Abstract

Various types of natural hazards are inextricably linked to the process of underground hard coal mining. Ventilation hazards—methane and spontaneous combustion of coal—are the most dangerous; they pose a major threat to the safety of the workers and decrease the effectiveness of the whole coal production process. One of the methods designed to limit the consequences of such hazards is based on the selection of a ventilation system that will be suitable for the given mining area. The article presents a case study of an active longwall area, where—due to increasing ventilation hazard (methane and spontaneous combusting of coal)—the whole system was rebuilt. The U-type ventilation system was used in the initial stage of the extraction process, however, it often generated methane in amounts that exceeded the allowable values. Consequently, such conditions forced the change of the ventilation system from a U–type to Y–type system. The new system was installed during the ongoing mining process, unlike the usual practice. The article presents the results of tests on mine gas concentrations and descriptive statistics for both types of ventilation system. The results clearly demonstrate that the U-type longwall ventilation system, in the case of high methane release hazard, prevents safe and effective operation. At the same time, the use of this system limits the carbon oxidation reactions in the goaf, leading to spontaneous heating and combustion, which is confirmed by the low concentrations of gases—by-products of these reactions. In turn, the use of the Y-type longwall ventilation system ensures safe and effective operation in areas with high methane release hazard, but at the same time deteriorates the safety associated with the spontaneous combusting of coal. The presented case—both from a scientific and practical perspective—is quite interesting and greatly broadens the knowledge in the scope of an efficient ventilation system for underground workings.

1. Introduction

1.1. Preliminaries, Objectives and Outline of the Study

Despite ongoing changes in the global economy, hard coal is still one of the basic energy raw materials in the world. In many countries, it is a strategic raw material for energy independence and security [1,2]. Therefore, any work which results in an improvement in the safety and efficiency of exploitation of this raw material plays an enormous economic and social role. The environmental element is also important here. Improving the safety of mining operations reduces emissions of methane (a greenhouse gas) and other by-products of spontaneous combustion of coal. All these aspects shape the image of the energy industry and show that it is based on conventional energy sources and cares about the environment and occupational safety.

The underground exploitation of hard coal—as one of the basic stages of the mining process—is linked to the occurrence of several types of hazards, including ventilation hazards, making the whole process dangerous [3,4,5,6,7,8,9]. The natural hazards (methane, dust, rock burst, spontaneous combustion of coal and water) are particularly dangerous as they put the workers and the continuity of the underground exploitation process at risk. As indicated by the authors of the works [10,11,12,13,14,15,16], these hazards lead to mining accidents and disasters. The occurrence of such natural hazards strongly impacts on the efficiency of the whole process. When the permissible concentrations of gases defined in Polish regulations emitted in the process of coal exploitation are exceeded, they prevent the safe conduct of mining exploitation [17]. The electrical power supply must be cut off (voltage must be switched off) for all electrical equipment installed in the longwall (shearer, conveyor, etc.) and the main gate if the concentration of methane in the air flowing out of the longwall exceeds 2% or 1% in the air flowing into the longwall area (according Polish regulations). This results in a sudden stoppage of the entire exploitation process, disturbing its continuity and effectiveness.

The methane and spontaneous combustion of coal are both natural ventilation hazards [18,19,20,21,22,23,24,25,26]. When activated—either by the release and ignition of methane or the spontaneous combustion of coal—they lead to serious injuries to the workers, halts in the mining process, the need to isolate the exploitation areas, or many other disturbances; these all have a negative impact on the coal extraction process. For this reason, the paper focuses on the analysis of both hazards as they often occur simultaneously. In such cases, they are referred to as concurrent hazards [27,28,29]. A significant rise in the level of ventilation hazards has been observed in hard coal mines in recent years. It is caused by an increase in the amount of methane released from the rock mass and from the side of the cave-in and the spontaneous combustion of coal–mainly in the goafs.

