Experimental Investigation and Energy Performance Simulation of Mongolian Ger with ETS Heater and Solar PV in Ulaanbaatar City

Abstract

1. Introduction

2. Methodology

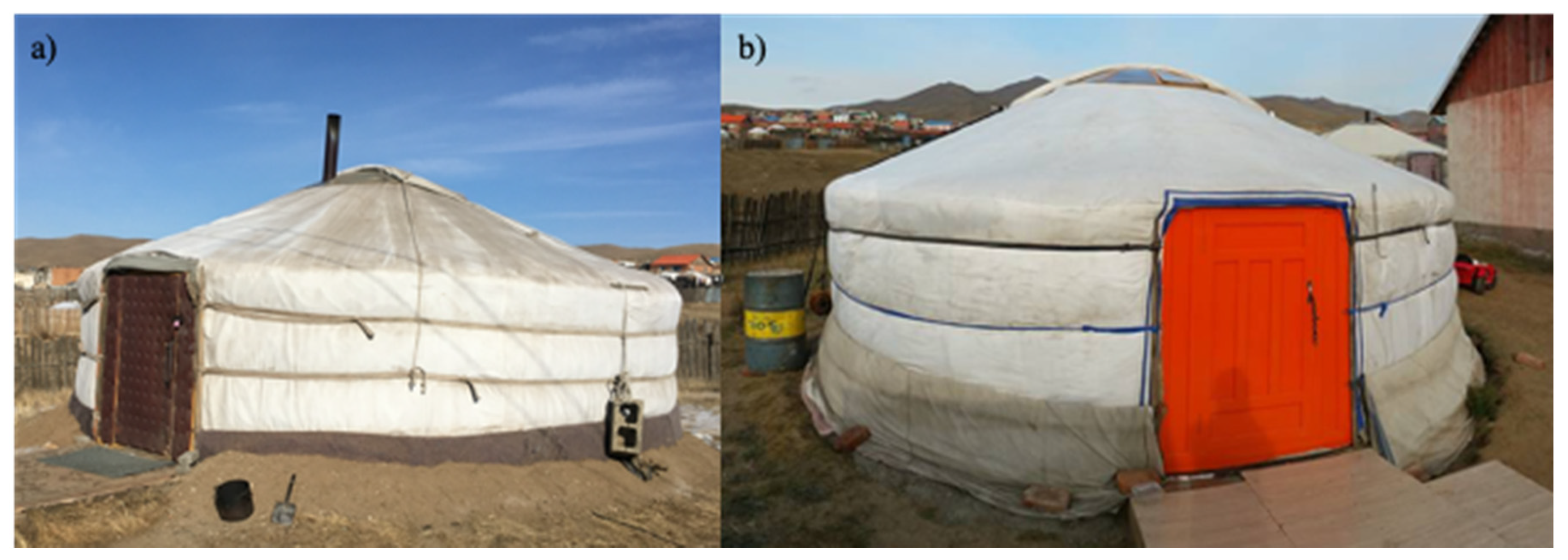

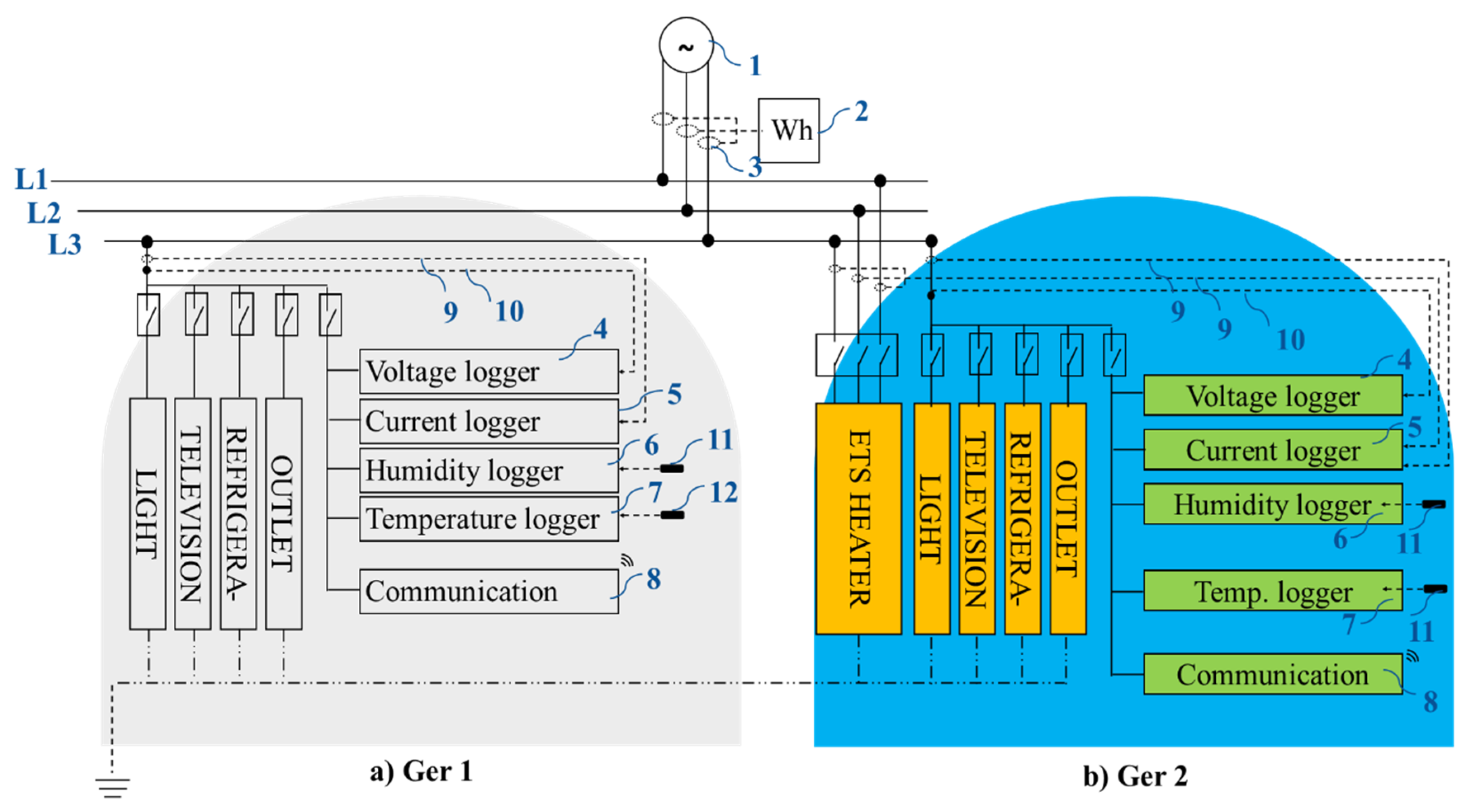

2.1. Experimentation with the Insulated Ger with ETS Heater

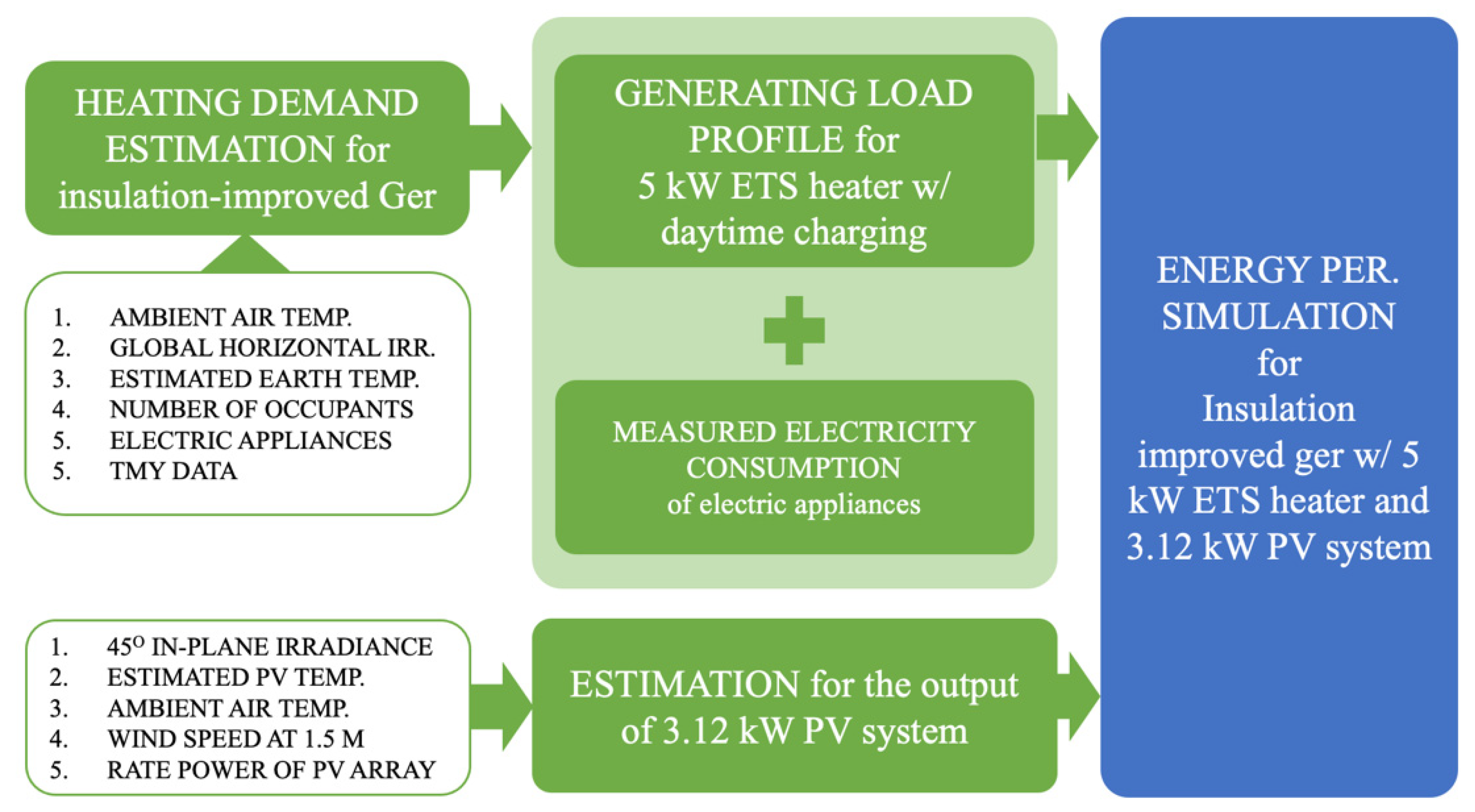

