An Analysis of the Current Status of Woody Biomass Gasification Power Generation in Japan

Abstract

1. Introduction

1.1. The Current State of Japanese Woody Biomass

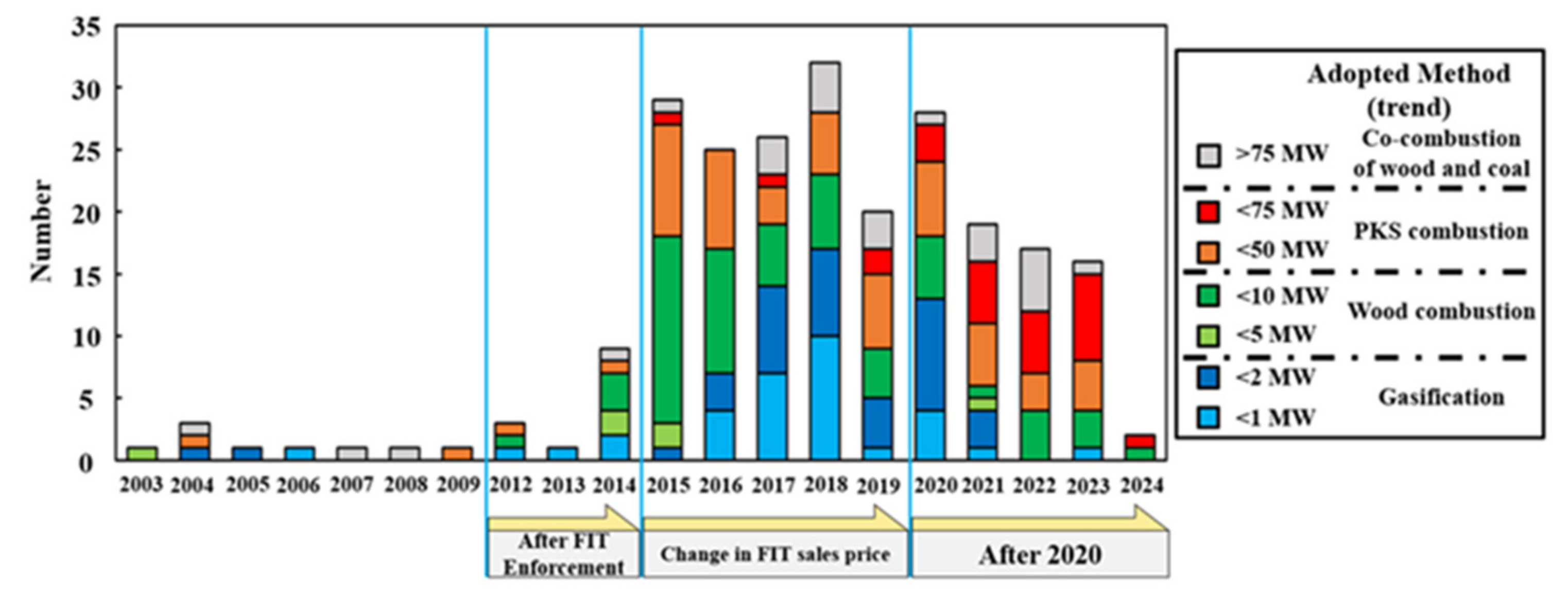

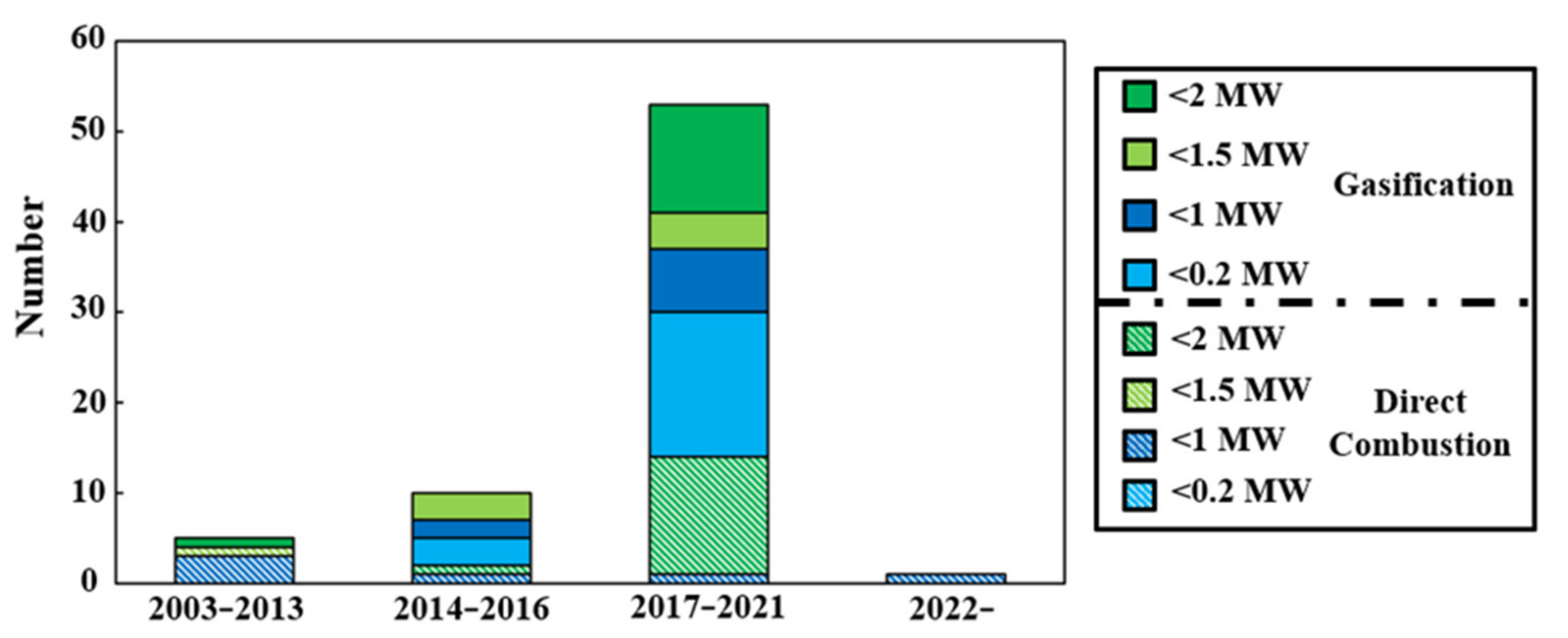

1.2. The Creation of Japanese Woody Biomass Power Generation Projects Database and Trend Analysis

2. Materials and Methods

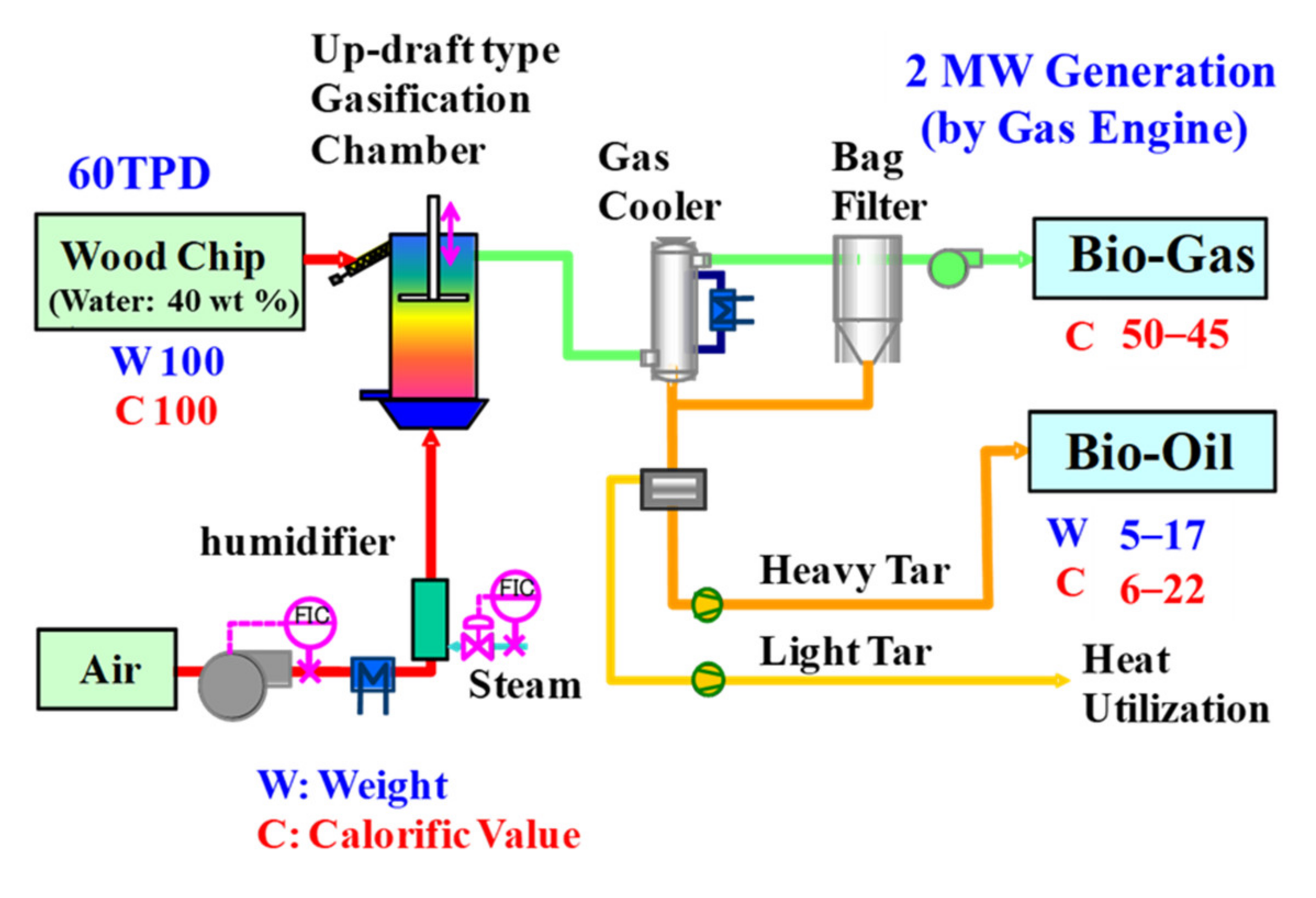

2.1. Gasification and Bio-Oil Coproduction System of a 2 MW Updraft Reactor

2.2. The Measurement Evaluation of 0.36 MW Small-Scale Gasification Power Generation Plant

