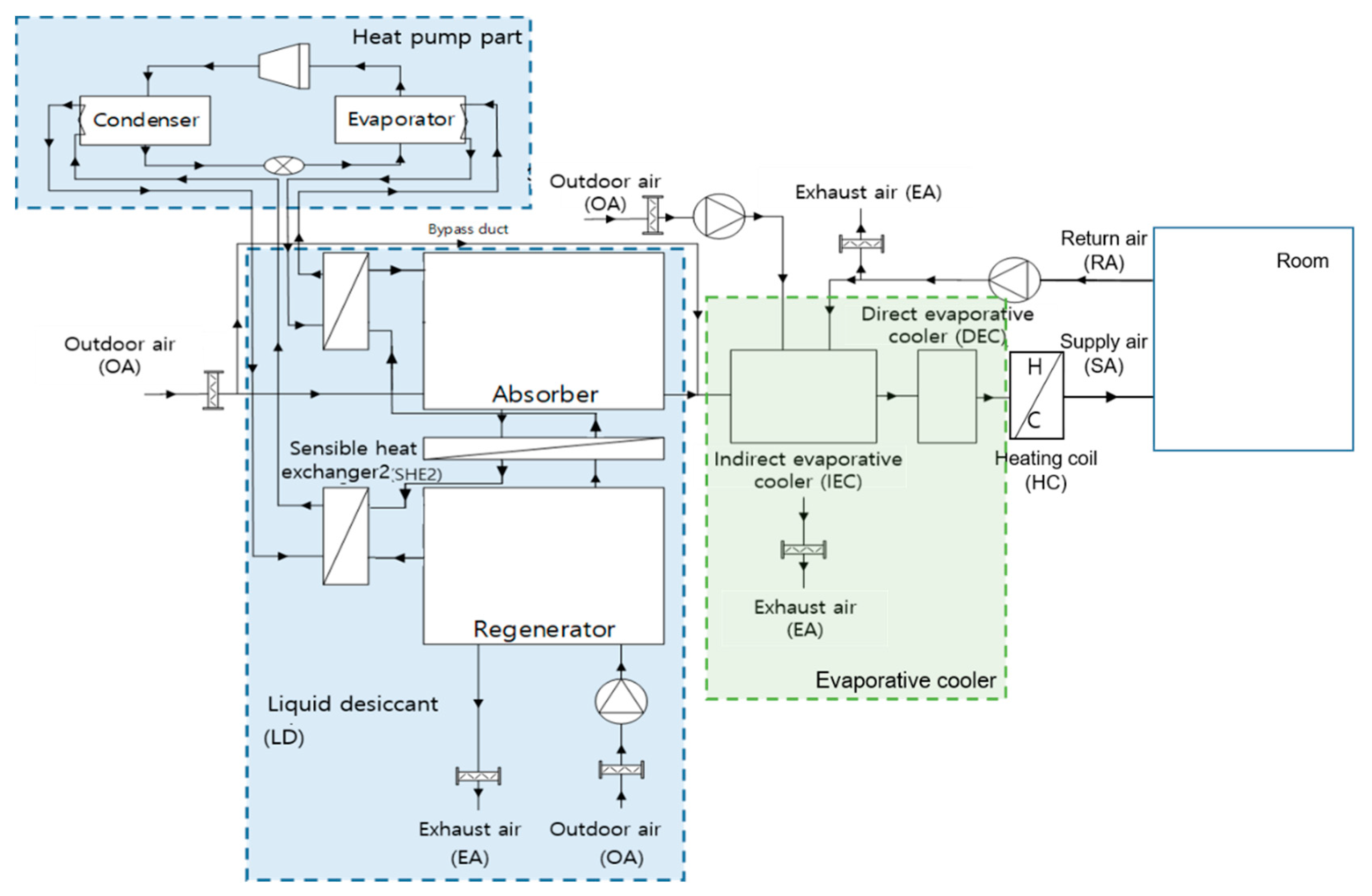

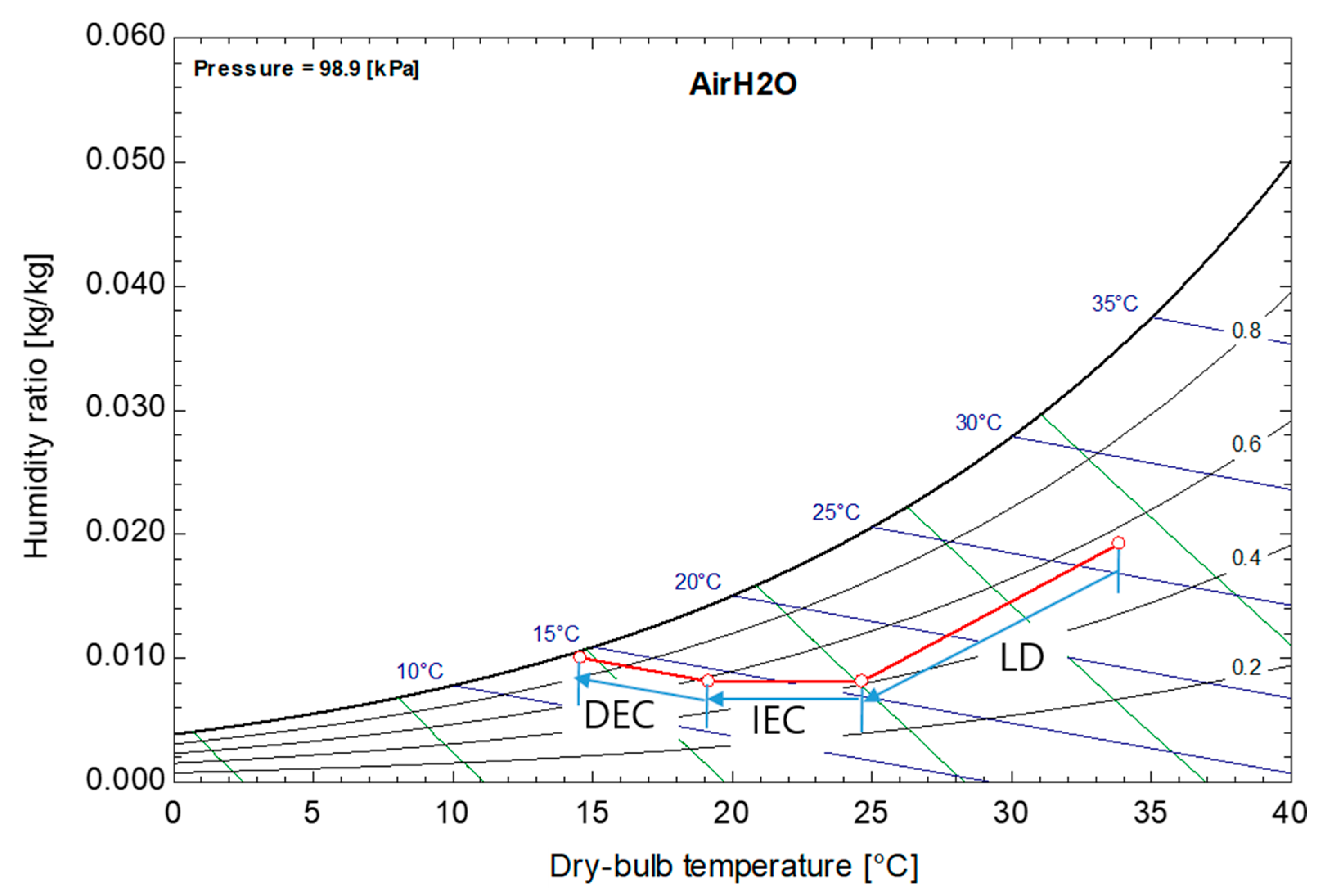

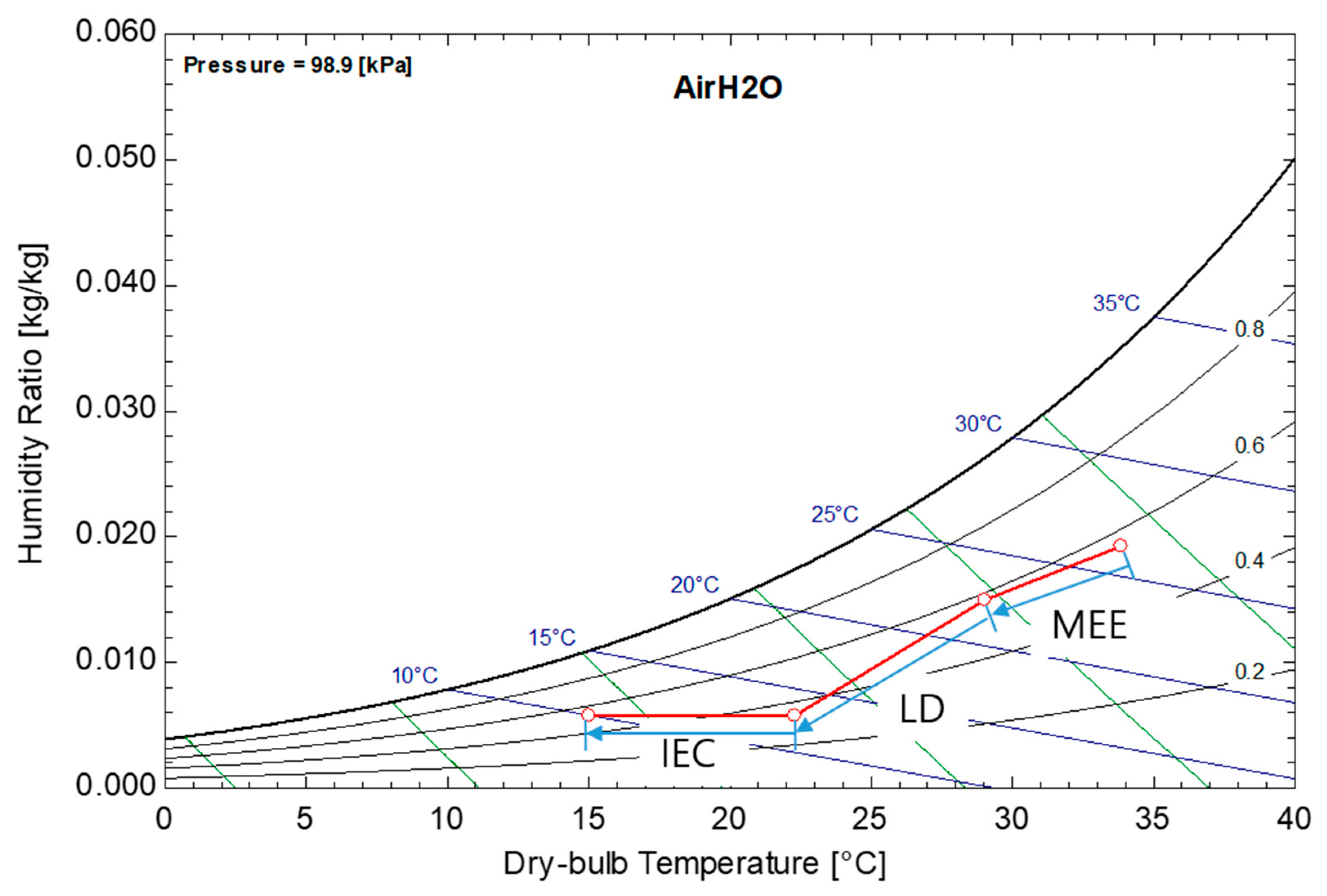

2.1. LDIDECOAS

2.1.1. System Configuration

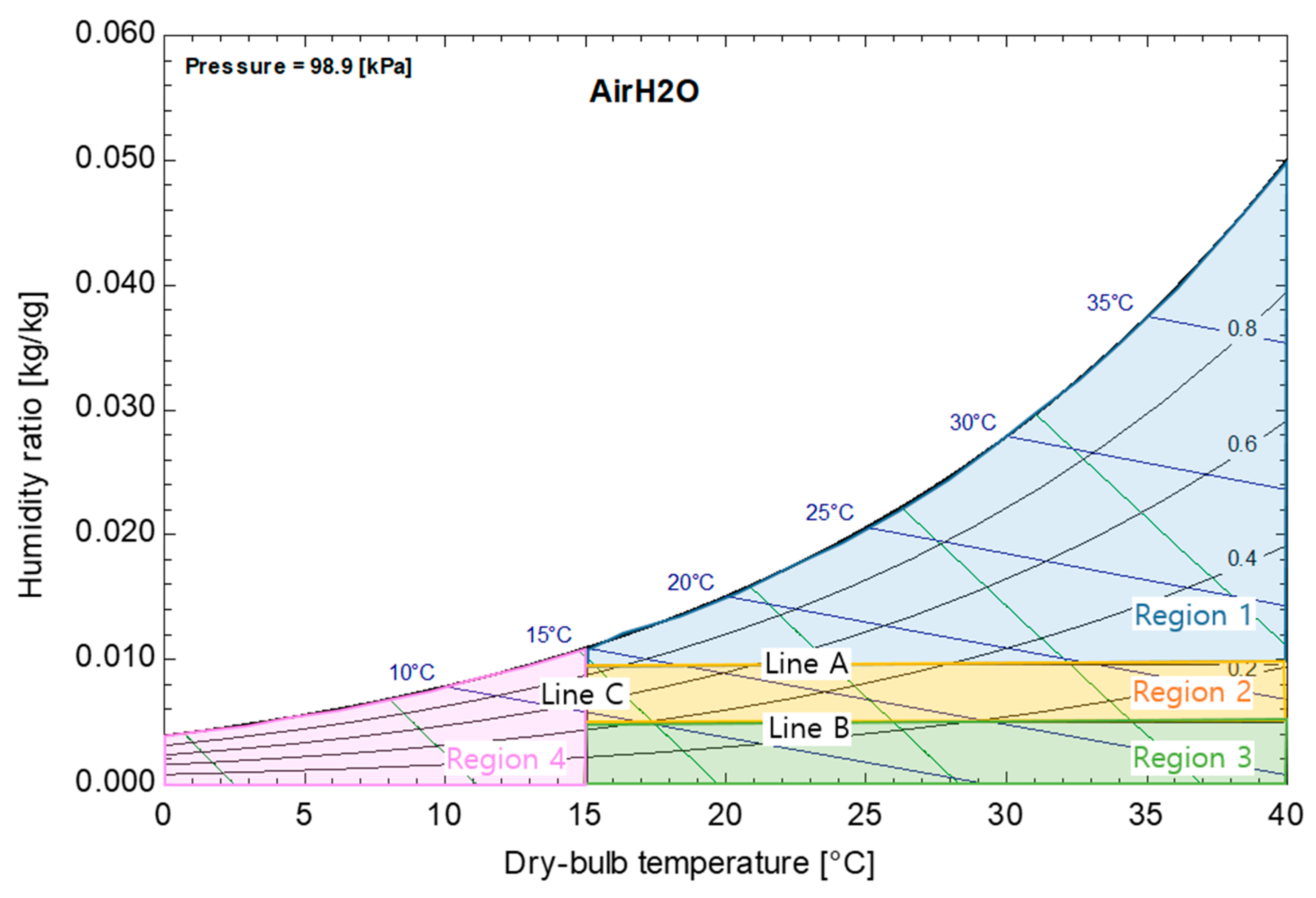

2.1.2. Annual Operational Strategies