2.2. Simulation of the Proposed System

2.3. Estimation of Heating Demand

2.4. Load Profile Generation of ETS Heater Daytime Charging

2.5. Estimation of Solar PV Output

3. Results and Discussion

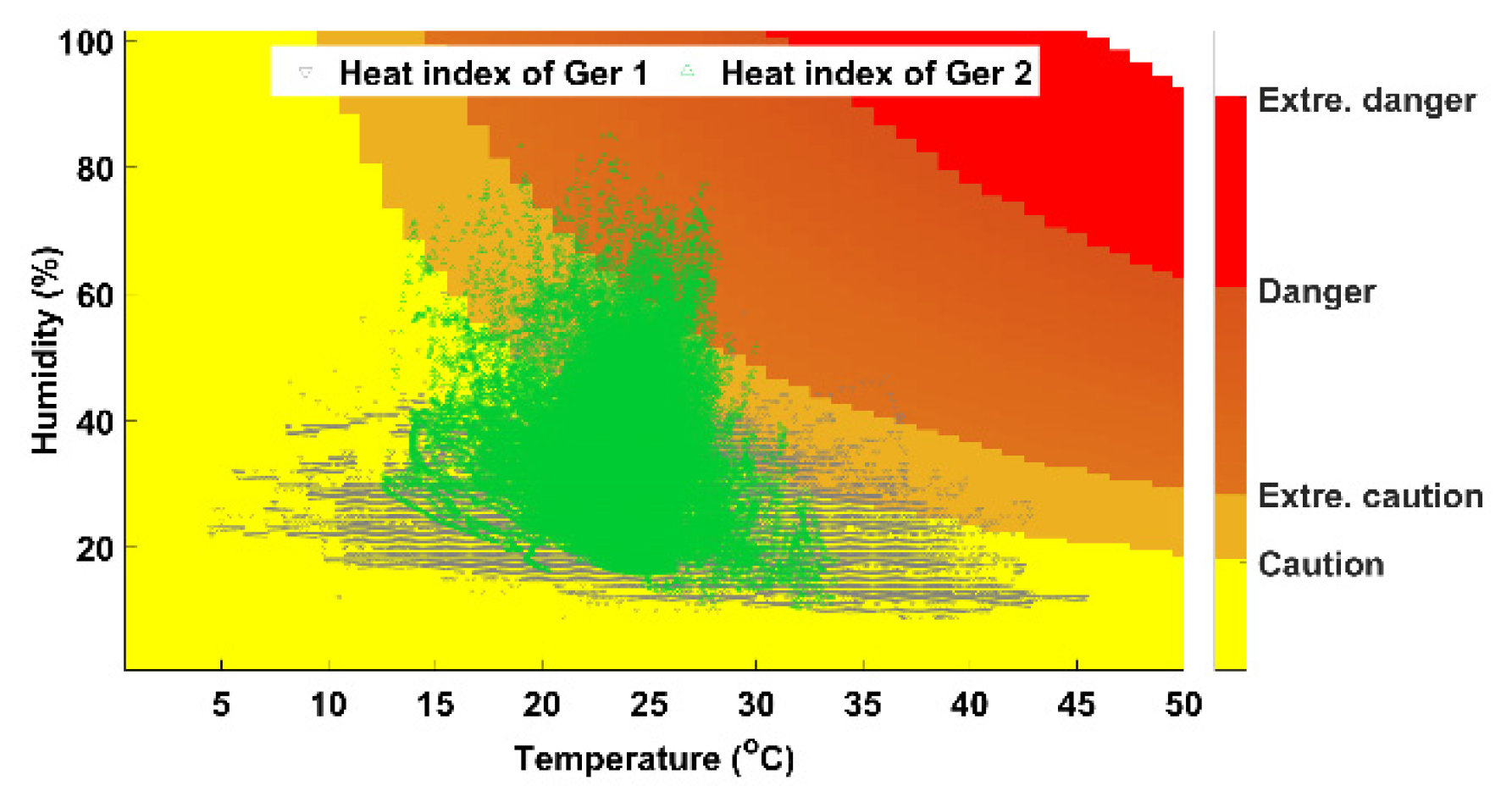

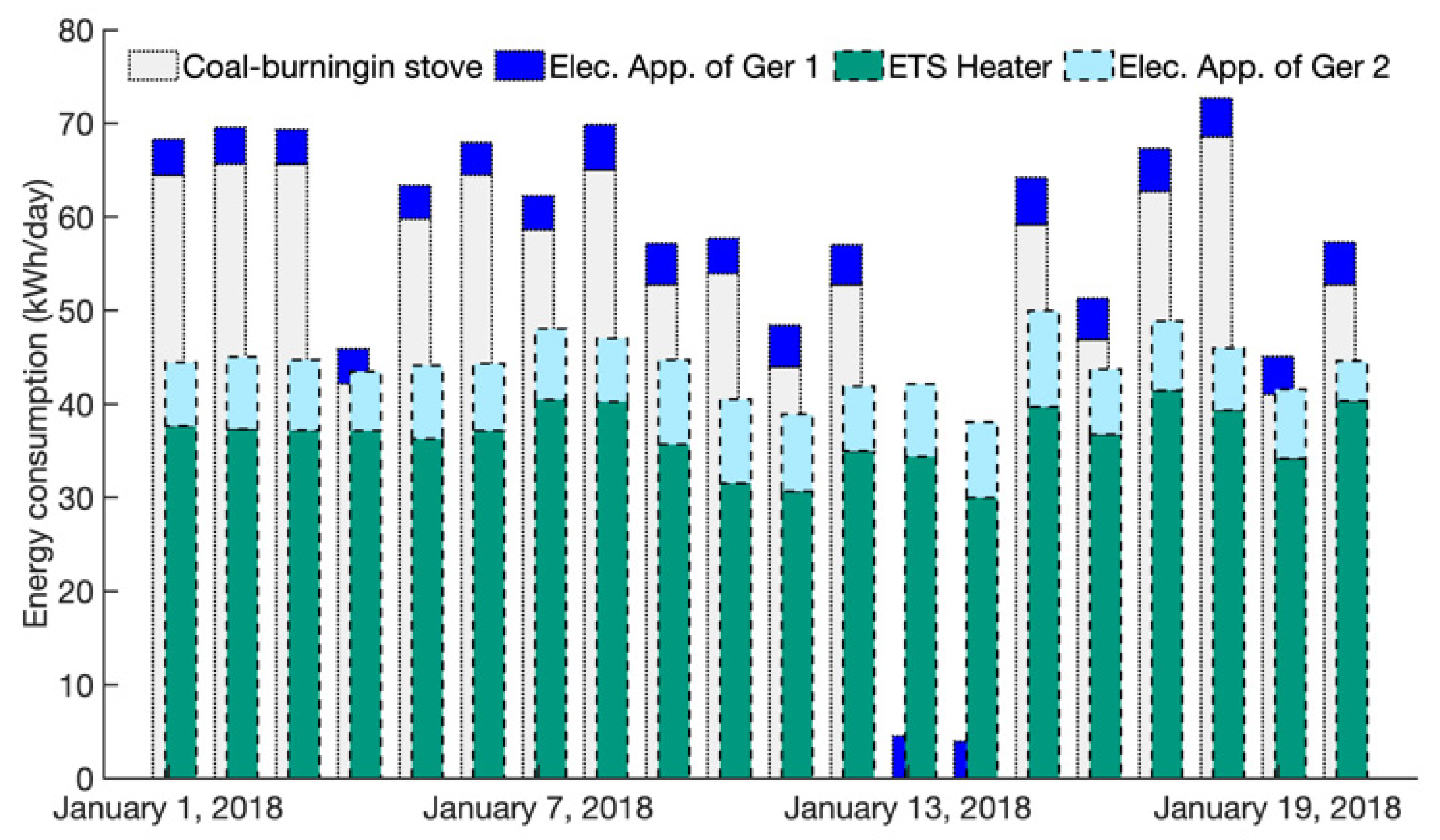

3.1. Experimental Results

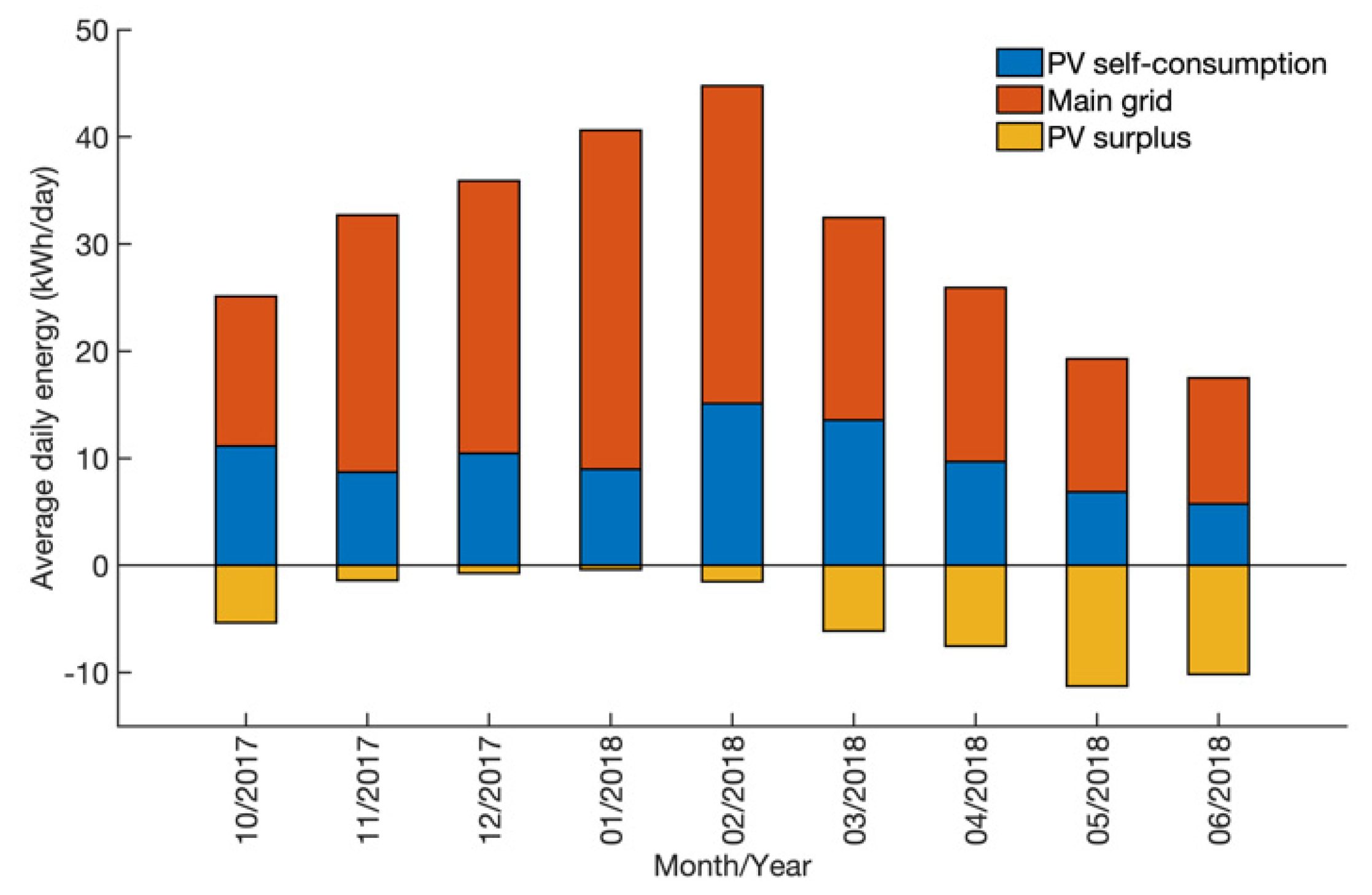

3.2. Simulation Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Envelope Elements of Mongolian Ger

| № | Description of Ger 1′s Envelope Elements | Description of Ger 2′s Envelope Elements | |

