The Numerical Simulation Study of the Oil–Water Seepage Behavior Dependent on the Polymer Concentration in Polymer Flooding

Abstract

1. Introduction

2. Methodology

2.1. Assumption

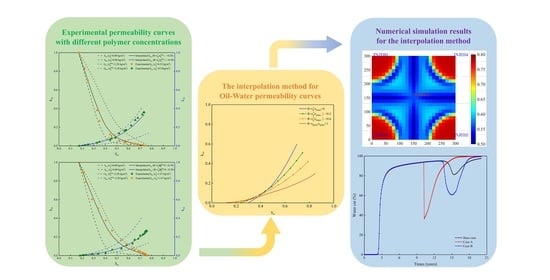

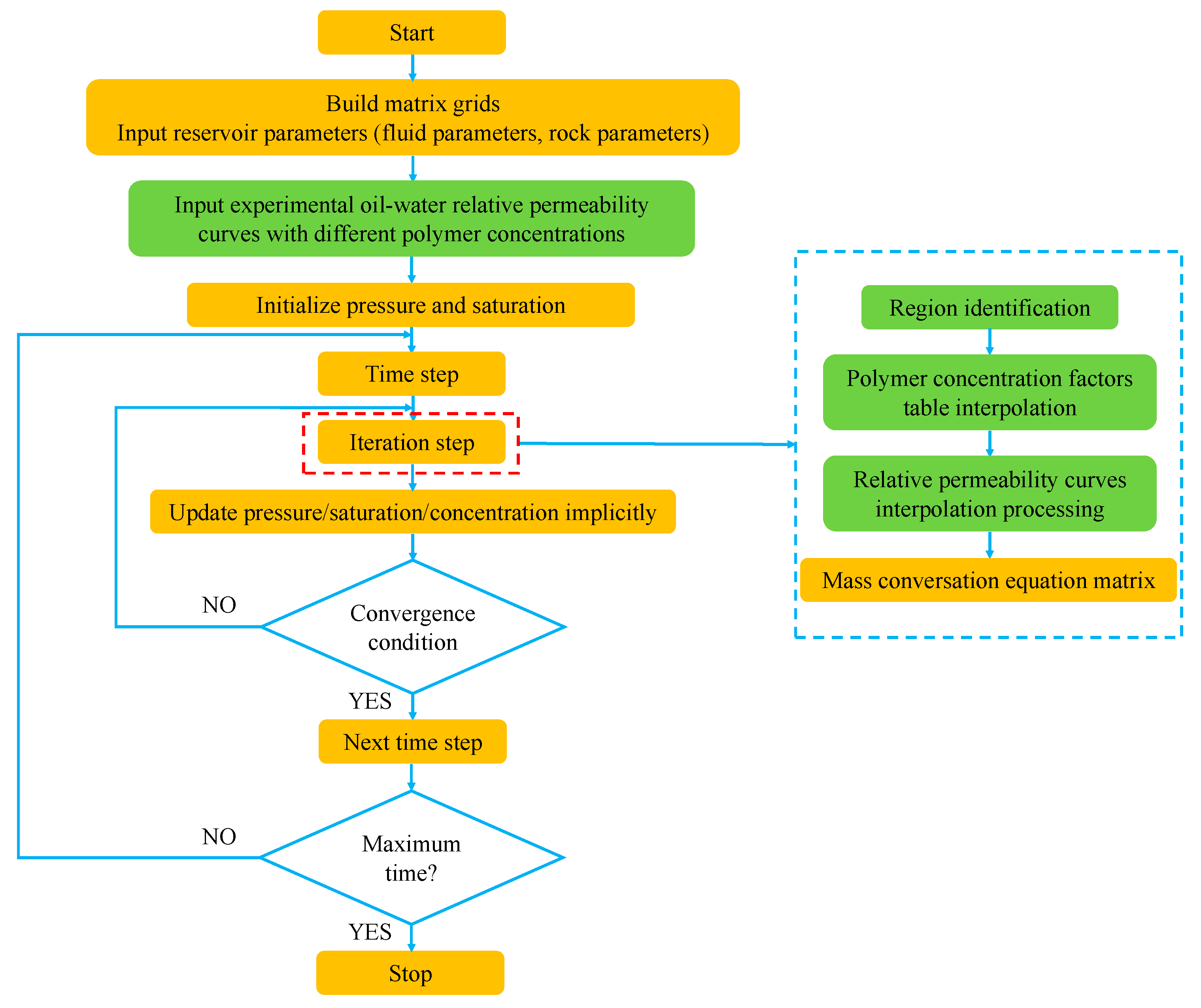

