A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach

Abstract

1. Introduction

2. Literature Review

2.1. Cold-Chain Products and Emissions

2.2. Distribution Design of Cold-Chain Products

2.3. Solution Approaches Towards the Analysis of Cold Chains

- Which inspection strategy helps to ensure the potency of delivered products?

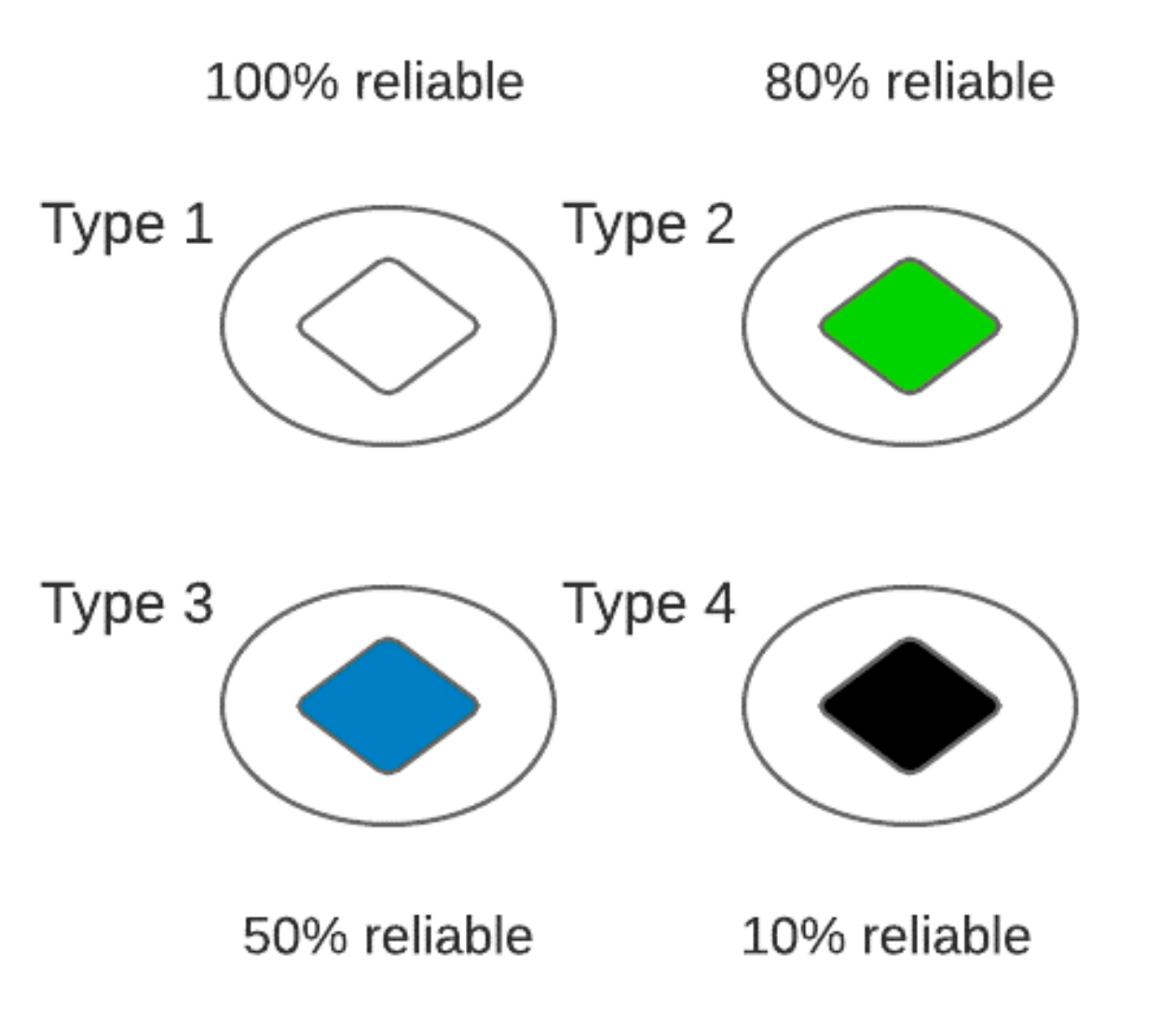

- What is the impact of different-quality products on the value of objective functions?

