Study on Bearing Capacity of Tank Foundation with Alternatively Arranged Vortex-Compression Nodular Piles

Abstract

1. Introduction

2. Experimental Work

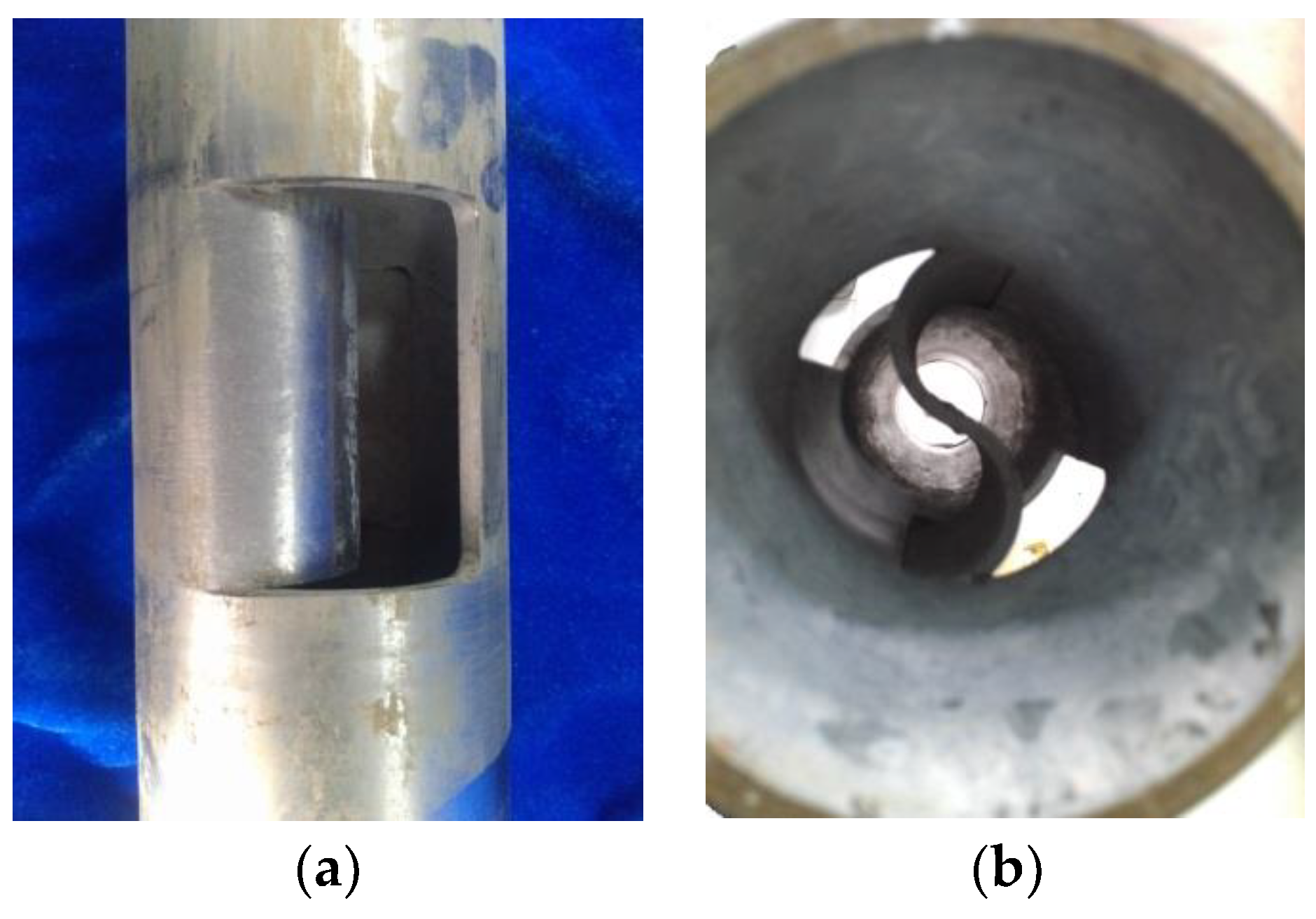

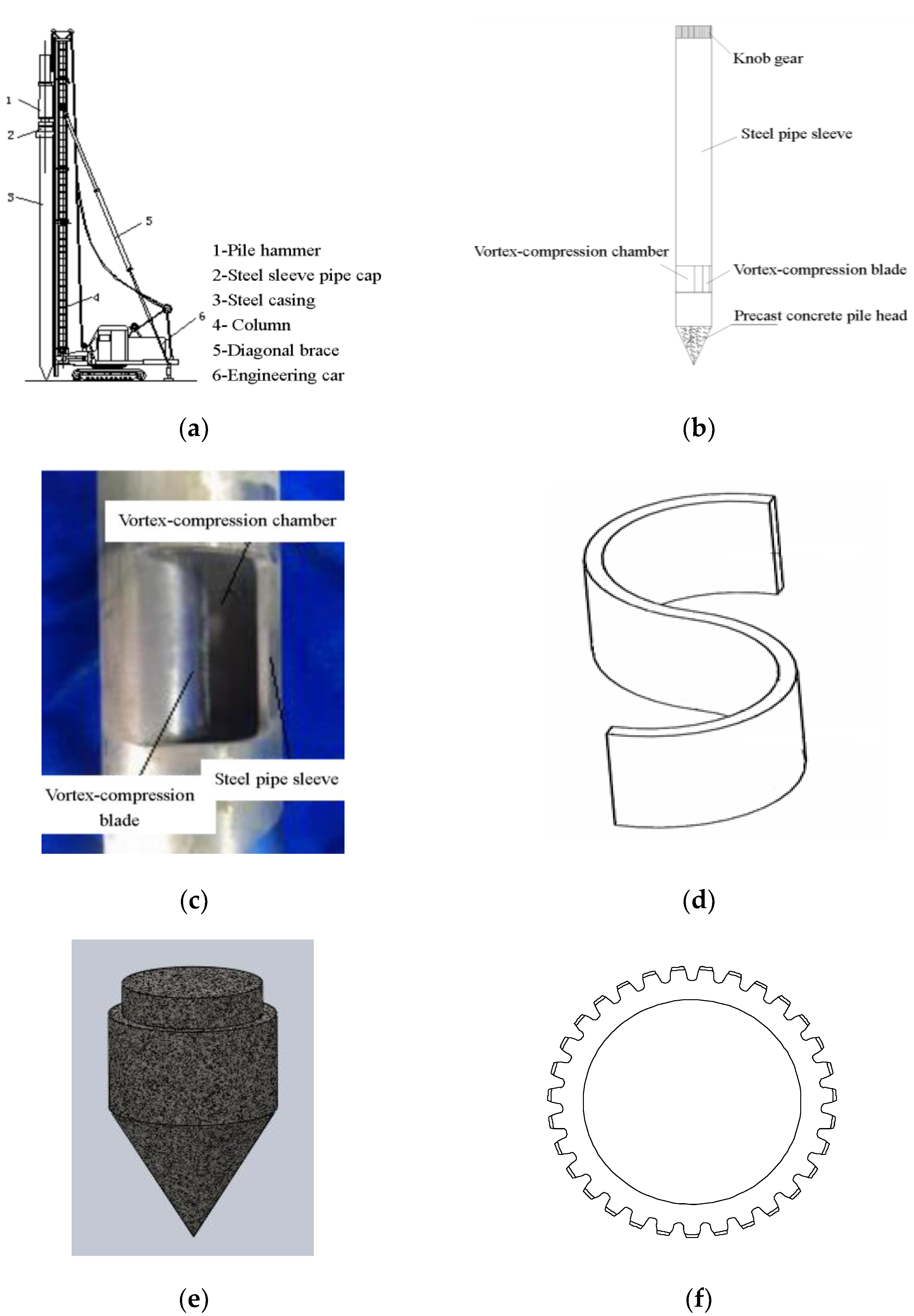

2.1. Technical Information of Pile Forming

2.1.1. Pile Forming Mechanism

2.1.2. Pile-Forming Process

- Step 1:

- Determine the position using the concrete precast pile head and make the pile steel pipe in place.

- Step 2:

- Drive the steel casing to the designated depth by using the pile frame equipment, and remove the hammering equipment.

- Step 3:

- Inject pre-calculated volume of concrete into the steel pipe through the pipeline.

- Step 4:

- Install the rotary torsion equipment and rotate the steel pipe to form the first nodular part.

- Step 5:

- Slowly rotate the steel pipe in the same direction and lift it to the next depth where the nodular is designed.

- Step 6:

- Continue to rotate the steel pipe to form the next nodular part by using the rotating and twisting equipment.

- Step 7:

- Inject the concrete until it returns to the pile top elevation, rotate and retrieve the steel pipe, and finally place the reinforcement cage.

