Thermodynamic Analysis of Iron Ore Sintering Process Based on Biomass Carbon

Abstract

1. Introduction

2. Methodology

2.1. Raw Materials

2.1.1. Solid Fuel

2.1.2. Iron Ore

2.1.3. Other Materials

2.1.4. Distribution Ratio

2.1.5. Air

2.2. Products

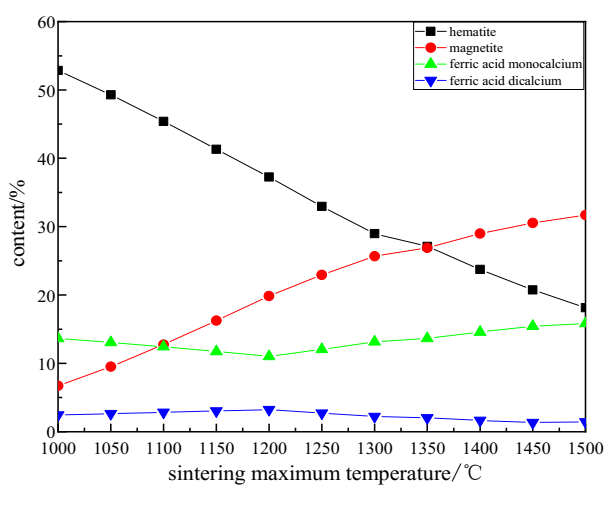

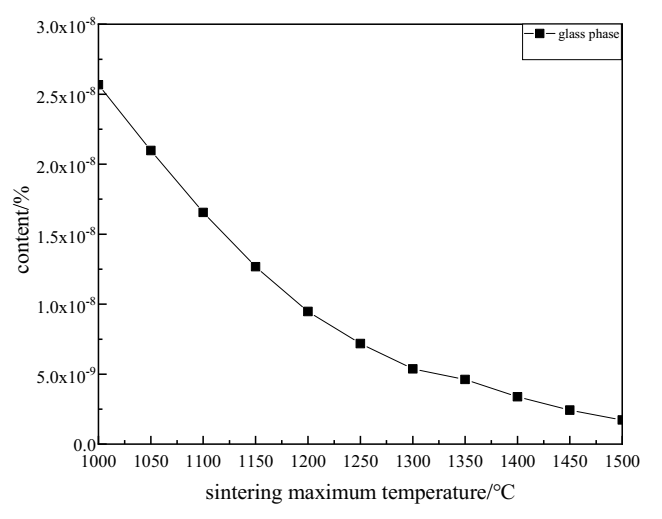

2.2.1. Sinter Ore

2.2.2. Sinter Gases

2.3. Indexes

3. Effect of Biomass Charcoal Substitution on Sintering Technical Indicators

3.1. Chemical Composition

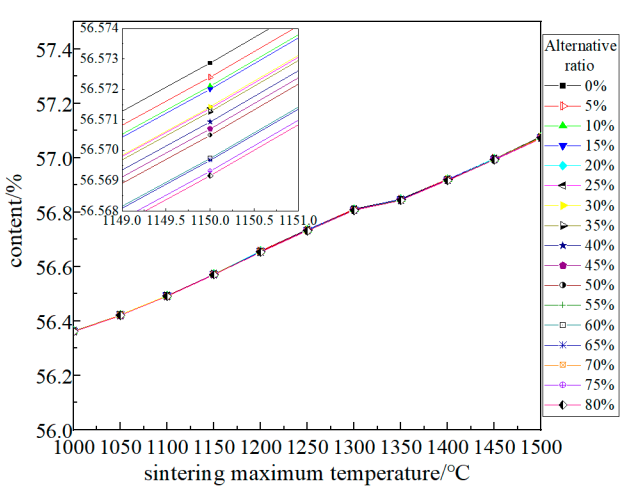

3.1.1. Fe