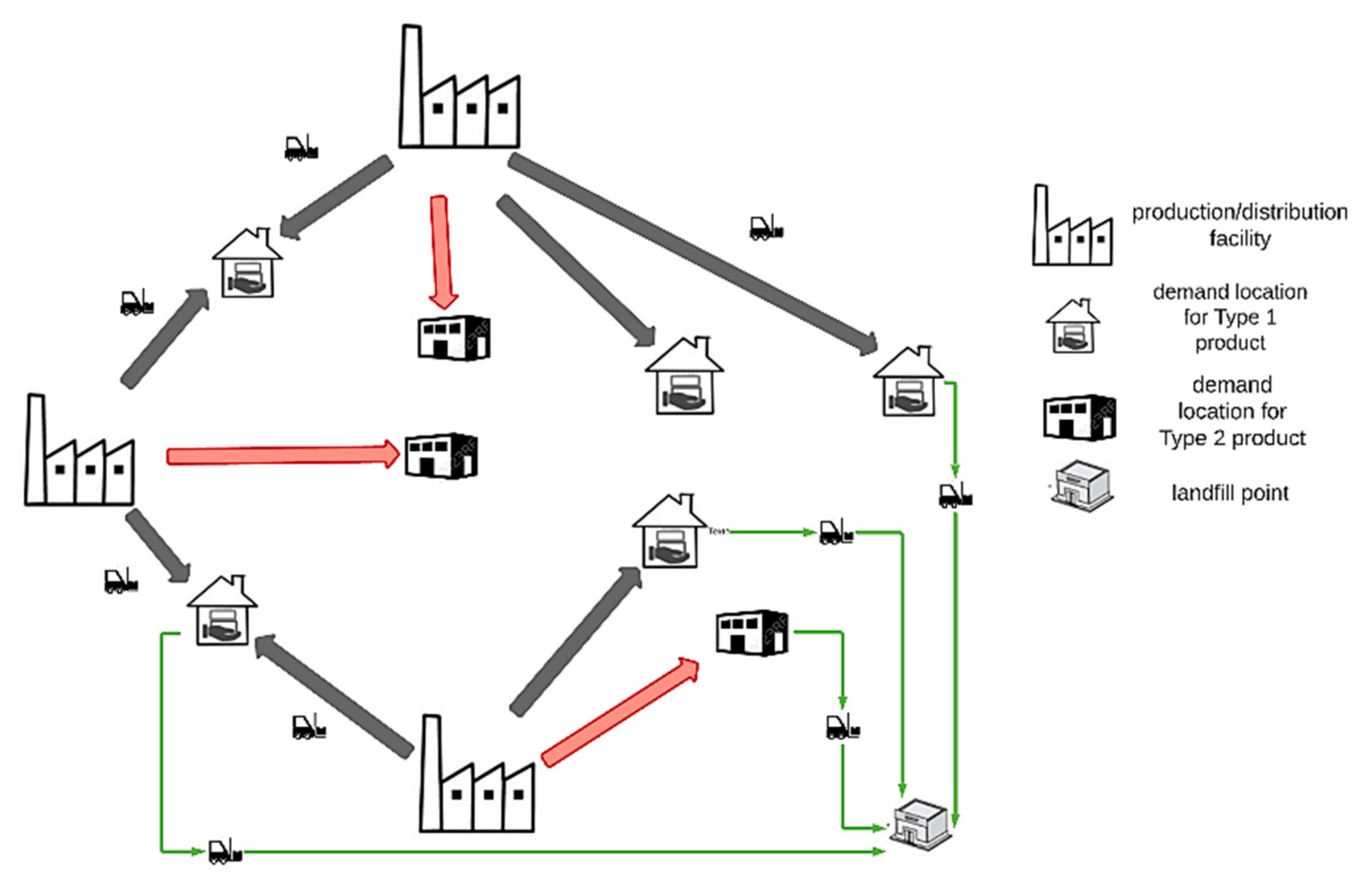

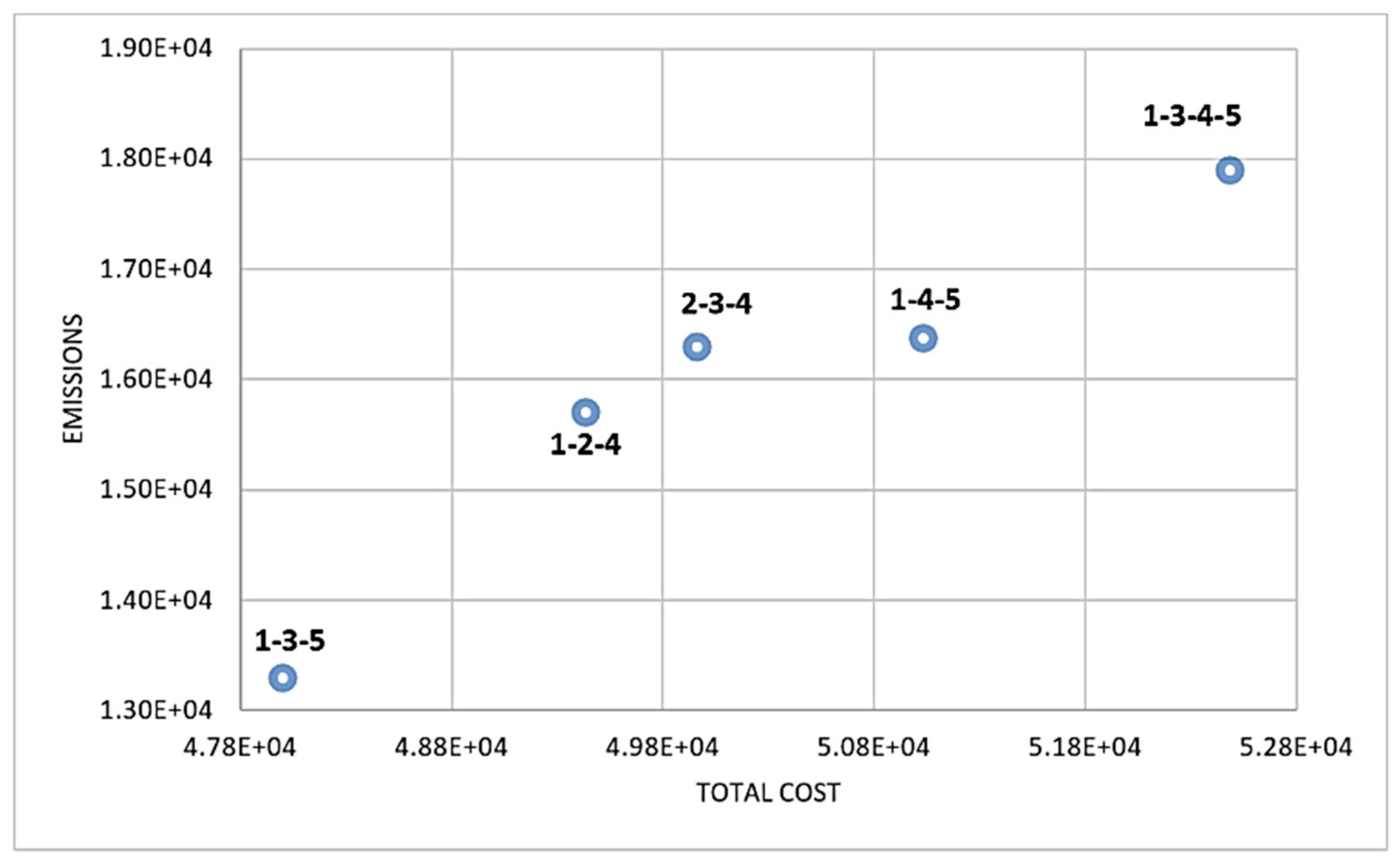

- What is the role of selecting a distribution point and the trade-off between cost and emissions in the cold-chain distribution system?

