Review of Methods Used for Selecting Pumps as Turbines (PATs) and Predicting Their Characteristic Curves

Abstract

1. Introduction

2. PAT Modeling Approaches

- Empirical models

- 1D models that recreate the unknown geometry of the machine

- 1D models that use a known geometry

- 2D models

- 3D-CFD (Computational Fluid Dynamics) models

3. Basic Models

4. Models that Predict the Characteristic Curves of a PAT

4.1. Empirical Models

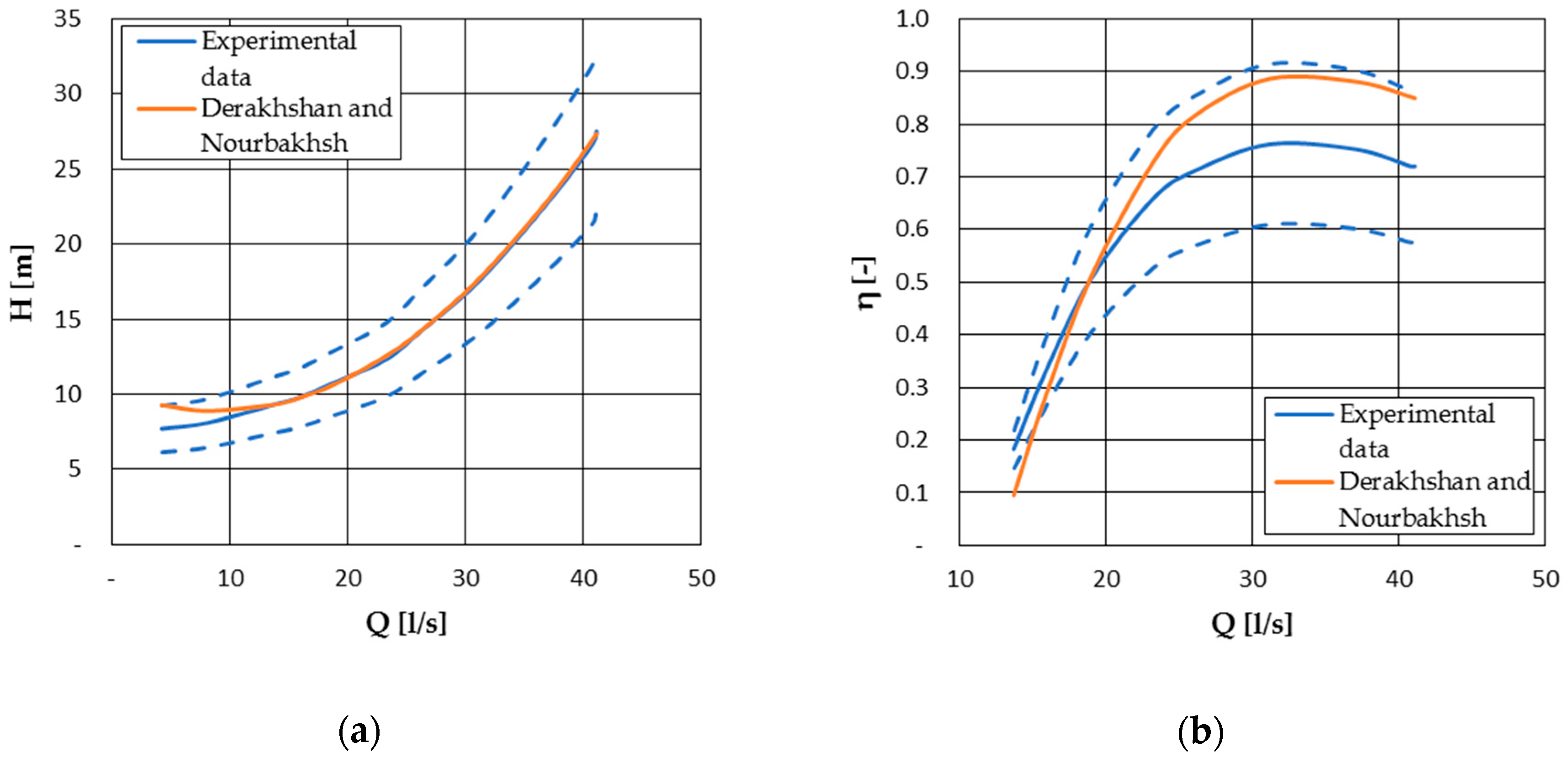

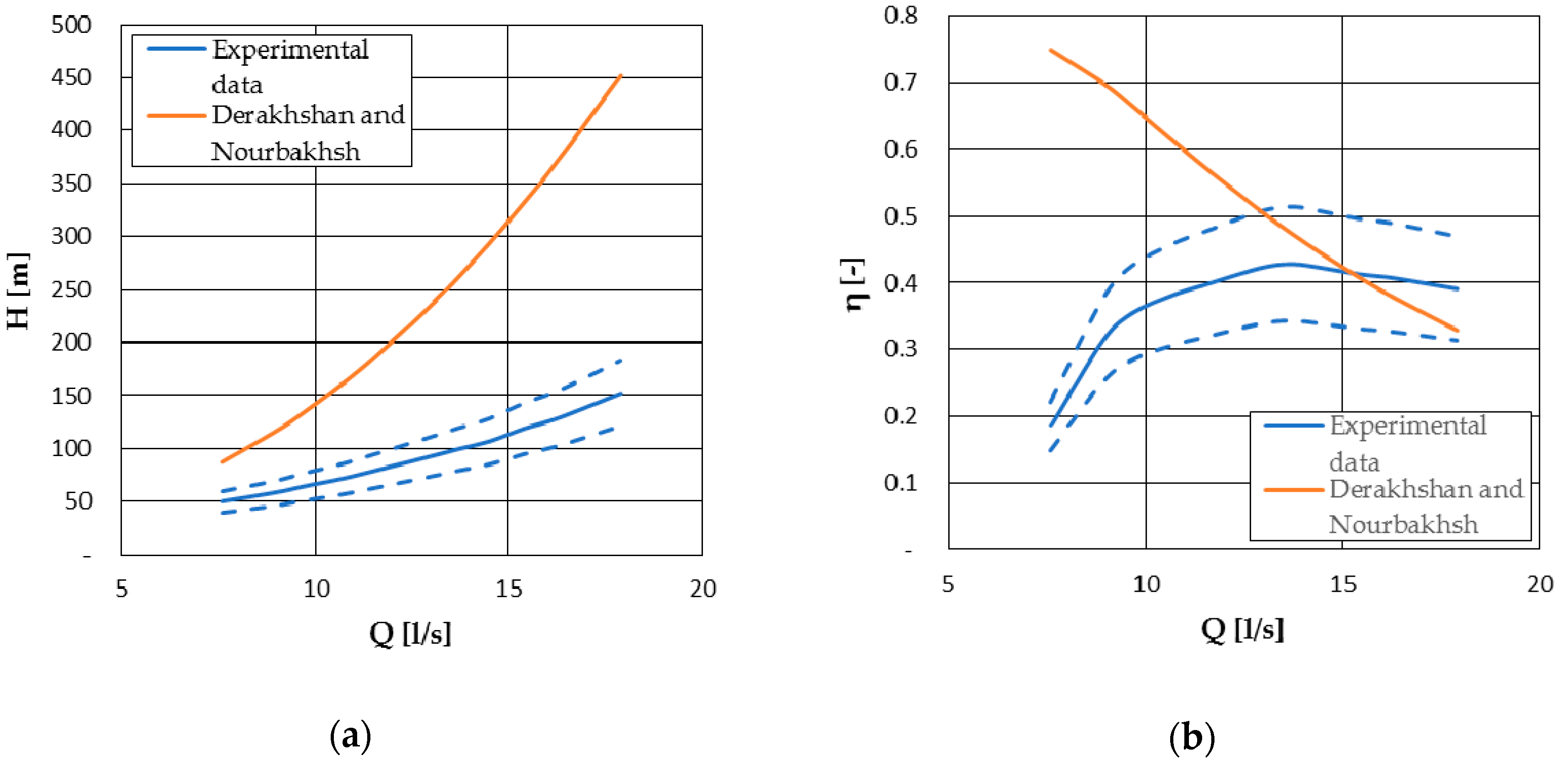

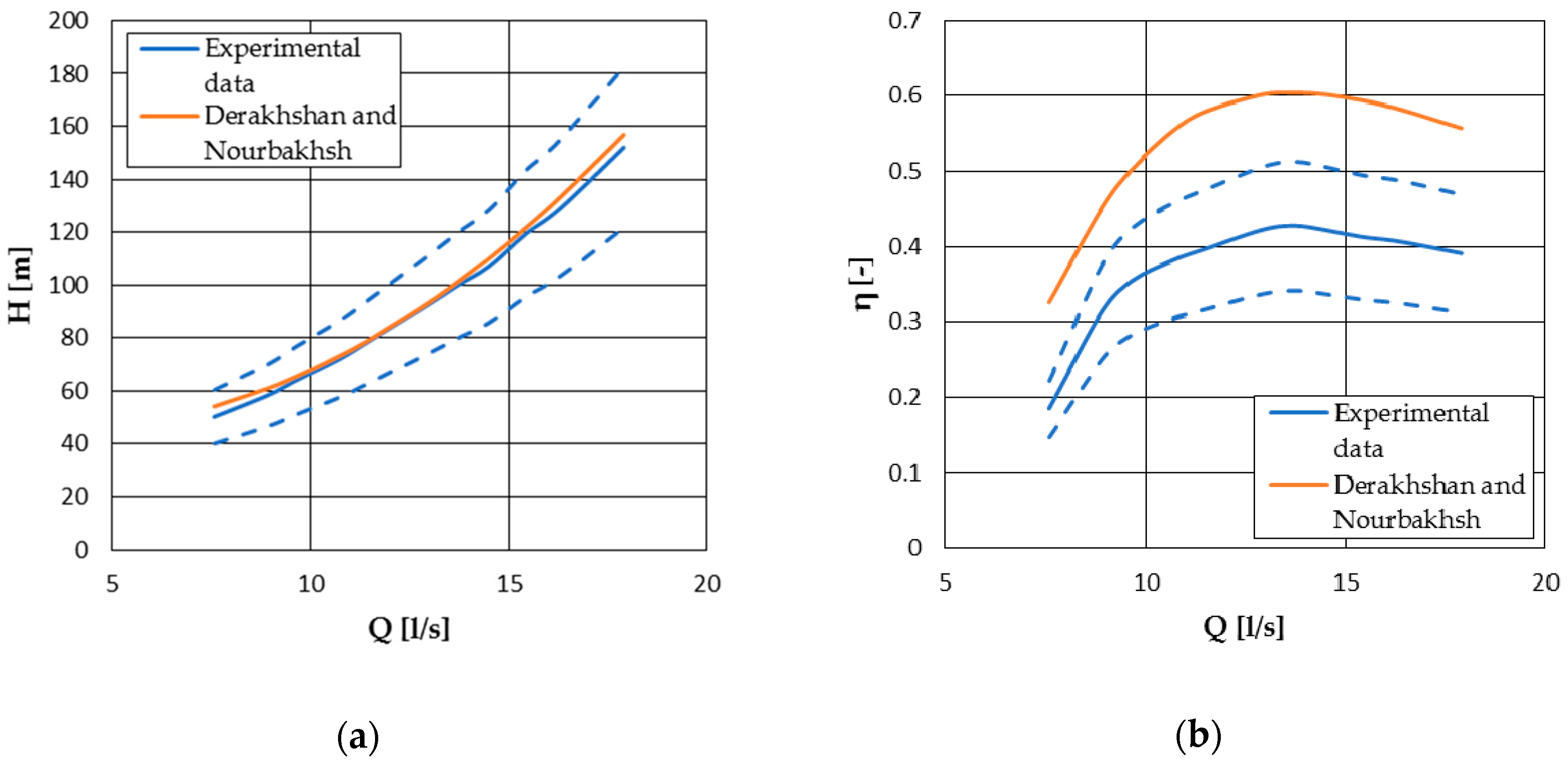

4.1.1. Derakhshan and Nourbakhsh Model

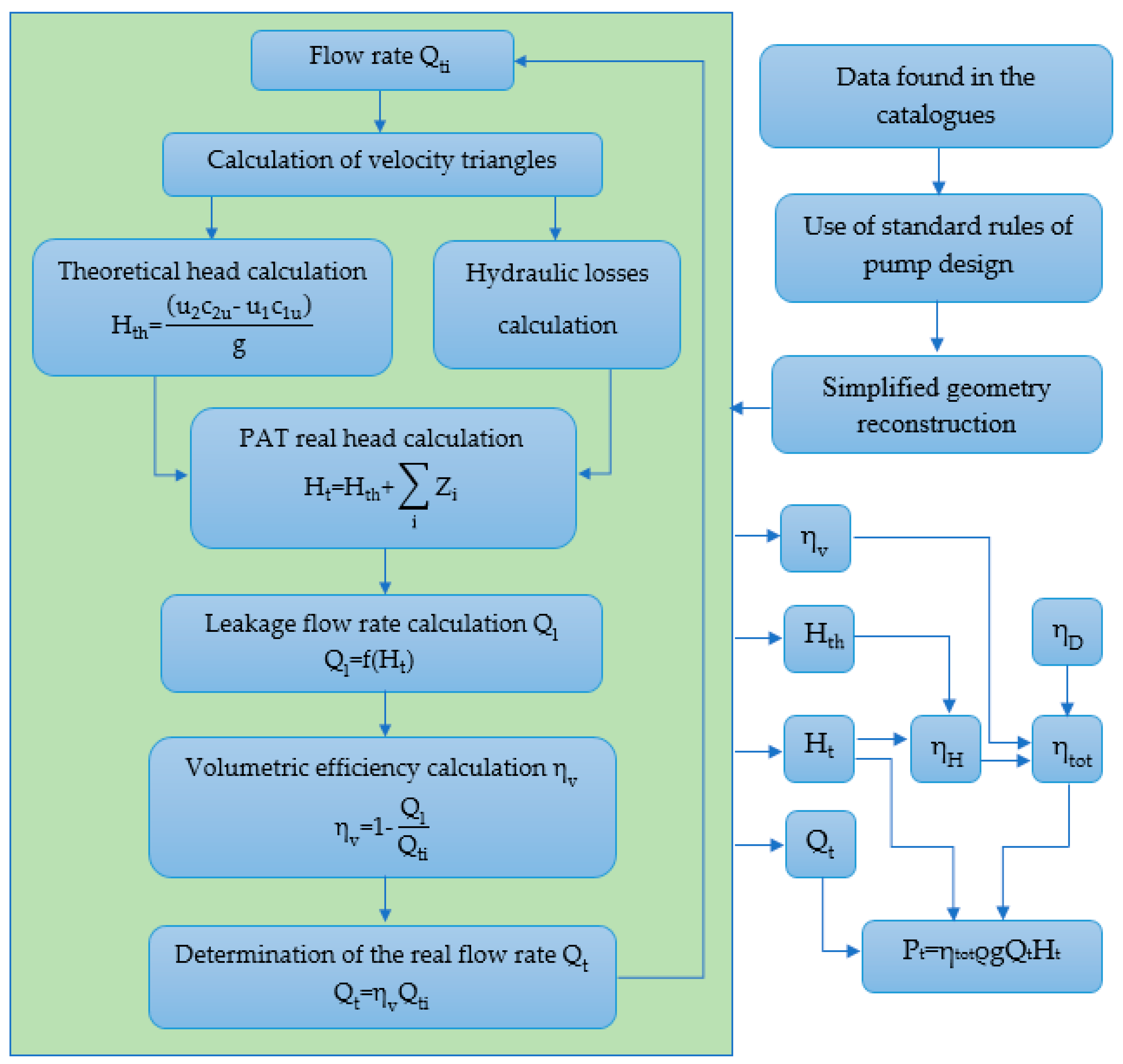

4.2. 1D Models That Recreate the Geometry of the Machine

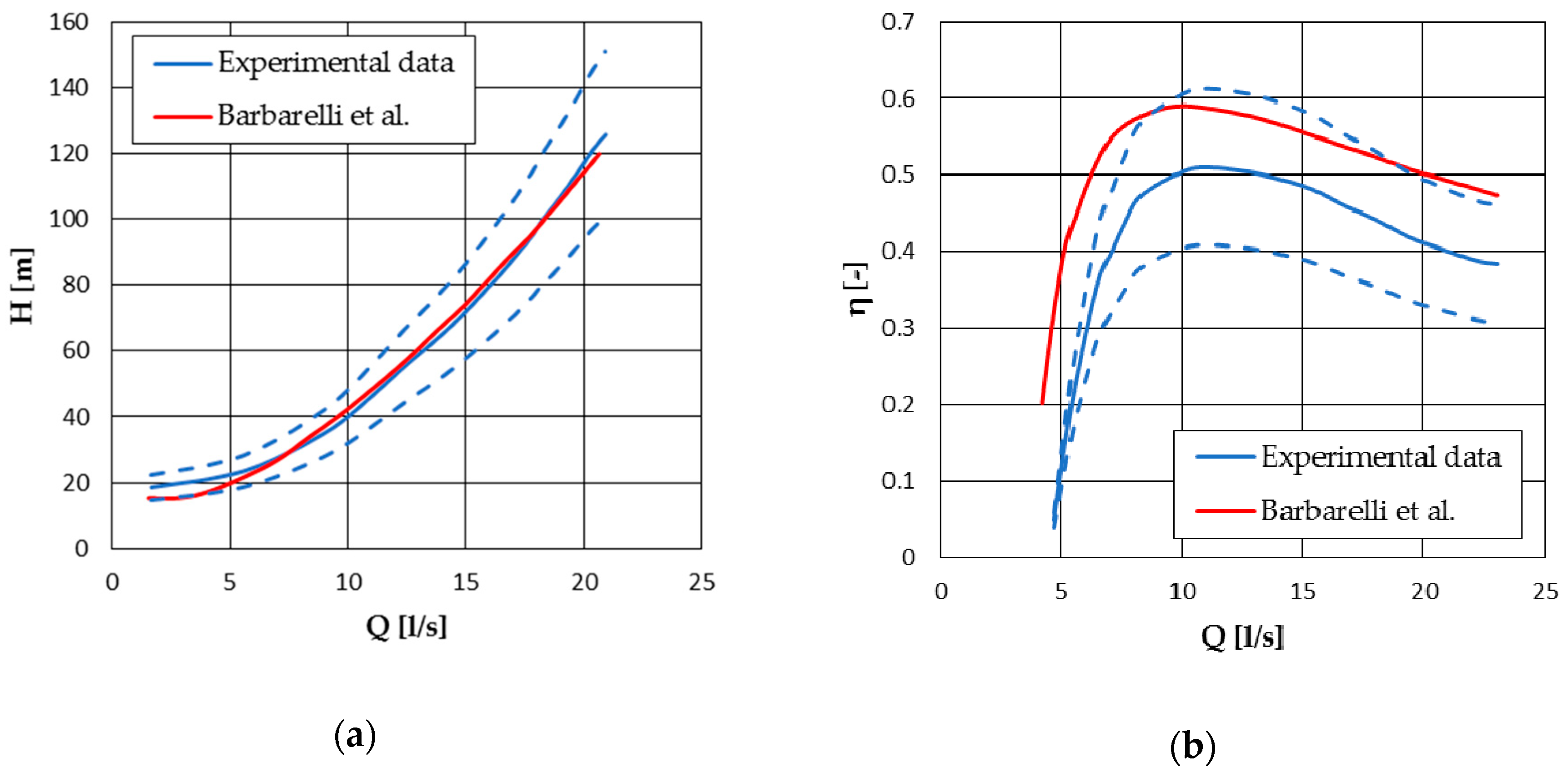

4.2.1. Barbarelli et al. Model

- Pump head at BEP

- Pump flow rate at BEP

- Maximum power