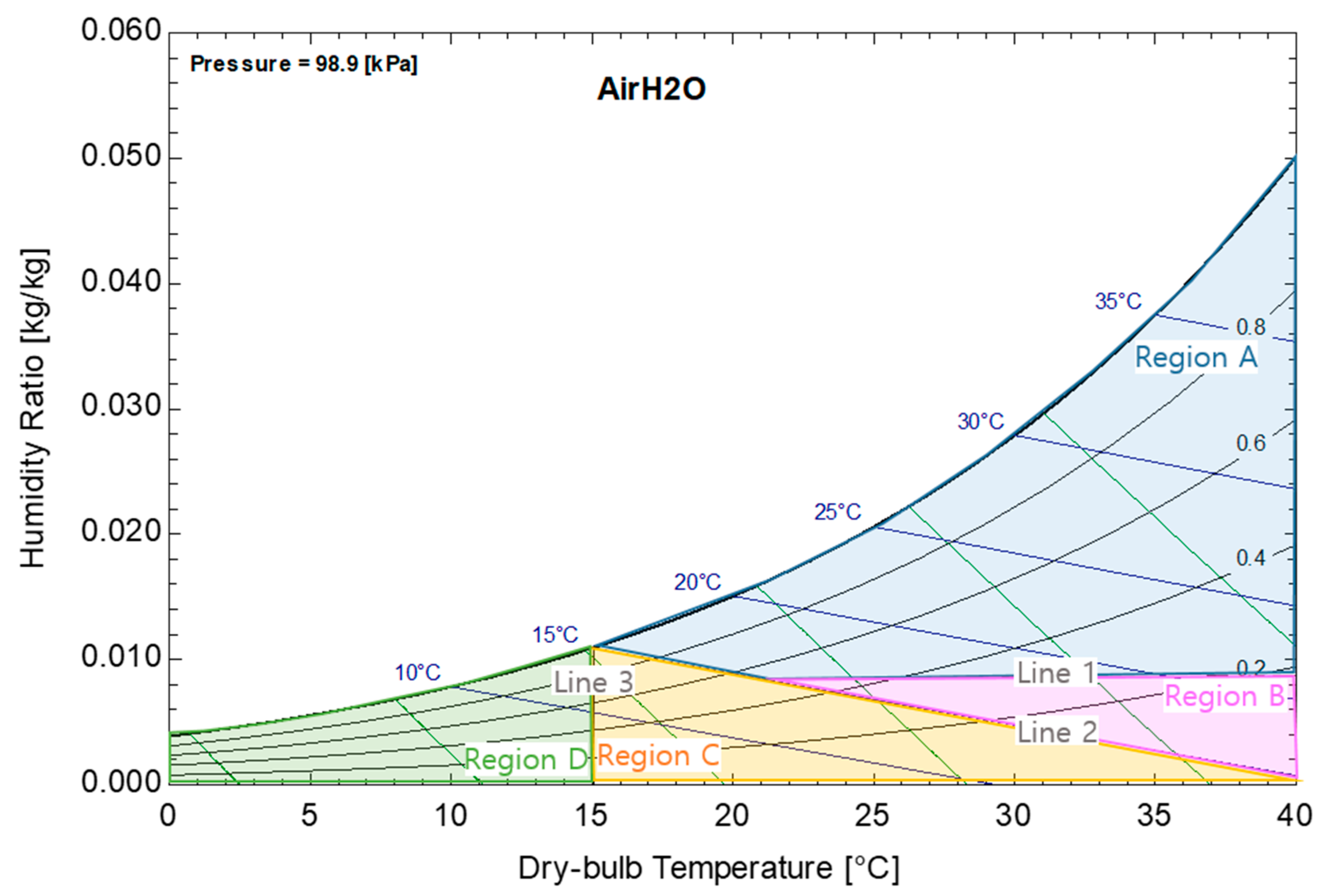

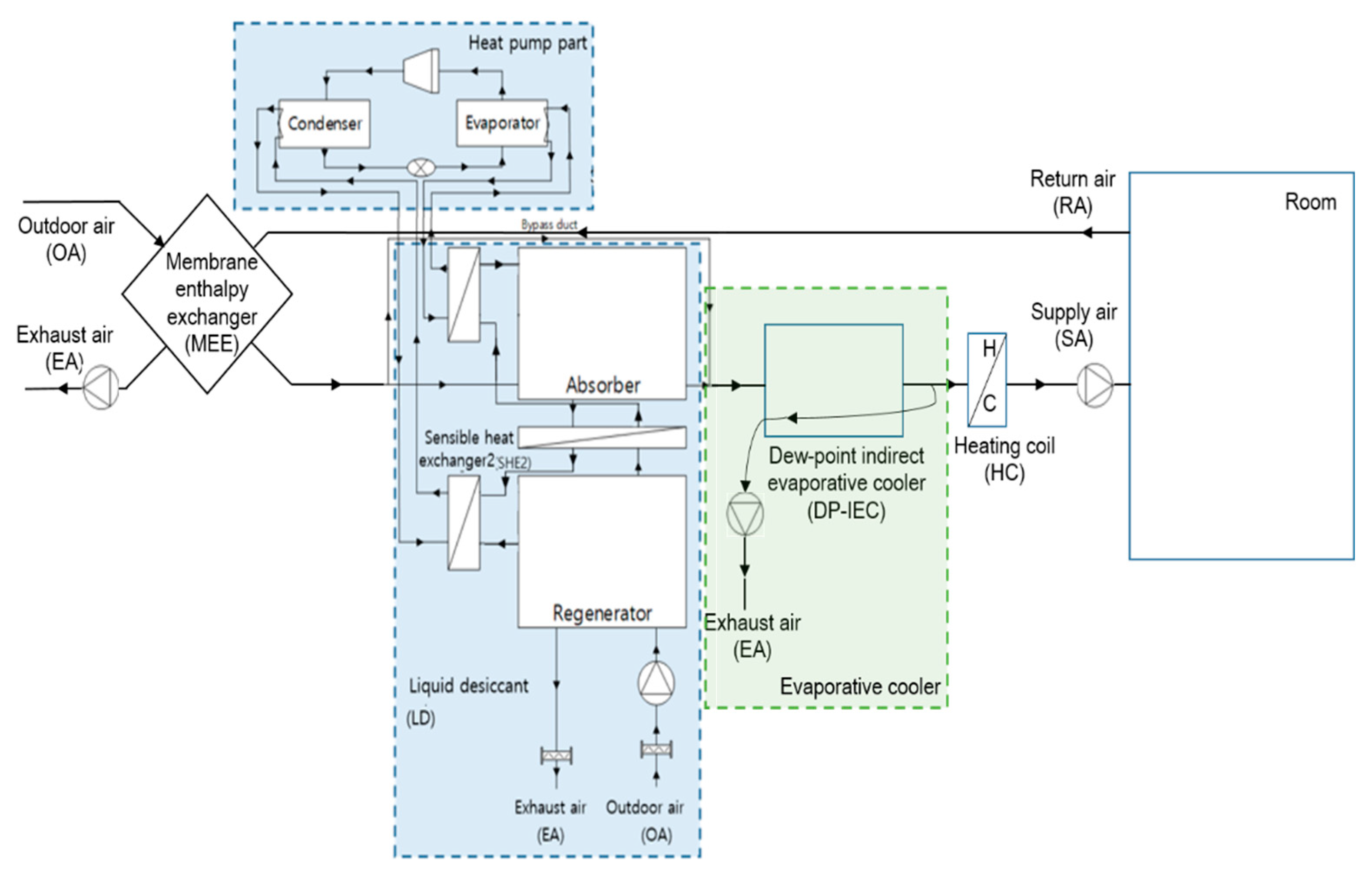

2.2. LDEOAS

2.2.1. System Configuration

2.2.2. Annual Operational Strategies

2.3. Heat Pump-Driven Liquid Desiccant Unit

3. Energy Simulation