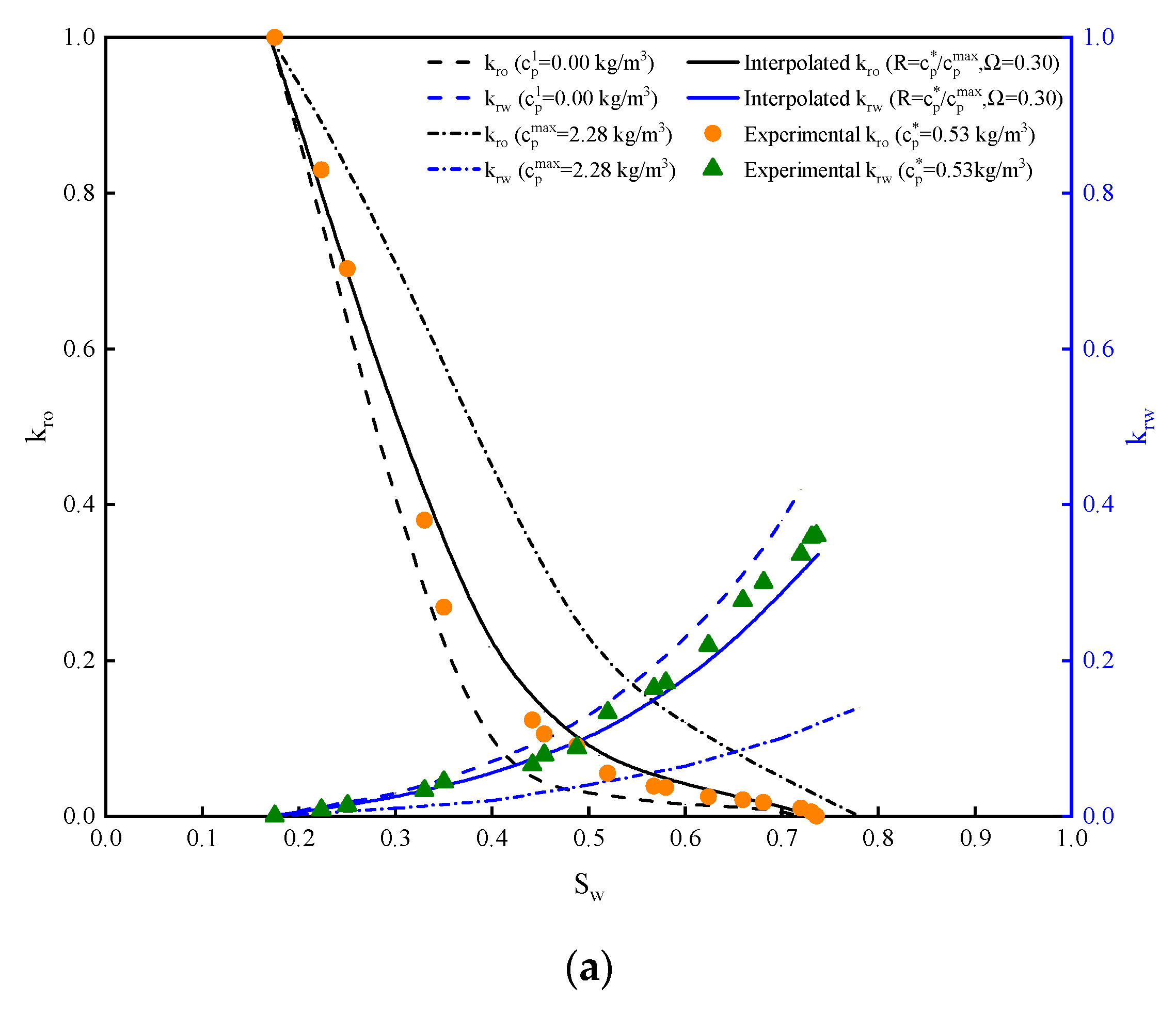

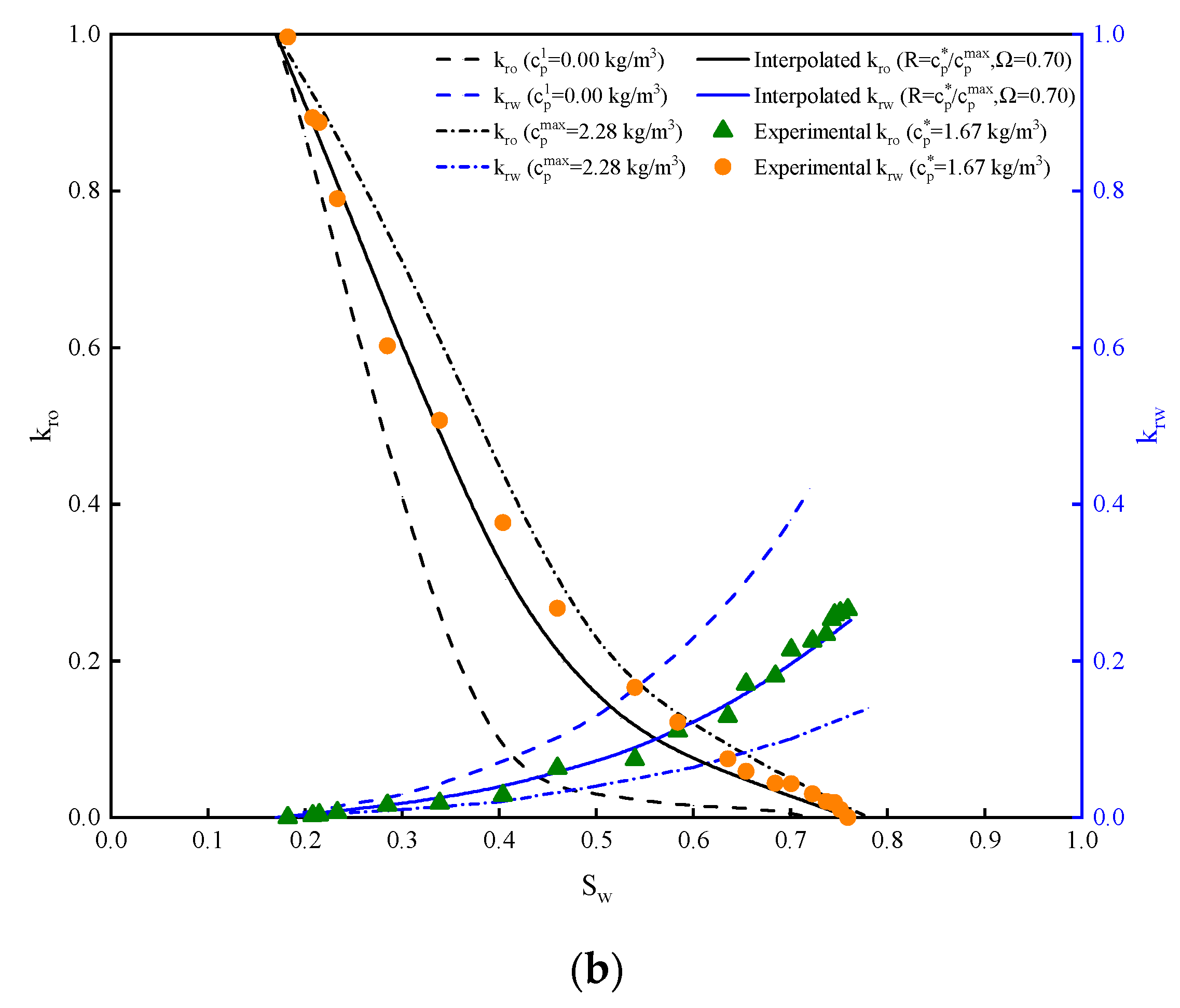

2.2. Polymer Concentration Interpolation Model of Oil–Water Relative Permeabilities

2.3. Mathematical Model

- (1)

- Polymer adsorption effect

- (2)

- Polymer viscosity effect

- (3)

- Polymer rheology effect

- (4)