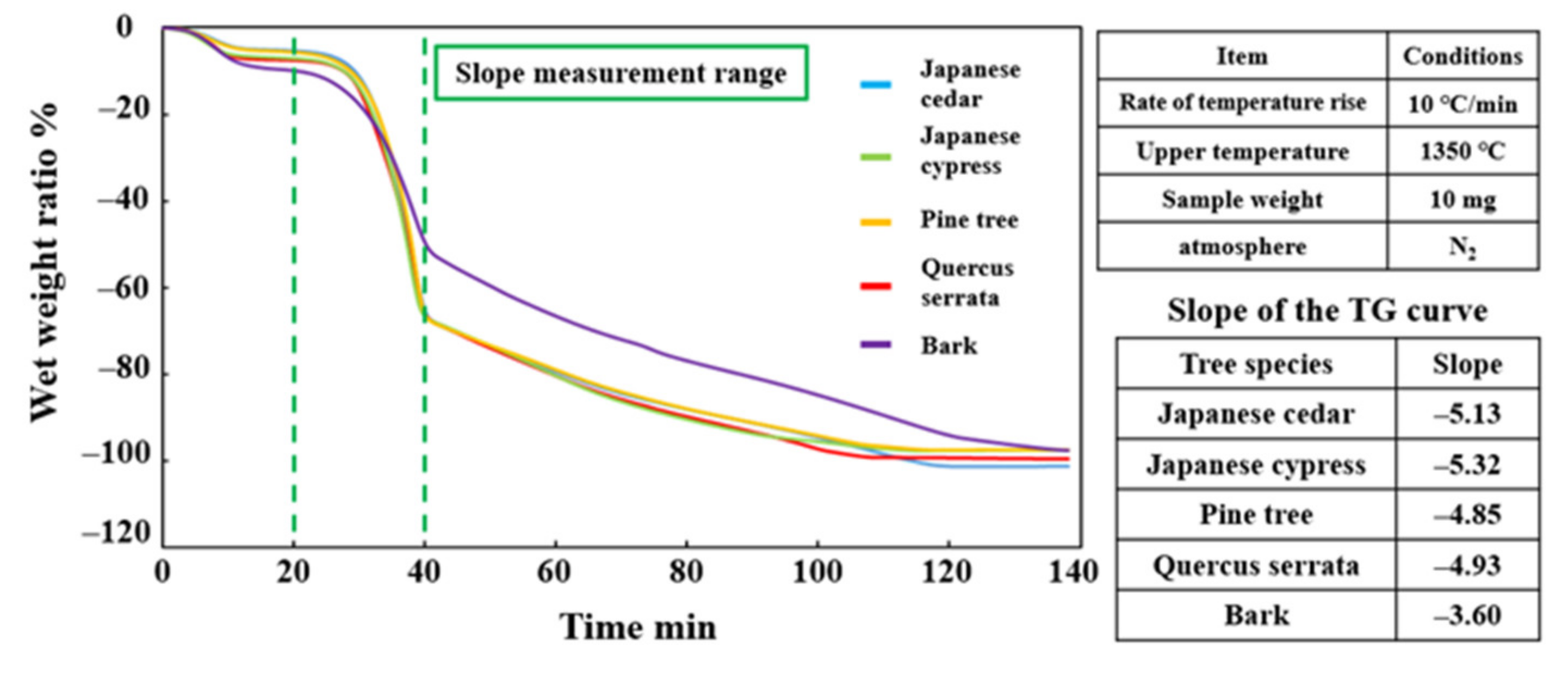

2.3. Pyrolysis Characteristics of Japanese Tree Species

3. Results and Discussion

3.1. Gasification and Bio-Oil Coproduction System of a 2 MW Updraft Reactor

- Notably, 2 MW-scale power generation requires 60–70 TPD of wood chips, and it was found that it would be difficult to collect them at Chichibu City.

- There was no engineering, procurement, and construction (EPC) service provider that could construct the plant. This was, in part, because most plant manufacturers had to prioritize receiving orders for large-scale, direct combustion projects at that time.

- At that time, the energy input of solar light power generation drastically increased due to FIT, and restrictions on system interconnection started to emerge.

- The issues with this system are that initial running costs for the gas engine are high, and a treatment process for light tar is required. The cost of the gas engine had to be covered by the FIT sales price, but no specific measures regarding light tar treatment could be found.