The goafs act as activators of these hazards to a very large extent. The reasons for this include poor insulation of the goaf from the mining zone, coal that had not been extracted (e.g., some amount of coal left in the seam or the presence of an anticipated sub-economic coal seam), and the mining process conducted in the vicinity of old goafs. These factors increase the threat to the mining process. This applies both to the methane release hazard as well as to the spontaneous combustion of coal [30,31,32,33,34,35].

In the case of the extraction of coal beds that are rich in methane and, at the same time, in the areas impacted by the goafs, the methane release hazard caused by the flow of the gas increases. The probability of spontaneous combustion of coal is also higher when the extraction of deposits is extensive. Both are tightly linked to the ventilation of the longwall, including the flow of air (filtration) through the goafs. The above-mentioned facts support the conclusion that the goafs have a significant impact on the formation of methane release hazards and spontaneous combustion of coal in the area of active exploitation. Therefore, they must be treated as an integral part of the mining process.

In the case of the mining process conducted in areas rich in methane, the methane that is accumulated in the goafs and flows to the active workings can increase the probability of the ignition and combustion of methane. In turn, the air flows from the longwall to the goaf create conditions for spontaneous combustion of the coal left in these goafs. The air flowing through pores and crevices in the goafs can thermally activate the coal. This process may result in the emission of carbon combustion products into the atmosphere in the form of poisonous gases (CO) and smoke [36]. In addition, the spontaneous combustion of coal can be a factor that leads to the ignition of methane. Therefore, in order to ensure the safety of the workers and the continuity of the production process, various actions are designed to identify the processes related to the flow of gases through mining excavations and goafs that affect the formation of ventilation hazards in the whole area. One such process that has an impact on the shaping of the ventilation hazards—methane release and spontaneous combustion of coal—in the active mining area is the routine ventilation of longwalls.

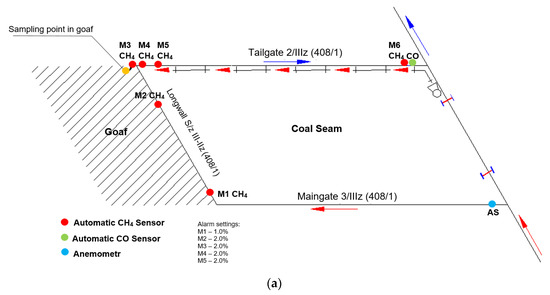

The global mining industry uses several systems of routine ventilation of active longwalls. The most common and, at the same time, a popular system is the U-type ventilation system. In Poland, as much as 70% of active longwalls are based on this type of ventilation (Figure 1a). The second—applied relatively often—is the Y-type ventilation system (Figure 1b) [37].

Figure 1.

Diagram of the U-type ventilation system (a) and the Y-type system with routine ventilation of tailgate (b).

Both systems are used in the areas where methane release and spontaneous combustion hazards occur simultaneously. However, they have a different impact on the formation of these threats in the area of exploitation.

A common feature of both systems is the manner in which the air is supplied to the longwall through the tailgate; the difference is in the discharge of the used air. The U-type ventilation system discharges the air through the tailgate that runs along the body of coal; the Y-type ventilation system uses the tailgate that runs along the goafs. Additionally, the Y-type ventilation system involves the process of routine ventilation of the area of the longwall outlet (the intersection of the longwall and the tailgate). This involves a stream of fresh air fed through the tailgate located along the body of coal (Figure 1b) [38,39,40].

The manner of air distribution for both systems in the area of active mining works impacts on the development of the ventilation hazard related to the ongoing extraction process. This impact, however, is completely different.

