Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products

Abstract

1. Introduction

2. Methodology

2.1. Process Modeling

2.2. Techno-Economic Assumptions

2.3. Sensitivity Analysis

2.4. Economies of Scale

3. Results

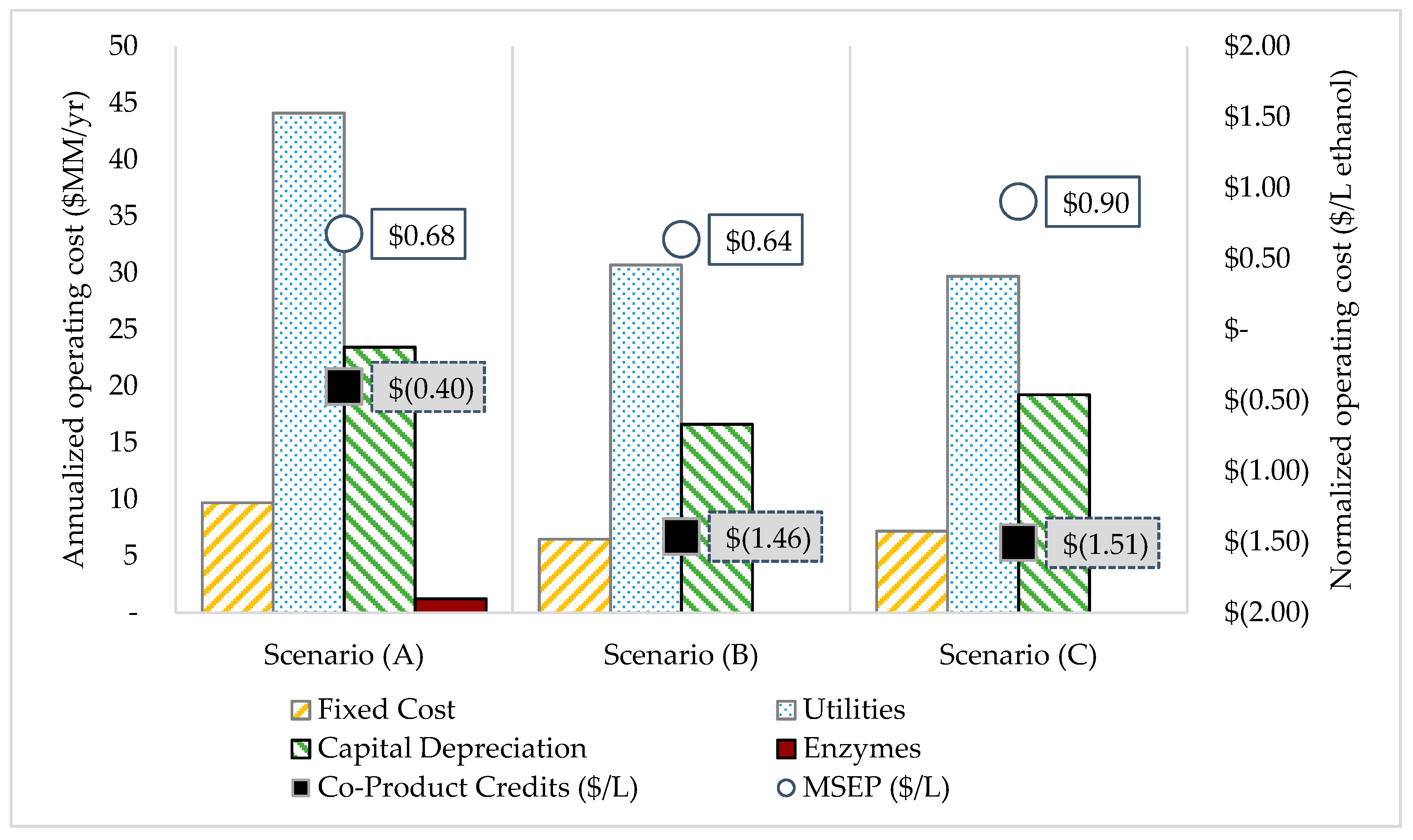

3.1. Economic Analysis

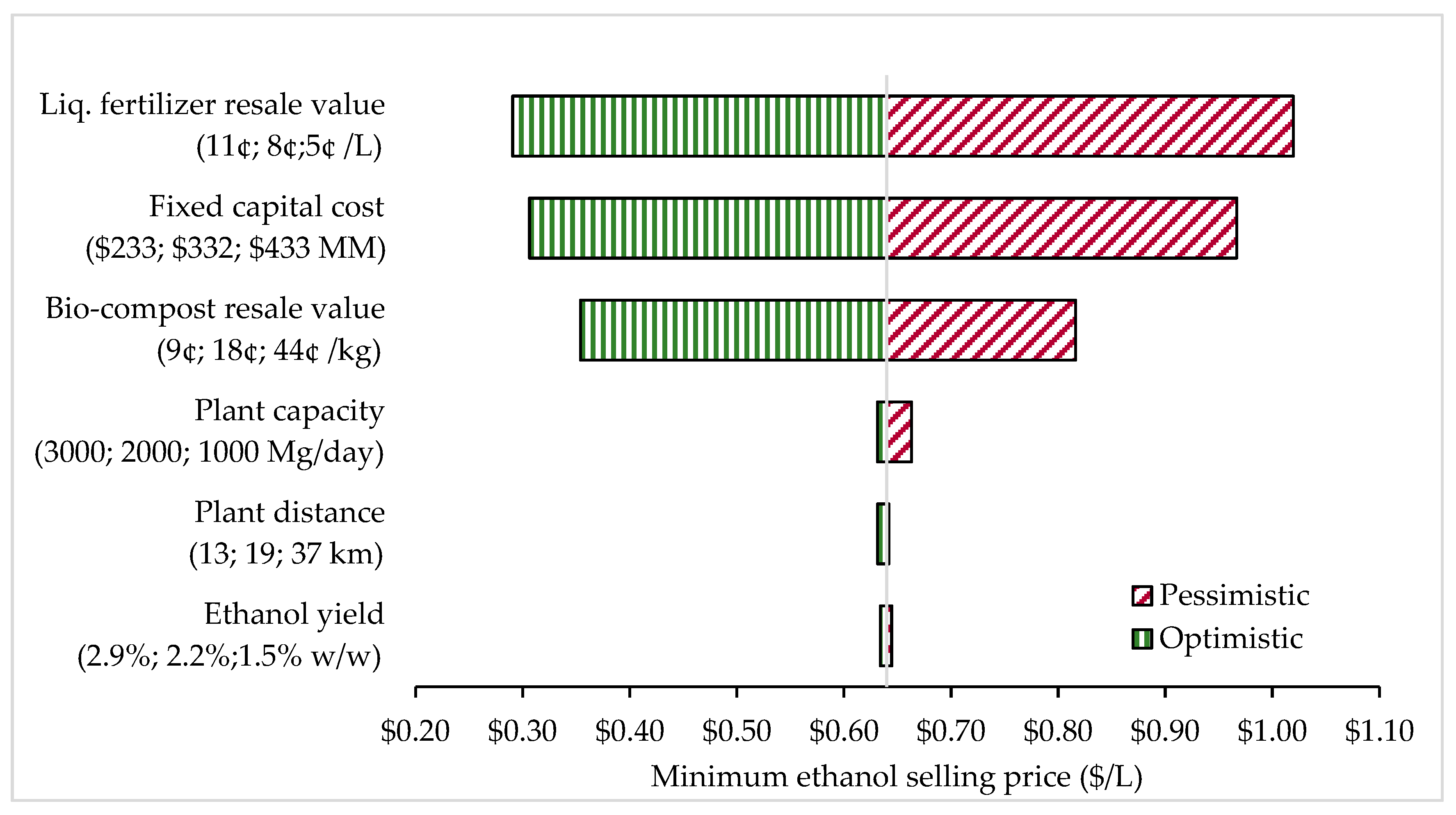

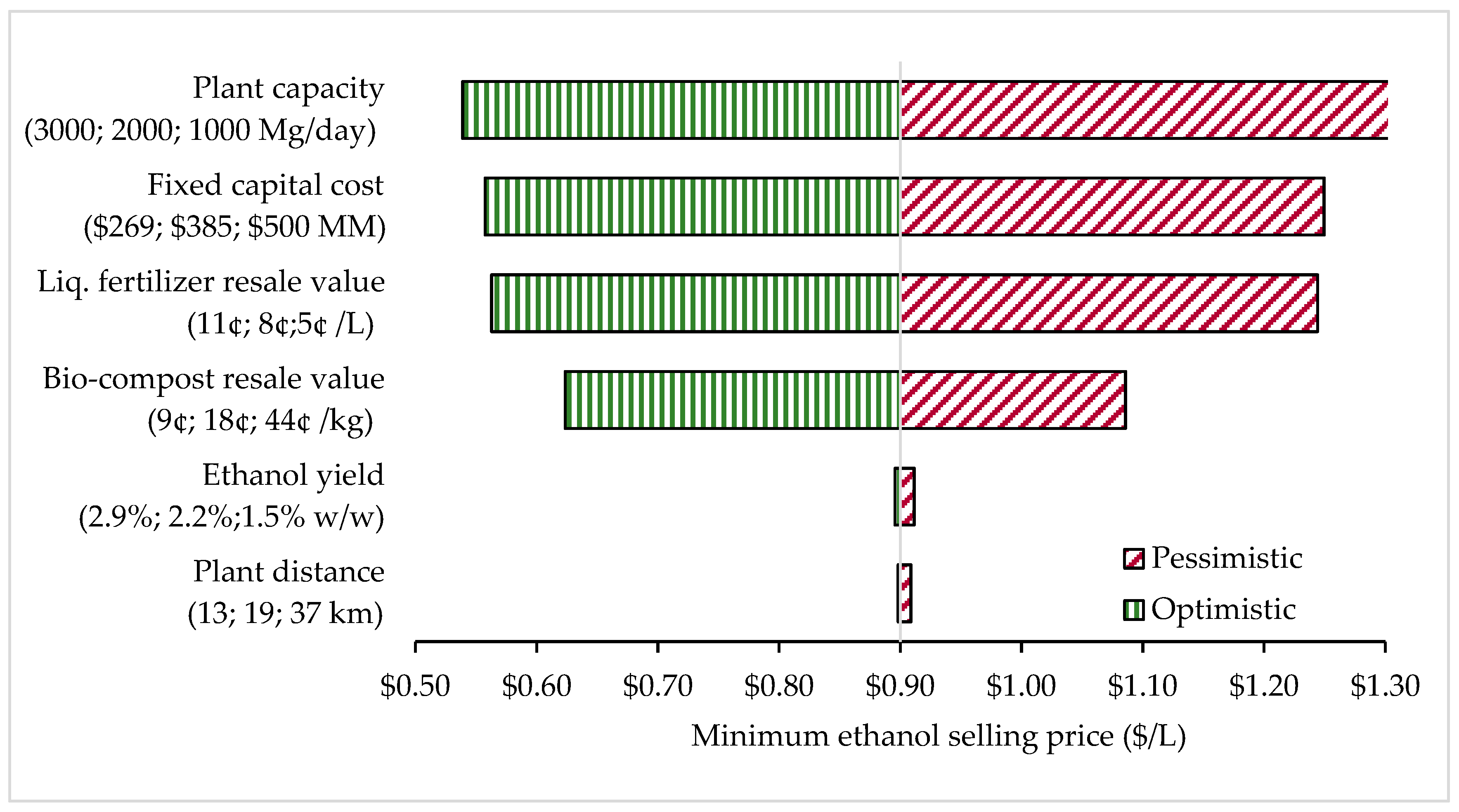

3.2. Sensitivity Analysis

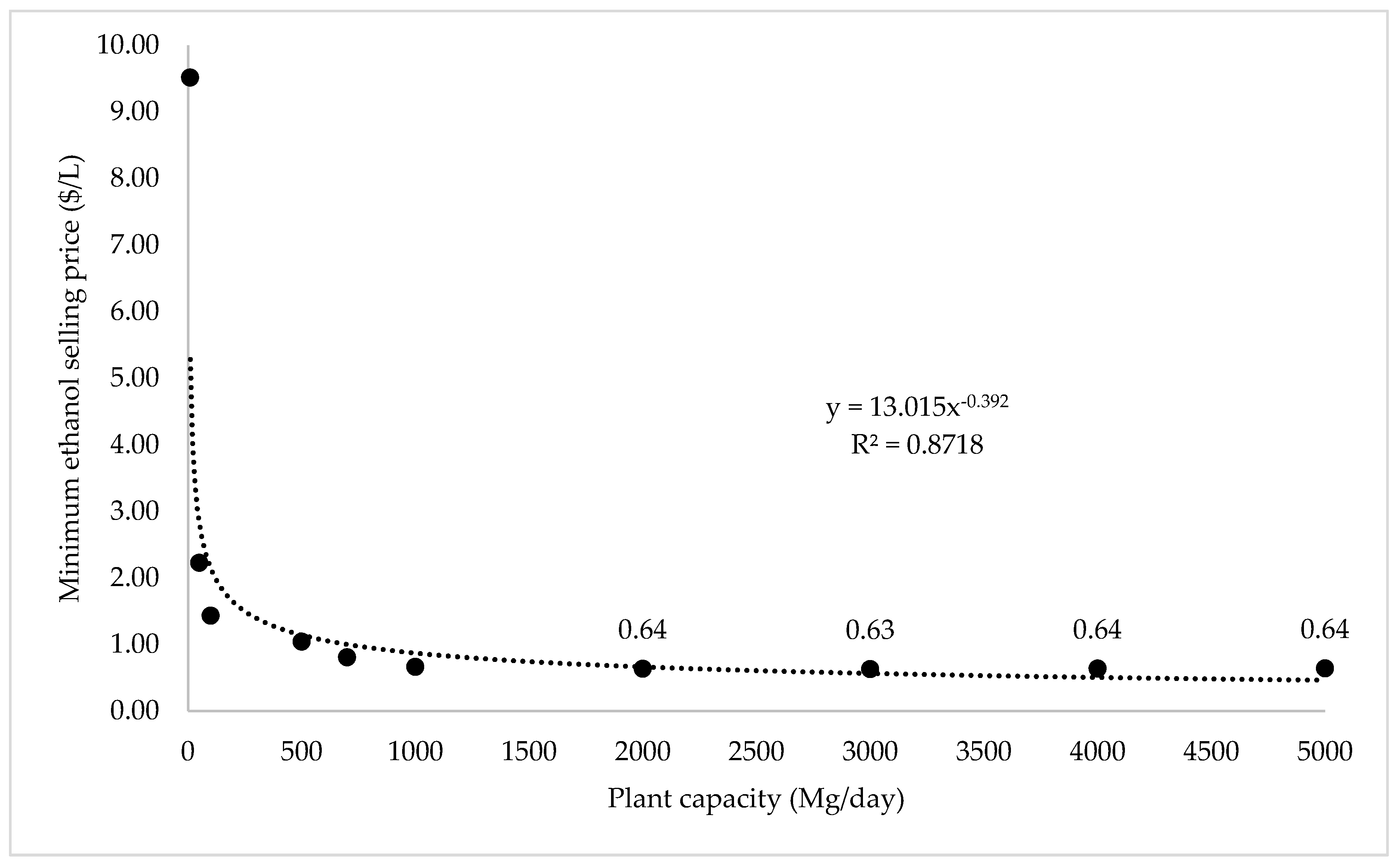

3.3. Economies of Scale

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EPA. Overview for Renewable Fuel Standard; The United States Environmental Protection Agency: Washington, DC, USA, 2017.

