Technical and Economic Analysis of the External Surface Heating System on the Example of a Car Park

Abstract

1. Introduction

2. Description of Possible Heating Solutions

2.1. Electric Heating Systems

2.2. Liquid Heating Systems

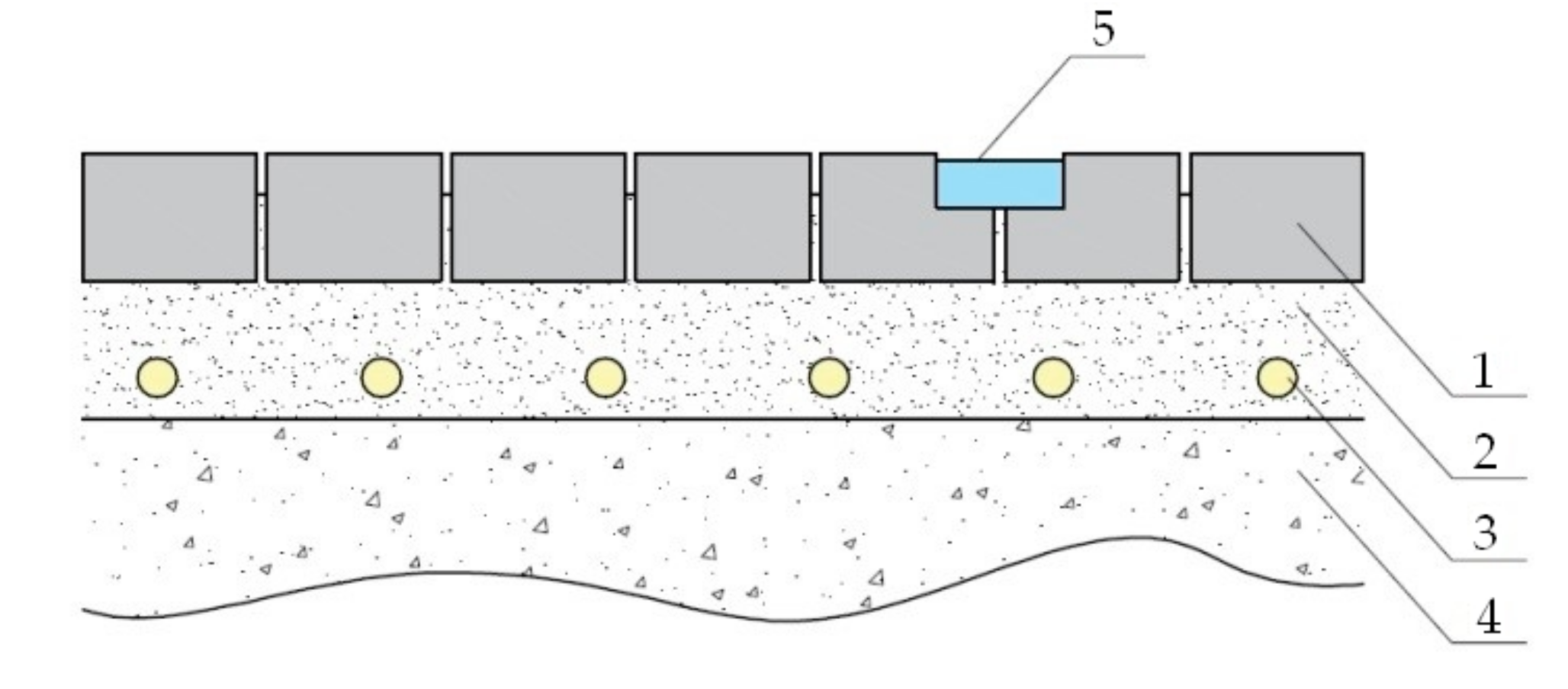

3. Description of the Car Park Heating System

- electric heating, electricity supply,

- liquid heating powered by system heat from the district heating network,

- liquid heating powered by a hard coal boiler,

- liquid heating powered by a biomass boiler,

- liquid heating powered by a heating oil boiler,

- liquid heating powered by a natural gas condensing boiler,

- liquid heating powered by a heat pump with a vertical ground exchanger.

