Densified Laser-Induced Graphene for Flexible Microsupercapacitors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Laser Pyrolysis of Polyimide

2.2. Characterizations of the d-LIG Electrodes

2.3. Fabrication of Flexible dLIG Microsupercapacitors

2.4. Electrochemical Measurements

3. Results and Discussion

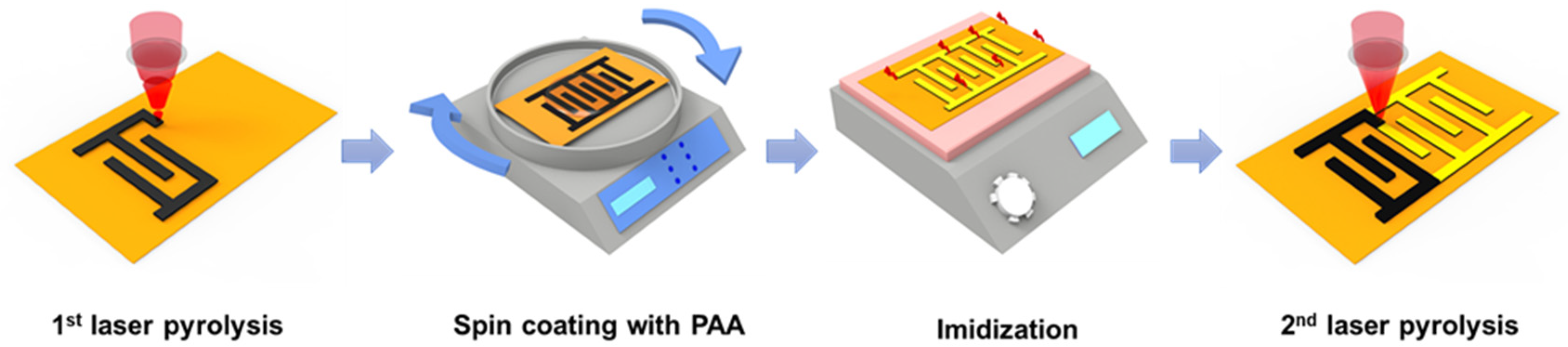

3.1. Fabrication of d-LIG Microsupercapacitors

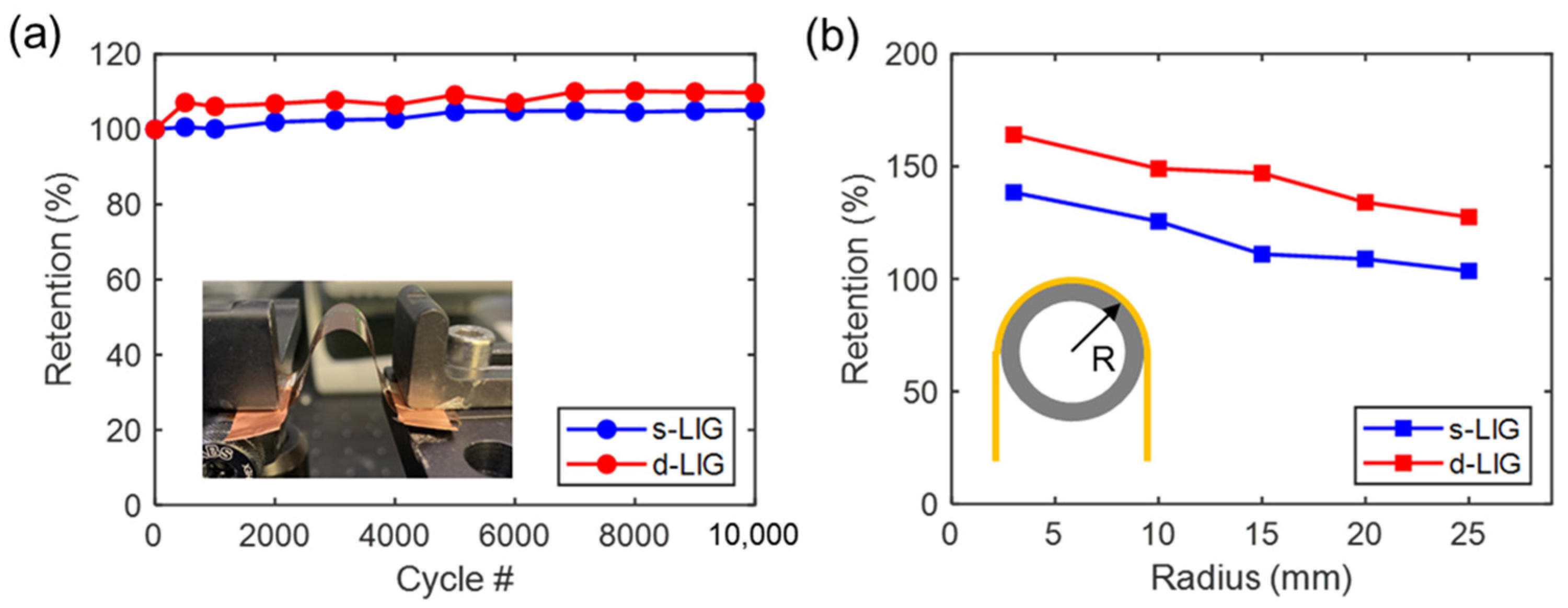

3.2. Flexibility of d-LIG Electrodes

3.3. Electrochemical Performance of the d-LIG Microsupercapacitor

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pech, D.; Brunet, M.; Taberna, P.-L.; Simon, P.; Fabre, N.; Mesnilgrente, F.; Conédéra, V.; Durou, H. Elaboration of a microstructured inkjet-printed carbon electrochemical capacitor. J. Power Sources 2010, 195, 1266–1269. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Song, M.-S.; Kong, B.; Cui, Y. Flexible and Stretchable Energy Storage: Recent Advances and Future Perspectives. Adv. Mater. 2017, 29, 1603436. [Google Scholar] [CrossRef] [PubMed]

- Pech, D.; Brunet, M.; Durou, H.; Huang, P.; Mochalin, V.; Gogotsi, Y.; Taberna, P.-L.; Simon, P. Ultrahigh-power micrometre-sized supercapacitors based on onion-like carbon. Nat. Nanotechnol. 2010, 5, 651–654. [Google Scholar] [CrossRef] [PubMed]

- Joo, Y.; Kim, M.; Kanimozhi, C.; Huang, P.S.; Wong, B.M.; Roy, S.S.; Arnold, M.S.; Gopalan, P. Effect of Dipolar Molecule Structure on the Mechanism of Graphene-Enhanced Raman Scattering. J. Phys. Chem. C 2016, 120, 13815–13824. [Google Scholar] [CrossRef]

- Huang, C.S.; Kim, M.; Wong, B.M.; Safron, N.S.; Arnold, M.S.; Gopalan, P. Raman Enhancement of a Dipolar Molecule on Graphene. J. Phys. Chem. C 2014, 118, 2077–2084. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.; Yacaman, M.J.; Yakobson, B.I.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef] [PubMed]

