Combustible Material Content vs. Fire Properties of Electric Cables †

Abstract

1. Introduction

2. Research Problem

- d—cable diameter, m;

- Vcombust—non-metallic volume of cable components (combustible), m3/1m bunched cable according to EN 50399 [16];

- n—number of cores (conductors).

3. Experimental Section

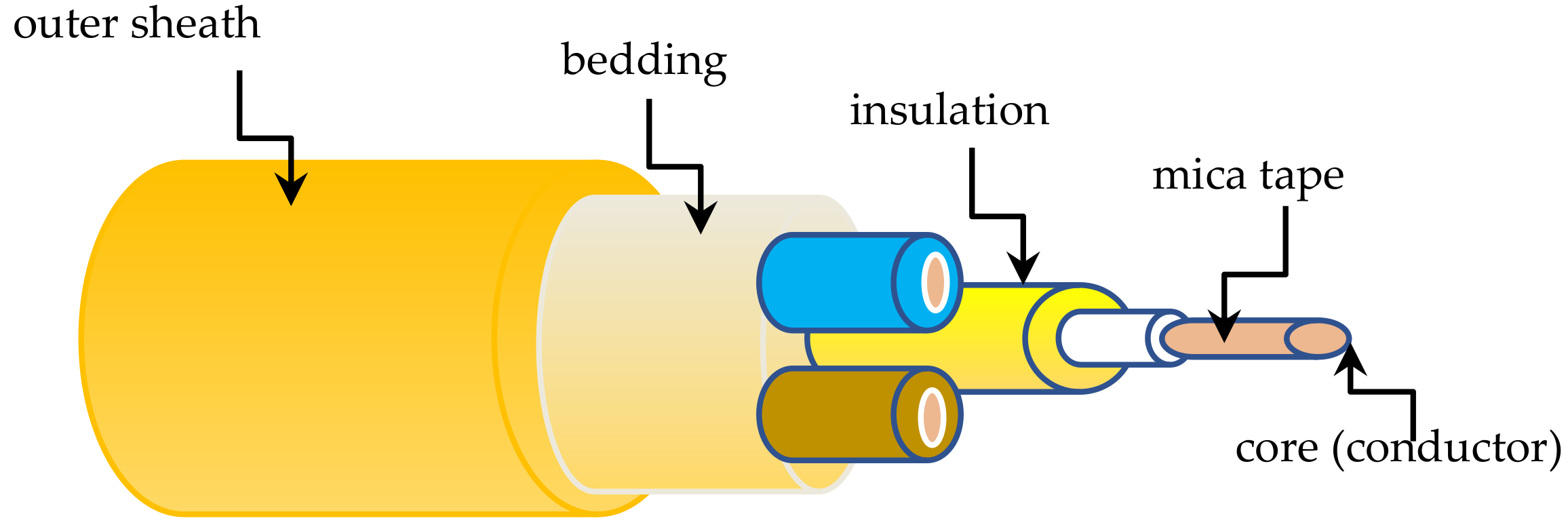

