Performance and Exhaust Emissions of a Gas-Turbine Engine Fueled with Biojet/Jet A-1 Blends for the Development of Aviation Biofuel in Tropical Regions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

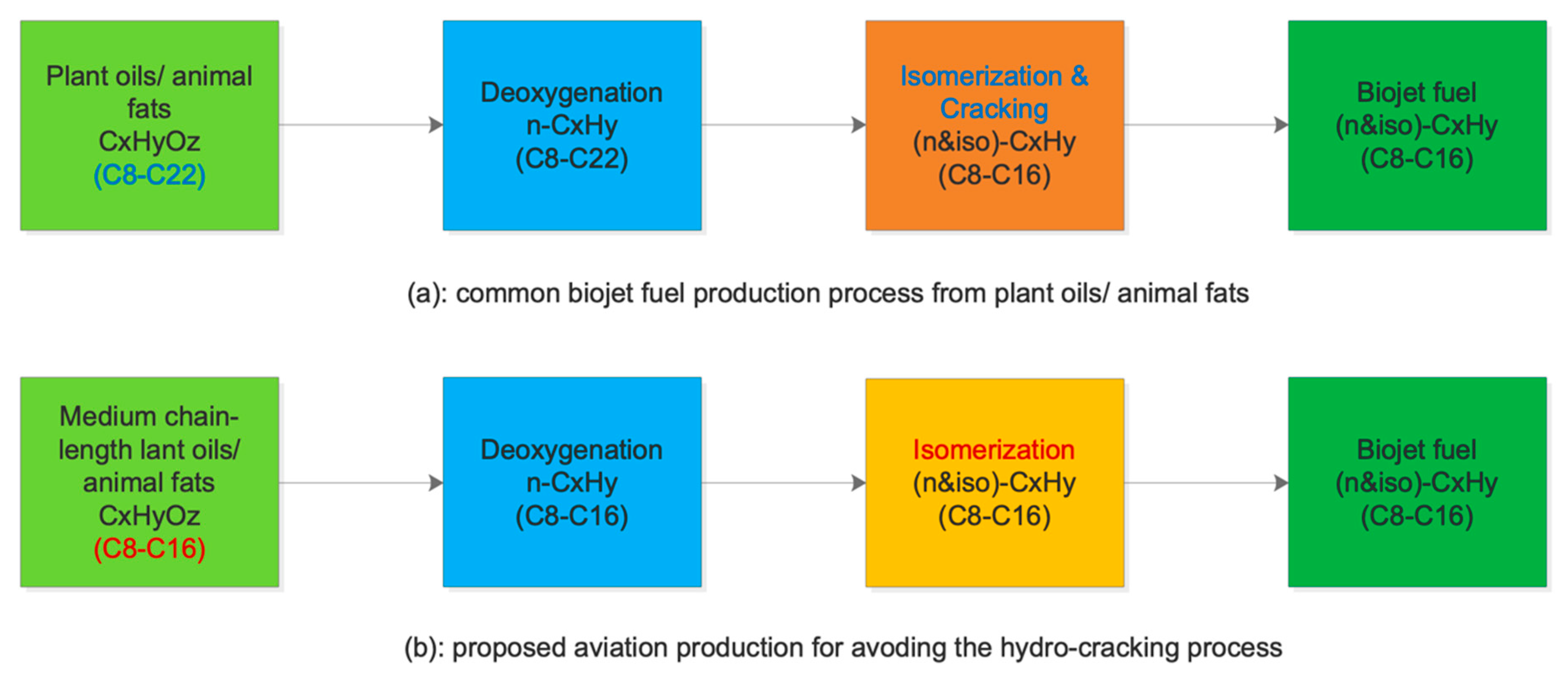

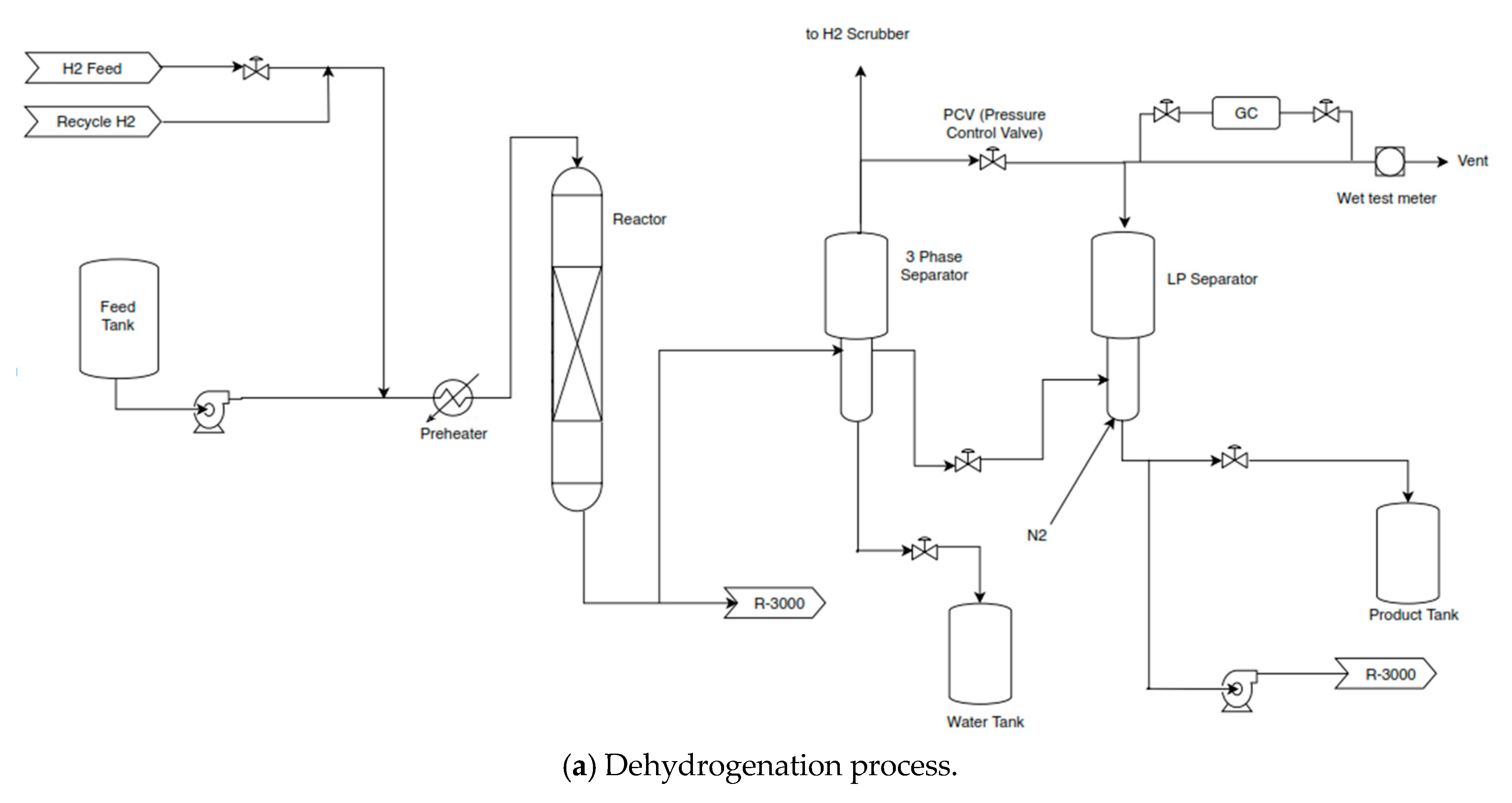

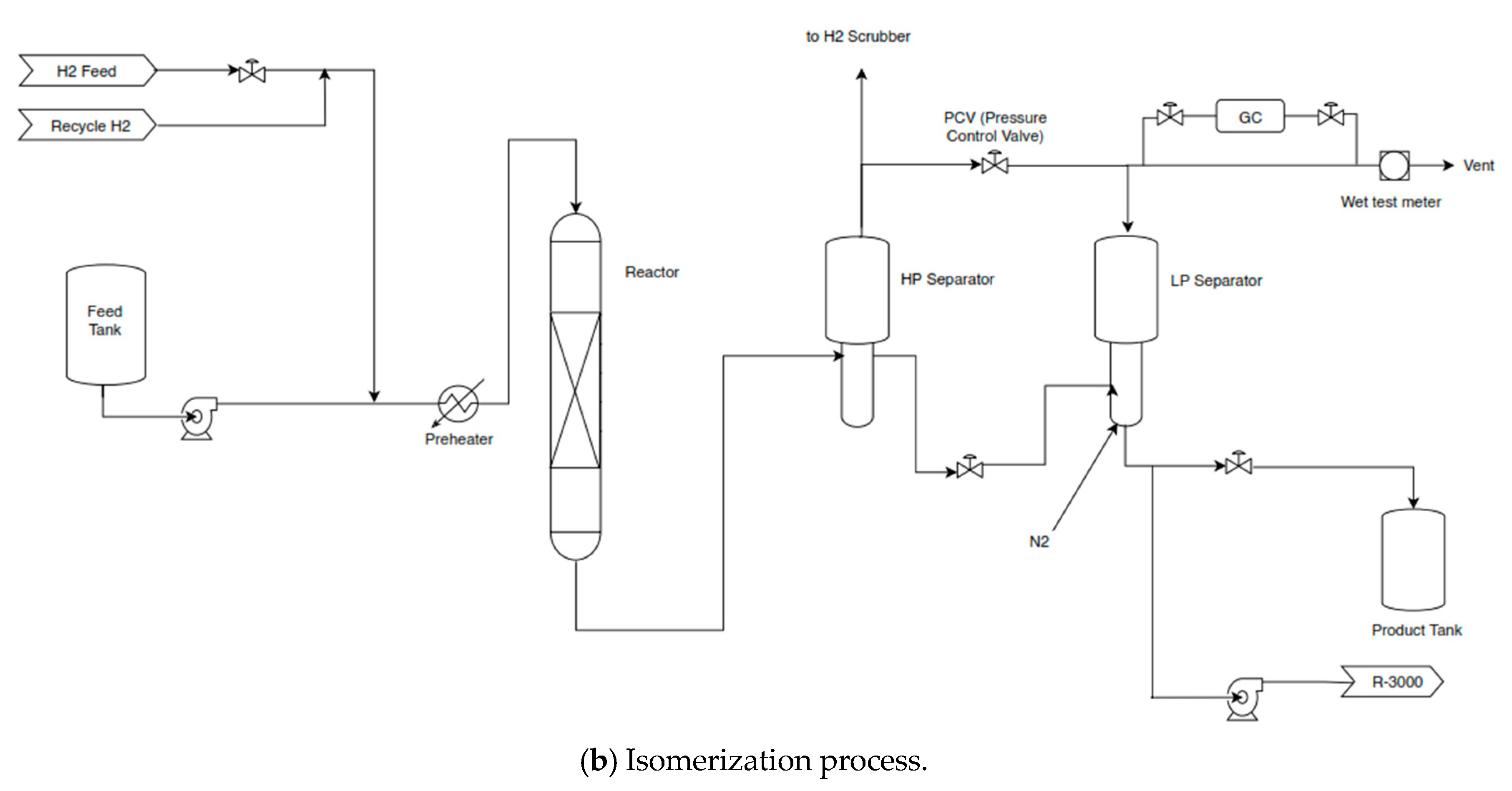

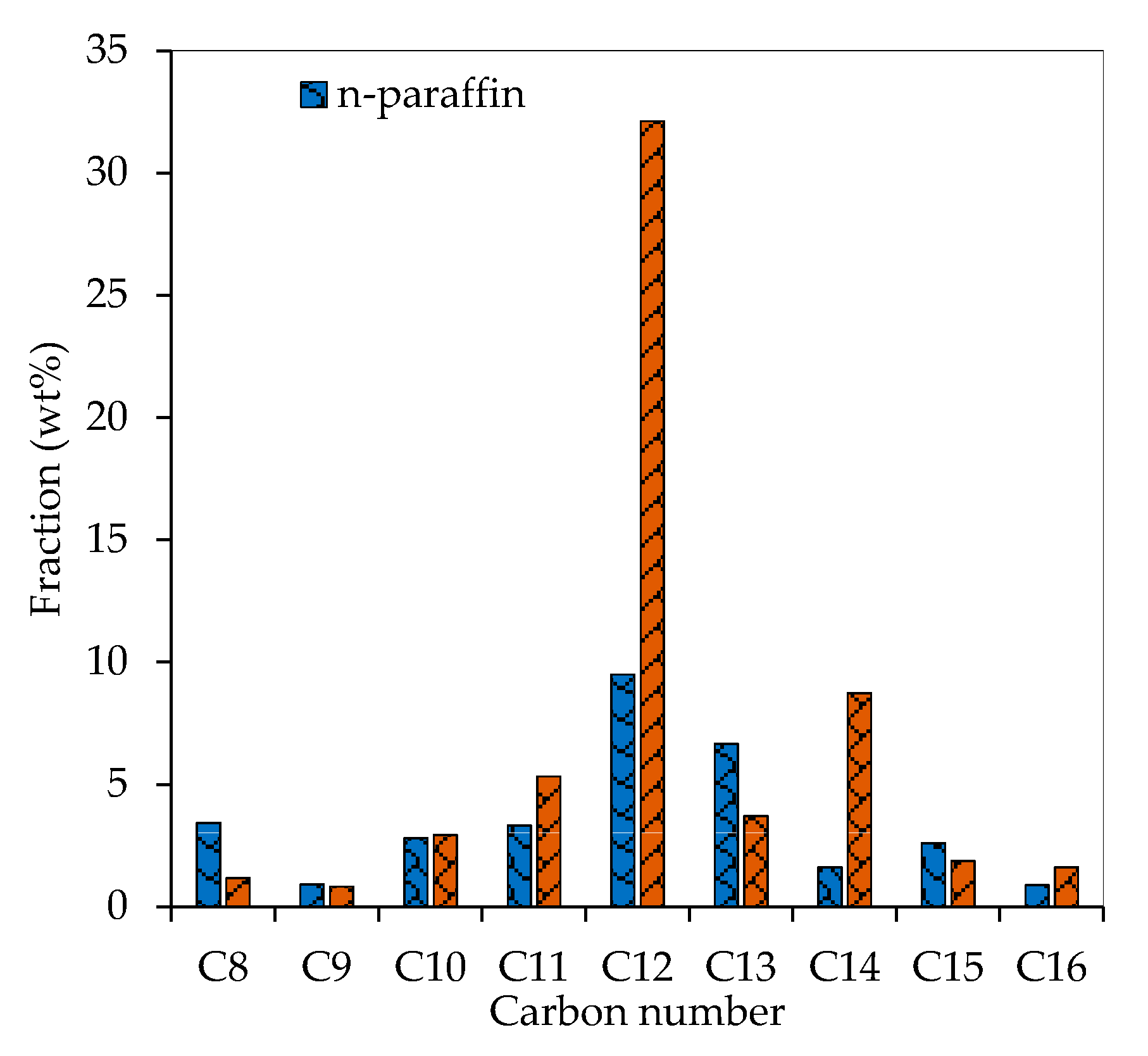

2.2. Production Process

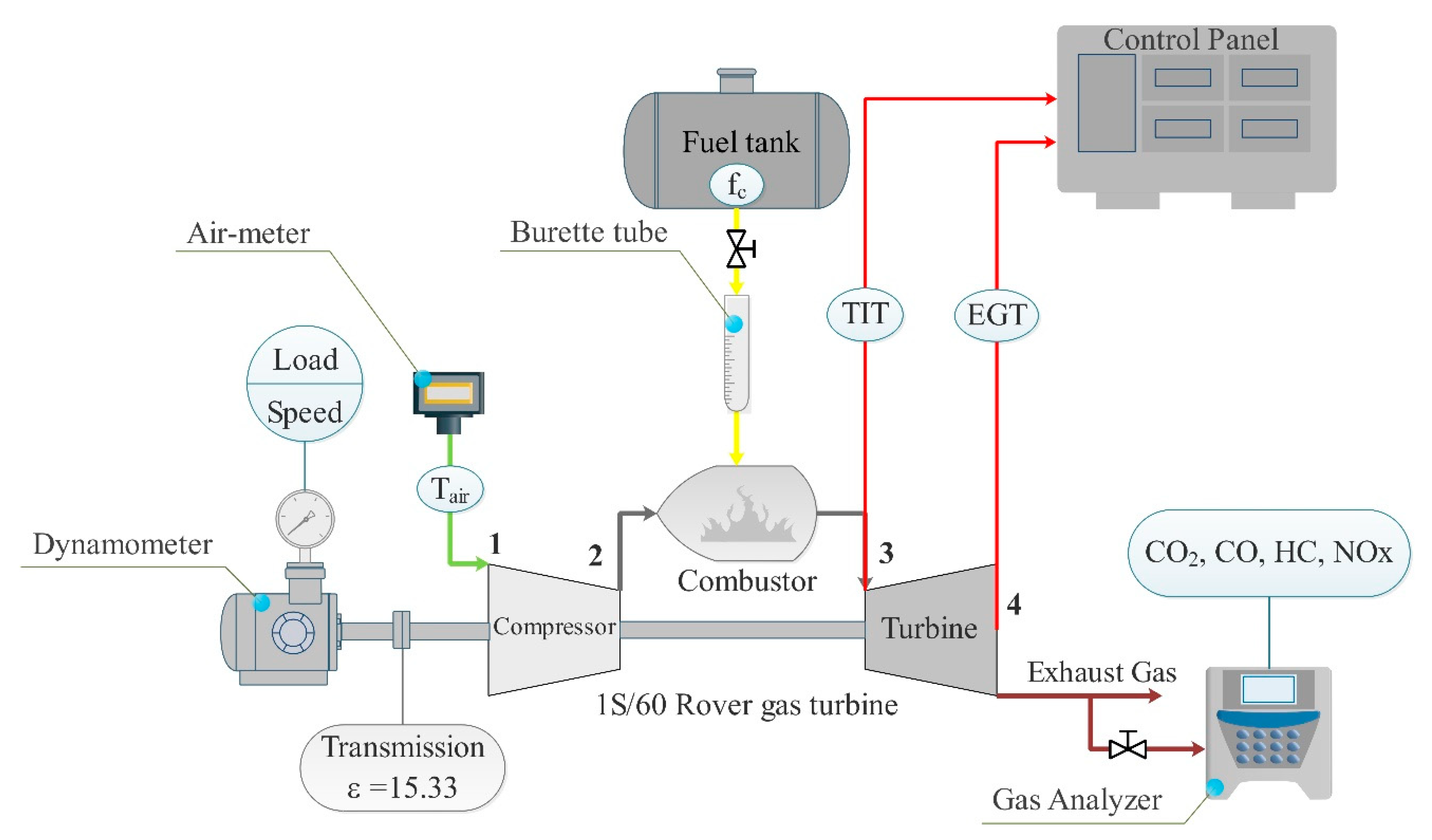

2.3. Experiment Setup

3. Results and Discussion

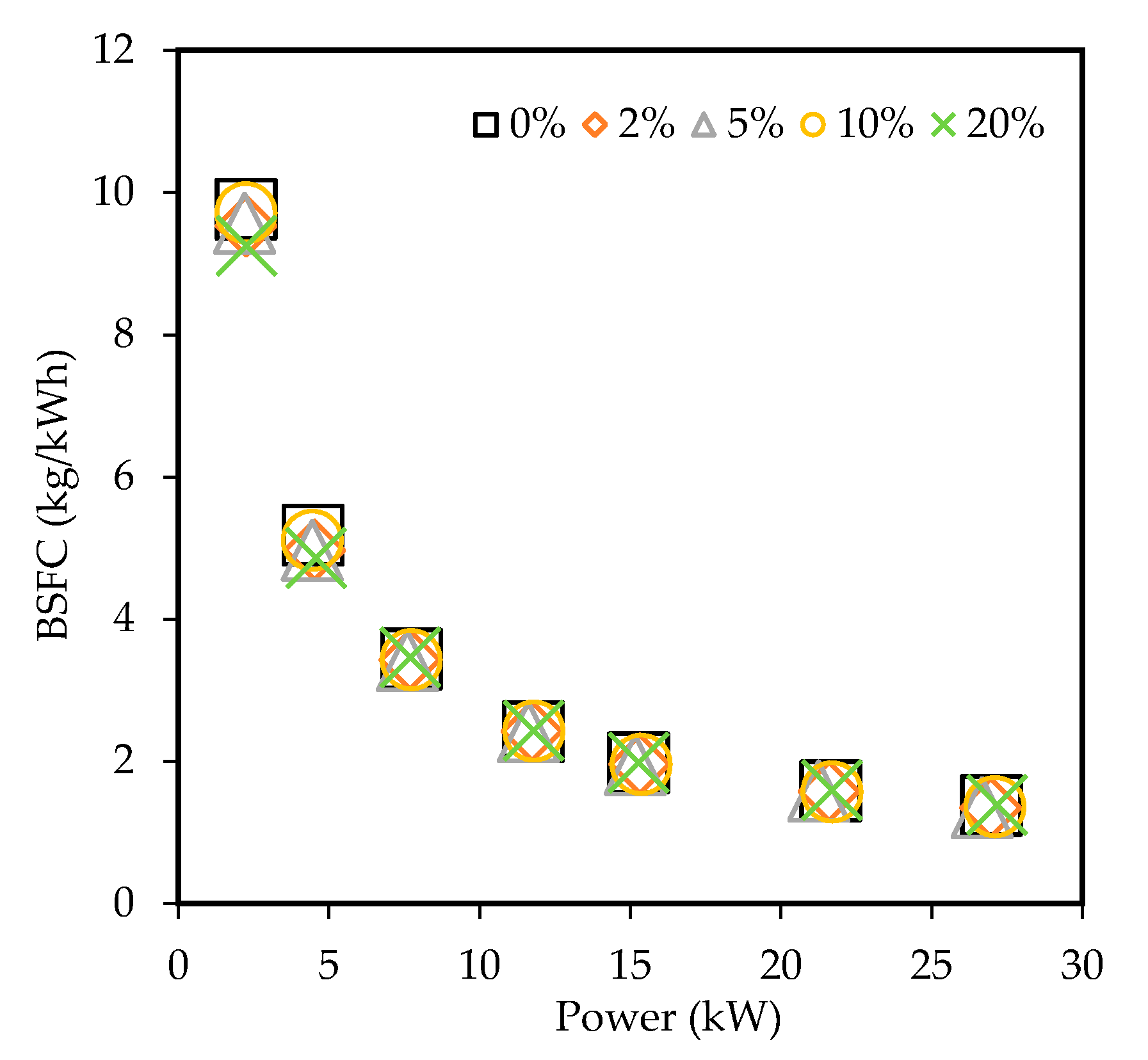

3.1. Performance Parameters

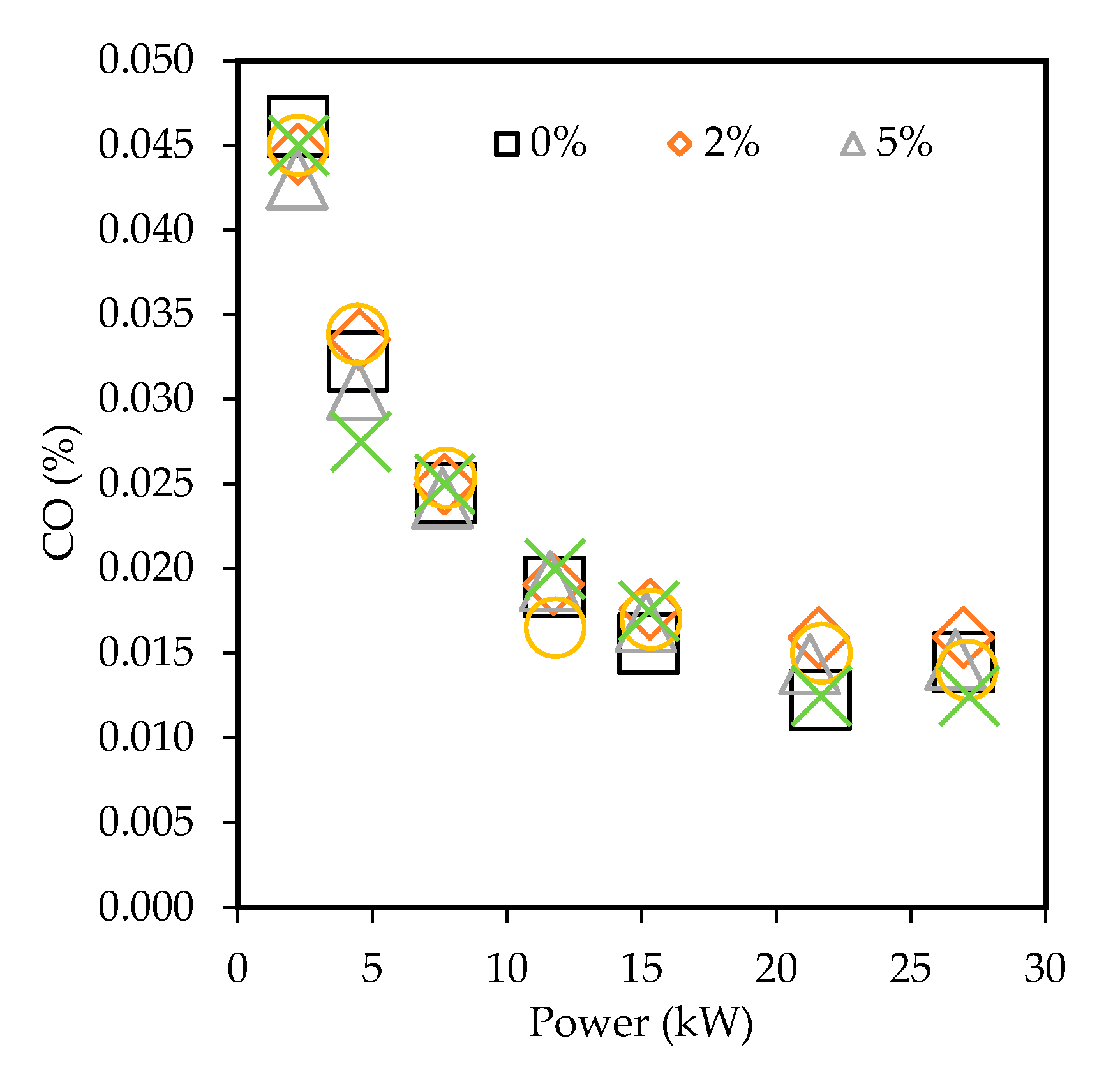