- Hsia, B.; Marschewski, J.; Wang, S.; In, J.B.; Carraro, C.; Poulikakos, D.; Grigoropoulos, C.P.; Maboudian, R. Highly flexible, all solid-state micro-supercapacitors from vertically aligned carbon nanotubes. Nanotechnology 2014, 25, 055401. [Google Scholar] [CrossRef]

- Dai, L.; Chang, D.W.; Baek, J.-B.; Lu, W. Carbon Nanomaterials for Advanced Energy Conversion and Storage. Small 2012, 8, 1130–1166. [Google Scholar] [CrossRef]

- Peng, Z.; Ye, R.; Mann, J.A.; Zakhidov, D.; Li, Y.; Smalley, P.R.; Lin, J.; Tour, J.M. Flexible Boron-Doped Laser-Induced Graphene Microsupercapacitors. ACS Nano 2015, 9, 5868–5875. [Google Scholar] [CrossRef]

- In, J.B.; Hsia, B.; Yoo, J.H.; Hyun, S.; Carraro, C.; Maboudian, R.; Grigoropoulos, C.P. Facile fabrication of flexible all solid-state micro-supercapacitor by direct laser writing of porous carbon in polyimide. Carbon 2015, 83, 144–151. [Google Scholar] [CrossRef]

- Jang, J.; Yeom, J.W.; Kang, W.K.; Haq, M.R.; Lu, X.; Shin, D.; Kim, S.M.; In, J.B. Laser Pyrolysis of Imprinted Furan Pattern for the Precise Fabrication of Microsupercapacitor Electrodes. Micromachines 2020, 11, 746. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Wang, S.; Wu, J.; Yu, Y.; Li, R.; Eda, S.; Chen, J.; Feng, G.; Lawrie, B.; Hu, A. Bisphenol A Sensors on Polyimide Fabricated by Laser Direct Writing for Onsite River Water Monitoring at Attomolar Concentration. ACS Appl. Mater. Interfaces 2016, 8, 17784–17792. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Lv, C.; Watanabe, A. Laser Direct Writing and Selective Metallization of Metallic Circuits for Integrated Wireless Devices. ACS Appl. Mater. Interfaces 2018, 10, 915–924. [Google Scholar] [CrossRef] [PubMed]