4. Assessment of the Economic and Ecological Efficiency of the Installation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FIFA Quality Programme for Football Turf. In Handbook of Requirements; 2015. Available online: https://football-technology.fifa.com/media/1239/fqp-handbook-of-requirements-2015-v31-w-cover.pdf (accessed on 9 December 2020).

- Introduction to UEFA Turf Manual. Available online: https://www.isss-sportsurfacescience.org/downloads/documents/TKJERP5K15_ Artificial_Turf.pdf (accessed on 9 December 2020).

- Czarniecki, D.; Słyś, D. Technical and financial analysis of heating turf on the sports field. Czas. Inżynierii Lądowej Środowiska Archit. 2016, 63, 39–52. [Google Scholar]

- Onyszczuk, G.; Siuta-Olcha, A. Outdoor Heating Systems—A Case Design Of Soil Conditioning. Polska Inżynieria Środowiska Pięć Lat Po Wstąpieniu Do Unii Europejskiej 2009, 3, 179–190. [Google Scholar]

- Nowak, K. Heating of external surfaces by means of heat pumps. E3S Web Conf. 2018, 44, 00128. [Google Scholar] [CrossRef]

- Shen, W.; Ceylan, H.; Gopalakrishnan, K.; Kim, S.; Nahvi, A. Sustainability Assessment of Alternative Snow-Removal Methods for Airport Apron Paved Surfaces. 2017. Available online: https://www.airporttech.tc.faa.gov/DesktopModules/EasyDNNNews/DocumentDownload.ashx?portalid=0&moduleid=3682&articleid=1&documentid=1 (accessed on 9 December 2020).

- Board, T.R.; National Academies of Sciences, E. Guidelines for the Selection of Snow and Ice Control Materials to Mitigate Environmental Impacts. Prep. NCHRP Proj. 2007, 194p. [Google Scholar] [CrossRef]

- Fay, L.; Nazari, M.H.; Jungwirth, S.; Muthumani, A. Snow and Ice Control Environmental Best Management Practices. Environ. Sustain. Transp. Infrastruct. 2015, 147–161. [Google Scholar] [CrossRef]

- Fu, L.; Sooklall, R.; Perchanok, M.S. Effectiveness of Alternative Chemicals for Snow Removal on Highways. Transp. Res. Rec. 2006, 1948, 125–134. [Google Scholar] [CrossRef]

- Bye, B.; Fæhn, T.; Rosnes, O. Residental Energy Efficiency and European Carbon Policies A CGE-Analysis with Bottom-up Information on Energy Efficiency Technologies; Discussion Papers; Research Department, Statistics Norway: Oslo, Norway, 2015. [Google Scholar]

- Chance, T. Towards sustainable residential communities; the Beddington Zero Energy Development (BedZED) and beyond. Environ. Urban. 2009, 21, 527–544. [Google Scholar] [CrossRef]

- Jiang, B.; Sun, Z.; Liu, M. China’s energy development strategy under the low-carbon economy. Energy 2010, 35, 4257–4264. [Google Scholar] [CrossRef]

- Adl-Zarrabi, B.; Mirzanamadi, R.; Johnsson, J. Hydronic Pavement Heating for Sustainable Ice-free Roads. Transp. Res. Procedia 2016, 14, 704–713. [Google Scholar] [CrossRef]

- ASHRAE. Ashrae 2015 ASHRAE Handbook-HVAC Applications; ASHRAE: Atlanta, GA, USA, 2015; ISBN 978-1-936504-93-0. [Google Scholar]

- Fay, L.; Shi, X. Environmental Impacts of Chemicals for Snow and Ice Control: State of the Knowledge. Water Air Soil Pollut. 2012, 223, 2751–2770. [Google Scholar] [CrossRef]