3.1. Building Model

3.2. System Models

3.2.1. Liquid Desiccant System Model

3.2.2. Membrane Enthalpy Exchanger Model

3.2.3. Evaporative Cooler Models (DP-IEC Model and the IEC and DEC Unit Models)

3.2.4. Heat Pump Model

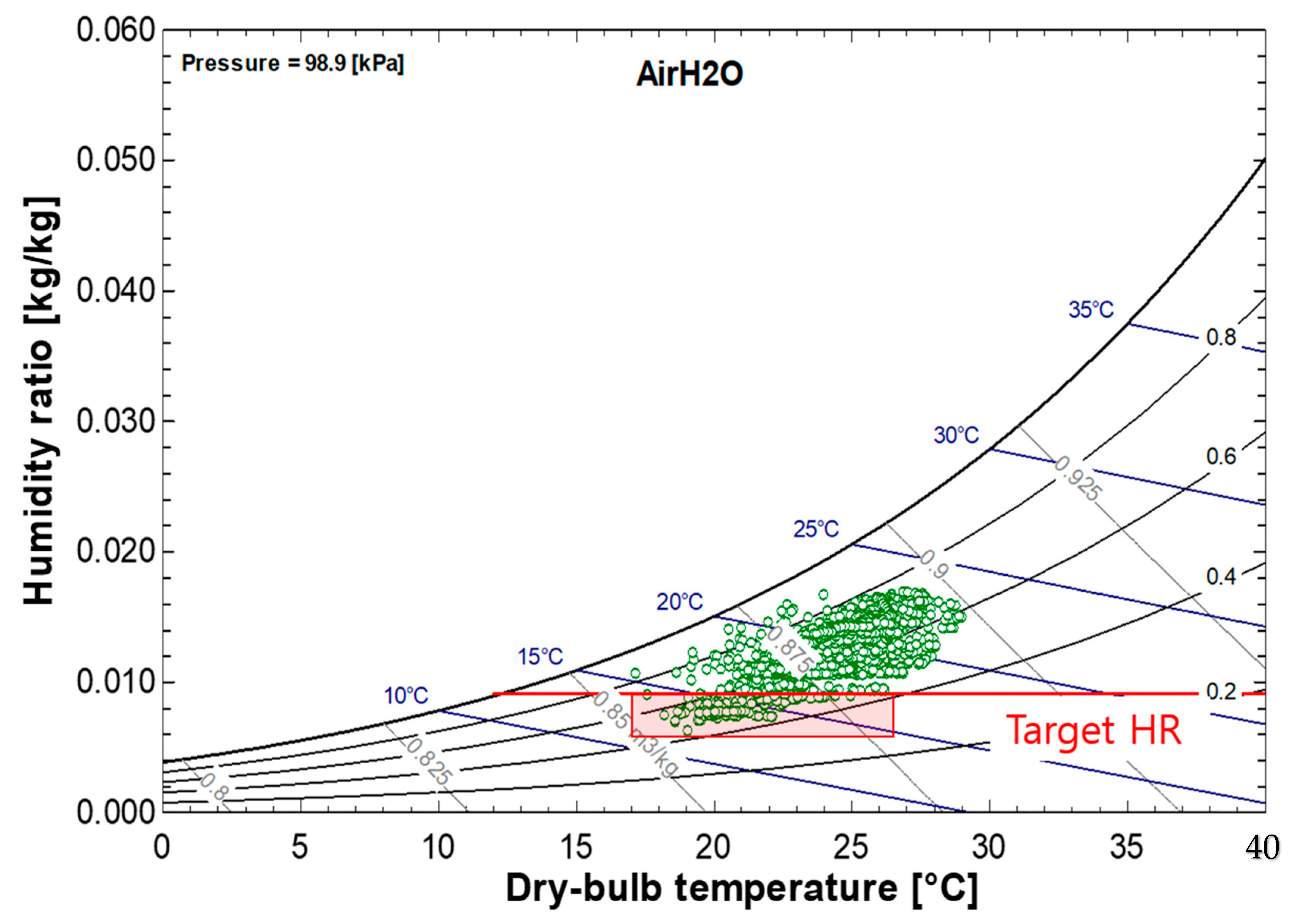

3.3. Target Air Conditions

3.4. Performance Index

4. Simulation Results and Analysis

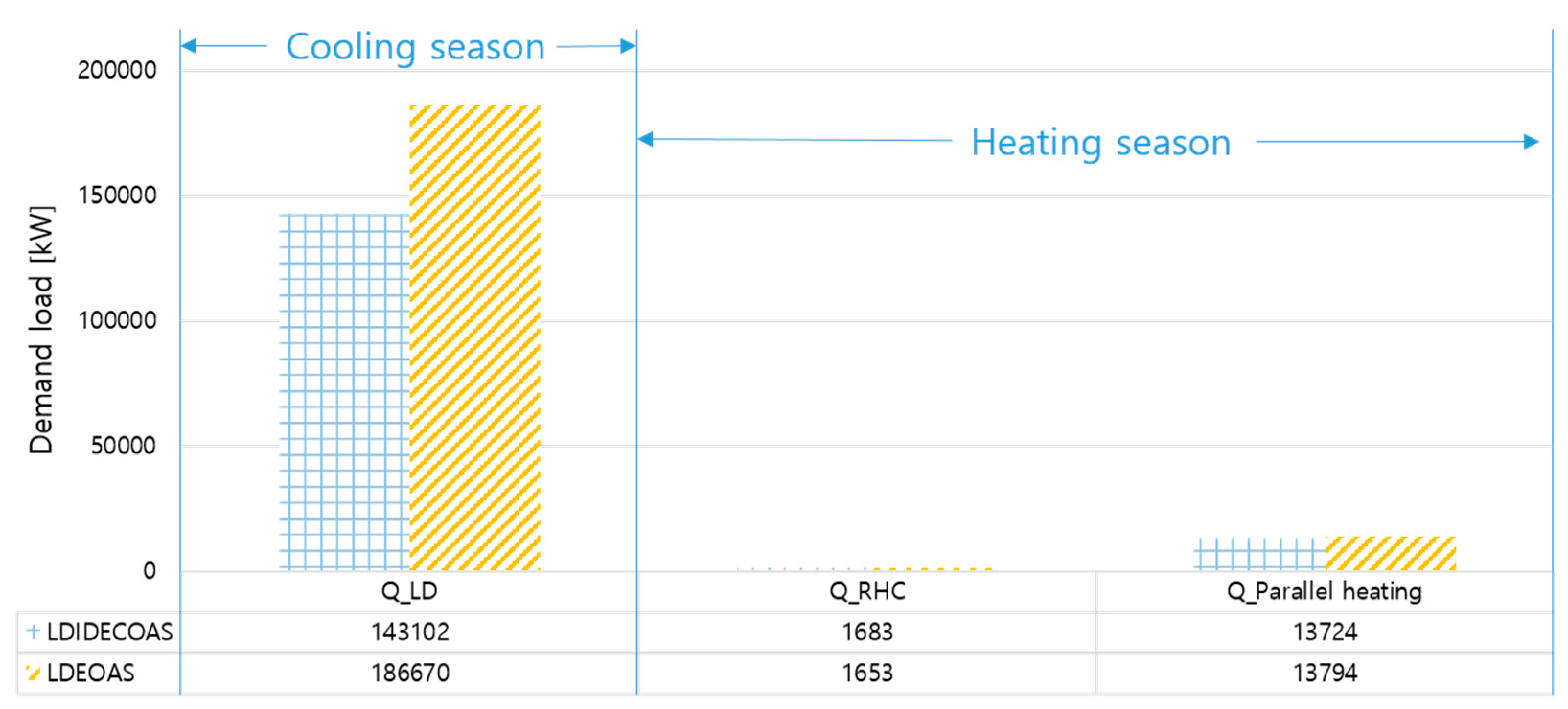

4.1. Comparison and Analysis of the Demand Load

4.2. Comparison of Energy Consumption

