Valorization of Cynara Cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production

Abstract

1. Introduction

- Sustainability, using natural products (such as vegetable oils) or even some wastes with a difficult management (for instance, frying oils).

- Reuse of some of the by-products obtained during the process. For instance, in the case of biolubricant production, they can be used in the machineries of the biorefinery.

- Added-value by-products, depending on their degree of purity.

- High yields, in order to be as competitive and effective as other equivalent facilities used in oil industry.

- Contribution to a sustainable economic development of disadvantaged regions.

- It is the fourth largest utilized agricultural area in Spain, with 2.5·106 hectares, implying almost 11% of the total utilized agricultural area in this country [17]. This way, the use of biomass and agricultural wastes to create value-added products could be extensive in a region with such a great agricultural tradition.

- Due to its variety of agricultural production, different kinds of biorefineries could be feasible in this region, depending on the raw material they are based on. This ensures a great diversification and adaptation to different markets, making the economic development of this region stable.

- However, Extremadura region has the fifteenth (out of seventeen) gross domestic product per capita, with 18,769 € (far below national average, 25,730 €) [18]. Thus, the implementation of biorefineries could be a good way to develop poor areas in a sustainable way.

- Finally, its privileged location in the Iberian Peninsula could make the commercialization of the products manufactured possible; as it is between important industrial areas such as Lisbon, Madrid or Seville (see Figure 2). Consequently, the production of biorefineries could have business goals at a regional, national and international level, which could make the dimensioning of biorefineries variable.

