Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study

Abstract

1. Introduction

2. Literature Review

2.1. Fundamentals of Industry 4.0

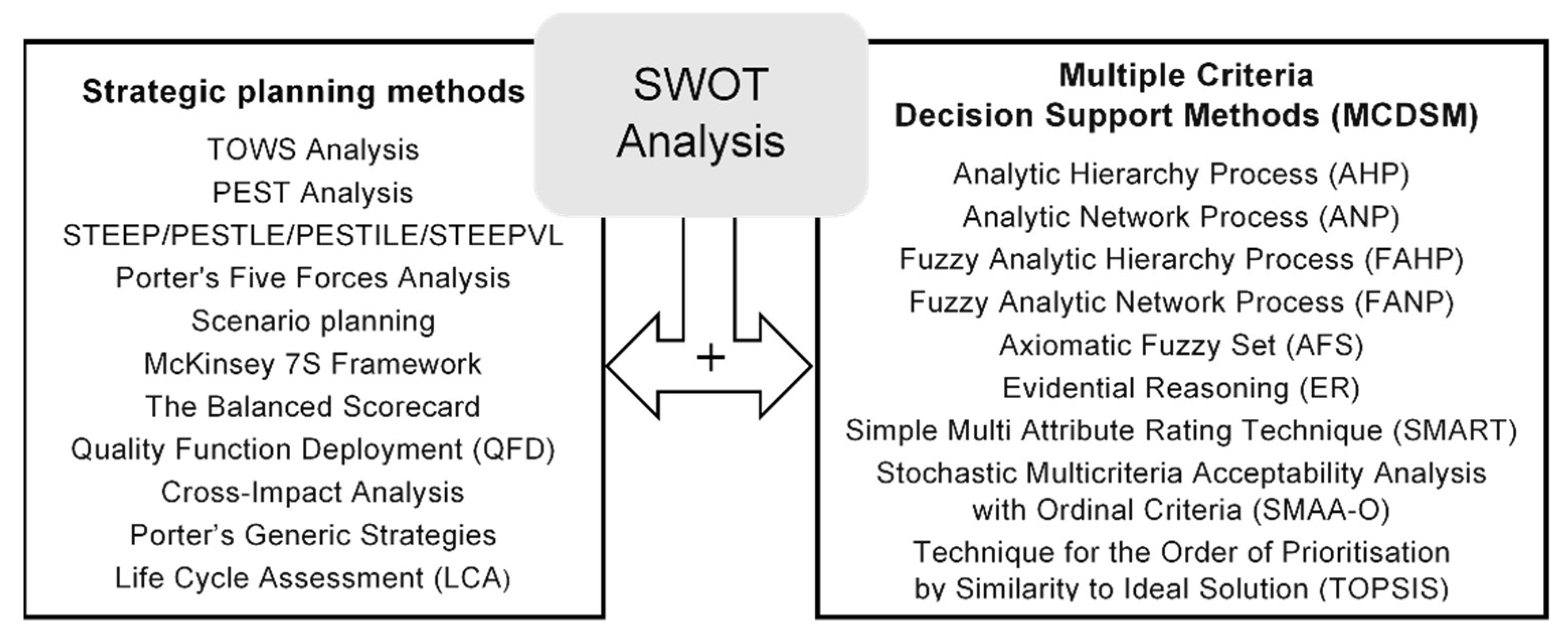

2.2. SWOT Analysis—Conceptual Framework

- the inability to assess the importance of the identified factors;

- unspecified framework of analysis (which may include any number of factors);

- reliance on expert opinion.

- describing factors too broadly;

- assigning factors to inappropriate groups;

- identifying factors subjectively;

- misinterpreting factors;

- basing the analysis on incomplete, outdated, or erroneous information.