- Head at zero flow

- Impeller diameter

- Size of the pump

- Design mode

- Known geometry mode

- Mixed mode

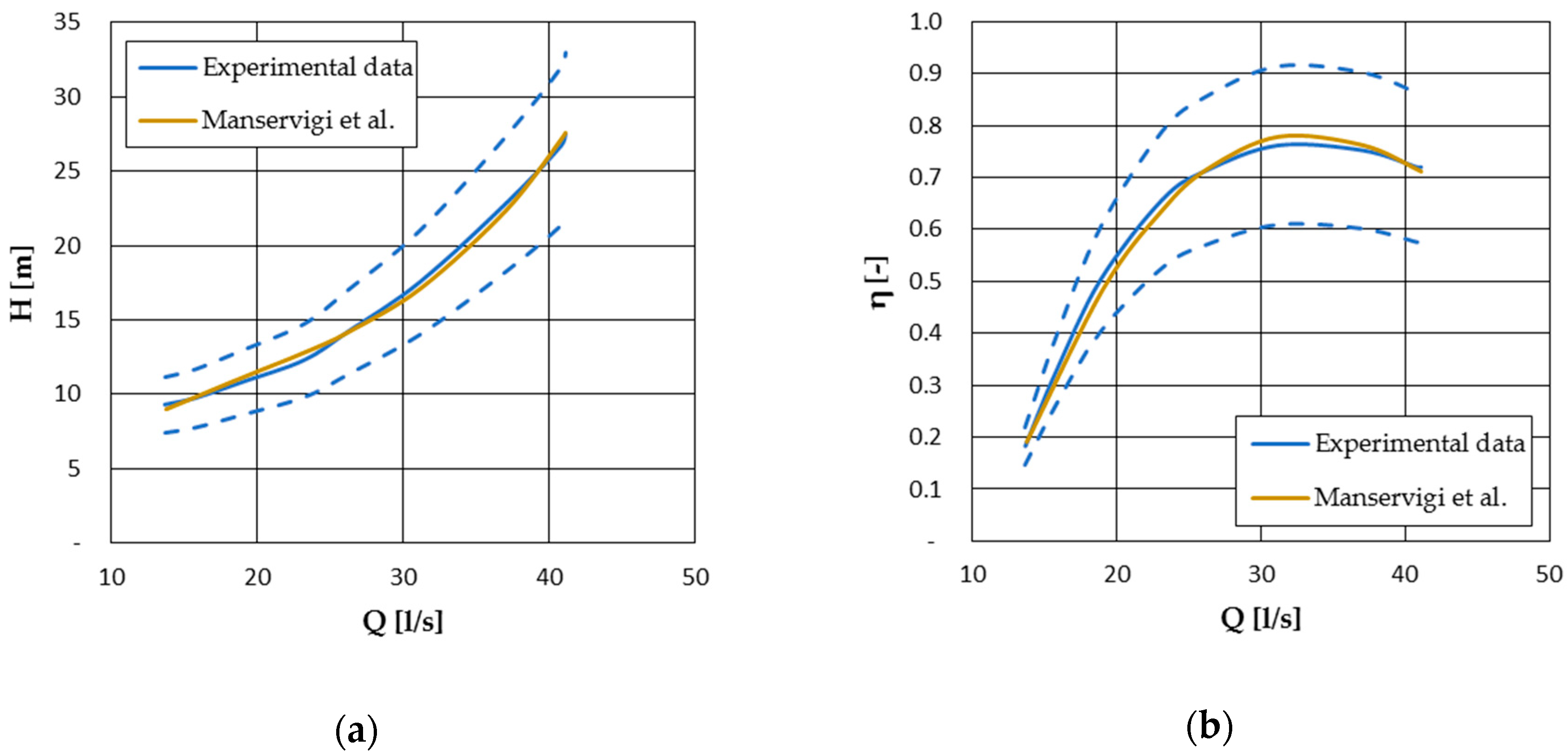

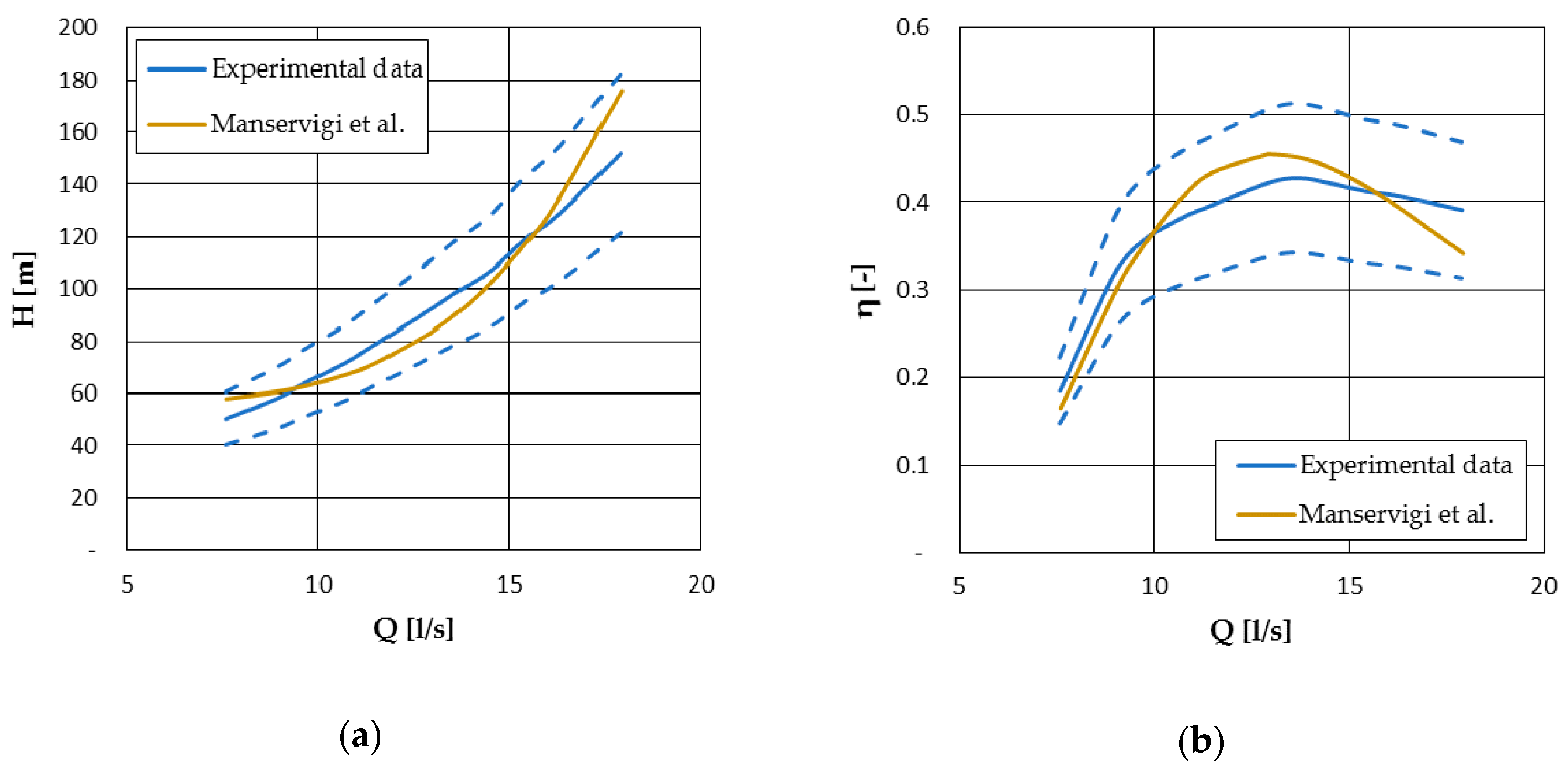

4.2.2. Manservigi et al. Model

- Head coefficient ψ

- Power coefficient π

- Efficiency η

4.3. 1D Models That Use a Known Geometry

4.4. 3D-CFD Models

5. Applicability of the Various Methods

5.1. Basic Models

5.2. Models That Predict the Characteristic Curves of a PAT

6. Discussion

- Prediction error

- Simplicity of application

- Number of parameters involved

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Best Efficiency Point | |

| Absolute velocity | |

| Circumferential component of absolute velocity in PAT impeller outlet section | |

| Circumferential component of absolute velocity in PAT impeller inlet section | |