The U-type ventilation system limits the probability of spontaneous combustion of coal that was left in the goafs. This is caused by the fact that this hazard is impacted by the flow of air rich in oxygen through the goafs—the air flows from the longwall. The air is a component required for the oxidation of coal that leads to spontaneous heating followed by spontaneous combustion of coal. The intensity of such a flow of air in the case of the U-type ventilation system is substantially smaller when compared to the flow in the Y-type ventilation system. In the case of the former, the air flows to the goafs only from the side of the tailgate and along the longwall. When using the Y-type system, the air flows also in the area where the longwall intersects with the tailgate. If there is a methane release hazard, especially in the area where the longwall intersects with the tailgate, its intensity will be greater for the U-type ventilation system than the Y-type. This intensity significantly depends on the physical parameters of the goafs, including the strength parameters of roof rocks (compressive and tensile strength), the porosity of the rocks the goafs, the total moisture content of rocks, the depth at which the exploitation is carried out and the thickness of the seam [37,41,42]. All these factors have a significant impact on porosity and, as a result, on the permeability of the goafs. The presence of hollow spaces in the goafs affects their permeability, which is the basic property characterising the porous medium and is fundamental for the process of airflow through these goafs and the emission of gases into the workings.

The highest amount of methane getting to the longwall working flows from the goafs. The highest methane accumulation when using the U-type ventilation system occurs in the area of the intersection of the longwall and the tailgate, whereas in the case of using the Y-type system, methane concentration is substantially smaller, as an additional air stream is supplied to this area [40,43].

Therefore, it can be concluded that the routine ventilation system activates, to a large extent, both hazards. The selection of the routine ventilation system—along with the physical parameters of the air supplied—should be preceded by a detailed analysis of the area where mining activities will be conducted.

Usually, the selection of an adequate longwall routine ventilation system in the case of concurrent hazards—related to methane and spontaneous combustion of coal—in the exploited deposit, impacts on the tendency of coal to spontaneously combust. The depth of exploitation in Polish coal mines constantly rises, which results in an increase in the initial temperature of the deposits, which in turn shortens the incubation time of spontaneous heating of coal [44]. This also increases the initial stress of the rock mass—later leading to the formation of bigger areas of cracks around the excavations. Such areas form porous centres that are permeable and can impact on the ventilation process [45].

If there is a high methane release hazard, the preventive measures used to reduce this hazard also have an adverse effect on the risk of coal spontaneous combustion, mainly due to the increased intensity of ventilation of the longwall and, consequently, increased airflow through the goafs.

The most preferable solution in this case is usually the system that is capable of limiting, as much as possible, the flow of the air through the goafs [37,40,46]. This reduces the possibility of spontaneous combustion of coal in the goafs. Hence, the most popular system in such cases is the U–type ventilation system. It, however, when applied in the areas with deposits rich in methane, prevents effective measures to minimize the methane release hazard. If methane release hazard prevents the effective conduct of the mining process, additional steps are necessary to limit the hazard. If they also fail, the type of the ventilation system must be changed from the U-type to the Y-type system. In practice, such change is not easy, but there have been cases when the system was changed successfully. The paper presents and discusses the case of such a change.

The issues that must be dealt with when changing the ventilation system have not been presented in any of the available papers to date. The area of the impact analysis of the ventilation system type on the concurrent hazards—methane and the spontaneous combustion of coal—have not been discussed sufficiently to date. In terms of safety of operation as well as its efficiency and efficacy, this research area plays a key role. Therefore, the authors hope that the case presented in the paper will fill the research and information gap and will point to a new approach to solving the ventilation problems. This proves that the solution presented in the paper is new and has not been applied to date.

The results of the analysis that are presented in the paper show that, in some cases, there is a need to undertake urgent and decisive measures in order to maintain the mining process. The objective of this paper is to present practical experience related to the change in the longwall ventilation system during ongoing mining and with concurrent hazards. This analysis also made it possible to determine the influence of the ventilation system on the formation of methane release hazard and the spontaneous combustion of coal (in Poland, it is referred to as endogenous fire) in the area of exploitation. As already mentioned, the analysis was conducted for the actual longwall. In terms of the formation of methane release hazard and spontaneous combustion of coal, the results of gas concentrations characterising this hazard were presented for two stages of longwall ventilation: for the initial stage of the U-type longwall ventilation system and for the Y-type ventilation system.

Undoubtedly, the method of solving the problem of exploitation in conditions of coexistence of ventilation hazards for the tested longwall is original and rarely used in practice. This is one of the reasons it deserves to be presented more extensively, all the more so because it enabled the safe operation of the longwall without additional obstacles. The results obtained clearly indicate a significant influence of the ventilation system on the formation of ventilation hazards for the two different ventilation systems tested.