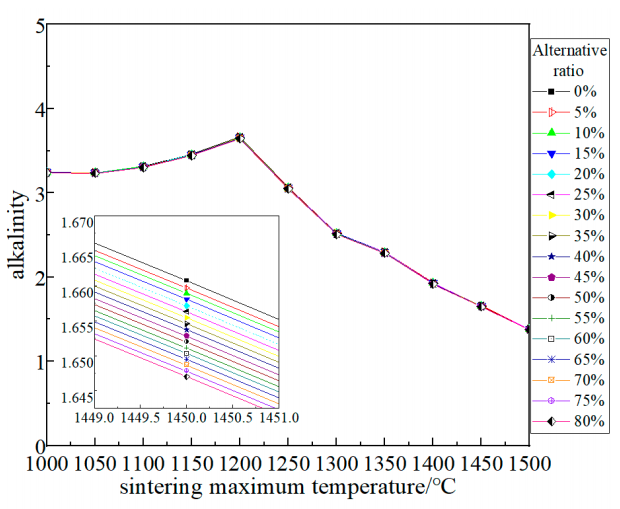

3.1.2. Basicity

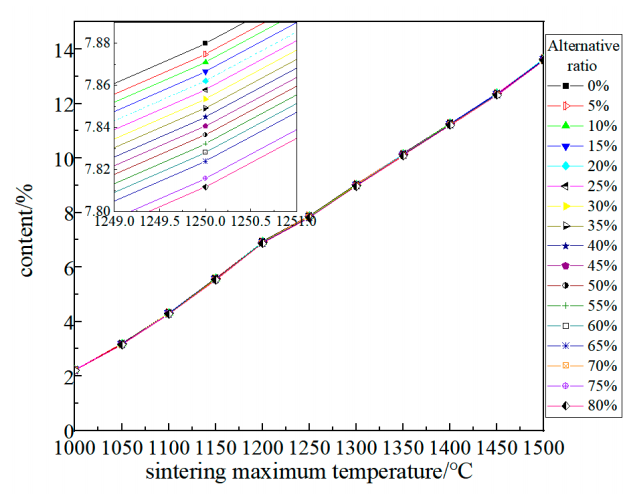

3.1.3. FeO

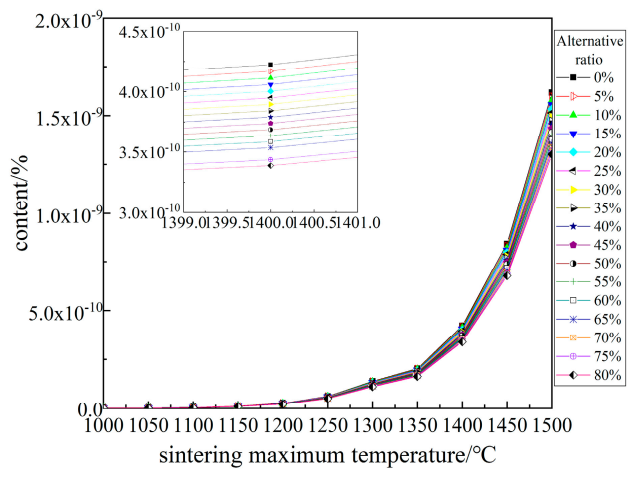

3.1.4. S

3.2. Metallurgical Performance

3.2.1. Reduction Degradation Index

3.2.2. Reduction Index

4. Effect of Straw Charcoal Substitution on Sintering Pollutant Gases Emissions

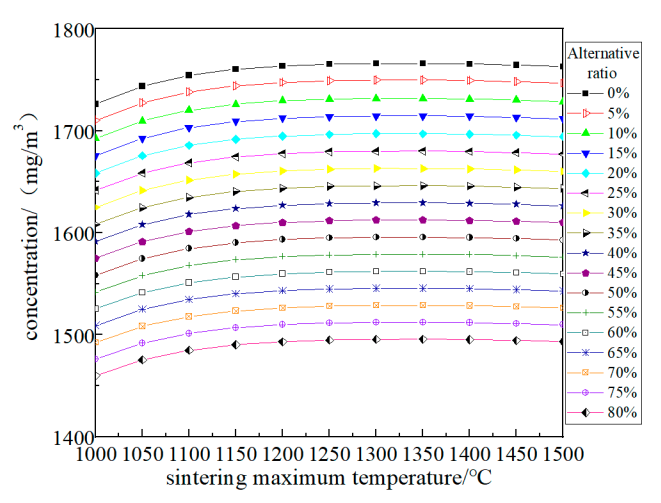

4.1. SO2

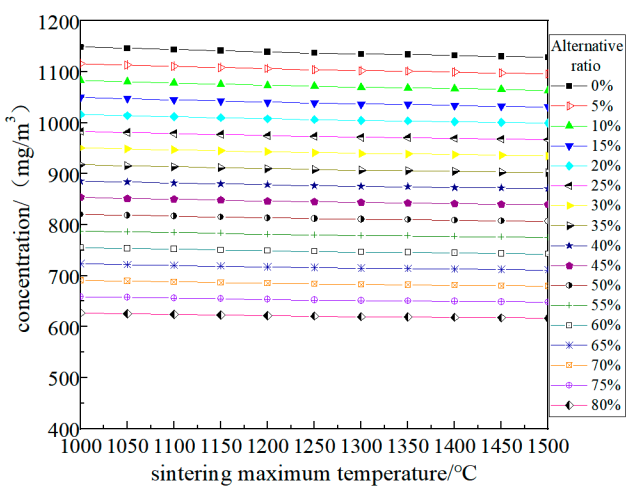

4.2. NOx

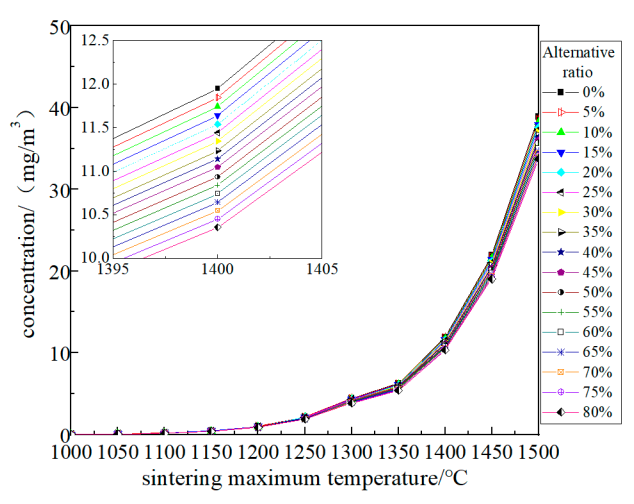

4.3. CO

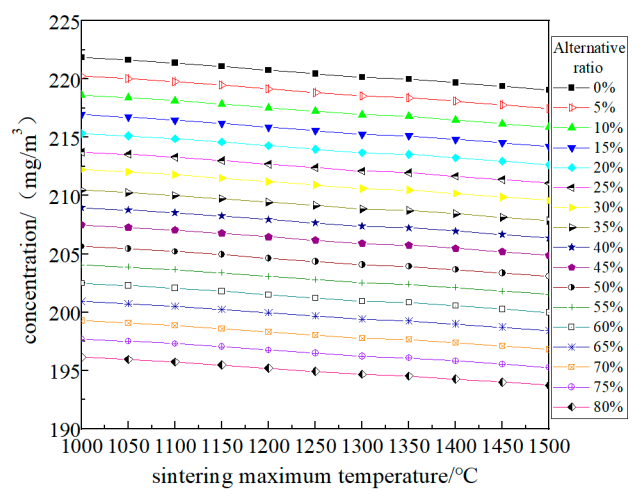

4.4. CO2

5. Conclusions

- (1)

- Through the thermodynamics analysis by using straw charcoal instead of coke breeze in the sinter process, the result shows that the sintering technical indicators of sinter ore, including chemical compositions and metallurgical properties, will not be affected with the substitution of straw charcoal. Meanwhile, the sintering technical indicators will get changed with the change of sintering maximum temperature. When the sintering maximum temperature is about 1300 to 1400 °C, sinter ore with high quality can be produced.