| Computational Fluid Dynamics | |

| Head conversion factor | |

| Flow rate conversion factor | |

| Impeller diameter | |

| Hydraulic diameter | |

| Gravitational acceleration | |

| Ratio between PAT head and PAT head at BEP | |

| Head | |

| Head at BEP | |

| Pump head at BEP | |

| PAT head at BEP | |

| Site head | |

| PAT head | |

| Theoretical head | |

| Index of the summation | |

| Turbulent kinetic energy | |

| Parameter necessary at Zlowflow calculation | |

| Length | |

| Power loss | |

| Rotational speed | |

| Number of data | |

| Pump rotational speed | |

| PAT specific speed | |

| PAT rotational speed | |

| Ratio between PAT power and PAT power at BEP | |

| Power | |

| Pump As Turbine | |

| Power at BEP | |

| PAT power at BEP | |

| Pumped-Hydro Energy Storage | |

| Pressure Reducing Valve | |

| PAT power | |

| Ratio between PAT flow rate and PAT flow rate at BEP | |

| Flow rate | |

| Flow rate at BEP | |

| Pump flow rate at BEP | |

| PAT flow rate at BEP | |

| Leakage flow rate | |

| Site flow rate | |

| PAT flow rate | |

| PAT flow rate – initial value at the i-th iteration | |

| Root Mean Square Relative Error | |

| Source term | |

| Tangential velocity in PAT impeller outlet section | |

| Tangential velocity in PAT impeller inlet section | |

| Fluid velocity in the xi direction | |

| Water Distribution Network | |

| Generic axis direction | |

| Experimental value of a quantity | |

| Simulated value of a quantity | |

| Hydraulic loss | |

| Dynamic loss | |

| Friction loss | |

| Hydraulic loss at low flow rate | |

| Runner hydraulic loss | |

| Volute hydraulic loss | |

| , β | Dimensionless specific speed |