Some of the features of the paper prove that it is original and innovative. First, to our knowledge, there are no studies in the scientific literature on the development of the hazard of methane release into the air of the longwalls with the Y-type ventilation system. Therefore, this study is an original scientific contribution devoted to the problem of the occurrence of methane release hazard for longwalls with this specific type of the ventilated system. This is especially important, since the Y-type ventilation system is often used in actual mines. However, the issue of the methane release hazard has, to date, mainly concerned only longwalls with the U–type system. Secondly, the testing ground is the actual longwall that, when active, had two types of ventilation system—the U-type and the Y-system. To date, to the authors’ knowledge, there are no papers that present the results of research concerning the formation of the methane release hazard or spontaneous combustion of coal related to such a case. Thirdly, the authors used the measurements of the concentrations of gases emitted into the air of the excavations to demonstrate the impact of the applied longwall ventilation system on the formation of methane release hazard and the potential for the spontaneous combustion of coal, characterised by the concentrations of gases. Finally, there are no available publications that present and discuss the methane release hazard together with the spontaneous combustion of coal. Research activity within this area has been focused either on an analysis of the hazard of coal spontaneous combustion or methane release, whereas practice has shown that both hazards occur simultaneously.

All these factors prove that the research presented is original and, at the same time, show its broad range of application. The results extend the knowledge of the mining process.

1.2. Brief Literature Review of Ventilation of Longwalls and Methane and Coal Spontaneous Combustion Hazards

The issues concerning the occurrence of ventilation hazards in underground mine workings have been presented numerous times in the literature. Several researchers are engaged in intensive research on the recognition of processes related to the release of methane into the mine’s air, e.g., [47,48,49,50,51,52] and the process of coal spontaneous combustion, e.g., [53,54,55,56,57,58,59,60,61].

The work on the release of methane from coal seams allowed, inter alia, for the construction of a simplified mathematical model of methane release from coal seams to mine workings [47] or the development of a mathematical model of methane release in coal seams [48], and provided a great extent of valuable knowledge related to the sorption capacity of coal and surrounding rocks, which affects the release of methane into mine workings [49,50,51,52]. In turn, the works [53,54,55,56,57,58,59,60,61] present several interesting results indicating that a side effect of the process of spontaneous combustion of coal is the release of gases such as carbon monoxide, ethylene, propylene, acetylene, and hydrogen into the air. The presence of these gases as indicator gases in mines’ air has been used for many years to assess the process of spontaneous combustion of coal. The results are used for tests related to the ventilation of underground workings.

The subject of the selection of the longwall ventilation system and its influence on the co-occurrence of methane release hazard and spontaneous combustion of coal during mining is discussed in the world literature to a relatively limited extent. Most of the works focus on matters related to the issue of the independent occurrence of these hazards and the process of ventilating the workings in general [40,62,63,64,65,66,67,68,69].

One of the works devoted to the issue of ventilating the longwall is [62] and concerns the problem of designing a system for ventilating excavations at large depths. The authors of the work focused mainly on planning the ventilation parameters that are required during operation. The work represents a very general approach to this process. Gillies and Wu in their work [63] carried out tests of longwall ventilation systems in Australian mines. The authors presented the practices used to ventilate excavations during coal mining and drew attention to the basic problems of selecting a ventilation system for mining excavations. Mayes and Gillies [64] carried out an analysis of longwall ventilation methods in Australian mines and discussed popular solutions. The analysis covered sixteen large mining parcels, which allowed the authors of the paper to present the main problems occurring during the ventilation of excavations, as well as the best engineering practices to solve them. This work contains interesting practical tips for the underground ventilation process.

