An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines

Abstract

1. Introduction

2. Theory and Background

2.1. Behavior and Properties of Linear Permanent Magnets

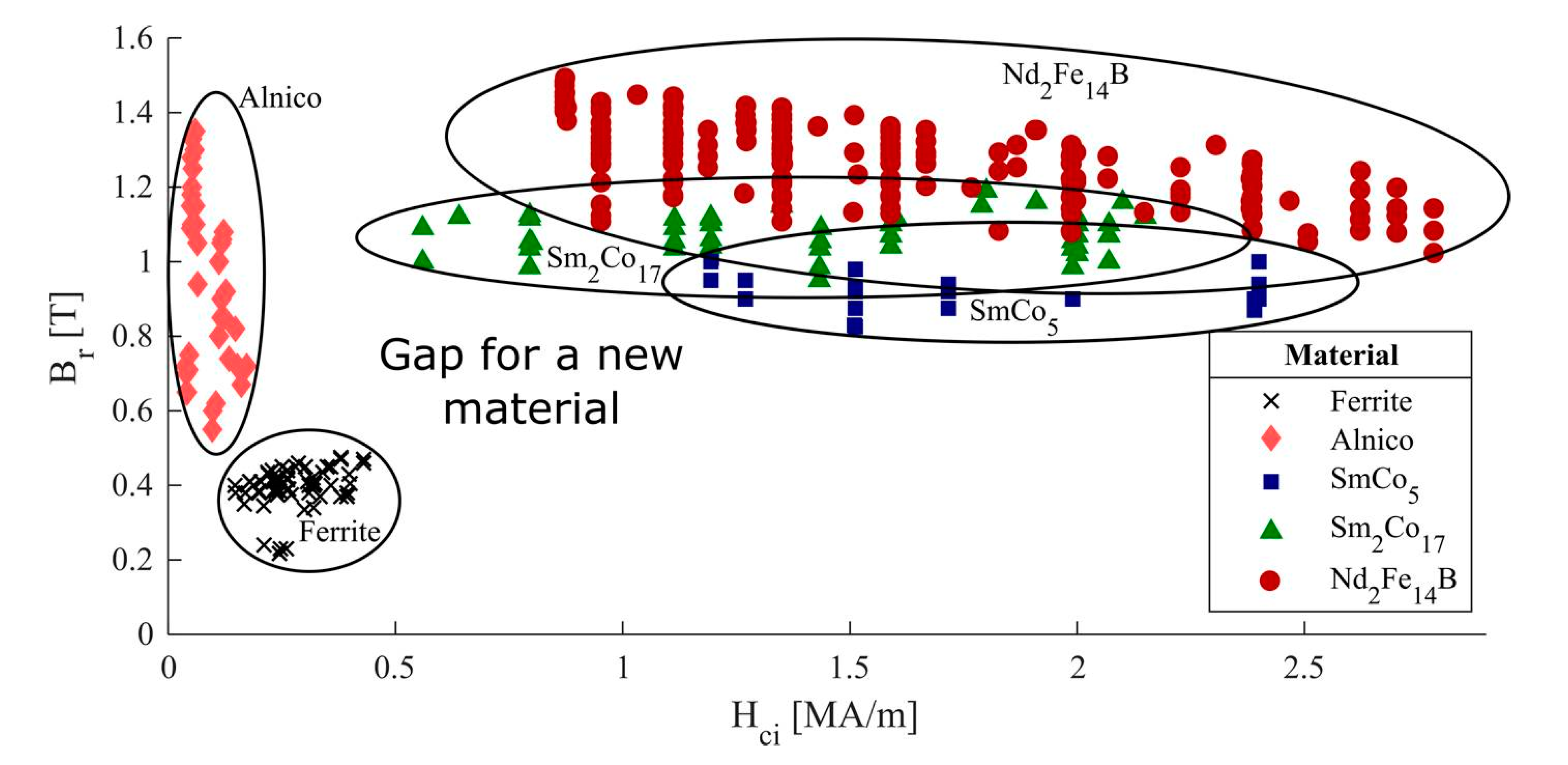

2.2. Materials That Could Be Used in Future Electrical Machines

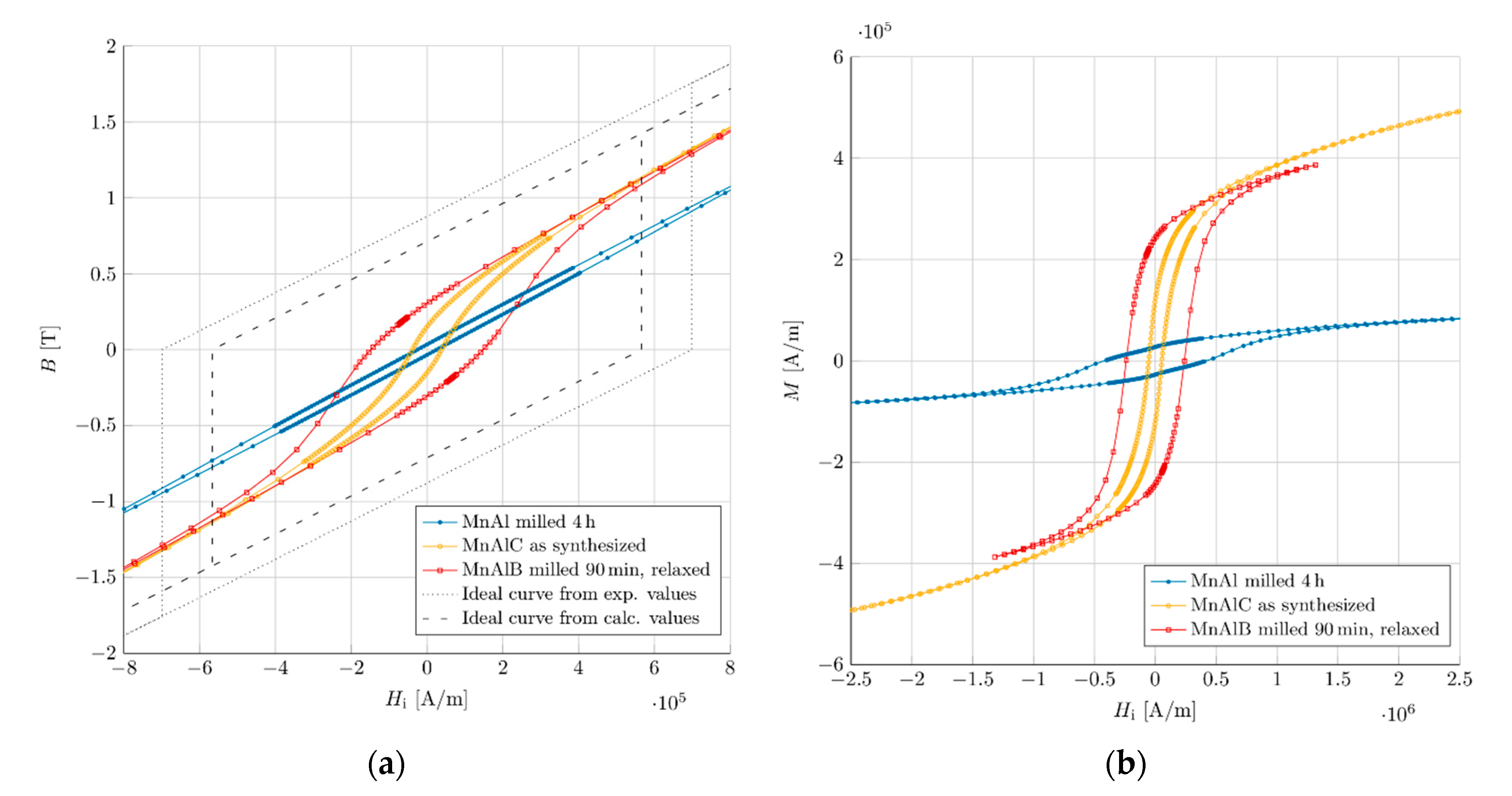

3. Experimental Data for MnAl

3.1. Energy Product and Coercivity for MnAl

3.2. Calculations on MnAl

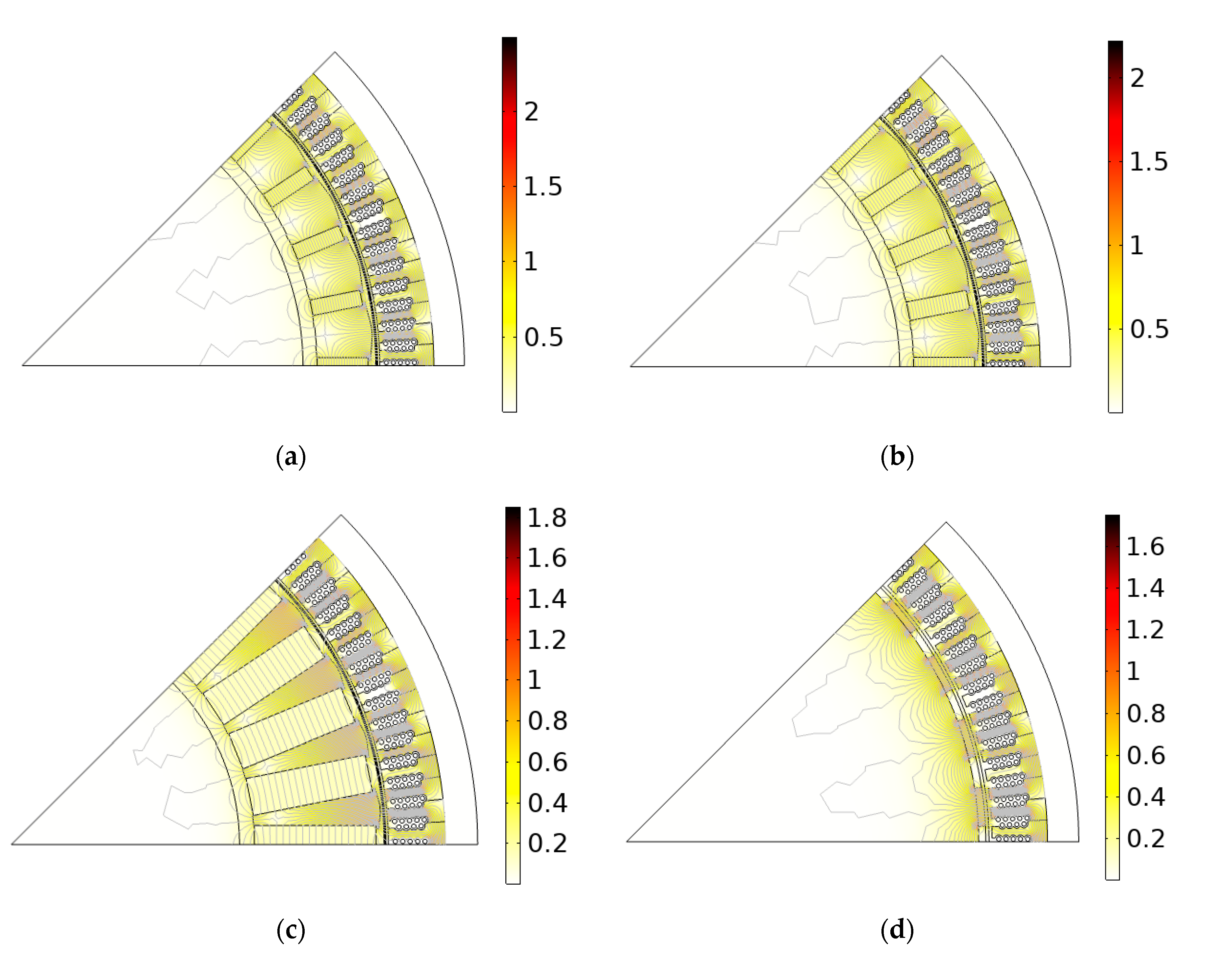

4. Simulations of Generators with Different PMs

5. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Hofmann, M.; Hofmann, H.; Hageluken, C.; Hool, A. Critical raw materials: A perspective from the materials science community. Sustain. Mater. Technol. 2018, 17. [Google Scholar] [CrossRef]

- Haque, N.; Hughes, A.; Lim, S.; Vernon, C. Rare earth elements: Overview of mining, mineralogy, uses, sustainability and environmental impact. Resources 2014, 3, 614–635. [Google Scholar] [CrossRef]