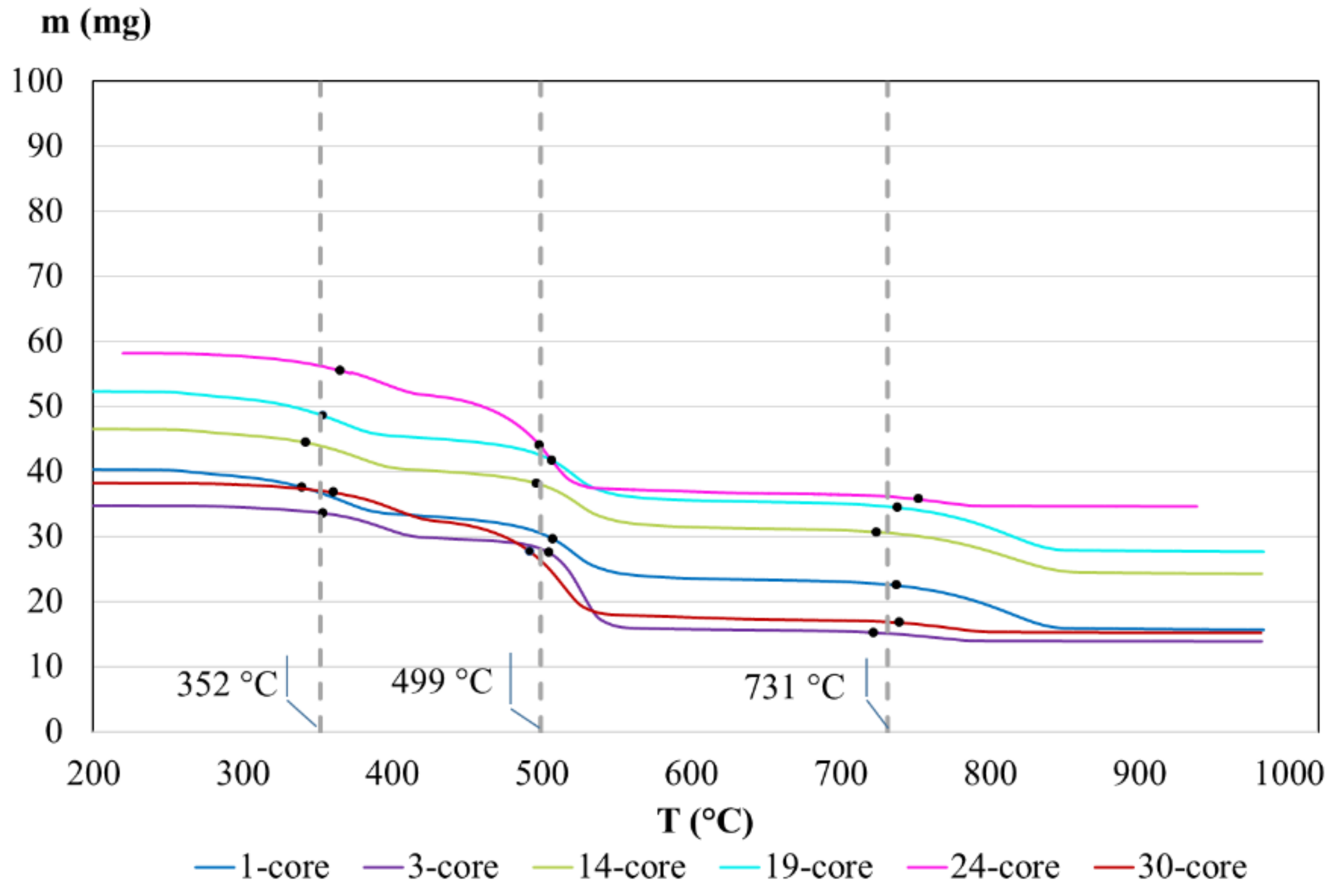

3.1. Samples

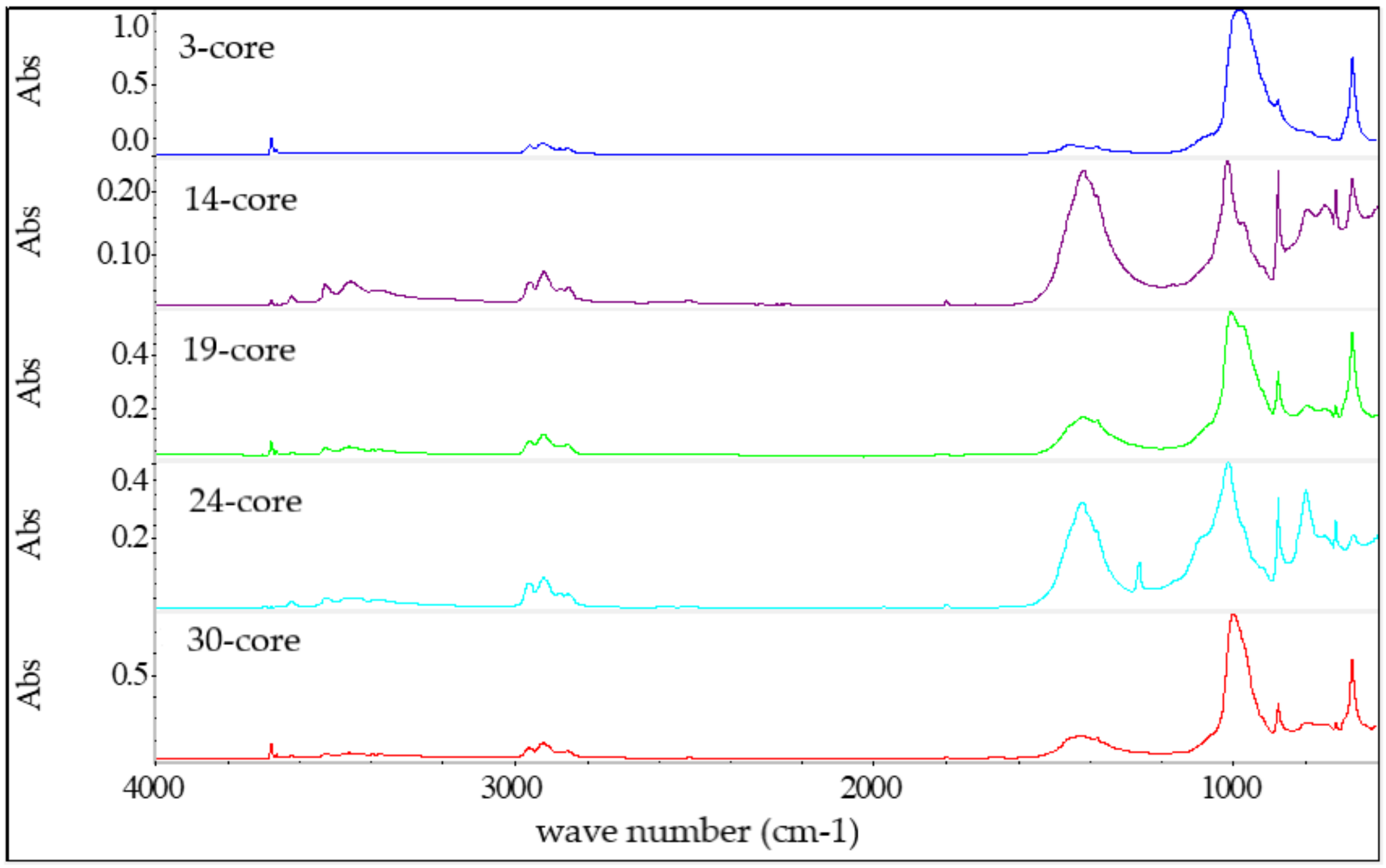

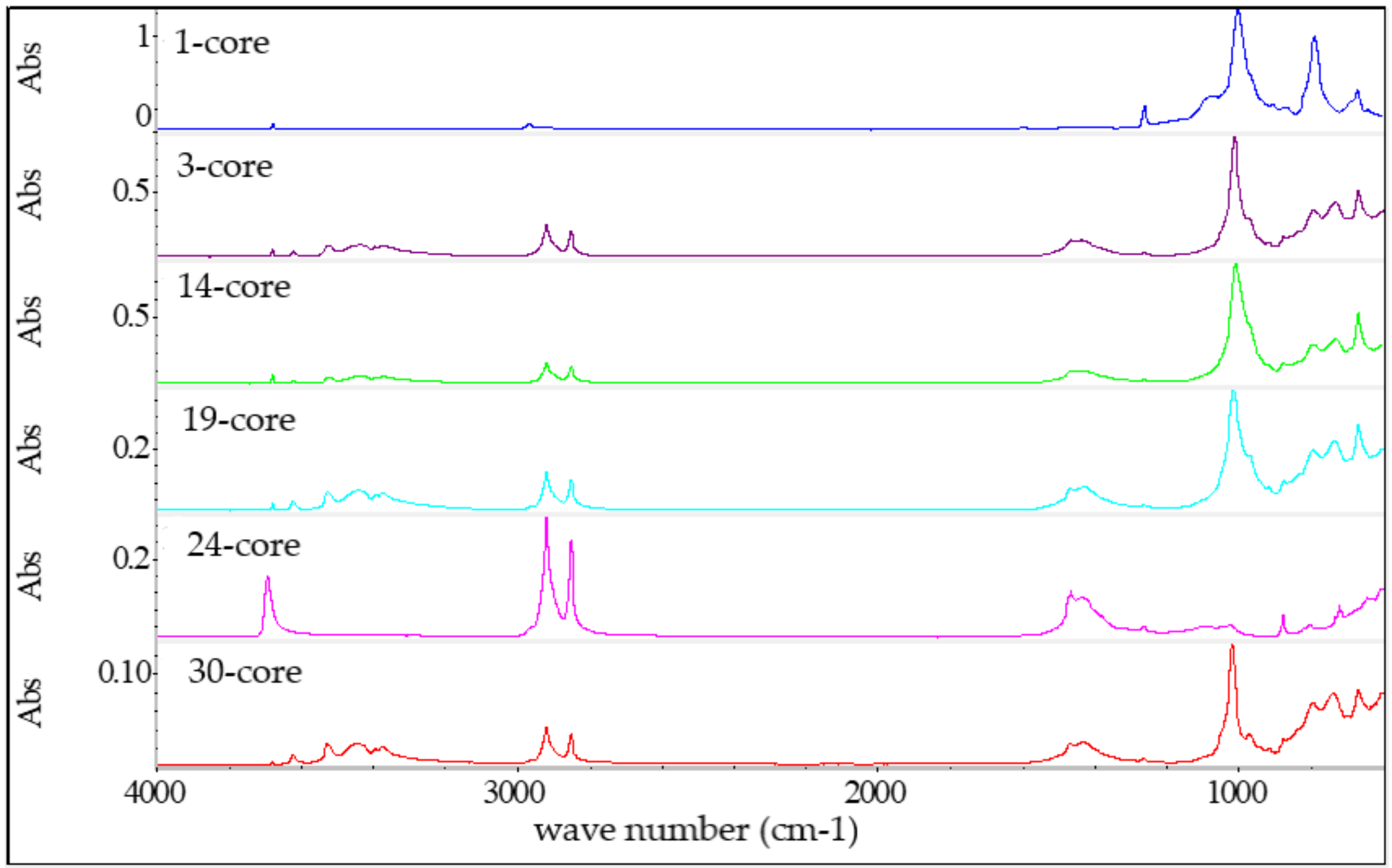

3.2. Methods

3.2.1. Small-Scale Experiments

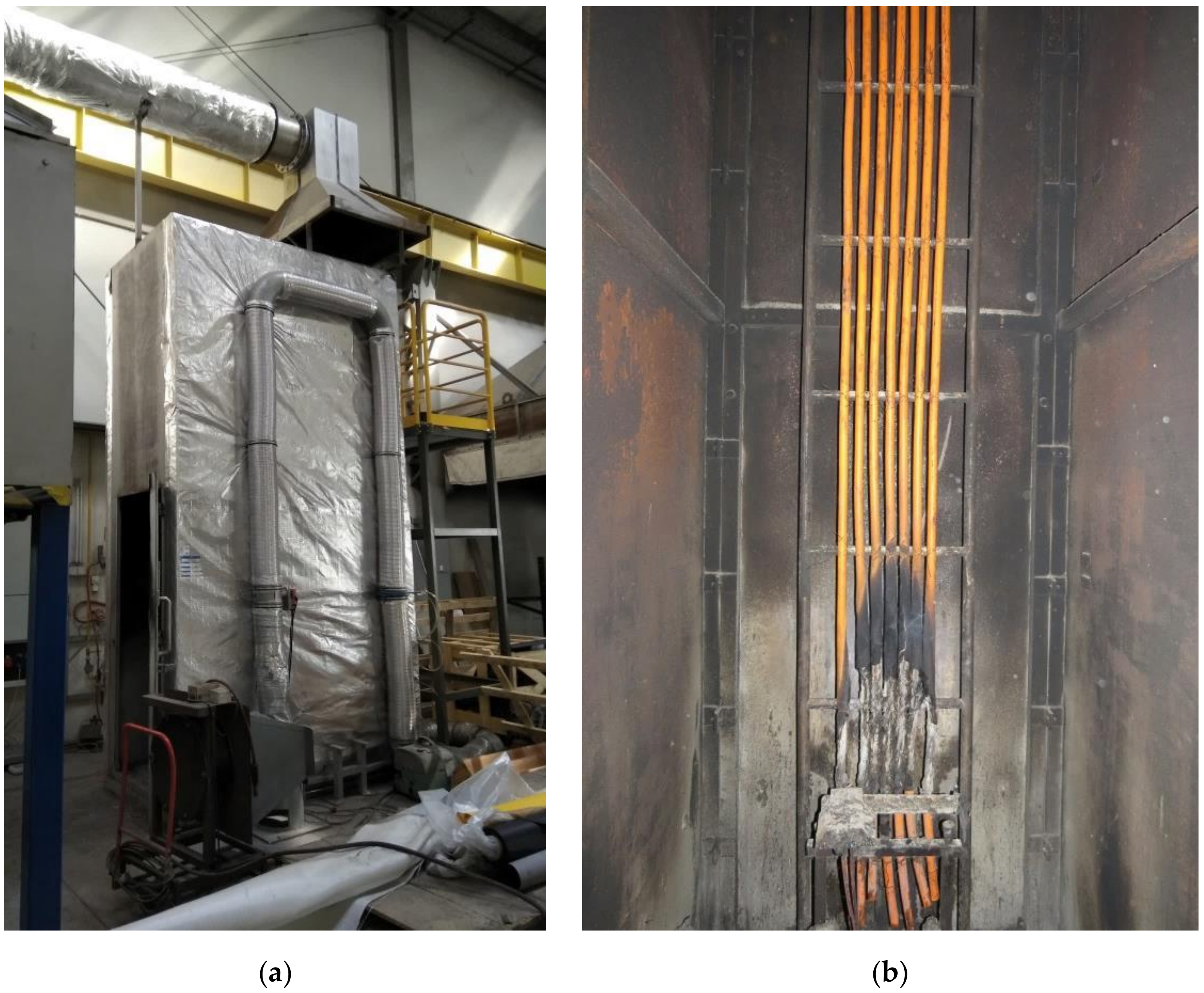

3.2.2. Large-Scale Experiments

- -

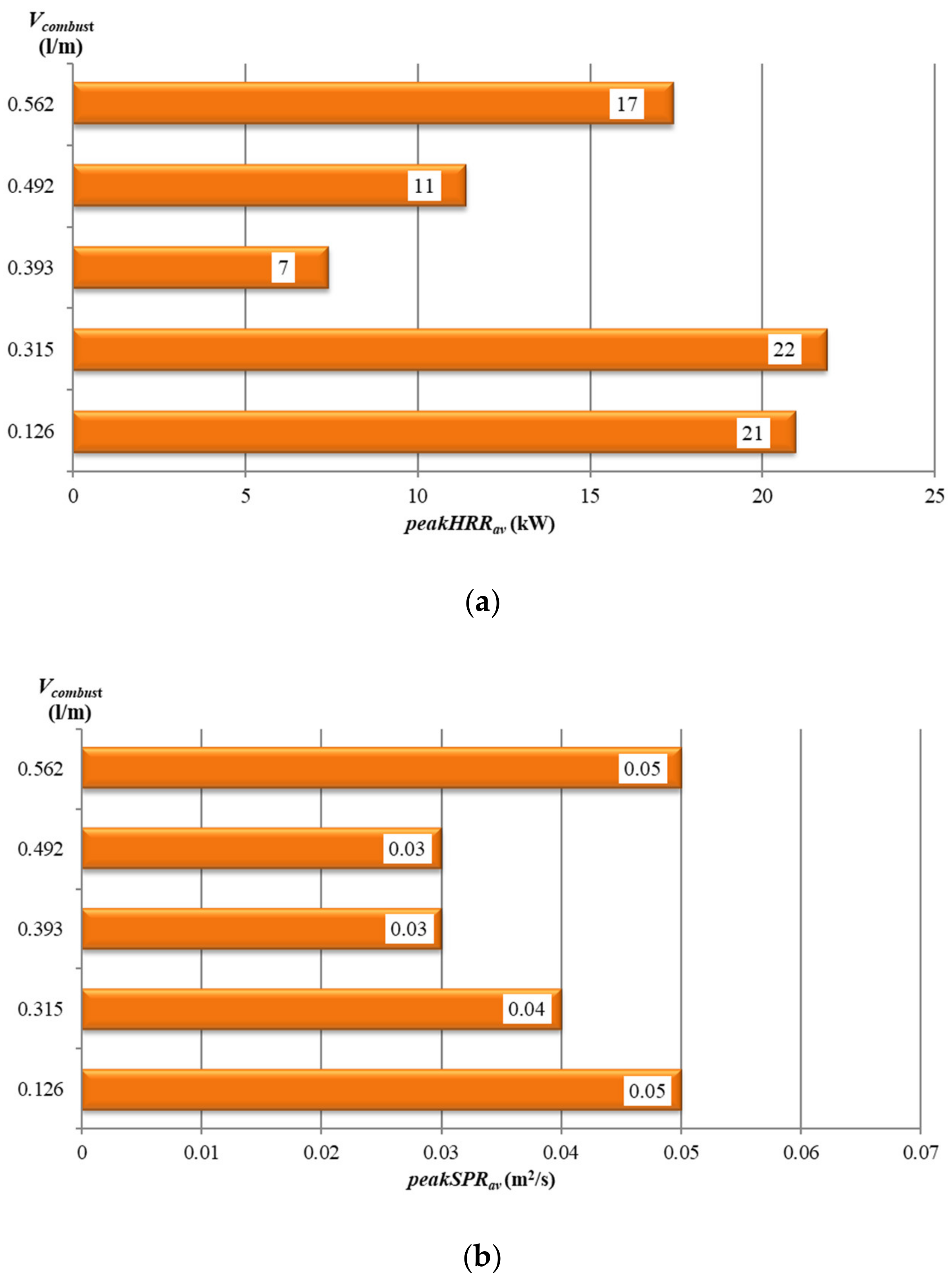

- Heat production: peakHRRav, THR1200s;

- -

- Smoke emission: peakSPRav, TSP1200s;

- -

- Presence of burning droplets; and

- -

- Range of flame spread FS.

4. Discussion and Conclusions

- The construction of the cable strongly influences the fire behavior due to the creation of a barrier for flame penetration and emission of combustion effluents though:

- a.

- Inside the closed agglomeration of non-combustible metallic cores (conductors);

- b.

- The intumescent structures formed from ATH/ZnB fillers and fire retardants in outer sheath material during the self-sustained combustion process after the ignition of cables;

- The inhomogeneous distribution of non-combustible inorganic fillers or different contents of fillers and flame retardants within the polymer fraction cause an unobvious fire behavior of cables;

- The amount of organic combustible compounds strongly influences smoke production during the combustion processes;

- The use of bedding in multicore cable construction results in lower values of combustion parameters (peakHRRav, THR1200s, peakSPRav, and TSP1200s), e.g., better fire properties of cables.

Author Contributions

Funding

Conflicts of Interest

References

- Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 Laying Down Harmonised Conditions for the Marketing of Construction Products and Repealing Council Directive 89/106/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32011R0305&from=EN (accessed on 29 September 2020).

