Study on the Performance of Multiple Sources and Multiple Uses Heat Pump System in Three Different Cities

Abstract

1. Introduction

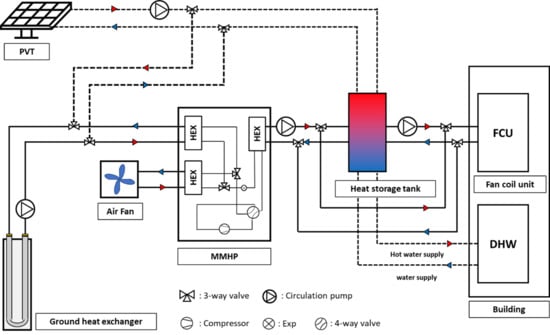

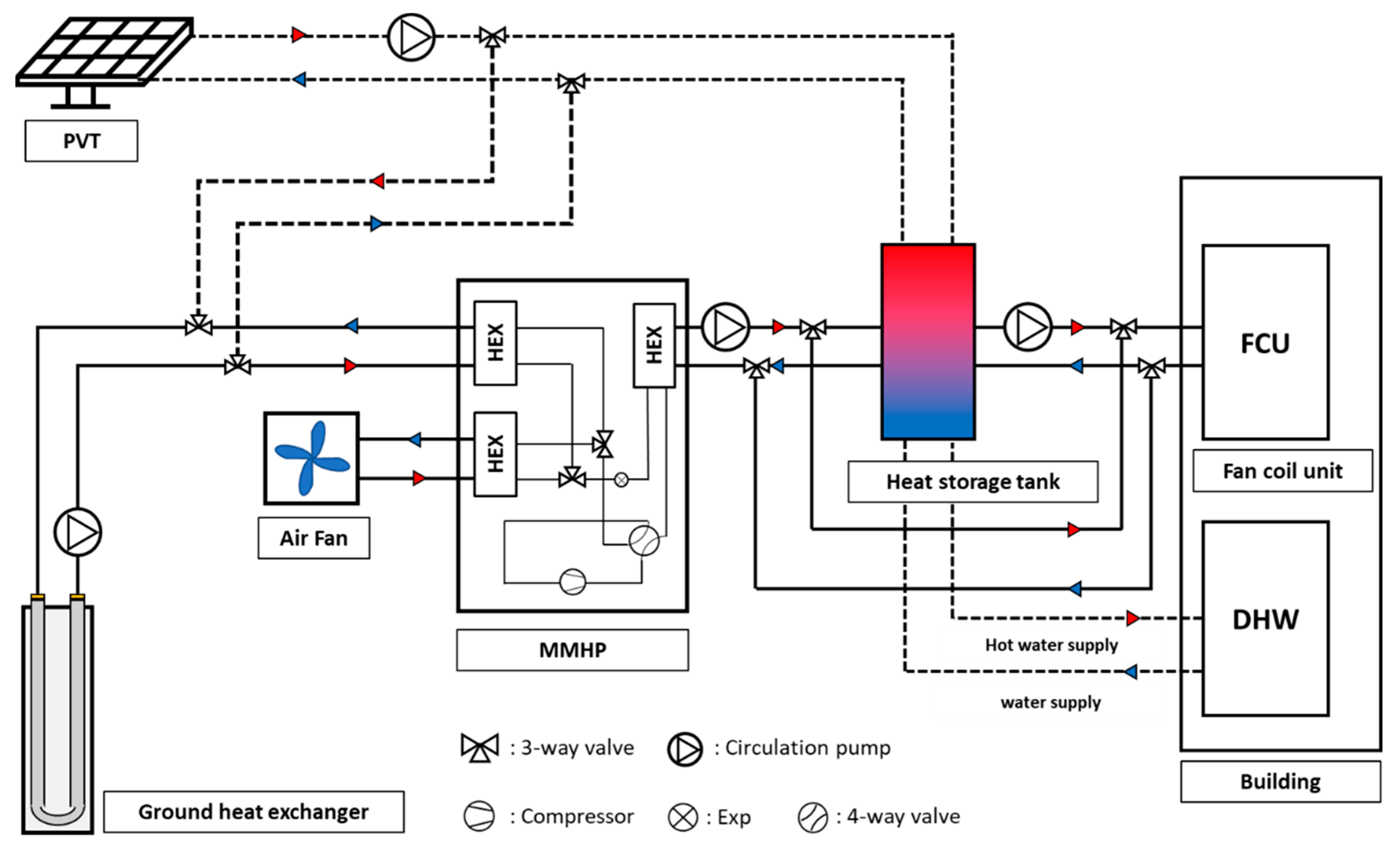

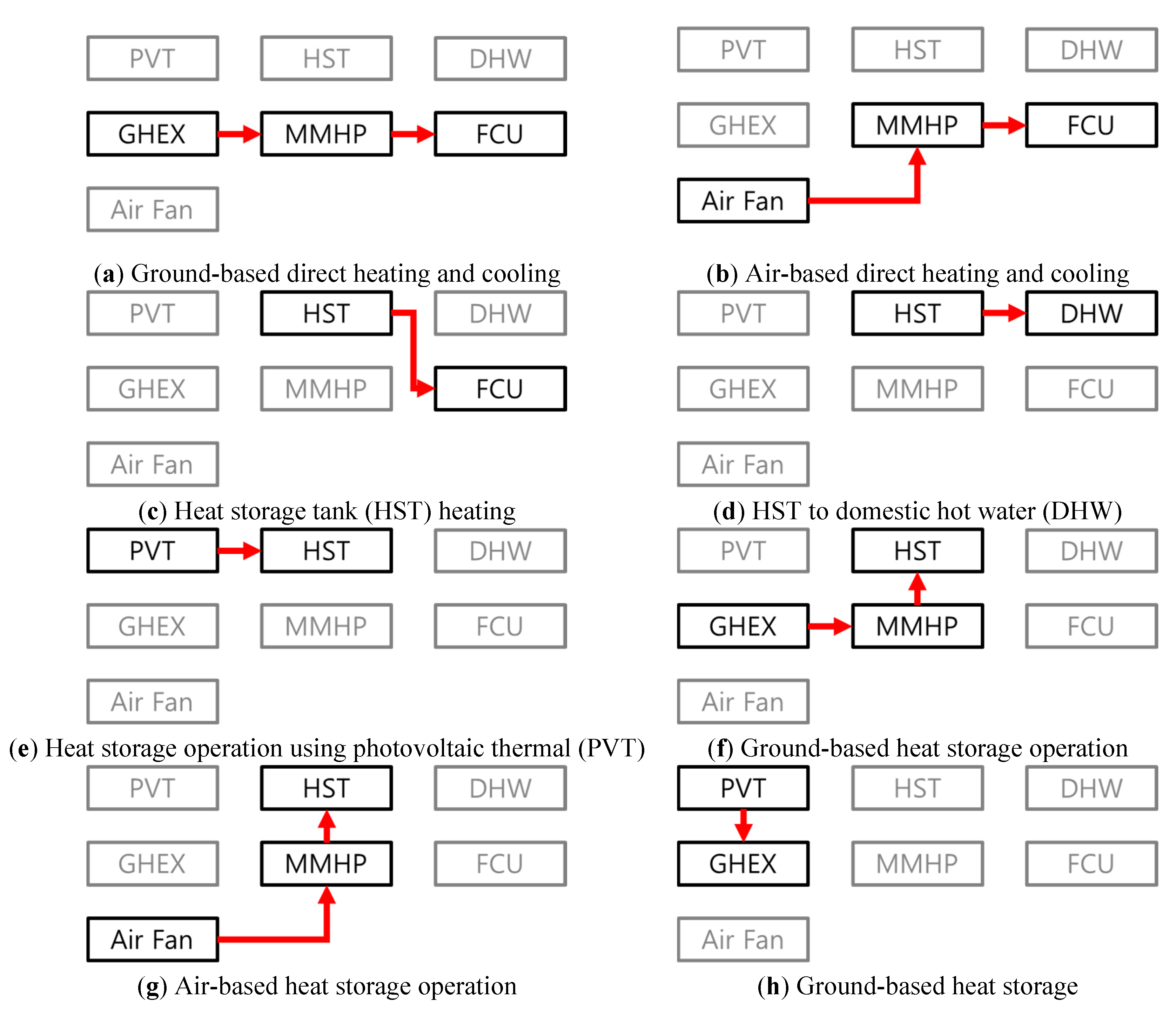

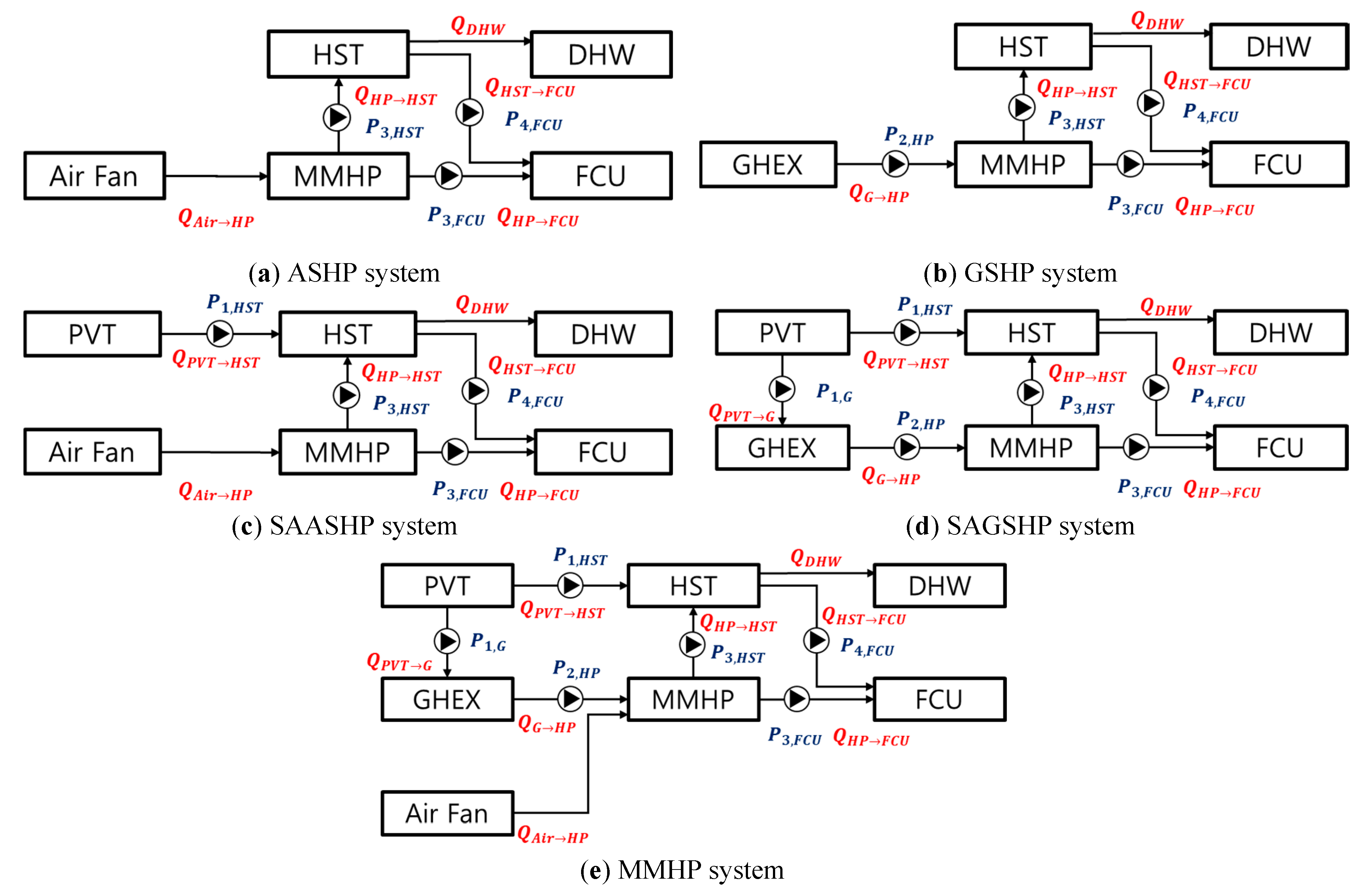

