Study on Dynamic Characteristics of Residual Char of CFB Boiler Based on CPFD Method

Abstract

1. Introduction

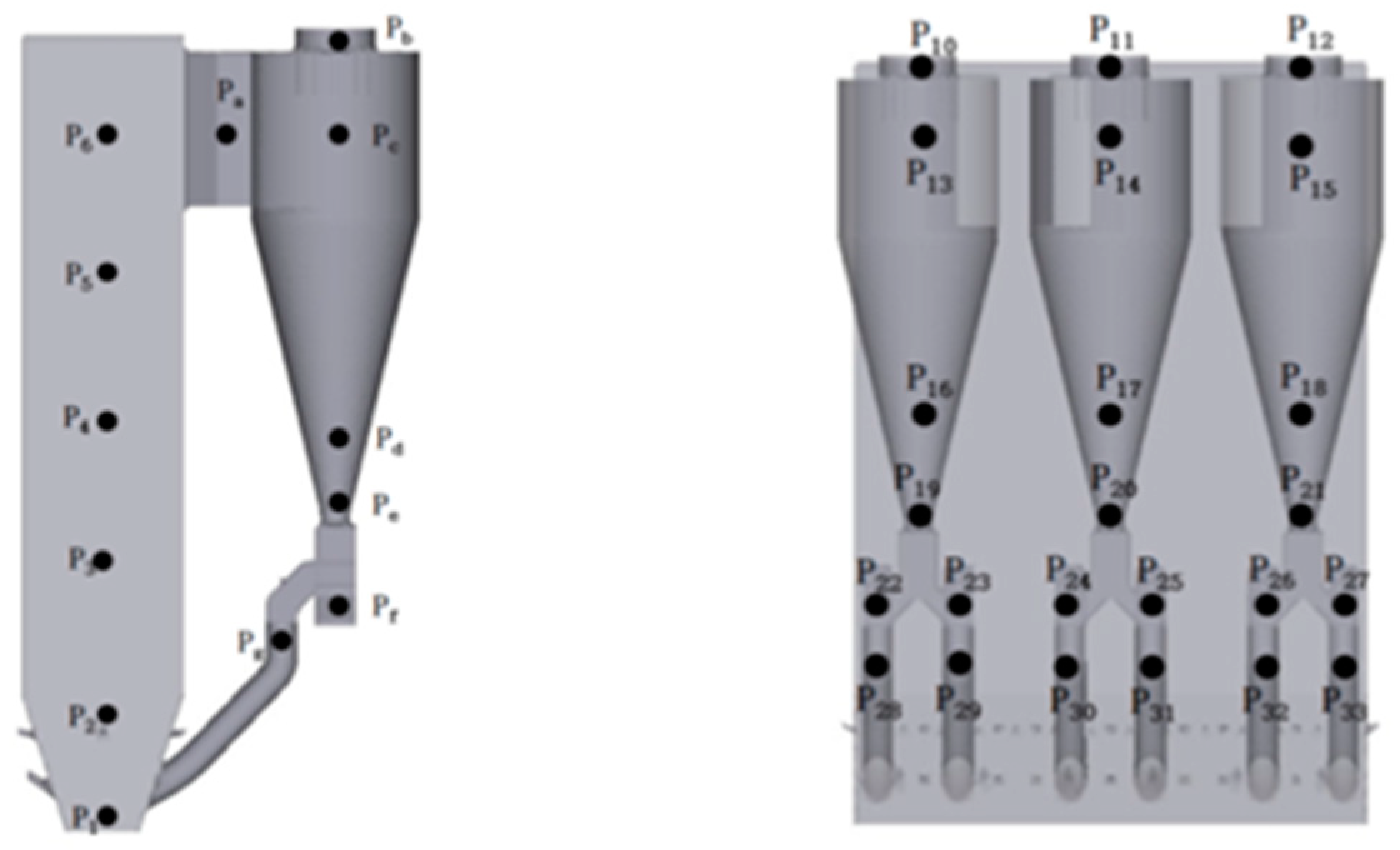

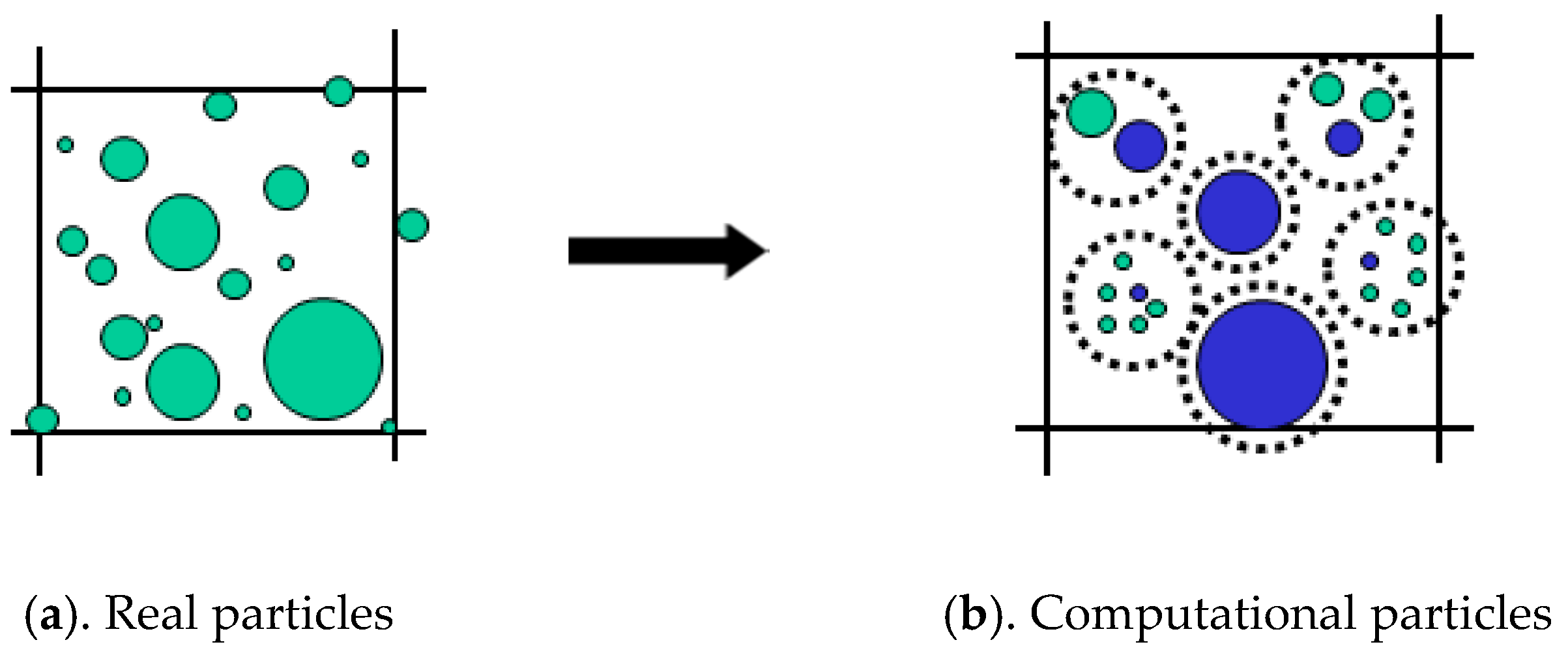

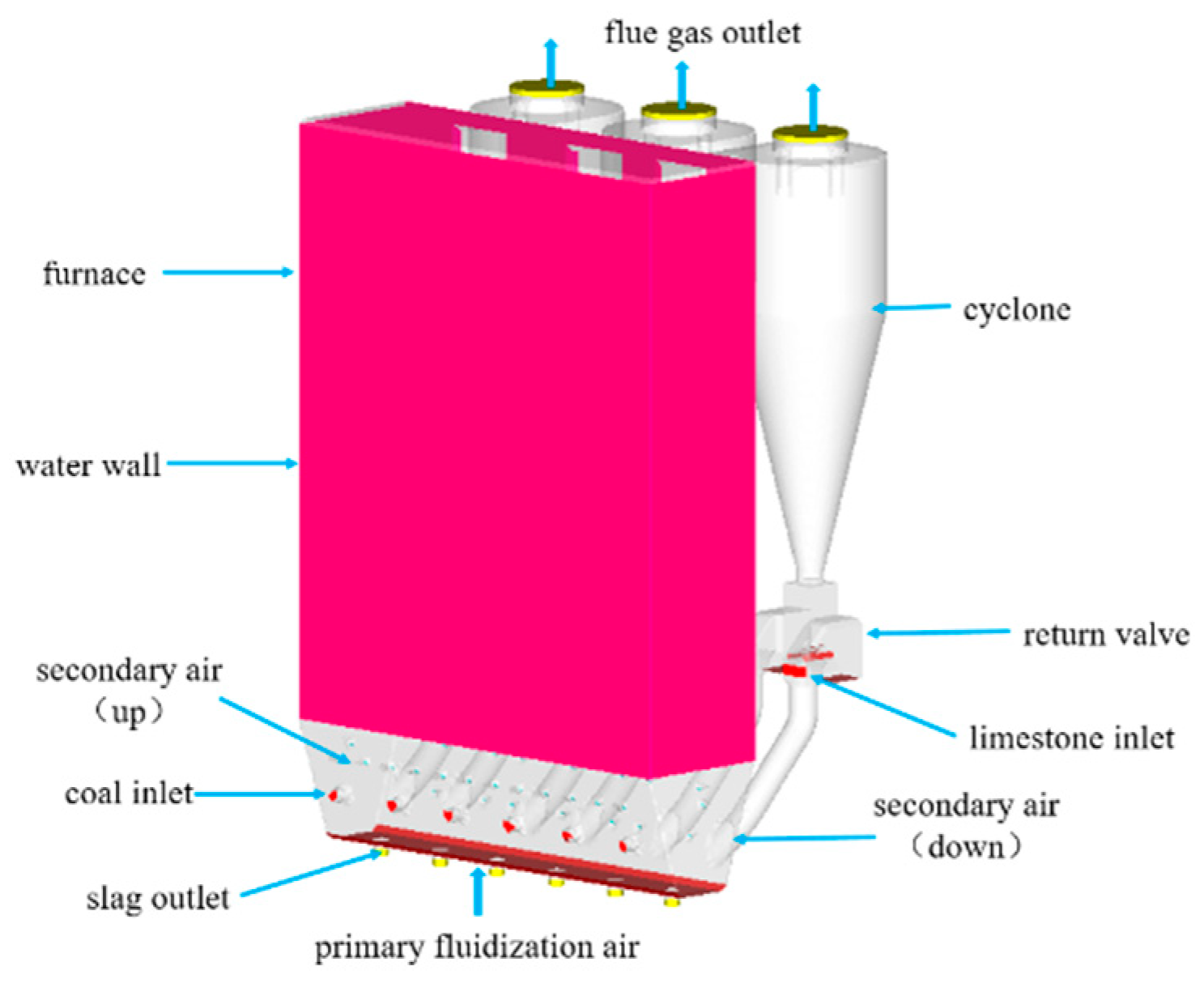

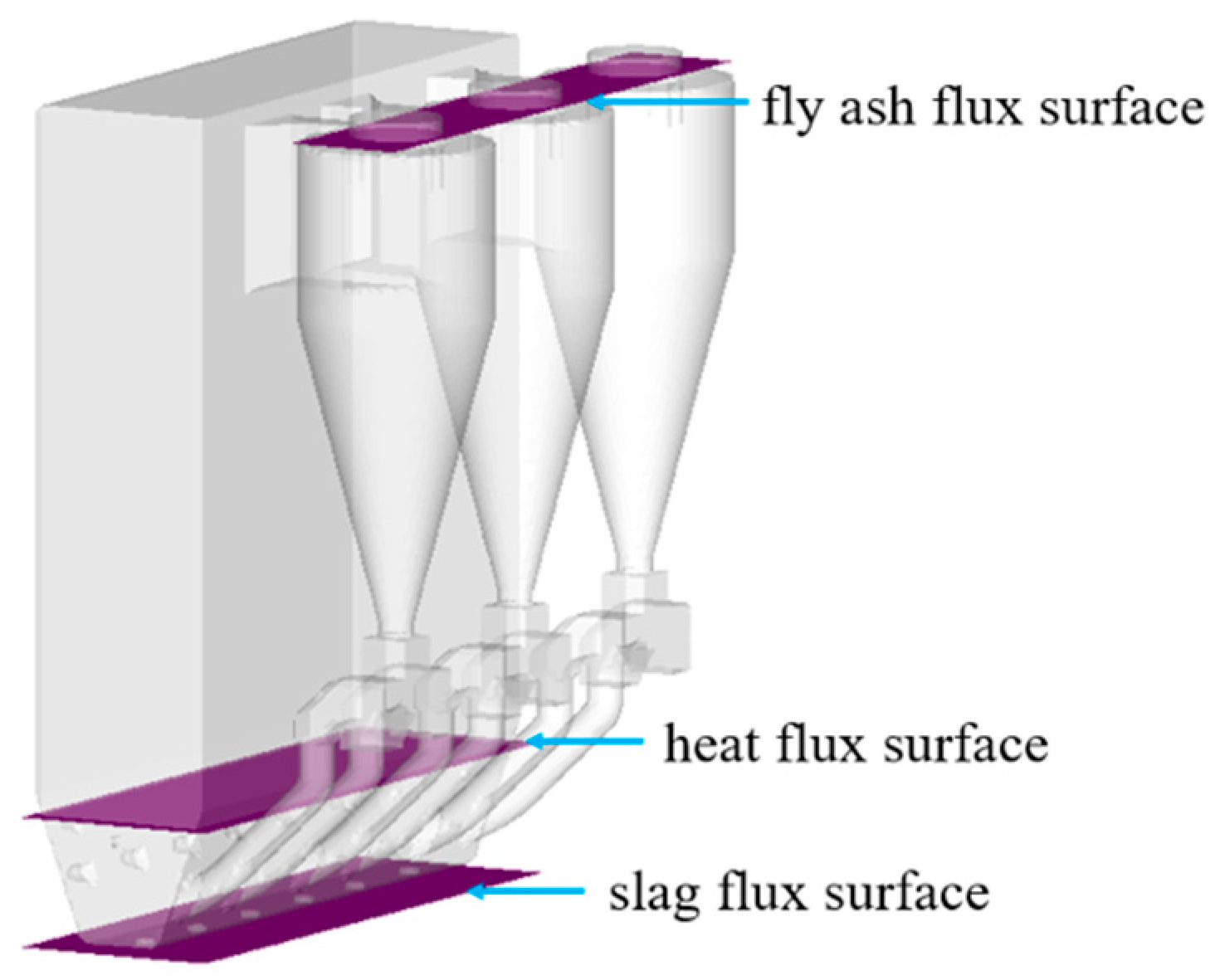

2. Boiler Characteristic Analysis

3. Model Construction

3.1. Governing Equation

3.2. Chemical Reaction Model

3.3. Simulation Condition Setting

4. Results and Discussion

4.1. Simulation Parameter Determination

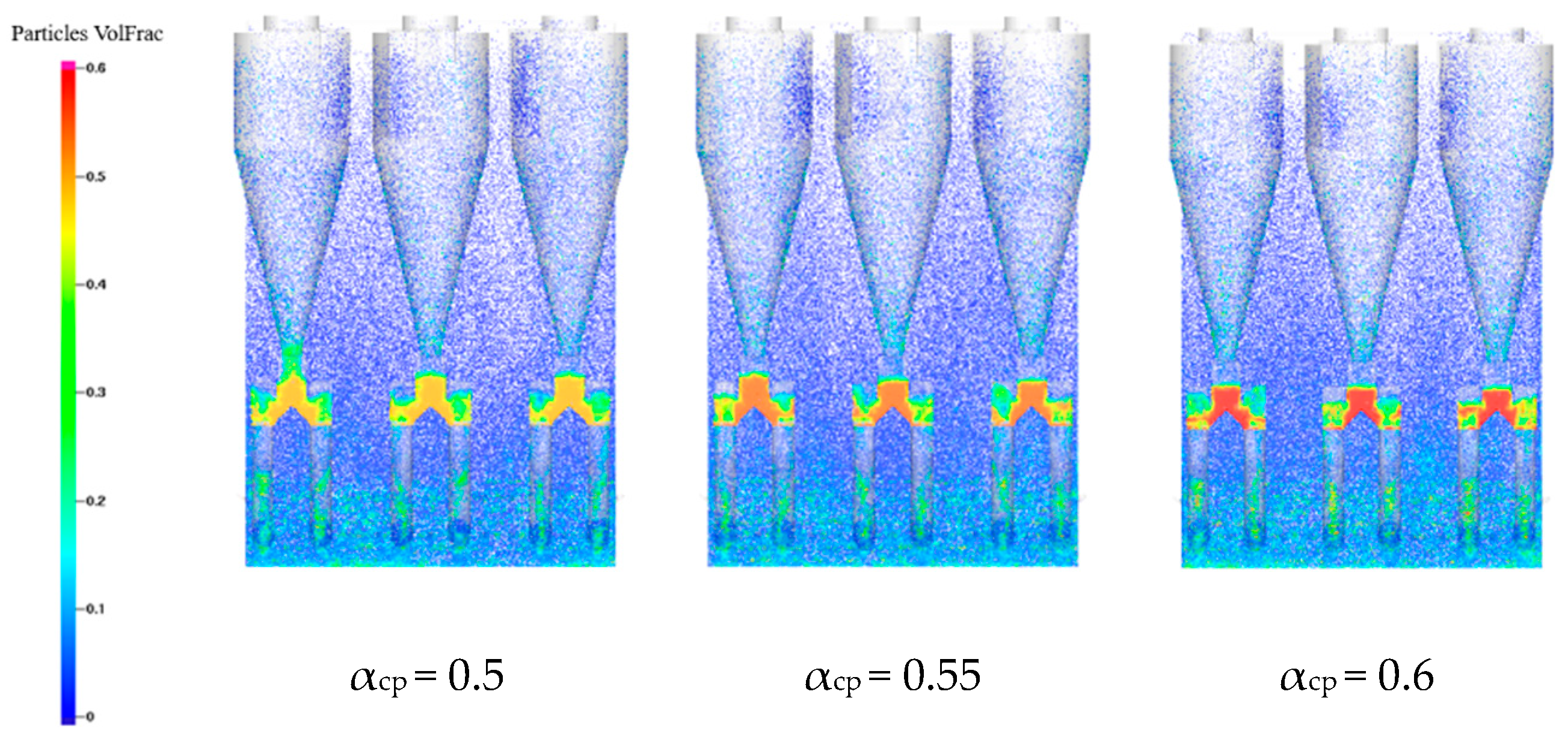

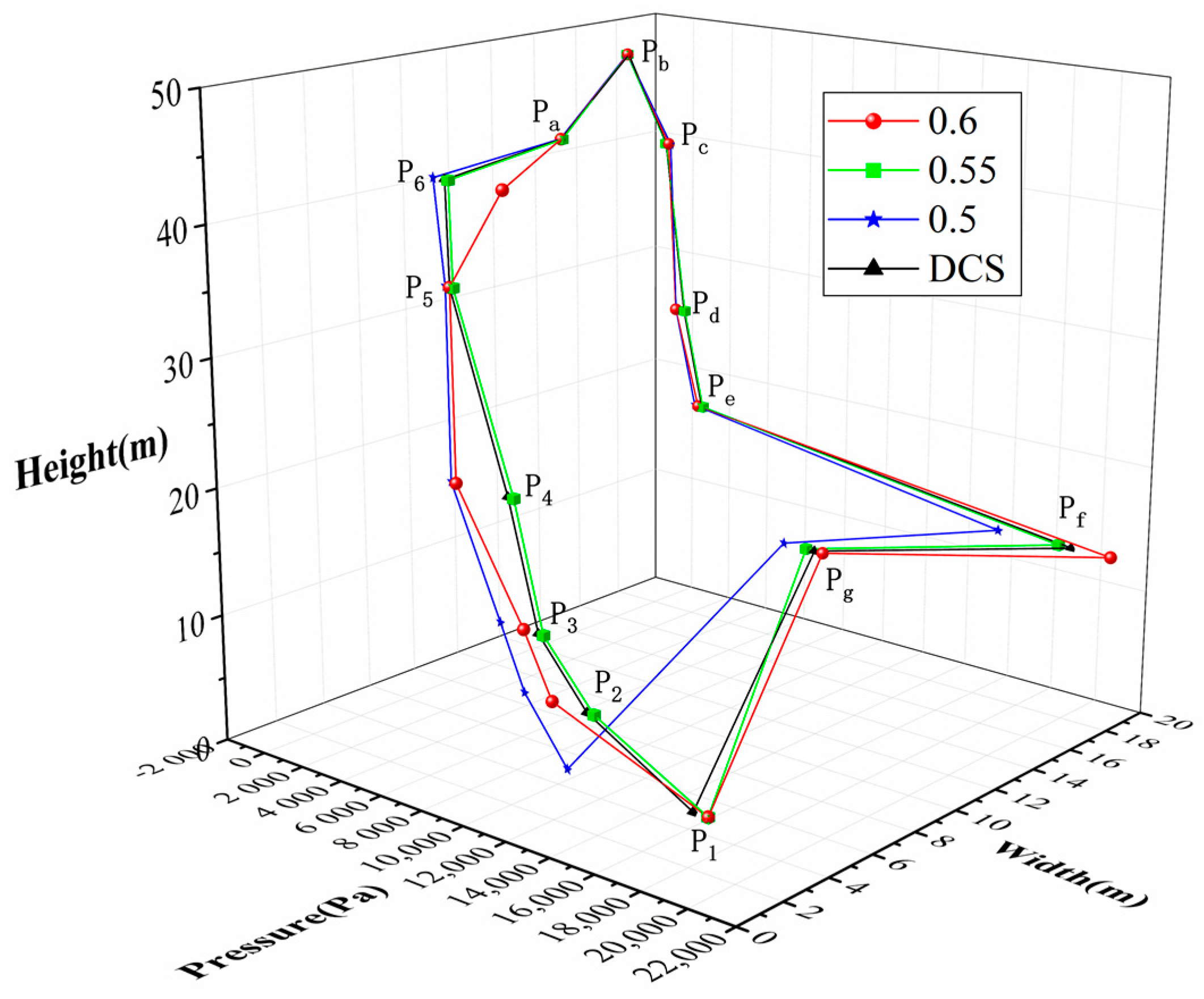

4.1.1. Determination of Particle Packing Limit

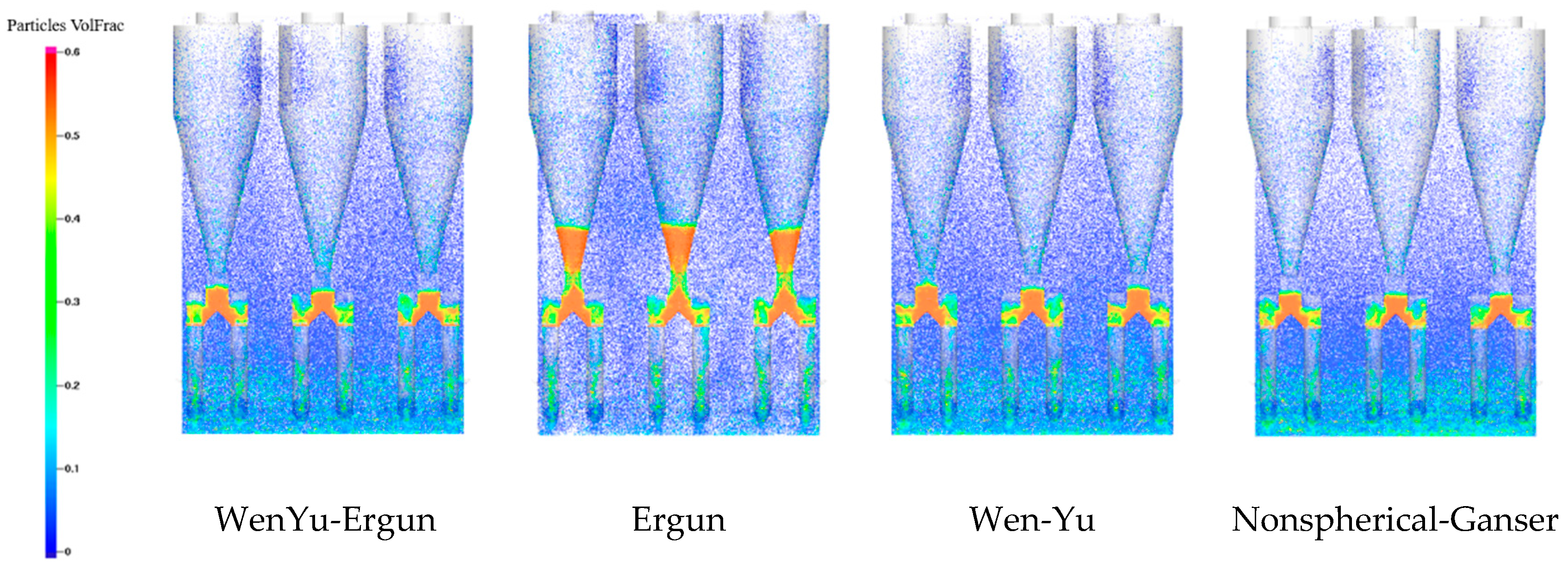

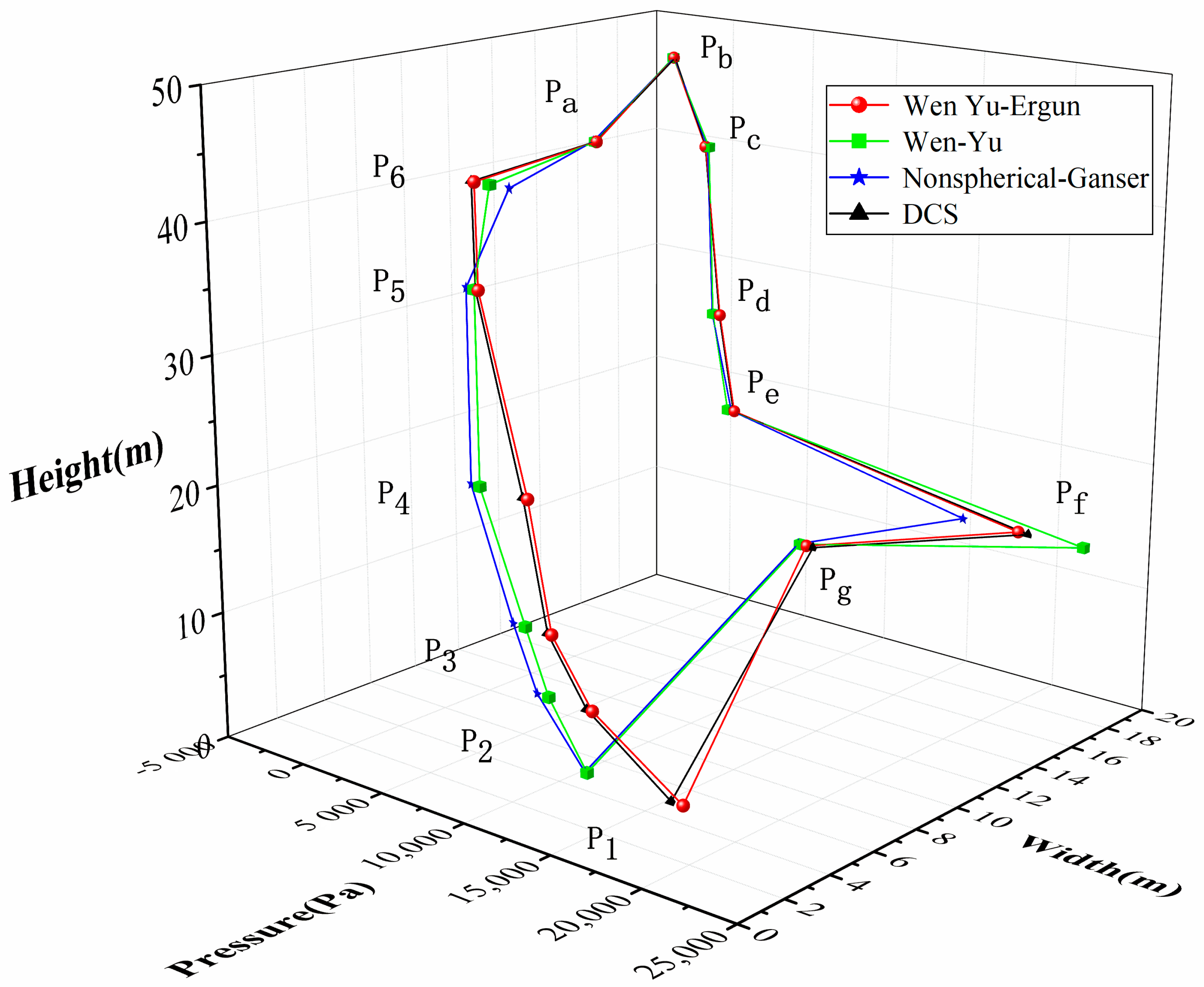

4.1.2. Determination of the Drag Model

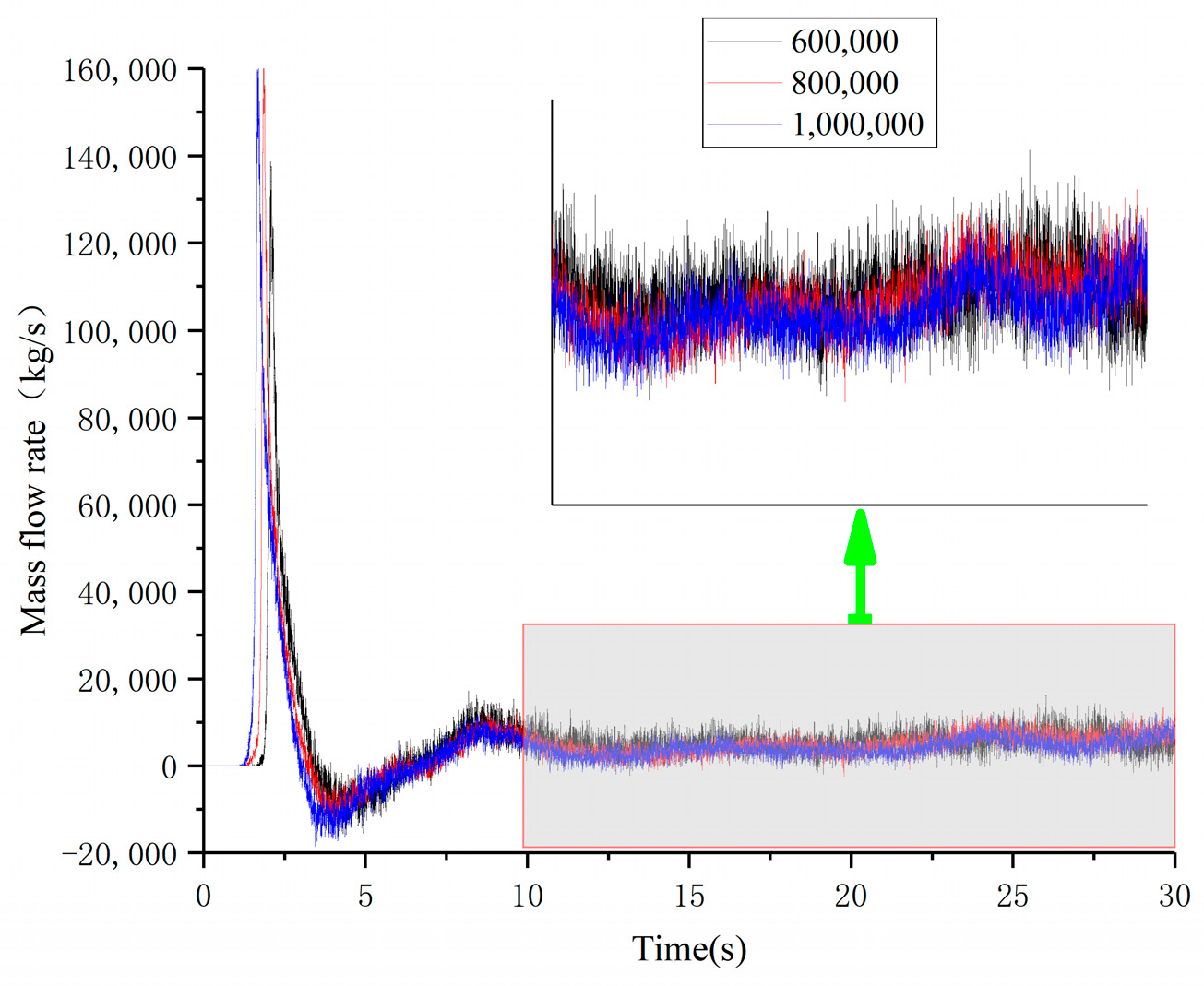

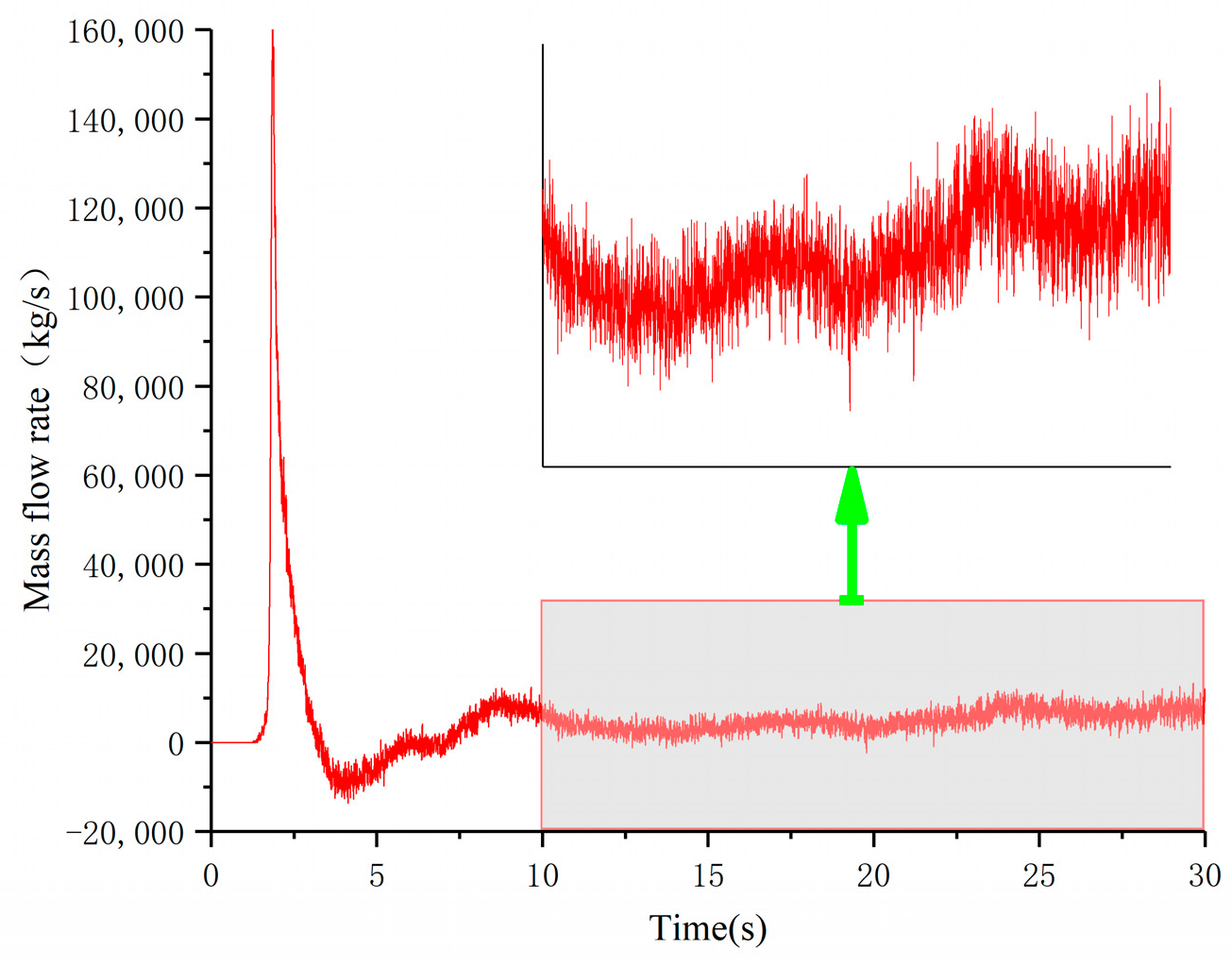

4.1.3. Grid Independence Test

4.2. Numerical Analysis

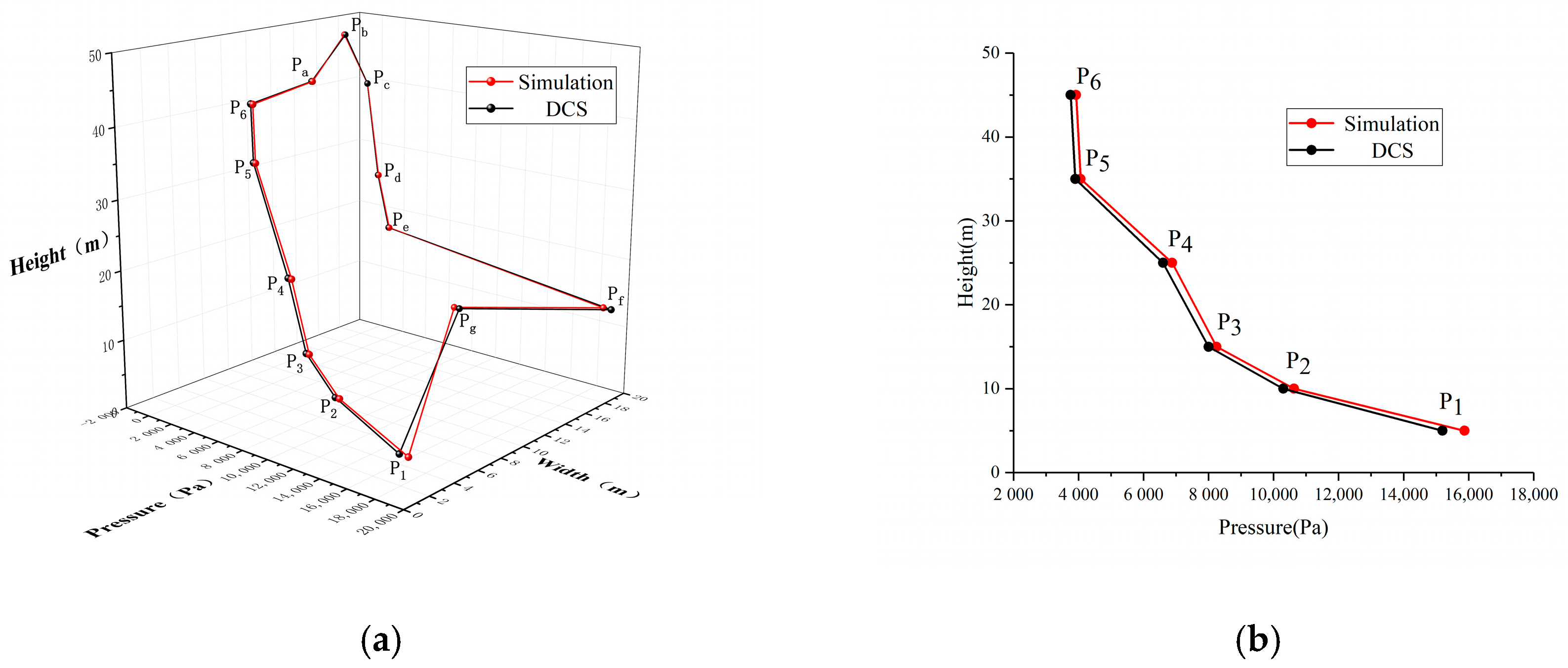

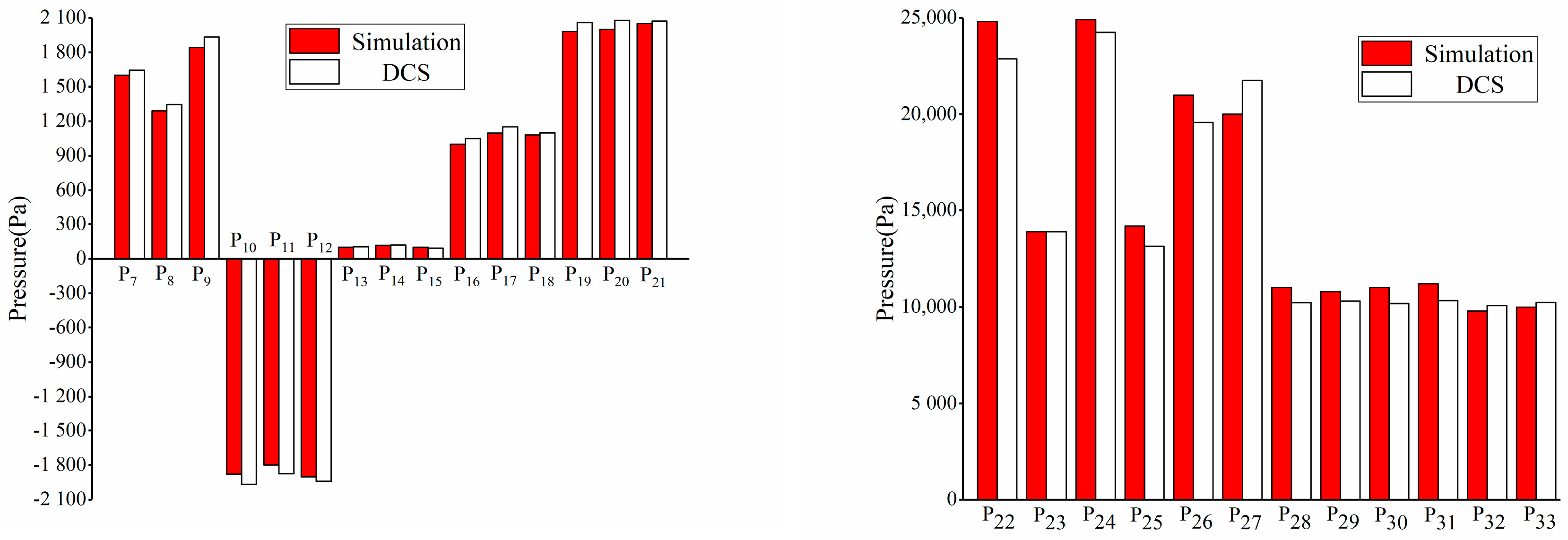

4.2.1. Numerical Model Verification

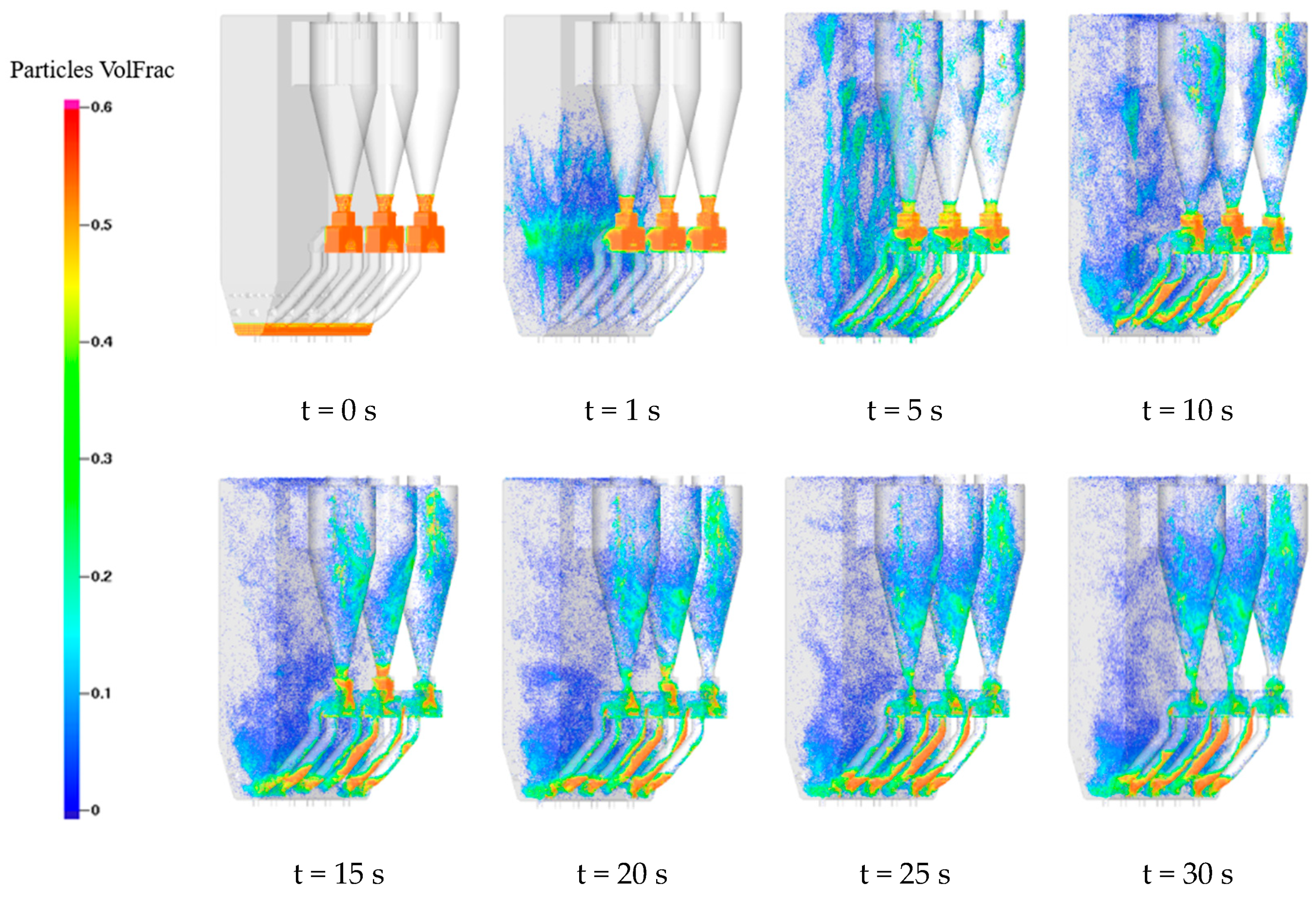

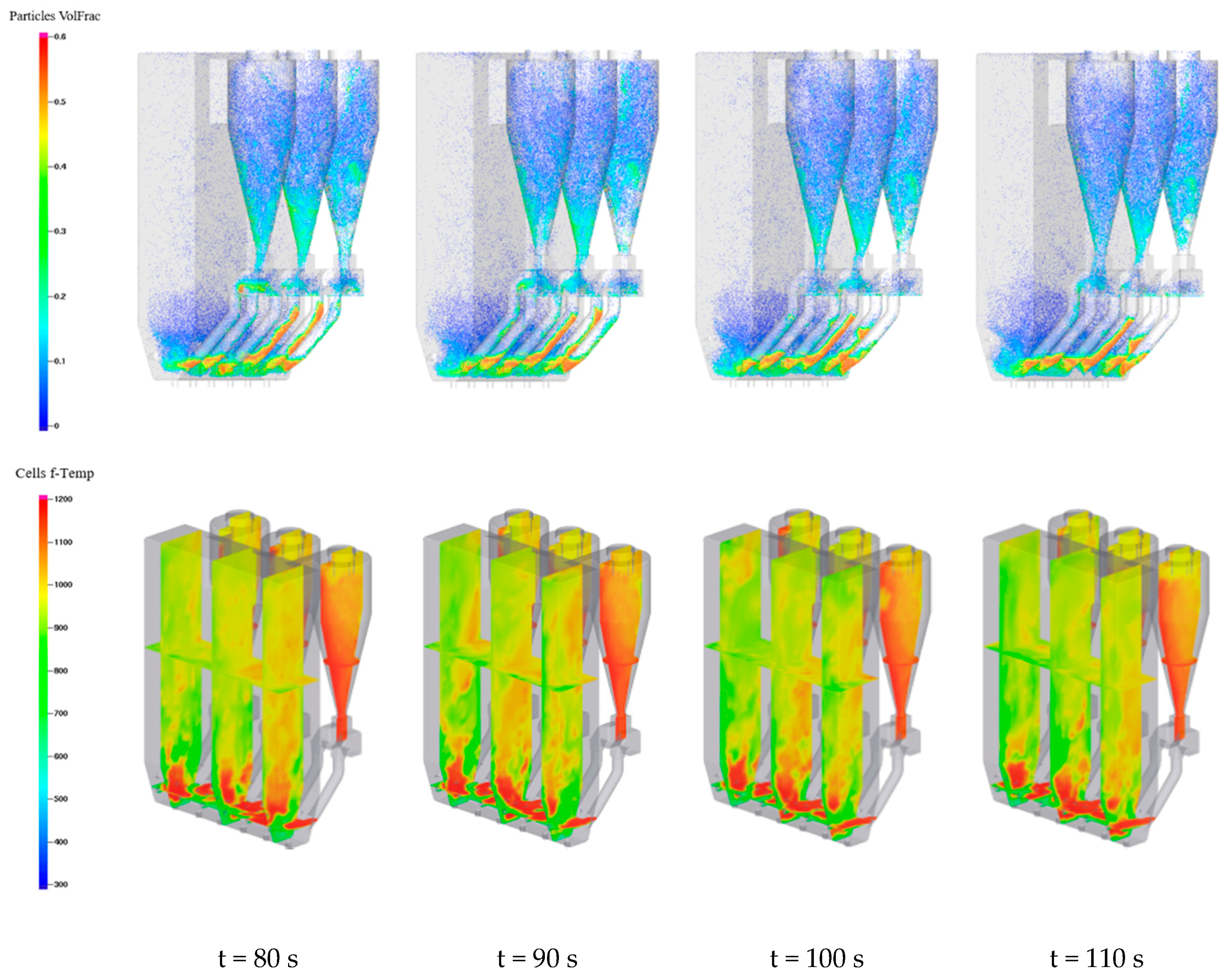

4.2.2. Gas-Solid Flow Characteristics Analysis

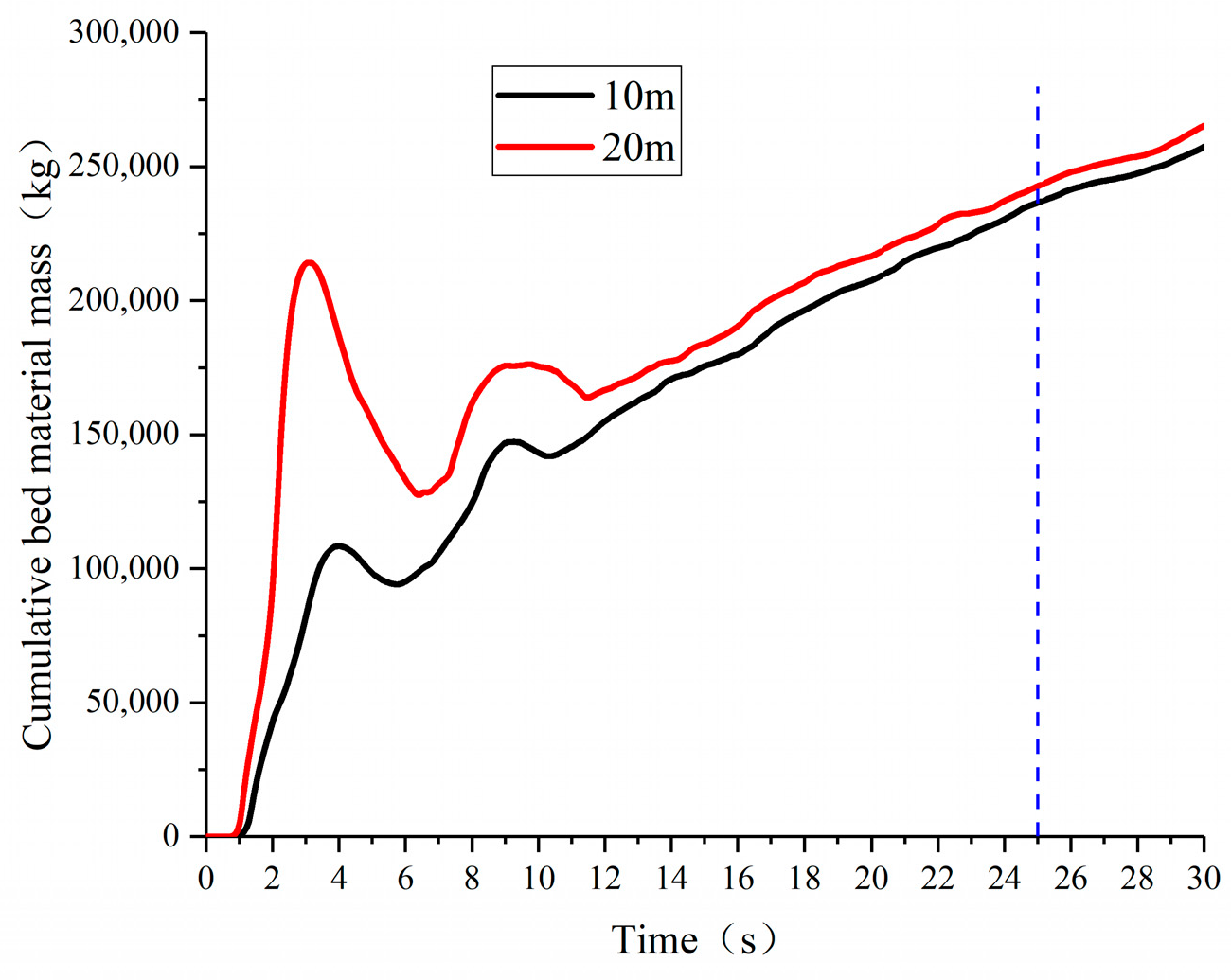

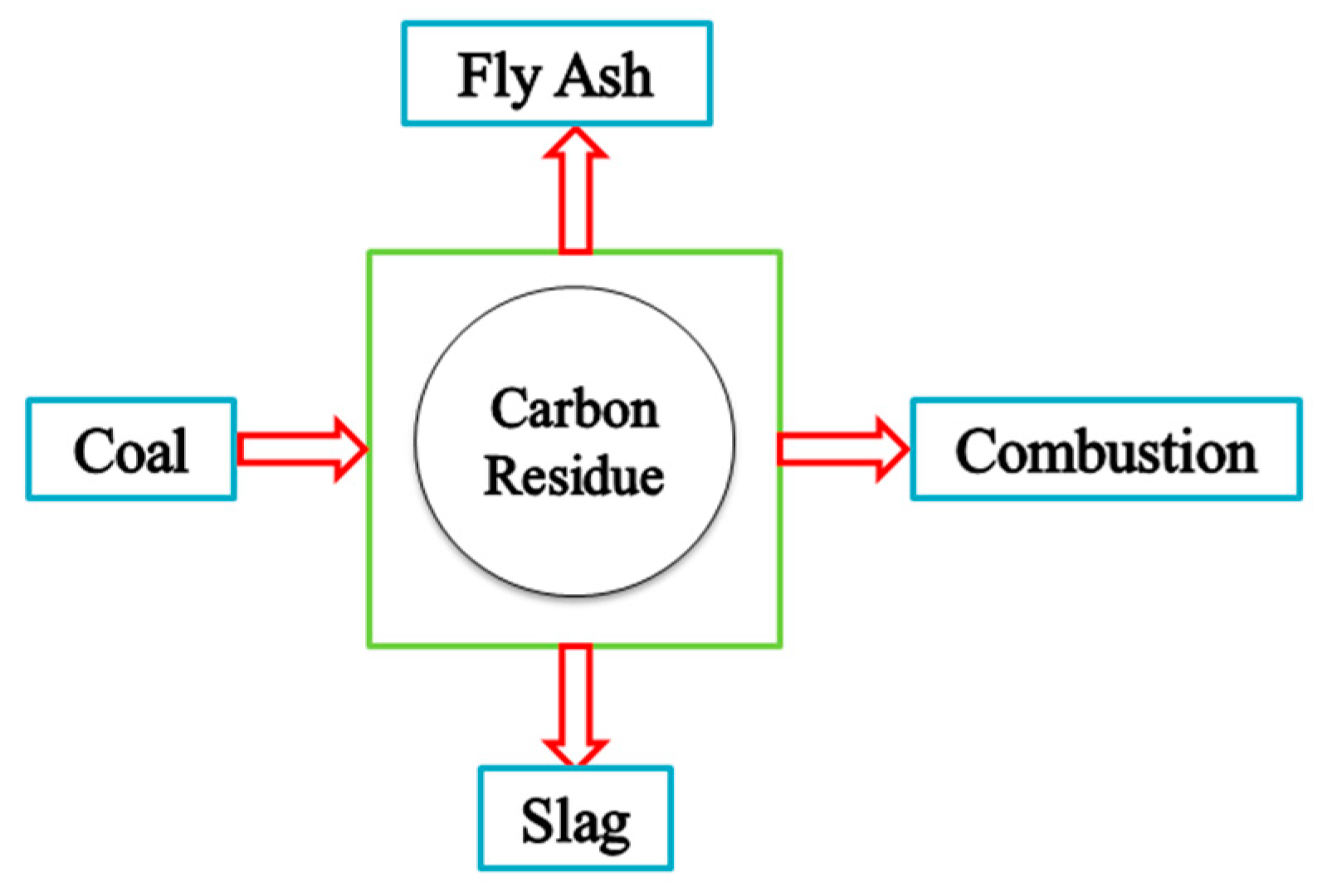

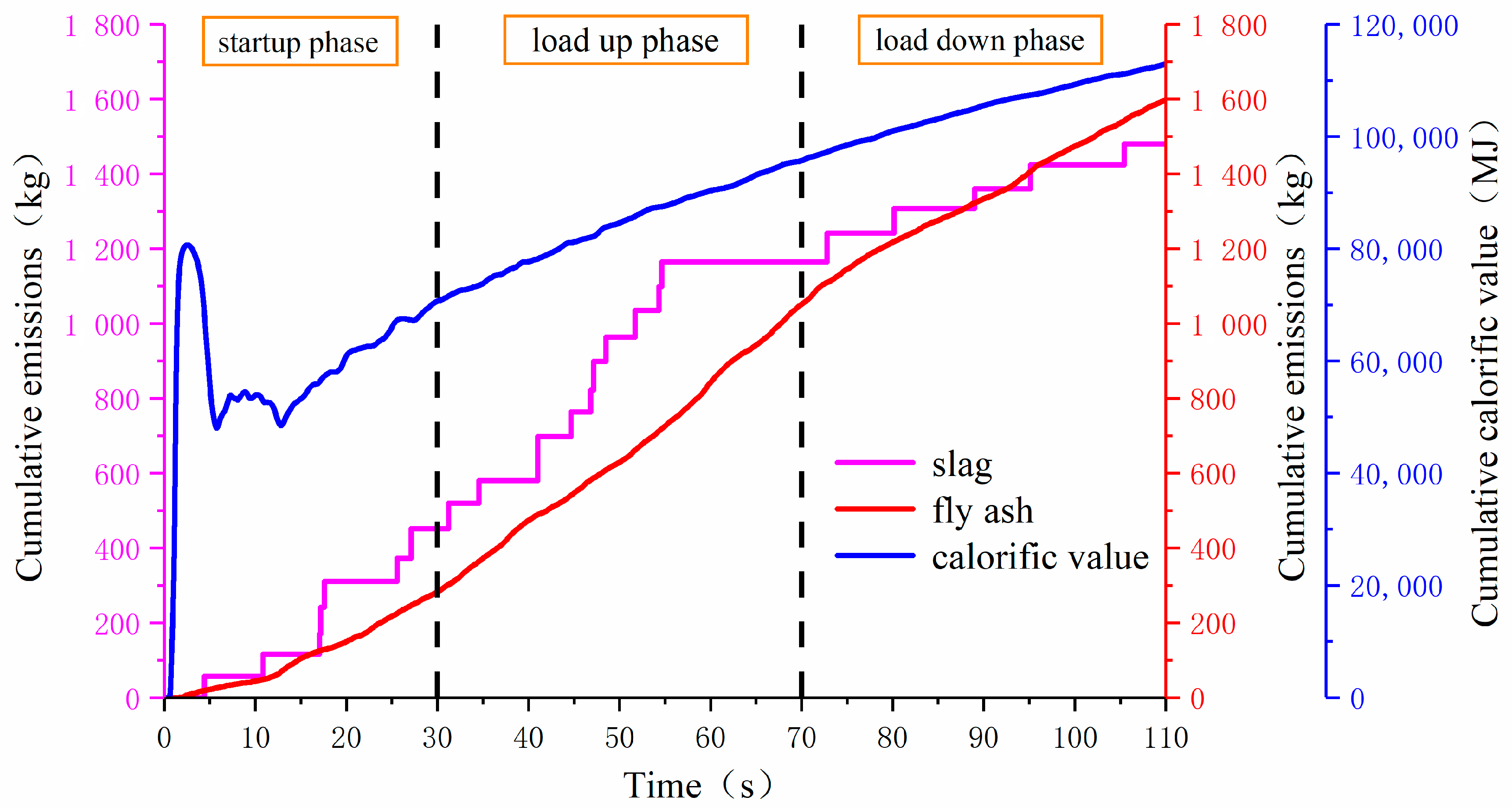