2. Materials and Methods

2.1. Feedstock

2.2. Biodiesel Production

2.3. Biolubricant Production

Reaction Monitoring

2.4. Biolubricant Production Optimization

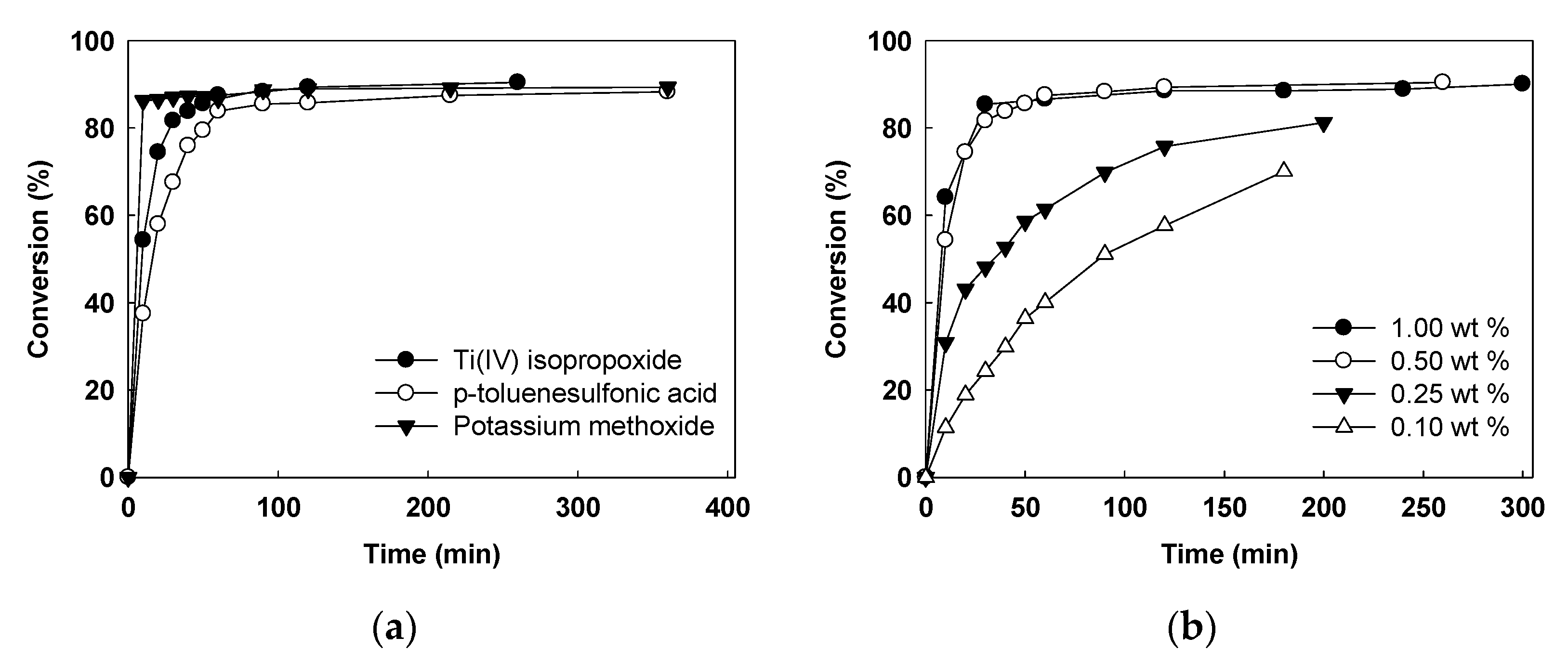

2.4.1. Influence of the Kind of Catalyst

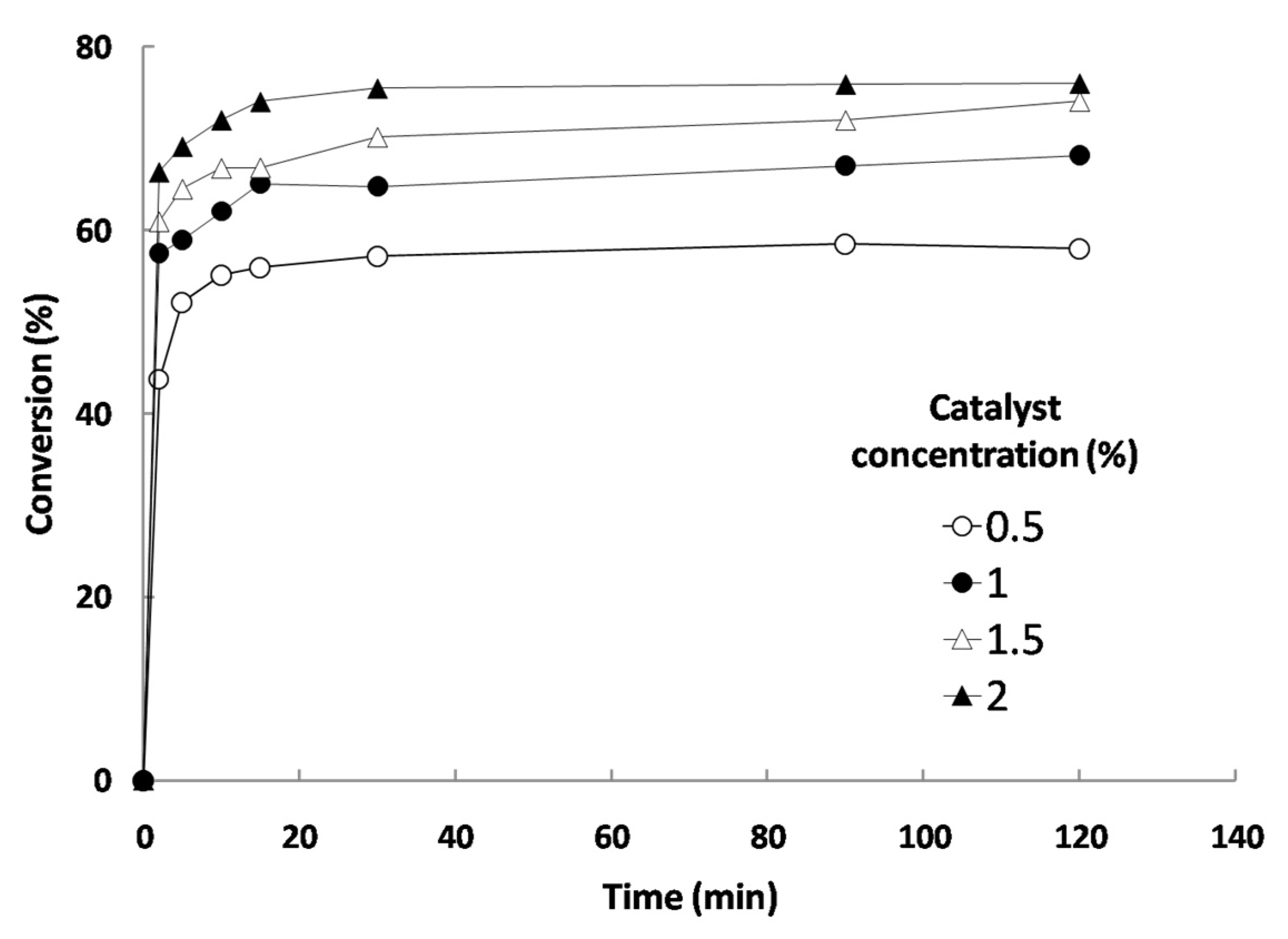

2.4.2. Influence of Catalyst Concentration

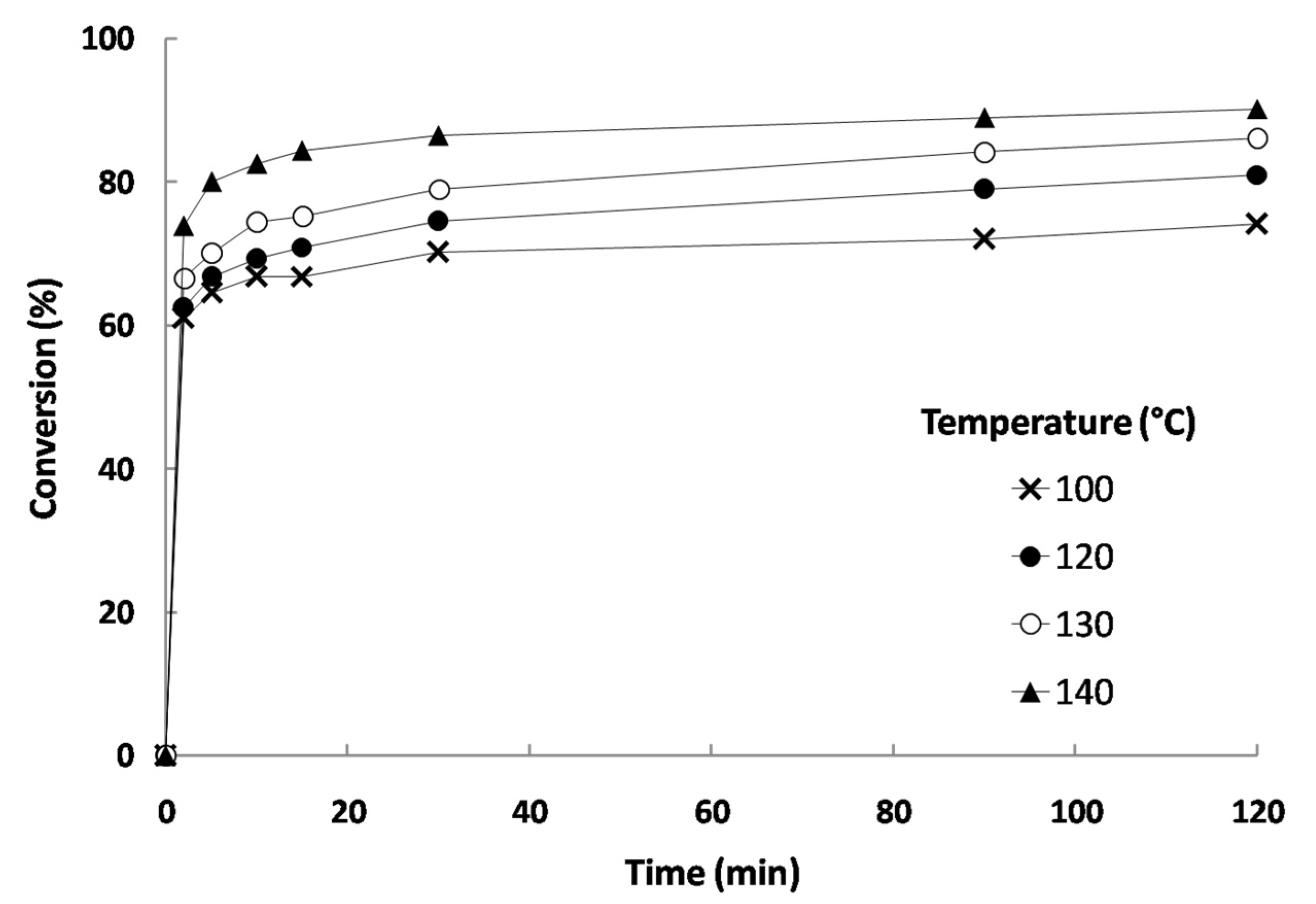

2.4.3. Influence of Temperature

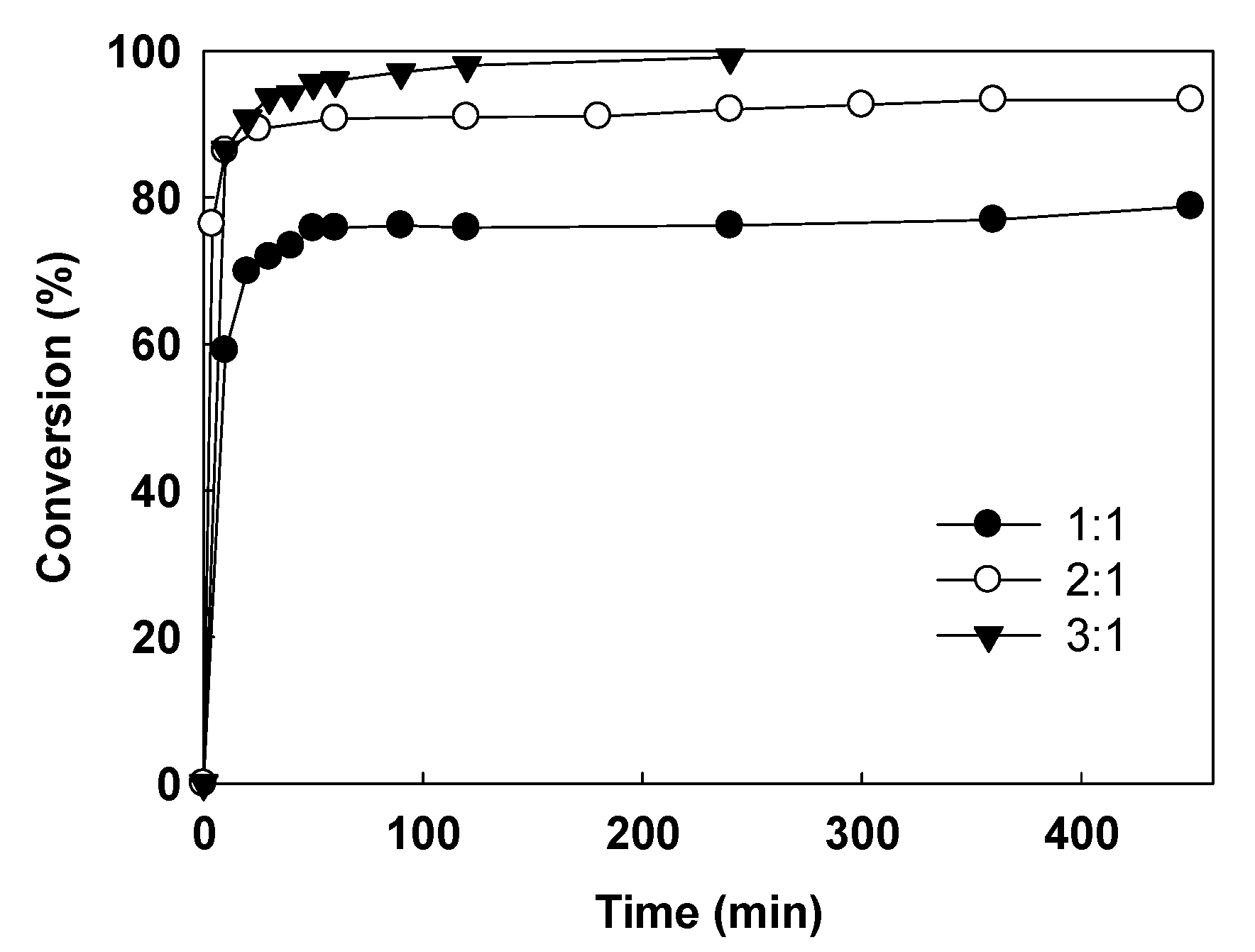

2.4.4. Influence of Alcohol/FAME Ratio

2.4.5. Influence of the Kind of Alcohol

2.5. Biolubricant Characterization

2.5.1. General Characterization

2.5.2. Viscosity and Viscosity Index

2.5.3. Oxidative Stability

2.5.4. FT-IR Analysis

3. Results and Discussion

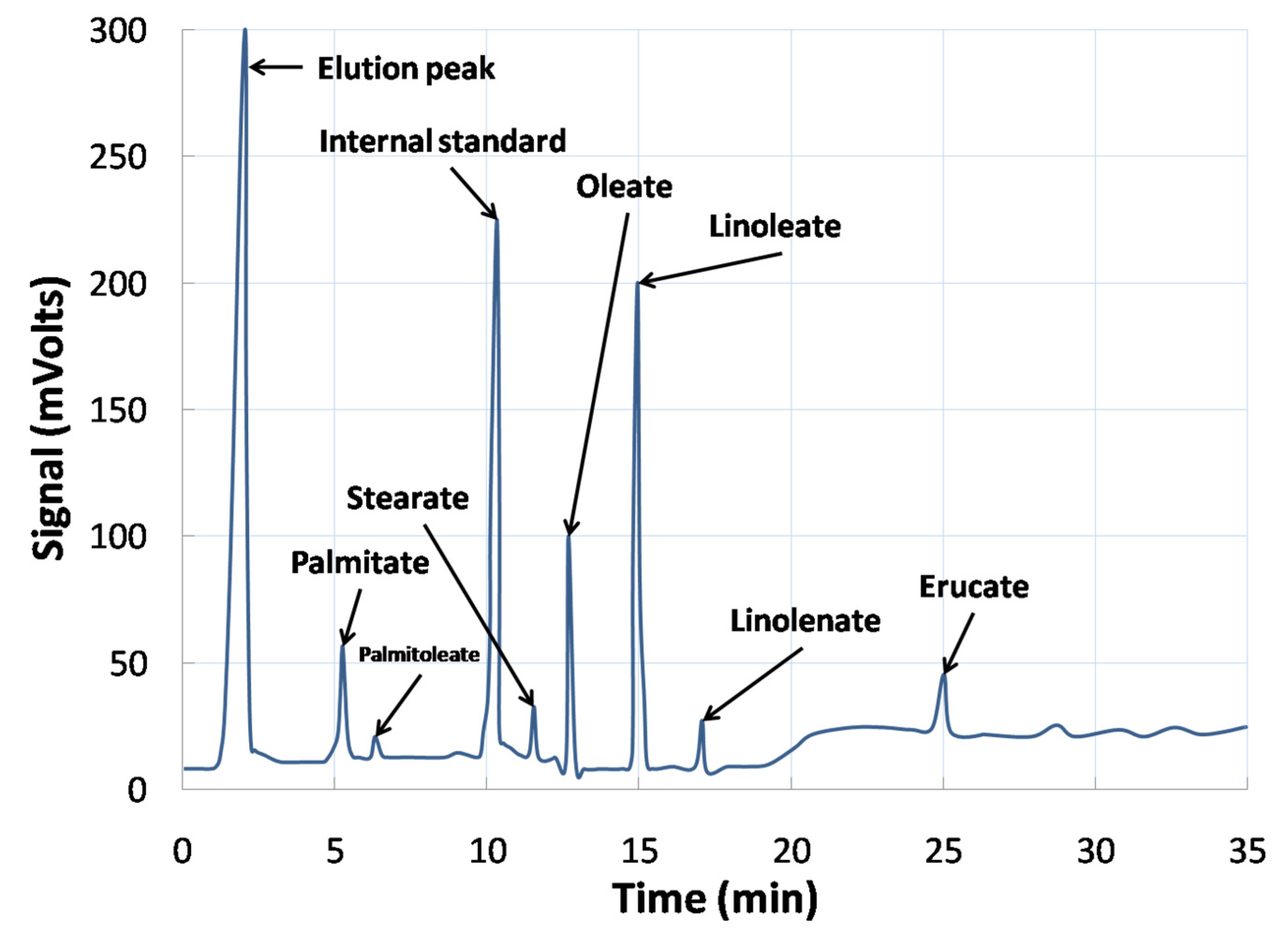

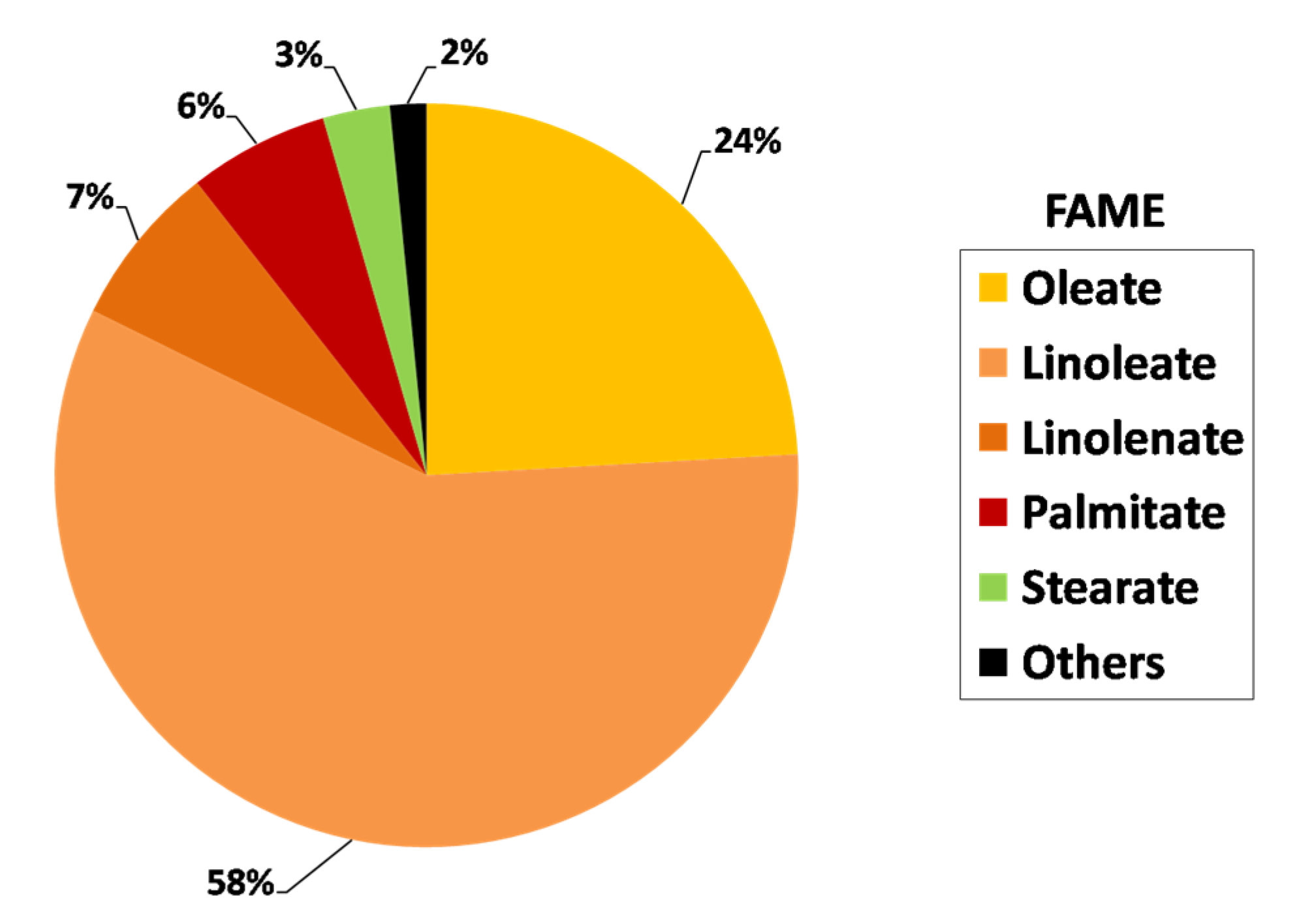

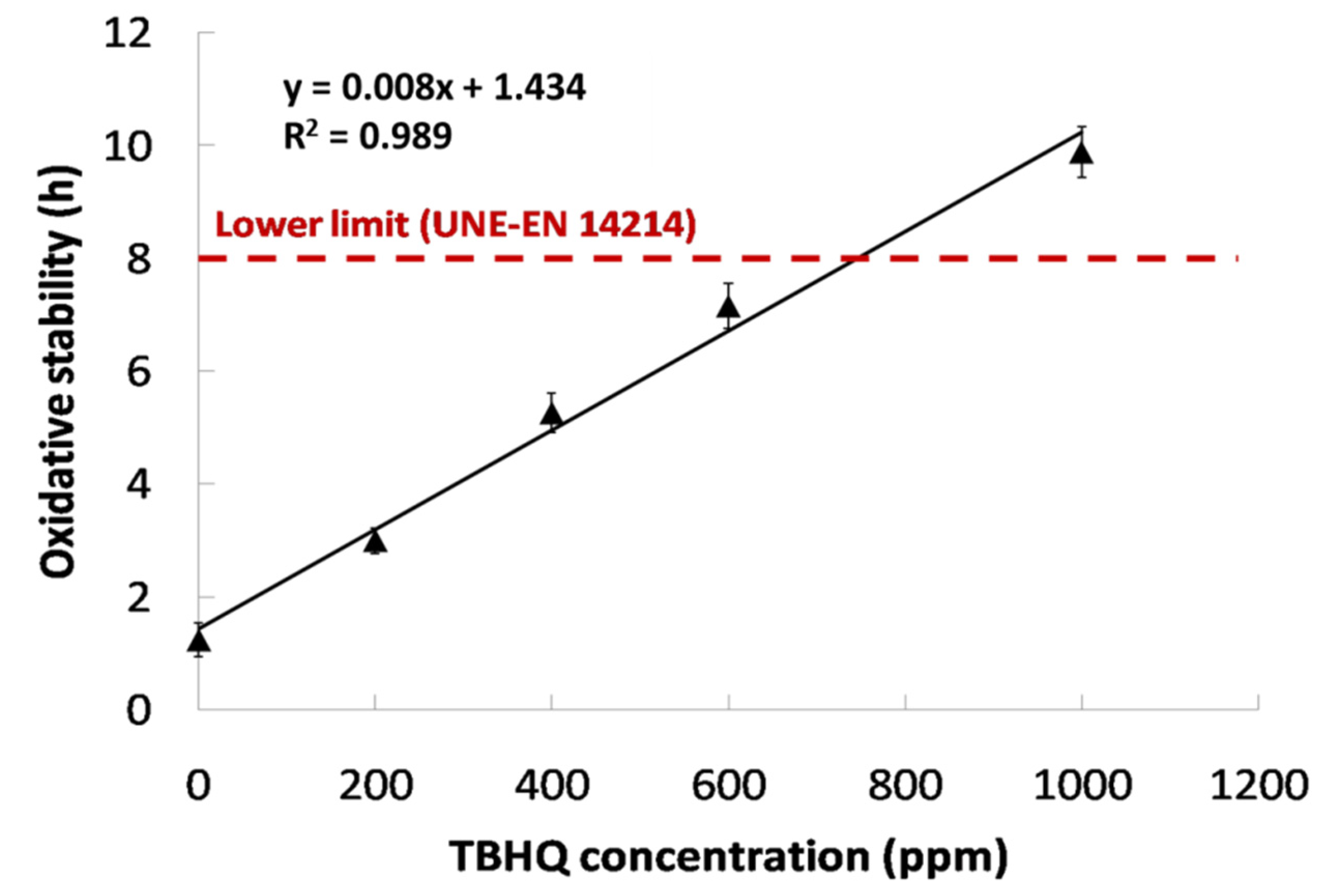

3.1. Biodiesel from Cynara Cardunculus

3.2. Biolubricant Production

3.2.1. Effect of the Kind of Catalyst and Catalyst Concentration

3.2.2. Effect of Temperature

3.2.3. Effect of Alcohol/FAME Ratio

3.3. Characteristics of the Final Biolubricant and Effect of the Kind of Alcohol Used

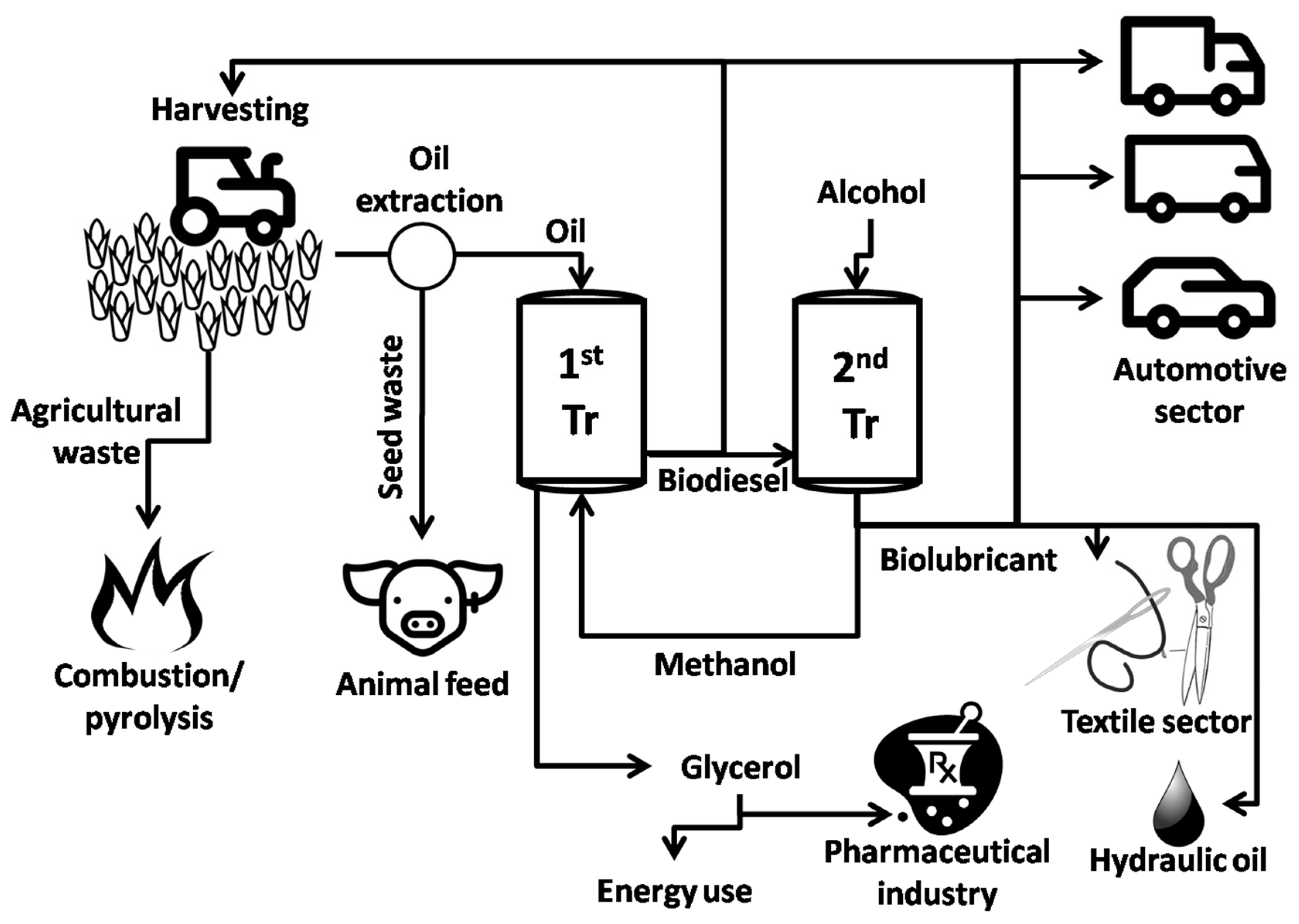

3.4. Chemical Route and Biorefinery Proposal