The paper [65] presents a critical analysis of the longwall ventilation systems in the context of methane release hazard. There, attention was drawn to the problem of a pressure drop (lasting at least one day) and its impact on the increase in methane release hazard. In turn, the work by Wang et al. [66] presents numerical research on the characteristics of ventilation airflow through the U-type longwall ventilation system. The results obtained confirm the general views on the use of this system, which were also confirmed in this work. The paper [67] presents the effect of ventilation on the spontaneous heating of coal.

Diamond and Garcia, in their work [68], evaluated the impact of mining practices on methane emissions and methane release hazard control systems. This work is a part of the presentation of practical experience in the field of longwall excavation ventilation. Wang et al., in their work [69], carried out research aimed at determining the characteristics of airflow through the longwall for different stages of the operation. This is another example of searching for methods to optimise the ventilation process. The paper [40] describes the characteristics of the most frequently used longwall ventilation systems in Polish hard coal mines. The material provided is valuable due to its practical approach to the problem of choosing the ventilation system.

The longwall ventilation systems are inextricably linked to the methane release hazard, which results in slightly less work being devoted to the fire hazard. There are also some valuable studies on this subject. The largest number of works in the area of the risk of coal spontaneous combustion concern goafs [70,71,72,73]. Furthermore, a large number of papers related to the methane release hazard are also devoted to goafs. This is due to the fact, as has already been mentioned before, that the goafs are of key importance for the formation of ventilation hazards in the area of mining operations.

In this respect, Karacan, in his work [70], pointed out that methane emissions from the longwall ventilation system are an important indicator of how much methane a mine produces and how much air needs to be provided to keep methane levels below the regulatory limits, including goafs. Zhang, in his paper [71], presented the results of the study on the distribution of air and gases in the sheared goafs of a longwall with the U-type ventilation system. Tutak and Brodny, in their work [72], studied the effect of the auxiliary devices used for the U-type ventilation system on the methane concentration in the upper corner of the longwall. They also presented the results of a study on the influence of the longwall ventilation system on the risk of spontaneous combustion of coal in the goafs [73]. In both cases, it was especially important to treat the goaf as a porous and permeable medium.

The problem of spontaneous combustion of coal left in the goafs and its influence on the ventilation process has also been discussed thoroughly in the works [74,75,76,77].

Lu and Qin, in their work [74], used numerical simulation to determine the distribution of gas concentration in the goaf, which resulted in the determination of a potential zone in which coal may spontaneously ignite. In turn, [75] presented the results of the analysis of coal spontaneous combustion in goafs using numerical modeling. The results obtained allowed to conclude that the risk associated with spontaneous combustion of coal is influenced by the concentration of oxygen in the goaf, the longwall ventilation system and the inclination of the seam. The paper [76] also presents the results of research on the prevention of spontaneous combustion of coal left in the goafs of one of the longwalls in the Haizi coal mine. Pan et al., in [77], used the measurement data on the concentration of carbon monoxide and oxygen in goafs and carried out numerical tests to determine three zones in goafs of one of the longwalls associated with the spontaneous combustion of coal.

Moreover, the authors of the works [78,79] have designated such zones in the goafs of the cave-in longwalls.

Taraba et al. [80,81] carried out numerical research in which they simulated the process of self-heating of coal in goafs. Yuan and Smith [82] used numerical research to predict the process of the heating and spontaneous combustion of coal in the goaf. The paper [83] also presents the results of similar studies.

In turn, the paper [84] presents the cutting roof and release pressure technique to determine the area of occurrence of three zones related to the process of spontaneous ignition of coal in the goaf.

Since spontaneous combustion of coal can lead to the ignition of methane, this subject has also been presented in several interesting and valuable works [85,86,87].

Brune and Saki, in their work [86], on the basis of research carried out with the use of Computational Fluid Dynamics (CFD), determined the places in goafs where methane occurs in explosive concentrations and presented a method of feeding nitrogen to goafs, which neutralizes the methane release hazard and, at the same time, spontaneous combustion of coal. The research referred to the longwall with the U-type ventilation system. Li et al., in turn, presented the results of the research consisting of determining the effect of spontaneous combustion of coal in goafs on methane decomposition [87]. The tests were also carried out for the U-type ventilation system. Zhang et al. presented the results of the numerical analysis of methane emission from goafs into the tailgate with the U-type ventilation system [88].