- Bracmort, K. The Renewable Fuel Standard (RFS): Waiver Authority and Modification of Volumes; Congressional Research Service: Washington, DC, USA, 2018.

- Meyer, S.; Schmidhuber, J.; Barreiro-Hurlé, J. Cross-trade in Biofuels: How Uncoordinated Environmental Legislation Fuels Resource Use and GHG Emissions. EuroChoices 2013, 12, 45–52. [Google Scholar] [CrossRef]

- Uçkun Kıran, E.; Trzcinski, A.P.; Liu, Y. Platform chemical production from food wastes using a biorefinery concept. J. Chem. Technol. Biotechnol. 2015, 90, 1364–1379. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef]

- Thi, N.B.D.; Kumar, G.; Lin, C.-Y. An overview of food waste management in developing countries: Current status and future perspective. J. Environ. Manag. 2015, 157, 220–229. [Google Scholar] [CrossRef]

- EPA. Advancing Sustainable Materials Management: 2015 Fact Sheet Assessing Trends in Material Generation, Recycling, Composting, Combustion with Energy Recovery and Landfilling in the United States; United States Environmental Protection Agency: Washington, DC, USA, 2018. Available online: https://www.epa.gov/sites/production/files/2018-07/documents/2015_smm_msw_factsheet_07242018_fnl_508_002.pdf (accessed on 1 November 2018).

- EPA. Overview of Greenhouse Gases; United States Environmental Protection Agency: Washington, DC, USA, 2018.

- Ermolaev, E.; Jarvis, Å.; Sundberg, C.; Smårs, S.; Pell, M.; Jönsson, H. Nitrous oxide and methane emissions from food waste composting at different temperatures. Waste Manag. 2015, 46, 113–119. [Google Scholar] [CrossRef]

- Lopez, V.M.; de la Cruz, F.B.; Barlaz, M.A. Chemical composition and methane potential of commercial food wastes. Waste Manag. 2016, 56, 477–490. [Google Scholar] [CrossRef]

- Woon, K.S.; Lo, I.M.C.; Chiu, S.L.H.; Yan, D.Y.S. Environmental assessment of food waste valorization in producing biogas for various types of energy use based on LCA approach. Waste Manag. 2016, 50, 290–299. [Google Scholar] [CrossRef]

- Noor, Z.Z.; Yusuf, R.O.; Abba, A.H.; Abu Hassan, M.A.; Mohd Din, M.F. An overview for energy recovery from municipal solid wastes (MSW) in Malaysia scenario. Renew. Sustain. Energy Rev. 2013, 20, 378–384. [Google Scholar] [CrossRef]

- De Lange, W.; Nahman, A. Costs of food waste in South Africa: Incorporating inedible food waste. Waste Manag. 2015, 40, 167–172. [Google Scholar] [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Levis, J.W.; Barlaz, M.A.; Themelis, N.J.; Ulloa, P. Assessment of the state of food waste treatment in the United States and Canada. Waste Manag. 2010, 30, 1486–1494. [Google Scholar] [CrossRef] [PubMed]

- Manaf, L.A.; Samah, M.A.A.; Zukki, N.I.M. Municipal solid waste management in Malaysia: Practices and challenges. Waste Manag. 2009, 29, 2902–2906. [Google Scholar] [CrossRef]

- Hafid, H.S.; Rahman, N.A.; Md Shah, U.K.; Baharudin, A.S. Enhanced fermentable sugar production from kitchen waste using various pretreatments. J. Environ. Manag. 2015, 156, 290–298. [Google Scholar] [CrossRef] [PubMed]

- Vavouraki, A.I.; Angelis, E.M.; Kornaros, M. Optimization of thermo-chemical hydrolysis of kitchen wastes. Waste Manag. 2013, 33, 740–745. [Google Scholar] [CrossRef] [PubMed]

- Cekmecelioglu, D.; Uncu, O.N. Kinetic modeling of enzymatic hydrolysis of pretreated kitchen wastes for enhancing bioethanol production. Waste Manag. 2013, 33, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Richard, T. Dual Enzymatic Saccharification of Food Waste for Ethanol Fermentation. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, IEEE, Yichang, China, 16–18 September 2011; pp. 4472–4474. [Google Scholar]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Mohd Azhar, S.H.; Abdulla, R.; Jambo, S.A.; Marbawi, H.; Gansau, J.A.; Mohd Faik, A.A.; Rodrigues, K.F. Yeasts in sustainable bioethanol production: A review. Biochem. Biophys. Rep. 2017, 10, 52–61. [Google Scholar] [CrossRef]