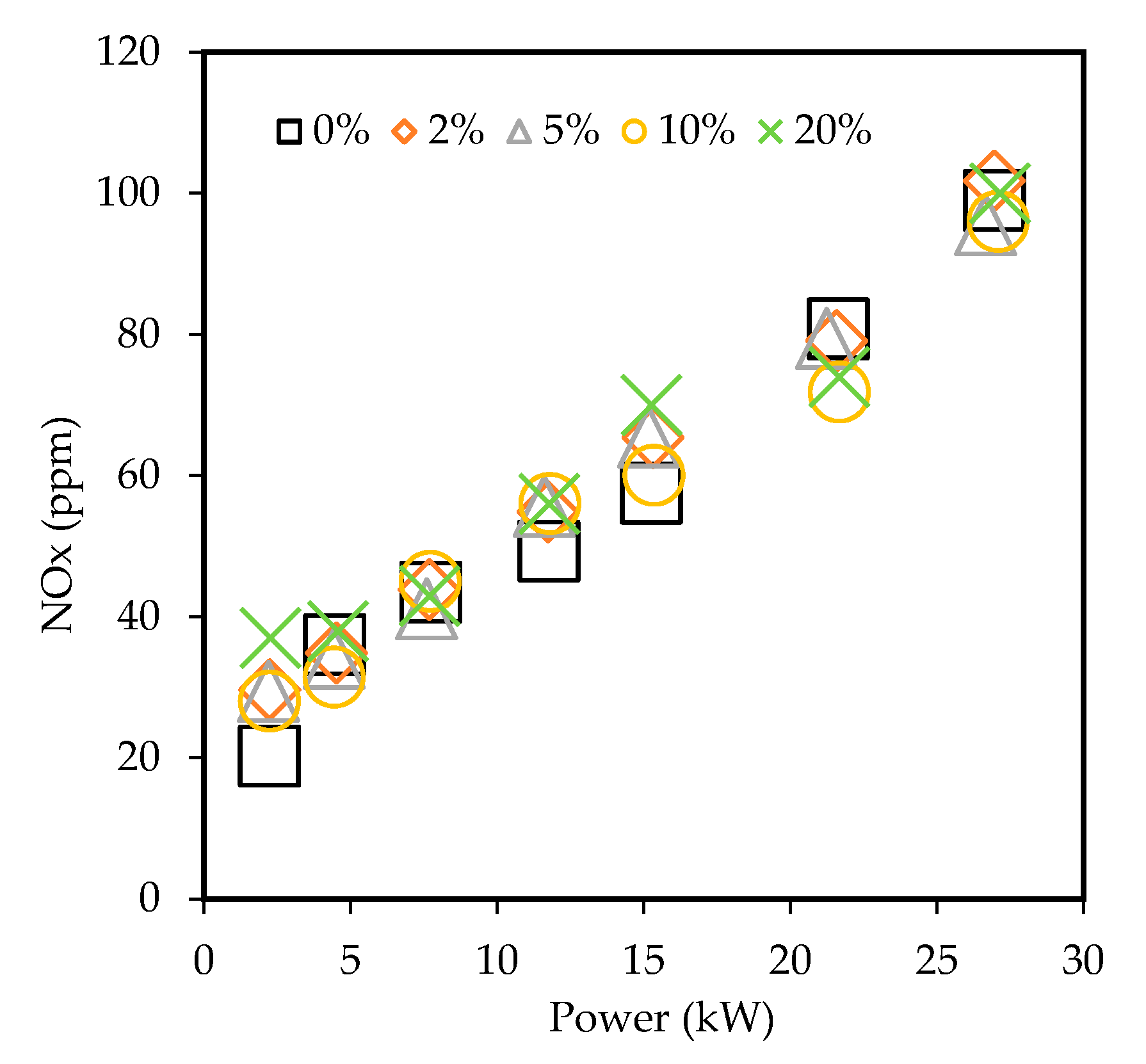

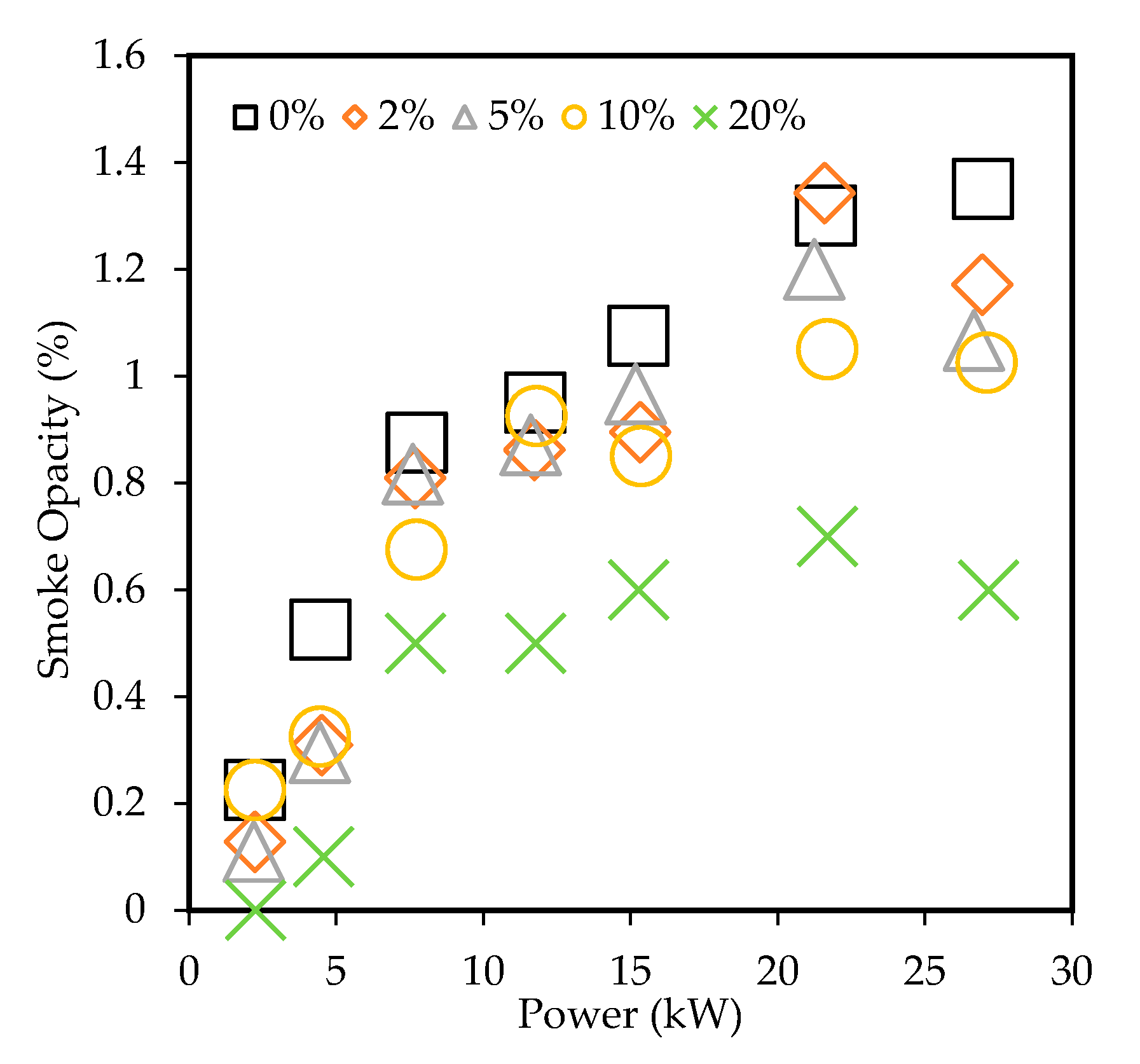

3.2. Exhaust-Gas Emissions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Air Transport Association. IATA Economic Briefing: Airline Fuel and Labour Cost Share; International Air Transport Association: Geneva, Switzerland, February 2010. [Google Scholar]

- European Directive 2008/101/CE on Aviation Gas Emission; Official Journal of the European Union: Strasbourg, France, 2009.

- International Air Transport Association. IATA 2014 Report on Alternative Fuels; International Air Transport Association: Montreal, Geneva, December 2014. [Google Scholar]