|---|---|---|---|

| 1 | Crown wheel | Layer 1: 150 wooden frame with 0.17 ther. cond. Layer 2: 50 felt with 0.04 thermal conductivity Layer 3: 3 glass with 0.8 thermal conductivity | Layer 1: 150 wooden frame with 0.17 thermal cond. Layer 2: 50 felt with 0.04 thermal conductivity Layer 3: 3 glass with 0.8 thermal conductivity Layer 4: 4 polycarbonate sheet |

| 2 | Roof | Layer 1: Φ30 wooden pole with 0.17 ther. cond. Layer 2: 2 linen with 0.04 thermal conductivity Layer 3: 50 felt with 0.04 thermal conductivity Layer 4: 2 linen with 0.04 thermal conductivity | Layer 1: Φ30 wooden pole with 0.17 thermal cond. Layer 2: 2 linen with 0.04 thermal conductivity Layer 3: 50 felt with 0.04 thermal conductivity Layer 4: 2 linen with 0.04 thermal conductivity Layer 5: 3 alum. foil with 0.04 thermal cond. |

| 3 | Wall | Layer 1: 2 linen with 0.04 thermal conductivity Layer 2: 14 wooden lattice with 0.17 therm. cond. Layer 3: 2 linen with 0.04 thermal conductivity Layer 4: 50 felt with 0.04 thermal conductivity Layer 5: 2 linen with 0.04 thermal conductivity | Layer 1: 2 linen with 0.04 thermal conductivity Layer 2: 14 wooden lattice with 0.17 thermal cond. Layer 3: 2 linen with 0.04 thermal conductivity Layer 4: 80 felt with 0.04 thermal conductivity Layer 5: 2 linen with 0.04 thermal conductivity Layer 6: 3 alum. foil with 0.04 thermal cond. |

| 4 | Door | Layer 1: 20 wood with 0.17 thermal cond. Layer 2: 20 felt with 0.04 thermal conductivity | Layer 1: 20 wood with 0.17 thermal cond. Layer 2: 20 felt with 0.04 thermal conductivity Layer 3: 3 alum. foil with 0.04 thermal cond. |

| 5 | Door frame | Layer 1: 30 wood with 0.17 thermal cond. Layer 2: 40 felt with 0.04 thermal conductivity | Layer 1: 30 wood with 0.17 thermal cond. Layer 2: 40 felt with 0.04 thermal conductivity Layer 3: 3 alum. foil with 0.04 thermal cond. |

| 6 | Floor | Layer 1: 20 wood with 0.17 thermal cond. Layer 2: 50 Styrofoam with 0.03 thermal cond. | Layer 1: 20 wood with 0.17 thermal cond. Layer 2: 150 Styrofoam with 0.03 thermal cond. Layer 3: 3 alum. foil with 0.04 thermal cond. |

Appendix B. Data Description

| № | Parameters | Period | Resolution | Application of Data | |||

|---|---|---|---|---|---|---|---|

| Experimental Investigation | Estimation of Heating Demand | Estimation of Solar PV Output | Simulation of Proposed System | ||||

| 1. Wireless communication base modular logger | |||||||

| 1.1 | Indoor air temperature of Ger 1 ( | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 1.2 | Indoor air humidity of Ger 1 () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 1.3 | Consumption of major elec. app. of Ger 1 () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 1.4 | Coal weight () | 01/Jan/18–20/Jan/18 | 3 h | + | |||

| 1.5 | Indoor air temperature of Ger 2 ( | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 1.6 | Indoor air humidity of Ger 2 () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 1.7 | Consumption of major elec. app. of Ger 2 () | 28/Oct/17–08/Jun/18 | 2 min | + | + | ||

| 1.8 | Consumption of ETS heater () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 2. Meteorological weather station data | |||||||

| 2.1 | Outdoor air temperature ( | 28/Oct/17–08/Jun/18 | 2 min | + | + | + | |

| 2.2 | Outdoor air humidity () | 28/Oct/17–08/Jun/18 | 2 min | ||||

| 2.3 | Global horizontal irradiance () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 2.4 | 45o plane of array irradiance () | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 2.5 | Wind speed (m/s) | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 3. Other data | |||||||