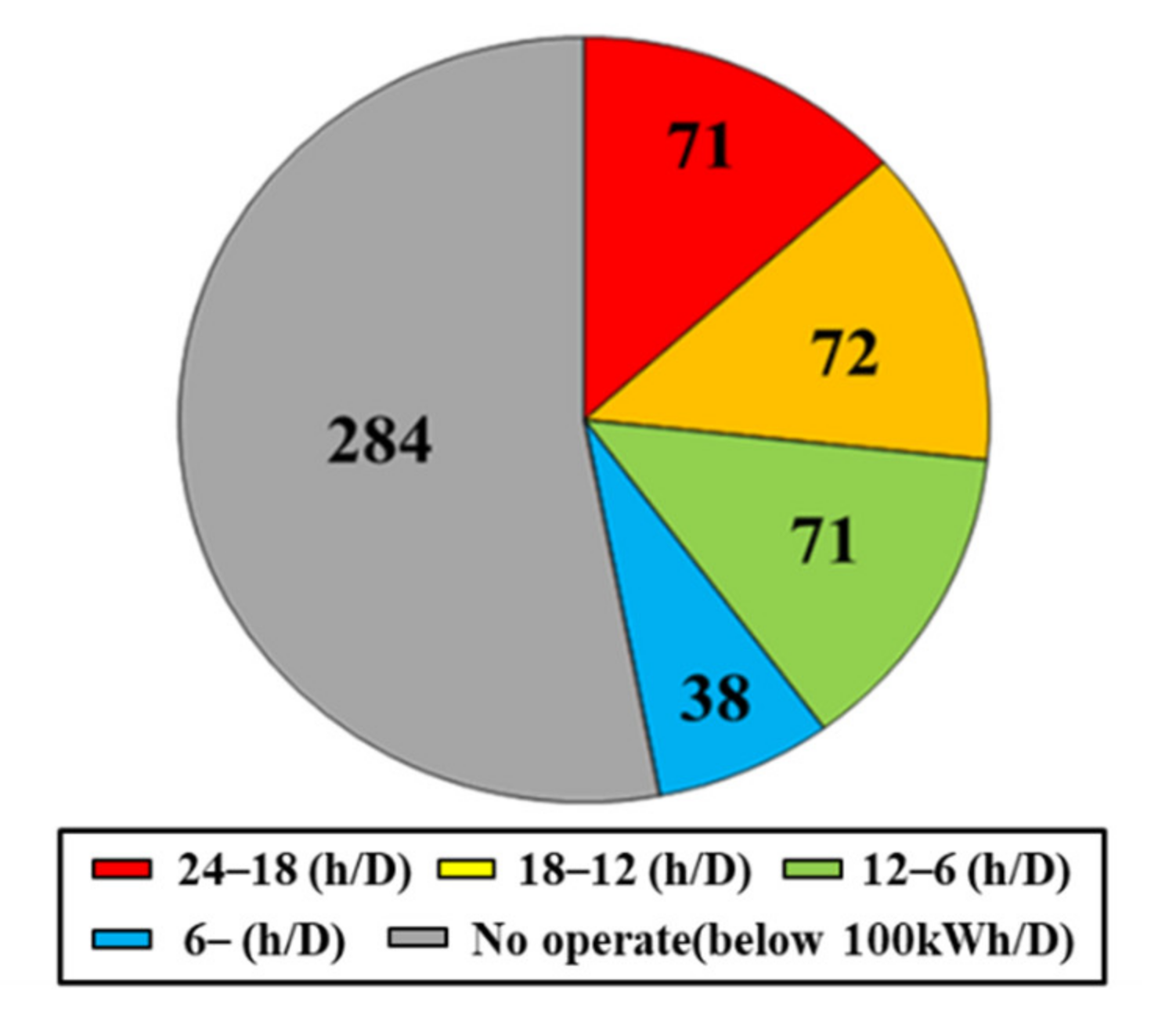

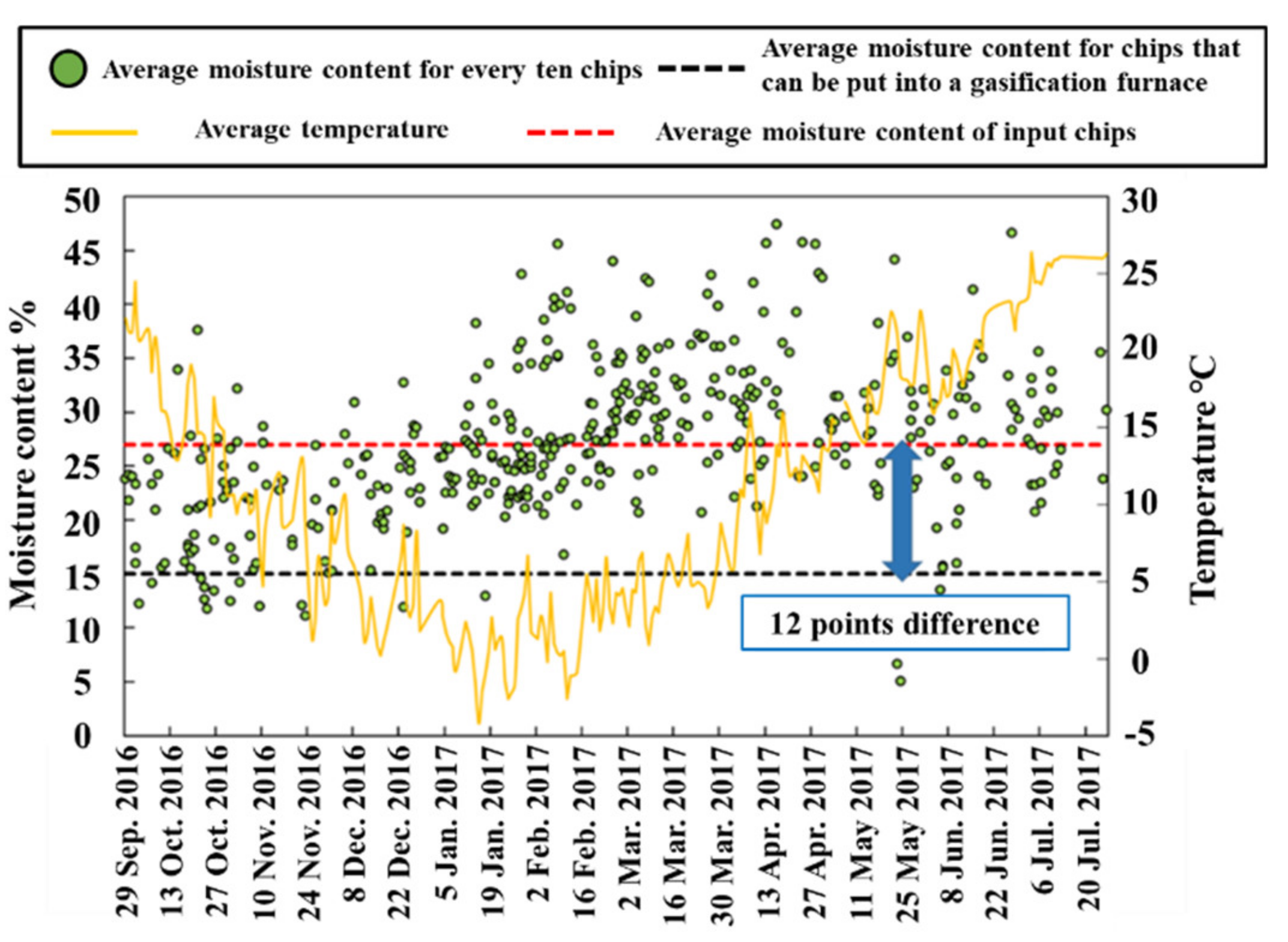

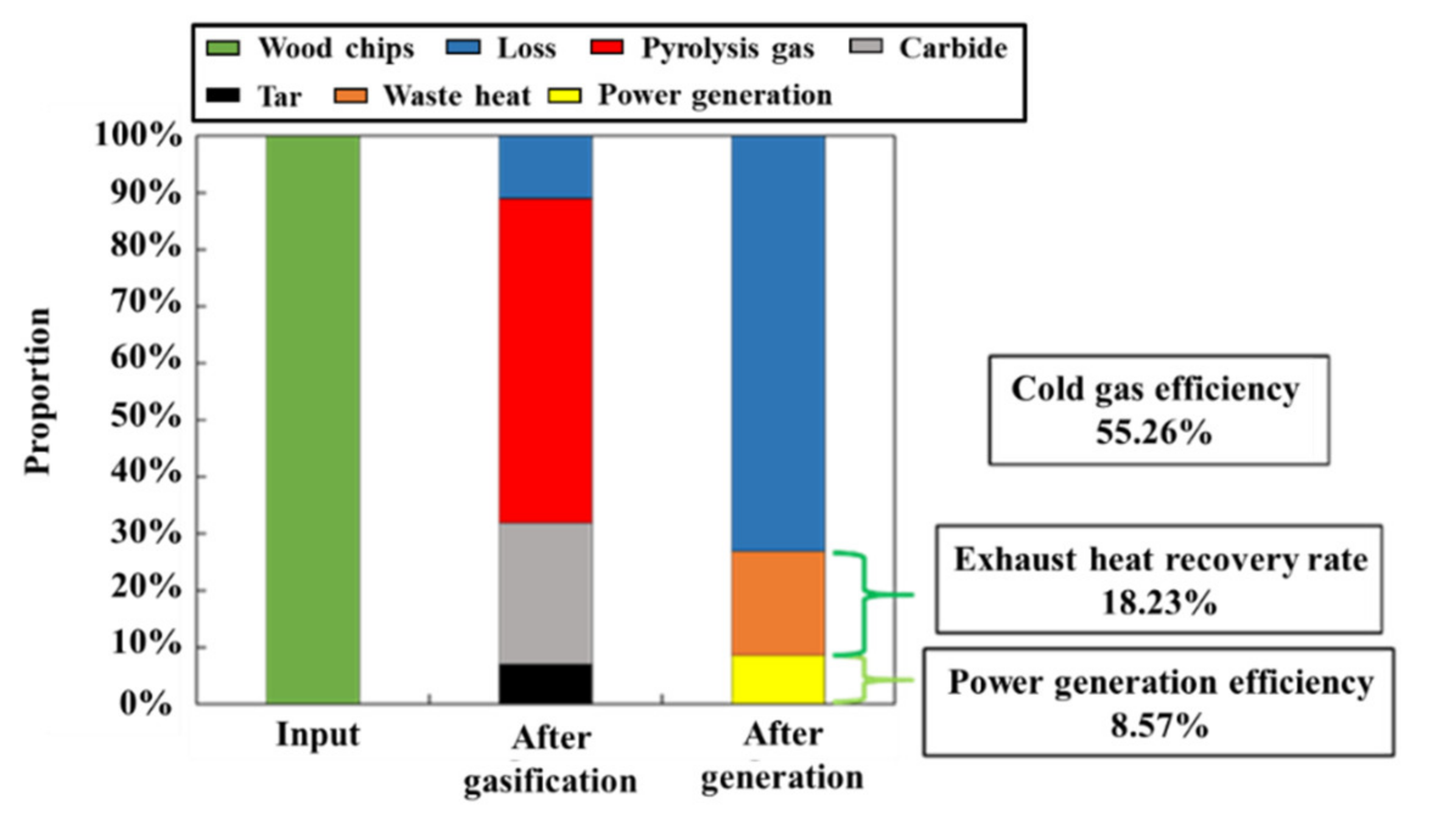

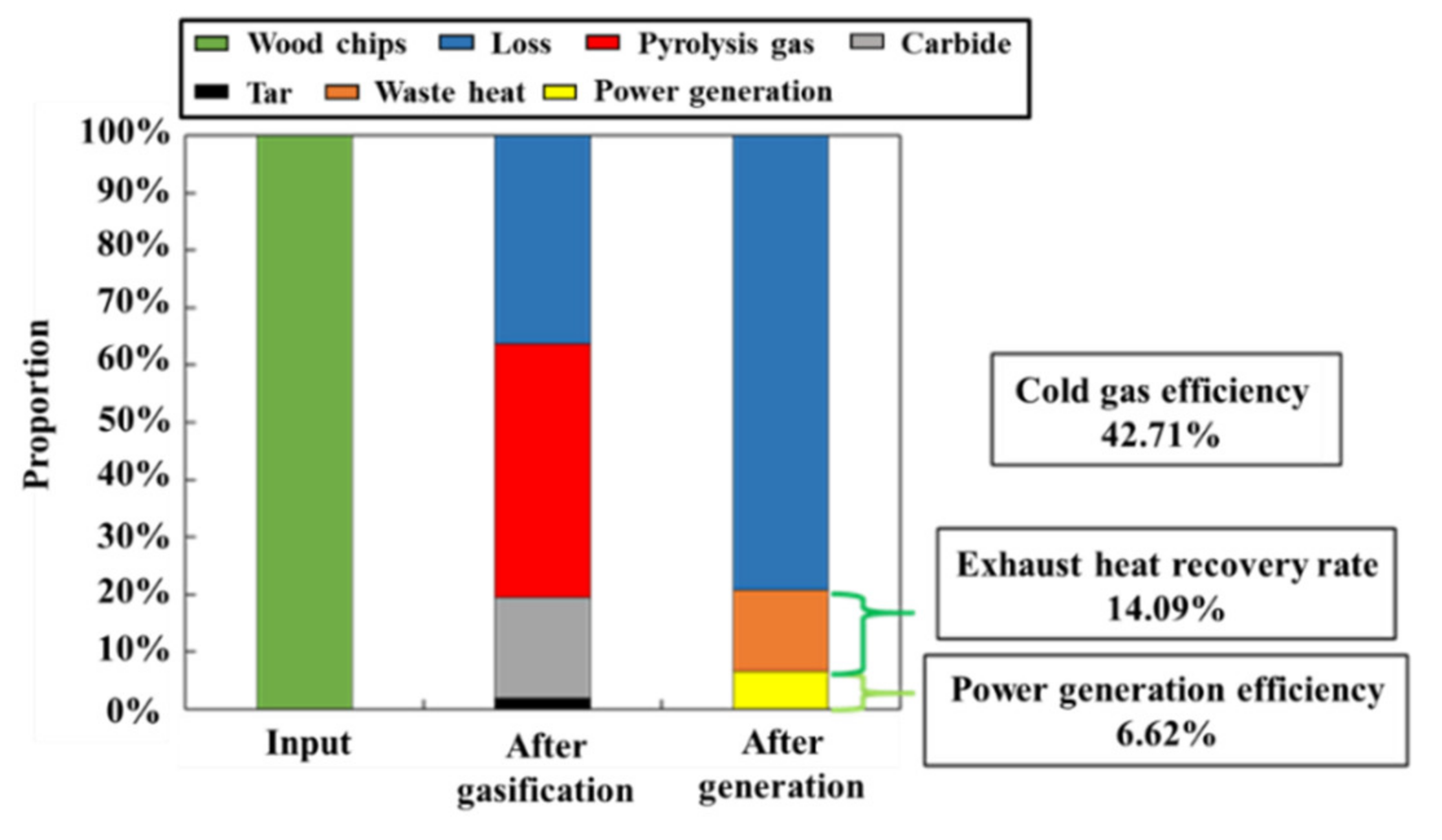

3.2. The Measurement Evaluation of 0.36 MW Small-Scale Gasification Power Generation Plant

3.3. Pyrolysis Characteristics of Japanese Tree Species

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakamura, R.; Shiba, H.; Matsumoto, A. Price Formation and Regional Economic of Wooden Biomass Energy. Stud. Reg. Sci. 2013, 43, 429–449. [Google Scholar] [CrossRef]

- Matsuda, S. What is the Really Effective Biomass Utilization? J. Soc. Environ. Stud. 2011, 24, 493–502. [Google Scholar]

- Aikawa, T. Recommendations for Woody Biomass Power Generation under FIT—For the Realization of a Sustainable Use of Bioenergy; Renewable Energy Institute: Tokyo, Japan, 2016; pp. 1–12. [Google Scholar]

- Sasauchi, K.; Horio, M. Technology strategy of small-scale biomass CHP of post-feed in Tariffs. In Proceedings of the 2019 Biomass Science Conference, Fukushima, Japan, 11–13 December 2019; pp. 9–10. [Google Scholar]

- Komada, T. Outline and Future Perspective of Ultra-small Biomass Power Generator Volter 40. Nihon Enerugii Gakkai Kikanshi Enermix 2017, 96, 802–808. [Google Scholar]