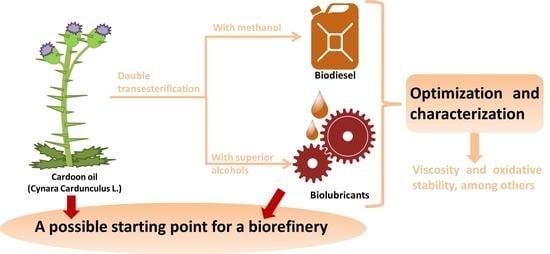

- Biodiesel and two different biolubricants were obtained by the same chemical reaction, that is, transesterification.

- As it will be explained in Figure 14, many by-products are obtained, which are valuable depending on their degree of purity.

- The main by-product obtained in the second transesterification (that is, methanol) can be reused for the first transesterification.

- The different molecular structure can explain the differences in the properties of these biolubricants, especially in the case of viscosity (see Table 3).

- The first step after harvest was oil extraction, where two main products were obtained: On one hand, the oil which is used as the raw material for biodiesel and biolubricant production; on the other hand, an interesting by-product with a great source of vegetable proteins could be used to feed farm animals.

- Afterwards, the first transesterification to obtain fatty acid methyl esters was carried out, by adding methanol and catalyst. This way, biodiesel was produced, which is one of the main products of this biorefinery. In this step, another interesting by-product was obtained, that is, glycerol (which can be more or less valuable depending on its degree of purity, for many uses, such as energy or pharmaceutical purposes [42]).