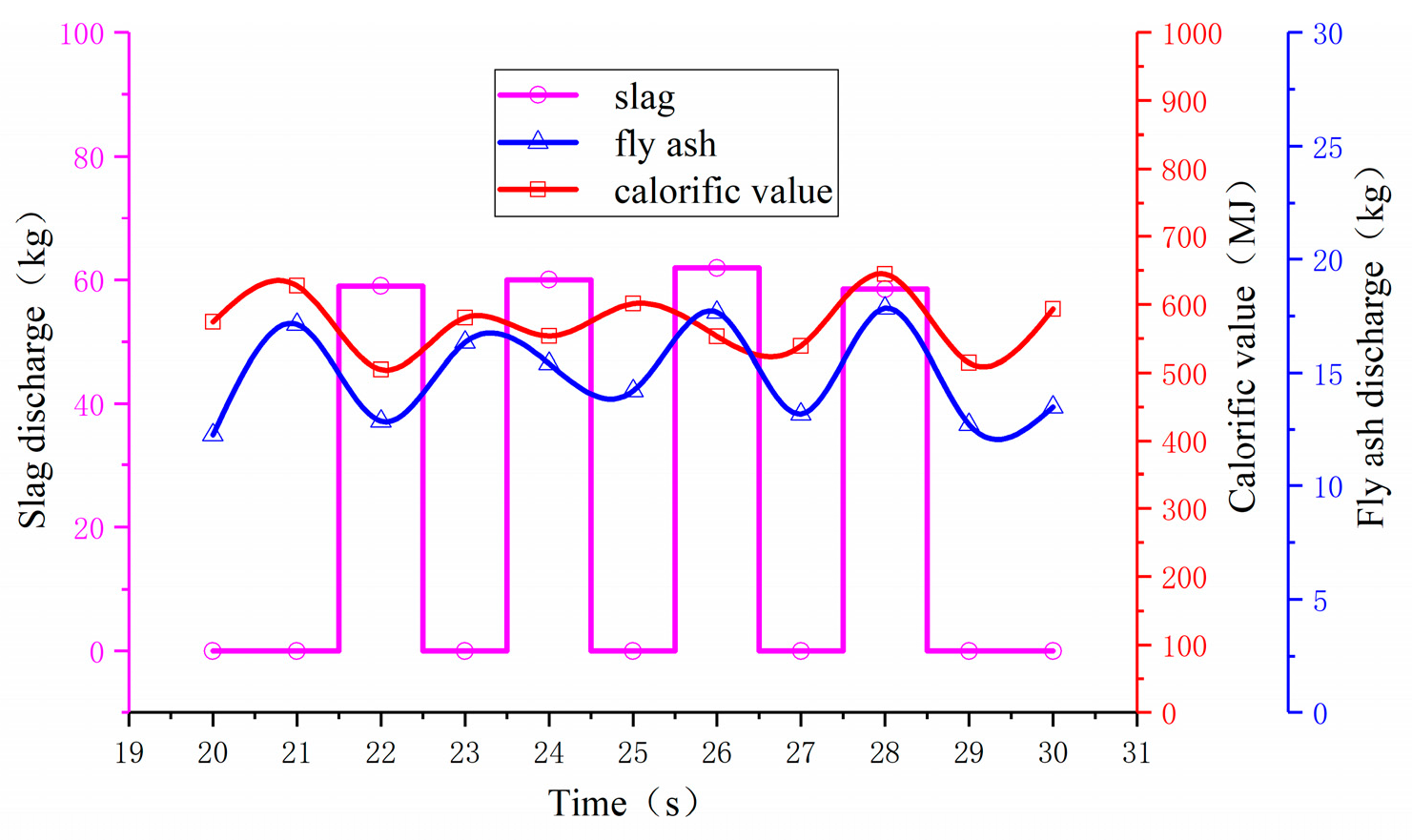

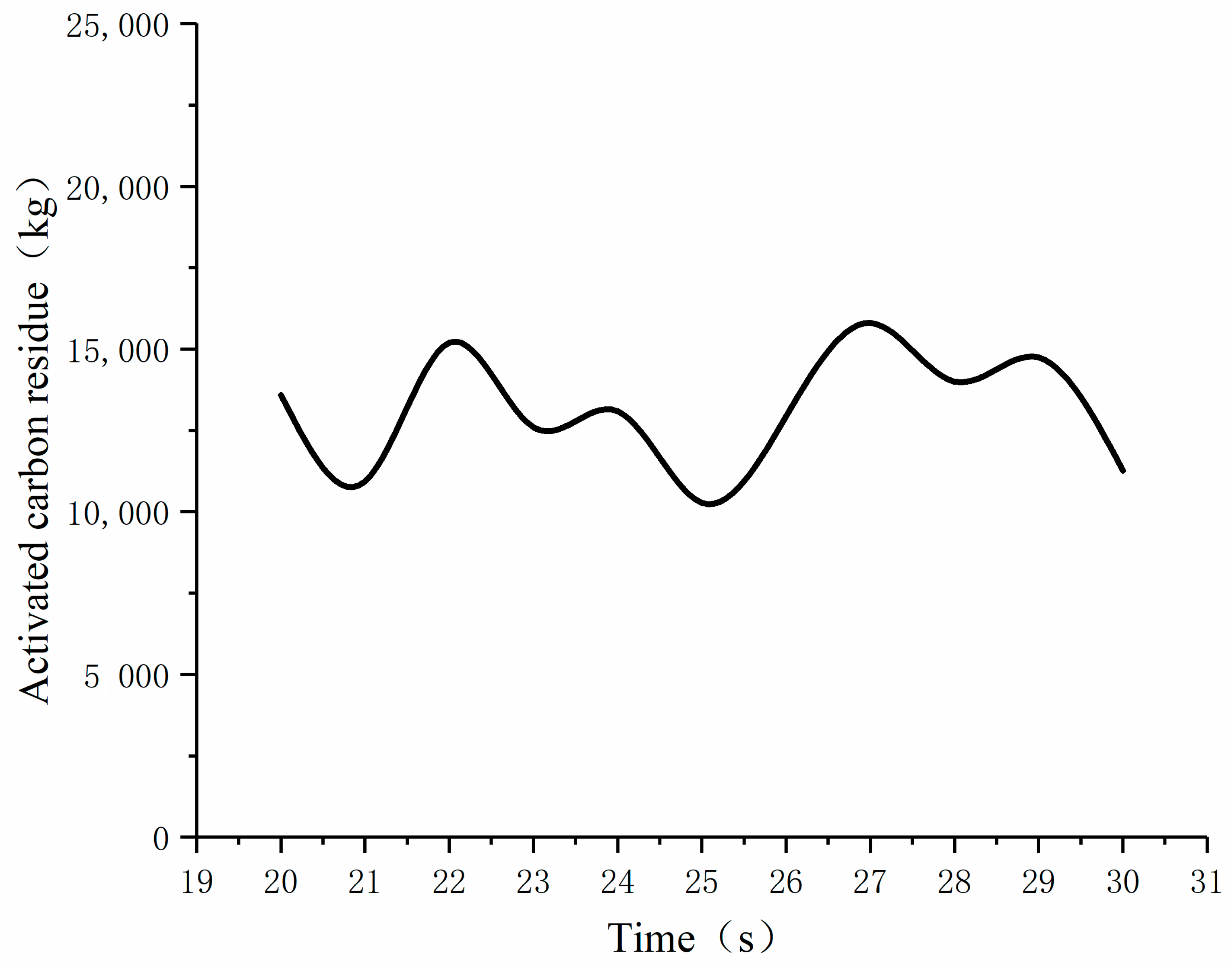

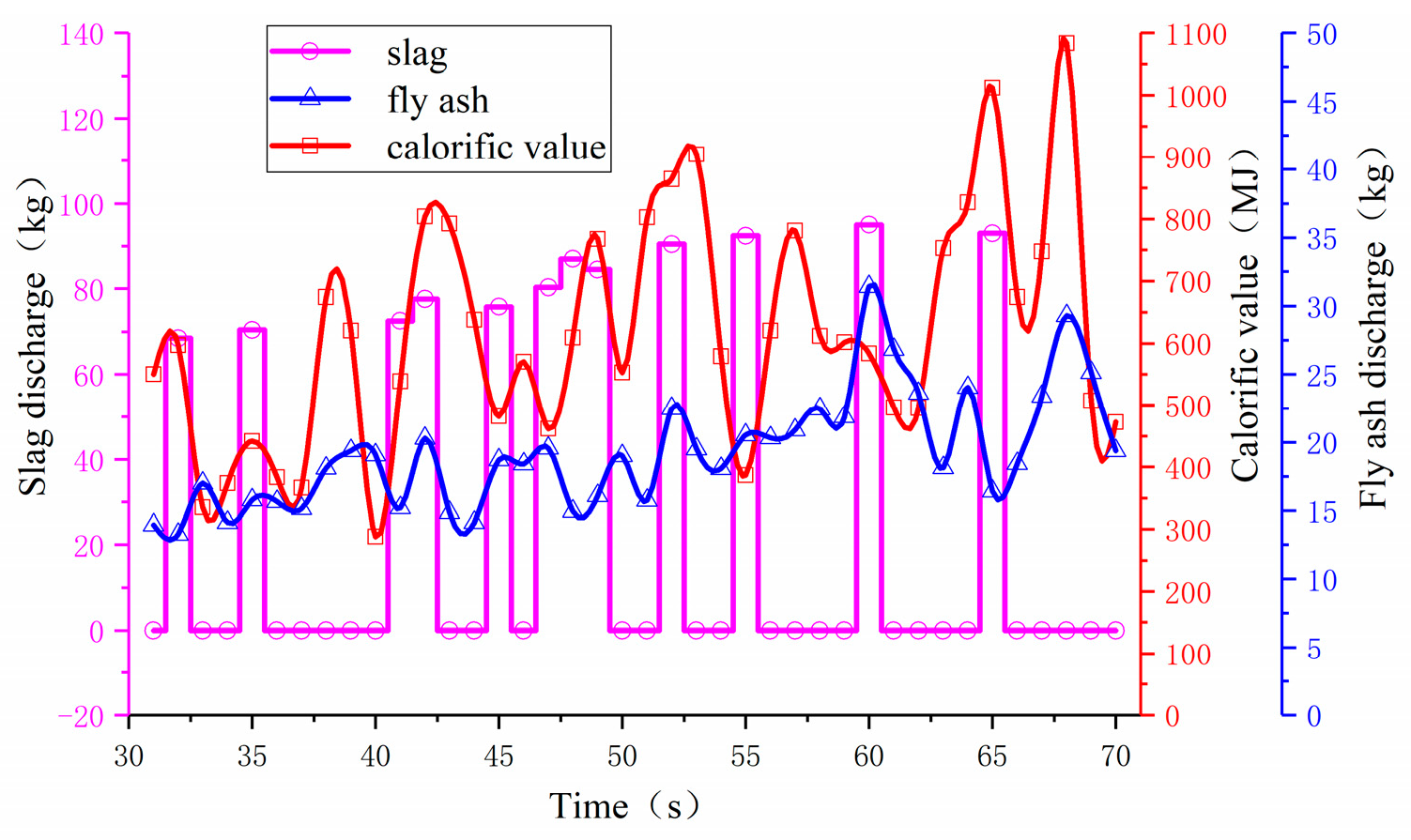

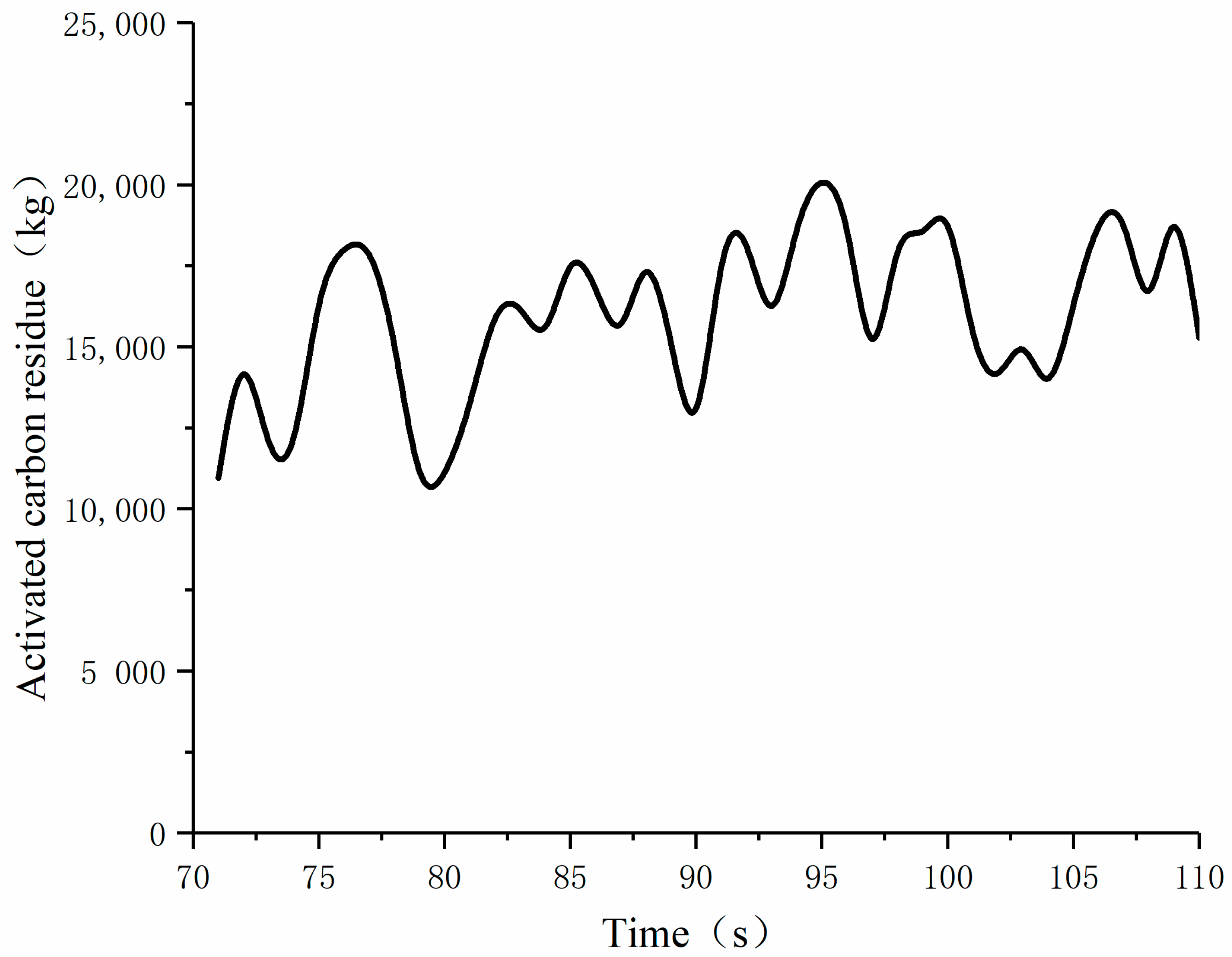

4.2.3. Analysis of Dynamic Characteristics of Residual Char

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| a | particle acceleration (m·s−2) |

| Ap | particle surface area (m2) |

| Aw | area of the local wall (m2) |

| C | Smagorinsky constant |

| Cv | specific heat (J·kg−1·K−1) |

| Cd | drag coefficient |

| d | diameter (m) |

| D | turbulent mass diffusion coefficient for gas (m2·s−1) |

| Dp | interphase momentum-transfer coefficient |

| ewc | effective emissivity for the wall-cell combination |

| f | particle distribution function |

| F | interphase momentum-transfer rate |

| Fs | particle friction force (N) |

| g | gravitational acceleration (m·s−2) |

| h | specific enthalpy (J·kg−1) |

| Ip | wall erosion impact value |

| K | chemical reaction rate coefficient |

| m | mass (kg) |

| Nu | Nusselt number |

| p | pressure (Pa) |

| Pp | pressure constant |

| q | heat transfer flux (J·m−2·s−1) |

| Q | energy source |

| qD | enthalpy diffusion (J·m−1·s−1) |

| r | reaction rate (kmol·m−3·s−1) |

| R | universal gas constant (J·kmol−1·K−1) |

| rp | particle radius (m) |

| Re | Reynolds number |