2.3. SWOT Analysis in the Context of Regional Industry Development

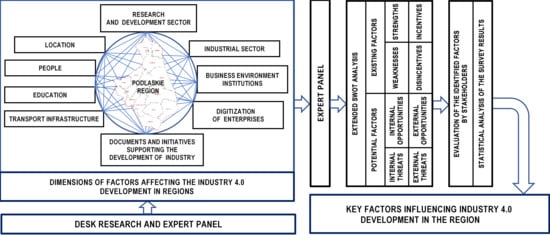

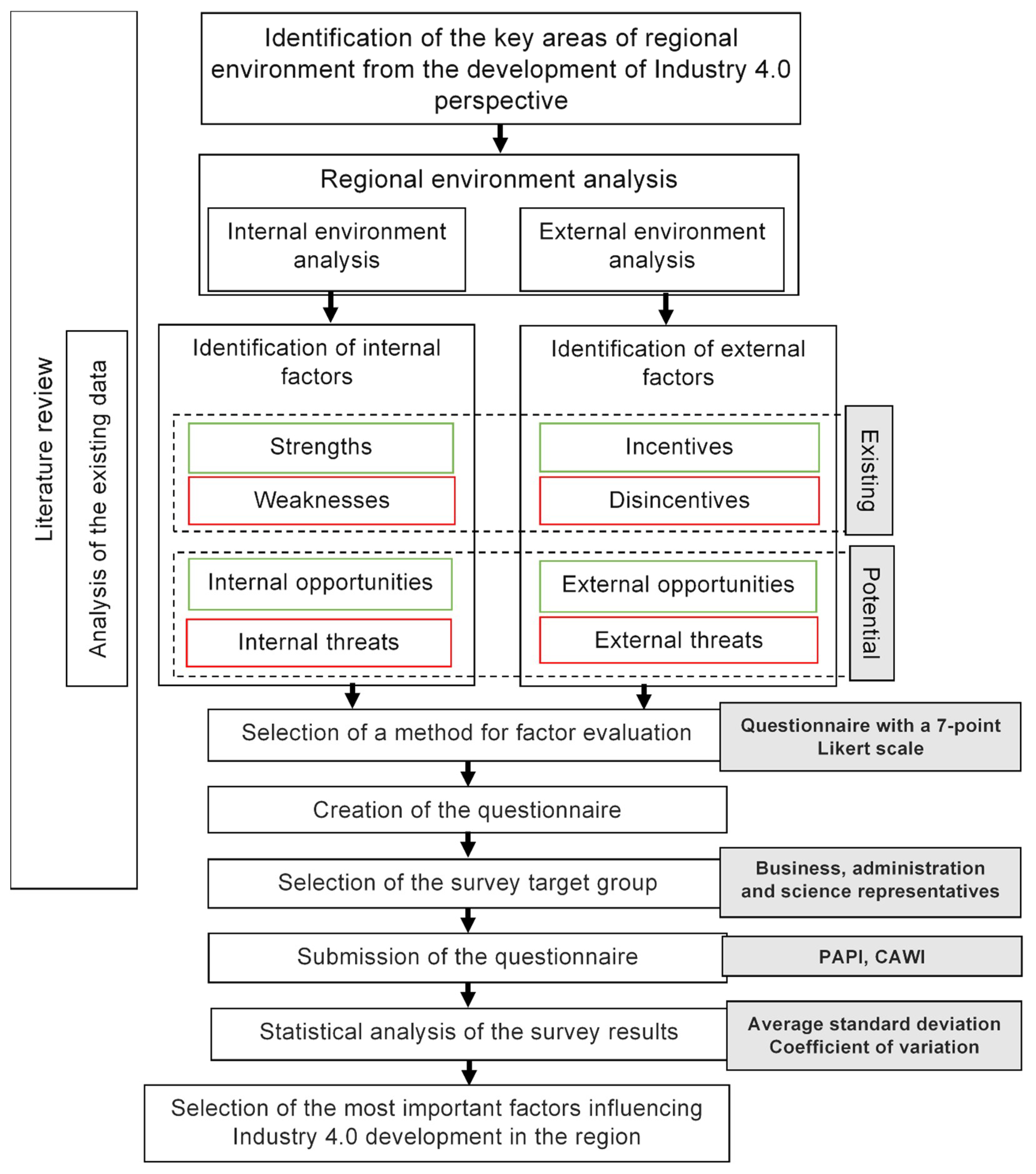

3. Research Methodology

3.1. Identification of the Key Areas of the Regional Environment

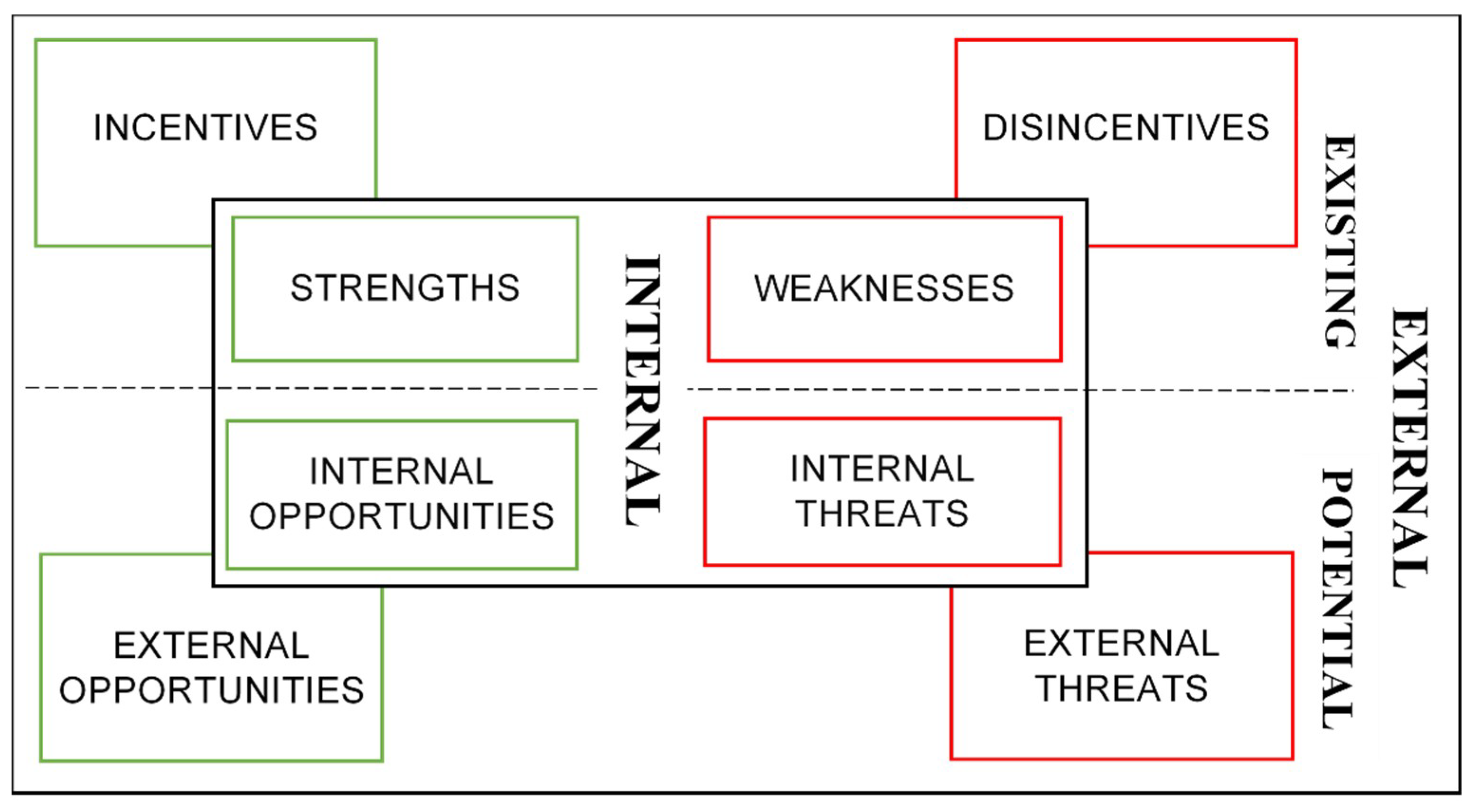

3.2. Extended SWOT Analysis

- strengths—positive factors, which originate in the studied area and exist during the study;

- weaknesses—negative factors, which originate in the studied area and exist during the study;

- incentives—positive factors, which originate in the external environment and exist during the study;

- disincentives—negative factors, which originate in the external environment and exist during the study;

- internal opportunities—positive factors, which may originate in the studied area;

- external opportunities—positive factors, which may originate in the external environment;

- internal threats—negative factors, which may originate in the studied area;

- external threats—negative factors, which may originate in the external environment.

- national and regional statistical yearbooks and studies containing data on the national and regional situation of: economy, demographics, industry, agriculture, trade, transport, and digitization;

- studies on the investment attractiveness of regions;

- reports on the implementation of national and regional strategy objectives;

- reports on research and development activity, innovation support centers, and business environment organizations.

4. Case Study

4.1. Characteristics of the Region

4.2. Extended SWOT Analysis of the Region

- 11 strengths (S) and 15 weaknesses (W);

- 10 incentives (I) and 8 disincentives (D);

- 12 internal opportunities (IO) and 6 external opportunities (EO);

- 5 internal threats (IT) and 9 external threats (ET).