- Weng, Z.H.; Jowitt, S.M.; Mudd, G.M.; Haque, N. Assessing rare earth element mineral deposit types and links to environmental impacts. Trans. Institutions Min. Metall. Sect. B Appl. Earth Sci. 2014, 122, 83–96. [Google Scholar] [CrossRef]

- Smith Stegen, K. Heavy rare earths, permanent magnets, and renewable energies: An imminent crisis. Energy Policy 2015, 79, 1–8. [Google Scholar] [CrossRef]

- Eriksson, S.; Bernhoff, H. Rotor design for PM generators reflecting the unstable neodymium price. In Proceedings of the 2012 20th International Conference on Electrical Machines, ICEM 2012, Marseille, France, 2–5 September 2012; pp. 1419–1423. [Google Scholar]

- Balaram, V. Rare earth elements: A review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 2019, 10, 1285–1303. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P.; Hake, J.F.; Voßenkaul, D.; Friedrich, B. Environmental impacts of rare earth mining and separation based on eudialyte: A new European way. Resources 2016, 5, 32. [Google Scholar] [CrossRef]

- Alonso, E.; Sherman, A.M.; Wallington, T.J.; Everson, M.P.; Field, F.R.; Roth, R.; Kirchain, R.E. Evaluating rare earth element availability: A case with revolutionary demand from clean technologies. Environ. Sci. Technol. 2012, 46, 3406–3414. [Google Scholar] [CrossRef]

- De Santiago, J.; Bernhoff, H.; Ekergård, B.; Eriksson, S.; Ferhatovic, S.; Waters, R.; Member, S.; Leijon, M. Electrical Motor Drivelines in Commercial All-Electric Vehicles: A Review. IEEE Trans. Veh. Technol. 2012, 61, 475–484. [Google Scholar] [CrossRef]

- Tripathi, S.M.; Tiwari, A.N.; Singh, D. Grid-integrated permanent magnet synchronous generator based wind energy conversion systems: A technology review. Renew. Sustain. Energy Rev. 2015, 51, 1288–1305. [Google Scholar] [CrossRef]

- Schlör, H.; Zapp, P.; Marx, J.; Schreiber, A.; Venghaus, S.; Hake, J.-F. The social footprint of permanent magnet production based on rare earth elements-a social life cycle assessment scenario. Energy Procedia 2017, 142, 984–990. [Google Scholar] [CrossRef]

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Acta Materialia Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Pan, D.; Zhang, Z.; Choi, C.J. Prospect and status of iron-based rare-earth-free permanent magnetic materials. J. Magn. Magn. Mater. 2019, 469, 535–544. [Google Scholar] [CrossRef]

- Khazdozian, H.A.; Hadimani, R.L.; Jiles, D.C. Development of rare earth free permanent magnet generator using Halbach cylinder rotor design. Renew. Energy 2017, 112, 84–92. [Google Scholar] [CrossRef]