2. Description of the MMHP System

3. Simulation Model

3.1. Overview of the Building Model

3.2. Heating, Cooling, and DHW Load

3.3. Modeling of the MMHP System

3.3.1. Ground Heat Exchanger Component

3.3.2. PVT Component

3.3.3. Heat Pump Component

3.3.4. System Capacity

3.4. Case Conditions

4. Results and Discussion

4.1. Performance Characteristic Analysis

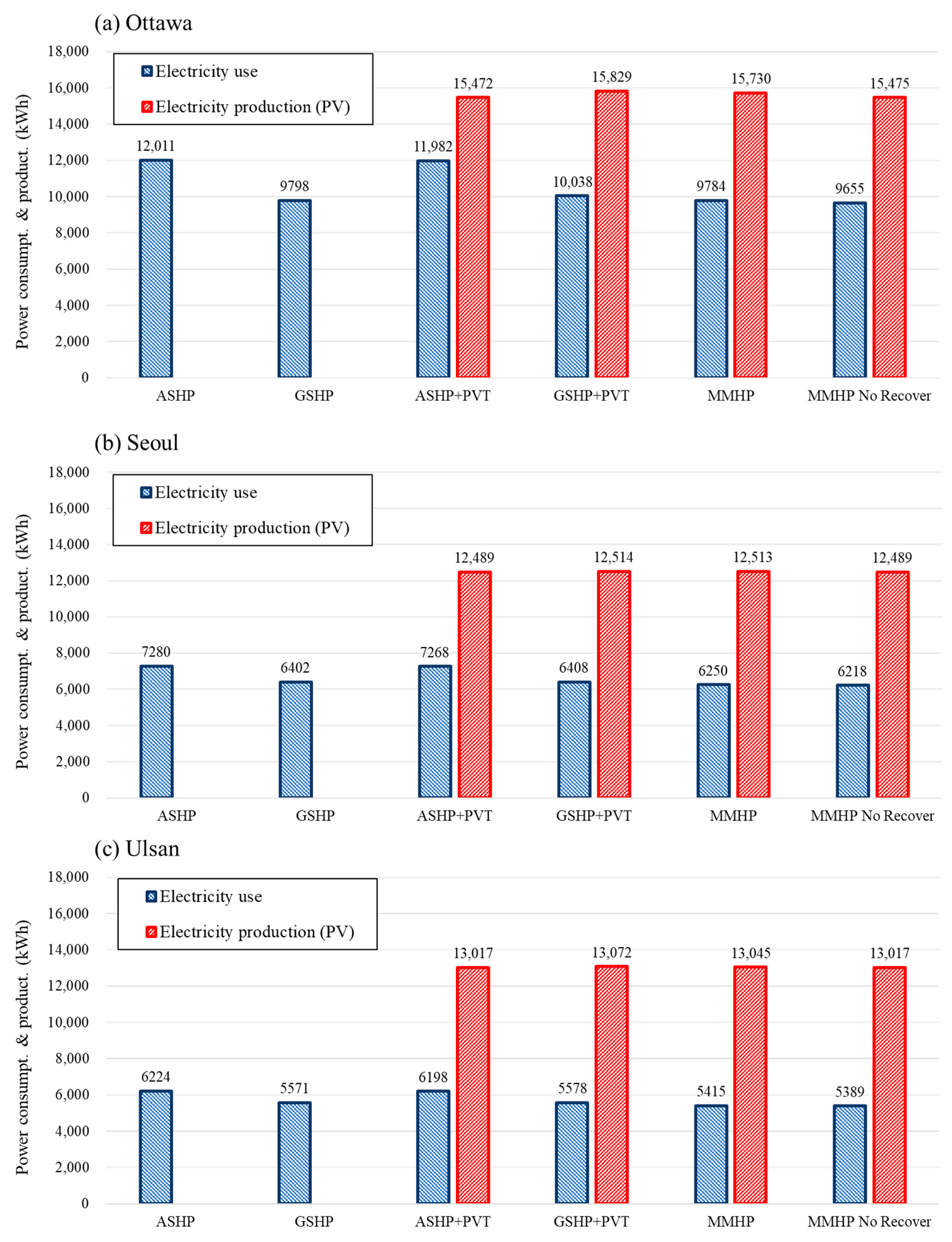

4.2. System-Based Energy and Performance Analysis

5. Conclusions

- The MMHP system operates by comparing the temperatures of solar, air, and ground heat and by selecting an efficient heat source. Therefore, it operates using ground heat when the heating load is high because the outside temperature is low. However, the system uses both ground and air in interseason periods as the outside temperature is relatively high. In addition, the use of solar heat also increases in interseason periods owing to the outside temperature.