- Kauko, H.; Rohde, D.; Hafner, A. Local Heating Networks with Waste Heat Utilization: Low or Medium Temperature Supply? Energies 2020, 13, 954. [Google Scholar] [CrossRef]

- Kemmler, T.; Thomas, B. Design of Heat-Pump Systems for Single- and Multi-Family Houses using a Heuristic Scheduling for the Optimization of PV Self-Consumption. Energies 2020, 13, 1118. [Google Scholar] [CrossRef]

- Huculak, M.; Jarczewski, W.; Dej, M. Economic aspects of the use of deep geothermal heat in district heating in Poland. Renew. Sustain. Energy Rev. 2015, 49, 29–40. [Google Scholar] [CrossRef]

- Thygesen, R. An Analysis of Different Solar-Assisted Heating Systems and Their Effect on the Energy Performance of Multifamily Buildings—A Swedish Case. Energies 2017, 10, 88. [Google Scholar] [CrossRef]

- Pisarev, V.; Rabczak, S.; Nowak, K. Ventilation system with ground heat exchanger. J. Ecol. Eng. 2016, 17, 163–172. [Google Scholar] [CrossRef]

- Strzeszewski, M. PN-EN 12831-1:2017-08 Standard. Key changes in the methodology of building design heat load calculations. Ciepłownictwo Ogrzew. Went. 2017, 48, 11. [Google Scholar] [CrossRef]

- Katsaprakakis, D. Computational Simulation and Dimensioning of Solar-Combi Systems for Large-Size Sports Facilities: A Case Study for the Pancretan Stadium, Crete, Greece. Energies 2020, 13, 2285. [Google Scholar] [CrossRef]

- System KAN-therm at Football Stadiums. Available online: http://en.kan-therm.com/kan/upload/KAN-Folder-football-EN-v2 (accessed on 9 December 2020).

- Sękowski, K.; Juchnicki, J. KAN-Therm System Open Surface Heating; Warszaw, Poland. 2004. Available online: http://pl.kan-therm.com/download/files/pl/6-guidebooks/poradnik-ogrzewanie-powierzchni-otwartych-pl.pdf (accessed on 9 December 2020).

- Lanini, S.; Delaleux, F.; Py, X.; Olivès, R.; Nguyen, D. Improvement of borehole thermal energy storage design based on experimental and modelling results. Energy Build. 2014, 77, 393–400. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Yang, Y. Experience on the application of a ground source heat pump system in an archives building. Energy Build. 2011, 43, 3263–3270. [Google Scholar] [CrossRef]

- Spitler, J.D.; Bernier, M. 2—Vertical borehole ground heat exchanger design methods. In Advances in Ground-Source Heat Pump Systems; Rees, S.J., Ed.; Woodhead Publishing: Cambridge, UK; Sawston, UK, 2016; ISBN 978-0-08-100311-4. Available online: https://www.sciencedirect.com/science/article/pii/B9780081003114000029 (accessed on 9 December 2020).

- Ochsner, K. Geothermal Heat Pumps: A Guide for Planning and Installing; Routledge, London, 2012; ISBN 978-1-84977-144-3.

- Kopeć, P. Calculation and selection of ground heat exchanger for a heat pump. J. Civil Eng. Environ. Archit. 2015, 32, 167–176. [Google Scholar] [CrossRef]

- Licharz, H.; Rösmann, P.; Krommweh, M.S.; Mostafa, E.; Büscher, W. Energy Efficiency of a Heat Pump System: Case Study in Two Pig Houses. Energies 2020, 13, 662. [Google Scholar] [CrossRef]

- Mirowski, A. Design, construction and acceptance guidelines for heat pump installations 2014.

- Conrad, J.; Greif, S. Modelling Load Profiles of Heat Pumps. Energies 2019, 12, 766. [Google Scholar] [CrossRef]

- Rubik, M. Heat Pumps in Low-Temperature Geothermal Systems (In Polish); Oficyna Wydawnicza Multico: Warszawa, Poland, 2011; ISBN 978-83-7763-180-5. [Google Scholar]

- Pollutant Emission Calculator. Available online: https://vaillant-partner.pl/kalkulatory-on-line/kalkulator-emisji-zanieczyszczen/ (accessed on 9 December 2020).