- Inaccessible pore volume fraction

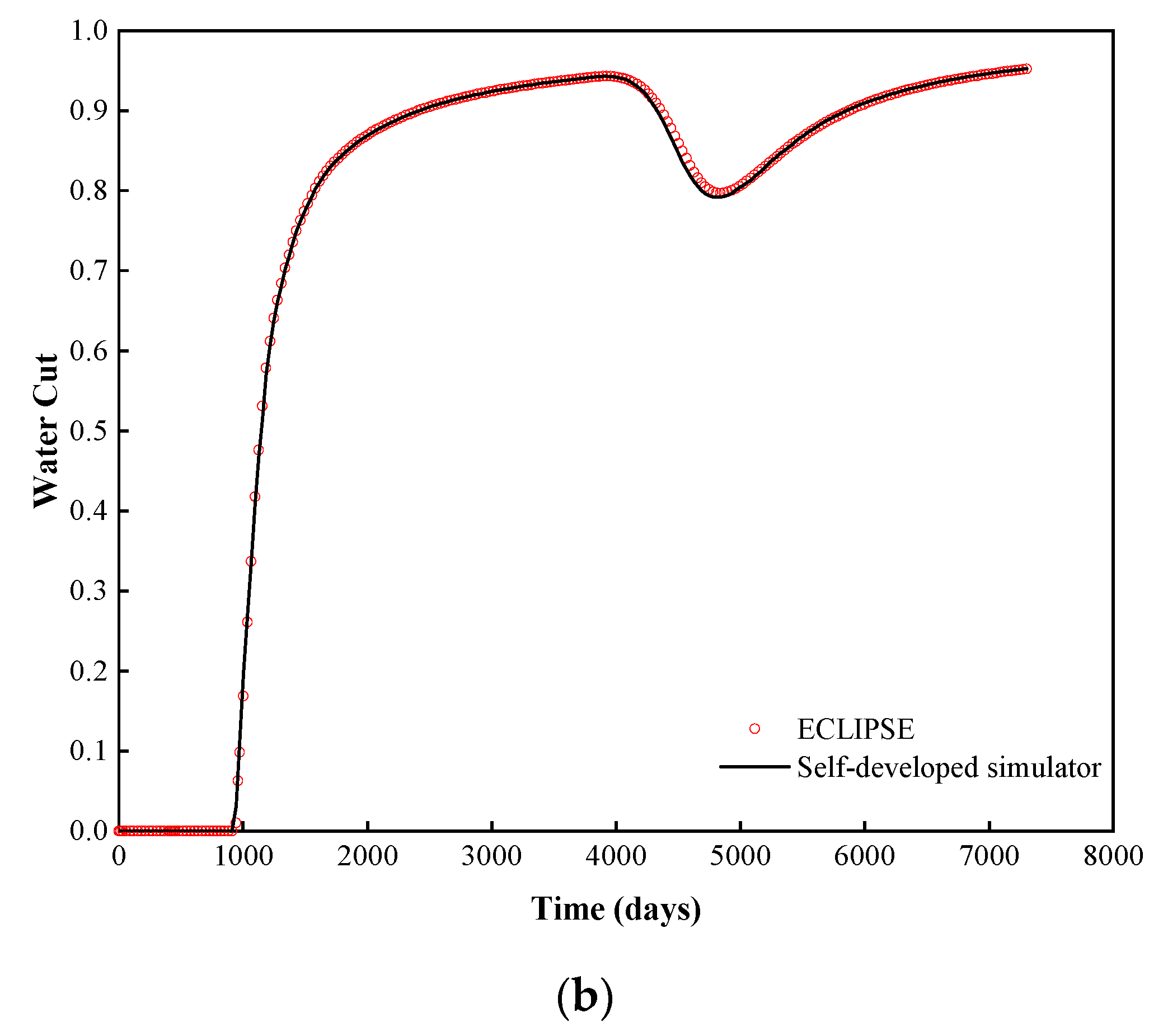

3. Solution and Verification

4. Results and Discussion

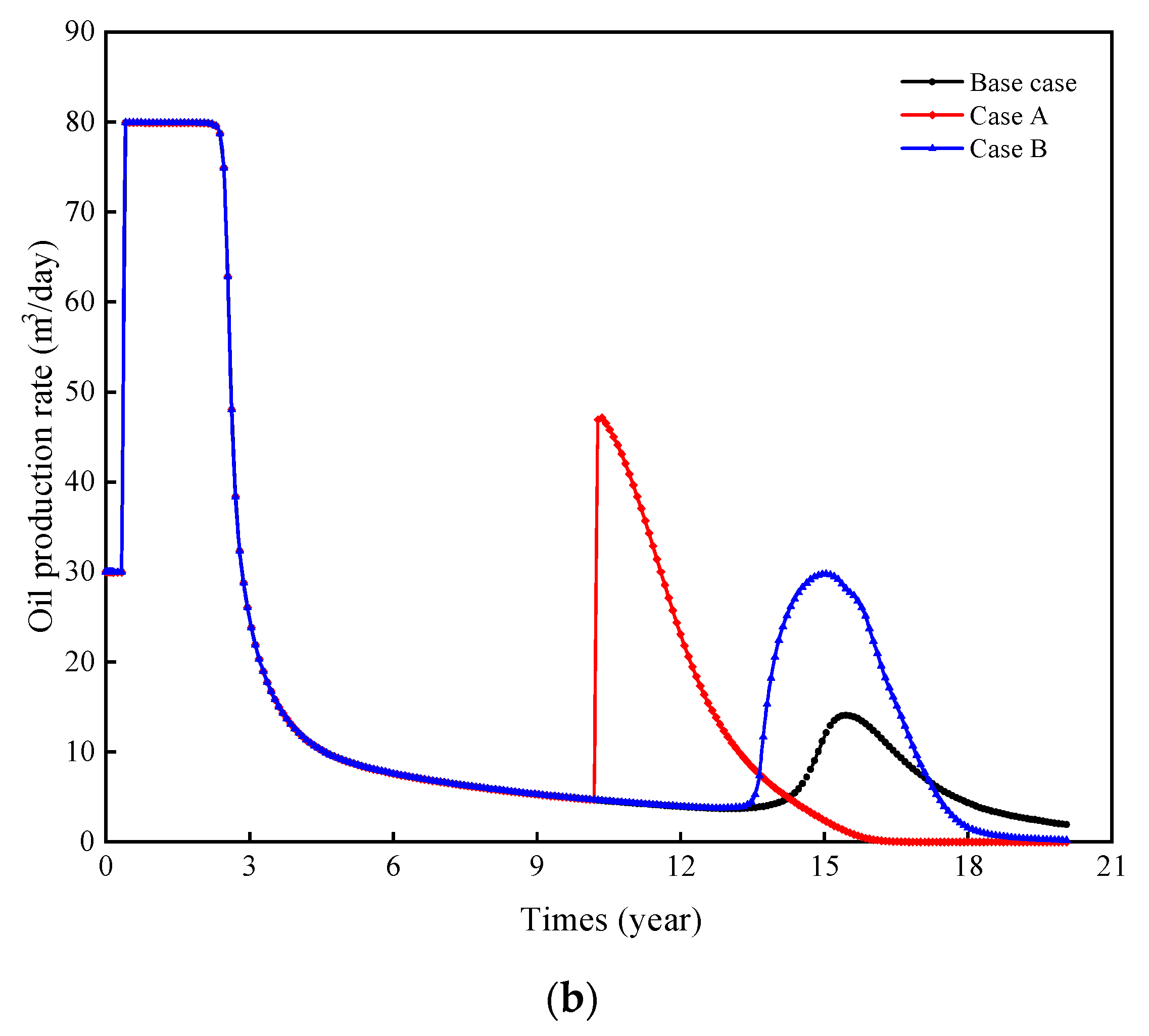

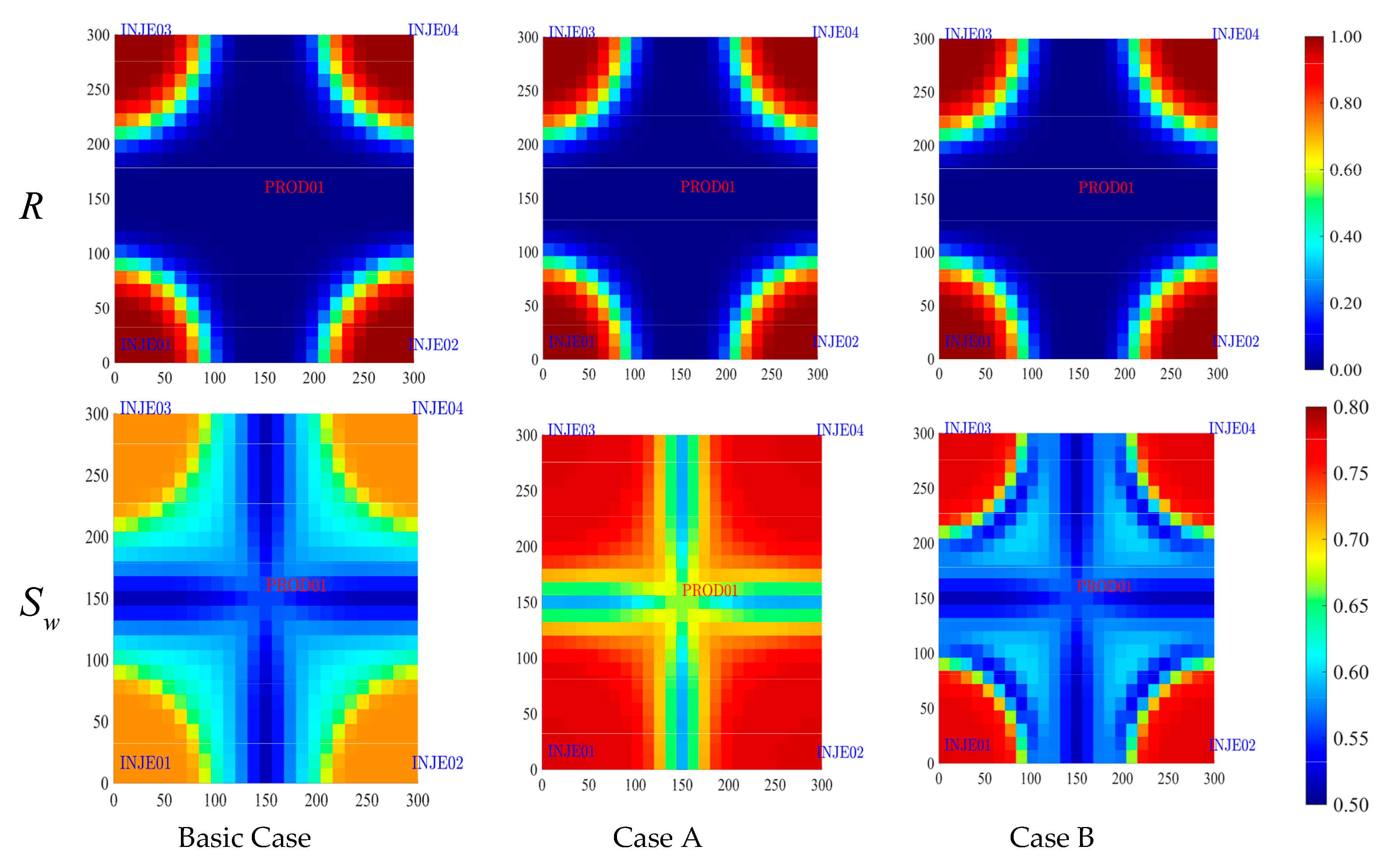

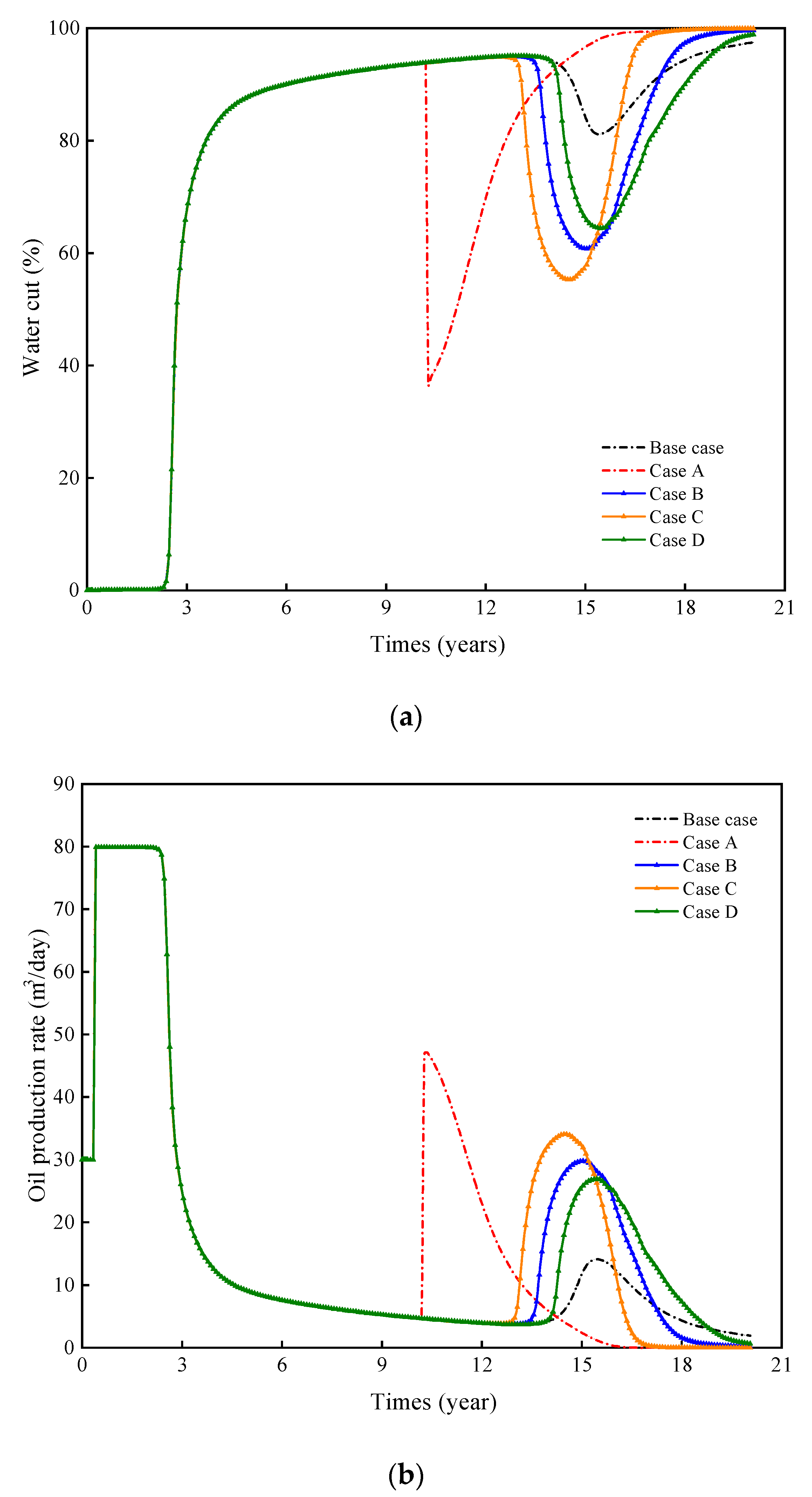

4.1. Cases Study

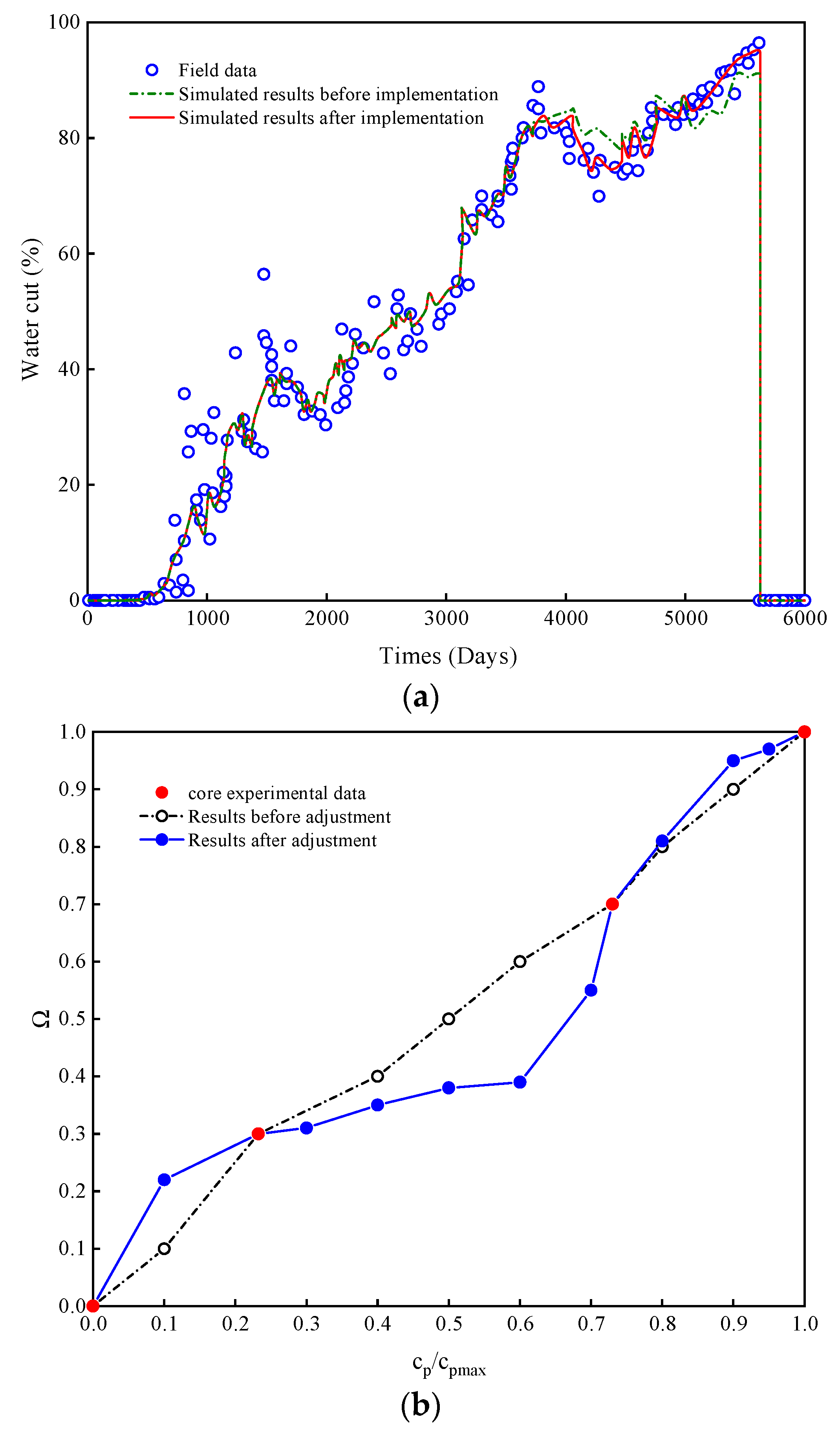

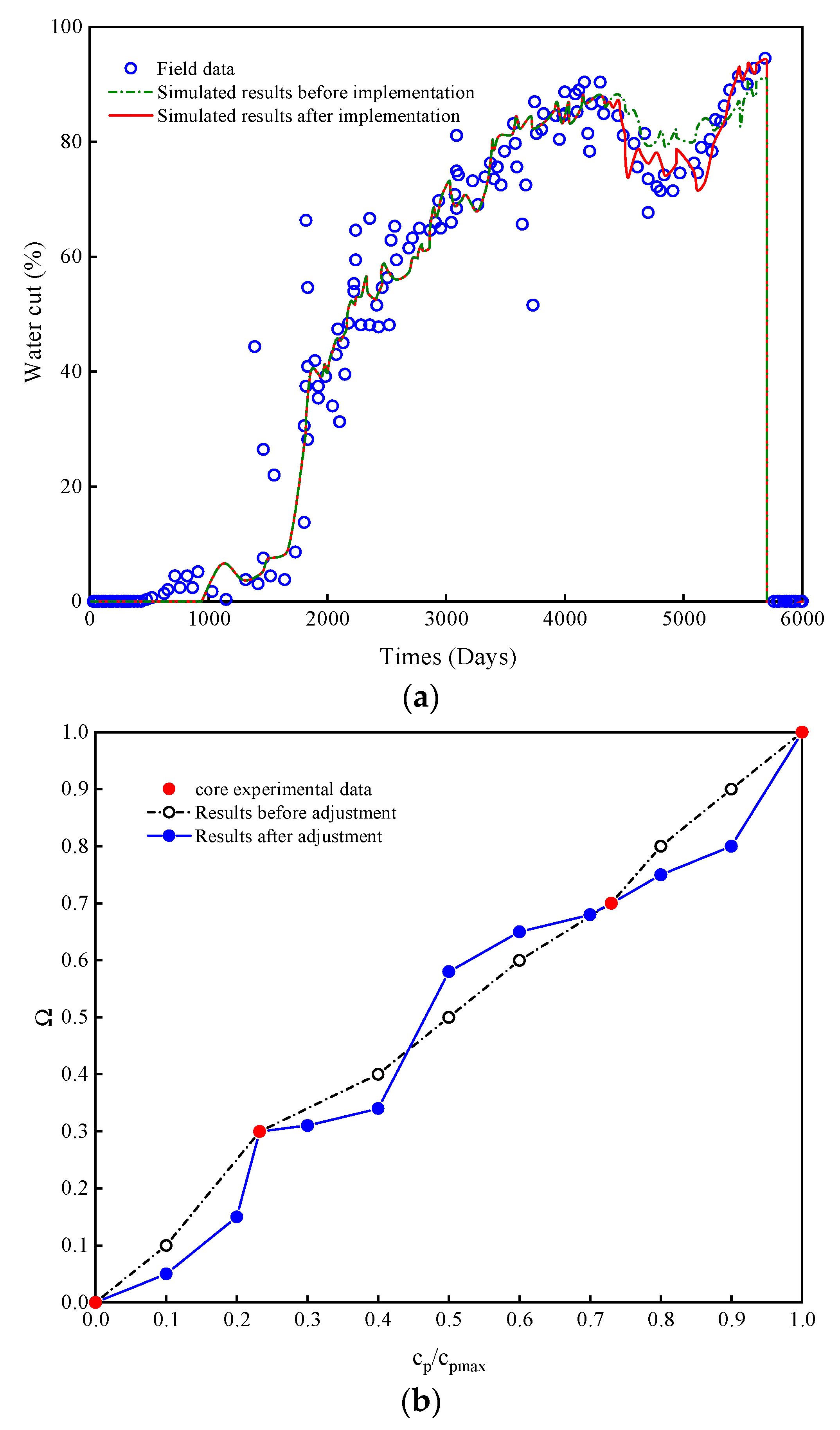

4.2. Field Study

5. Conclusions

- (1)

- With the normalized polymer concentration , a polymer concentration interpolation model for numerical research is proposed to dynamically calculate the corresponding flow mobility of the oil–water phases based on experimental validation.

- (2)

- Compared with that in the commercial simulator, the proposed interpolation method could more effectively enhance the numerical predictions of the oil production rate and the water cut.

- (3)