| Sh | interphase energy exchange rate |

| T | temperature (K) |

| u | velocity vector (m·s−1) |

| up | local mass-averaged particle velocity (m·s−1) |

| w | weighting factor |

| Xwc | view factor between the wall and cell |

| Yi | mass fraction |

| Greek Letters | |

| α | impact angle |

| θ | volume fraction |

| ϕ | viscous dissipation |

| ε | a small number on the order of 10−7 to remove the singularity |

| λ | thermal conductivity (W·m−2·K−1) |

| μ | viscosity (kg·m−1·s−1) |

| σ | Stefan-Boltzmann constant |

| ρ | density (kg·m−3) |

| τ | stress tensor (Pa) |

| ξ | char conversion rate |

| Δ | length scale |

| Subscripts | |

| cp | close pack |

| g | gas phase |

| i | the ith species |

| l | laminar flow |

| p | solid phase |

| t | turbulent flow |

References

- Huang, Z.; Deng, L.; Che, D. Development and technical progress in large-scale circulating fluidized bed boiler in China. Front. Energy 2020, 1–16. [Google Scholar] [CrossRef]

- Cheng, L.; Ji, J.; Wei, Y.; Wang, Q.; Fang, M.; Luo, Z.; Ni, M.; Cen, K. A note on large-size supercritical CFB technology development. Powder Technol. 2020, 363, 398–407. [Google Scholar] [CrossRef]