4.3. Assessment of Factor Importance

5. Discussion of the Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schwab, K. The Fourth Industrial Revolution; Penguin Random House: London, UK, 2017; ISBN 978-0-241-30075-6. [Google Scholar]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Mwape, M.C.; Mpofu, N.S.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. Hindawi J. Eng. 2020, 2020, 8090521. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Mohamed, N.; Al-Jaroodi, J.; Lazarova-Molnar, S. Industry 4.0: Opportunities for Enhancing Energy Efficiency in Smart Factories. In Proceedings of the 2019 IEEE International Systems Conference (SysCon), Institute of Electrical and Electronics Engineers (IEEE), Orlando, FL, USA, 8–11 April 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Li, G.; Hou, Y.; Wu, A. Fourth Industrial Revolution: Technological drivers, impacts and coping methods. Chin. Geogr. Sci. 2017, 27, 626–637. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the STRATEGIC initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group; Acatech: München, Germany, 2013; Available online: https://en.acatech.de/publication/recommendations-for-implementing-the-strategic-initiative-industrie-4-0-final-report-of-the-industrie-4-0-working-group/ (accessed on 10 June 2020).

- Horak, J.; Boksova, J. Business risks connected with Industry 4.0. In Managing and Modelling of Financial Risks, Proceedings of the 8th International Scientific Conference, Ostrava, Czech Republic, 5–6 September 2016; Culik, M., Ed.; VSB-Technical University of Ostrava: Ostrava, Czech Republic, 2016; pp. 300–306. [Google Scholar]

- Fonseca, L.M. Industry 4.0 and the digital society: Concepts, dimensions and envisioned benefits. In Proceedings of the 12th International Conference on Business Excellence, Bucharest, Romania, 22–23 March 2018; Sciendo: Warsaw, Poland, 2018; pp. 386–397. [Google Scholar] [CrossRef]

- Szum, K.; Magruk, A. Analiza uwarunkowań rozwoju Przemysłu 4.0 w województwie podlaskim. Akademia Zarz. 2019, 3, 73–91. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Ministry of Economic Development. Strategy for Responsible Development for the Period up to 2020 (Including the Perspective up to 2030); Ministry of Economic Development: Warsaw, Poland, 2017. (In Polish)

- Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and the Committee of the Regions: The European Green Deal. Communication No. COM/2019/640. European Commission: Brussels, Belgium, 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 20 June 2020).

- Jarzabkowski, P.; Kaplan, S. Strategy tools-in-use: A framework for understanding “technologies of rationality” in practice. Strat. Mgmt. J. 2015, 36, 537–558. [Google Scholar] [CrossRef]

- Madsen, D.Ø. SWOT Analysis: A Management Fashion Perspective. Int. J. Bus. Res. 2016, 16, 39–56. [Google Scholar] [CrossRef]

- Nazarko, J.; Ejdys, J.; Halicka, K.; Magruk, A.; Nazarko, Ł.; Skorek, A. Application of Enhanced SWOT Analysis in the Future-oriented Public Management of Technology. Procedia Eng. 2017, 182, 482–490. [Google Scholar] [CrossRef]

- Terrados, J.; Almonacid, G.; Pérez-Higueras, P. Proposal for a combined methodology for renewable energy planning. Application to a Spanish region. Renew. Sustain. Energy Rev. 2009, 13, 2022–2030. [Google Scholar] [CrossRef]

- Yılmaz, M. Turkey’s Industrial 4.0 Compliance: SWOT Analysis. In Proceedings of the International Congress on Afro-Eurasian Research V, Nicosia, Cyprus, 19–22 April 2019; pp. 192–201. [Google Scholar]

- Karppi, I.; Kokkonen, M.; Lähteenmäki-Smith, K. SWOT-Analysis as a Basis for Regional Strategies, Nordregio Working Paper 2001:4; Nordregio: Stockholm, Sweden, 2001; Available online: https://pdfs.semanticscholar.org/a722/4b4ebf58433cde3433f3898f7ca4725b2c07.pdf?_ga=2.164274170.497523203.1591777618-1278803450.1591647985 (accessed on 10 June 2020).

- Fang, T.; Tang, M.; Cheng, L.; Zhao, C. SWOT Analysis of Industry Development Strategy in Yingkou. In Proceedings of the 2011 International Conference on Management and Service Science, Wuhan, China, 12–14 August 2011. [Google Scholar] [CrossRef]

- Koshesh, O.S.; Jafari, H.R. The Environmental Strategic Analysis of Oil & Gas Industries in the Kurdistan Region Using PESTLE, SWOT and FDEMATEL. Pollution 2019, 5, 537–554. [Google Scholar] [CrossRef]

- Kim, Y.J.; Park, J. A Sustainable Development Strategy for the Uzbekistan Textile Industry: The Results of a SWOT-AHP Analysis. Sustainability 2019, 11, 4613. [Google Scholar] [CrossRef]

- Arbolino, R.; Boffardi, R.; Lanuzza, F.; Ioppolo, G. Monitoring and evaluation of regional industrial sustainability: Evidence from Italian regions. Land Use Policy 2018, 75, 420–428. [Google Scholar] [CrossRef]

- Sammut-Bonnici, T.; Galea, D. SWOT analysis. In Willey Encyclopedia of Management: Volume 12 Strategic Management, 3rd ed.; McGee, J., Sammut-Bonnici, T., Eds.; John Wiley & Sons: Chichister, UK, 2014; pp. 495–502. [Google Scholar] [CrossRef]

- Gürel, E.; Tat, M. SWOT analysis: A theoretical review. J. Int. Soc. Res. 2017, 10, 994–1006. [Google Scholar] [CrossRef]

- Sztando, A. Analiza strategiczna jednostek samorządu terytorialnego. In Metody Oceny Rozwoju Regionalnego; Strahl, D., Ed.; Wydawnictwo Akademii Ekonomicznej im; Oskara Langego we Wrocławiu: Wrocław, Poland, 2006; pp. 113–159. ISBN 83-7011-723-6. (In Polish) [Google Scholar]

- Nazarko, J.; Kędzior, Z. (Eds.) Uwarunkowania Rozwoju Nanotechnologii w Województwie Podlaskim. Wyniki analiz STEEPVL i SWOT; Oficyna Wydawnicza Politechniki Białostockiej: Białystok, Poland, 2010. [Google Scholar]

- Houben, G.; Lenie, K.; Vanhoof, K. A knowledge-based SWOT-analysis system as an instrument for strategic planning in small and medium sized enterprises. Decis. Support Syst. 1999, 26, 125–135. [Google Scholar] [CrossRef]

- Helms, M.M.; Nixon, J. Exploring SWOT analysis–where are we now? A review of academic research from the last decade. J. Strat. Manag. 2010, 3, 215–251. [Google Scholar] [CrossRef]

- Morrison, M. History of the SWOT Analysis (Brief). Available online: https://rapidbi.com/history-of-the-swot-analysis/ (accessed on 10 June 2020).