| , | Dimensionless pump specific speed |

| , | Dimensionless PAT specific speed |

| Dimensionless parameter necessary to calculate CH | |

| Rate of dissipation of turbulent kinetic energy | |

| Efficiency | |

| Efficiency at BEP | |

| Disc efficiency | |

| Hydraulic efficiency | |

| Hydraulic efficiency at BEP (pump mode) | |

| PAT efficiency | |

| PAT total efficiency | |

| Volumetric efficiency | |

| Pump efficiency at BEP | |

| PAT efficiency at BEP | |

| Pump efficiency | |

| λ | Friction coefficient |

| μ | Dynamic viscosity |

| μt | Turbulent viscosity |

| ξ | Dynamic loss coefficient |

| Power coefficient | |

| Density | |

| Adjustable constant | |

| PAT slip factor | |

| Head coefficient |

References

- Chapallaz, J.M.; Eichenberger, P.; Fischer, G. Manual on Pumps Used as Turbines; Vieweg: Braunschweig, Germany, 1992. [Google Scholar]

- Patelis, M.; Kanakoudis, V.; Gonelas, K. Pressure management and energy recovery capabilities using PATs. Procedia Eng. 2016, 162, 503–510. [Google Scholar] [CrossRef]

- Meirelles Lima, G.; Luvizotto, E., Jr.; Brentan, B.M. Selection of Pumps as Turbines Substituting Pressure Reducing Valves. Procedia Eng. 2017, 186, 676–683. [Google Scholar] [CrossRef]

- Alberizzi, J.C.; Renzi, M.; Nigro, A.; Rossi, M. Study of a Pump-as-Turbine (PaT) speed control for a Water Distribution Network (WDN) in South-Tyrol subjected to high variable water flow rates. Energy Procedia 2018, 148, 226–233. [Google Scholar] [CrossRef]

- Venturini, M.; Alvisi, S.; Simani, S.; Manservigi, L. Energy Production by Means of Pumps as Turbine in Water Distribution Networks. Energies 2017, 10, 1666. [Google Scholar] [CrossRef]