- ATAG. Beginner’s Guide to Aviation Biofuels; Air Transport Action Group: Geneva, Switzerland, May 2009. [Google Scholar]

- Gupta, K.; Rehman, A.; Sarviya, R. Bio-fuels for the gas turbine: A review. Renew. Sustain. Energy Rev. 2010, 14, 2946–2955. [Google Scholar] [CrossRef]

- Blakey, S.; Rye, L.; Wilson, C.W. Aviation gas turbine alternative fuels: A review. Proc. Combust. Inst. 2011, 33, 2863–2885. [Google Scholar] [CrossRef]

- Timko, M.T.; Herndon, S.C.; Blanco, E.D.L.R.; Wood, E.C.; Yu, Z.; Miake-Lye, R.C.; Knighton, W.B.; Shafer, L.; DeWitt, M.J.; Corporan, E. Combustion Products of Petroleum Jet Fuel, a Fischer–Tropsch Synthetic Fuel, and a Biomass Fatty Acid Methyl Ester Fuel for a Gas Turbine Engine. Combust. Sci. Technol. 2011, 183, 1039–1068. [Google Scholar] [CrossRef]

- Corporan, E.; DeWitt, M.J.; Klingshirn, C.D.; Anneken, D.; Shafer, L.; Streibich, R. Comparisons of emissions characteristics of several turbine engines burning Fischer-Tropsch and hydroprocessed esters and fatty acids alternative Jet fuels. In Proceedings of the InASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11 June 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 425–436. [Google Scholar]