- When the heat pump COP values of the ASHP, GSHP, and MMHP systems were analyzed by month, the GSHP system exhibited higher values than the ASHP system, except during the interseason periods of May and October. However, in the interseason periods, the heat pump COP of the ASHP system was higher. The MMHP system had a higher COP than the GSHP and ASHP systems because it selectively used the optimal heat source between air heat and ground heat. The annual average value of heat pump COP was 3.75 for the ASHP system, 4.26 for the GSHP system, and 4.56 for the MMHP system.

- The electricity use of the MMHP system was 13–19% and 1–3% lower than those of the ASHP and GSHP systems, respectively.

- In terms of annual energy use, MMHP systems can be used efficiently in areas where both cooling and heating are required throughout the year. However, it is disadvantageous to use various heat sources in regions dominated by heating and cooling loads.

- The electricity use of the MMHP system was higher when the ground temperature recovery operation was conducted. It was determined that this was due to the electricity use of the circulation pump for ground temperature recovery. However, considering both the power generation of PVT and the recovery of the ground temperature, it is possible that performing the ground recovery operation is advantageous in terms of energy efficiency and system sustainability. When the ground temperature recovery operation was applied, electricity use increased by 129 kWh owing to the circulation pump, but the PV power production increased by 255 kWh because of the decrease in the back-side temperature of the PVT system. In addition, the decrement in ground temperature in 10 years decreased by 25% through ground temperature recovery operations.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | Area |

| C | Specific heat capacity (kJ/Kg·K) |

| Cap | Capacity (kW) |

| COP | Coefficient of performance (-) |

| e | Exponential function (-) |

| E | Energy (kW) |

| G | Total solar radiation (kJ/hr·K) |

| IAM | Incidence angle modifier (-) |

| L | Length (m) |

| m | Flow rate (kg/hr) |

| P | Power drawn (kW) |

| Q | Amount of heat (kW) |

| T | Temperature (°C) |

| X | Multiplier for photovoltaic cell efficiency (1/°C or h·m2/kJ) |

| α | Heat transfer coefficient (-) |

| η | Efficiency (-) |

| τα | Transmittance-absorptance product for solar collector (-) |

| Subscript | |

| absorbed | absorber heat |

| air | air |

| back | back |

| conv | convection |

| cooling | cooling |

| ct | cell temperature |

| f | fluid |

| gr | ground |

| heating | heating |

| i | in |

| lat | latent heat |

| load | load side |

| loss | loss energy |

| nom | nominal |

| o | out |

| p | pipe |

| pv | photovoltaic |

| rad | incidence radiation |

| source | source side |

| top | top |

| u | tube |

| Abbreviations | |

| ASHP | air source heat pump |

| COP | coefficient of performance |

| DHW | domestic hot water |

| FCU | fan coil unit |

| GHEX | ground heat exchanger |

| GSHP | ground source heat pump |

| HST | heat storage tank |

| HVAC | heating, ventilation, and air conditioning |

| MMHP | multiple sources and multiple uses heat pump |

| PV | photovoltaic |

| PVT | photovoltaic thermal |

| SAASHP | solar assisted air source heat pump |

| SAGSHP | solar assisted ground source heat pump |

References

- Korea Energy Agency (KEA). Available online: www.energy.or.kr (accessed on 26 July 2020).

- Ministry of Economy and Finance of Korea. Available online: www.moef.go.kr (accessed on 26 July 2020).

- Jeong, Y.D.; Yu, M.G.; Nam, Y. Feasibility Study of a Heating, Cooling and Domestic Hot Water System Combining a Photovoltaic-Thermal System and a Ground Source Heat Pump. Energies 2017, 10, 1243. [Google Scholar] [CrossRef]

- Xi, C.; Lin, L.; Hongxing, Y. Long term operation of a solar assisted ground coupled heat pump system for space heating and domestic hot water. Energy Build. 2011, 43, 1835–1844. [Google Scholar] [CrossRef]

- Bae, S.; Nam, Y.; da Cunha, I. Economic Solution of the Tri-Generation System Using Photovoltaic-Thermal and Ground Source Heat Pump for Zero Energy Building (ZEB) Realization. Energies 2019, 12, 3304. [Google Scholar] [CrossRef]

- Razavi, S.H.; Ahmadi, R.; Zahedi, A. Modeling, simulation and dynamic control of solar assisted ground source heat pump to provide heating load and DHW. Appl. Therm. Eng. 2018, 129, 127–144. [Google Scholar] [CrossRef]