- Rossi, M.; Nigro, A.; Pisaturo, G.R.; Renzi, M. Technical and economic analysis of Pump-as-Turbine (PaT) used in Italian Water Distribution Network (WDN) for electrical energy production. Energy Procedia 2019, 158, 117–122. [Google Scholar] [CrossRef]

- Barbarelli, S.; Amelio, M.; Florio, G.; Scornaienchi, N.M. Procedure Selecting Pumps Running as Turbines in Micro Hydro Plants. Energy Procedia 2017, 126, 549–556. [Google Scholar] [CrossRef]

- Barbarelli, S.; Amelio, M.; Florio, G. Using a statistical-numerical procedure for the selection of pumps running as turbines to be applied in water pipelines: Study cases. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 323–340. [Google Scholar] [CrossRef]

- Algieri, A.; Zema, D.A.; Nicotra, A.; Zimbone, S.M. Potential energy exploitation in collective irrigation systems using pumps as turbines: A case study in Calabria (Southern Italy). J. Clean. Prod. 2020, 257, 120538. [Google Scholar] [CrossRef]

- Renzi, M.; Rudolf, P.; Stefan, D.; Nigro, A.; Rossi, M. Energy recovery in oil refineries through the installation of axial Pumps-as-Turbines (PATs) in a wastewater sewer: A case study. Energy Procedia 2019, 158, 135–141. [Google Scholar] [CrossRef]

- Barbarelli, S.; Amelio, M.; Florio, G. Experimental activity at test rig validating correlations to select pumps running as turbines in microhydro plants. Energy Convers. Manag. 2017, 149, 781–797. [Google Scholar] [CrossRef]

- Sivakumar, N.; Das, D.; Padhy, N.P. Economic analysis of Indian pumped storage schemes. Energy Convers. Manag. 2014, 88, 168–176. [Google Scholar] [CrossRef]

- Scheliecher, W.C.; Oztekin, A. Hydraulic design and optimisation of a modular pump-turbine runner. Energy Convers. Manag. 2015, 93, 388–398. [Google Scholar] [CrossRef]

- Williams, A.A.; Simpson, R. Pico hydro—Reducing technical risks for rural electrification. Renew. Energy 2009, 34, 1986–1991. [Google Scholar] [CrossRef]

- Arriaga, M. Pump as turbine—A pico-hydro alternative in Lao People’s Democratic Republic. Renew. Energy 2010, 35, 1109–1115. [Google Scholar] [CrossRef]

- Motwani, K.H.; Jain, S.V.; Patel, R.N. Cost analysis of pump as turbine for pico hydropower plants—A case study. Procedia Eng. 2013, 51, 721–726. [Google Scholar] [CrossRef]

- Alatorre-Frenk, C.; Thomas, T.H. The Pumps-As-Turbines (PATs) Approach to Small Hydropower; Word Congress on Renewable Energy: Reading, UK, 1990. [Google Scholar]

- Childs, S.M. Convert Pumps to Turbines and Recover HP. Hydrocarb. Process. Pet. Refin. 1962, 41, 173–174. [Google Scholar]

- Derakhshan, S.; Nourbakhsh, A. Experimental study of characteristic curves of centrifugal pumps working as turbines in different specific speed. Exp. Therm. Fluid Sci. 2008, 32, 800–807. [Google Scholar] [CrossRef]

- Williams, A.A. The turbine performance of centrifugal pumps: A comparison of prediction methods. Proc. Inst. Mech. Eng. 1994, 208, 59–66. [Google Scholar] [CrossRef]

- Hancock, J.W. Centrifugal Pump or Water Turbine. Pump Line News 1963, 6, 25–27. [Google Scholar]

- Stefanizzi, M. Theoretical and Expertimental Analysis of Pumps as Turbines. Ph.D. Thesis, Politecnico di Bari, Bari, Italy, 2018. [Google Scholar]

- Yang, S.S.; Derakhshan, S.; Kong, F.Y. Theoretical, numerical and experimental prediction of pump as turbine preformance. Renew. Energy 2012, 48, 507–513. [Google Scholar] [CrossRef]

- Visser, F.C.; Brouwers, J.J.H.; Badie, R. Theoretical analysis of inertially irrootational and solenoidal flow in two-dimensional radial-flow pump and turbine impellers with equiangular blades. J. Fluid Mech. 1994, 269, 107–141. [Google Scholar] [CrossRef]

- Paeng, K.S.; Chung, M.K. A new slip factor for centrifugal impellers. Proc. Inst. Mech. Eng. 2001, 215, 645–649. [Google Scholar] [CrossRef]

- Rossi, M.; Renzi, M. Analytical Prediction Models for Evaluating Pump-As-Turbines (PATs) Performance. Energy Procedia 2017, 118, 238–242. [Google Scholar] [CrossRef]

- Barbarelli, S.; Amelio, M.; Florio, G. Predictive model estimating the performances of centrifugal pumps used as turbines. Energy 2016, 107, 103–121. [Google Scholar] [CrossRef]

- Manservigi, L.; Venturini, M.; Losi, E. Application of a physics-based model to predict the performance curves of pumps as turbines. AIP Conf. Proc. 2019, 2191, 020106. [Google Scholar]

- Amelio, M.; Barbarelli, S. A one-dimensional numerical model for calculating the efficiency of pumps as turbines for implementation in micro-hydro power plants. In Proceedings of the ESDA: 7th Biennal ASME Conference Engineering Systems Design and Analysis, Manchester, UK, 19–22 July 2004. [Google Scholar]