3. Research Framework and Method

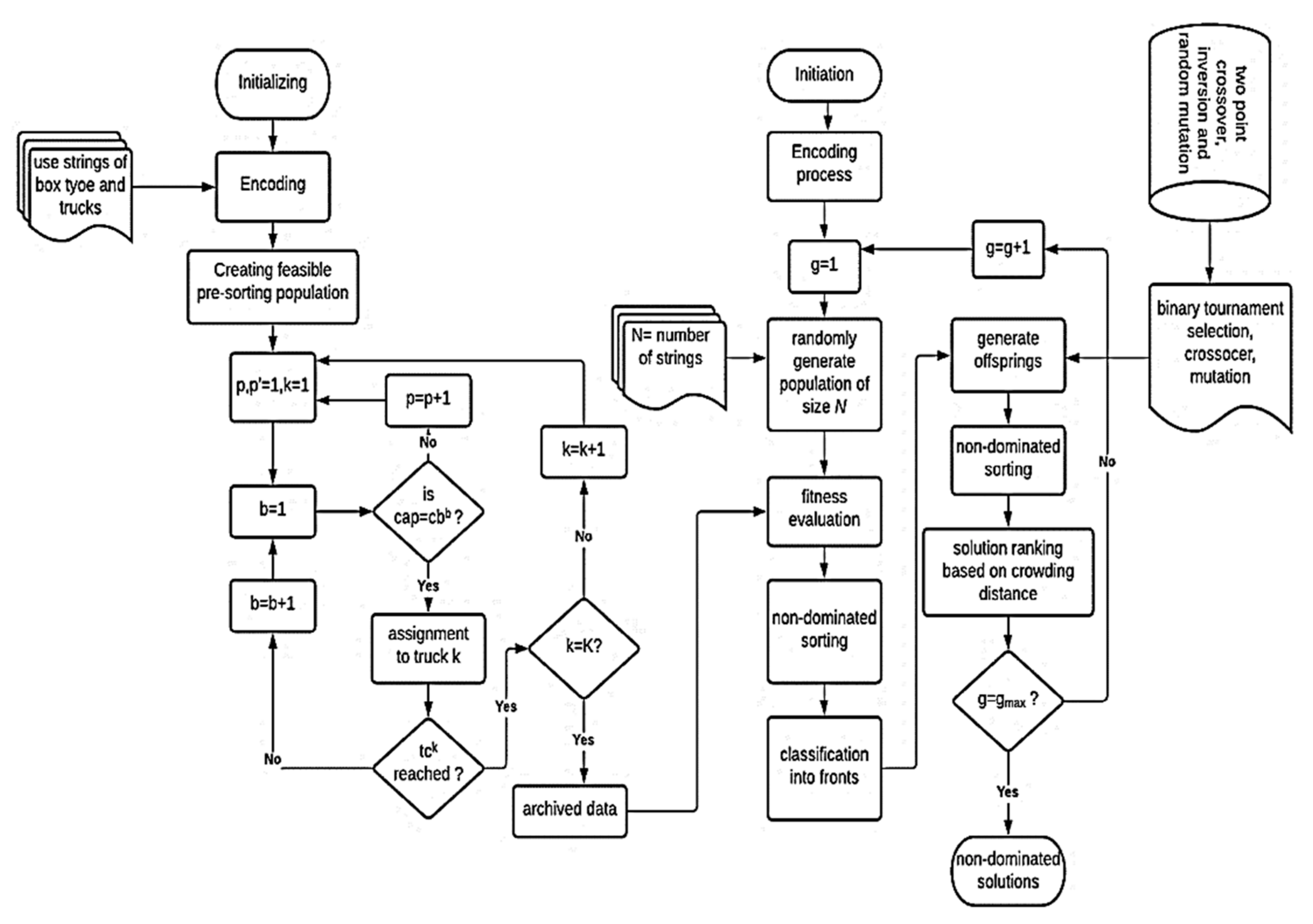

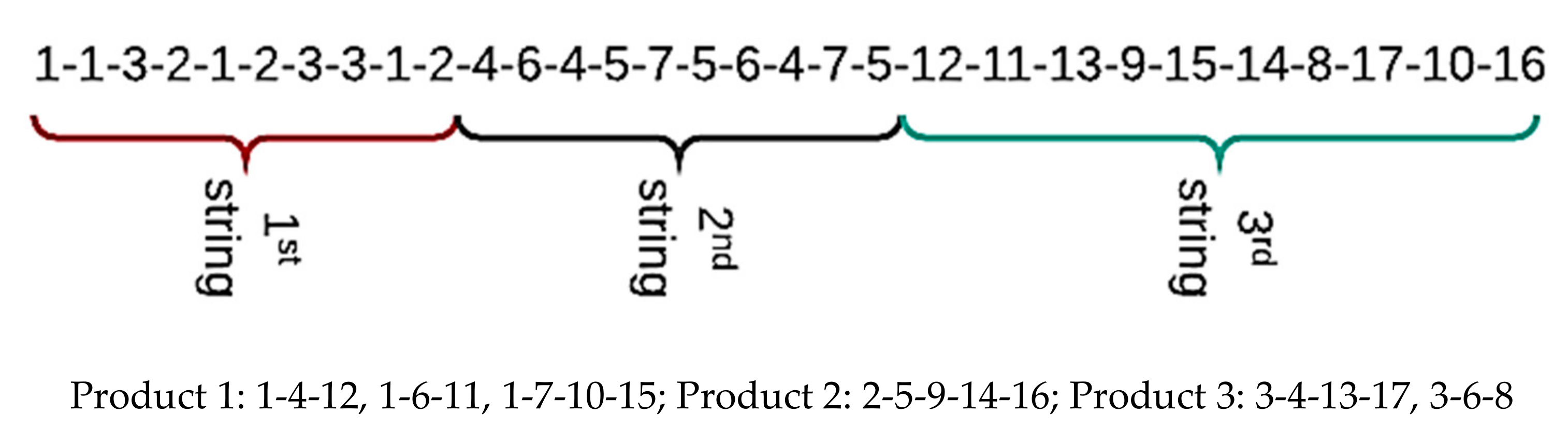

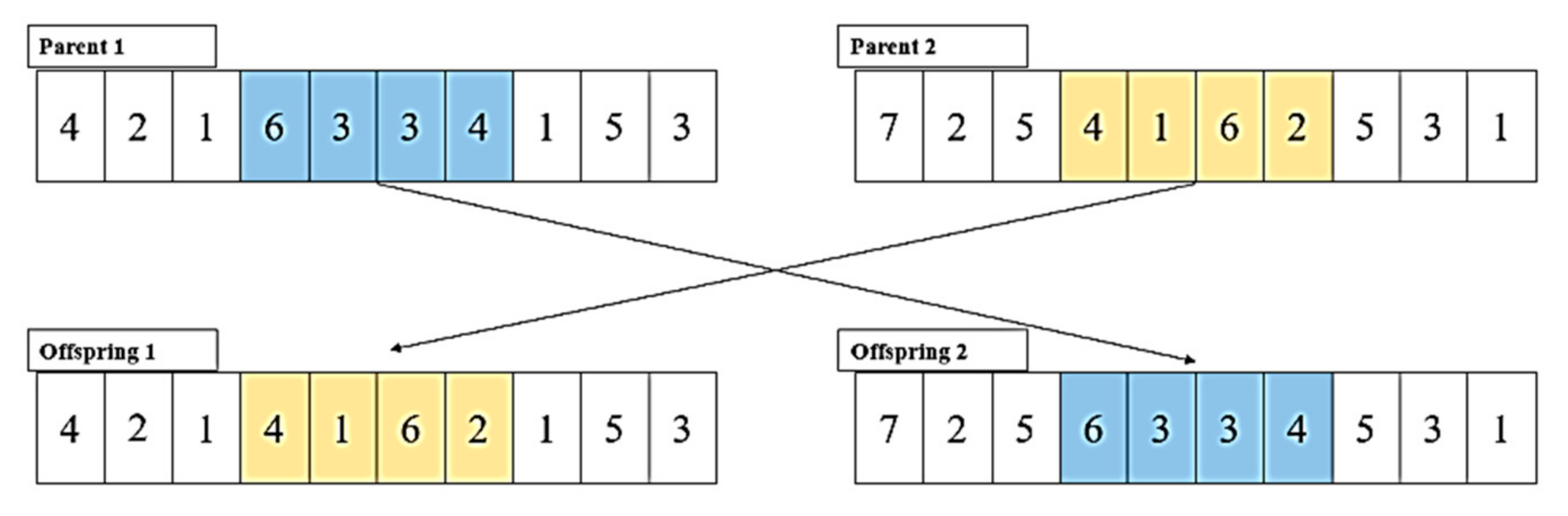

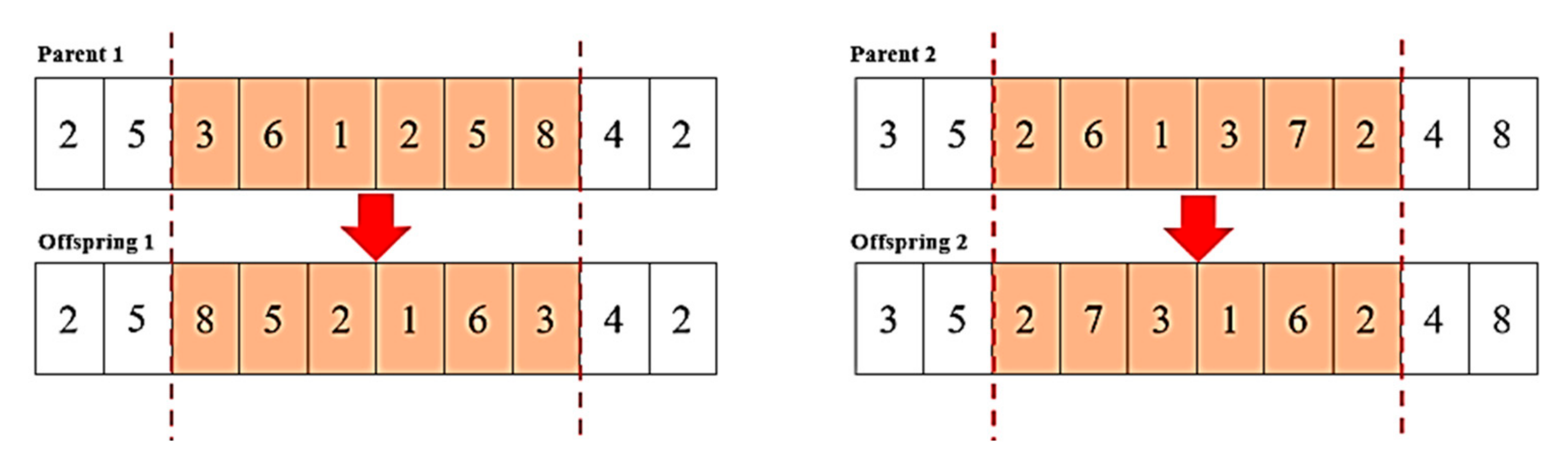

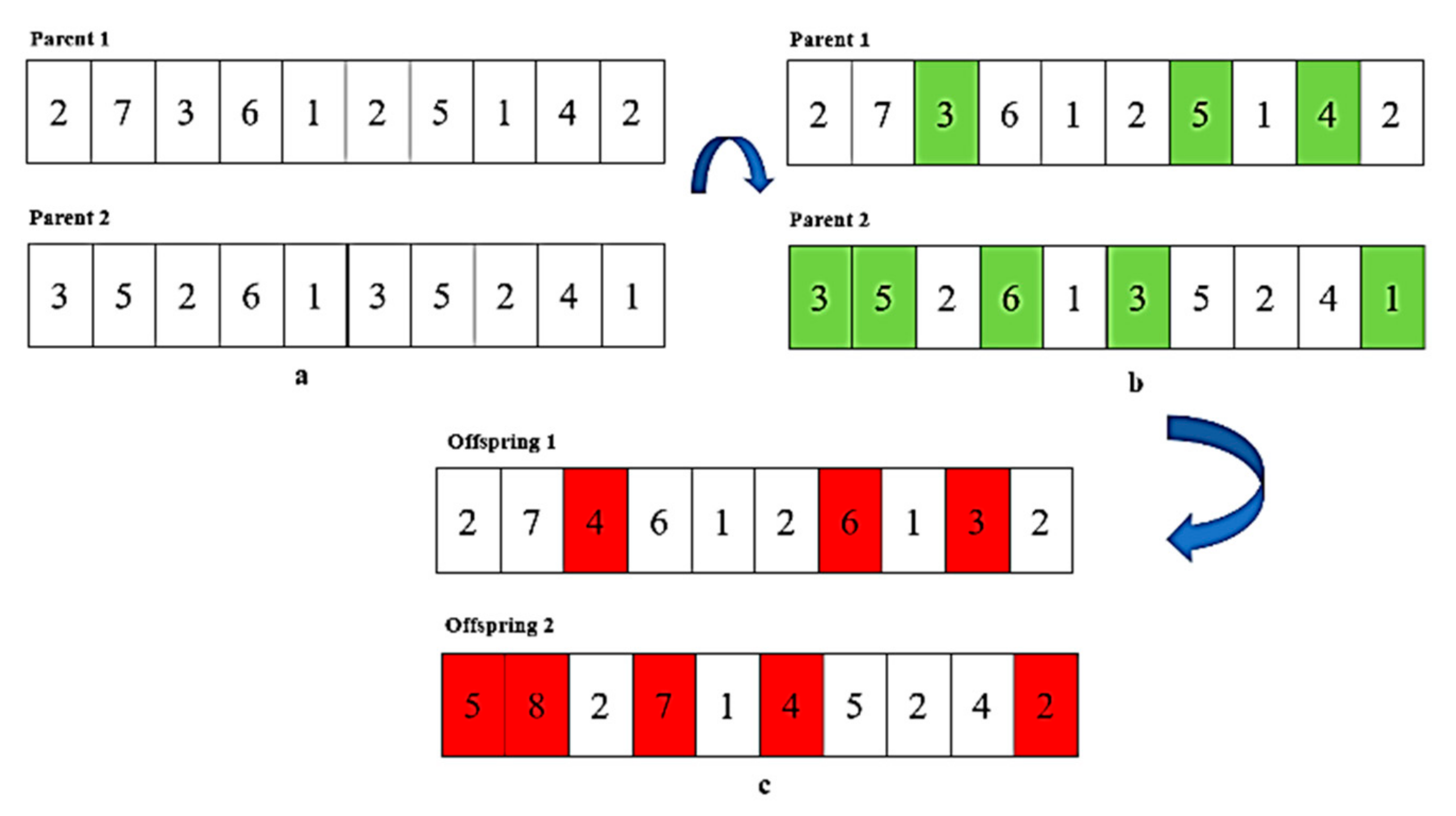

3.1. Solution Approach

3.1.1. Adaptive NSGA-II (aNSGA-II)

3.1.2. SPEA-II

- (a)

- The IGD calculates the uniformity and solution quality of approximate pareto front (AF) by considering the distance between a real pareto front (RF) and an approximate pareto front (AF). It performs the calculation by using the Euclidean distance approach between RF and AF. The relationship for IGD is provided in (22) where is the measure of Euclidean distance.

- (b)

- The hypervolume value (HyV) is an estimate of the covered space size. The space size is calculated between an approximate pareto front (AF) and a reference point defined by z. Its relationship is given in (23). The set constitutes the value of reference points which are dominated by the respective approximated fronts, s is the number of objective functions and V is the measure of Lebesgue. The first two terms of HyV (AF) relationship are used in this study as it there are two objective functions (i.e., s = 2)

4. Results and Discussions

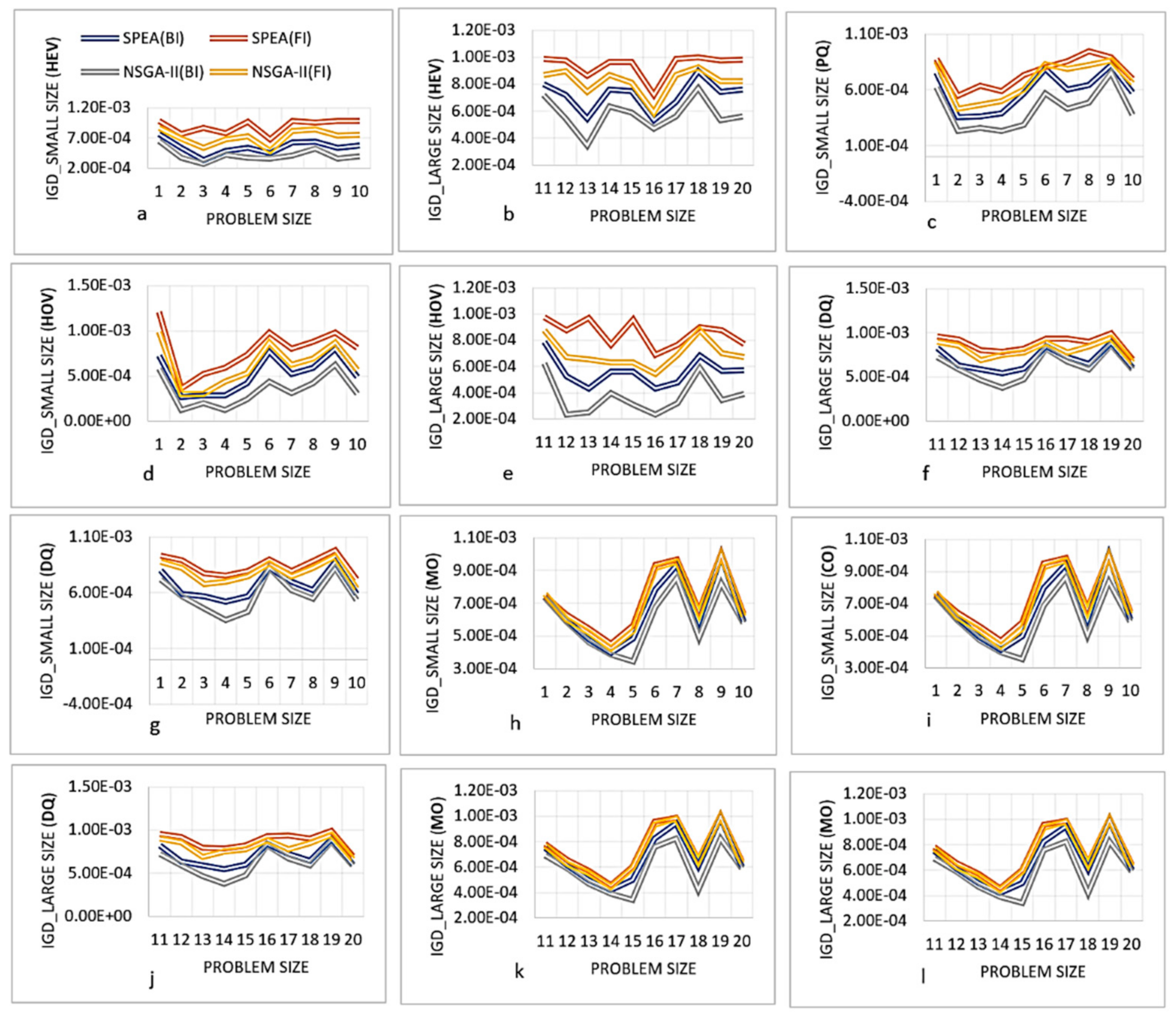

Results

- (a)

- There were no large-scale differences between the results of small and large size problems of a particular variant. Thus, the heuristics are powerful enough to address the complexity of a given problem.

- (b)

- The termination criteria based on returning solutions after BI works well compared to FI. BI is a more exhaustive search mechanism which seeks stability and refinement of solutions before returning them.

- (c)

- The adaptive NSGA-II (BI) has the standout scores of HyV and IGD for all test cases, ensures better uniformity and convergence of solutions; however, it took more time due to the pre-sorting.

- (d)

- The HyV and IGD scores of Mo and Co strategies are somewhat similar in small- and large-scale problems; however, this aspect will be further examined with the help of a detailed analysis of cost.

- (e)

- The homogeneous (HoV) and PQ distributions are favored as they have improved scores compared to the scores of heterogeneous (HeV) and DQ products-based analysis. This might be because such aspects pose less complexity in computation and hence the model performs well in such cases. Based on the presented analysis, NSGA-II (BI) was selected to carry out further analysis due to its improved performance.