- (2)

- The sintering maximum temperature has a slight effect on pollutant emissions, which can be ignored. Biomass replacement has a significant effect on the reduction in pollutant gases emissions. When using straw charcoal for sinter at the substitution ratio of 80%, SO2 concentration decreases by about 18% compared to that with no substitution, and that of NOx and CO2 is about 46% and 14%, respectively. CO concentration also decreases, but the degree is slight.

Author Contributions

Funding

Conflicts of Interest

References

- Gan, M.; Fan, X.; Ji, Z.; Chen, X.; Jiang, T.; Li, G.; Yu, Z. Influence of Modified Biomass Fuel on Iron Ore Sintering. Dry. Roasting Calcining Miner. 2015, 30, 241–248. [Google Scholar] [CrossRef]

- Hu, J.; Wu, M.; Chen, X.; Du, S.; Cao, W.; She, J. Hybrid modeling and online optimization strategy for improving carbon efficiency in iron ore sintering process. Inf. Sci. 2019, 483, 232–246. [Google Scholar] [CrossRef]

- Zhou, J.C.; Li, X.P.; Shangguan, F.Q.; Zhang, C.X. Status of energy consumption and energy-saving technical measures of sintering process in China. Energy Metall. Ind. 2010, 29, 23–26. [Google Scholar]

- Bartocci, P.; Wang, L.; Skreiberg, Ø.; Liberti, F.; Bidini, G.; Fantozzi, F. Biocarbon Production and Use as a Fuel. Biofuels Biorefin. 2019, 9, 295–324. [Google Scholar] [CrossRef]

- Ooi, T.C.; Thompson, D.; Anderson, D.R.; Fisher, R.; Fray, T.; Zandi, M. The effect of charcoal combustion on iron-ore sintering performance and emission of persistent organic pollutants. Combust. Flame 2011, 158, 979–987. [Google Scholar] [CrossRef]

- Schmole, P. Measures to Reduce CO2 and Other Emissions in the Steel Industry in Germany and Europe. In Proceedings of the 5th International Congress on the Science and Technology of Ironmaking, Shanghai, China, 20–22 October 2009; Volume 9, pp. 68–76. [Google Scholar]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- World Energy Outlook; IEA: Paris, France, 2012.

- Xie, H.; Li, R.; Yu, Z.; Wang, Z.; Yu, Q.; Qin, Q. Combined steam/dry reforming of bio-oil for H2/CO syngas production with blast furnace slag as heat carrier. Energy 2020, 200, 117481. [Google Scholar] [CrossRef]

- Kalisz, S.; Ciukaj, S.; Mroczek, K.; Tymoszuk, M.; Wejkowski, R.; Pronobis, M.; Kubiczek, H. Full-scale study on halloysite freside additive in 230 t/h pulverized coal utility boiler. Energy 2015, 92, 33–39. [Google Scholar] [CrossRef]

- Ooi, T.C.; Aries, E.; Ewan, B.C.; Thompson, D.; Anderson, D.R.; Fisher, R.; Tognarelli, D. The study of sunflower seed husks as a fuel in the iron ore sintering process. Miner. Eng. 2007, 21, 167–177. [Google Scholar] [CrossRef]

- Lovel, R.; Vining, K.; Dell’Amico, M. Iron ore sintering with charcoal. Miner. Process. Extr. Metall. 2007, 116, 85–92. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Zhao, K.; Xing, H.; Kang, Y. Modified biomass fuel instead of coke for iron ore sintering. Ironmak. Steelmak. 2020, 47, 188–194. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Zhao, K.; Xing, H.; Kang, Y. Effect of biomass on reaction performance of sintering fuel. Energy Mater. 2019, 54, 3262–3272. [Google Scholar] [CrossRef]