- Then, the second transesterification of fatty acid methyl esters with superior alcohols was carried out, in order to obtain biolubricants. Thus, depending on the kind of alcohol, two different biolubricants were obtained, devoted to several industrial sectors. In addition, methanol is produced as a by-product, which can be re-used in the first transesterification (which is one of the main characteristics of biorefineries: the possibility of re-using different by-products to make the process more sustainable).

- Thus, multiple value-added products (especially biodiesel and biolubricants) were obtained, which can be directly distributed and commercialized or re-used.

- Consequently, the production of biodiesel and biolubricants can be exploited by the own biorefinery, in order to fuel its machinery (such as tractors for harvesting) or to carry out maintenance tasks (biolubricant use in this kind of facilities).

- However and due to the low oxidative stability of the raw material, it was necessary to add antioxidants to both biodiesel and biolubricants, especially in order to keep their properties during storage.

4. Conclusions

- Cardoon can be a suitable starting point for the implementation of a biorefinery for biodiesel and biolubricant production. Thus, the biorefinery proposed can be easily implemented, as it requires two similar steps (that is, two successive transesterification reactions of the oil or FAME with different alcohols), which simplifies the facilities required for this purpose.

- Concerning the first transesterification, where biodiesel is produced, the quality of this biofuel was acceptable, requiring the use of antioxidants to improve its oxidative stability due to the high content of methyl linoleate.

- Regarding the second transesterification, where biolubricants are produced, high yields of them were obtained, which makes their production feasible at reasonable conditions (including temperature and catalyst concentration). Also, there was a wide range of properties covered by these biolubricants, especially for viscosity, whose values were clearly different depending on the alcohol used for biolubricant production. Consequently, their use can be diverse. Moreover, the low acid number and the high flash and combustion points make these products suitable for storage and shipping.

- The main reaction conditions were studied and their effect on ester conversion was analyzed. Ti(IV) isopropoxide showed the most appropriated characteristics to be used as catalyst in this process. Catalyst concentration, temperature and HE:ME molar ratio showed positive effects on the conversion of the reaction. In the case of biolubricant production with 2-ethyl-1-hexanol, the total conversion was obtained with 1% wt Ti(IV) isopropoxide, 3:1 molar ratio and 160 °C. For the biolubricant production with 2,2-dimethyl-1,3-propanediol, the optimum chemical conditions were: 1.5% wt Ti(IV) isopropoxide, 1:1 molar ratio and 130 °C.

- The characteristics of the raw material, especially the fatty acid profile of vegetable oils, played an important role on the performance of the final products, including biodiesel and biolubricants, especially concerning oxidative stability.

- The wide variety of products obtained, including some intermediate products such as biodiesel, glycerol and methanol, makes the diversification of this kind of industry easier, varying the production depending on the specific demand. Moreover, most of these products can be re-used in the same biorefinery.