- The National Centre for Emissions Management. Poland’s National Inventory Report. 2019. Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/krajowa_inwentaryzacja_emisji/NIR_POL_2019_23.05.2019.pdf (accessed on 9 December 2020).

- Kaczmarczyk, M.; Sowiżdżał, A.; Tomaszewska, B. Energetic and Environmental Aspects of Individual Heat Generation for Sustainable Development at a Local Scale—A Case Study from Poland. Energies 2020, 13, 454. [Google Scholar] [CrossRef]

- Moroń, W.; Rybak, W. NOx and SO2 emissions of coals, biomass and their blends under different oxy-fuel atmospheres. Atmos. Environ. 2015, 116, 65–71. [Google Scholar] [CrossRef]

- Mori, T.; Iwama, Y.; Hayama, H.; Mushtaha, E. Optimization of a Wood Pellet Boiler System Combined with CO2HPs in a Cold Climate Area in Japan. Energies 2020, 13, 5531. [Google Scholar] [CrossRef]

- Jåstad, E.O.; Bolkesjø, T.F.; Trømborg, E.; Rørstad, P.K. The role of woody biomass for reduction of fossil GHG emissions in the future North European energy sector. Appl. Energy 2020, 274, 115360. [Google Scholar] [CrossRef]

- Mac Kinnon, M.A.; Brouwer, J.; Samuelsen, S. The role of natural gas and its infrastructure in mitigating greenhouse gas emissions, improving regional air quality, and renewable resource integration. Prog. Energy Combust. Sci. 2018, 64, 62–92. [Google Scholar] [CrossRef]

- Li, H.; You, S.; Zhang, H.; Zheng, W.; Zheng, X.; Jia, J.; Ye, T.; Zou, L. Modelling of AQI related to building space heating energy demand based on big data analytics. Appl. Energy 2017, 203, 57–71. [Google Scholar] [CrossRef]

- Xue, J.; Xu, Y.; Zhao, L.; Wang, C.; Rasool, Z.; Ni, M.; Wang, Q.; Li, D. Air pollution option pricing model based on AQI. Atmos. Pollut. Res. 2019, 10, 665–674. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, G.Q.P.; Feng, J.; Wu, Y. Delivering a low-carbon community in China: Technology vs. strategy? Habitat Int. 2013, 37, 130–137. [Google Scholar] [CrossRef]

- Basolo, V.; Strong, D. Understanding the neighborhood: From residents’ perceptions and needs to action. Hous. Policy Debate 2002, 13, 83–105. [Google Scholar] [CrossRef]

- Yang, T.; Chen, H.; Zhang, Y.; Zhang, S.; Feng, F. Towards Low-Carbon Urban Forms: A Comparative Study on Energy Efficiencies of Residential Neighborhoods in Chongming Eco-Island. Energy Procedia 2016, 88, 321–324. [Google Scholar] [CrossRef]

- Yazawa, K.; Shakouri, A. Cost-Efficiency Trade-off and the Design of Thermoelectric Power Generators. Environ. Sci. Technol. 2011, 45, 7548–7553. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.J.; Wang, X.M.; Zhao, G.C.; Wang, X. An investigation into neighborhood residents’ cognition of and participation in low-carbon behavior: A case study in Chengyang district of Qingdao, China. Int. J. Sustain. Dev. Plan. 2018, 13, 818–837. [Google Scholar] [CrossRef]