- Gan, M.; Fan, X.; Chen, X.; Ji, Z.; Lv, W.; Wang, Y.; Yu, Z.; Jiang, T. Reduction of Pollutant Emission in Iron Ore Sintering Process by Applying Biomass Fuels. ISIJ Int. 2012, 52, 1574–1578. [Google Scholar] [CrossRef]

- Xu, H. Sinter Production; Chemical Industry Press: Beijing, China, 2013; pp. 242–253. [Google Scholar]

- Mou, J.L.; Morrison, R.J. Sinter Plant Operations: Raw Materials. In Ironmaking and Steelmaking Processes; Springer: Cham, Switzerland, 2016; pp. 3–26. [Google Scholar] [CrossRef]

- Mezibricky, R.; Frohlichova, M.; Maslejova, A. Phase composition of iron ore sinters produced with biomass as a substitute for the coke fuel. Arch. Metall. Mater. 2015, 60, 2956–2963. [Google Scholar] [CrossRef]

- GB/28662-2012. Emission Standard of Air Pollutants for Sintering and Pelletizing of Iron and Steel Industry; China Standard Press: Beijing, China, 2012. [Google Scholar]

- Chen, X. Sinter Batcher; Metallurgical Industry Press: Beijing, China, 2014; pp. 9–11. [Google Scholar]

- Jiang, D.-J.; He, M.-G.; Gan, Q.; He, Q. Experiment on Influence of FeO on Sinter Property under High Basicity Condition. China Metall. 2008, 18, 14–21. [Google Scholar] [CrossRef]

- Seshadri, P. Characterisation of structure of iron ore sinter and its behaviour during reduction at low temperatures. Ironmak. Steelmak. 2002, 29, 169–174. [Google Scholar] [CrossRef]

- Lei, C.; Wei, Y.-G. Pulverization of Iron Ore Sinter in Low Temperature Reduction Process. Chin. J. Process Eng. 2015, 15, 284–288. [Google Scholar]

- Cen, K.-F. Advanced Combustion; Zhejiang University Press: Hangzhou, China, 2002; pp. 563–567. [Google Scholar]

- Khanna, R.; Mansuri, I.; Sahajwalla, V. Recycling waste bakelite as an alternative carbon resource for ironmaking applications. ISIJ Int. 2014, 54, 613–619. [Google Scholar] [CrossRef]

- Cavaliere, P. Sintering: Most Efficient Technologies for Greenhouse Emissions Abatement. In Clean Ironmaking and Steelmaking Processes; Springer: Cham, Switzerland, 2019; pp. 111–165. [Google Scholar] [CrossRef]

| C | H | O | S | N | |

|---|---|---|---|---|---|

| Coke breeze | 81.84 | 2.46 | 1.03 | 0.5 | 0.72 |

| Straw charcoal | 71.60 | 4.76 | 6.88 | 0.083 | 0.32 |

| Iron Ore | Fe2O3 | Fe2O3·H2O | FeO | SiO2 | CaO | Al2O3 | MgO | S |

|---|---|---|---|---|---|---|---|---|

| Composition | 49.79 | 37.21 | 5.73 | 3.86 | 0.39 | 2.62 | 0.17 | 0.11 |

| TFe | FeO | SiO2 | CaO | Al2O3 | MgO | S | |

|---|---|---|---|---|---|---|---|

| Limestone | 1.58 | 0 | 1.42 | 48.85 | 0.76 | 3.62 | 0.04 |

| Dolomite | 0.18 | 0 | 1.19 | 33.15 | 0.68 | 18.25 | 0.024 |

| Quicklime | 0.37 | 0 | 3.08 | 67.88 | 0.96 | 1.41 | 0.13 |

| Return mine | 56.13 | 7.35 | 5.22 | 9.22 | 2.88 | 2.15 | 0.024 |

| Converter slag | 17.89 | 13.24 | 10.78 | 45.62 | 3.15 | 8.02 | 0.14 |

| Fuel | Mixed Iron Ore | Limestone | Dolomite | Quicklime | Return Mine | Converter Slag | |