- Stefanizzi, M.; Capurso, T.; Torresi, M.; Pascazio, G.; Ranaldo, S.; Camporeale, S.M.; Fortunato, B.; Monteriso, R. Development of a 1-D Performance Prediction Model for Pumps as Turbines. In Proceedings of the 3rd EWaS International Conference, Lefkada, Greece, 27–30 June 2018. [Google Scholar]

- Capurso, T.; Stefanizzi, M.; Pascazio, G.; Ranaldo, S.; Camporeale, S.M.; Fortunato, B.; Torresi, M. Slip Factor Correction in 1-D Performance Prediction Model for PATs. Water 2019, 11, 565. [Google Scholar] [CrossRef]

- Frosina, E.; Buono, D.; Senatore, A. A Performance Prediction Method for Pumps as Turbines (PAT) Using a Computational Fluid Dynamics (CFD) Modeling Approach. Energies 2017, 10, 103. [Google Scholar] [CrossRef]

- Perez-Sanchez, M.; Simao, M.; Lopez-Jimenez, P.A.; Ramos, H.M. CFD Analyses and Experiments in a PAT Modeling: Pressure Variation and System Efficiency. Fluids 2017, 2, 51. [Google Scholar] [CrossRef]

- Rossi, M.; Nigro, A.; Renzi, M. Experimental and numerical assessment of a methodology for performance prediction Pumps-as-Turbines (PATs) operating in off-design conditions. Appl. Energy 2019, 248, 555–566. [Google Scholar] [CrossRef]

- Li, W.G. Effects of viscosity on turbine mode performance and flow of a low specific speed centrifugal pump. Appl. Math. Model. 2016, 40, 904–926. [Google Scholar] [CrossRef]

| Model | ||

|---|---|---|

| Alatorre–Frenk | ||

| Algieri et al. | ||

| Barbarelli et al. | ||

| Childs | ||

| Grover | ||

| Hancock | ||

| Hergt | ||

| Schmiedl | ||

| Sharma | ||

| Stefanizzi | - | |

| Stepanoff | ||

| Yang et al. |

| Model | Use of Site Data | Output | Based on | |||

|---|---|---|---|---|---|---|

| CQ | CH | ηt | Theoretical Considerations | Experimental Data | ||

| Alatorre–Frenk [17] | - | ✘ | ✘ | ✘ | - | ✘ |

| Algieri et al. [9] | ✘ | ✘ | ✘ | - | - | ✘ |

| Barbarelli et al. [11] | ✘ | ✘ | ✘ | ✘ | - | ✘ |

| Childs [18] | - | ✘ | ✘ | - | ✘ | - |

| Derakhshan and Nourbakhsh [19] | ✘ | - | ✘ | - | - | ✘ |

| Grover [20] | ✘ | ✘ | ✘ | - | - | ✘ |

| Hancock [21] | - | ✘ | ✘ | - | ✘ | - |

| Hergt [20] | ✘ | ✘ | ✘ | - | - | - |

| Schmiedl [20] | - | ✘ | ✘ | - | - | - |

| Sharma [20] | - | ✘ | ✘ | - | ✘ | - |

| Stefanizzi [22] | ✘ | - | ✘ | - | - | ✘ |

| Stepanoff [20] | - | ✘ | ✘ | - | ✘ | - |

| Yang et al. [23] | - | ✘ | ✘ | - | ✘ | ✘ |

| Model | Input | Output | Based on | |||||

|---|---|---|---|---|---|---|---|---|

| Pump BEP | Catalogue Information | Machine Geometry | Characteristic Curves | Flux Lines | Experimental Data | Theoretical Considerations | CFD | |

| Derakhshan and Nourbakhsh [19] | ✘ | - | - | ✘ | - | ✘ | - | - |

| Barbarelli et al. [27] | ✘ | ✘ | - | ✘ | - | - | ✘ | - |

| Manservigi et al. [28] | ✘ | ✘ | - | ✘ | - | - | ✘ | - |

| Stefanizzi [30] | - | - | ✘ | ✘ | - | - | ✘ | - |

| Frosina et al. [32] | - | - | ✘ | ✘ | ✘ | - | - | ✘ |

| Perez–Sanchez et al. [33] | - | - | ✘ | ✘ | ✘ | - | - | ✘ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amelio, M.; Barbarelli, S.; Schinello, D. Review of Methods Used for Selecting Pumps as Turbines (PATs) and Predicting Their Characteristic Curves. Energies 2020, 13, 6341. https://doi.org/10.3390/en13236341

Amelio M, Barbarelli S, Schinello D. Review of Methods Used for Selecting Pumps as Turbines (PATs) and Predicting Their Characteristic Curves. Energies. 2020; 13(23):6341. https://doi.org/10.3390/en13236341

Chicago/Turabian StyleAmelio, Mario, Silvio Barbarelli, and Domenico Schinello. 2020. "Review of Methods Used for Selecting Pumps as Turbines (PATs) and Predicting Their Characteristic Curves" Energies 13, no. 23: 6341. https://doi.org/10.3390/en13236341

APA StyleAmelio, M., Barbarelli, S., & Schinello, D. (2020). Review of Methods Used for Selecting Pumps as Turbines (PATs) and Predicting Their Characteristic Curves. Energies, 13(23), 6341. https://doi.org/10.3390/en13236341