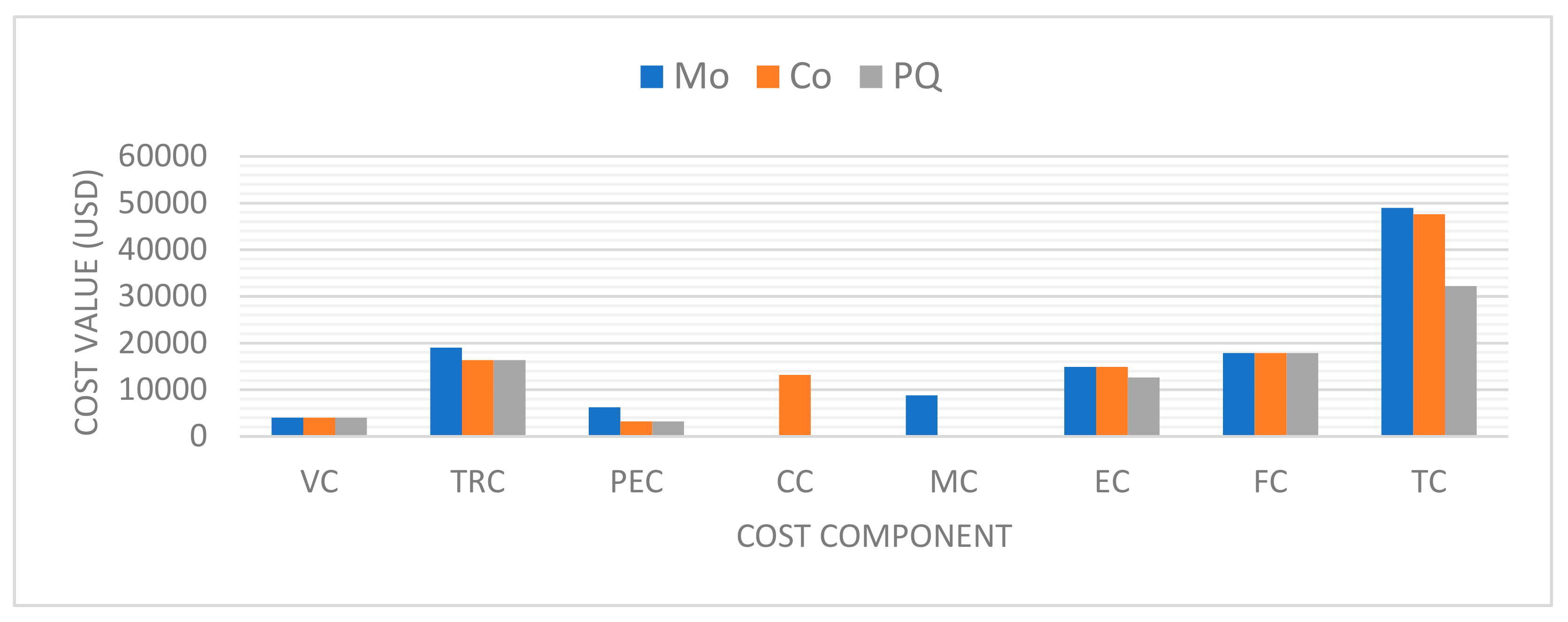

- (a)

- The TC value is minimum when products are in perfect quality. It is because there are no costs related to conformity and monitoring inspection. Also, transportation and emission costs are lower in this case as there are no landfilled products and hence no need to transport the bad products to the landfilled points.

- (b)

- The conformity inspection performs better compared to the monitoring inspection in the presence of quality issues and it results in almost 2% less cost.

- (c)

- A higher value of TC in the monitoring only strategy is due to the higher transportation and penalty cost. It segregates the bad-quality products and sends them to the landfill point which results in higher transportation and penalty cost.

- (d)

- As established earlier, conformity is an expensive strategy, and the results show that the CC is $13,175 which is almost 50% higher than the MC ($8825). However, this difference is discounted by the costs of transportation and penalty of bad products in the monitoring strategy.

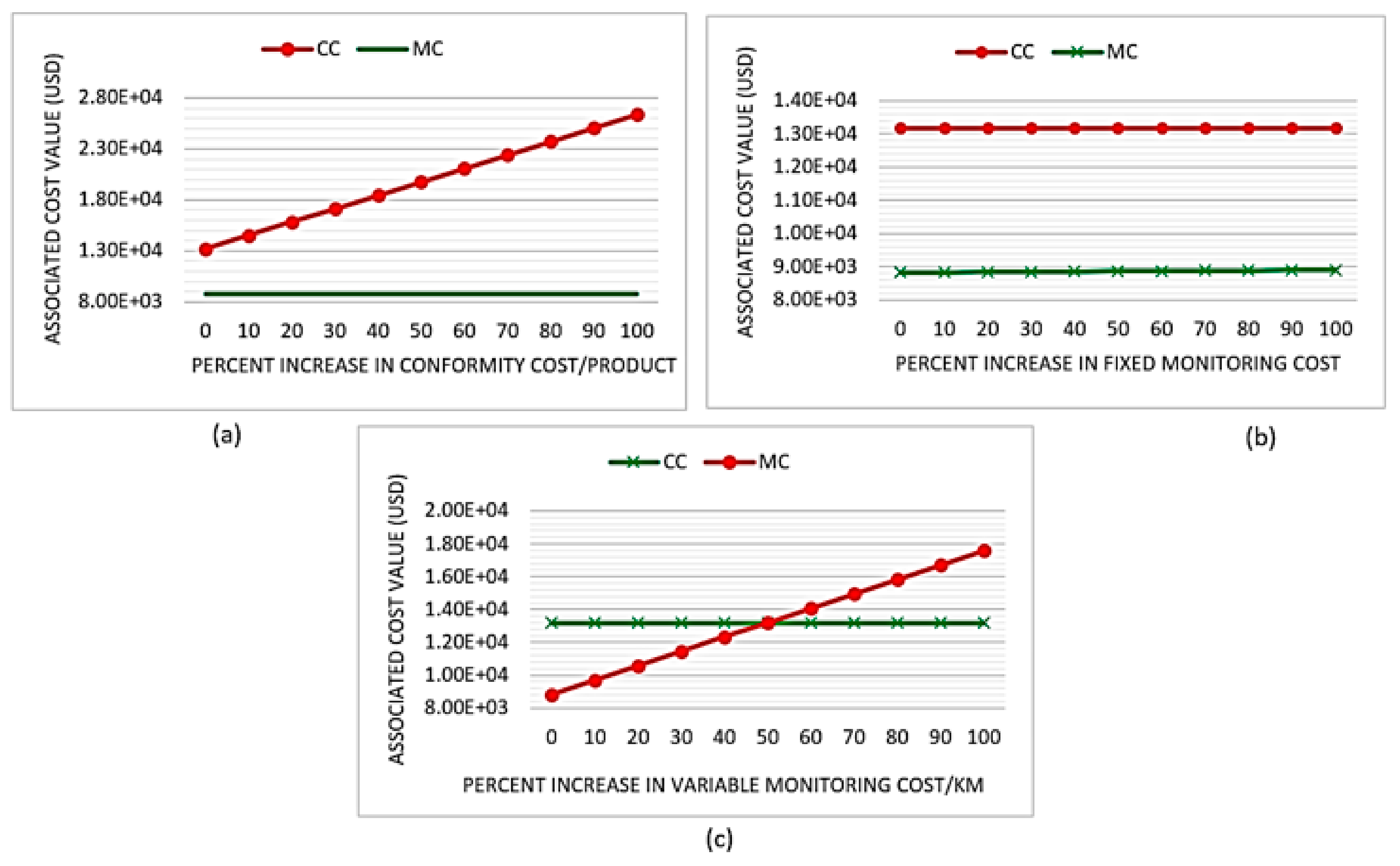

- Conformity only is not an ideal approach for product-quality assessment during the transit.

- Changes in fixed MC has least effect on selecting a strategy.

- The management should pay more attention towards the sensitivity of variable MC as it can alter the decision of inspection strategy at some point.

5. Research, Managerial, and Policy Implications

5.1. Research Implications

- This study implemented two algorithms with different termination criteria. The termination criterion based on the BI works well and NSGA-II (BI) has the best values of IGD and HyV in all test problems. It can be interesting to validate the findings using NSGA-II (BI) with and without the pre-sorting.

- There were no significant differences between the results of small and large problem sizes of a particular model variant. This indicates the robustness of the solution approaches. Furthermore, the model worked well in the absence of an additional scale of complexity.

- The geographical location of a candidate distribution point regarding the density of destination points impacts the solutions. A careful selection of a distribution point is imperative as it can influence the cost and emissions of the distribution system. In other words, the objective function values are sensitive to minor changes in the combination of distribution points. In this regard, minor changes can amount to higher differences in the values of objective functions.

5.2. Managerial and Policy Implications

- A thoughtful selection of distribution centers is imperative as it affects the objective functions of cost and emissions. A distribution network of PQ products is always advantageous in obtaining the lower values of cost and emissions; however, it is not always practical. The real-life situations contain products in different states of quality. Thus, managers can examine the quality of products prior to dispatching so that an optimal decision can be made. The state of quality of products can be recorded along with the data of cost, time, and emissions. Such information will offer an enabling approach to sustain the perishability and usefulness of products for customers by delivering products in optimal quality.

- The problem addressed in this study can be appealing to the underdeveloped countries where imperfect refrigeration, energy shortfall, and the inability to deliver products responsively are more pertinent issues. The model and its implications are applicable to the distribution of vaccines, ice-creams, and medicines. The vaccines in particular needs a more controlled transportation mechanism as they have a limited shelf life. A long transportation route, quality deterioration, or an imperfect refrigeration can result in the expiry of vaccines. Since the demand of vaccines for the epidemic diseases is more in the underdeveloped countries, the presented findings may assist the policy makers in assessing how quality deterioration may impact the overall costs and emissions of distribution centers.