2.2. Experimental Work Set Up

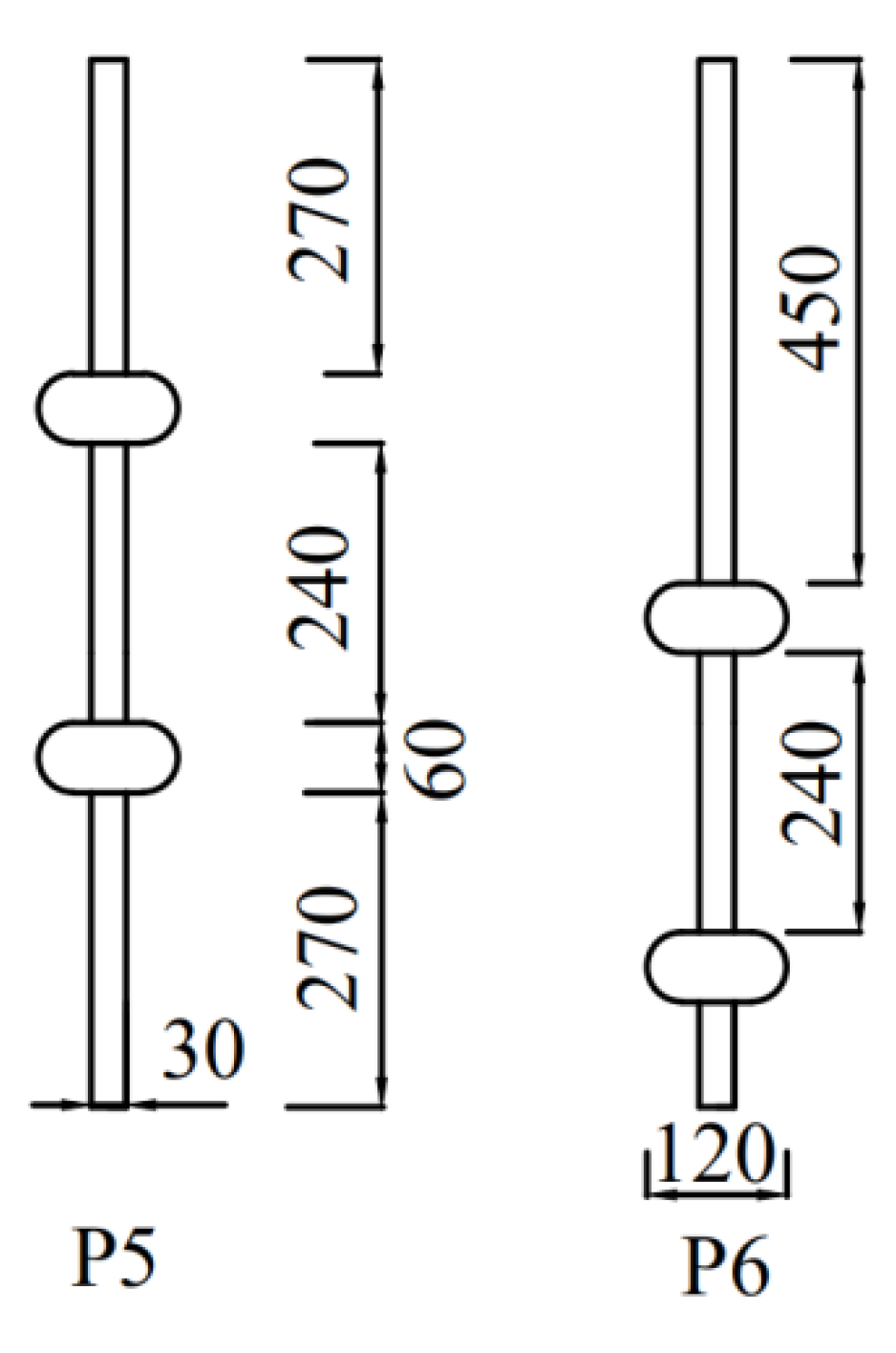

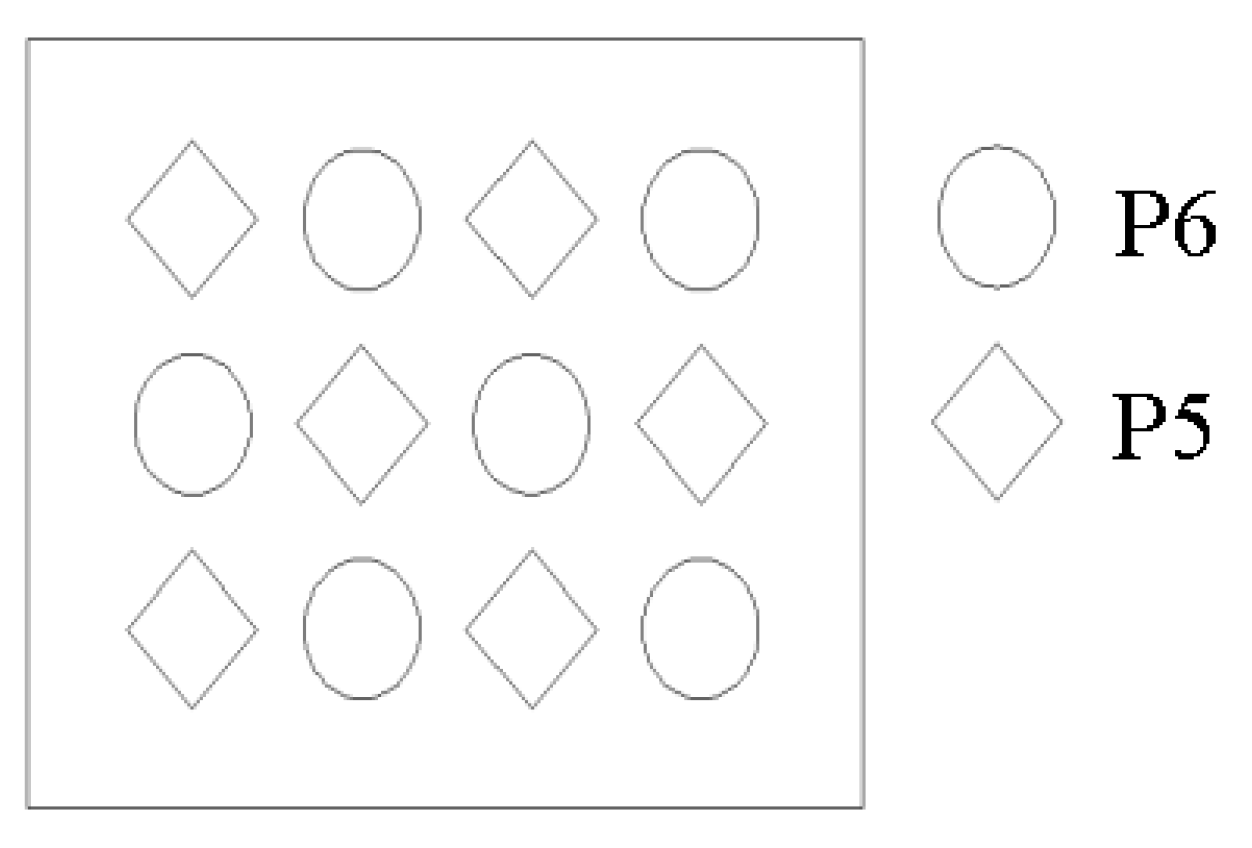

2.3. Equal-Section Pile and Nodular Pile

2.4. Sand

2.5. Test Procedure

3. Results and Discussions

3.1. Load Displacement Curve

3.2. Axial Force Analysis of Monopile

4. Simulations

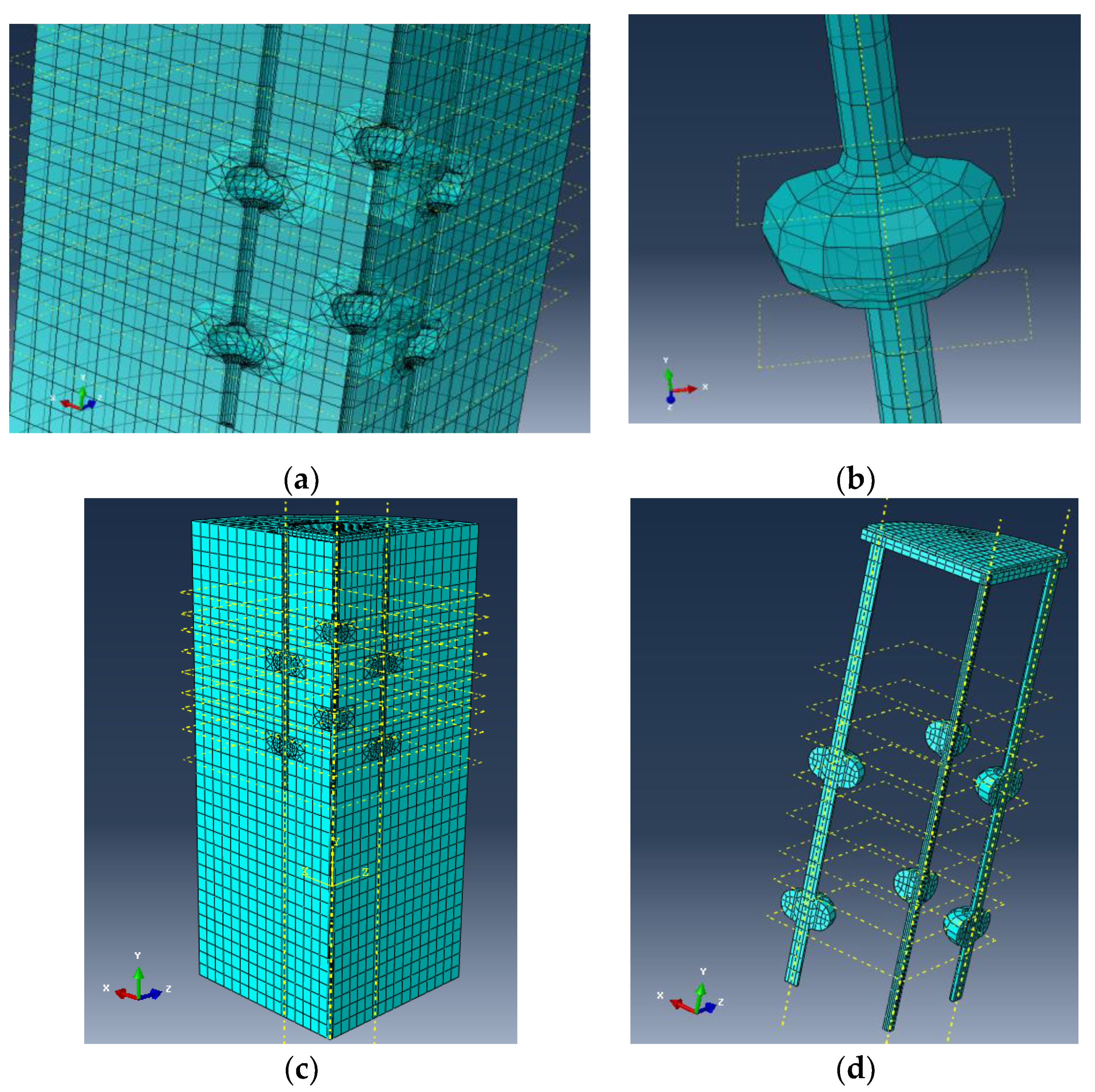

4.1. Finite Element Model Description

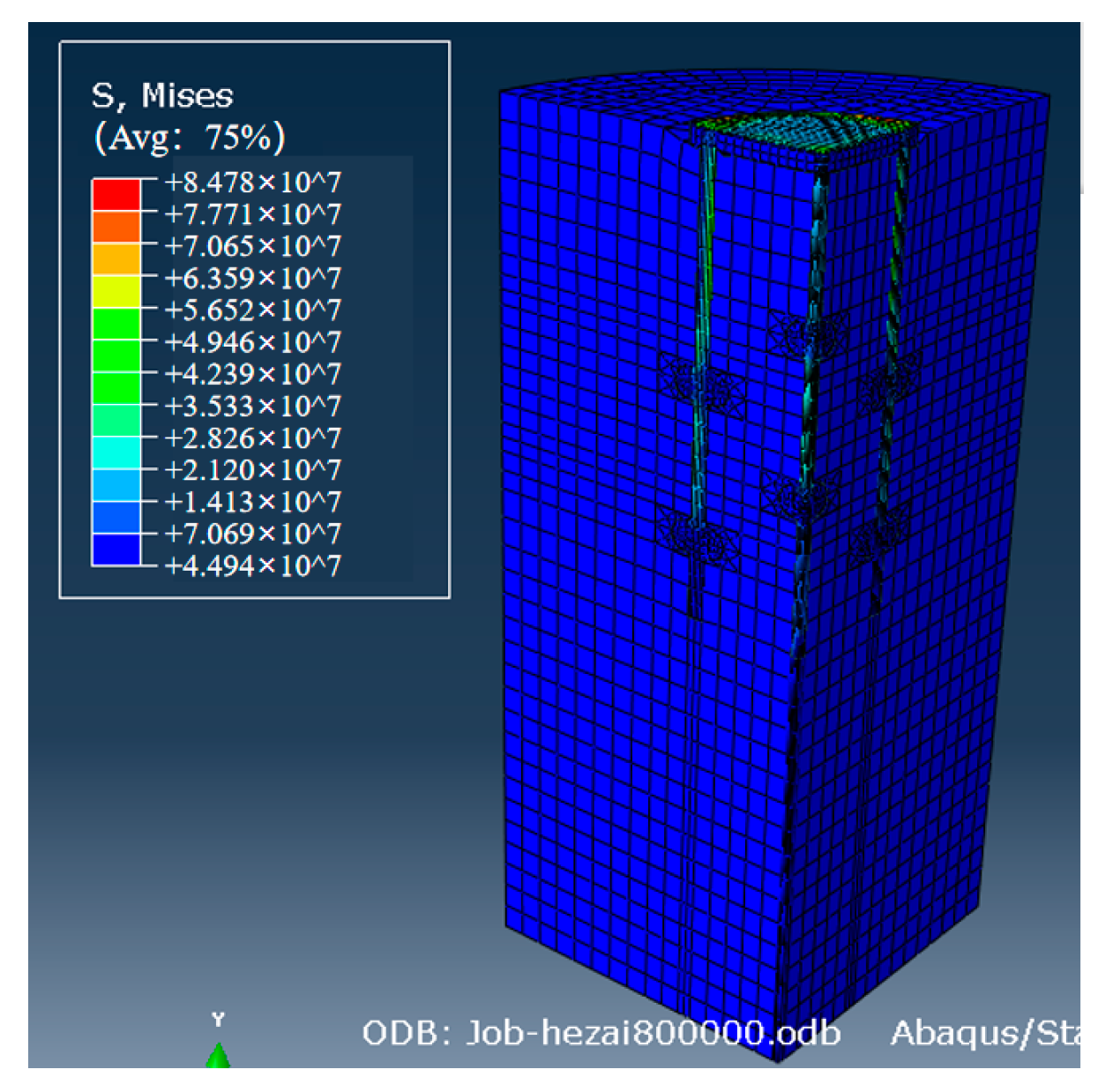

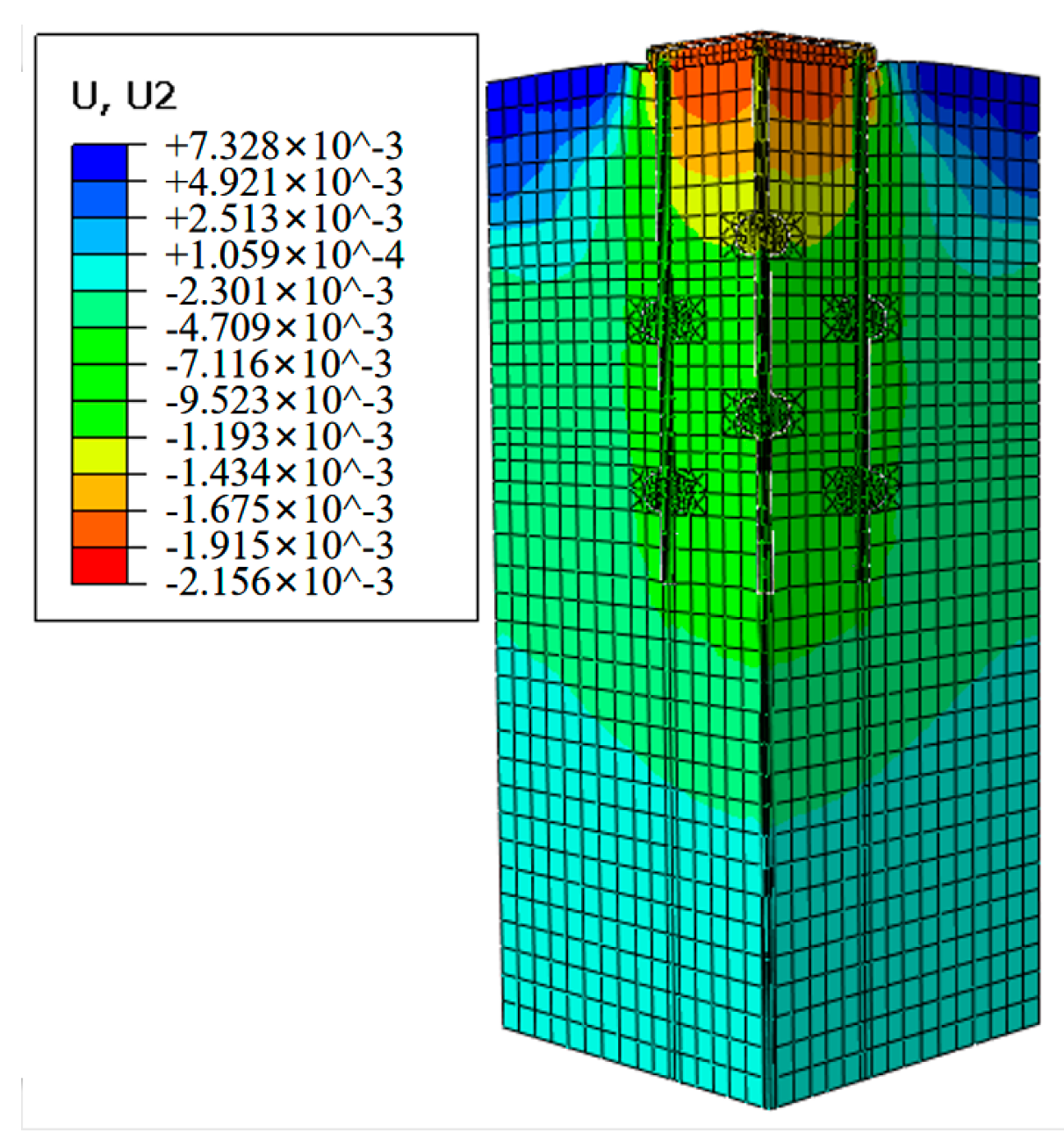

4.2. Comparison of Bearing Capacity of Equal-Section Pile Foundation and Vortex-Compression Nodular Pile Foundation