- Pavel, C.C.; Thiel, C.; Degreif, S.; Blagoeva, D.; Buchert, M.; Schüler, D.; Tzimas, E. Role of substitution in mitigating the supply pressure of rare earths in electric road transport applications. Sustain. Mater. Technol. 2017, 12, 62–72. [Google Scholar] [CrossRef]

- Kumari, A.; Kumar, M.; Pramanik, S.; Kumar, S. Recovery of rare earths from spent NdFeB magnets of wind turbine: Leaching and kinetic aspects. Waste Manag. 2020, 75, 486–498. [Google Scholar] [CrossRef]

- Riba, J.; López-Torres, C.; Romeral, L.; Garcia, A. Rare-earth-free propulsion motors for electric vehicles: A technology review. Renew. Sustain. Energy Rev. 2016, 57, 367–379. [Google Scholar] [CrossRef]

- De Gennaro, M.; Jürgens, J.; Zanon, A.; Gragger, J.; Schlemmer, E.; Fricassè, A.; Marengo, L.; Ponick, B.; Trancho, E.; Kinder, J.; et al. Designing, prototyping and testing of a ferrite permanent magnet assisted synchronous reluctance machine for hybrid and electric vehicles applications Interior Permanent Magnet machine United States of America. Sustain. Energy Technol. Assess. 2019, 31, 86–101. [Google Scholar] [CrossRef]

- Eklund, P.; Eriksson, S. Air Gap Magnetic Flux Density Variations due to Manufacturing Tolerances in a Permanent Magnet Synchronous Generator. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016. [Google Scholar]

- Eklund, P.; Sjökvist, S.; Eriksson, S.; Leijon, M. A Complete Design of a Rare Earth Metal-Free Permanent Magnet Generator. Machines 2014, 2, 120–133. [Google Scholar] [CrossRef]

- Sjökvist, S.; Eklund, P.; Eriksson, S. Determining demagnetisation risk for two PM wind power generators with different PM material and identical stators. IET Electr. Power Appl. 2016, 10, 593–597. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnets: Plugging the gap. Scr. Mater. 2012, 67, 524–529. [Google Scholar] [CrossRef]

- Fang, H.; Ångström, J.; Cedervall, J.; Svedlindh, P.; Gunnarsson, K.; Sahlberg, M. Directly obtained τ -phase MnAl, a high performance magnetic material for permanent magnets. J. Solid State Chem. 2016, 237, 300–306. [Google Scholar] [CrossRef]

- Hornfeck, A.J.; Edgar, R.F. The Output and Optimum Design of Permanent Magnets Subjected to Demagnetizing Forces. Electr. Eng. 1940, 59, 1017–1024. [Google Scholar] [CrossRef]

- Pyrhönen, J.; Jokinen, T.; Hrabovcová, V. Design of Rotating Electrical Machines; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 9780470695166. [Google Scholar]

- Rahman, M.; Slemon, G. Promising applications of neodymium boron Iron magnets in electrical machines. IEEE Trans. Magn. 1985, 21, 1712–1716. [Google Scholar] [CrossRef]

- Eklund, P.; Eriksson, S. The influence of permanent magnet material properties on generator rotor design. Energies 2019, 12, 1314. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent magnet applications. J. Magn. Magn. Mater. 2002, 248, 441–456. [Google Scholar] [CrossRef]

- Skomski, R.; Coey, J.M.D. Magnetic anisotropy—How much is enough for a permanent magnet? Scr. Mater. 2016, 112, 3–8. [Google Scholar] [CrossRef]

- Coey, J.M.D. Hard magnetic materials: A perspective. IEEE Trans. Magn. 2011, 47, 4671–4681. [Google Scholar] [CrossRef]

- Orimoloye, K.; Ryan, D.H.; Pinkerton, F.E.; Medraj, M. Intrinsic magnetic properties of Ce2Fe14B modified by Al, Ni, or Si. Appl. Sci. 2018, 8, 205. [Google Scholar] [CrossRef]