- Klingshirn, C.D.; DeWitt, M.; Striebich, R.; Anneken, D.; Shafer, L.; Corporan, E.; Wagner, M.; Brigalli, D. Hydroprocessed Renewable Jet Fuel Evaluation, Performance, and Emissions in a T63 Turbine Engine. J. Eng. Gas Turbines Power 2012, 134, 051506. [Google Scholar] [CrossRef]

- Lobo, P.; Christie, S.; Khandelwal, B.; Blakey, S.G.; Raper, D.W. Evaluation of Non-volatile Particulate Matter Emission Characteristics of an Aircraft Auxiliary Power Unit with Varying Alternative Jet Fuel Blend Ratios. Energy Fuels 2015, 29, 7705–7711. [Google Scholar] [CrossRef]

- Sundararaj, R.H.; Kumar, R.D.; Raut, A.K.; Sekar, T.C.; Pandey, V.; Kushari, A.; Puri, S. Combustion and emission characteristics from biojet fuel blends in a gas turbine combustor. Energy 2019, 182, 689–705. [Google Scholar] [CrossRef]

- ASTM D7566-20. Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Hong, T.D.; Soerawidjaja, T.H.; Reksowardojo, I.K.; Fujita, O.; Duniani, Z.; Pham, M.X. A study on developing aviation biofuel for the Tropics: Production process—Experimental and theoretical evaluation of their blends with fossil kerosene. Chem. Eng. Process. Process. Intensif. 2013, 74, 124–130. [Google Scholar] [CrossRef]