- Nazarko, J.; Ejdys, J.; Halicka, K.; Nazarko, Ł.; Kononiuk, A.; Olszewska, A. Factor Analysis as a Tool Supporting STEEPVL Approach to the Identification of Driving Forces of Technological Innovation. Procedia Eng. 2017, 182, 491–496. [Google Scholar] [CrossRef]

- Nazarko, J.; Kuźmicz, K.A. Introduction to the STEEPVL Analysis of the New Silk Road Initiative. Procedia Eng. 2017, 182, 497–503. [Google Scholar] [CrossRef]

- Nazarko, J.; Ejdys, J.; Gudanowska, A.E.; Halicka, K.; Kononiuk, A.; Magruk, A.; Nazarko, Ł. Roadmapping in Regional Technology Foresight: A Contribution to Nanotechnology Development Strategy. IEEE Trans. Eng. Manag. 2020. [Google Scholar] [CrossRef]

- Beyer, K. Since the Agrarian Age to the Knowledge Economy. Zesz. Nauk. Uniw. Szczec. Stud. Pr. Wydz. Nauk Ekon. Zarz 2012, 30, 11–21. (In Polish) [Google Scholar]

- Philbeck, T.; Davis, N. The Fourth Industrial Revolution: Shaping A New Era. J. Int. Aff. 2019, 72, 17–22. [Google Scholar]

- Nosalska, K.; Mazurek, G. Marketing principles for Industry 4.0 — a conceptual framework. Eng. Manag. Prod. Serv. 2019, 11, 9–20. [Google Scholar] [CrossRef]

- Agarwal, H.; Agarwal, R. First Industrial Revolution and Second Industrial Revolution: Technological Differences and the Differences in Banking and Financing of the Firms. Saudi J. Humanit. Soc. Sci. 2017, 2, 1062–1066. [Google Scholar] [CrossRef]

- Michalski, M. Od I do IV rewolucji przemysłowej. Człowiek w Cyberprzestrzeni 2017, 1, 4–10. (In Polish) [Google Scholar]

- Poór, P.; Basl, J. Readiness of Companies in Relation to Industry 4.0 Implementation. In Proceedings of the International Scientific Conference Hradec Economic Days 2019, Hradec Králové, Czech Republic, 5–6 February 2019; Jedlička, P., Marešová, P., Soukal, I., Eds.; University of Hradec Králové: Hradec Králové, Czech Republic, 2019; Volume 2, pp. 236–248. [Google Scholar] [CrossRef]

- Furmanek, W. The most important ideas of the fourth industrial revolution. Dydakt. Inform. 2018, 13, 55–63. [Google Scholar] [CrossRef]

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef]

- Taalbi, J. Origins and pathways of innovation in the third industrial revolution. Ind. Corp. Chang. 2019, 28, 1125–1148. [Google Scholar] [CrossRef]

- Olender-Skorek, M. The Fourth Industrial Revolution and Some Economic Theories. Soc. Inequal. Econ. Growth 2017, 51, 38–49. (In Polish) [Google Scholar] [CrossRef]

- Prisecaru, P. Challenges of the Fourth Industrial Revolution. Knowl. Horiz. Econ. 2016, 8, 57–62. [Google Scholar]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Pfeiffer, S. The Vision of “Industrie 4.0” in the Making—a Case of Future Told, Tamed, and Traded. Nanoethics 2017, 11, 107–121. [Google Scholar] [CrossRef]

- United Nations Industrial Development Organization. What can Policymakers Learn from Germany’s Industrie 4.0 Development Strategy? UNIDO: Vienna, Austria, 2018. Available online: https://www.unido.org/api/opentext/documents/download/11712839/unido-file-11712839 (accessed on 20 June 2020).

- Mohamed, M. Challenges and Benefits of Industry 4.0: An overview. Int. J. Supply Oper. Manag. 2019, 5, 256–265. [Google Scholar] [CrossRef]

- Liao, Y.; Louresa, E.R.; Deschampsa, F.; Brezinskia, G.; Venâncioa, A. The impact of the fourth industrial revolution: A cross-country/region comparison. Production 2018, 28, 1–18. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fetterman, D. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Basl, J. Pilot study of readiness of Czech companies to implement the principles of Industry 4.0. Manag. Prod. Eng. Rev. 2017, 8, 3–8. [Google Scholar] [CrossRef]

- Cordes, F.; Stacey, N. Is UK Industry Ready for the Fourth Industrial Revolution? The Boston Consulting Group: Boston, MA, USA, 2017. Available online: https://media-publications.bcg.com/Is-UK-Industry-Ready-for-the-Fourth-Industrial-Revolution.pdf (accessed on 20 June 2020).

- Turkes, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Capusneanu, S. Drivers and Barriers in Using Industry 4.0: A Perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Tay, S.I.; Chuan, L.T.; Aziati, A.H.N.; Ahmad, A.N.A. An Overview of Industry 4.0: Definition, Components, and Government Initiatives. J. Adv. Res. Dyn. Control Syst. 2018, 10, 1379–1387. [Google Scholar]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Olsen, T.L.; Tomlin, B. Industry 4.0: Opportunities and Challenges. Manuf. Serv. Oper. Manag. 2020, 22, 113–122. [Google Scholar] [CrossRef]

- Wyrwicka, M.K.; Mrugalska, B. “Industry 4.0”–Towards Opportunities and Challenges of Implementation. In Proceedings of the 24th International Conference on Production Research, Poznań, Poland, 30 July–3 August 2017; Fertsh, M., Stachowiak, A., Mrugalska, B., Oleśków-Szłapka, J., Hadaś, Ł., Cyplik, P., Golińska-Dawson, P., Eds.; DEStech Publications: Lancaster, PA, USA, 2018; pp. 382–387. [Google Scholar] [CrossRef]

- Xu, M.H.; David, J.M.; Kim, S. The Fourth Industrial Revolution: Opportunities and Challenges. Int. J. Financial Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- Brunelli, J.; Lukic, V.; Milton, T.; Tantardini, M. Five Lessons from the Frontlines of Industry 4.0; The Boston Consulting Group: Boston, MA, USA, 2017; Available online: http://image-src.bcg.com/Images/BCG-Five-Lessons-from-the-Frontlines-of-Industry-4.0-Nov-2017_tcm9-175989.pdf (accessed on 10 June 2020).