- Smith, K.S.; Huyck, H.L.O. An overview of the abundance, relative mobility, bioavailability, and human toxicity of metals. Rev. Econ. Geol. Environ. Geochem. Miner. Depos. 1999, 6A,B, 29–73. [Google Scholar] [CrossRef]

- Mohapatra, J.; Liu, J.P. Rare-Earth-Free Permanent Magnets: The Past and Future, 1st ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Park, J.H.; Hong, Y.K.; Bae, S.; Lee, J.J.; Jalli, J.; Abo, G.S.; Neveu, N.; Kim, S.G.; Choi, C.J.; Lee, J.G. Saturation magnetization and crystalline anisotropy calculations for MnAl permanent magnet. J. Appl. Phys. 2010, 107, 1–4. [Google Scholar] [CrossRef]

- Kōno, H. Erratum: “On the Ferromagnetic Phase in Manganese-Aluminum System”. J. Phys. Soc. Jpn. 1959, 14, 237. [Google Scholar] [CrossRef]

- Koch, A.J.J.; Hokkeling, P.; v.d. Steeg, M.G.; De Vos, K.J. New material for permanent magnets on a base of MNnd AL. J. Appl. Phys. 1960. [Google Scholar] [CrossRef]

- Crew, D.C.; McCormick, P.G.; Street, R. MnAl and MnAlC permanent magnets produced by mechanical alloying. Scr. Metall. Mater. 1995, 32, 315–318. [Google Scholar] [CrossRef]

- Patel, K.; Zhang, J.; Ren, S. Rare-earth-free high energy product manganese-based magnetic materials. Nanoscale 2018, 10, 11701–11718. [Google Scholar] [CrossRef]

- Pareti, L.; Bolzoni, F.; Leccabue, F.; Ermakov, A.E. Magnetic anisotropy of MnAl and MnAlC permanent magnet materials. J. Appl. Phys. 1986, 59, 3824–3828. [Google Scholar] [CrossRef]

- Fazakas, E.; Varga, L.K.; Mazaleyrat, F. Preparation of nanocrystalline Mn-Al-C magnets by melt spinning and subsequent heat treatments. J. Alloys Compd. 2007, 434–435, 611–613. [Google Scholar] [CrossRef]

- Zeng, Q.; Baker, I.; Cui, J.B.; Yan, Z.C. Structural and magnetic properties of nanostructured Mn-Al-C magnetic materials. J. Magn. Magn. Mater. 2007, 308, 214–226. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Yaqub, R.; Baker, I. Microstructure and magnetic properties of bulk nanocrystalline MnAl. Metals 2014, 4, 20–27. [Google Scholar] [CrossRef]

- McCallum, R.W.; Lewis, L.; Skomski, R.; Kramer, M.J.; Anderson, I.E. Practical aspects of modern and future permanent magnets. Annu. Rev. Mater. Res. 2014, 44, 451–477. [Google Scholar] [CrossRef]

- Sakka, Y.; Nakamura, M.; Hoshimoto, K. Rapid Quenching and Properties of Hard Magnetic Materials in MnAI-X (X = Ti, Cu, Ni, C, B) Systems. Available online: https://link.springer.com/article/10.1007/BF00544507 (accessed on 8 July 2020).

- Kamino, K.; Kawaguchi, T.; Nagakura, M. Magnetic Properties of MnAl System Alloys. IEEE Trans. Magn. 1966, 2, 506–510. [Google Scholar] [CrossRef]

- Mix, T.; Bittner, F.; Müller, K.H.; Schultz, L.; Woodcock, T.G. Alloying with a few atomic percent of Ga makes MnAl thermodynamically stable. Acta Mater. 2017, 128, 160–165. [Google Scholar] [CrossRef]

- Kronmüller, H. Theory of Nucleation Fields in Inhomogeneous Ferromagnets. Phys. Status Solidi 1987, 144, 385–396. [Google Scholar] [CrossRef]