4.3. Simulation Analysis of Influencing Factors on Bearing Characteristics of Vortex-Compression Nodular Pile Foundation

4.3.1. Analysis of Influence of Load on Bearing Characteristics

4.3.2. Analysis of influence of Cushion Thickness on Bearing Capacity

4.3.3. Influence Analysis of Cushion Modulus on Bearing Capacity

4.3.4. Influence Analysis of Modulus of Soil Around Pile on Bearing Characteristics

4.3.5. Influence Analysis of Pile Modulus on Bearing Characteristics

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fang, P.F.; Xie, X.Y.; Qi, J.L. Engineering character of a new-style pretensioned spun goncrete nodular Pile. Geo Shanghai 2014. [Google Scholar] [CrossRef]

- Pavan, K.T.; Papa, R.G.; Veerabhadra, R.P. Comparative study of different foundation and sidewall systems for large storage tanks. In Recent Advances in Structural Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 1, pp. 193–205. [Google Scholar]

- Chen, L.H.; Liu, X.L. Reasonable selection of tank foundation consolidation method. Petrol. Plan. Des. 2005, 16, 44–45. [Google Scholar]

- Zhang, J.W. Discussion on several problems on poor foundation consolidation of large storage tank (To be continued). Petrol. Eng. Constr. 2002, 28, 6–10. [Google Scholar]

- Zhang, S.; Zhao, M.; He, L.; Zhang, L. Calculation of settlement of composite foundation with rigid piles under flexible ground. J. Highway Transp. Res. Dev. 2013, 5, 15–21. [Google Scholar] [CrossRef]

- Lin, P. Foundation consolidation of large oil tank by gravel pile. Guangdong Chem. 2013, 40, 134–141. [Google Scholar]

- Jia, J.H. Study on Working Behavior of Gravel Pile Composite Foundation of Large Storage Tank; Hebei Agricultural University: Baoding, China, 2009. [Google Scholar]