- Lyu, J.; Yang, H.; Ling, W.; Nie, L.; Yue, G.; Li, R.; Chen, Y.; Wang, S. Development of a supercritical and an ultra-supercritical circulating fluidized bed boiler. Front. Energy 2017, 13, 114–119. [Google Scholar] [CrossRef]

- Konist, A.; Järvik, O.; Pikkor, H.; Neshumayev, D.; Pihu, T. Utilization of pyrolytic wastewater in oil shale fired CFBC boiler. J. Clean. Prod. 2019, 234, 487–493. [Google Scholar] [CrossRef]

- Yue, G.; Cai, R.; Lu, J.; Zhang, H. From a CFB reactor to a CFB boiler – The review of R&D progress of CFB coal combustion technology in China. Powder Technol. 2017, 316, 18–28. [Google Scholar] [CrossRef]

- Cai, R.; Ke, X.; Lyu, J.; Yang, H.; Zhang, M.; Yue, G.; Ling, W. Progress of circulating fluidized bed combustion technology in China: a review. Clean Energy 2017, 1, 36–49. [Google Scholar] [CrossRef]

- Wang, W.; Jing, S.; Sun, Y.; Liu, J.; Niu, Y.; Zeng, D.; Cui, C. Combined heat and power control considering thermal inertia of district heating network for flexible electric power regulation. Energy 2019, 169, 988–999. [Google Scholar] [CrossRef]

- Adams, D.; Oh, D.-H.; Kim, D.-W.; Lee, C.-H.; Oh, M. Prediction of SOx–NOx emission from a coal-fired CFB power plant with machine learning: Plant data learned by deep neural network and least square support vector machine. J. Clean. Prod. 2020, 270, 122310. [Google Scholar] [CrossRef]