- Stanford, M.G.; Yang, K.; Chyan, Y.; Kittrell, C.; Tour, J.M. Laser-Induced Graphene for Flexible and Embeddable Gas Sensors. ACS Nano 2019, 13, 3474–3482. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, C.; Sha, J.; Fei, H.; Li, Y.; Tour, J.M. Efficient Water-Splitting Electrodes Based on Laser-Induced Graphene. ACS Appl. Mater. Interfaces 2017, 9, 26840–26847. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Zhang, J.; Peng, Z.; Li, Y.; Gao, C.; Ji, Y.; Ye, R.; Kim, N.D.; Zhong, Q.; Yang, Y.; et al. High-Performance Pseudocapacitive Microsupercapacitors from Laser-Induced Graphene. Adv. Mater. 2016, 28, 838–845. [Google Scholar] [CrossRef]

- Tao, L.Q.; Tian, H.; Liu, Y.; Ju, Z.Y.; Pang, Y.; Chen, Y.Q.; Wang, D.Y.; Tian, X.G.; Yan, J.C.; Deng, N.Q.; et al. An intelligent artificial throat with sound-sensing ability based on laser induced graphene. Nat. Commun. 2017, 8, 14579. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Lv, C.; Watanabe, A. Cost-effective fabrication of high-performance flexible all-solid-state carbon micro-supercapacitors by blue-violet laser direct writing and further surface treatment. J. Mater. Chem. A 2016, 4, 1671–1679. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Hu, C.; Luo, J.; Liu, S.; Song, J.; Shi, Y.; Chen, C.; Zhang, Z.; Ogawa, S.; et al. Laser direct writing of heteroatom-doped porous carbon for high-performance micro-supercapacitors. Energy Storage Mater. 2020, 25, 404–415. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Laser direct writing of high-performance flexible all-solid-state carbon micro-supercapacitors for an on-chip self-powered photodetection system. Nano Energy 2016, 30, 790–800. [Google Scholar] [CrossRef]

- Shen, D.; Zou, G.; Liu, L.; Zhao, W.; Wu, A.; Duley, W.W.; Zhou, Y.N. Scalable High-Performance Ultraminiature Graphene Micro-Supercapacitors by a Hybrid Technique Combining Direct Writing and Controllable Microdroplet Transfer. ACS Appl. Mater. Interfaces 2018, 10, 5404–5412. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.; James, D.K.; Tour, J.M. Laser-Induced Graphene. Acc. Chem. Res. 2018, 51, 1609–1620. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Liu, Y.; Li, Q.; Wei, J.; Li, X.; Zhang, Y.; Liu, J. In situ formation of phosphorus-doped porous graphene via laser induction. Rsc. Adv. 2020, 10, 23953–23958. [Google Scholar] [CrossRef]

- Singh, S.P.; Li, Y.; Zhang, J.; Tour, J.M.; Arnusch, C.J. Sulfur-Doped Laser-Induced Porous Graphene Derived from Polysulfone-Class Polymers and Membranes. ACS Nano 2018, 12, 289–297. [Google Scholar] [CrossRef]

- Kim, K.Y.; Choi, H.; Van, T.C.; In, J.B. Simultaneous densification and nitrogen doping of laser-induced graphene by duplicated pyrolysis for supercapacitor applications. J. Power Sources 2019, 441, 227199. [Google Scholar] [CrossRef]

- Choi, H.; Nguyen, P.T.; In, J.B. Laser transmission welding and surface modification of graphene film for flexible supercapacitor applications. Appl. Surf. Sci. 2019, 483, 481–488. [Google Scholar] [CrossRef]

- Peng, Z.; Lin, J.; Ye, R.; Samuel, E.L.; Tour, J.M. Flexible and stackable laser-induced graphene supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 3414–3419. [Google Scholar] [CrossRef]

- Ye, R.Q.; Peng, Z.W.; Wang, T.; Xu, Y.N.; Zhang, J.B.; Li, Y.L.; Nilewski, L.G.; Lin, J.; Tour, J.M. In Situ Formation of Metal Oxide Nanocrystals Embedded in Laser-Induced Graphene. ACS Nano 2015, 9, 9244–9251. [Google Scholar] [CrossRef]

- Choi, H.; Nguyen, P.T.; Tran, C.V.; In, J.B. Micro-patterned metal current collectors for high aspect ratio flexible graphene supercapacitors. Appl. Surf. Sci. 2020, 510, 145432. [Google Scholar] [CrossRef]