- Dong, H.B. Experimental Study on CFG Pile Composite Foundation in Foundation Consolidation of Large Storage Tank; China University of Petroleum: Qingdao, China, 2007. [Google Scholar]

- Song, X.G. Study on Bearing Behavior of CFG Pile Composite Foundation in Saturated Loess Foundation Consolidation of Large Oil Tank; Lanzhou Jiaotong University: Lanzhou, China, 2008. [Google Scholar]

- Li, P. Finite Element Numerical Analysis of Deformation Behavior of Gravel Pile Composite Foundation for Large Oil Storage Tank; Ocean University of China: Qingdao, China, 2010. [Google Scholar]

- Liu, H.J.; Shi, X.R.; Wang, X.H. Finite element numerical analysis on differential settlement of composite foundation of storage tank group. Qingdao J. Ocean Univ. China (Soc. Sci.) 2016, 46, 117–123. [Google Scholar]

- Li, C.B.; Xue, S.F.; Liu, X.H. Pile Forming Equipment and Method for Vortex Compression Nodular Piles. China: ZL2014101136668, 2014-12-10. CN103835289A. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=SCPD&dbname=SCPD2014&filename=CN103835289A&v=Rim3ylsWTszpRhbAHJM8PCMN4h9FqLKSUo9oW%25mmd2FVzLe51UlegvfT5uKGWJfZf8CJl (accessed on 10 October 2020).

- Li, C.B.; Xue, S.F.; Yu, R.G.; Zhang, Y.M.; Sun, X.; Liu, X.H.; Zhao, Z.J. Laboratory experimental study on the application of vortex compression equipment in foundation consolidation. J. Chongqing Jianzhu Univ. 2014, 36, 78–81. [Google Scholar]

- Li, C.B.; Xue, S.F.; Yu, R.G.; Zhang, Y.M.; Zhang, M.; Liu, X.H.; Zhao, Z.J. Mechanism of vortex squeezing expansion and its application in geotechnical engineering. Forest Eng. 2014, 30, 137–140, 146. [Google Scholar] [CrossRef]

- Nazir, A. Model study of single pile with wings under uplift loads. Appl. Ocean Res. 2020, 100, 1–17. [Google Scholar]

- Chen, Y.D.; Deng, A.; Wang, A.T.; Sun, H.S. Performance of screw—Shaft pile in sand: Model test and DEM simulation. Comput. Geotech. 2018, 104, 118–130. [Google Scholar] [CrossRef]

- Sakr, M. Relationship between Installation Torque and Axial Capacities of Helical Piles in Cohesionless Soils. DFI J. Deep Found. Inst. 2015, 7, 44–58. [Google Scholar] [CrossRef]

- Houda, M.; Jenck, O.; Emeriault, F. Physical evidence of the effect of vertical cyclic loading on soil improvement by rigid piles: A small-scale laboratory experiment using Digital Image Correlation. Acta Geotech. 2016, 11, 325–346. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, J.J.; Wang, J.H. Numerical analysis of bearing capacity of drilled displacement piles with a screw-shaped shaft in sand. Marine Geotechnol. 2016, 661–669. [Google Scholar] [CrossRef]

- Ye, X.; Wang, S.; Wang, Q.; Sloan, S.W.; Sheng, D.C. Numerical and experimental studies of the mechanical behaviour for compaction grouted soil nails in sandy soil. Comput. Geotech. 2017, 90, 202–214. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, S.; Liu, S. Discrete Element Simulations of Shallow Plate-Load Tests. Int. J. Geomech. 2016, 16, 04015077.1–04015077.12. [Google Scholar] [CrossRef]

- Nabizadeh, F.; Choobbasti, A.J. Field Study of Capacity Helical Piles in Sand and Silty Clay. Transp. Infrastruct. Geotechnol. 2016, 4, 1–15. [Google Scholar] [CrossRef]

- Shoda, D.; Kawabata, T.; Uchida, K. Mechanical Behavior on Pile with Multi-Stepped Two Diameters under Combined Load; Transactions of The Japanese Society of Irrigation, Drainage and Rural Engineering: Tokyo, Japan; Minato-ku, Japan, 2011; Volume 78, pp. 157–165. [Google Scholar]

- Mendoza, C.C.; Cunha, R.; Lizcano, A. Mechanical and numerical behavior of groups of screw (type) piles founded in a tropical soil of the Midwestern Brazil. Comput. Geotech. 2015, 67, 187–203. [Google Scholar] [CrossRef]

- Aoyama, S.; Mao, W.; Goto, S.; Towhata, I. Application of Advanced Procedures to Model Tests on the Subsoil Behavior Under Vertical Loading of Group Pile in Sand. Ind. Geotech. J. 2015, 46, 1–13. [Google Scholar] [CrossRef]

- Khazaei, J.; Eslami, A. Postgrouted helical piles behavior through physical modeling by FCV. Marine Geotechnol. 2016, 35, 528–537. [Google Scholar] [CrossRef]