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.; Talib, M.F. Industry 4.0: A review on industrial automation and robotic. J. Teknol. 2016, 78, 137–143. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.M.; Bhosle, S. Industry 4.0–A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-57870-5. [Google Scholar] [CrossRef]

- Yáñez, F. The 20 Key Technologies of Industry 4.0 and Smart Factories: The Road to the Digital Factory of the Future: The Road to the Digital Factory of the Future; Independently Published: Chicago, IL, USA, 2017; ISBN 978-1973402107. [Google Scholar]

- Pfohl, H.C.; Yahsi, B.; Kurnaz, T. The Impact of Industry 4.0 on the Supply Chain. In Innovations and Strategies for Logistics and Supply Chains, Proceedings of the Hamburg International Conference of Logistics (HICL), Hamburg, Germany, 24–25 September 2015; Kersten, W., Blecker, T., Ringle, C.M., Eds.; Epubli GmbH: Hamburg, Germany, 2015; pp. 29–58. [Google Scholar] [CrossRef]

- Szulewski, P. IT integration is a spirit of the Industry 4.0 manufacturing environment. Mechanik 2018, 8–9, 630–636. (In Polish) [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.O.; Terra da Silva, M.; Franco Gonçalves, R.; Sacomano, J.B. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Puyt, R.; Lie, F.B.; De Graaf, F.J.; Wilderom, C.P.M. Origins of SWOT Analysis. Acad. Manag. Proc. 2020, 17416:1–17416:6. [Google Scholar] [CrossRef]

- Ommani, A.M. Strengths, weaknesses, opportunities and threats (SWOT) analysis for farming system businesses management: Case of wheat farmers of Shadervan District, Shoushtar Township. Iran. Afr. J. Bus. Manag. 2011, 5, 9448–9454. [Google Scholar]

- Ghazinoory, S.; Abdi, M.; Azadegan-Mehr, M. SWOT methodology: A state-of-the-art review for the past, a framework for the future. J. Bus. Econ. Manag. 2011, 12, 24–48. [Google Scholar] [CrossRef]

- Bell, G.G.; Rochford, L. Rediscovering SWOT’s integrative nature: A new understanding of an old framework. Int. J. Manag. Educ. 2016, 14, 310–326. [Google Scholar] [CrossRef]

- Thamrin, H.; Pamungkas, E.W. A Rule Based SWOT Analysis Application: A Case Study for Indonesian Higher Education Institution. Procedia Comput. Sci. 2017, 116, 144–150. [Google Scholar] [CrossRef]

- Jain, A. SWOT Analysis in Thirukkural: Comparative Analysis with Humphrey SWOT Matrix. IOSR J. Bus. Manag. 2015, 15, 31–34. [Google Scholar]

- Rehak, D.; Grasseova, M. The Ways of Assessing the Security of Organization Information Systems through SWOT Analysis. In Cases on E-Readiness and Information Systems Management in Organizations: Tools for Maximizing Strategic Alignment; Alshawi, M., Arif, M., Eds.; Business Science Reference: Hershey, PA, USA, 2011; pp. 162–184. [Google Scholar] [CrossRef]

- Weinrich, H. The TOWS Matrix A Tool for Situational Analysis. Long Range Plan. 1982, 15, 54–66. [Google Scholar] [CrossRef]

- Gottfried, O.; De Clercq, D.; Blair, E.; Weng, X.; Wang, C. SWOT-AHP-TOWS analysis of private investment behavior in the Chinese biogas sector. J. Clean. Prod. 2018, 184, 632–647. [Google Scholar] [CrossRef]

- Al-Mayahi, I.; Mansoor, S.P. UAE E-Government: SWOT analysis and TOWS Matrix. In Proceedings of the 10th International Conference on ICT And Knowledge Engineering, Bangkok, Thailand, 21–23 November 2012; pp. 201–204. [Google Scholar]

- Nedomlelova, I.; Werner, J. Readiness of the Usti Nad Labem Region for the Implementation of the Industry 4.0 Concept. In Proceedings of the 13th International Conference Liberec Economic Forum, Liberec, Czech Republic, 11–13 September 2017; Technical University of Liberec: Liberec, Czech Republic, 2017; pp. 87–97. [Google Scholar]

- Mařík, V. Industry 4.0—The Initiative for the Czech Republic. 2016. Available online: http://ricaip.eu/wp-content/uploads/2018/11/Industry-4-0_The-Initiative-for-the-Czech-Republic.pdf (accessed on 26 August 2020).

- Dominiak, J. The role of the business environment in regional development in Poland. Stud. Industrial Geogr. Comm. Pol. Geogr. Soc. 2013, 22, 44–64. (In Polish) [Google Scholar]

- Association of Organizers of Innovation and Entrepreneurship Centers in Poland. Analysis of the Potential of Innovation Centres accredited by the Ministry of Entrepreneurship and Technology. Poznań/Warszawa, Poland, 2020. Available online: https://www.smart.gov.pl/images/Raport-z-badania-akredytowanych-osrodkow-innowacji-na-zlecenie-MPIT.pdf (accessed on 26 August 2020). (In Polish)

- Klitou, D.; Conrads, J.; Rasmussen, M.; Probsst, L.; Pedersen, B. Key Lessons from National Industry 4.0 policy Initiatives in Europe. European Commission: Brussels, Belgium, 2017. Available online: https://ec.europa.eu/growth/tools-databases/dem/monitor/sites/default/files/DTM_Policy%20initiative%20comparison%20v1.pdf (accessed on 26 August 2020).

- Hervas-Oliver, J.L.; Gonzalez-Alcaide, G.; Rojas-Alvarado, R.; Monto-Mompo, S. Emerging regional innovation policies for industry 4.0: Analyzing the digital innovation hub program in European regions. Compet. Rev. 2020, in press. [Google Scholar] [CrossRef]

- Burnasov, A.; Ilyushkina, M.; Kovalev, Y.; Stepanov, A. Convergence and divergence processes in regional development. Stud. Ind. Geogr. Comm. Pol. Geogr. Soc. 2014, 26, 25–30. [Google Scholar] [CrossRef]

- Jakobi, Á. Evaluation of spatial categories and regional inequalities in the information age. Europa XXI 2009, 19, 93–102. [Google Scholar] [CrossRef]

- Goddard, J.; Kempton, L. Connecting Universities to Regional Growth: A Practical Guide; European Commission: Brussels, Belgium, 2011. Available online: https://ec.europa.eu/regional_policy/sources/docgener/presenta/universities2011/universities2011_en.pdf (accessed on 26 August 2020).