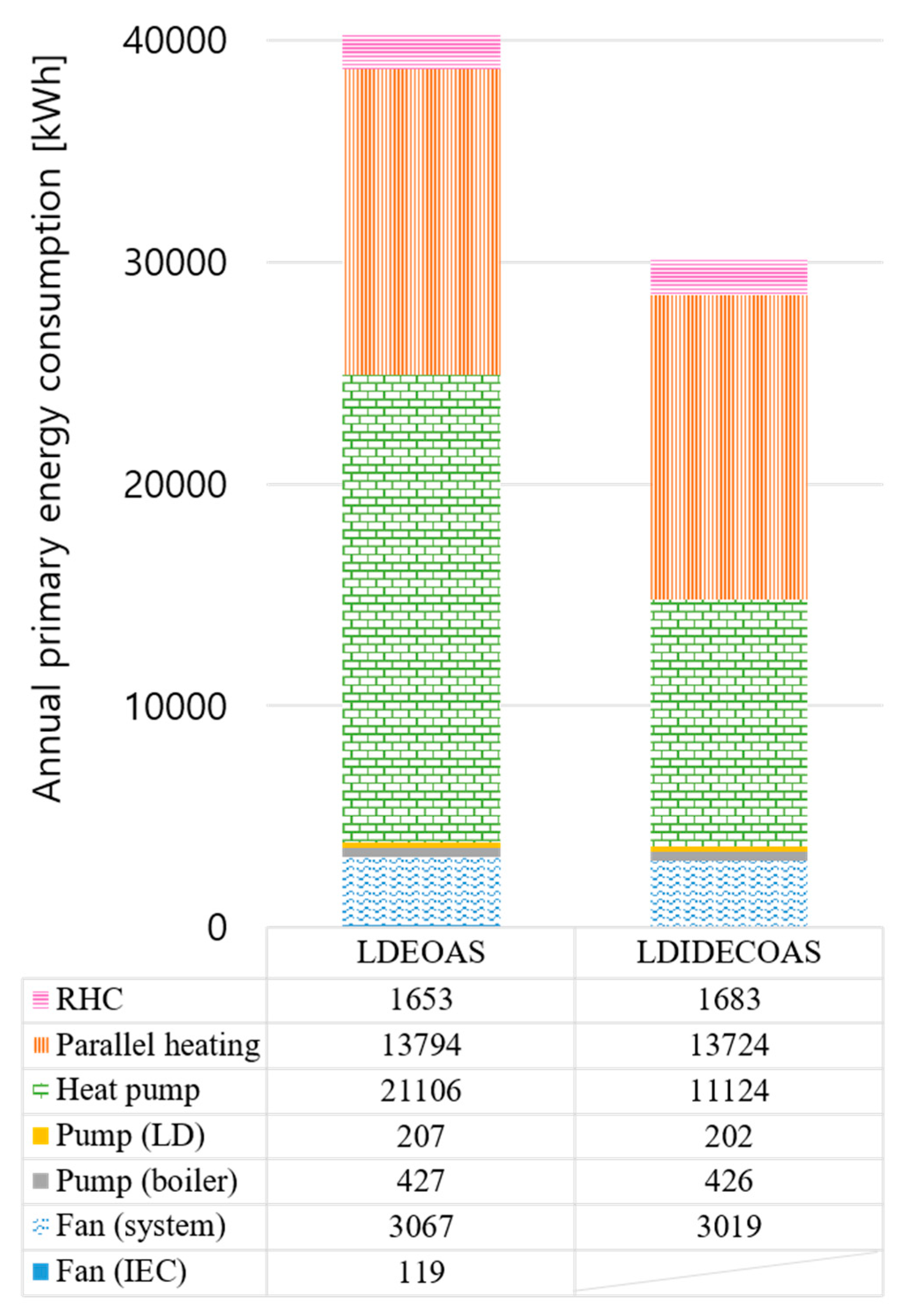

4.2.1. Comparison of Annual Energy Consumption

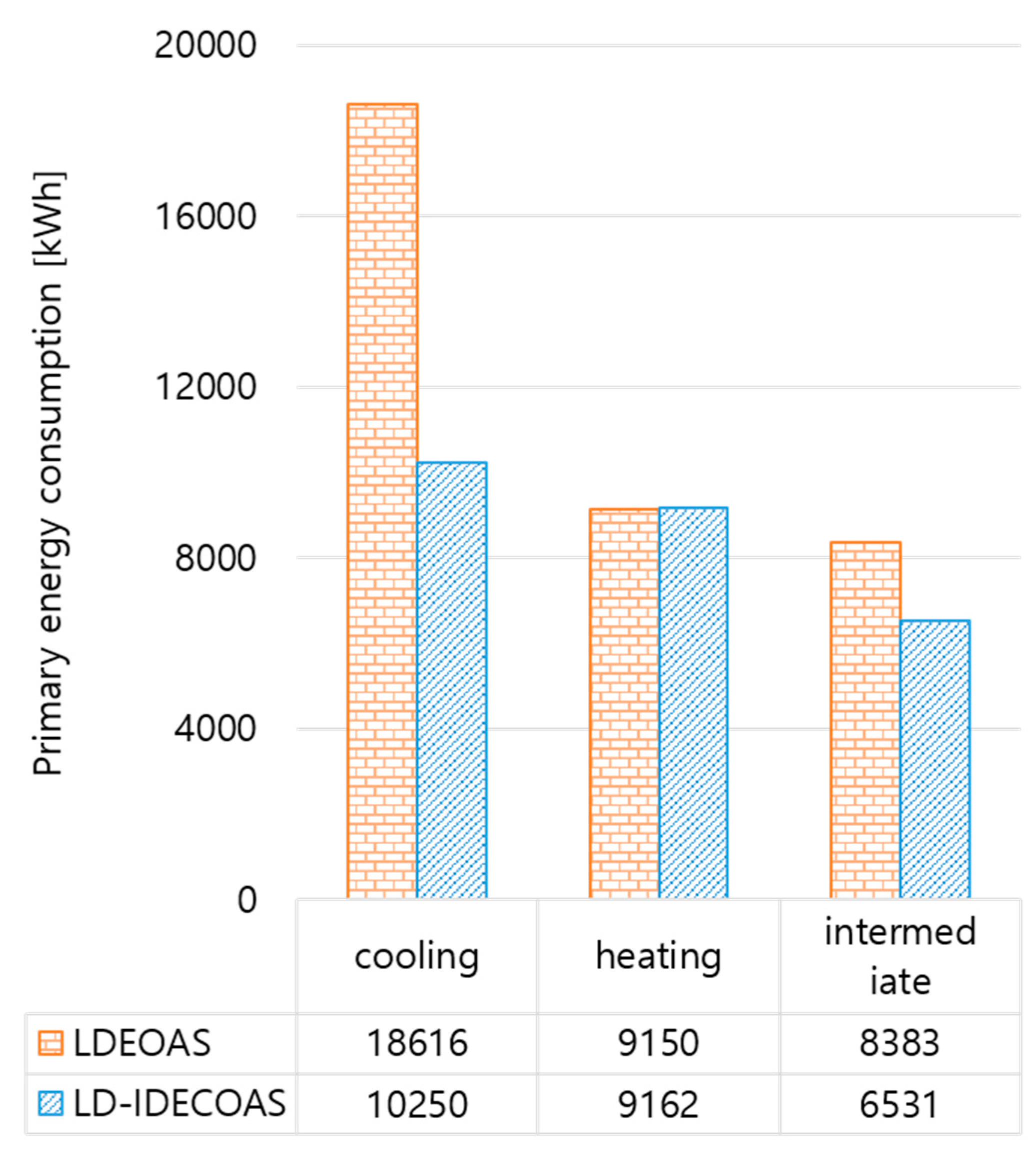

4.2.2. Comparison of Seasonal Energy Consumption

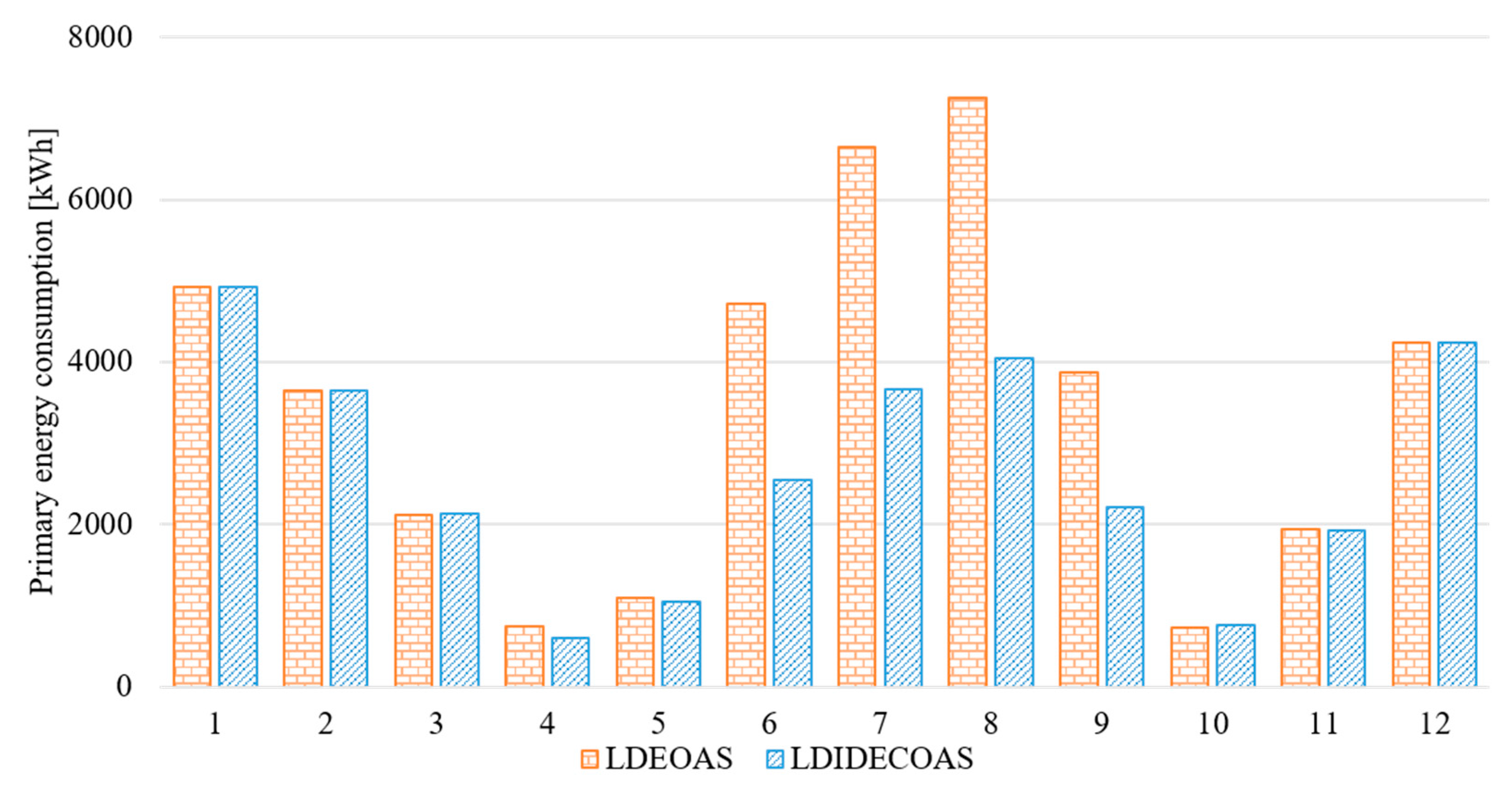