- Edström, A.; Chico, J.; Jakobsson, A.; Bergman, A.; Rusz, J. Electronic structure and magnetic properties of L10 binary alloys. Phys. Rev. B - Condens. Matter Mater. Phys. 2014, 90, 1–5. [Google Scholar] [CrossRef]

- Rial, J.; Palmero, E.M.; Bollero, A. Efficient Nanostructuring of Isotropic Gas-Atomized MnAl Powder by Rapid Milling (30 s). Engineering 2020, 6, 173–177. [Google Scholar] [CrossRef]

- Chikazumi, S. Physics of Ferromagnetism, 2nd ed.; Oxford University Press: New York, NY, USA, 1997; Volume 66, ISBN 0198517769. [Google Scholar]

- Ohtani, T.; Kato, N.; Kojima, S.; Kojima, K.; Sakamoto, Y.; Konno, I.; Tsukahara, M.; Kubo, T. Magnetic properties of Mn-Al-C permanent magnet alloys. IEEE Trans. Magn. 1977, 13, 1328–1330. [Google Scholar] [CrossRef]

- Yanagitani, A.; Okawa, A.; Tanaka, Y. Characteristics of MnAlC Rapidly Solidified Powders. 1994. Available online: https://www.sciencedirect.com/science/article/abs/pii/0921509394908621 (accessed on 7 August 2020).

- Jimenez-Villacorta, F.; Lewis, L.H. Advanced Permanent Magnetic Materials. In Nanomagnetism; 2014; Available online: https://www.onecentralpress.com/wp-content/uploads/2014/12/CHAPTER-7-MG-23-LATEST.pdf (accessed on 6 September 2020).

- Eriksson, S.; Solum, A.; Leijon, M.; Bernhoff, H. Simulations and experiments on a 12 kW direct driven PM synchronous generator for wind power. Renew. Energy 2008, 33, 674–681. [Google Scholar] [CrossRef]

- Eklund, P.; Sjolund, J.; Berg, M.; Leijon, M.; Eriksson, S. Experimental Evaluation of a Rare Earth-Free Permanent Magnet Generator. IEEE Trans. Energy Convers. 2020, 8969, 1. [Google Scholar] [CrossRef]

| Quantity | Symbol [unit] | NdFeB | SmCo | Ferrite | Alnico | Reference |

|---|---|---|---|---|---|---|

| Remanence | Br [T] | 1.08–1.49 | 0.87–1.19 | 0.20–0.46 | 0.55–1.37 | [27] |

| Intrinsic coercivity | Hci [kA/m] | 876–2710 | 1350–2400 | 140–405 | 38–151 | [27] |

| Relative permeability | µr [-] | 1.0–1.1 | 1.0–1.1 | 1.05–1.2 | 1.3–6.2 | [27] |

| Energy product | (BH)max [kJ/m3] | 220–430 | 143–251 | 6.4–41.8 | 10.7–83.6 | [27] |

| Density | D [kg/dm3] | 7.4–7.5 | 8.2–8.5 | 4.9–5.1 | 6.8–7.3 | 1, 2 |

| Electrical resistivity | ρ [nΩm] | 12–16 | 50–60 or 530–900 | 107–1011 | 470–750 | 1, 3, 4, 5 |

| Curie temperature | Tc [°C] | 310 | 720–820 | 450 | 800 | [28] |

| Maximal operation temperature | Tmax [°C] | 150 | 250–350 | 300 | 500 | [28] |

| Ms | Mr | Hc | BHMAX | |||

|---|---|---|---|---|---|---|

| µ0Ms2/4 | µ0Mr2/4 | Exp. | Info | |||

| emu/g | emu/g | Oe | kJ/m3 | kJ/m3 | kJ/m3 | |

| 137 | N.A. | N.A. | 153 | N.A. | N.A | MnAl, calculated by [48] Chosen as CASE 1. |