- Li, L. Education supply chain in the era of Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 579–592. [Google Scholar] [CrossRef]

- Biosca, O.; Spiekerman, K.; Stępniak, M. Transport Accessibility at Regional Scale. Europa XXI 2013, 24, 5–17. [Google Scholar] [CrossRef]

- Švarcová, J.; Urbanek, T.; Povolna, L.; Sobotková, E. Implementation of R&D Results and Industry 4.0 Influenced by Selected Macroeconomic Indicators. Appl. Sci. 2019, 9, 1846. [Google Scholar] [CrossRef]

- Czauż, A.; Dąbrowska, E.; Kamińska, A.; Koronkiewicz, G.; Maślach, D.; Muczyński, M. Diagnoza Strategiczna Województwa Podlaskiego; Podlaskie Regionalne Obserwatorium Terytorialne: Białystok, Poland, 2018; Available online: http://iph.bialystok.pl/wp-content/uploads/2018/12/DIAGNOZA_CA% C5%81O%C5%9A%C4%86_21.12.2018_last.pdf (accessed on 10 June 2020). (In Polish)

- Podlasie Regional Territorial Observatory. Strategic Diagnosis of Podlaskie Voivodeship; Podlasie Regional Territorial Observatory: Białystok, Poland, 2018. (In Polish) [Google Scholar]

- Statistical Office in Białystok. Statistical Yearbook of Podlaskie Voivodship; Statistical Office in Białystok: Białystok, Poland, 2018. (In Polish)

- Statistical Office in Białystok. Statystyczne Vademecum Samorządowca; Statistical Office in Bialystok: Białystok, Poland, 2019. Available online: https://bialystok.stat.gov.pl/vademecum/vademecum_ podlaskie/portret_wojewodztwa/wojewodztwo_podlaskie.pdf (accessed on 26 August 2020). (In Polish)

- Statistics Poland; Statistical Office in Szczecin. Transport–Activity Results in 2017; Statistics Poland: Warszawa, Szczecin, Poland, 2017. (In Polish)

- Statistics Poland. Research and Experimental Development in Poland in 2017; Statistic Poland: Warszawa, Poland, 2018. (In Polish)

- Statistics Poland; Information Society in Poland. Results of Statistical Surveys in the Years 2014–2018; Statistic Poland: Warszawa, Poland, 2018. (In Polish)

- Statistics Poland. Statistical Yearbook of Industry; Statistic Poland: Warszawa, Poland, 2018. (In Polish)

- Dąbrowska, E.; Dębkowska, K.; Ejdys, J.; Fiedorczuk, M.; Muczyński, M.; Panfiluk, E.; Szpilko, D. The Demand of Enterprises for Services Provided by Business Environment Institutions in the Podlasie Region; Podlaskie Voivodship Marshal’s Office: Białystok, Poland, 2016. (In Polish) [Google Scholar]

- Wojewódzki Urząd Pracy w Białymstoku Centrum Informacji i Planowania Kariery Zawodowej. Instytucje i Organizacje Otoczenia Biznesu w Województwie Podlaskim; WUP: Białystok, Poland, 2018. Available online: https://wupbialystok.praca.gov.pl/documents/102984/974011/Instytucje%20otoczenia%20biznesu%20-%20podlaskie%202018%20-%202019/f00ec9bf-8497-4505-b545-38a58d85d8c6 (accessed on 10 June 2020). (In Polish)

- Sztando, A. Model of development strategy construction procedure of territorial self-government unit. Bibl. Region. 2013, 13, 247–266. (In Polish) [Google Scholar] [CrossRef]

- Nazarko, J. Regionalny Foresight Gospodarczy. Metodologia i Instrumentarium Badawcze; Związek Pracodawców Warszawy i Mazowsza: Warszawa, Poland, 2013. (In Polish) [Google Scholar]

- Dębkowska, K. Regionalny Foresight Gospodarczy. Scenariusze Wzrostu Gospodarczego Województwa Mazowieckiego; Związek Pracodawców Warszawy i Mazowsza: Warszawa, Poland, 2013. (In Polish) [Google Scholar]

- Ejdys, J. Regionalny Foresight Gospodarczy. Scenariusze Rozwoju Lokalnego Województwa Mazowieckiego; Związek Pracodawców Warszawy i Mazowsza: Warszawa, Poland, 2013. (In Polish) [Google Scholar]

- Nazarko, J. Regionalny Foresight Gospodarczy. Scenariusze Rozwoju Innowacyjności Mazowieckich Przedsiębiorstw; Związek Pracodawców Warszawy i Mazowsza: Warszawa, Poland, 2013. (In Polish) [Google Scholar]

- Ebneyamini, S.; Sadeghi Moghadam, M.R. Toward Developing a Framework for Conducting Case Study Research. Int. J. Qual. Methods 2018, 17, 1–11. [Google Scholar] [CrossRef]

- Zaidah, Z. Case study as a research method. J. Kemanusiaan 2007, 9, 1–6. [Google Scholar]

- Verleye, K. Designing, writing-up and reviewing case study research: An equifinality perspective. J. Serv. Manag. 2019, 30, 549–576. [Google Scholar] [CrossRef]

- Morisson, A.; Pattinson, M. Industry 4.0: A Policy Brief from the Policy Learning Platform on Research and Innovation; European Union: Brussels, Belgium, 2016; Available online: https://www.interregeurope.eu/fileadmin/user_upload/plp_uploads/policy_briefs/INDUSTRY_4.0_Policy_Brief.pdf (accessed on 26 August 2020). (In Polish)

- Nazarko, J.; Ejdys, J.; Halicka, K.; Nazarko, Ł.; Kononiuk, A.; Olszewska, A. Structural Analysis as an Instrument for Identification of Critical Drivers of Technology Development. Procedia Eng. 2017, 182, 474–481. [Google Scholar] [CrossRef]

- Lepore, D.; Spigarelli, F. Integrating Industry 4.0 plans into regional innovation strategies. Local Econ. 2020. [Google Scholar] [CrossRef]

- GreenTech Made in Germany 2018. Environmental Technology Atlas for Germany, Federal Ministry for the Environment, Nature Conservation and Nuclear, Berlin, Germany 2018. Available online: https://www.bmu.de/en/publication/greentech-made-in-germany-2018-environmental-technology-atlas-for-germany/ (accessed on 20 June 2020).