- Sérgio, F.; Eliseu, M.; Luís, C.; Valter, S.; Paulo, B.; Cândida, V. Experimental and Modeling Analysis of Brewers’ Spent Grains Gasification in a Downdraft Reactor. Energies 2019, 12, 4413. [Google Scholar]

- Famoso, F.; Prestipino, M.; Brusca, S.; Galvagno, A. Designing sustainable bioenergy from residual biomass: Site allocation criteria and energy/exergy performance indicators. Appl. Energy 2020, 274, 1–17. [Google Scholar] [CrossRef]

- Nakagawa, H. Operational Status of the First Unit in Japan by the Gasification CHP with Wood Biomass Pellet as Fuel; The Japan Institute of Energy: Tokyo, Japan, 2016; pp. 102–103. [Google Scholar]

- Gabriele, C.; Paolo, D.; Claudia, B.; Simone, M.; Enrico, M.; Michele, M.; Alberto, P. Syngas Production, Clean-Up and Wastewater Management in a Demo-Scale Fixed-Bed Updraft Biomass Gasification Unit. Energies 2020, 13, 2594. [Google Scholar]

- Hoshi, A.; Akazawa, T.; Wakashima, S.; Fujimoto, I.; Kikuoka, Y. Study on waste heat recovery from exhaust Smoke in Co-Generation System Using Woody Biomass Fuels. Trans. Jpn. Soc. Mech. Eng. 2011, 77, 334–343. [Google Scholar]

- Endo, M.; Nagase, H.; Yokomaku, H. Characterization of Tar Cracking Tendency under Each Operating Condition through Downdraft Gasifier of Woody Biomass; The Japan Institute of Energy: Fukuoka, Japan, 2007; pp. 164–165. [Google Scholar]

- Morita, A. Investigation of Prediction Method and Fundamental Thermo-decomposition Properties on Gasification of Woody Biomass. J. High Temp. Soc. 2009, 35, 85–90. [Google Scholar] [CrossRef]

- Kurosawa, K.; Iwasaki, T.; Sato, M.; Koido, K. Pyrolysis and gasification characteristics of Erianthus blended woody fuel for a domestic stable biomass supply. In Proceedings of the 2019 Biomass Science Conference, Hiroshima, Japan, 16–17 January 2019; pp. 61–62. [Google Scholar]

- Yamasaki, Y. Biomass Gasification Power Generation Technology in Europe. J. Jpn. Inst. Energy 2005, 84, 1019–1025. [Google Scholar] [CrossRef][Green Version]

- Sasauchi, K.; Iguchi, J.; Horio, M. Quantification of Fuel Standards for Biomass Gasification Power Generation. In Proceedings of the 2019 Biomass Science Conference, Hiroshima, Japan, 16–17 January 2019; pp. 5–6. [Google Scholar]

- Okuyama, K.; Miyagoshi, Y.; Suzuki, Y.; Iwasaki, T. Present Status and Future Enhancement of Updraft Biomass Gasifier. J. Jpn. Inst. Energy 2012, 91, 1047–1052. [Google Scholar]

- Yamagata Green Power. Available online: http://www.jbmd.co.jp/bus_results/yamagata.html (accessed on 10 June 2020). (In Japanese).

- Koizumi, T.; Omura, K.; Onoda, H.; Nagata, K.; Suzuki, Y.; Ushiyama, T. Assessment of High−efficient Energy Utilization System of Woody Biomass. In Proceedings of the 2013 Symposium on Environmental Engineering, Tokyo, Japan, 10–12 July 2013; pp. 304–307. [Google Scholar]

- Miyahara, I.; Omura, K.; Onoda, H. Actual measurement evaluation of small- and medium-scale woody biomass gasification power generation system. In Proceedings of the 2018 Symposium on Environmental Engineering, Tokyo, Japan, 11–12 July 2018; p. 205. [Google Scholar]

- Sato, R.; Kadoma, T.; Fujimoto, Y.; Ogata, N.; Ninomiya, Y.; Horio, M. A report on successful continuous operation of wood pellet gasifier achieved after overcoming severe clinker formation. In Proceedings of the 2019 Biomass Science Conference, Fukushima, Japan, 11–13 December 2019; pp. 29–30. [Google Scholar]

- Jyozuka, T.; Wada, T. Operational situation—2MW woody biomass gasification power plant. In Proceedings of the 2018 Symposium on Environmental Engineering, Tokyo, Japan, 11–12 July 2018; p. 215. [Google Scholar]

- Miyagi, T.; Honma, S.; Kobayashi, T.; Omura, K.; Onoda, H. Assessment of Small- and Medium-sized Woody Biomass CHP (Combined Heat and Power) System. In Proceedings of the 2016 Symposium on Environmental Engineering, Kanazawa, Japan, 29 June–1 July 2016; p. 214. [Google Scholar]

- Taniguchi, M.; Nishiyama, A.; Sasauchi, K.; Ito, Y.; Akamatsu, F. Considerations Based on Reaction Rate on Char Gasification Behavior in Two-stage Gasifier for Biomass. J. High Temp. Soc. 2009, 35, 77–83. [Google Scholar]