- Rahman, M.A.; Sengupta, S. Uplift Capacity of Inclined Underreamed Piles Subjected to Vertical Load. J. Inst. Eng. 2017, 98, 533–544. [Google Scholar] [CrossRef]

- Long, J.; Zhao, M.; Zhang, L.; Zhang, G.B. Pile-soil Stress Ratio of Pile-supported and Geogird-reinforced Composite Foundation. J. Highway Transp. Res. Dev. 2010, 6, 18–23. [Google Scholar] [CrossRef]

- Liu, K.; Xie, X.; Shi, S.; Zhu, X. Numerical Analysis on the Performance of a Cushioned Foundation with a Mixture of Both Rigid and Flexible Piles. In Proceedings of the US-China Workshop on Ground Improvement Technologies, Orlando, FL, USA, 14 March 2009. [Google Scholar]

- Ferrantelli, A.; Fadejev, J.; Kurnitski, J. Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions. Energies 2019, 12, 770. [Google Scholar] [CrossRef]

- Gao, L.; Han, C.; Xu, Z.; Jin, Y.; Yan, J. Experimental Study on Deformation Monitoring of Bored Pile Based on BOTDR. Appl. Sci. 2019, 9, 2435. [Google Scholar] [CrossRef]

- Prendergast, L.J.; Gandina, P.; Gavin, K. Factors Influencing the Prediction of Pile Driveability Using CPT-Based Approaches. Energies 2020, 13, 3128. [Google Scholar] [CrossRef]

- Baca, M.; Brząkała, W.; Rybak, J. Bi-Directional Static Load Tests of Pile Models. Appl. Sci. 2020, 10, 5492. [Google Scholar] [CrossRef]

| Number | Effective Pile Length (mm) | Pile Diameter (mm) | Diameter of Nodular Part (mm) | Number of Nodular Part | Bottom Elevation of Nodular Part (mm) | Distance Between Nodular Parts (mm) |

|---|---|---|---|---|---|---|

| P1 | 900 | 30 | - | - | - | - |

| P2 | 900 | 30 | 120 | 1 | −810 | - |

| P3 | 900 | 30 | 120 | 1 | −570 | - |

| P4 | 900 | 30 | 120 | 1 | −330 | - |

| P5 | 900 | 30 | 120 | 2 | −330, −630 | 240 |

| P6 | 900 | 30 | 120 | 2 | −510, −810 | 240 |

| P7 | 900 | 30 | 120 | 2 | −390, −810 | 360 |

| Number | Point 1 Depth (mm), Corresponding Axial Force (kN) | Point 2 | Point 3 | Point 4 | Point 5 | Point 6 | Point 7 |

|---|---|---|---|---|---|---|---|

| P1 | 0, 5.4 | −200, 5.3 | −360, 5.3 | −600, 5.3 | −760, 5.3 | −820, 5.3 | −900, 2.7 |

| P2 | 0, 15.0 | −100, 14.9 | −420, 14.9 | −650, 14.7 | −790, 14.2 | −900, 2.8 | −950, 2.7 |

| P3 | 0, 14.4 | −100, 14.3 | −560, 14.3 | −680, 4.9 | −830, 3.0 | −890, 2.6 | −970, 1.6 |

| P4 | 0, 12.8 | −100, 12.8 | −290, 12.8 | −530, 3.6 | −700, 2.9 | −880, 2.7 | −980, 1.7 |

| P5 | 0, 22.7 | −280, 22.6 | −340, 18.7 | −520, 17.6 | −620, 17.2 | −740, 4.2 | −980, 1.6 |

| P6 | 0, 22.7 | −270, 22.7 | −470, 22.7 | −590, 16.7 | −790, 15.6 | −910, 2.8 | −980, 2.2 |

| P7 | 0, 29.1 | −370, 29.2 | −470, 24.1 | −630, 22.9 | −790, 20.0 | −910, 3.4 | −980, 2.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.-B.; Li, G.-J.; Yu, R.-G.; Li, J.; Ma, X.-S. Study on Bearing Capacity of Tank Foundation with Alternatively Arranged Vortex-Compression Nodular Piles. Energies 2020, 13, 5273. https://doi.org/10.3390/en13205273

Li C-B, Li G-J, Yu R-G, Li J, Ma X-S. Study on Bearing Capacity of Tank Foundation with Alternatively Arranged Vortex-Compression Nodular Piles. Energies. 2020; 13(20):5273. https://doi.org/10.3390/en13205273

Chicago/Turabian StyleLi, Chun-Bao, Gao-Jie Li, Ran-Gang Yu, Jing Li, and Xiao-Song Ma. 2020. "Study on Bearing Capacity of Tank Foundation with Alternatively Arranged Vortex-Compression Nodular Piles" Energies 13, no. 20: 5273. https://doi.org/10.3390/en13205273

APA StyleLi, C.-B., Li, G.-J., Yu, R.-G., Li, J., & Ma, X.-S. (2020). Study on Bearing Capacity of Tank Foundation with Alternatively Arranged Vortex-Compression Nodular Piles. Energies, 13(20), 5273. https://doi.org/10.3390/en13205273