4.2.3. Comparison of Monthly Energy Consumption

4.3. Comparison of Supply Air Conditions

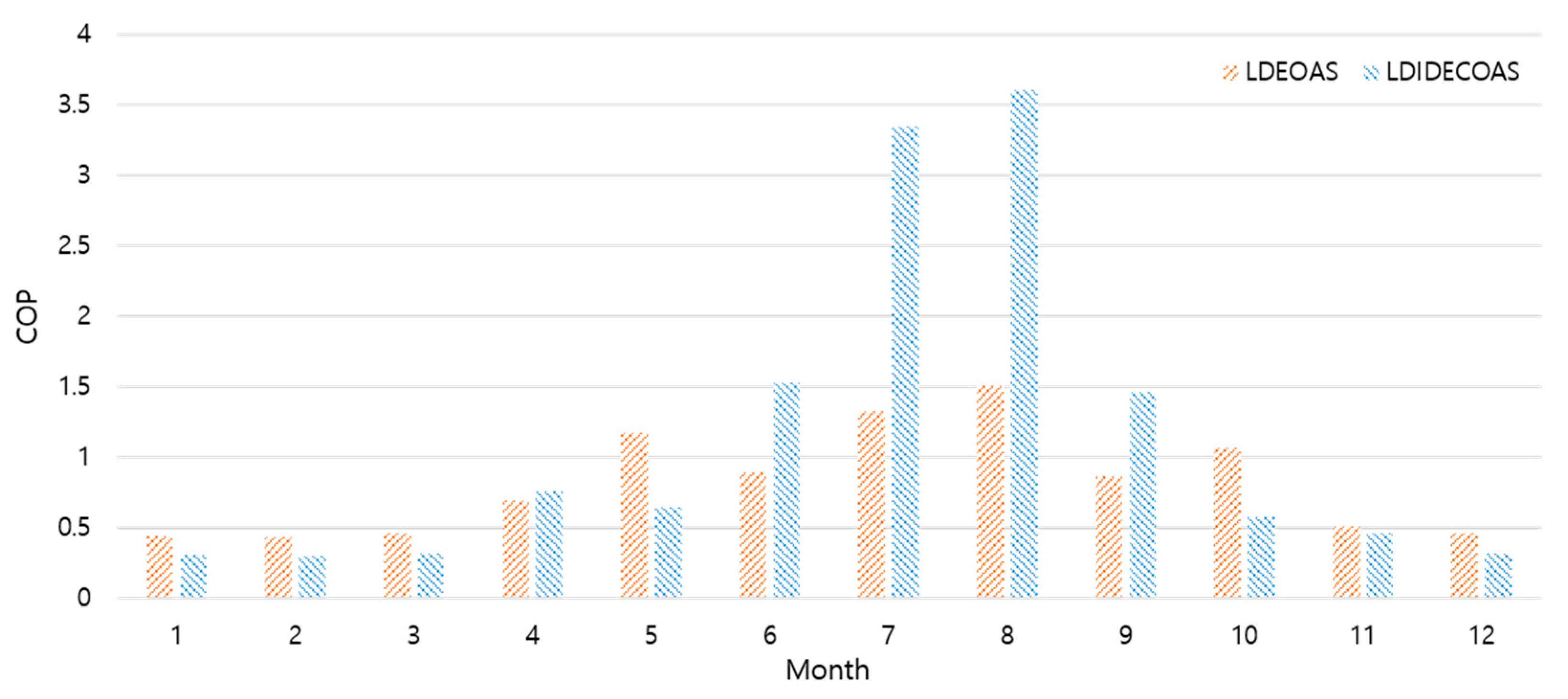

4.4. Comparison of COP

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Surface area-to-volume ratio of the packing (2/m3) | |