- Yang, W.; Wang, B.; Lei, S.; Wang, K.; Chen, T.; Song, Z.; Ma, C.; Zhou, Y.; Sun, L. Combustion optimization and NOx reduction of a 600 MWe down-fired boiler by rearrangement of swirl burner and introduction of separated over-fire air. J. Clean. Prod. 2019, 210, 1120–1130. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, B.; Hong, F.; Chen, F. Design and application of the feed water control strategy for a 350 MW circulating fluidized bed boiler. Appl. Therm. Eng. 2017, 125, 1–8. [Google Scholar] [CrossRef]

- Gao, M.; Hong, F.; Yan, G.; Liu, J.; Chen, F. Mechanism modelling on the coordinated control system of a coal-fired subcritical circulating fluidized bed unit. Appl. Therm. Eng. 2019, 146, 548–555. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, M.; Hong, F.; Liu, J.; Wang, X. Control-oriented modelling and investigation on quick load change control of subcritical circulating fluidized bed unit. Appl. Therm. Eng. 2019, 163, 114420. [Google Scholar] [CrossRef]

- Hong, F.; Yan, G.; Gao, M. The operation control and application of CFB boiler unit with high blending ratio of coal slurry. Control Eng. Pract. 2019, 85, 80–89. [Google Scholar] [CrossRef]