- Fukushi, K.; Watanabe, H. Demonstration Report of the 40kW small scale Biomass Gasifier Power Plant. In Proceedings of the 2017 Biomass Science Conference, Tokyo, Japan, 18–19 January 2017; pp. 1–2. [Google Scholar]

- Namba, K.; Ida, T.; Sano, H. Pyrolytic and Combustion Characteristics of Woody Bio-Pellets. J. Jpn. Inst. Energy 2004, 83, 788–793. [Google Scholar] [CrossRef]

- Yukumoto, M.; Nakashima, E.; Ueno, K. STUDY OF PYROLYSIS AND GASIFICATION PROCESS OF WOODY BIOMASS. Stud. Sogo Kogaku 2011, 23, 9–15. [Google Scholar]

- Mizoguchi, S.; Takeda, T.; Kukizaki, M.; Shimanuki, Y. Study on generation and prevention of clinker during combustion of bark pellets. In Proceedings of the 2018 Biomass Science conference, Miyagi, Japan, 17–18 January 2018; pp. 73–74. [Google Scholar]

- Omura, K.; Hadi, P.A.; Onoda, H. LCCO2 of coal co-firing with imported torrefied woody biomass in Japan. J. E3S Web Conf. 2018, 74, 1–8. [Google Scholar] [CrossRef]

| Item | Analysis Results | Analysis Method | ||

|---|---|---|---|---|

| Microcontaminants | (wet wt.%) | 0.37 | JIS K 2276 | |

| Residual carbon content | (wet wt.%) | 11.5 | JIS K 2270 | |

| Proximate analysis | Water | (wet wt.%) | 6.7 | JIS K 2275-3 |

| Ash | (wet wt.%) | <0.01 | JIS K 2272 | |

| Volatile matter | (wet wt.%) | 91.2 | JIS M 8812 | |

| Fixed carbon | (wet wt.%) | 2.1 | JIS M 8812 calculation method | |

| Heating value | Higher heating value | (MJ/kg) | 30.97 | JIS K 2279 |

| (kcal/kg) | 7400 | |||

| Lower heating value | (MJ/kg) | 29.34 | ||

| (kcal/kg) | 7010 | |||

| Elemental analysis | C | (dry wt.%) | 69.46 | JIS M 8819 |

| H | (dry wt.%) | 7.22 | ||

| N | (dry wt.%) | 0.16 | ||

| O | (dry wt.%) | 23.06 | Calculation method | |

| S | (dry wt.%) | 0.03 | Postcombustion—ion chromatography and gravimetric methods | |

| Cl | (dry wt.%) | 0.07 | Postcombustion—ion chromatography | |

| Density | 15 ℃ | (g/cm3) | 1113 | JIS K 2249 |

| 15 ℃ | (g/cm3) | 1104 | ||

| 50 ℃ | (g/cm3) | 1091 | ||

| pH | (-) | 2.5 | Compliant with JIS K 2252 and glass electrode method | |

| Flashpoint | (℃) | 111.0 | JIS K 2265-4 | |

| Temperature (°C) | Viscosity (mPa∙s) (cP) | Kinematic viscosity (mm2/s) (cSt) | ||

| 15 | 658 | 591 | ||

| 30 | 267 | 242 | ||

| 50 | 190 | 174 | ||

| Continuous Operating Period | From 27 February 2017 to 28 February 2017 | From 30 May 2017 to 4 June 2017 | |

|---|---|---|---|

| Item | Unit | Value | |

| Wood moisture | (%) | 33.65 | 27.67 |

| Wood input (WB) | (t) | 17.04 | 19.62 |

| Power generation output | (kWh) | 5558 | 5392 |

| Operating time | (h) | 39 | 41.5 |

| Heat recovery amount | (kWh) | 11,821 | 11,466 |

| Item | Unit | Japanese Cedar | Japanese Cypress | Pine | Quercus serrata | |

|---|---|---|---|---|---|---|

| Lower heating value | (MJ/kg) | 19.66 | 19.71 | 19.25 | 19.08 | |

| Proximate analysis | Water | (%) | 8.30 | 9.85 | 7.94 | 9.98 |

| Ash | (%) | 0.41 | 0.37 | 0.76 | 0.75 | |

| Volatile matter | (%) | 82.7 | 83.8 | 84.6 | 83.1 | |

| Fixed carbon | (%) | 16.9 | 15.8 | 14.7 | 16.1 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baba, Y.; Pandyaswargo, A.H.; Onoda, H. An Analysis of the Current Status of Woody Biomass Gasification Power Generation in Japan. Energies 2020, 13, 4903. https://doi.org/10.3390/en13184903

Baba Y, Pandyaswargo AH, Onoda H. An Analysis of the Current Status of Woody Biomass Gasification Power Generation in Japan. Energies. 2020; 13(18):4903. https://doi.org/10.3390/en13184903

Chicago/Turabian StyleBaba, Yasutsugu, Andante Hadi Pandyaswargo, and Hiroshi Onoda. 2020. "An Analysis of the Current Status of Woody Biomass Gasification Power Generation in Japan" Energies 13, no. 18: 4903. https://doi.org/10.3390/en13184903

APA StyleBaba, Y., Pandyaswargo, A. H., & Onoda, H. (2020). An Analysis of the Current Status of Woody Biomass Gasification Power Generation in Japan. Energies, 13(18), 4903. https://doi.org/10.3390/en13184903