- By combining with the core experimental results, the presented method has been successfully applied in the field history matching of the main productive zone in the Y oilfield, leading to the flexibility improvement of the history matching process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Adsorption coefficient | |

| Adsorption coefficient | |

| Formation volume factor | |

| Depth of the reservoir | |

| Gravity acceleration | |

| Permeability | |

| Relative permeability | |

| Adsorption exponent coefficient | |

| Pressure | |

| Volume production rate | |

| Saturation | |

| Time | |

| Density | |

| Porosity | |

| Normalized polymer concentration | |

| Subscript | |

| Oil | |

| Polymer | |

| Rock | |

| Water |

References

- Raffa, P.; Broekhuis, A.A.; Picchioni, F. Polymeric surfactants for enhanced oil recovery: A review. J. Pet. Sci. Eng. 2016, 145, 723–733. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, S.; Feng, N.; Xu, J.; Qin, J.; He, Y.; Yu, H. Semi-analytical modeling for water injection well in tight reservoir considering the variation of waterflood—Induced fracture properties—Case studies in Changqing Oilfield, China. J. Pet. Sci. Eng. 2017, 159, 740–753. [Google Scholar] [CrossRef]

- Wang, Y.; Ayala, L.F. Explicit Determination of Reserves for Variable-Bottomhole-Pressure Conditions in Gas Rate-Transient Analysis. SPE J. 2019. [Google Scholar] [CrossRef]

- Van, S.L.; Chon, B.H. Chemical Flooding in Heavy-Oil Reservoirs: From Technical Investigation to Optimization Using Response Surface Methodology. Energies 2016, 9, 711. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of Polymer-Flooding Technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, W.; Fu, J.; Lu, J.; Yin, H. The Performance of Polymer Flooding in Heterogeneous Type II Reservoirs-An Experimental and Field Investigation. Energies 2017, 10, 454. [Google Scholar] [CrossRef]

- Sorbie, K.S. Network Modeling of Xanthan Rheology in Porous Media in the Presence of Depleted Layer Effects. In Proceedings of the 1989 SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–11 October 1989. [Google Scholar]

- Lopez, X.; Blunt, M.J. Predicting the Impact of Non-Newtonian Rheology on Relative Permeability Using Pore-Scale Modeling. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. [Google Scholar]

- Bo, Q.; Zhong, T.; Liu, Q. Pore Scale Network Modeling of Relative permeability in Chemical flooding. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 20–21 October 2003. [Google Scholar]