- Bidwe, A.R.; Varela, G.D.; Dieter, H.; Scheffknecht, G. Experimental study of the effect of friction phenomena on actual and calculated inventory in a small-scale CFB riser. Particuology 2015, 21, 41–47. [Google Scholar] [CrossRef]

- Chourasia, S.; Alappat, B.J. Effects of various parameters on the attrition of bed material in a recirculating fluidized bed with a draft tube. Particuology 2018, 38, 61–70. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, H.; Yang, S.; Yue, G.; Su, J.; Fu, Z. Effect of Bed Pressure Drop on Performance of a CFB Boiler. Energy Fuels 2009, 23, 2886–2890. [Google Scholar] [CrossRef]

- Park, C.; Basu, P. A model for prediction of transient response to the change of fuel feed rate to a circulating fluidized bed boiler furnace. Chem. Eng. Sci. 1997, 52, 3499–3509. [Google Scholar] [CrossRef]

- Snider, D.M.; Clark, S.M.; O’Rourke, P.J. Eulerian–Lagrangian method for three-dimensional thermal reacting flow with application to coal gasifiers. Chem. Eng. Sci. 2011, 66, 1285–1295. [Google Scholar] [CrossRef]

- Snider, D. An Incompressible Three-Dimensional Multiphase Particle-in-Cell Model for Dense Particle Flows. J. Comput. Phys. 2001, 170, 523–549. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, X.; Zhong, W. Simulations of Coal Combustion in a Pressurized Supercritical CO2 Circulating Fluidized Bed. Energy Fuels 2020, 134, 4977–4992. [Google Scholar] [CrossRef]