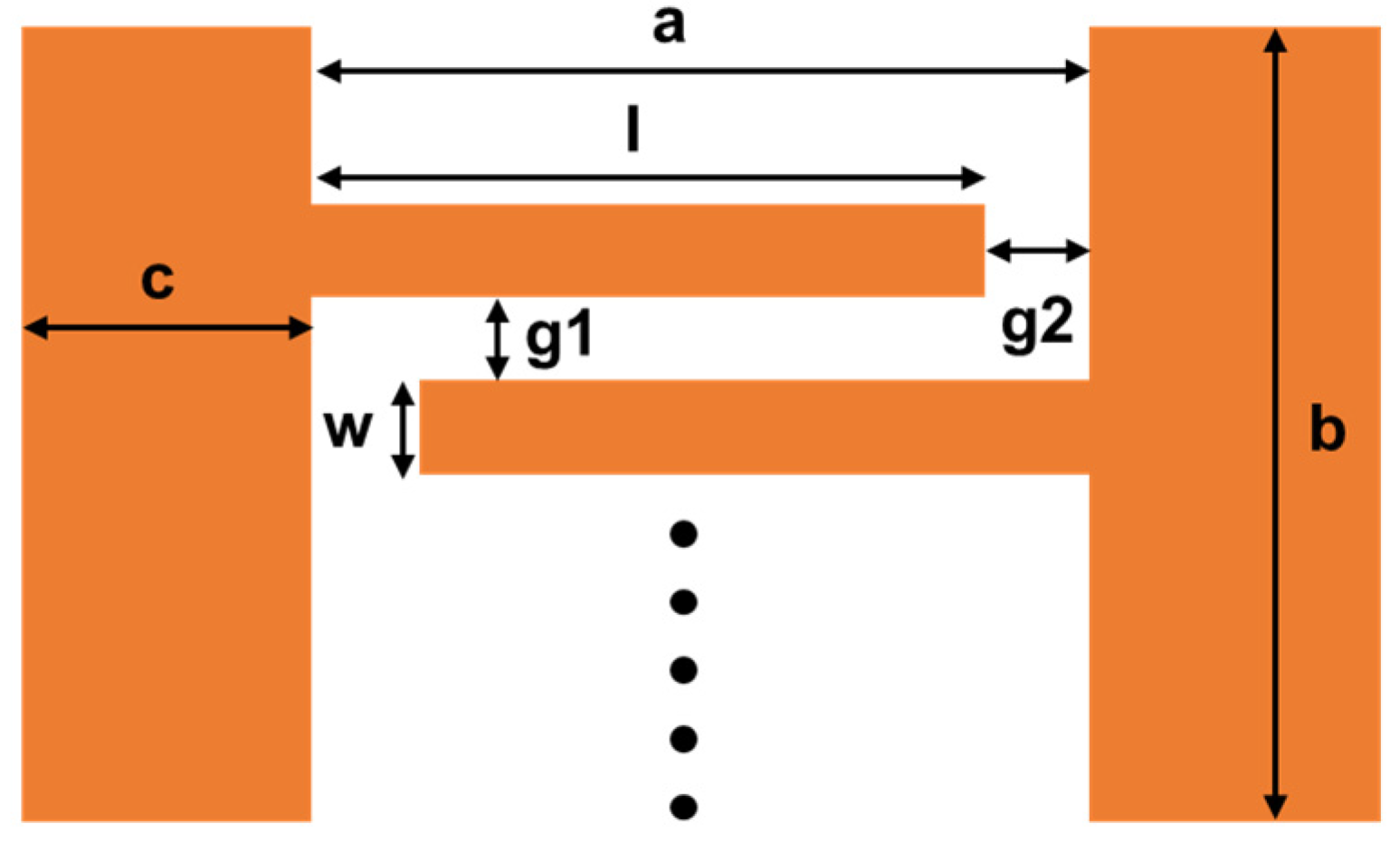

| Location | Dimension (µm) |

|---|---|

| Lateral length of active device area (a) | 5700 |

| Vertical length of active device area (b) | 9060 |

| Pad electrode width (c) | 2660 |

| Finger electrode length (l) | 5350 |

| Finger electrode width (w) | 800 |

| Vertical Gap between finger electrodes (g1) | 250 |

| Gap between finger and pad electrodes (g2) | 350 |

| Number of fingers (N) | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.B.; Jang, J.; Zhou, H.; Lee, Y.; In, J.B. Densified Laser-Induced Graphene for Flexible Microsupercapacitors. Energies 2020, 13, 6567. https://doi.org/10.3390/en13246567

Lee JB, Jang J, Zhou H, Lee Y, In JB. Densified Laser-Induced Graphene for Flexible Microsupercapacitors. Energies. 2020; 13(24):6567. https://doi.org/10.3390/en13246567

Chicago/Turabian StyleLee, Jung Bae, Jina Jang, Haoyu Zhou, Yoonjae Lee, and Jung Bin In. 2020. "Densified Laser-Induced Graphene for Flexible Microsupercapacitors" Energies 13, no. 24: 6567. https://doi.org/10.3390/en13246567

APA StyleLee, J. B., Jang, J., Zhou, H., Lee, Y., & In, J. B. (2020). Densified Laser-Induced Graphene for Flexible Microsupercapacitors. Energies, 13(24), 6567. https://doi.org/10.3390/en13246567