| 3.1 | Typical Meteorological Year (TMY) data | + | |||||

| 3.2 | Physical characteristic data for ger | + | |||||

| 3.3 | Thermal and technical data of ger’s envelope materials | + | + | ||||

| 4. Composed and estimated data | |||||||

| 4.1 | Estimated earth temperature, | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 4.2 | Binary number of adult occupants | 28/Oct/17–08/Jun/18 | 2 min | + | + | ||

| 4.2 | Binary number of child occupants | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 4.3 | Binary number of elec. application operation | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 4.4 | Estimated heating demand | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| Binary numbers of the ETS heater operation | 28/Oct/17–08/Jun/18 | 2 min | + | ||||

| 4.5 | Generated load profile of daily heating demand | 28/Oct/17–08/Jun/18 | 2 min | + | |||

| 4.6 | Estimated output power of solar PV | 28/Oct/17–08/Jun/18 | 2 min | + | |||

Appendix C. The Validation of the Estimated Heating Demand and Solar PV Output

| Year | Estimated Heating Demand | Estimated PV Output | ||||

|---|---|---|---|---|---|---|

| MAPE, % | MBE, kWh | RMSE, kWh | MAPE, % | MBE, kWh | RMSE, kWh | |

| 2017/10 | 17.96 | 3.58 | 1.52 | 5.38 | 1.00 | 0.985 |

| 2017/11 | 13.31 | 4.17 | 2.23 | 16.13 | 2.15 | 1.26 |

| 2017/12 | 11.98 | 3.99 | 2.33 | 23.94 | 1.84 | 0.51 |

| 2018/01 | 5.54 | 2.02 | 0.36 | 9.78 | 0.80 | 0.54 |

| 2018/02 | 3.83 | 1.26 | 0.91 | 6.26 | 1.06 | 0.42 |

| 2018/03 | 24 | 5.21 | 3.47 | 3.40 | 0.51 | 0.51 |

| 2018/04 | 23.40 | 3.58 | 3.45 | |||

| 2018/05 | 2.6 | 0.56 | 0.57 | |||

| 2018/06 | ||||||

References

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040; USDOE Energy Information Administration (EIA): Washington, DC, USA, 2016.

- Mongolian Statistical Information Service. National Statistics Office. Available online: www.1212.mn (accessed on 10 November 2019).

- Edwards, R. Irvine Understanding and Addressing the Impact of air Pollution on Children’s Health in Mongolia; University of California, UNICEF Mongolia, and Mongolia’s Public Health Institute: Ulaanbaatar, Mongolia, 2016. [Google Scholar]

- Davy, P.K.; Gerelmaa, G.; Andreas, M.; Trompetter, W.J.; Barry, B.J.; Shagjjambe, D.; Sereeter, L. Air particulate matter pollution in Ulaanbaatar, Mongolia: Determination of composition, source contributions and source locations. Atmos. Pollut. Res. 2011, 2, 126–137. [Google Scholar] [CrossRef]

- Guttikunda, S.K.; Lodoysamba, S.; Bulgansaikhan, B.; Dashdondog, B. Particulate pollution in Ulaanbaatar, Mongolia. Air Qual. Atmos. Health 2013, 6, 589–601. [Google Scholar] [CrossRef]

- Gantumur, T.; Lim, S.R.R.; Ganjali, M.R.; Kistelegdi, I. A review and systemization of the traditional Mongolian yurt (GER). Pollack Period. 2018, 13, 19–30. [Google Scholar]

- Mauvieux, B.; Alain, R.; Yvan, T. The yurt: A mobile home of nomadic populations dwelling in the Mongolian steppe is still used both as a sun clock and a calendar. Chronobiol. Int. 2014, 31, 151–156. [Google Scholar] [CrossRef] [PubMed]

- Gantumur, T.; Kistelegdi, I. Comparative analysis for traditional yurts using thermal dynamic simulations in Mongolian climate. Pollack Period. 2019, 14, 97–108. [Google Scholar]

- Cooke, W.B.H.; Stephen, H.R.; Sulatisky, M.T. Thermal energy storage in forced-air electric furnaces. IEEE Trans. Ind. Appl. 1980, IA-16, 127–133. [Google Scholar] [CrossRef]

- Miriam, V.G. Electric thermal-storage heaters. Electron. Power 1964, 10, 68–71. [Google Scholar]