| Name | Details | |

|---|---|---|

| heated surface A, m2 | 2900 | |

| unit installation power Qj, W/m2 | 210 | |

| heat flow to the heating loops Q, kW | 610 | |

| electricity | energy cost, $/kWh | 0.13 |

| system heat | energy cost, $/kWh | 0.06 |

| hard coal | energy cost, $/kWh | 0.03 |

| energy value, kWh/kg | 7.22 | |

| efficiency, % | 85.0 | |

| biomass-pellet | energy cost, $/kWh | 0.04 |

| energy value, kWh/kg | 5.28 | |

| efficiency, % | 85.0 | |

| fuel oil | energy cost, $/kWh | 0.09 |

| energy value, kWh/l | 10.2 | |

| efficiency, % | 95.0 | |

| natural gas | energy cost, $/kWh | 0.05 |

| energy value, kWh/m3 | 9.86 | |

| efficiency, % | 98.0 | |

| Name. | Details |

|---|---|

| heat flow to the heating loops Q, kW | 610 |

| selected heat pump | 2× Viessmann Vitocal 300G PRO 302.C230 |

| workplace B/B, °C/°C | 5/10 |

| heating power QPC, kW | 2 × 305 |

| power consumption of the heat pump P, kW | 2 × 35.9 |

| seasonal coefficient of performance SCOP | 3.9 |

| amount of heat to be taken from the ground Qk, kW | 454 |

| length of the vertical heat exchanger L, m | 9072 |

| amount of drillings n | 61 |

| Heating system | Components | Total Capital Expenditure (Kin), $ |

|---|---|---|

| electric heating power supply (I) | electric heating elements with complete accessories, control system and automatics | 66,685 |

| liquid heating supplied from the district heating network (II) | heating junction, liquid pipe system, other elements of the system: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 95,265 |

| liquid heating powered by a hard coal boiler (III) | coal boiler, liquid pipe system, other elements of the system: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 107,173 |

| liquid heating powered by a biomass boiler (IV) | biomass boiler, liquid pipe system, other elements of the system: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 119,081 |

| liquid heating with fuel oil boiler (V) | fuel oil boiler, liquid pipe system, other elements of the system: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 100,028 |

| liquid heating powered by a natural gas boiler (VI) | natural gas boiler, liquid pipe system, other elements of the system: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 100,028 |

| liquid heating powered by a ground source heat pump (VII) | heat pump, lower and upper heat source, other system components: heat exchanger, pipelines, fittings, automation system, labour and system start-up | 345,900 |