- Managers can adapt one of the two strategies, i.e., monitoring or conformity strategy, to ensure that higher quality products reach to the customers. Adapting any of these strategies depends on the data related to cost, distance etc. Our results show that the conformity strategy is a more viable option as it results in less cost as well as it delivers all products to the destination points. Compared to it, monitoring strategy landfills the bad products which decreases the quantity of delivered products.

- The monitoring only (Mo) is an expensive strategy as it has higher transportation and penalty costs. The MC is more sensitive towards changes, as compared to the CC; however, management should pay attention towards change in the parameters of CC (as higher rate of changes can impact the decision of selecting a strategy).

- Experience shows that a product in damaged state can seldom be repaired to a state as good as new. Thus, if customer satisfaction is prioritized rather than cost, a manager may opt for monitoring strategy as it is not concerned with delivering products which have issues related to quality.

- There is more perishability if a product is in bad condition of quality. This can enhance the chances of product failure and landfilling. To avoid this, higher transportation speeds can be used for a responsive delivery. Though this practice may deliver products before large-scale quality disruptions, higher speed of delivery can cause an increase in emissions. Thus, a careful analysis of quality condition, perishability, and delivery speed is needful on the part of manager.

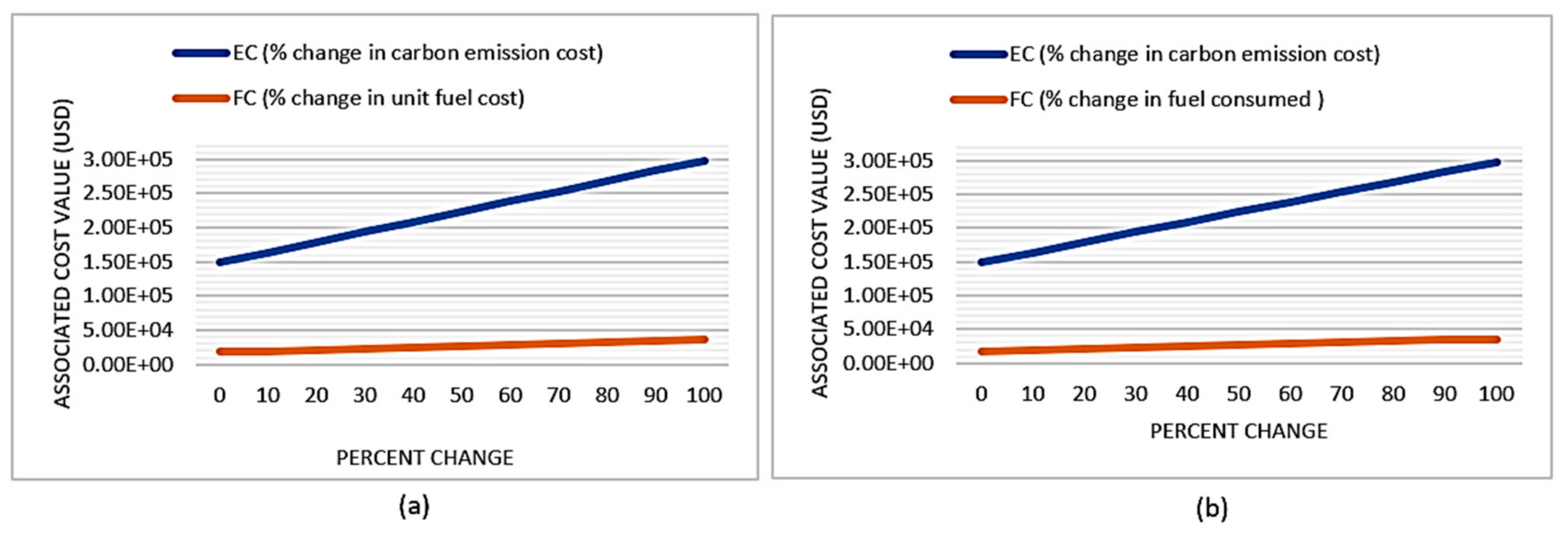

- The cost of carbon emission needs to be controlled as it impacts the objective functions of cost and emissions. The results showed that the importance of carbon emission surpassed the need to control fuel price and fuel consumption per km. However, these findings are in light of developed economies where fuel prices undergo minor revisions. A different result might be anticipated in underdeveloped economies where fuel prices undergo major revisions.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Pseudocode of SPEA-II |

| Define: Size of population, size of archive, crossover, and mutation probabilities |

| Initialize the population |

| Define an empty archive |

| For i = 1−size of population |

| Calculate the fitness function values of population and external archive |

| Copy all pareto fronts from population to archive |

| If pareto fronts > capacity of archive do |

| Perform truncation |

| Apply tournament selection and genetic operators |

| Add solutions to the external archive |

| End for |

References

- Sinha, A.K.; Verma, A.R.; Chandrakar, A.; Khes, S.P.; Panda, P.S.; Dixit, S. Evaluation of cold chain and logistics management practice in drug district of Chhattisgarh: Pointer from central India. Int. J. Community Med. Public Health 2017, 4, 390–395. [Google Scholar] [CrossRef]

- Fan, J.; Li, J.; Wu, Y.; Wang, S.; Zhao, D. The effects of allowance price on energy demand under a personal carbon trading scheme. Appl. Energy 2016, 170, 242–249. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time-Temperature Management Along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Fera, M.; Fruggiero, F.; Lambiase, A.; Macchiaroli, R.; Miranda, S. The role of uncertainty in supply chains under dynamic modeling. Int. J. Ind. Eng. Comput. 2017, 8, 119–140. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y. Optimization of Location–Routing Problem for Cold Chain Logistics Considering Carbon Footprint. Int. J. Environ. Res. Public Health 2018, 15, 86. [Google Scholar] [CrossRef] [PubMed]

- Konur, D.; Campbell, J.; Monfared, S. Economic and environmental considerations in a stochastic inventory control model with order splitting under di_erent delivery schedules among suppliers. Omega 2017, 71, 46–65. [Google Scholar] [CrossRef]

- Grace, D. Food Safety in Low and Middle Income Countries. Int. J. Environ. Res. Public Health 2015, 12, 10490–10507. [Google Scholar] [CrossRef] [PubMed]

- John, M. Top Markets Report Cold Chain; International Trade Administration, 2016. Available online: https://legacy.trade.gov/topmarkets/pdf/Cold_Chain_Executive_Summary.pdf (accessed on 18 November 2020).

- Balamurugan, T.; Karunamoorthy, L.; Arunkumar, N.; Santhosh, D. Optimization of Inventory Routing Problem to Minimize Carbon Dioxide Emission. Int. J. Simul. Model. 2018, 17, 42–54. [Google Scholar] [CrossRef]

- Ali, I.; Nagalingam, S.; Gurd, B. A resilience model for cold chain logistics of perishable products. Int. J. Logist. Manag. 2018, 29, 922–941. [Google Scholar] [CrossRef]

- Hariga, M.; As’ad, R.; Shamayleh, A. Integrated economic and environmental models for a multistage cold supply chain under carbon tax regulation. J. Clean. Prod. 2017, 166, 1357–1371. [Google Scholar] [CrossRef]

- Shamayleh, A.; Hariga, M.; As’Ad, R.; Diabat, A. Economic and environmental models for cold products with time varying demand. J. Clean. Prod. 2019, 212, 847–863. [Google Scholar] [CrossRef]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Saif, A.; Elhedhli, S. Cold supply chain design with environmental considerations: A simulation-optimization approach. Eur. J. Oper. Res. 2016, 251, 274–287. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of Vehicle Routing Problem with Time Windows for Cold Chain Logistics Based on Carbon Tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef]

- Kazemian, I.; Aref, S. A green perspective on capacitated time-dependent vehicle routing problem with time windows. Int. J. Supply Chain Inventory Manag. 2017, 2, 20–38. [Google Scholar] [CrossRef]

- Bozorgi, A.; Pazour, J.; Nazzal, D. A new inventory model for cold items that considers costs and emissions. Int. J. Prod. Econ. 2014, 155, 114–125. [Google Scholar] [CrossRef]