| C | Solution concentration (-) |

| Specific heat capacity () | |

| Compressor frequency | |

| Heat of water vaporization (=2257 kJ/kg) | |

| Mass flow rate (kg/s) | |

| Function of the part-load ratio | |

| Water-vapor partial pressure (Pa) | |

| Vapor pressure of desiccant solution (kPa) | |

| Load () | |

| Temperature (°C) | |

| Inlet desiccant solution temperature (°C) | |

| Volumetric flow rate (m3/s) | |

| W | Effective mechanical power (W/m2) |

| Z | Packing height (m) |

| Abbreviations | |

| OA | Outdoor air |

| CC | Cooling coil |

| COP | Coefficient of performance |

| DBT | Dry-bulb temperature [°C] |

| DEC | Direct evaporative cooler |

| DP-IEC | Dew-point evaporative cooler |

| EA | Exhausted air |

| EES | Engineering equation solver |

| HC | Heating coil |

| HP | Heat pump |

| HPLD | Heat pump-integrated liquid desiccant system |

| HR | Humidity ratio |

| HVAC | Heating ventilation and air conditioning |

| IEC | Indirect evaporative cooler |

| LD | Liquid desiccant |

| LDEOAS | Liquid desiccant and dew-point evaporative-cooler-assisted 100% outdoor air system |

| LDIDECOAS | Liquid desiccant and indirect and direct evaporative-cooler-assisted 100% outdoor air system |

| MEE | Membrane enthalpy exchanger |

| RA | Return air |

| RH | Relative humidity [%] |

| RHC | Reheat coil |

| SA | Supply air |

| SHE | Sensible heat exchanger |

| VAV | Variable air volume |

| WBT | Wet-bulb temperature [°C] |

| Greek Symbols | |

| Effectiveness [-] | |

| Humidity ratio [kg/ kga] | |

| Function of the vapor-pressure depression of the desiccant solution to the vapor pressure of pure water | |

| Subscripts | |

| Air | |

| c | Cooling mode |

| eq | Equilibrium |

| Inlet | |

| lat | Space latent |

| Outlet | |

| pri | Primary side |

| ref | Reference |

| s | Saturated |

| Desiccant solution | |

| sec | Secondary side |

| sen | Space sensible |

References

- Kim, M.H.; Park, J.S.; Jeong, J.W. Energy saving potential of liquid desiccant in evaporative-cooling-assisted 100% outdoor air system. Energy 2013, 59, 726–736. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.Y. Experimental study of a counter flow regenerative evaporative cooler with finned channels. Int. J. Heat Mass Transf. 2013, 65, 173–179. [Google Scholar] [CrossRef]

- Cho, H.J.; Jeong, J.W. Evaluation of thermal comfort in an office building served by a liquid desiccant-assisted evaporative cooling air-conditioning system. Energy Build. 2018, 172, 361–370. [Google Scholar] [CrossRef]

- Kim, M.H.; Yoon, D.S.; Kim, H.J.; Jeong, J.W. Retrofit of a liquid desiccant and evaporative cooling-assisted 100% outdoor air system for enhancing energy saving potential. Appl. Therm. Eng. 2016, 96, 441–453. [Google Scholar] [CrossRef]

- Lin, J.; Huang, S.M.; Wang, R.; Chua, K.J. Thermodynamic analysis of a hybrid membrane liquid desiccant dehumidification and dew point evaporative cooling system. Energy Convers. Manag. 2018, 156, 440–458. [Google Scholar] [CrossRef]

- Shin, J.H.; Park, J.Y.; Jo, M.S.; Jeong, J.W. Impact of heat pump-driven liquid desiccant dehumidification on the energy performance of an evaporative cooling-assisted air conditioning system. Energies 2018, 11, 345. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, X.; Jiang, Y. Performance optimization of heat pump driven liquid desiccant dehumidification systems. Energy Build. 2012, 52, 132–144. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Liu, X. Model-based investigation of a heat pump driven, internally cooled liquid desiccant dehumidification system. Build. Environ. 2018, 143, 431–442. [Google Scholar] [CrossRef]

- Kim, M.H.; Park, J.Y.; Jeong, J.W. Energy saving potential of a thermoelectric heat pump-assisted liquid desiccant system in a dedicated outdoor air system. Energies 2017, 10, 1306. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Bozorgmehr, M.; Delfani, S.; Esmaeelian, J. Experimental investigation of two-stage indirect/direct evaporative cooling system in various climatic conditions. Build. Environ. 2009, 44, 2073–2079. [Google Scholar] [CrossRef]

- Zhao, X.; Duan, Z.; Zhan, C.; Riffat, S.B. Dynamic performance of a novel dew point air conditioning for the UK buildings. Int. J. Low-Carbon Technol. 2009, 4, 27–35. [Google Scholar] [CrossRef]

- Glanville, P.; Kozlov, A.; Maisotsenko, V. Dew point evaporative cooling: Technology review and fundamentals. ASHRAE Trans. 2011, 117, 111–118. [Google Scholar]

- Kozubal, E.; Woods, J.; Burch, J.; Boranian, A.; Merrigan, T. Desiccant Enhanced Evaporative Air-Conditioning (DEVap): Evaluation of a New Concept in Ultra Efficient Air Conditioning. Contract 2011, 303, 275–3000. [Google Scholar]

- Ham, S.W.; Lee, S.J.; Jeong, J.W. Operating energy savings in a liquid desiccant and dew point evaporative cooling-assisted 100% outdoor air system. Energy Build. 2016, 116, 535–552. [Google Scholar] [CrossRef]

- Duan, Z. Investigation of a Novel Dew Point Indirect Evaporative Air Conditioning System for Buildings. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2011. [Google Scholar]

- Lin, J.; Bui, D.T.; Wang, R.; Chua, K.J. On the fundamental heat and mass transfer analysis of the counter-flow dew point evaporative cooler. Appl. Energy 2018, 217, 126–142. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Regression models for performance prediction of counter flow dew point evaporative cooling systems. Energy Convers. Manag. 2019, 185, 562–573. [Google Scholar] [CrossRef]

- Klein, S.A. Engineering Equation Solver for Microsoft Windows Operating Systems. Available online: https://fchartsoftware.com/assets/downloads/ees_manual.pdf (accessed on 21 January 2020).

- Mitchell, J.W.; Braun, J.E. Principles of Heating, Ventilating, and Air Conditioning; Wiley: Hoboken, NJ, USA, 2012; ISBN 9780470624579. [Google Scholar]

- Lowenstein, A. Review of Liquid Desiccant Technology for HVAC Applications. HVAC&R Res. 2008, 14, 819–839. [Google Scholar]

- Sahlot, M.; Riffat, S.B. Desiccant cooling systems: A review. Int. J. Low-Carbon Technol. 2016, 11, 489–505. [Google Scholar] [CrossRef]

- Alizadeh, S. Performance of a solar liquid desiccant air conditioner—An experimental and theoretical approach. Sol. Energy 2008, 82, 563–572. [Google Scholar] [CrossRef]

- Katejanekarn, T.; Kumar, S. Performance of a solar-regenerated liquid desiccant ventilation pre-conditioning system. Energy Build. 2008, 40, 1252–1267. [Google Scholar] [CrossRef]

- Madani, H.; Claesson, J.; Ahmadi, N.; Lundqvist, P. Experimental Analysis of a Variable Capacity Heat Pump System Focusing on the Compressor and Inverter Loss Behavio. Available online: http://docs.lib.purdue.edu/iracc (accessed on 21 January 2020).