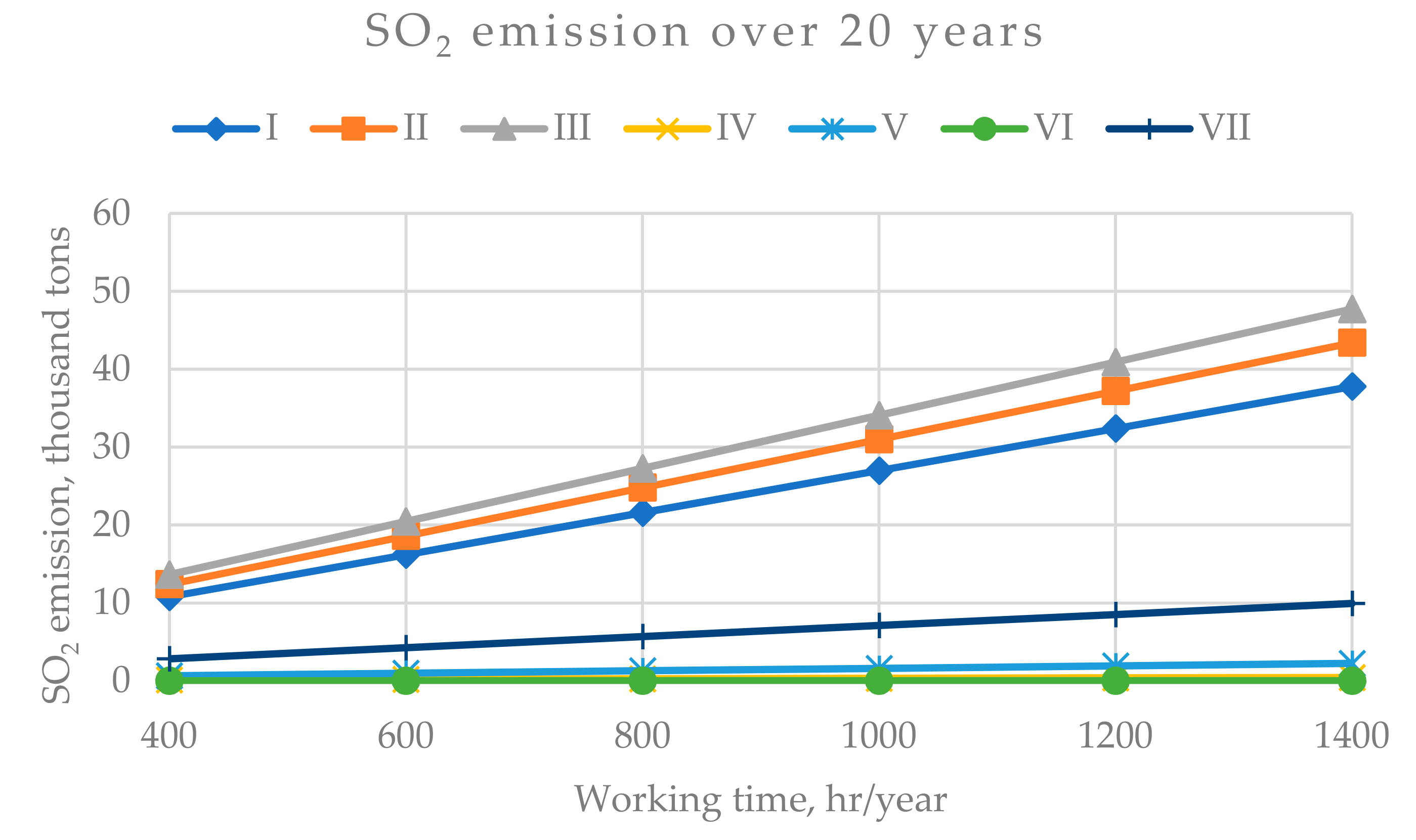

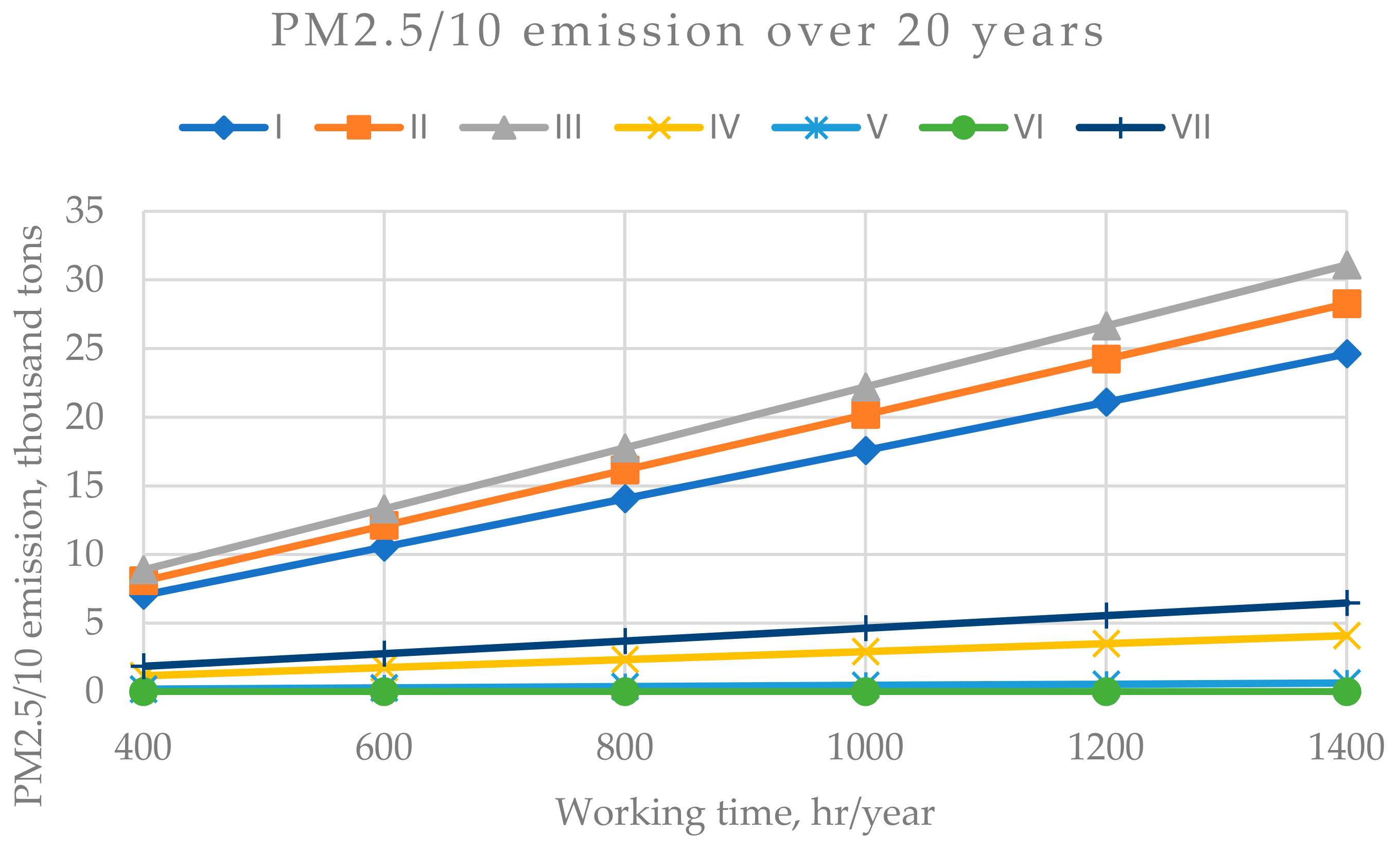

| Heating System | Specific Emissions of Pollutants | |||

|---|---|---|---|---|

| CO2, kg/kWh | NOX, g/kWh | SO2, g/kWh | dust, g/kWh | |

| electric heating power supply (I) | 228 | 0.24 | 2.21 | 1.44 |

| liquid heating supplied from the district heating network (II) | 260 | 0.27 | 2.54 | 1.65 |

| liquid heating powered by a hard coal boiler (III) | 280 | 0.30 | 2.79 | 1.82 |

| liquid heating powered by a biomass boiler (IV) | 270 | 0.23 | 0.03 | 0.24 |

| liquid heating with fuel oil boiler (V) | 299 | 0.22 | 0.13 | 0.04 |

| liquid heating powered by a natural gas boiler (VI) | 218 | 0.17 | 0.000008 | 0.00005 |

| liquid heating powered by a ground source heat pump (VII) | 60 | 0.06 | 0.58 | 0.38 |