- Coleman, W.R.; Grastataro, C.M. American electric power system electric thermal storage program: An evaluation of performance within the home. IEEE Trans. Power Appar. Syst. 1981, 12, 4741–4749. [Google Scholar] [CrossRef]

- Bedouani, B.Y.; Moreau, A.; Parent, M.; Blaise, L. Central electric thermal storage (ETS) feasibility for residential applications: Part 1. Numerical and experimental study. Int. J. Energy Res. 2001, 25, 53–72. [Google Scholar] [CrossRef]

- Bedouani, B.Y.; Labreque, B.; Parent, M.; Legault, A. Central electric thermal storage (ETS) feasibility for residential applications: Part 2. Techno-economic study. Int. J. Energy Res. 2001, 25, 73–83. [Google Scholar] [CrossRef]

- Steven, W.; Pinard, J.-P. Opportunities for smart electric thermal storage on electric grids with renewable energy. IEEE Trans. Smart Grid 2016, 8, 1014–1022. [Google Scholar]

- Patrick, S.S.; Bharatkumar, V.S.; Claudio, A.C.; Soren, K.H. Electric thermal storage system impact on northern communities’ microgrids. IEEE Trans. Smart Grid 2017, 10, 852–863. [Google Scholar]

- Kylesconverter. Available online: http://www.kylesconverter.com/ (accessed on 10 November 2019).

- Kavgic, M.; Mavrogianni, A.; Mumovic, D.; Summerfield, A.; Stevanovic, Z.; Djurovic-Petrovic, M. A review of bottom-up building stock models for energy consumption in the residential sector. Build. Environ. 2010, 45, 1683–1697. [Google Scholar] [CrossRef]

- Tamami, K.; Paul, R.A. Earth Temperature and Thermal Diffusivity at Selected Stations in the United States; National Bureau of Standards: Gaithersburg, MD, USA, 1965.

- Luketa-Hanlin, A.; Stein, J. Improvement and validation of a transient model to predict photovoltaic module temperature. In World Renewable Energy Forum; Denver, CO, USA, 2012. Available online: https://energy.sandia.gov (accessed on 10 November 2019).

- SUURI-KEIKAKU Co., Ltd.; Japan International Cooperation Agency (JICA). Capacity Development Project for Air Pollution Control in Ulaanbaatar City-Phase 1, 2, Mongolia. June 2017. Available online: https://openjicareport.jica.go.jp/pdf/12289195.pdf (accessed on 10 August 2020).

| Details | Value |

|---|---|

| Nominal rating, kW | 5 |

| Thermal capacity, kWh | 3 |

| Voltage, V | 3/N/PE~400 |

| Dimension, mm | 850 × 450 × 600 |

| Weight, kg | 184 |

| Details | Quantity, pcs | Rate Power, | Weekday Schedule | Weekend Schedule |

|---|---|---|---|---|

| Occupants | 2 adults and 2 children | 93 69 | 00:00–09:00 18:00–24:00 | 00:00–24:00 |

| Major electric appliance | 1 elect. stove | 1500 | 07:30–07:50 18:30–18:50 | 09:30–09:50 13:30–13:50 19:30–19:50 |

| Light | 1 halo. lamp | 50 | 18:00–23:00 | 18:00–23:00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayandelger, B.-E.; Ueda, Y.; Adiyabat, A. Experimental Investigation and Energy Performance Simulation of Mongolian Ger with ETS Heater and Solar PV in Ulaanbaatar City. Energies 2020, 13, 5840. https://doi.org/10.3390/en13215840

Bayandelger B-E, Ueda Y, Adiyabat A. Experimental Investigation and Energy Performance Simulation of Mongolian Ger with ETS Heater and Solar PV in Ulaanbaatar City. Energies. 2020; 13(21):5840. https://doi.org/10.3390/en13215840

Chicago/Turabian StyleBayandelger, Bat-Erdene, Yuzuru Ueda, and Amarbayar Adiyabat. 2020. "Experimental Investigation and Energy Performance Simulation of Mongolian Ger with ETS Heater and Solar PV in Ulaanbaatar City" Energies 13, no. 21: 5840. https://doi.org/10.3390/en13215840

APA StyleBayandelger, B.-E., Ueda, Y., & Adiyabat, A. (2020). Experimental Investigation and Energy Performance Simulation of Mongolian Ger with ETS Heater and Solar PV in Ulaanbaatar City. Energies, 13(21), 5840. https://doi.org/10.3390/en13215840