- Cuce, P.M.; Riffat, S. A state of the art review of evaporative cooling systems for building applications. Renew. Sustain. Energy Rev. 2016, 54, 1240–1249. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.; Li, Y.; Ge, T.; Wang, R. Study on a novel thermally driven air conditioning system with desiccant dehumidification and regenerative evaporative cooling. Build. Environ. 2010, 45, 2473–2484. [Google Scholar] [CrossRef]

- Gommed, K.; Grossman, G. Experimental investigation of a liquid desiccant system for solar cooling and dehumidification. Sol. Energy 2007, 81, 131–138. [Google Scholar] [CrossRef]

- Katejanekarn, T.; Chirarattananon, S.; Kumar, S. An experimental study of a solar-regenerated liquid desiccant ventilation pre-conditioning system. Sol. Energy 2009, 83, 920–933. [Google Scholar] [CrossRef]

- Bergero, S.; Chiari, A. Performance analysis of a liquid desiccant and membrane contactor hybrid air-conditioning system. Energy Build. 2010, 42, 1976–1986. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Standard 90.1-2019: Energy Standard for Buildings Except Low-Rise Residential Buildings; American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2019; ISSN 1041-2336. [Google Scholar]

- ASHRAE. International Weather Files For Energy Calculations 2.0 (IWEC2); American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2010; ISBN 9781936504206. [Google Scholar]

- MOLIT. Guideline for Energy Saving Design of Buildings; Ministry of Land, Infrastructure and Transport of Korea: Sejong Special Governing City, Korea, 2017; Available online: http://www.law.go.kr.

- Chung, T.W.; Luo, C.M. Vapor pressures of the aqueous desiccants. J. Chem. Eng. Data 1999, 44, 1024–1027. [Google Scholar] [CrossRef]

- Goswami, D.Y.; Fumo, N. Study of an aqueous lithium chloride desiccant system: Air dehumidification and desiccant regeneration. Sol. Energy 2002, 72, 351–361. [Google Scholar]

- DOE, EnergyPlus Engineering Reference: The Reference to EnergyPlus Calculations. U.S. Dep. Energy 2010, 1–847.

- Munters, Product Sheet: Celdek. Available online: http://munters.com/globalassets/inriver/resources/celdek-gg.pdf (accessed on 21 January 2020).

- Menerga, Products and Solutions: Frecolair. Available online: http://menerga.com/products-solutions/frecolair/ (accessed on 21 January 2020).

- Riangvilaikul, B.; Kumar, S. An experimental study of a novel dew point evaporative cooling system. Energy Build. 2010, 42, 637–644. [Google Scholar] [CrossRef]

- Jin, H. Parameter Estimation Based Models of Water Source Heat Pumps; Oklahoma State University: Stillwater, OK, USA, 2002; Volume 6. [Google Scholar]

- Jin, H.; Spitler, J.D. A parameter estimation based model of water-to-water heat pumps for use in energy calculation programs. ASHRAE Trans. 2002, 108 Pt 1, 3–17. [Google Scholar]

- Stanke, D.A.; Danks, R.A.; Muller, C.O.; Hedrick, R.L.; Fisher, F.J.; Osborn, J.E.; Butler, D.S.; Gallo, F.M.; Rasmussen, R.D.; Alevantis, L.E.; et al. Ventilation for acceptable indoor air quality. ASHRAE Stand. 2010, 2007, 1–70. [Google Scholar]

- KEA. Building Energy Efficiency Rating Certification System Operating Regulations; Korea Energy Agency; Available online: http://building.energy.or.kr (accessed on 21 January 2020).

- ASHARE. ASHRAE Standard 55-2010: Thermal Environmental Conditions for Human Occupancy; American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2010; ISSN 1041-2336. [Google Scholar]

| Building | 300 m3 (10 × 10 × 3) | ||

|---|---|---|---|

| Location | Seoul, Korea | ||

| Occupancy density | 5 people/100 m2 (ASHRAE Standard 62.1) | ||

| Occupancy/HVAC schedules | ASHRAE Standard 90.1 (ASHRAE Standard 90.1) | ||

| Target room condition | Cooling season | 24 °C, 55% | |

| Heating season | 20 °C | ||

| Target supply air condition | Cooling season | 15 °C | |

| Heating season | 20 °C | ||

| Internal heat gain | People | Sensible | 75 W/person |

| Latent | 45 W/person | ||

| Electronics | PC: 140 W/person (Sensible) | ||

| Lighting | 13 W/m2 | ||

| U-values | Exterior wall | 0.259 W/m2 K | |

| Roof | 0.149 W/m2 K | ||

| Window | 1.46 W/m2 K | ||

| Floor | 0.289 W/m2 K | ||

| Window-to-wall ratio | 17% | ||

| 4.582 | −18.382 | 21.312 | |||

| −0.159 | 0.567 | −0.666 | |||

| 0.007 | −0.019 | 0.013 |

| Reference Values | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (m3/s) | (m3/s) | (nominal capacity) (W) | (K) | ||||||||||||||||

| 5.678 × 10−4 | 5.678 × 10−4 | 14,215.35 | 283.00 | ||||||||||||||||

| Model Coefficients | |||||||||||||||||||

| A1 | A2 | A3 | A4 | A5 | |||||||||||||||

| −2.8581 × 100 | 4.3425 × 100 | −9.6592 × 10−1 | 1.0978 × 10−1 | 4.6779 × 10−2 | |||||||||||||||

| Systems | MEE (h) | LD (h) |

|---|---|---|

| LDEOAS | 1770 | 1538 |

| LD-IDECOAS | - | 1959 |

| LDEOAS | LDIDECOAS | |

|---|---|---|

| MEE (h) | LD (h) | LD (h) |

| 1770 | 1727 (˟1538) | 1959 |

| Parameters | LDIDECOAS | LDEOAS | Unit |

|---|---|---|---|

| 11.95 | 11.76 | °C | |

| 11.99 | 11.79 | °C | |

| 1.61 | 1.12 | g/Kg |

| Seasons | LDEOAS | LD-IDECOAS | |

|---|---|---|---|

| MEE (h) | LD (h) | LD (h) | |

| Summer | 1295 | 1335 (˟1290) | 1463 |

| Intermediate season | 475 | 392 (˟248) | 496 |

| Month | LDEOAS | LD-IDECOAS | ||

|---|---|---|---|---|

| MEE (h) | LD (h) | LD (h) | ||

| 4 | 66 | 17 | (˟0) | 17 |

| 5 | 114 | 72 | (˟43) | 137 |

| 6 | 315 | 355 | (˟310) | 441 |

| 7 | 480 | 480 | (˟480) | 508 |

| 8 | 500 | 500 | (˟500) | 514 |

| 9 | 230 | 284 | (˟205) | 295 |

| 10 | 49 | 19 | (˟0) | 47 |

| 11 | 16 | 0 | (˟0) | 0 |

| Categories | LDEOAS | LDIDECOAS | |

|---|---|---|---|

| Average humidity ratio | Summer | 4.7 g/kg | 9.1 g/kg |

| Intermediate season | 6.7 g/kg | 7.2 g/kg | |

| Winter | 5.4 g/kg | 2.6 g/kg | |

| Average dry-bulb temperature | 12.9 °C | 15 °C | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Jeong, J.-W. Energy Performance Comparison between Two Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems. Energies 2020, 13, 522. https://doi.org/10.3390/en13030522

Liu S, Jeong J-W. Energy Performance Comparison between Two Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems. Energies. 2020; 13(3):522. https://doi.org/10.3390/en13030522

Chicago/Turabian StyleLiu, Su, and Jae-Weon Jeong. 2020. "Energy Performance Comparison between Two Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems" Energies 13, no. 3: 522. https://doi.org/10.3390/en13030522

APA StyleLiu, S., & Jeong, J.-W. (2020). Energy Performance Comparison between Two Liquid Desiccant and Evaporative Cooling-Assisted Air Conditioning Systems. Energies, 13(3), 522. https://doi.org/10.3390/en13030522