- Kaczorek-Chrobak, K.; Fangrat, J. Relationship between Non-Metallic Material Content and Fire Properties of Electric Cables. In Proceedings of the INTERFLAM2019 Conference, London, UK, 1–3 July 2019. [Google Scholar]

- Bourbigot, S.; Sarazin, J.; Bachelet, P. Small Scale Evaluation and Characterization of Simulated Low Voltage Cables with and without Electrical Current. Fire Mater. 2015, 12, 12–22. [Google Scholar]

- Kaczorek-Chrobak, K. Electric Cables Used in Buildings—Dependency of Fire Properties on Constructional and Material Parameters. Ph.D. Thesis, Instytut Techniki Budowlanej, Warsaw, Poland, 2020. [Google Scholar]

- Grayson, S.J.; Van Hees, P.; Green, A.M.; Vercellotti, U. Assessing the Fire Performance of Electric Cables (FIPEC). Fire Mater. 2001, 25, 49–60. [Google Scholar] [CrossRef]

- Carcillo, M.; Caro, A.-S.; Sonnier, R.; Ferry, L.; Gesta, E.; Lagreve, C. Fire behaviour of electrical cables in cone calorimeter: Influence of cables structure and layout. Fire Saf. J. 2018, 99, 12–21. [Google Scholar]

- Meinier, R.; Sonnier, R.; Zavaleta, P.; Suard, S.; Ferry, L. Fire behavior of halogen-free flame retardant electrical cables with the cone calorimeter. J. Hazard. Mater. 2018, 342, 306–316. [Google Scholar] [CrossRef]

- Braun, E.; Shields, J.R.; Harris, R.H. Flammability Characteristics of Electrical Cables Using the Cone Calorimeter; NIST Report, NISTIR 88 4003; Department of Commerce: Washington, DC, USA, 1989.

- Hirshler, M.M. Survey of fire testing of electrical cables. Fire Mater. 1992, 16, 107–118. [Google Scholar] [CrossRef]

- Cogen, J.M.; Jow, J.; Lin, T.S.; Whaley, P.D. New Approaches to Halogen Free Polyolefin Flame Retardant Wire and Cable Compounds. In Proceedings of the 52nd IWCS/Focus International Wire and Cable Symposium, Philadelphia, PA, USA, 13 November 2003; pp. 102–107. [Google Scholar]

- McCarthy, S. Environmentally Benign Resins and Additives, For Use in the Wire and Cable Industry; Technical Report; The Massachusetts Toxics Use Reduction Institute University of Massachusetts Lowell: Amhrest, MA, USA, 2003. [Google Scholar]

- Kaczorek, K. Bench Scale Fire Toxicity Measurements of Polymers and Cables. Master’s Thesis, University of Central Lancashire, Preston, UK, 2009. [Google Scholar]

- Kaczorek-Chrobak, K. Reakcja na ogień kabli bezhalogenowych oraz kabli na bazie PVC (Reaction to fire of PVC based halogen-free electric cables). Elektroinfo 2015, 10, 25–27. (In Polish) [Google Scholar]

- CLC/TS 50576 Electric Cables—Extended Application of Test Results for Reaction to Fire. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030340235 (accessed on 23 November 2020).

- Sundström, B.-A.; Försth, M.; Johansson, P.; Grayson, S.; Journeaux, T. Prediction of Fire Classification of Cables. Extended Application of Test Data. In Proceedings of the 12th International Fire Science & Engineering Conference, Nottingham, UK, 5–7 July 2010. [Google Scholar]

- EN 50399. Common Test Methods for Cables Under Fire Conditions—Heat Release and Smoke Production Measurement on Cables During Flame Spread Test—Test Apparatus, Procedures, Results. Available online: https://standards.iteh.ai/catalog/standards/clc/aec73708-d180-4cf3-b532-fb0850ed0705/pren-50399 (accessed on 23 November 2020).