- de Loubens, R.; Vaillant, G.; Regaieg, M.; Yang, J.; Moncorgé, A.; Fabbri, C.; Darche, G. Numerical Modeling of Unstable Waterfloods and Tertiary Polymer Floods into Highly Viscous Oils. SPE J. 2018, 23, 1909–1928. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, L.; Zhu, G.; Yao, J.; Sun, H.; Song, W.; Yang, Y.; Zhao, J. A Pore-Scale Investigation of Residual Oil Distributions and Enhanced Oil Recovery Methods. Energies 2019, 12, 3732. [Google Scholar] [CrossRef]

- Jingfu, D.; Yunpeng, L.; Xiaofei, J.; Xiaohui, W.; Bin, L. Dynamic Inverting Method for the Relative Permeability Curves in the Stable Polymer Flooding and Its Application. Pet. Geol. Oilfield Dev. Daqing 2017, 36, 106–109. [Google Scholar]

- Wang, Y.; Li, G.; Reynolds, A.C. Estimation of Depths of Fluid Contacts by History Matching Using Iterative Ensemble-Kalman Smoothers. SPE J. 2010, 15, 509–525. [Google Scholar] [CrossRef]

- Hou, J.; Wang, D.; Luo, F.; Li, Z.; Bing, S. Estimation of the Water–Oil Relative Permeability Curve from Radial Displacement Experiments. Part 1: Numerical Inversion Method. Energy Fuels 2012, 26, 4291–4299. [Google Scholar] [CrossRef]

- Bingyan, H.; Xu, C.; Gen, K.; Qiong, L.; Yong, L.; Ke, A. Inverse of parameters of core polymer flooding using iterative ensemble Kalman filter. Prog. Geophys. 2018, 33, 2330–2335. [Google Scholar]

- Liu, Y.; Hou, J.; Liu, L.; Zhou, K.; Zhang, Y.; Dai, T.; Guo, L.; Cao, W. An Inversion Method of Relative Permeability Curves in Polymer Flooding Considering Physical Properties of Polymer. SPE J. 2018, 23, 1929–1943. [Google Scholar] [CrossRef]

- Delshad, M.; Bhuyan, D.; Pope, G.A.; Lake, L.W. Effect of Capillary Number on the Residual Saturation of a Three-Phase Micellar Solution. In Proceedings of the SPE Enhanced Oil Recovery Symposium; Society of Petroleum Engineers: Tulsa, OK, USA, 1986. [Google Scholar]

- Amaefule, J.O.; Handy, L.L. The Effect of Interfacial Tensions on Relative Oil/Water Permeabilities of Consolidated Porous Media. Soc. Pet. Eng. J. 1982, 22, 371–381. [Google Scholar] [CrossRef]

- Jin, M. A Study of Nonaqueous Phase Liquid Characterization and Surfactant Remediation. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 1995. [Google Scholar]

- Pope, G.A.; Wu, W.; Narayanaswamy, G.; Delshad, M.; Sharma, M.M.; Wang, P. Modeling Relative Permeability Effects in Gas-Condensate Reservoirs with a New Trapping Model. SPE Reserv. Eval. Eng. 2000, 3, 171–178. [Google Scholar] [CrossRef]

- John, A.; Han, C.; Delshad, M.; Pope, G.A.; Sepehrnoori, K. A New Generation Chemical Flooding Simulator. SPE J. 2005, 10, 206–216. [Google Scholar] [CrossRef]

- Han, C.; Delshad, M.; Sepehrnoori, K.; Pope, G.A. A Fully Implicit, Parallel, Compositional Chemical Flooding Simulator. SPE J. 2007, 12, 322–338. [Google Scholar] [CrossRef]

- Guo, C.; Gang, Z.; Yuanle, M.A. Mathematical model of enhanced oil recovery for viscous-elastic polymer flooding. J. Tsinghua Univ. Technol. 2006, 46, 882–885. [Google Scholar]

- Zhenbo, S.; Guo, C.; Gang, S. A new mathematical model for polymer flooding. Acta Pet. Sin. 2008, 29, 409–413. [Google Scholar]

- Jing, W.; Huiqing, L.I.U.; Chaofeng, W.; Haiyang, P. Discussions on some problems about the mathematical model of polymer flooding. Acta Pet. Sin. 2011, 32, 857–861. [Google Scholar]

- Wang, J.; Liu, H.-Q.; Xu, J. Mechanistic Simulation Studies on Viscous-Elastic Polymer Flooding in Petroleum Reservoirs. J. Dispers. Sci. Technol. 2013, 34, 417–426. [Google Scholar] [CrossRef]

- Schlumberger ECLIPSE Reservoir Simulation Software Manuals. 2018.

- Dayong, C.; Yanlai, L.; Na, F.; Hua, Z.; Zhiqiang, Z. Experimental study on variation law of relative permeability curves of polymer flooding. Reserv. Eval. Dev. 2019, 9, 56–59. [Google Scholar]

- Jiang, W.; Zhang, J.; Song, K.; Tang, E.; Huang, B. Study on the surfactant/polymer combination flooding relative permeability curves in Offshore heavy oil reservoirs. In Advances in Materials and Materials Processing IV, PTS 1 and 2; Jiang, Z., Han, J., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2014; Volumes 887–888, p. 53. [Google Scholar]

- Barreau, P.; Lasseux, D.; Bertin, H.; Glenat, P.; Zaitoun, A. An experimental and numerical study of polymer action on relative permeability and capillary pressure. Pet. Geosci. 1999, 5, 201–206. [Google Scholar] [CrossRef]

- Zaitoun, A.; Kohler, N. Two-Phase Flow through Porous Media: Effect of an Adsorbed Polymer Layer. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988. [Google Scholar]

- Todd, M.R.; Longstaff, W.J. The Development, Testing, and Application Of a Numerical Simulator for Predicting Miscible Flood Performance. J. Pet. Technol. 1972, 24, 874–882. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer retention in porous media. In Polymer-Improved Oil Recovery; Sorbie, K.S., Ed.; Springer: Dordrecht, The Netherlands, 1991; pp. 126–164. [Google Scholar]