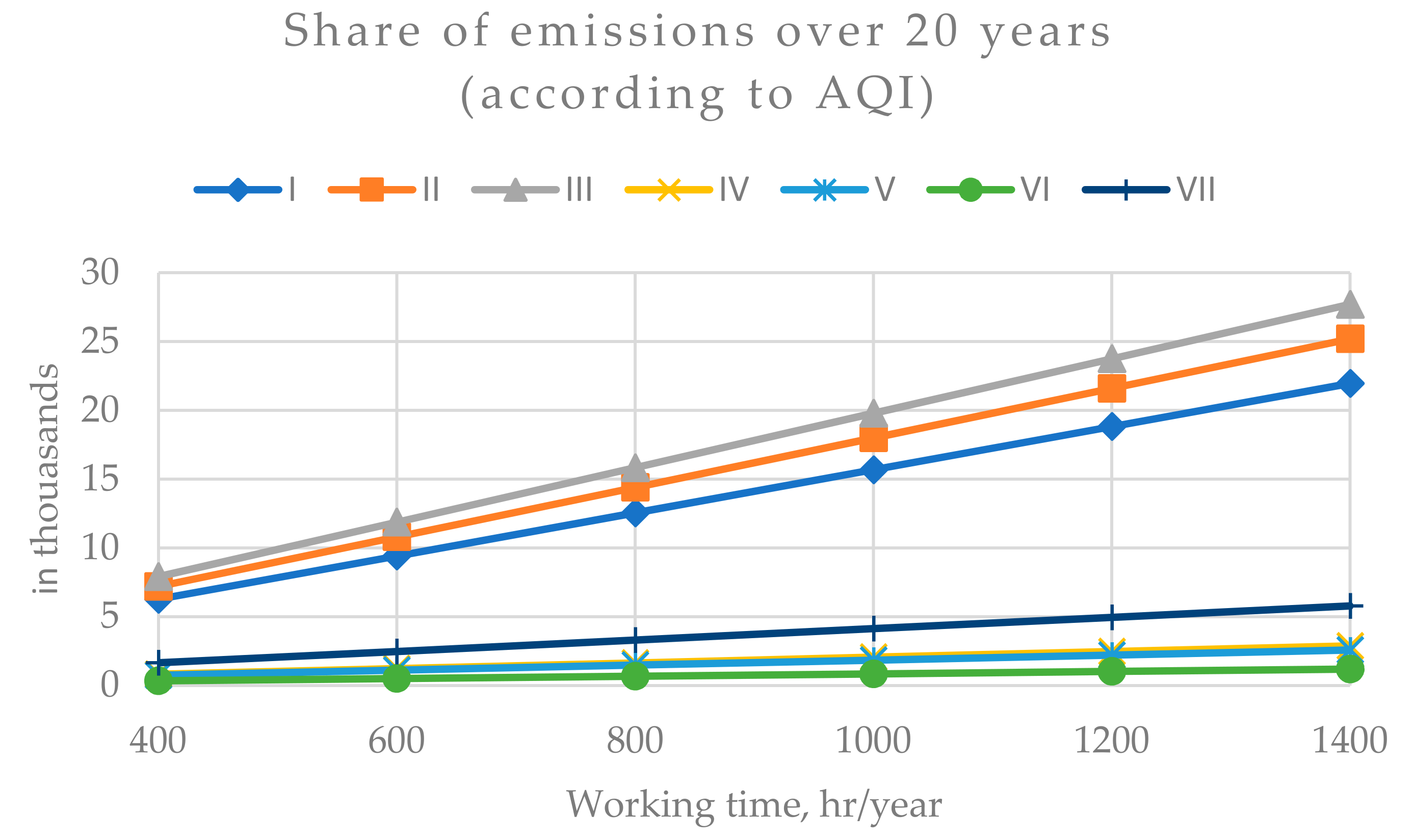

| Share of Contaminants by AQI | |||

|---|---|---|---|

| CO2 | NOX | SO2 | PM2.5/10 |

| 0.198 | 0.157 | 0.354 | 0.291 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowak, K.; Rabczak, S. Technical and Economic Analysis of the External Surface Heating System on the Example of a Car Park. Energies 2020, 13, 6530. https://doi.org/10.3390/en13246530

Nowak K, Rabczak S. Technical and Economic Analysis of the External Surface Heating System on the Example of a Car Park. Energies. 2020; 13(24):6530. https://doi.org/10.3390/en13246530

Chicago/Turabian StyleNowak, Krzysztof, and Sławomir Rabczak. 2020. "Technical and Economic Analysis of the External Surface Heating System on the Example of a Car Park" Energies 13, no. 24: 6530. https://doi.org/10.3390/en13246530

APA StyleNowak, K., & Rabczak, S. (2020). Technical and Economic Analysis of the External Surface Heating System on the Example of a Car Park. Energies, 13(24), 6530. https://doi.org/10.3390/en13246530