- Qin, G.; Tao, F.; Li, L. A Vehicle Routing Optimization Problem for Cold Chain Logistics Considering Customer Satisfaction and Carbon Emissions. Int. J. Environ. Res. Public Heal. 2019, 16, 576. [Google Scholar] [CrossRef]

- Li, Y.; Lim, M.K.; Tseng, M.-L. A green vehicle routing model based on modified particle swarm optimization for cold chain logistics. Ind. Manag. Data Syst. 2019, 119, 473–494. [Google Scholar] [CrossRef]

- Manikas, I.; Terry, L.A. A case study assessment of the operational performance of a multiple fresh produce distribution centre in the UK. Br. Food J. 2009, 111, 421–435. [Google Scholar] [CrossRef]

- Zangeneh, M.; Akram, A.; Nielsen, P.; Keyhani, A. Developing location indicators for Agricultural Service Center: A Delphi–TOPSIS–FAHP approach. Prod. Manuf. Res. 2015, 3, 124–148. [Google Scholar] [CrossRef]

- Chen, H.-K.; Hsueh, C.-F.; Chang, M.-S. Production scheduling and vehicle routing with time windows for perishable food products. Comput. Oper. Res. 2009, 36, 2311–2319. [Google Scholar] [CrossRef]

- Yi, W.-J.; Zou, L.-L.; Guo, J.; Wang, K.; Wei, Y.-M. How can China reach its CO2 intensity reduction targets by 2020? A regional allocation based on equity and development. Energy Policy 2011, 39, 2407–2415. [Google Scholar] [CrossRef]

- GhannadPour, S.F.; Noori, S.; Tavakkoli-Moghaddam, R. Multiobjective Dynamic Vehicle Routing Problem With Fuzzy Travel Times and Customers’ Satisfaction in Supply Chain Management. IEEE Trans. Eng. Manag. 2013, 60, 777–790. [Google Scholar] [CrossRef]

- Li, L.; Yang, Y.; Qin, G. Optimization of Integrated Inventory Routing Problem for Cold Chain Logistics Considering Carbon Footprint and Carbon Regulations. Sustainability 2019, 11, 4628. [Google Scholar] [CrossRef]

- Drezner, Z.; Scott, C.H. Location of a distribution center for a perishable product. Math. Methods Oper. Res. 2013, 78, 301–314. [Google Scholar] [CrossRef]

- Khan, A.S.; Pruncu, C.; Khan, R.; Naeem, K.; Ghaffar, A.; Ashraf, P.; Room, S. A Trade-Off Analysis of Economic and Environmental Aspects of a Disruption Based Closed-Loop Supply Chain Network. Sustainability 2020, 12, 7056. [Google Scholar] [CrossRef]

- Mejjaouli, S.; Babiceanu, R.F. Cold supply chain logistics: System optimization for real-time rerouting transportation solutions. Comput. Ind. 2018, 95, 68–80. [Google Scholar] [CrossRef]

- Verbič, M. Discussing the parameters of preservation of perishable goods in a cold logistic chain model. Appl. Econ. 2006, 38, 137–147. [Google Scholar] [CrossRef]

- Song, M.-X.; Li, J.-Q.; Han, Y.-Q.; Han, Y.-Y.; Liu, L.-L.; Sun, Q. Metaheuristics for solving the vehicle routing problem with the time windows and energy consumption in cold chain logistics. Appl. Soft Comput. 2020, 95, 106561. [Google Scholar] [CrossRef]

- Yan, L.; Grifoll, M.; Zheng, P. Model and Algorithm of Two-Stage Distribution Location Routing with Hard Time Window for City Cold-Chain Logistics. Appl. Sci. 2020, 10, 2564. [Google Scholar] [CrossRef]

- Qiang, X.; Appiah, M.Y.; Boateng, K.; Appiah, F.V. Route optimization cold chain logistic distribution using greedy search method. OPSEARCH 2020, 57, 1115–1130. [Google Scholar] [CrossRef]

- Wang, Z.; Wen, P. Optimization of a Low-Carbon Two-Echelon Heterogeneous-Fleet Vehicle Routing for Cold Chain Logistics under Mixed Time Window. Sustainability 2020, 12, 1967. [Google Scholar] [CrossRef]

- Zhao, B.; Gui, H.; Li, H.; Xue, J. Cold Chain Logistics Path Optimization via Improved Multi-Objective Ant Colony Algorithm. IEEE Access 2020, 8, 142977–142995. [Google Scholar] [CrossRef]

- Osvald, A.; Stirn, L.Z. A vehicle routing algorithm for the distribution of fresh vegetables and similar perishable food. J. Food Eng. 2008, 85, 285–295. [Google Scholar] [CrossRef]

- Ho, W.K.; Ang, J.C.; Lim, A. A hybrid search algorithm for the vehicle routing problem with time windows. Int. J. Artif. Intell. Tools 2001, 10, 431–449. [Google Scholar] [CrossRef]

- Zheng, G.; Liu, L.; Deng, L. Location-Routing Optimization of Cold Chain Distribution Center Based on Hybrid Genetic Algorithm—Tabu Search. In Proceedings of the 14th COTA International Conference of Transportation Professionals, Changsha, China, 4–7 July 2014. [Google Scholar]

- Wang, S.; Tao, F.; Shi, Y. Optimization of Inventory Routing Problem in Refined Oil Logistics with the Perspective of Carbon Tax. Energies 2018, 11, 1437. [Google Scholar] [CrossRef]

- Shen, L.; Tao, F.; Wang, S. Multi-Depot Incomplete Open Vehicle Routing Problem with TimeWindows Based on Carbon Trading. Int. J. Environ. Res. Public Health 2018, 15, 2025. [Google Scholar] [CrossRef]

- Wang, M.; Mao, C.; Yang, C.C. Research on cold chain logistics node location based on genetic algorithms. Sci. Technol. Manag. 2009, 11, 6. [Google Scholar]

- Holland, J.H. An efficient genetic algorithm for the traveling salesman problem. Eur. J. Oper. Res. 1975, 145, 606–617. [Google Scholar]

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A fast-elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In Proceedings of the International Conference on Parallel Problem Solving From Nature; Springer: Berlin/Heidelberg, Germany, 2000; pp. 849–858. [Google Scholar]

- Walley, N.; Whitehead, B. It’s not easy being green. Reader Bus. Environ. 1994, 36, 4. [Google Scholar]

- Hull, C.E.; Rothenberg, S. Firm performance: The interactions of corporate social performance with innovation and industry differentiation. Strat. Manag. J. 2008, 29, 781–789. [Google Scholar] [CrossRef]

- Hart, S.L. Beyond greening: Strategies for a sustainable world. Harv. Business Rev. 1997, 75, 66–77. [Google Scholar]

- Coronella, S.; Caputo, F.; Leopizzi, R.; Venturelli, A. Corporate social responsibility in Economia Aziendale scholars’ theories. Meditari Account. Res. 2018, 26, 640–656. [Google Scholar] [CrossRef]

| Ref | Year | Inspection Strategy | Emission Aspects | Product Types | Product-Quality Analysis | Vehicle Types | Cost Related to Quality | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TE | DE | Single | Multi | Ho | He | PC | IC | ||||

| Verbic et al. [29] | 2006 | ✓ | |||||||||

| Wang et al. [15] | 2018 | ✓ | ✓ | ✓ | |||||||

| Mejjaouli et al. [28] | 2018 | ✓ | ✓ | ✓ | |||||||

| Qin et al. [18] | 2019 | ✓ | ✓ | ✓ | |||||||

| Li et al. [19] | 2019 | ✓ | ✓ | ✓ | |||||||

| Li et al. [25] | 2019 | ✓ | ✓ | ||||||||

| Song et al. [30] | 2020 | ✓ | |||||||||

| Yan et al. [31] | 2020 | ✓ | ✓ | ✓ | |||||||

| Qiang et al. [32] | 2020 | ✓ | ✓ | ||||||||

| Wang et al. [33] | 2020 | ✓ | ✓ | ✓ | ✓ | ||||||

| Zhao et al. [34] | 2020 | ✓ | ✓ | ✓ | |||||||

| Customer Location | Vehicle Type | Product Type | Size of Product Regarding Box Capacity | Demand | Time Window | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| K1 | K2 | P1 | P2 | P3 | P1 | P2 | P3 | P1 | P2 | P3 | [Eij Lij] | |