- Ruizhong, J.; Yongzheng, C.; Yong, H.; Xin, Q.; Yihua, G.; Jianchun, X. Numerical simulation of polymer flooding considering reservoir property time variation. Fault Block Oil Gas Field 2019, 26, 751–755. [Google Scholar]

| Normalized Polymer Concentration (R) | |

|---|---|

| 0 | |

| 0.24 | |

| ... | ... |

| 1 |

| Parameter | Value | Unit |

|---|---|---|

| Reservoir dimension | 300 × 300 × 10 | m |

| Grid number | 25 × 25 × 1 | - |

| Depth | 2100 | m |

| Permeability | 700 × 700 × 70 | mD |

| Porosity | 0.25 | - |

| Initial oil saturation | 83.0 | % |

| Initial water saturation | 17.0 | % |

| Oil density | 850 | kg/m3 |

| Water density | 1000 | kg/m3 |

| Oil formation volume factor | 1.16 | - |

| Water formation volume factor | 1.05 | - |

| 0.08 | - |

| Cases | Treatment of the Relative Permeability Curve in Polymer Flooding |

|---|---|

| Base Case (ECLIPSE simulator [27]) | Curve at |

| Case A | Curve at |

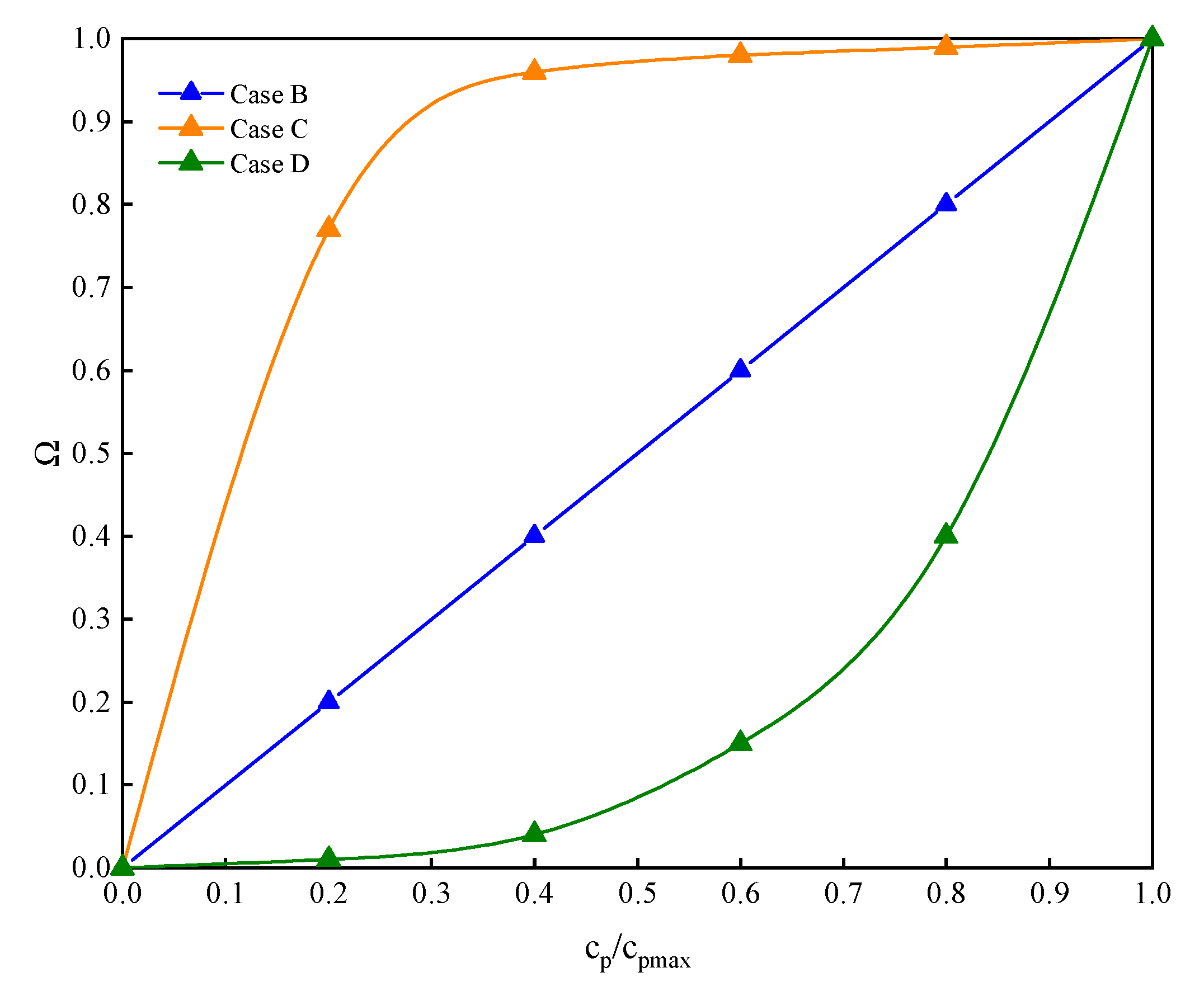

| Case B | Curve calculated by the interpolation factor |

| Case C | Curve calculated by the interpolation factor |

| Case D | Curve calculated by the interpolation factor |

| 0.00 | 0.00 | 0.00 | 0.00 |

| 0.20 | 0.20 | 0.77 | 0.01 |

| 0.40 | 0.40 | 0.96 | 0.04 |

| 0.60 | 0.60 | 0.98 | 0.15 |

| 0.80 | 0.80 | 0.99 | 0.40 |

| 1.00 | 1.00 | 1.00 | 1.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liu, X.; Meng, L.; Jiang, R.; Fan, H. The Numerical Simulation Study of the Oil–Water Seepage Behavior Dependent on the Polymer Concentration in Polymer Flooding. Energies 2020, 13, 5125. https://doi.org/10.3390/en13195125

Wang Q, Liu X, Meng L, Jiang R, Fan H. The Numerical Simulation Study of the Oil–Water Seepage Behavior Dependent on the Polymer Concentration in Polymer Flooding. Energies. 2020; 13(19):5125. https://doi.org/10.3390/en13195125

Chicago/Turabian StyleWang, Qiong, Xiuwei Liu, Lixin Meng, Ruizhong Jiang, and Haijun Fan. 2020. "The Numerical Simulation Study of the Oil–Water Seepage Behavior Dependent on the Polymer Concentration in Polymer Flooding" Energies 13, no. 19: 5125. https://doi.org/10.3390/en13195125

APA StyleWang, Q., Liu, X., Meng, L., Jiang, R., & Fan, H. (2020). The Numerical Simulation Study of the Oil–Water Seepage Behavior Dependent on the Polymer Concentration in Polymer Flooding. Energies, 13(19), 5125. https://doi.org/10.3390/en13195125