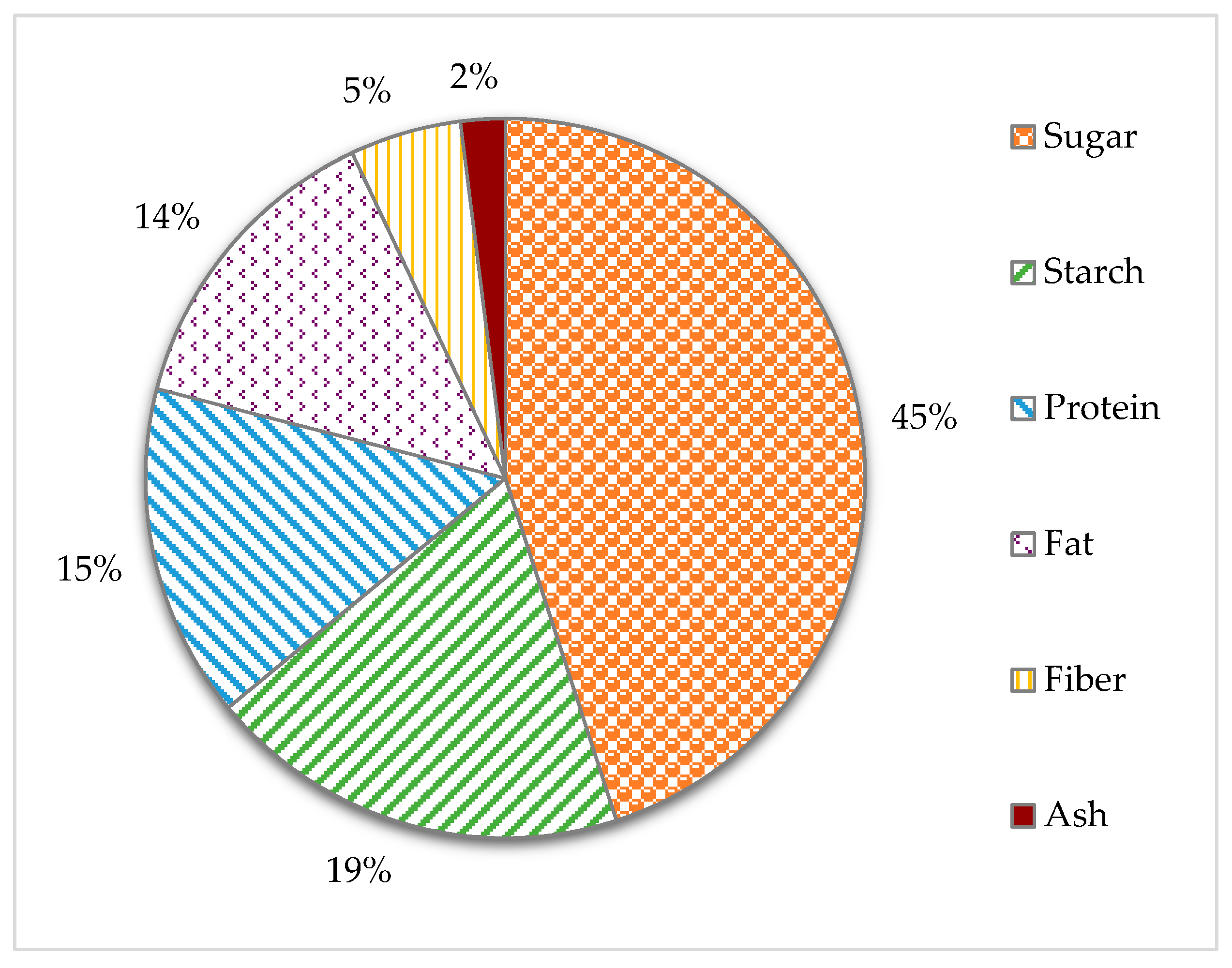

- Hafid, H.S.; Nor ’Aini, A.R.; Mokhtar, M.N.; Talib, A.T.; Baharuddin, A.S.; Umi Kalsom, M.S. Over production of fermentable sugar for bioethanol production from carbohydrate-rich Malaysian food waste via sequential acid-enzymatic hydrolysis pretreatment. Waste Manag. 2017, 67, 95–105. [Google Scholar] [CrossRef]

- Uncu, O.N.; Cekmecelioglu, D. Cost-effective approach to ethanol production and optimization by response surface methodology. Waste Manag. 2011, 31, 636–643. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, Z.; Zhang, R. Overview of biomass pretreatment for cellulosic ethanol production. Int. J. Agric. Biol. Eng. 2009, 2, 51–68. [Google Scholar]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current status and future directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, N.I.S. Comparative Assessment of the Economic and Environmental Impacts of Food Waste Fermentation on Value-Added Products. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2019. [Google Scholar]

- Suwannarat, J.; Ritchie, R.J. Anaerobic digestion of food waste using yeast. Waste Manag. 2015, 42, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Karmee, S.K. Liquid biofuels from food waste: Current trends, prospect and limitation. Renew. Sustain. Energy Rev. 2016, 53, 945–953. [Google Scholar] [CrossRef]