| J1 | 0 | 1 | 1 | 0 | 0 | 0.51 | 0.42 | 0.36 | 250 | 0 | 0 | [07:10, 09:30] |

| J2 | 1 | 1 | 0 | 1 | 1 | 0 | 300 | 180 | [06:45, 10:00] | |||

| J3 | 1 | 0 | 1 | 0 | 1 | 200 | 0 | 220 | [07:00, 09:45] | |||

| J4 | 1 | 0 | 1 | 1 | 0 | 150 | 200 | 0 | [08:10, 10:20] | |||

| J5 | 0 | 1 | 0 | 1 | 0 | 0 | 265 | 0 | [07:20, 10:30] | |||

| Notation | Description |

|---|---|

| set of product types | |

| set of distribution facilities | |

| set of demand locations | |

| set of available trucks | |

| set of packaging boxes | |

| distance between distribution point i and demand location j | |

| capacity of distribution point for product p | |

| cost of using truck k | |

| conformity cost of product p | |

| transportation cost of truck k per unit distance covered | |

| exploitation cost of driver | |

| transportation cost per unit product p to landfilling point | |

| penalty cost of landfilled product | |

| fixed cost of monitoring | |

| variable cost of monitoring per km | |

| unit cost of emissions generated by truck k per km | |

| waiting cost per box b if truck k arrives in advance | |

| penalty cost per box b if truck k arrives beyond its scheduled time | |

| unloading time of product p at location j | |

| time window for delivery to location j | |

| arrival time of truck k at demand location j | |

| capacity of truck k | |

| capacity of box b | |

| size of product p | |

| demand of product p at location j | |

| probability of failure of product p due to spoilage and quality condition | |

| spoilage rate of product p during transportation | |

| quality condition of product p | |

| emissions generated by truck k per km | |

| emissions generated by product p due to spoilage | |

| emissions due to unloading per min | |

| unit-fuel cost | |

| fuel consumed by truck k per km | |

| emissions due to waiting per min | |

| vehicle speed between points i and j | |

| 1, if inspection is adopted for box b | |

| 1, if product p is needed at demand location j | |

| 1, if truck k is used for delivering product p to location j from i else 0 | |

| number of boxes used between i and j | |

| 1, if monitoring strategy is adopted for box b of truck k else 0 | |

| 1, if conformity strategy is adopted for box b of truck k else 0 | |

| number of trucks k used for delivering products to location j | |

| number of landfilled products |

| General Form | Equations (2), (3), and (7)–(9) | Equations (3) and (4) |

|---|---|---|

| J | Product Type | Demand | x-Coordinate | y-Coordinate | Time Window | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | ||||

| 1 | 1 | 0 | 0 | 1 | 140 | 0 | 0 | 200 | 235.2 | 165.4 | 08:30–11:45 |

| 2 | 0 | 1 | 0 | 0 | 0 | 300 | 0 | 0 | 168.7 | 320.3 | 08:00–10:55 |

| 3 | 0 | 0 | 1 | 1 | 0 | 0 | 185 | 250 | 155.3 | 185.9 | 07:30–09:50 |

| 4 | 1 | 0 | 0 | 1 | 200 | 0 | 0 | 225 | 212.2 | 286.4 | 07:00–10:00 |

| 5 | 0 | 1 | 1 | 0 | 0 | 170 | 260 | 0 | 356.0 | 307.2 | 08:15–10:55 |

| 6 | 1 | 0 | 1 | 1 | 320 | 0 | 250 | 190 | 210.6 | 190.6 | 07:30–10:00 |

| 7 | 1 | 1 | 0 | 0 | 200 | 200 | 0 | 0 | 337.6 | 284.7 | 07:40–10:00 |

| 8 | 1 | 0 | 0 | 1 | 155 | 0 | 0 | 0 | 205.5 | 120.6 | 08:30–10:45 |

| 9 | 0 | 1 | 1 | 1 | 0 | 260 | 180 | 200 | 265.3 | 410.2 | 07:30–10:20 |

| 10 | 1 | 1 | 0 | 1 | 175 | 300 | 0 | 245 | 340.7 | 245.4 | 08:45–11:00 |

| 11 | 1 | 1 | 0 | 0 | 230 | 305 | 0 | 0 | 189.3 | 365.8 | 08:30–11:00 |

| 12 | 1 | 0 | 0 | 1 | 200 | 0 | 0 | 160 | 306.6 | 272.7 | 08:30–11:40 |

| 13 | 1 | 1 | 1 | 0 | 220 | 160 | 275 | 0 | 200.4 | 348.6 | 08:00–10:45 |

| 14 | 0 | 1 | 0 | 1 | 0 | 185 | 0 | 300 | 175.3 | 320.3 | 07:30–10:50 |

| 15 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 155 | 256.1 | 198.2 | 08:45–11:10 |

| 16 | 1 | 1 | 0 | 1 | 250 | 175 | 0 | 200 | 285.4 | 375.5 | 07:30–11:00 |

| 17 | 1 | 0 | 0 | 1 | 140 | 0 | 0 | 180 | 175.8 | 342.6 | 08:55–11:25 |

| 18 | 1 | 1 | 0 | 0 | 165 | 290 | 0 | 0 | 130.4 | 280.6 | 08:00–10:35 |

| 19 | 1 | 0 | 0 | 1 | 200 | 0 | 0 | 245 | 270.6 | 312.1 | 07:20–09:50 |

| 20 | 1 | 0 | 0 | 0 | 280 | 0 | 0 | 0 | 345.3 | 176.2 | 07:50–10:45 |

| 21 | 0 | 1 | 0 | 1 | 0 | 250 | 0 | 160 | 435.4 | 294.7 | 08:20–10:35 |

| 22 | 1 | 0 | 1 | 1 | 155 | 0 | 305 | 185 | 234.7 | 137.5 | 08:00–10:40 |

| 23 | 1 | 1 | 0 | 0 | 200 | 260 | 0 | 0 | 210.9 | 248.3 | 09:00–11:30 |

| 24 | 1 | 1 | 1 | 1 | 330 | 165 | 150 | 240 | 356.5 | 250.7 | 07:40–10:00 |

| 25 | 1 | 0 | 0 | 1 | 265 | 0 | 0 | 250 | 268.7 | 182.4 | 08:40–11:15 |

| S. No | Distribution Point | x-Coordinate | y-Coordinate | Capacity Regarding Products |

|---|---|---|---|---|

| 1 | I1 | 220.5 | 355.4 | (1300, 940, 600, 1450) |

| 2 | I2 | 355.2 | 170.6 | (1550, 1000, 750, 1100) |

| 3 | I3 | 245.7 | 180.3 | (1180, 1130, 500, 1350) |

| 4 | I4 | 140.6 | 430.8 | (1850, 870, 570, 1200) |

| 5 | I5 | 320.6 | 280.5 | (1400, 1000, 700, 1600) |

| Vehicle Type | Max. Capacity (Boxes) | Fuel Consumption (L/km) | Coefficient of Emission (Kg/L) |

|---|---|---|---|

| K1 | 200 | 0.18 | 3.3 |

| K2 | 240 | 0.24 | 3.44 |

| K3 | 265 | 0.36 | 4.2 |

| Value | Value | Value | |||

|---|---|---|---|---|---|

| ($2/p, $3.5/p, $5/p, $6.5/p) | $0.2/km | (0.18, 0.27, 0.48, 0.63) | |||

| $1/km | $2.4/box | (0.92, 0.86, 0.79, 0.60) | |||

| $150 | $3.8 | 0.76/km | |||

| $7/product | 0.7min/product | 0.26/product | |||

| $35/product | 60 boxes | 0.274/min | |||

| $80 | 0.125 m3 | 0.162/min | |||

| $0.0025/km | (0.005 m3,0.00625 m3,0.008 m3,0.013 m3) | 40 km/h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.S.; Salah, B.; Zimon, D.; Ikram, M.; Khan, R.; Pruncu, C.I. A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach. Energies 2020, 13, 6612. https://doi.org/10.3390/en13246612

Khan AS, Salah B, Zimon D, Ikram M, Khan R, Pruncu CI. A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach. Energies. 2020; 13(24):6612. https://doi.org/10.3390/en13246612

Chicago/Turabian StyleKhan, Abdul Salam, Bashir Salah, Dominik Zimon, Muhammad Ikram, Razaullah Khan, and Catalin I. Pruncu. 2020. "A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach" Energies 13, no. 24: 6612. https://doi.org/10.3390/en13246612

APA StyleKhan, A. S., Salah, B., Zimon, D., Ikram, M., Khan, R., & Pruncu, C. I. (2020). A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach. Energies, 13(24), 6612. https://doi.org/10.3390/en13246612