- For further studies, the use of natural antioxidants or genetically modified raw materials, when required, should be taken into account, in order to make the process more sustainable.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lathi, P.S.; Mattiasson, B. Green approach for the preparation of biodegradable lubricant base stock from epoxidized vegetable oil. Appl. Catal. B Environ. 2007, 69, 207–212. [Google Scholar] [CrossRef]

- Nagendramma, P.; Kaul, S. Development of ecofriendly/biodegradable lubricants: An overview. Renew. Sustain. Energy Rev. 2012, 16, 764–774. [Google Scholar] [CrossRef]

- do Valle, C.P.; Rodrigues, J.S.; Fechine, L.M.U.D.; Cunha, A.P.; Queiroz Malveira, J.; Luna, F.M.T.; Ricardo, N.M.P.S. Chemical modification of Tilapia oil for biolubricant applications. J. Clean. Prod. 2018, 191, 158–166. [Google Scholar] [CrossRef]

- Vitiello, R.; Tesser, R.; Russo, V.; Turco, R.; Andini, S.; Di Serio, M. Loop reactor modeling for lubricants synthesis. Chem. Eng. J. 2017, 329, 295–304. [Google Scholar] [CrossRef]

- McNutt, J.; He, Q.S. Development of biolubricants from vegetable oils via chemical modification. J. Ind. Eng. Chem. 2016, 36, 1–12. [Google Scholar] [CrossRef]

- Chen, J.; Bian, X.; Rapp, G.; Lang, J.; Montoya, A.; Trethowan, R.; Bouyssiere, B.; Portha, J.F.; Jaubert, J.N.; Pratt, P.; et al. From ethyl biodiesel to biolubricants: Options for an Indian mustard integrated biorefinery toward a green and circular economy. Ind. Crop. Prod. 2019, 137, 597–614. [Google Scholar] [CrossRef]

- Gominho, J.; Curt, M.D.; Lourenço, A.; Fernández, J.; Pereira, H. Cynara cardunculus L. as a biomass and multi-purpose crop: A review of 30 years of research. Biomass Bioenergy 2018, 109, 257–275. [Google Scholar] [CrossRef]

- Francaviglia, R.; Bruno, A.; Falcucci, M.; Farina, R.; Renzi, G.; Russo, D.E.; Sepe, L.; Neri, U. Yields and quality of Cynara cardunculus L. wild and cultivated cardoon genotypes. A case study from a marginal land in Central Italy. Eur. J. Agron. 2016, 72, 10–19. [Google Scholar] [CrossRef]

- Oliveira, I.; Gominho, J.; Diberardino, S.; Duarte, E. Characterization of Cynara cardunculus L. stalks and their suitability for biogas production. Ind. Crop. Prod. 2012, 40, 318–323. [Google Scholar] [CrossRef]

- Raccuia, S.A.; Melilli, M.G. Biomass and grain oil yields in Cynara cardunculus L. genotypes grown in a Mediterranean environment. Field Crop. Res. 2007, 101, 187–197. [Google Scholar] [CrossRef]

- Curt, M.D.; Sánchez, G.; Fernández, J. The potential of Cynara cardunculus L. for seed oil production in a perennial cultivation system. Biomass Bioenergy 2002, 23, 33–46. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesca y Alimentación. Cultivo del Cardo. Available online: https://www.mapa.gob.es/ministerio/pags/biblioteca/hojas/hd_1986_12.pdf (accessed on 14 July 2020).

- Ciancolini, A.; Alignan, M.; Pagnotta, M.A.; Vilarem, G.; Crinò, P. Selection of Italian cardoon genotypes as industrial crop for biomass and polyphenol production. Ind. Crop. Prod. 2013, 51, 145–151. [Google Scholar] [CrossRef]

- Manaf, I.S.A.; Embong, N.H.; Khazaai, S.N.M.; Rahim, M.H.A.; Yusoff, M.M.; Lee, K.T.; Maniam, G.P. A review for key challenges of the development of biodiesel industry. Energy Convers. Manag. 2019, 185, 508–517. [Google Scholar] [CrossRef]

- Moncada, B.J.; Aristizábal, M.V.; Cardona, A.C.A. Design strategies for sustainable biorefineries. Biochem. Eng. J. 2016, 116, 122–134. [Google Scholar] [CrossRef]

- Pinheiro Pires, A.P.; Arauzo, J.; Fonts, I.; Domine, M.E.; Fernández Arroyo, A.; Garcia-Perez, M.E.; Montoya, J.; Chejne, F.; Pfromm, P.; Garcia-Perez, M. Challenges and Opportunities for Bio-oil Refining: A Review. Energy Fuels. 2019, 33, 4683–4730. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica y el Reto Demográfico. Superficie Agraria Útil. Available online: miteco.gob.es (accessed on 14 August 2020).

- Instituto Nacional de Estadística. Producto Interior Bruto de España. Available online: https://www.ine.es/dyngs/INEbase/es/operacion.htm?c=Estadistica_C&cid=1254736167628&menu=resultados&idp=1254735576581#!tabs-1254736158133 (accessed on 14 August 2020).

- UNE-EN-12634:1999. Productos Petrolíferos y Lubricantes. Determinación del Índice de Ácido. Método de Valoración Potenciométrica en un Medio no Acuoso; Asociación Española de Normalización: Madrid, Spain, 1999. [Google Scholar]

- Martínez, G.; Sánchez, N.; Encinar, J.M.; González, J.F. Fuel properties of biodiesel from vegetable oils and oil mixtures. Influence of methyl esters distribution. Biomass Bioenergy 2014, 63, 22–32. [Google Scholar]

- Nogales-Delgado, S.; Encinar, J.M.; Guiberteau, A.; Márquez, S. The Effect of Antioxidants on Corn and Sunflower Biodiesel Properties under Extreme Oxidation Conditions. JAOCS J. Am. Oil Chem. Soc. 2019, 97, 201–212. [Google Scholar] [CrossRef]

- 14214:2013, U.-E. Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Biodiesel Engines and Heating Applications—Requirements and Test Methods. Available online: https://infostore.saiglobal.com/preview/98708742874.pdf?sku=2013 (accessed on 14 August 2020).