|---|---|---|---|---|---|---|---|

| Proportion/% | 4 | 53.97 | 4.56 | 2.85 | 2.92 | 27.2 | 3.28 |

| System | Mineral | Formula |

|---|---|---|

| Ferrite system | Hematite | Fe2O3 |

| Magnetite | Fe3O4 | |

| Iron silicate system | Fayatite | 2FeO·SiO2 |

| Calcium silicate system | Wollastonite | CaO·SiO2 |

| Calcium orthosilicate | 2CaO·SiO2 | |

| 3CaO·SiO2 | ||

| Calcium ferrite system | CaO·Fe2O3 | |

| - | 2CaO·Fe2O3 | |

| CaO·2Fe2O3 | ||

| Calcium iron olivine system | Calcium iron olivine | CaO·FeO·SiO2 |

| Hedenbergite | CaO·FeO·2SiO2 | |

| Iron yellow feldspar | 2CaO·FeO·SiO2 | |

| Calcium magnesium silicate system | Forsterite | 2MgO·SiO2 |

| Magnesium metasilicate | MgO·SiO2 | |

| Calcium magnesium silicate | CaO·MgO·SiO2 | |

| Diopside | CaO·MgO·2SiO2 | |

| Merwinite | 3CaO·MgO·2SiO2 | |

| Akermanite | 2CaO·MgO·2SiO2 | |

| Calcium magnes | 5CaO·2MgO·6SiO2 |

| Chemical Composition (Mass Fraction) | Metallurgical Performance | |||||

|---|---|---|---|---|---|---|

| TFe/% | CaO/SiO2 | FeO/% | S/% | Reduction Degradation Index (RDI) (+3.15 mm)/% | Degree of Reduction (RI)/% | |

| Allowable range of fluctuation | ±0.40 | ±0.05 | ±0.50 | - | ||

| Index | ≥57 | ≥1.70 | ≤9.00 | ≤0.030 | ≥72.00 | ≥78.00 |

| Mineral | Formula | Compressive Temperature (°C) | Reduction Rate (%) |

| Hematite | Fe2O3 | 2670 | 49.9 |

| Magnetite | Fe3O4 | 3690 | 26.7 |

| Fayatite | 2FeO·SiO2 | 2000 | 1.0 |

| Wollastonite | CaO·SiO2 | 672.8 | - |

| Ferric acid–calcium | CaO·Fe2O3 | 3700 | 40.1 |

| Ferric acid–dicalcium | 2CaO·Fe2O3 | 1420 | 28.5 |

| Calcium iron olivine (glass phase) | CaO·FeO·SiO2 | 460 | 3.1 |

| Diopside | CaO·MgO·2SiO2 | 580.2 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Yu, Z.; Wang, P.; Xie, H.; Wen, Y.; Li, J. Thermodynamic Analysis of Iron Ore Sintering Process Based on Biomass Carbon. Energies 2020, 13, 5988. https://doi.org/10.3390/en13225988

Zhou M, Yu Z, Wang P, Xie H, Wen Y, Li J. Thermodynamic Analysis of Iron Ore Sintering Process Based on Biomass Carbon. Energies. 2020; 13(22):5988. https://doi.org/10.3390/en13225988

Chicago/Turabian StyleZhou, Mi, Zhenyu Yu, Panlei Wang, Huaqing Xie, Yongcai Wen, and Jianming Li. 2020. "Thermodynamic Analysis of Iron Ore Sintering Process Based on Biomass Carbon" Energies 13, no. 22: 5988. https://doi.org/10.3390/en13225988

APA StyleZhou, M., Yu, Z., Wang, P., Xie, H., Wen, Y., & Li, J. (2020). Thermodynamic Analysis of Iron Ore Sintering Process Based on Biomass Carbon. Energies, 13(22), 5988. https://doi.org/10.3390/en13225988