- Xie, J.; Zhong, W.; Shao, Y.; Liu, Q.; Liu, L.; Liu, G. Simulation of Combustion of Municipal Solid Waste and Coal in an Industrial-Scale Circulating Fluidized Bed Boiler. Energy Fuels 2017, 31, 14248–14261. [Google Scholar] [CrossRef]

- Zhong, W.; Xie, J.; Shao, Y.; Liu, X.; Jin, B. Three-dimensional modeling of olive cake combustion in CFB. Appl. Therm. Eng. 2015, 88, 322–333. [Google Scholar] [CrossRef]

- Desroches-Ducarne, E.; Dolignier, J.; Marty, E.; Martin, G.; Delfosse, L. Modelling of gaseous pollutants emissions in circulating fluidized bed combustion of municipal refuse. Fuel 1998, 77, 1399–1410. [Google Scholar] [CrossRef]

- Cozzani, V. Reactivity in Oxygen and Carbon Dioxide of Char Formed in the Pyrolysis of Refuse-Derived Fuel. Ind. Eng. Chem. Res. 2000, 39, 864–872. [Google Scholar] [CrossRef]

- Diaz-Bossio, L.M.; Squier, S.E.; Pulsifer, A.H. Reductive decomposition of calcium sulfate utilizing carbon monoxide and hydrogen. Chem. Eng. Sci. 1985, 40, 319–324. [Google Scholar] [CrossRef]

- Xie, J.; Zhong, W.; Jin, B.; Shao, Y.; Liu, H. Three-Dimensional Eulerian–Eulerian Modeling of Gaseous Pollutant Emissions from Circulating Fluidized-Bed Combustors. Energy Fuels 2014, 28, 5523–5533. [Google Scholar] [CrossRef]