| 123 | 16.9 | 672 | 124 | 2.3 | 2.0 | Drop synth. MnAlC by [23], Only tauphase considered. 10% weight from nonmagnetic phases removed. |

| 111 | 15.2 | 672 | 101 | 1.9 | 1.6 | Drop synth. MnAlC by [23], highest exp. Ms. Chosen as CASE 2. |

| 123 | 52.0 | 1658 | 124 | 22 | 18.6 | MnAlC 2 h ball-milled and relaxed from [23], 24% weight from nonmagnetic phases removed |

| 75.8* | 42.0 | 3010 | 47 | 14 | 12.3 | MnAlB 90 min ball-milled and relaxed, highest exp. (BH)max |

| 115 | 47.1 | 2757 | 108 | 18.1 | 15.6 | MnAlC, drop synth., 4 h milled and relaxed from [23], 28% weight from nonmagnetic phases removed |

| 83 | 34 | 2757 | 56 | 9.4 | 8.3 | Drop synth, 4 h milling and relaxed from [23] Best result according to first author in [23]. |

| Parameter | Value |

|---|---|

| Stator inner diameter [mm] | 760 |

| Air gap height [mm] | 6.6 |

| Length of the generator [mm] | 224 |

| Number of slots per phase per pole [-] | 5/4 |

| Rotational speed [rpm] | 127 |

| Parameter | MnAl (Case 1) | MnAlC (Case 2) | Y40 Ferrite (Case 3) | N40 NdFeB (Case 4) |

|---|---|---|---|---|

| Rotor type [-] | Spoke type | Spoke type | Spoke type | Surface-mounted |

| Number of poles [-] | 32 | 32 | 32 | 32 |

| PM height [mm] | 16.76 | 20.14 | 38 | 7.3 |

| PM width [mm] | 54.02 | 64.93 | 122.5 | 40 |

| Remanence Br [T] | 0.878 | 0.712 | 0.38 | 1.26 |

| Recoil permeability µrec [-] | 1 | 1 | 1.0772 | 1.05 |

| Density [kg/m3] | 5100 | 5100 | 4900 | 7500 |

| No-load RMS voltage [V] | 219.6 | 219.2 | 220.42 | 219.9 |

| Load RMS voltage [V] | 207.2 | 207.6 | 209.8 | 208.9 |

| Output power [W] | 11 933 | 11 977 | 12 135 | 12 233 |

| Weight of PMs [kg] | 33.1 | 47.8 | 163.5 | 15.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kontos, S.; Ibrayeva, A.; Leijon, J.; Mörée, G.; Frost, A.E.; Schönström, L.; Gunnarsson, K.; Svedlindh, P.; Leijon, M.; Eriksson, S. An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines. Energies 2020, 13, 5549. https://doi.org/10.3390/en13215549

Kontos S, Ibrayeva A, Leijon J, Mörée G, Frost AE, Schönström L, Gunnarsson K, Svedlindh P, Leijon M, Eriksson S. An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines. Energies. 2020; 13(21):5549. https://doi.org/10.3390/en13215549

Chicago/Turabian StyleKontos, Sofia, Anar Ibrayeva, Jennifer Leijon, Gustav Mörée, Anna E. Frost, Linus Schönström, Klas Gunnarsson, Peter Svedlindh, Mats Leijon, and Sandra Eriksson. 2020. "An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines" Energies 13, no. 21: 5549. https://doi.org/10.3390/en13215549

APA StyleKontos, S., Ibrayeva, A., Leijon, J., Mörée, G., Frost, A. E., Schönström, L., Gunnarsson, K., Svedlindh, P., Leijon, M., & Eriksson, S. (2020). An Overview of MnAl Permanent Magnets with a Study on Their Potential in Electrical Machines. Energies, 13(21), 5549. https://doi.org/10.3390/en13215549