- Lazzarin, R.M. Dual source heat pump systems: Operation and performance. Energy Build. 2012, 52, 77–85. [Google Scholar] [CrossRef]

- Macía, A.; Bujedo, L.A.; Magraner, T.; Chamorro, C.R. Influence parameters on the performance of an experimental solar-assisted ground-coupled absorption heat pump in cooling operation. Energy Build. 2013, 66, 282–288. [Google Scholar] [CrossRef]

- Xia, L.; Ma, Z.; Kokogiannakis, G.; Wang, S.; Gong, X. A model-based optimal control strategy for ground source heat pump systems with integrated solar photovoltaic thermal collectors. Appl. Energy 2018, 228, 1399–1412. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; Carli, M.D.; Galgaro, A. An analysis of solar assisted ground source heat pumps in cold climates. Energy Convers. Manag. 2015, 106, 660–675. [Google Scholar] [CrossRef]

- Bakirci, K.; Ozyurt, O.; Comakli, K.; Comakli, O. Energy analysis of a solar-ground source heat pump system with vertical closed-loop for heating applications. Energy 2011, 36, 3224–3232. [Google Scholar] [CrossRef]

- Eslami-nejad, P.; Bernier, M. Coupling of geothermal heat pumps with thermal solar collectors using double U-tube boreholes with two independent circuits. Appl. Therm. Eng. 2011, 31, 3066–3077. [Google Scholar] [CrossRef]

- Nam, Y.; Ooka, R.; Shiba, Y. Development of dual-source hybrid heat pump system using groundwater and air. Energy Build. 2010, 42, 909–916. [Google Scholar] [CrossRef]

- Corberán, J.M.; Cazorla-Marín, A.; Marchante-Avellaneda, J.; Montagud, C. Dual source heat pump, a high efficiency and cost-effective alternative for heating, cooling and DHW production. Int. J. Low Carbon Technol. 2018, 13, 161–176. [Google Scholar]

- Danny, J.; Georg, F.; Danjana, T. Simulation and performance analysis of combined parallel solar thermal and ground or air source heat pump systems. Sol. Energy 2017, 150, 500–511. [Google Scholar]

- Beginning Farmers Center. Available online: www.returnfarm.com (accessed on 26 August 2019).

- Framework Act on Low Carbon, Green Growth. Available online: www.law.go.kr (accessed on 26 August 2019).

- Natural Resources Canada. National Energy Coed of Canada for Buildings 2017; Natural Resources Canada: Hamilton, ON, Canada, 2017.

- ASHRAE. Energy Standard for Buildings Except Low-Rise Residential Buildings; ASHRAE Standard 90.1; ASHRAE: Atlanta, GA, USA, 2004. [Google Scholar]

- ASHRAE. ASHRAE Handbook HVAC Application; ASHRAE: Atlanta, GA, USA, 2011. [Google Scholar]

- Hellström, G. Duct Ground Heat Storage Model Manual for Computer Code; Department of Mathematical Physics, University of Lund: Lund, Sweden, 1989. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Process, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- TRNSYS 17. HVAC Library Mathematical Reference; TESS Libs 17: Milwaukee, WI, USA, 2012; Volume 6. [Google Scholar]

- Kim, M.-H.; Kim, D.-W.; Yun, R.; Heo, H. Operational Energy Saving Potential of Thermal Effluent Source Heat Pump System for Greenhouse Heating in Jeju. Int. J. Air Cond. Refrig. 2017, 25, 1–12. [Google Scholar]

- LG Airconditioner Engineering Product Data Book. Available online: https://www.lg.com/global/business/heating-awhp (accessed on 18 September 2020).

- Government of Canada. Available online: https://www.nrcan.gc.ca (accessed on 26 July 2020).