- Patel, M.K.; Pericleous, K.; Cross, M. Numerical modelling of circulating fluidized beds. Int. J. Comput. Fluid Dyn. 1993, 1, 161–176. [Google Scholar] [CrossRef]

- Beetstra, R.; Van Der Hoef, M.M.; Kuipers, J.A.M. Drag force of intermediate Reynolds number flow past mono- and bidisperse arrays of spheres. AIChE J. 2007, 53, 489–501. [Google Scholar] [CrossRef]

- Gidaspow, D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Description; Academic Press: Boston, MA, USA, 1994. [Google Scholar]

- Chhabra, R.; Agarwal, L.; Sinha, N. Drag on non-spherical particles: an evaluation of available methods. Powder Technol. 1999, 101, 288–295. [Google Scholar] [CrossRef]

| The Main Components | Geometric Size (m) |

|---|---|

| Furnace width × depth | 32 × 10 |

| Furnace height (to air distribution board) | 48 |

| Cyclone separator diameter | ø 10 |

| Rear chimney width × depth | 22 × 9 |

| Items | Control Equations |

|---|---|

| Gas-phase mass conservative equation | |

| Gas-phase momentum conservation equation | |

| Species conservation equation for the gas phase | |

| Gas-phase energy conservation equation | |

| Transport equation for particle distribution function | |

| Equation for particle acceleration | |

| Equation for particle contact normal stress | |

| Lumped-heat equation for the particle | |

| Mass exchange rate | |

| Interphase momentum transfer |

| Chemical Reaction Equations | |

|---|---|

| R1 | |

| R2 | |

| R3 | |

| R4 | |

| R5 | |

| R6 | |

| R7 | |

| R8 | |

| R9 | |

| R10 | |

| R11 | |

| R12 |

| Reaction Rate r (mol·m−3·s−1) | Reaction Rate Coefficient K | |

|---|---|---|

| R1 | ||

| R2 | ||

| R3 | ||

| R4 | ||

| R5 | ||

| R6 | ||

| R7 | ||

| R8 | ||

| R9 | ||

| R10 | ||

| R11 | ||

| R12 |

| Item | Number | ||

|---|---|---|---|

| load change (MW) | 250 | 300 | 350 |

| coal inlet flowrate (kg/s) | 55 | 65 | 75 |

| primary air inlet flowrate (kg/s) | 110 | 125 | 140 |

| secondary air (up/down) inlet flowrate (kg/s) | 55/25 | 65/35 | 75/45 |

| slag outlet pressure (Pa) | 98,000 | 98,000 | 98,000 |

| flue gas outlet pressure (Pa) | 120,000 | 120,000 | 120,000 |

| water wall temperature (K) | 800 | 820 | 850 |

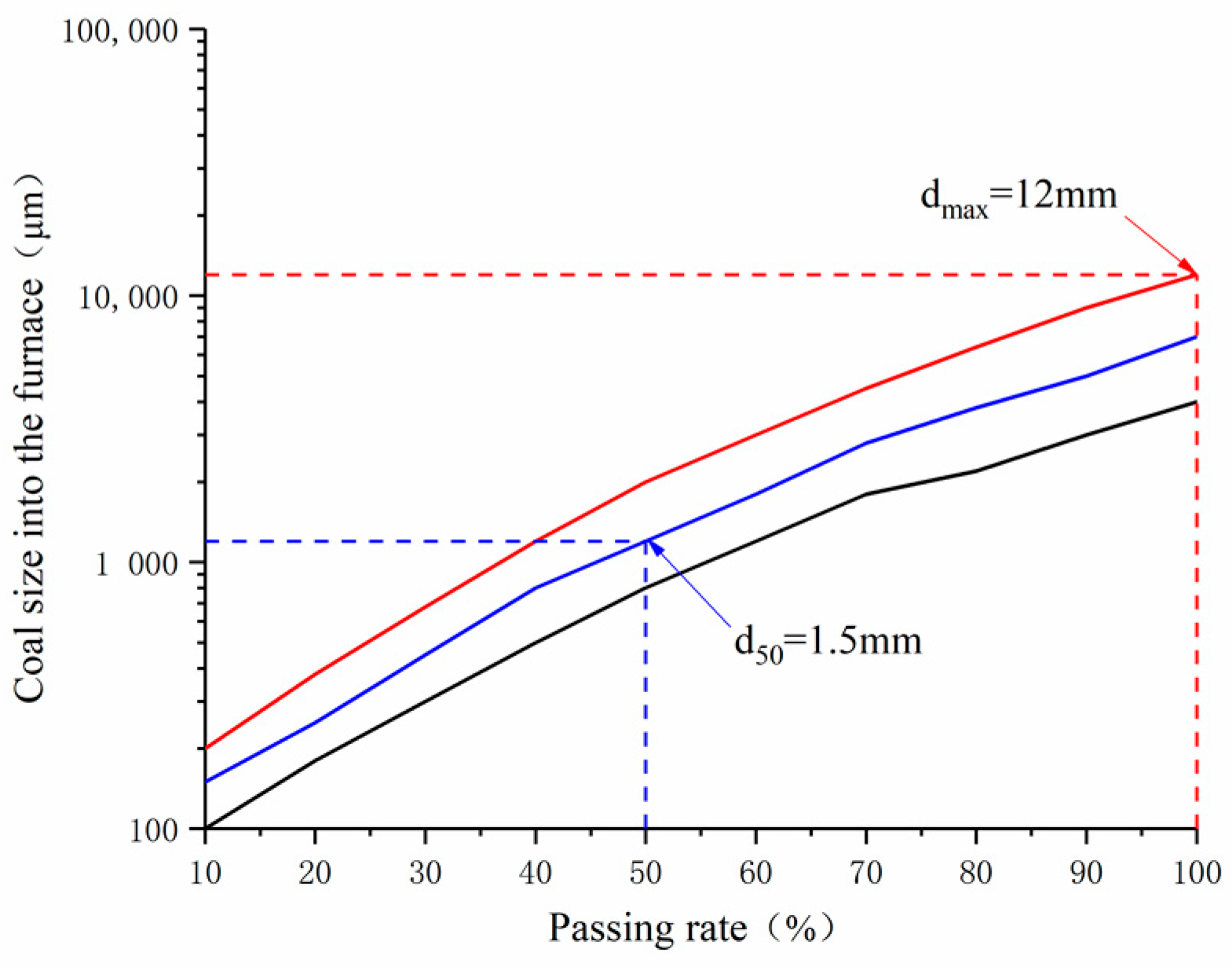

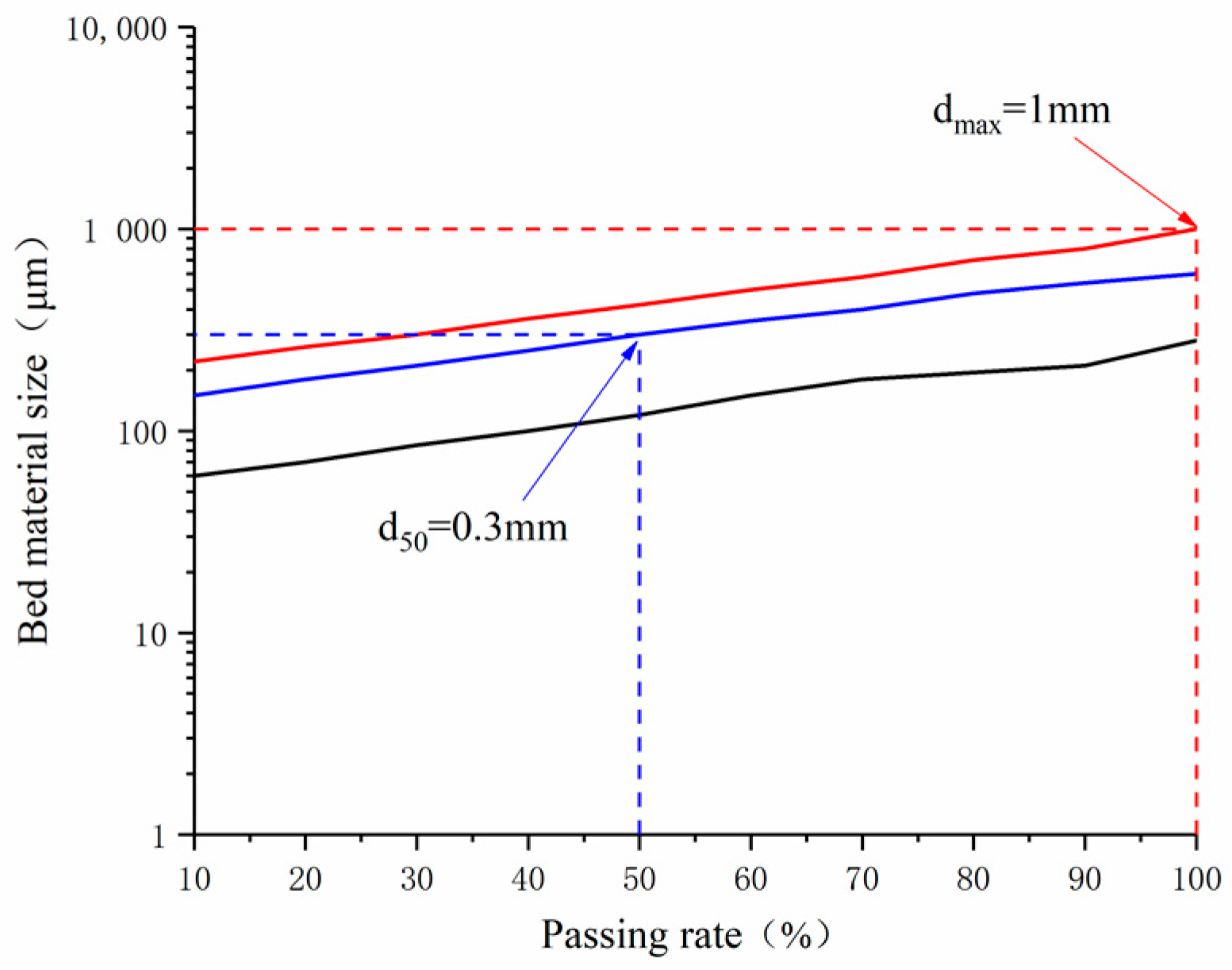

| Particle Type | Size Range (mm) | d50 (mm) |

|---|---|---|

| coal | 0~12 | 1.5 |

| limestone | 0~1 | 0.3 |

| Bed material | 0~1 | 0.3 |

| Simulation Phase | Simulation Time(s) | Load Change (MW) |

|---|---|---|

| start up | 0~30 | 0→250 |

| Load up | 30~50 | 250→300 |

| 50~70 | 300→350 | |

| Load down | 70~90 | 350→300 |

| 90~110 | 300→250 |

| Item | Number |

|---|---|

| Load (MW) | 250/300/350 |

| W (t/h) | 198/234/270 |

| X (%m) | 30 |

| Hc (MJ/kg) | 30 |

| Xz (%m) | 1.29 |

| Xf (%m) | 1.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, X.; Jia, L.; Wang, Y.; Guo, B.; Fan, H.; Qiao, X.; Zhang, M.; Jin, Y. Study on Dynamic Characteristics of Residual Char of CFB Boiler Based on CPFD Method. Energies 2020, 13, 5883. https://doi.org/10.3390/en13225883

Shen X, Jia L, Wang Y, Guo B, Fan H, Qiao X, Zhang M, Jin Y. Study on Dynamic Characteristics of Residual Char of CFB Boiler Based on CPFD Method. Energies. 2020; 13(22):5883. https://doi.org/10.3390/en13225883

Chicago/Turabian StyleShen, Xin, Li Jia, Yanlin Wang, Baihe Guo, Haodong Fan, Xiaolei Qiao, Man Zhang, and Yan Jin. 2020. "Study on Dynamic Characteristics of Residual Char of CFB Boiler Based on CPFD Method" Energies 13, no. 22: 5883. https://doi.org/10.3390/en13225883

APA StyleShen, X., Jia, L., Wang, Y., Guo, B., Fan, H., Qiao, X., Zhang, M., & Jin, Y. (2020). Study on Dynamic Characteristics of Residual Char of CFB Boiler Based on CPFD Method. Energies, 13(22), 5883. https://doi.org/10.3390/en13225883