- UNE-EN-ISO 3675. Crude Petroleum and Liquid Petroleum Products. Laboratory Determination of Density. Hydrometer Method; Asociación Española de Normalización: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 116:2015. Diesel and Domestic Heating Fuels—Determination of Cold Filter Plugging Point-Stepwise Cooling Bath Method; Asociación Española de Normalización: Madrid, Spain, 2015. [Google Scholar]

- UNE-EN 51023:1990. Petroleum Products. Determination of Flash and Fire Points. Cleveland Open Cup Method; Asociación Española de Normalización: Madrid, Spain, 1990. [Google Scholar]

- UNE-EN-ISO-12937:2000. Productos Petrolíferos. Determinación de Agua. Método de Karl Fischer por Valoración Culombimétrica; Asociación Española de Normalización: Madrid, Spain, 2001. [Google Scholar]

- UNE-EN 14111:2003. Fat and Oil Derivatives. Fatty Acid Methyl Esters (FAME). Determination of Iodine Value; Asociación Española de Normalización: Madrid, Spain, 2003. [Google Scholar]

- UNE-EN ISO 3104/AC:1999. Petroleum Products. Transparent and Opaque Liquids. Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity (ISO 3104:1994); Asociación Española de Normalización: Madrid, Spain, 1999. [Google Scholar]

- ASTM-D2270-10. Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C; American Society for Testing and Materials: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Focke, W.W.; Van Der Westhuizen, I.; Oosthuysen, X. Biodiesel oxidative stability from Rancimat data. Thermochim. Acta 2016, 633, 116–121. [Google Scholar] [CrossRef]

- Saluja, R.K.; Kumar, V.; Sham, R. Stability of biodiesel—A review. Renew. Sustain. Energy Rev. 2016, 62, 866–881. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales-Delgado, S.; Sánchez, N.; González, J.F. Biolubricants from rapeseed and castor oil transesterification by using titanium isopropoxide as a catalyst: Production and characterization. Catalysts 2020, 10, 366. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales, S.; González, J.F. Biorefinery based on different vegetable oils: Characterization of biodiesel and biolubricants. In Proceedings of the 3rd International Conference in Engineering Applications (ICEA), Azores, Island, 8–11 July 2019. [Google Scholar]

- McCormick, R.L.; Westbrook, S.R. Storage stability of biodiesel and biodiesel blends. Energy Fuels 2010, 24, 690–698. [Google Scholar] [CrossRef]

- Varatharajan, K.; Pushparani, D.S. Screening of antioxidant additives for biodiesel fuels. Renew. Sustain. Energy Rev. 2018, 82, 2017–2028. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. Safflower Biodiesel: Improvement of its Oxidative Stability by using BHA and TBHQ. Energies 2019, 12, 1940. [Google Scholar] [CrossRef]

- Uğuz, G.; Atabani, A.E.; Mohammed, M.N.; Shobana, S.; Uğuz, S.; Kumar, G.; Al-Muhtaseb, A.H. Fuel stability of biodiesel from waste cooking oil: A comparative evaluation with various antioxidants using FT-IR and DSC techniques. Biocatal. Agric. Biotechnol. 2019, 21, 101283. [Google Scholar] [CrossRef]

- Zhou, J.; Xiong, Y.; Liu, X. Evaluation of the oxidation stability of biodiesel stabilized with antioxidants using the Rancimat and PDSC methods. Fuel 2017, 188, 61–68. [Google Scholar] [CrossRef]

- Salimon, J.; Salih, N.; Yousif, E. Biolubricants: Raw materials, chemical modifications and environmental benefits. Eur. J. Lipid Sci. Technol. 2010, 112, 519–530. [Google Scholar] [CrossRef]

- Mobarak, H.M.; Niza Mohamad, E.; Masjuki, H.H.; Kalam, M.A.; Al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Mumtaz, M.W.; Adnan, A.; Anwar, F.; Mukhtar, H.; Raza, M.A.; Ahmad, F.; Rashid, U. Response surface methodology: An emphatic tool for optimized biodiesel production using rice bran and sunflower oils. Energies 2012, 5, 3307–3328. [Google Scholar] [CrossRef]

- Sánchez, N.; Encinar, J.M.; González, J.F. Sorption Enhanced Steam Reforming of Glycerol: Use of La-Modified Ni/Al2O3 as Catalyst. Ind. Eng. Chem. Res. 2016, 55, 3736–3741. [Google Scholar] [CrossRef]

| Alcohol Used | 2-ethyl-1-hexanol | 2,2-dimethyl-1,3-propanediol |

|---|---|---|

| Molecular structure |  |  |

| Melting point (°C) | −76 | 128 |

| Boiling point (°C) | 183–186 | 210 |

| Auto-ignition temperature (°C) | 288 | 399 |

| Density at 25 °C (g·mL−1) | 0.833 | 1.042 |

| Vapor pressure (mmHg at 20 °C) | 0.2 | <0.8 |

| Characteristic | Cardoon Biodiesel | UNE-EN 14214 |

|---|---|---|

| Fatty Acid Methyl Ester, % | 96.92 | 96.5 * |

| Density at 15 °C, mg·mL−1 | 879 | 860–900 |

| Viscosity at 40 °C, cSt | 4.179 | 3.5–5 |

| Moisture, % | 0.03 | 0.05 ** |

| Acid number (mg KOH·g−1) | 0.2048 | 0.5 ** |

| Iodine value (gI2·100 g−1) | 118.2 | 120 ** |

| Flash point, °C | 178 | 120 * |

| Combustion point, °C | 198 | -- |

| Cold filter plugging point, °C | −1 | −20–+5 |

| Oxidative stability 1, h | 1.35 | 8 * |

| Alcohol Used 1 | 2-ethyl-1-hexanol | 2,2-dimethyl-1,3-propanediol |

|---|---|---|

| Temperature, °C | 160 | 130 |

| Molar ratio | 3:1 | 1:1 |

| Catalyst concentration, % | 1 | 1.5 |

| Conversion 2, % | 99.1 | 92.76 |

| Viscosity at 40 °C, cSt | 8.6 | 18.85 |

| Viscosity at 100 °C, cSt | 3.1 | 4.29 |

| Viscosity index | 276 | 138 |

| Acid value, mg KOH·g−1 | 0.7 | 0.3 |

| Flash point, °C | 178 | 193 |

| Combustion point, °C | 188 | 204 |

| Oxidative stability, min | 88 | 163 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogales-Delgado, S.; Sánchez, N.; Encinar, J.M. Valorization of Cynara Cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production. Energies 2020, 13, 5085. https://doi.org/10.3390/en13195085

Nogales-Delgado S, Sánchez N, Encinar JM. Valorization of Cynara Cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production. Energies. 2020; 13(19):5085. https://doi.org/10.3390/en13195085

Chicago/Turabian StyleNogales-Delgado, Sergio, Nuria Sánchez, and José María Encinar. 2020. "Valorization of Cynara Cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production" Energies 13, no. 19: 5085. https://doi.org/10.3390/en13195085

APA StyleNogales-Delgado, S., Sánchez, N., & Encinar, J. M. (2020). Valorization of Cynara Cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production. Energies, 13(19), 5085. https://doi.org/10.3390/en13195085