- Kaczorek-Chrobak, K.; Fangrat, J. Influence of Constructional-Material Parameters on the Fire Properties of Electric Cables. Energies 2019, 12, 4569. [Google Scholar] [CrossRef]

- Girardin, B.; Fontaine, G.; Duquesne, S.; Bourbigot, S.; Delineau, L.; Försth, M.; Hewitt, F.; Witkowski, A.; Stec, A.; Hull, T.R. Small scale tests and numerical modelling of fire performance for electrical cable. In Proceedings of the 14th International Conference and Exhibition on Fire and Materials, San Francisco, CA, USA, 2–4 February 2015. [Google Scholar]

- Försth, M.; Sjostrom, J.; Wickstrom, U.; Anderssoon, P.; Girardin, B. Characterization of the thermal exposure in the EN 50399 cable test apparatus. In Proceedings of the International Conference and Exhibition on Fire and Materials, San Francisco, CA, USA, 2–4 February 2015; pp. 23–37. [Google Scholar]

- Janssens, M.; Parker, W.J. Oxygen Consumption Calorimetry. In Heat Release in Fires; Babrauskas, V., Grayson, S.J., Eds.; Elsevier Applied Science: London, UK, 1992; pp. 31–59. [Google Scholar]

- Yang, Y.; Shi, X.; Zhao, R. Flame Retardancy Behavior of Zinc Borate. J. Fire Sci. 1999, 17, 355–361. [Google Scholar] [CrossRef]

- Shen, K.K. Review of Recent Advances on the Use of Boron-based Flame Retardants. Polym. Green Flame Retard. 2014, 367–388. [Google Scholar] [CrossRef]

| Specimen No | No of Cores | Conductor Cross Section Size (No of Cores × 1.5 mm2) | Outer Diameter, mm | Vcombust, dm3/m | Bedding |

|---|---|---|---|---|---|

| 1 | 1 | 1.5 | 6.7 | 0.032 | none |

| 2 | 3 | 13.5 | 13.6 | 0.125 | Flame retardant XLPE |

| 3 | 14 | 21,0 | 22.4 | 0.314 | |

| 4 | 19 | 28,5 | 24.7 | 0.393 | |

| 5 | 24 | 36,0 | 27 | 0.492 | |

| 6 | 30 | 45,0 | 30.5 | 0.562 |

| Parameter | Specimen No 1 | Specimen No 2 |

|---|---|---|

| Vcombust (dm3/m of cable) | 0.393 | |

| peakHRRav (kW) | 7 | 8 |

| THR1200s (MJ) | 5 | 3 |

| FS (m) | 0.67 | 0.79 |

| Specimen No | No of Cores | Vcombust, L/m of cable | THR1200s, MJ | TSP1200s, m2 | FS, m | Δm, - | EHC, MJ | vav, (m/min) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.032 | 44 | 53 | 3.3 | 0.39 | 113.7 | 0.17 |

| 2 | 3 | 0.126 | 13 | 32 | 1.12 | 0.45 | 29.7 | 0.06 |

| 3 | 14 | 0.315 | 15 | 25 | 1.18 | 0.49 | 30.7 | 0.06 |

| 4 | 19 | 0.393 | 5 | 18 | 0.79 | 0.50 | 10.5 | 0.04 |

| 5 | 24 | 0.492 | 6 | 10 | 0.92 | 0.53 | 12.0 | 0.05 |

| 6 | 30 | 0.562 | 13 | 30 | 0.95 | 0.45 | 29.0 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczorek-Chrobak, K.; Fangrat, J. Combustible Material Content vs. Fire Properties of Electric Cables. Energies 2020, 13, 6172. https://doi.org/10.3390/en13236172

Kaczorek-Chrobak K, Fangrat J. Combustible Material Content vs. Fire Properties of Electric Cables. Energies. 2020; 13(23):6172. https://doi.org/10.3390/en13236172

Chicago/Turabian StyleKaczorek-Chrobak, Katarzyna, and Jadwiga Fangrat. 2020. "Combustible Material Content vs. Fire Properties of Electric Cables" Energies 13, no. 23: 6172. https://doi.org/10.3390/en13236172

APA StyleKaczorek-Chrobak, K., & Fangrat, J. (2020). Combustible Material Content vs. Fire Properties of Electric Cables. Energies, 13(23), 6172. https://doi.org/10.3390/en13236172