- Korean Institute of Architectural Sustainable Environment and Building Systems (KIAEBS). Design Guide for Ground Source Heat Pump System; KIAEBS S-4: Seoul, Korea, 2016. [Google Scholar]

| Item | Seoul | Ulsan | Ottawa | |

|---|---|---|---|---|

| Thermal transmittance | Wall | 0.17 W/m2K | 0.22 W/m2K | 0.247 W/m2K |

| Roof | 0.15 W/m2K | 0.18 W/m2K | 0.156 W/m2K | |

| Floor | 0.29 W/m2K | 0.35 W/m2K | 0.183 W/m2K | |

| Window | 1.0 W/m2K | 1.2 W/m2K | 1.9 W/m2K | |

| Infiltration | 0.775 1/h | |||

| Internal heating | Human body | 2160 kJ/h | ||

| Lighting | 27.126 kJ/h m2 | |||

| Equipment | 19.368 kJ/h m2 | |||

| Set temperature | Heating | 24 °C | ||

| Cooling | 26 °C | |||

| Peak Load | Ottawa | Seoul | Ulsan |

|---|---|---|---|

| Heating (kW) | 9.78 | 6.13 | 5.55 |

| Cooling (kW) | 1.22 | 3.05 | 4.03 |

| DHW (kW) | 0.9 | 0.9 | 0.9 |

| Component | Parameter | Ottawa | Seoul | Ulsan |

|---|---|---|---|---|

| Ground heat exchanger (Type 557a) | Type | Vertical closed loop | ||

| Number of boreholes | 1 | |||

| Borehole radius | 0.15 m | |||

| Borehole depth (m) | 360 | 105 | 95 | |

| Storage volume (m3) | 7774 | 2275 | 2059 | |

| PVT collector (Type 560) | Type | Unglazed water | ||

| Collector size (m2) | 6 m × 14 m | |||

| Number of tubes | 340 | |||

| PV efficiency | 16.10% | |||

| Collector slope | 45 | |||

| HST (Type 4c) | Tank volume (m3) | 1.12 | 0.70 | 0.63 |

| Heat loss coefficient | 0.694 W/m2 K | |||

| Set point temperature | 45 °C | |||

| Air source heat pump (Type 917) | Type | Air to Water | ||

| Capacity (kW) | 11.74 | 7.36 | 6.66 | |

| Ground source heat pump (Type 927) | Type | Water to water | ||

| Capacity (kW) | 11.74 | 7.36 | 6.66 | |

| FCU (Type 987) | Rated cooling capacity (kW) | 15 | 13.984 | 12.654 |

| Rated heating capacity (kW) | 15 | 13.984 | 12.654 | |

| Rated fan power (kW) | 0.168 | 0.105 | 0.095 | |

| Rated volumetric air flow rate (m3/s) | 0.78 | 0.49 | 0.44 | |

| Circulation pump (Type 3d) | Flow rate (kg/s) | 0.56 | 0.35 | 0.32 |

| Power consumption (kW) | 0.34 | 0.21 | 0.19 | |

| No | System | Space Heating | Space Cooling | Heat Storage | DHW | Recovery |

|---|---|---|---|---|---|---|

| 1 | ASHP | HST to FCU | ASHP to FCU | ASHP to HST | HST to DHW | - |

| ASHP to FCU | ||||||

| 2 | GSHP | HST to FCU | GSHP to FCU | GSHP to HST | ||

| GSHP to FCU | ||||||

| 3 | SAASHP | HST to FCU | ASHP to FCU | PVT to HST | ||

| ASHP to FCU | ASHP to HST | |||||

| 4 | SAGSHP | HST to FCU | GSHP to FCU | PVT to HST | PVT to ground | |

| GSHP to FCU | GSHP to HST | |||||

| 5 | MMHP | HST to FCU | MMHP to FCU (air or ground) | PVT to HST | ||

| MMHP to FCU (air or ground) | MMHP to HST (air or ground) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Nam, Y.; Bae, S.; Cho, S. Study on the Performance of Multiple Sources and Multiple Uses Heat Pump System in Three Different Cities. Energies 2020, 13, 5211. https://doi.org/10.3390/en13195211

Kim H, Nam Y, Bae S, Cho S. Study on the Performance of Multiple Sources and Multiple Uses Heat Pump System in Three Different Cities. Energies. 2020; 13(19):5211. https://doi.org/10.3390/en13195211

Chicago/Turabian StyleKim, Hongkyo, Yujin Nam, Sangmu Bae, and Soolyeon Cho. 2020. "Study on the Performance of Multiple Sources and Multiple Uses Heat Pump System in Three Different Cities" Energies 13, no. 19: 5211. https://doi.org/10.3390/en13195211

APA StyleKim, H., Nam, Y., Bae, S., & Cho, S. (2020). Study on the Performance of Multiple Sources and Multiple Uses Heat Pump System in Three Different Cities. Energies, 13(19), 5211. https://doi.org/10.3390/en13195211