- Mahlia, T.; Abdulmuin, M.; Alamsyah, T.; Mukhlishien, D. An alternative energy source from palm wastes industry for Malaysia and Indonesia. Energy Convers. Manag. 2001, 42, 2109–2118. [Google Scholar] [CrossRef]

- Brunerová, A.; Muller, M.; Šleger, V.; Ambarita, H.; Valášek, P. Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing. Sustainability 2018, 10, 4443. [Google Scholar] [CrossRef]

- Abdullah, N.; Gerhauser, H.; Sulaiman, F. Fast pyrolysis of empty fruit bunches. Fuel 2010, 89, 2166–2169. [Google Scholar] [CrossRef]

- Omar, R.; Idris, A.; Yunus, R.; Khalid, K.; Isma, M.A. Characterization of empty fruit bunch for microwave-assisted pyrolysis. Fuel 2011, 90, 1536–1544. [Google Scholar] [CrossRef]

- Palamae, S.; Dechatiwongse, P.; Choorit, W.; Chisti, Y.; Prasertsan, P. Cellulose and hemicellulose recovery from oil palm empty fruit bunch (EFB) fibers and production of sugars from the fibers. Carbohydr. Polym. 2017, 155, 491–497. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.P.S.A.; Alwani, M.S.; Ridzuan, R.; Kamarudin, H.; Khairul, A. Chemical Composition, Morphological Characteristics, and Cell Wall Structure of Malaysian Oil Palm Fibers. Polym. Technol. Eng. 2008, 47, 273–280. [Google Scholar] [CrossRef]

- Shinoj, S.; Visvanathan, R.; Panigrahi, S.; Kochubabu, M. Oil palm fiber (OPF) and its composites: A review. Ind. Crop. Prod. 2011, 33, 7–22. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Knothe, G.; Gerpen, J.V.; Krahl, J. The Biodiesel Handbook; AOCS Press: Cham-paign, Switzerland; Urbana, IL, USA, 2015. [Google Scholar]

- Vieira, B.M.; Elicker, C.; Nunes, C.F.P.; Bairros, A.V.; Becker, E.M.; De Oliveira, D.M.; Piva, E.; Fontoura, L.A.; De Pereira, C.M.P. The synthesis and characterization of Butia capitata seed oil as a FAME feedstock. Fuel 2016, 184, 533–535. [Google Scholar] [CrossRef]

- Silva, L.N.; Cardoso, C.C.; Pasa, V.M. Synthesis and characterization of esters from different alcohols using Macauba almond oil to substitute diesel oil and jet fuel. Fuel 2016, 166, 453–460. [Google Scholar] [CrossRef]

- ASTM D4054-19. Standard Practice for Evaluation of New Aviation Turbine Fuels and Fuel Additives; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Duong, L.; Reksowardojo, I.K.; Soerawidjaja, T.H.; Fujita, O.; Neonufa, G.F.; Nguyen, T.T.; Prakoso, T. Soap-derived biokerosene as an aviation alternative fuel: Production, composition, and properties of various blends with jet fuel. Chem. Eng. Process. Process. Intensif. 2020, 153, 107980. [Google Scholar] [CrossRef]

- Bahr, D.W.; Lefebvre, A.H.; Ballal, D.R. GAS TURBINE COMBUSTION—Alternative Fuels and Emissions. J. Eng. Gas Turbines Power 2010, 132, 116501. [Google Scholar] [CrossRef]

- Aviation Fuels Technical Review; Chevron Texaco Corporation: Houston, TX, USA, 2008.

- The Coordinating Research Council, Inc. Handbook of aviation fuel properties. In Society of Automotive Engineers Publications Department 400 Commonwealth Drive Warrendale, 3rd ed.; The Coordinating Research Council, Inc.: West Conshohocken, PA, USA, 2004; pp. 1–6. [Google Scholar]

- Duong, L.; Fujita, O.; Reksowardojo, I.K.; Soerawidjaja, T.H.; Neonufa, G. Experimental investigation of the effects of cycloparaffins and aromatics on the sooting tendency and the freezing point of soap-derived biokerosene and normal paraffins. Fuel 2016, 185, 855–862. [Google Scholar] [CrossRef]

- ASTM D1655-19a. Standard Specification for Aviation Turbine Fuels; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Reksowardojo, I.K.; Duong, L.; Soerawidjaja, T.H.; Nguyen, T.T.; Fujita, O.; Neonufa, G.F. Performance and Emission Characteristics of a Gas Turbine Engine Burning Soap-Derived Biokerosene/Jet A-1 Blends. SAE Int. J. Fuels Lubr. 2020, 13, 04-13-02-0007. [Google Scholar] [CrossRef]

- Calcote, H.; Manos, D. Effect of molecular structure on incipient soot formation. Combust. Flame 1983, 49, 289–304. [Google Scholar] [CrossRef]

- Olson, D.; Pickens, J.; Gill, R. The effects of molecular structure on soot formation II. Diffusion flames. Combust. Flame 1985, 62, 43–60. [Google Scholar] [CrossRef]

- Duong, L.; Reksowardojo, I.K.; Soerawidjaja, T.H.; Pham, D.N.; Fujita, O. The sooting tendency of aviation biofuels and jet range paraffins: Effects of adding aromatics, carbon chain length of normal paraffins, and fraction of branched paraffins. Combust. Sci. Technol. 2018, 190, 1710–1721. [Google Scholar] [CrossRef]

- Rahmes, T.; Kinder, J.; Crenfeldt, G.; LeDuc, G.; Abe, Y.; McCall, M.; Henry, T.; Zombanakis, G.; Lambert, D.; Lewis, C.; et al. Sustainable Bio-Derived Synthetic Paraffinic Kerosene (Bio-SPK) Jet Fuel Flights and Engine Tests Program Results. In Proceedings of the 9th AIAA Aviation Technology, Integration, and Operations Conference (ATIO); American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2009; p. 7002. [Google Scholar]

- Lobo, P.; Hagen, D.E.; Whitefield, P.D. Comparison of PM Emissions from a Commercial Jet Engine Burning Conventional, Biomass, and Fischer–Tropsch Fuels. Environ. Sci. Technol. 2011, 45, 10744–10749. [Google Scholar] [CrossRef]