- Bertran, E.; Sort, X.; Soliva, M.; Trillas, I. Composting winery waste: Sludges and grape stalks. Bioresour Technol 2004, 95, 203–208. [Google Scholar] [CrossRef] [PubMed]

- Cornel Waste Management Institute. Monitoring Compost Moisture—Cornell Composting; Cornell University: Ithaca, NY, USA, 1996. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E.; Ronald, E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: Boston, MA, USA, 2003. [Google Scholar]

- Poliafico, M.; Murphy, J. Anaerobic Digestion in Ireland: Decision Support System. Epartment of Civil, Structural and Environmental Engineering; Cork Institute of Technology: Cork, Ireland, 2007. [Google Scholar]

- Brown, R.C.; Brown, T.R. Biorenewable Resources: Engineering New Products from Agriculture, 2nd ed.; John Wiley & Sons, Inc.: Ames, IA, USA, 2014; pp. 287–326. [Google Scholar]

- Short, W.; Packey, D.J.; Holt, T. A Manual for the Economic Evaluation of Energy Efficiency and Renewable Energy Technologies; National Renewable Energy Lab.: Golden, CO, USA, 1995.

- Aden, A.; Foust, T. Technoeconomic analysis of the dilute sulfuric acid and enzymatic hydrolysis process for the conversion of corn stover to ethanol. Cellulose 2009, 16, 535–545. [Google Scholar] [CrossRef]

- Wright, M.M.; Daugaard, D.E.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 2010, 89, S2–S10. [Google Scholar] [CrossRef]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M.; et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Lab.: Golden, CO, USA, 2011. [CrossRef]

- Tao, L.; Schell, D.; Davis, R.; Tan, E.; Elander, R.; Bratis, A. NREL 2012 Achievement of Ethanol Cost Targets: Biochemical Ethanol Fermentation via Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Lab.: Golden, CO, USA, 2014. [CrossRef]

- Hofstrand, D. Ethanol profitability. Iowa State University Extension and Outreach. 2019. Available online: https://www.extension.iastate.edu/agdm/refirst.html (accessed on 1 November 2018).

- National Compost Prices. National Compost Prices 2006. Available online: http://www.recycle.cc/compostprices.pdf (accessed on 29 October 2018).

- Klein-Marcuschamer, D.; Oleskowicz-Popiel, P.; Simmons, B.A.; Blanch, H.W. The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol. Bioeng. 2012, 109, 1083–1087. [Google Scholar] [CrossRef]

- Wimer, J.G.; Summers, W.M. Quality Guidelines for Energy System Studies: Cost Estimation Methodology for NETL Assessments of Power Plant Performance; NETL: Pittsburgh, PA, USA, 2011.

- EIA. Iowa State Energy Profile. US Energy Inf Adm 2017. Available online: https://www.eia.gov/state/print.php?sid=IA (accessed on 1 November 2018).

- Ro, K.S.; Dietenberger, M.A.; Libra, J.A.; Proeschel, R.; Atiyeh, H.K.; Sahoo, K.; Park, W.J. Production of Ethanol from Livestock, Agricultural, and Forest Residuals: An Economic Feasibility Study. Environments 2019, 6, 97. [Google Scholar] [CrossRef]

- Klein-Marcuschamer, D.; Simmons, B.A.; Blanch, H.W. Techno-economic analysis of a lignocellulosic ethanol biorefinery with ionic liquid pre-treatment. Biofuels Bioprod. Biorefin. 2011, 5, 562–569. [Google Scholar] [CrossRef]

- Matsakas, L.; Kekos, D.; Loizidou, M.; Christakopoulos, P. Utilization of household food waste for the production of ethanol at high dry material content. Biotechnol. Biofuels 2014, 7, 4. [Google Scholar] [CrossRef]

| Parameter | Assumption |

|---|---|

| Plant capacity | 2000 Mg/day |

| Plant life | 20 years |

| FW collection distance | 19 km radius [33] |

| Equity | 100% with 0 salvage value |

| The internal rate of return (IRR) | 10% [35] |

| Type of depreciation | Double-declining balance (DDB) [37] 200% with seven years depreciation period [37] |

| Construction period | 2.5 years with total capital investment spent at 8%, 60%, and 32% per year (years before the operation) [37] |

| Startup time | Six months. During this period, revenues, variable operating costs, and fixed operating cost are at 50%, 75% and 100% of normal, respectively [37] |

| Income tax rate | 39% [40] |

| Generic Equipment Type | Operators Per Unit Per Shift |

|---|---|

| Crushers, mills, grinders | 1 |

| Evaporators | 0.2 |

| Furnace | 0.5 |

| Heat exchangers | 0.1 |

| Reactors/bioreactors | 0.5 |

| Clarifiers and thickeners | 0.2 |

| Centrifugal separators and filters | 0.2 |

| Mixers | 0.3 |

| Rotary and belt filters | 0.2 |

| Parameters | Optimistic | Base Case | Pessimistic |

|---|---|---|---|

| Ethanol yield (% w/w wet basis) | 2.9 | 2.2 | 1.5 |

| Plant capacity (Mg/day) | 3000 | 2000 | 1000 |

| Fixed capital cost ($MM) | −30% | Value estimated by SuperPro simulation | 30% |