- Nazarko, Ł. Responsible Research and Innovation–A New Paradigm of Technology Management. In Proceedings of the 9th International Scientific Conference “Business and Management 2016”, Vilnius, Lithuania, 12–13 May 2016. [Google Scholar] [CrossRef]

- Sony, M. Pros and cons of implementing Industry 4.0 for the organizations: A review and synthesis of evidence. Prod. Manuf. Res. 2020, 8, 244–272. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Nazarko, J.; Magruk, A. (Eds.) Kluczowe Nanotechnologie w Gospodarce Województwa Podlaskiego; Oficyna Wydawnicza Politechniki Białostockiej: Białystok, Poland, 2013. (In Polish) [Google Scholar]

- Habanik, J.; Grencikova, A.; Krajco, K. The impact of new technology on sustainable development. Eng. Econ. 2019, 30, 41–49. [Google Scholar] [CrossRef]

- Szász, L.; Demeter, K.; Rácz, B.-G.; Losonci, D. Industry 4.0: A review and analysis of contingency and performance effects. J. Manuf. Technol. Manag. 2020. [Google Scholar] [CrossRef]

- Morrar, R.; Arman, H.; Mousa, S. The Fourth Industrial Revolution (Industry 4.0): A Social Innovation Perspective. Technol. Innov. Manag. Rev. 2017, 7, 12–20. [Google Scholar] [CrossRef]

| Term | Web of Science | Scopus | ||||

|---|---|---|---|---|---|---|

| 2017 | 2018 | 2019 | 2017 | 2018 | 2019 | |

| Industry 4.0/Industrie 4.0 | 1017 | 1430 | 1629 | 1285 | 2249 | 3425 |

| Fourth Industrial Revolution/4th Industrial Revolution/Industrial Revolution 4.0/Revolution 4.0/4IR | 227 | 438 | 472 | 284 | 591 | 950 |

| Digital transformation | 242 | 450 | 607 | 378 | 771 | 1209 |

| Smart Manufacturing/Intelligent Manufacturing/Smart Production | 326 | 439 | 469 | 431 | 716 | 826 |

| Area | Analyzed Data |

|---|---|

| Location [85,86] | geographical location, distance from large markets, natural assets, natural resources, energy resources |

| People [79] | population size and structure, migration, residence structure, labor market |

| Education [79,87,88] | number of universities, number of people with higher education, graduate structure, education offer for Industry 4.0 |

| Transport infrastructure [79,89] | quality and availability of transport infrastructure, transport routes running through the voivodeship |

| Research and development (R & D) sector [79,90] | number of R & D entities, expenditure on R & D activities, number of R & D personnel, degree of consumption of research equipment |

| Digitization of enterprises [79,80] | degree of use of computers and the Internet, the degree of use of digital technologies and services in enterprises |

| Industrial sector [80] | regional industry structure, industry energy intensity, economic indicators (remuneration, average employment, capital expenditure), industrial innovation (product and process innovations and improvements), local leaders, export structure, the attractiveness of the region for investments |

| Business environment institutions [81,82] | availability of business and innovation support institutions and the quality of their services |

| Documents and initiatives supporting the development of Industry 4.0 [83,84] | documents regulating issues related to I4.0, the cooperation of local units (enterprises, public administration units, and the scientific sector), innovation and entrepreneurship support initiatives |

| Area | Factor | Value | Position in Poland | |

|---|---|---|---|---|

| Location [92] | Podlaskie is located in the north-eastern part of Poland. The external border of the province is at the same time the eastern border of the country (with Lithuania) and the European Union (with Belarus) | N/A | N/A | |

| People [93] | Population (thousand) | 1184.5 | 14 | |

| Economic age groups | Pre-working (%) | 17.4 | 10 | |

| Working (%) | 62.2 | 4 | ||

| Post-working (%) | 20.4 | 9 | ||

| Education [93,94] | Students of higher education institutions (per 10 thousand population) | 270 | 9 | |

| Students of technical universities (per 10 thousand population) | 72 | 8 | ||

| Number of people with higher education (%) | 24.5 | 6 | ||

| Transport infrastructure [94,95] | Railway lines (per 100 km2 in km) | 3.6 | 16 | |

| Hard surface public roads [per 100 km2 in km] | 66.2 | 13 | ||

| Expressways (km) | 61.2 | 12 | ||

| Motor vehicles [per 1000 population] | 525 | 16 | ||

| R & D sector [96] | Entities in Research and Development (R & D) | 120 | 10 | |

| Gross domestic expenditure on research and experimental development (GERD) per capita (in PLN) | 220.6 | 9 | ||

| Funds from the sector of business enterprises financing R & D in intramural expenditures on R & D (%) | 30.0 | 14 | ||

| Entities equipped with scientific and research equipment | 40 | 12 | ||

| Digitization of enterprises [97] | Use of computers and the internet | Enterprises using computers (%) | 94.8 | 12 |

| Enterprises with broadband access to the Internet (%) | 92.9 | 13 | ||

| Employees using computers (%) | 37.4 | 12 | ||

| Employees using computers with access to the Internet (%) | 31.6 | 13 | ||

| Use of digital technologies | Sending orders via the internet (%) | 32.3 | 8 | |

| Receiving orders via the internet (%) | 15.9 | 2 | ||

| 3D printing (%) | 1.6 | 12 | ||

| Industrial and service robots (%) | 4.9 | 16 | ||

| Big Data analysis (%) | 9.2 | 2 | ||

| Industrial sector [98] | Average paid employment in the industry (in thousands) | 53.9 | 16 | |

| Average monthly gross wages and salaries in the industry (in PLN) | 3461.5 | 14 | ||

| Investment outlays in the industry (in millions of PLN) | 1993.3 | 15 | ||

| Expenditures on innovation activity for product and business process innovations in the industry (in millions of PLN) | 328.1 | 15 | ||

| Share of net revenue from sales of new or improved products in net revenues from sales in the industry (%) | 4.9 | 13 | ||

| Energy intensity of gross value added for manufacturing sector (kgoe/PLN) | 0.39 | 14 | ||

| Business environment institutions [99] | Number of innovation centers and business incubators | 5 | 15 | |

| Business supporting non-banking financial institutions | 13 | 15 | ||

| Usage of services of business environment institutions by enterprises (%) | 18.7 | NA | ||

| Documents and initiatives supporting the development of Industry 4.0 [11,109] | European documents: Europe 2020 Strategy, Single Digital Market Strategy | N/A | N/A | |

| National documents: Long-term National Development Strategy 2030, Strategy for Responsible Development, National Regional Development Strategy | N/A | N/A | ||

| Regional documents: Strategy for socio-economic development of Eastern Poland until 2020, Development Strategy of Podlaskie Voivodeship until 2020 | N/A | N/A | ||

| Existing Factors | ||

|---|---|---|

| Internal Factors | External Factors | |

| Strengths | Incentives | |

| Positive Factors | S1: A strong support network for innovation and entrepreneurship S2: A group of innovative and competitive enterprises S3: The cooperation of enterprises in clusters S4: Activities and initiatives which increase knowledge among regional entrepreneurs S5: Relatively low labor costs S6: High potential of human resources in the region (many people with higher education) S7: A well-developed higher education system S8: Promotion of energy production from renewable sources in the region S9: Exceptional natural conditions of the region S10: The cooperation between regional universities and foreign education centers S11: Geographical location (the eastern border of the country and the EU, closeness to the capital city) | I1: EU innovation policy I2: EU cohesion policy I3: National support policy for the development of Industry 4.0 I4: Availability of funds (European and national) for the development of innovation I5: Tax breaks for entrepreneurs I6: Pushing for the implementation of energy-efficient green technologies I7: Creating a support network for entrepreneurs interested in implementing Industry 4.0 (the Future Industry Platform) I8: Worldwide popularity of the Industry 4.0 I9: Self-improvement trend I10: The availability of international research and publications dealing with issues related to Industry 4.0 |