- Runyon, J.; Valera-Medina, A.; Marsh, R.; Pugh, D.; Giles, A.; Runyon, J.; Chiaramonti, D. Emissions characterization tests for hydrotreated renewable jet fuel from used cooking oil and its blends. Appl. Energy 2017, 201, 84–93. [Google Scholar] [CrossRef]

| Oil | Fatty Acid Composition (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 8:0 | 10:0 | 12:0 | 14:0 | 16:0 | 18:0 | 18:1 | 18:2 | 18:3 | |

| Coconut oil [21] | 5–9 | 4–6 | 42–53 | 17–20 | 7–11 | 2–3 | 5–9 | 1–4 | 0–0.2 |

| Palm kernel [21] | 3–5 | 3–6 | 48–55 | 12–19 | 3–8 | 4–8 | 15–21 | 0.5 | - |

| Babassu [21,22] | 4–6 | 6–8 | 44–48 | 15–20 | 5–11 | 3–6 | 10–16 | 1–3 | - |

| Butia capitata [23] | 8 | 11 | 39 | 8 | 5 | 2 | 21 | 5 | - |

| Macauba [24] | 3 | 3 | 33 | 10 | 10 | 2 | 33 | 4 | - |

| Fatty Acid Carbon Chain | <C8:0 | C8:0 | C10:0 | C12:0 | C14:0 | C16:0 | C18:0 | C18:1 | C18:2 | C18:3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (wt%) | 0.5 | 7.8 | 6.7 | 47.5 | 18.1 | 8.8 | 2.6 | 6.2 | 1.6 | 0.2 |

| Property | Test Method | ASTM D1655 | Jet A-1 (J0) | J2 | J5 | J10 | J20 | MBJ (J100) |

|---|---|---|---|---|---|---|---|---|

| Density at 15 °C, kg/m3 | ASTM D4052 | 775–840 | 804.0 | 802.4 | 801.3 | 797.8 | 792.1 | 756.1 |

| Viscosity at −20 °C, mm2/s | ASTM D445 | Max 8.0 | 3.953 | 3.955 | 3.942 | 3.938 | 3.921 | 3.777 |

| Low heating value, MJ/kg | ASTM D4809 | Min 42.8 | 43.2 | 43.23 | 43.24 | 43.26 | 43.32 | 43.9 |

| Smoke point, mm | ASTM D1322 | Min 25.0 | 20.0 | 20.2 | 20.7 | 21.9 | 23.5 | 53.7 |

| Naphthalene, % v/v | ASTM D1840 | Max 3 | 2.0 | - | - | - | - | - |

| Freezing point, °C | ASTM D2386 | Max −47 | −51.0 | −51.1 | −51.1 | −51.2 | −51.3 | −53.0 |

| Flash point, °C | ASTM D56 | Min 38 | 41 | 40.7 | 40.5 | 40.4 | 40.1 | 36 |

| Aromatics, % v/v | ASTM D1319 | Max 25 | 19.5 | - | - | - | - | - |

| Total sulfur, % m/m | ASTM D4294 | Max 0.3 | 0.06 | - | - | - | - | 0.0037 |

| Engine Type | 1S/60 Type 08 |

|---|---|

| Compressor | Single stage centrifugal |

| Turbine | Single stage axial |

| Combustion chamber | Reverse flow |

| Governed speed | 46,000 rpm |

| Maximal fuel consumption | 0.635 kg/kWh |

| Maximal air mass flow | 0.603 kg/s |

| Average air/fuel ratio | 50:1 |

| Pressure ratio | 2.8:1 |

| Maximal continuous jet-pipe temperature | 580 °C (1076 °F) |

| Maximal oil temperature | 110 °C (230 °F) |

| Apparatus | Measurement | Range | Accuracy |

|---|---|---|---|

| Tachometer | Brake speed | 0–5000 rpm | ±50 rpm |

| Spring balance | Load | 0–50 lb | ±2 lb |

| TIT indicator | Turbine inlet temperature (TIT) | 300–900 °C | ±10 °C |

| EGT indicator | Exhaust gas temperature (EGT) | 250–620 °C | ±10 °C |

| Flask tube | Fuel measurement | 0–2000 mL | ±2 mL |

| Digital stopwatch | Time-measured fuel consumption | 0–99 min | ±0.01 s |

| Manometer | Pressure | −380–380 mm | ±1 mm |

| SPTC autocheck gas analyzer | Unburnt hydrocarbon | 0–60,000 ppm | ±1 ppm |

| Nitrogen oxide | 0–5000 ppm | ±1 ppm | |

| Carbon oxide | 0–10% | ±0.001% | |

| Carbon dioxide | 0–20% | ±0.01% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reksowardojo, I.K.; Duong, L.H.; Zain, R.; Hartono, F.; Marno, S.; Rustyawan, W.; Putri, N.; Jatiwiramurti, W.; Prabowo, B. Performance and Exhaust Emissions of a Gas-Turbine Engine Fueled with Biojet/Jet A-1 Blends for the Development of Aviation Biofuel in Tropical Regions. Energies 2020, 13, 6570. https://doi.org/10.3390/en13246570

Reksowardojo IK, Duong LH, Zain R, Hartono F, Marno S, Rustyawan W, Putri N, Jatiwiramurti W, Prabowo B. Performance and Exhaust Emissions of a Gas-Turbine Engine Fueled with Biojet/Jet A-1 Blends for the Development of Aviation Biofuel in Tropical Regions. Energies. 2020; 13(24):6570. https://doi.org/10.3390/en13246570

Chicago/Turabian StyleReksowardojo, Iman K., Long H. Duong, Rais Zain, Firman Hartono, Septhian Marno, Wawan Rustyawan, Nelliza Putri, Wisasurya Jatiwiramurti, and Bayu Prabowo. 2020. "Performance and Exhaust Emissions of a Gas-Turbine Engine Fueled with Biojet/Jet A-1 Blends for the Development of Aviation Biofuel in Tropical Regions" Energies 13, no. 24: 6570. https://doi.org/10.3390/en13246570

APA StyleReksowardojo, I. K., Duong, L. H., Zain, R., Hartono, F., Marno, S., Rustyawan, W., Putri, N., Jatiwiramurti, W., & Prabowo, B. (2020). Performance and Exhaust Emissions of a Gas-Turbine Engine Fueled with Biojet/Jet A-1 Blends for the Development of Aviation Biofuel in Tropical Regions. Energies, 13(24), 6570. https://doi.org/10.3390/en13246570