| Plant distance (km) | 13 | 19 | 37 |

| Liquid fertilizer resale value (¢/L) | 11 | 8 | 5 |

| Biocompost resale value (¢/kg) | 44 | 18 | 9 |

| Enzymes price (¢/L ethanol) | 0 | 0.9 | 18 |

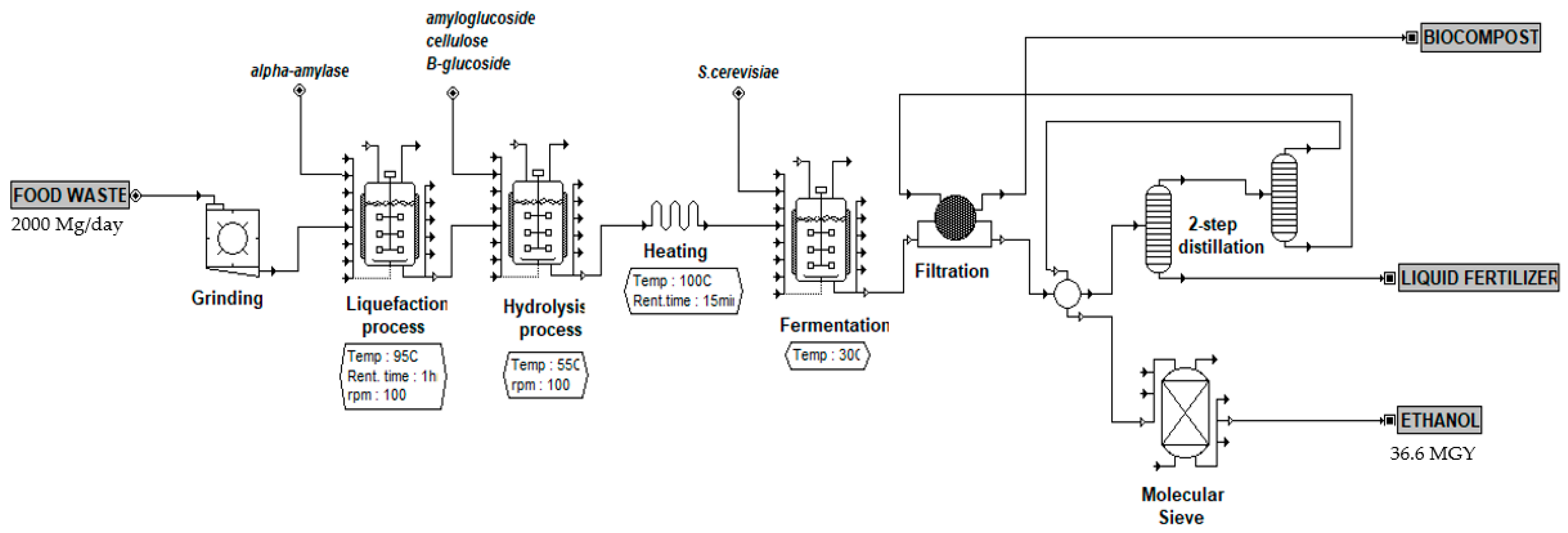

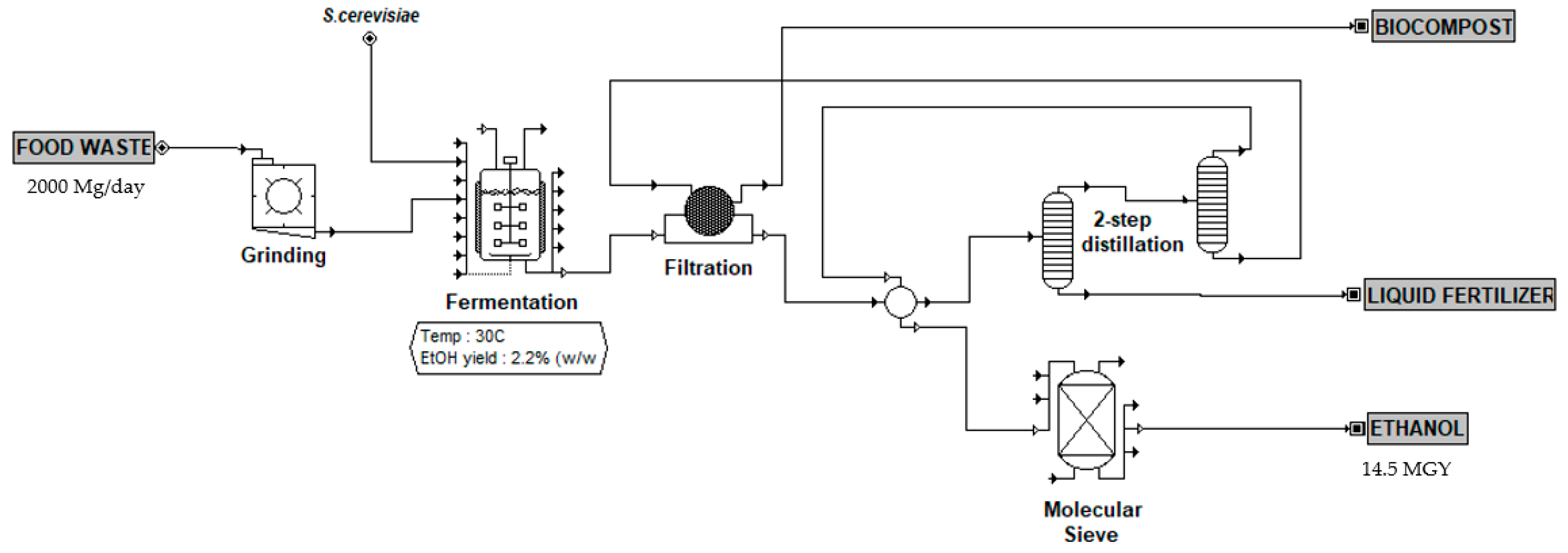

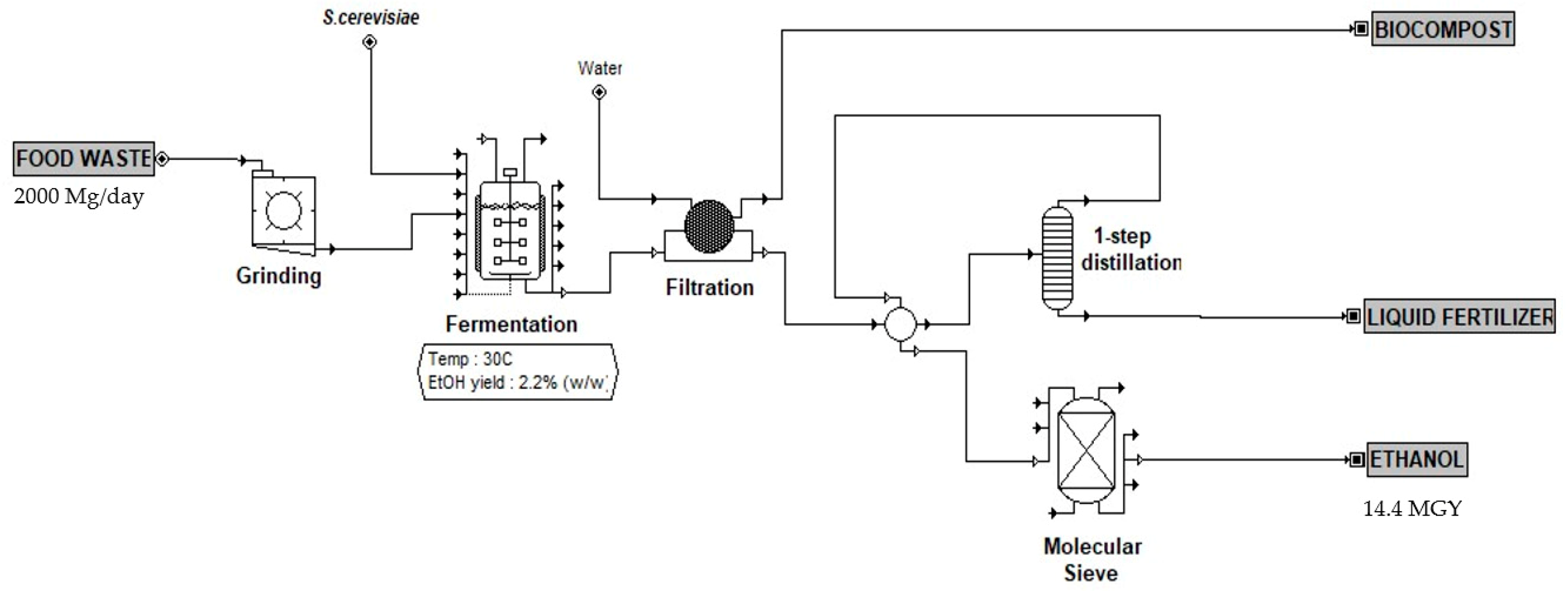

| Process Variations (Scenario) | TIEC ($MM) | TPI ($MM) | Annual Utilities ($MM) | Ethanol Production (MGY) | MESP $/gal ($/L) |

|---|---|---|---|---|---|

| 301 | 545 | 44 | 36.6 | 2.56 (0.68) |

| 214 | 387 | 30 | 14.5 | 2.41 (0.64) |

| 247 | 447 | 25 | 14.4 | 3.42 (0.90) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammad, N.I.S.; Rosentrater, K.A. Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products. Energies 2020, 13, 436. https://doi.org/10.3390/en13020436

Muhammad NIS, Rosentrater KA. Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products. Energies. 2020; 13(2):436. https://doi.org/10.3390/en13020436

Chicago/Turabian StyleMuhammad, Noor Intan Shafinas, and Kurt A. Rosentrater. 2020. "Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products" Energies 13, no. 2: 436. https://doi.org/10.3390/en13020436

APA StyleMuhammad, N. I. S., & Rosentrater, K. A. (2020). Techno-Economic Evaluation of Food Waste Fermentation for Value-Added Products. Energies, 13(2), 436. https://doi.org/10.3390/en13020436