| Weaknesses | Disincentives | |

| Negative Factor | W1: Low attractiveness of the region for investment W2: The advantage of less technologically advanced sectors in the regional economy W3: Low competitiveness and innovation of the regional industry W4: Low use of digital technologies in regional enterprises W5: Low levels of entrepreneurship W6: Low investment outlays in the regional industry W7: Low wages in the industrial sector W8: Weakness of the regional R & D sector W9: Low energy efficiency of basic industries W10: Low expenditure on research and development in regional enterprises W11: Emigration of competent staff from the region W12: Low quality and availability of transport infrastructure W13: Lack of assumptions for Industry 4.0 in regional strategic documents W14: Negative demographic trends (negative population growth, aging population) W15: Limited energy resources of the region | D1: Negative economic image of the region D2: Inflexible education system D3: Unclear and unstable legislation D4: The brain drain of Industry 4.0 technology specialists to high-income regions D5: A negative image of entrepreneurs in Polish society D6: High costs of implementing new energy-efficient technologies D7: Industrial espionage in cyberspace D8: A long and complicated process of commercialization |

| Potential Factor | ||

|---|---|---|

| Internal Factors | External Factors | |

| Positive Factors | Internal Opportunities | External Opportunities |

| IO1: Increasing use of energy-efficient green technologies in the local industry IO2: A growing number of spin-offs and spin-outs in the region IO3: The improvement of the cooperation effectiveness among businesses, science, and administrative institutions IO4: The development of the regional R & D sector IO5: The potential of the regional ICT sector IO6: The improvement of the quality of technical infrastructure IO7: The improvement of the quality and availability of transport infrastructure IO8: Adapting regional policy to the challenges of the Fourth Industrial Revolution IO9: The creation of regional policy instruments supporting the development of innovation IO10: The radical increase in energy production from renewable sources IO11: The launch of the North-Eastern Center of the Future Industry Competence IO12: New fields of education at regional universities that meet the needs of the digital revolution | EO1: The finalization of the international transport corridors running through the region EO2: The inflow of international investors EO3: The external transfer of energy-efficient technologies to local industry EO4: Creating new forms of assistance for young entrepreneurs EO5: The establishment of the European Business Cooperation Network EO6: The simplification of commercialization procedures | |

| Negative Factor | Internal Threats | External Threats |

| IT1: Increased labor costs IT2: Increased unemployment IT3: Increased competition among entrepreneurs IT4: Further outflow of competent staff from the region IT5: Insufficient renewable energy resources in the region | ET1: Growing differences between regions ET2: Stagnation of the national economy ET3: Withdrawal of countries from the EU ET4: The fall of the Eurozone ET5: Reduction of the EU financial support ET6: International conflicts ET7: New legal restrictions on digital technologies ET8: The lack of public acceptance of digital technologies ET9: The shortage in energy supply (disturbances in electricity supply, higher energy prices) | |

| Group | TGA | Highest-Rated Factors | Lowest-Rated Factors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Factor | AM | SD | CV | Factor | AM | SD | CV | ||

| Strengths | 4.90 | S1 | 5.35 | 1.20 | 22% | S11 | 3.53 | 1.09 | 31% |

| S2 | 5.30 | 1.07 | 20% | S4 | 4.68 | 1.33 | 28% | ||

| S6 | 5.15 | 1.31 | 25% | S10 | 4.80 | 1.26 | 26% | ||

| Incentives | 5.10 | I4 | 5.78 | 1.27 | 22% | I9 | 4.20 | 1.25 | 30% |

| I2 | 5.60 | 1.14 | 20% | I8 | 4.45 | 1.27 | 29% | ||

| I6 | 5.50 | 1.21 | 22% | I10 | 4.50 | 1.33 | 30% | ||

| Weaknesses | 5.22 | W6 | 5.63 | 1.02 | 18% | W14 | 4.38 | 1.04 | 24% |

| W8 | 5.60 | 1.23 | 22% | W12 | 4.68 | 1.38 | 30% | ||

| W9 | 5.58 | 1.00 | 18% | W13 | 4.88 | 1.17 | 24% | ||

| Disincentives | 5.03 | D6 | 5.80 | 1.09 | 19% | D5 | 4.18 | 1.26 | 30% |

| D4 | 5.55 | 1.21 | 22% | D7 | 4.60 | 1.24 | 27% | ||

| D3 | 5.20 | 1.43 | 28% | D2 | 4.90 | 1.42 | 29% | ||

| Group | TGA | Highest-Rated Factors | Lowest-Rated Factors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Factor | AM | SD | COV | Factor | AM | SD | COV | ||

| Internal opportunities | 5.35 | IO1 | 5.80 | 0.92 | 16% | IO11 | 4.98 | 1.11 | 22% |

| IO5 | 5.58 | 0.97 | 17% | IO9 | 5.10 | 1.13 | 22% | ||

| IO4 | 5.53 | 1.17 | 21% | IO7 | 5.13 | 1.15 | 22% | ||

| External opportunities | 5.57 | EO2 | 5.85 | 0.96 | 16% | EO5 | 5.20 | 1.00 | 19% |

| EO3 | 5.83 | 0.95 | 16% | EO4 | 5.35 | 1.18 | 22% | ||

| Internal threats | 5.17 | IT4 | 5.90 | 1.07 | 18% | IT2 | 4.20 | 1.22 | 29% |

| IT1 | 5.40 | 1.29 | 24% | IT3 | 5.18 | 1.24 | 24% | ||

| External threats | 4.91 | ET9 | 5.63 | 1.27 | 23% | ET4 | 3.78 | 1.13 | 30% |

| ET5 | 5.48 | 1.39 | 25% | ET3 | 3.80 | 1.43 | 31% | ||

| ET7 | 5.45 | 1.27 | 23% | ET6 | 4.63 | 1.36 | 29% | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szum, K.; Nazarko, J. Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study. Energies 2020, 13, 5972. https://doi.org/10.3390/en13225972

Szum K, Nazarko J. Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study. Energies. 2020; 13(22):5972. https://doi.org/10.3390/en13225972

Chicago/Turabian StyleSzum, Katarzyna, and Joanicjusz Nazarko. 2020. "Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study" Energies 13, no. 22: 5972. https://doi.org/10.3390/en13225972

APA StyleSzum, K., & Nazarko, J. (2020). Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study. Energies, 13(22), 5972. https://doi.org/10.3390/en13225972