Zmarzły and Trzaskalik, in their work [89], presented the results of measurements of methane concentration in the area of the crossing of a longwall with a ventilation gallery for the U-type system.

The works presented here are only a part of the contribution to the broadly understood topic of ensuring ventilation safety in the process of the underground mining operation.

Therefore, the issues covered in this work should be a valuable addition to this material and indicate the practical possibilities of applying a completely new solution to improve the state of ventilation in case of combined hazards.

However, none of the works present the results of the influence of the ventilation system on the simultaneous formation of methane release hazard and spontaneous combustion of coal. Therefore, the issues covered in this work should be a valuable addition to this material and show a practical and completely new solution to improve the state of ventilation in case of combined hazards.

From both a scientific and utilitarian perspective, this issue seems to be extremely important and interesting.

2. Materials and Methods

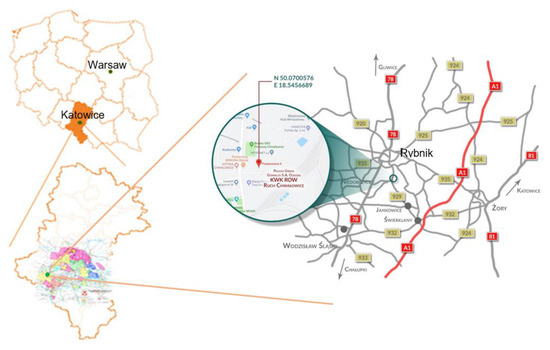

The analysis of the impact of the longwall ventilation system on the formation of the methane release hazard and the risk of spontaneous combustion of coal was carried out for one of the longwalls in the mine in the ROW area (Rybnik Mining District) (Figure 2). The mine is located in the southern part of Poland. The size of its mining area is 21.76 km2 and its operational resources amount to 144,643 thousand tons of coal.

Figure 2.

Location of the tested mine (own elaboration based on [90]).

The longwall was exploited with a longitudinal system with the roof rock cave-in in the direction from the boundaries of the field of exploitation. It was 240 m long, 870 m of coal was mined, and the thickness of the coal bed ranged from 1.6 to about 2.0 m.

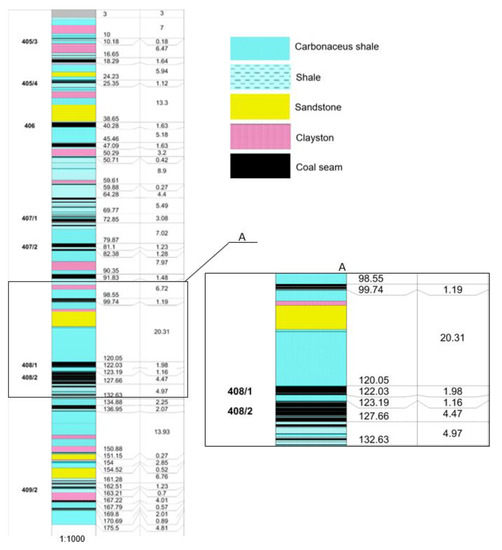

The physical and chemical parameters of the rocks in the roof of the exploited seam are shown in Table 1 and the profile of the rocks in the direct roof is shown in Figure 3.

Table 1.

Physical and chemical parameters of the rocks in the floor and roof of the exploited seam.

Figure 3.

Profile of the seam and the direct roof of the longwall.

The hard coal deposited in the seam 408/1 is lustrous, rarely matte, with a strand-type structure and with occasional pyrite, and, less often, calcite coatings. The content of individual macerals in the coal is shown in Table 2.

Table 2.

Petrographic composition of the coal deposited in the seam 408/1.

The susceptibility of the rocks in the roof and the floor to spontaneous sparking, which can ignite methane in the longwall due to the high variability of their quartz content, was determined as high. The maximum primary temperature of the rocks deposited at a depth of 780 m was 24.9 °C.

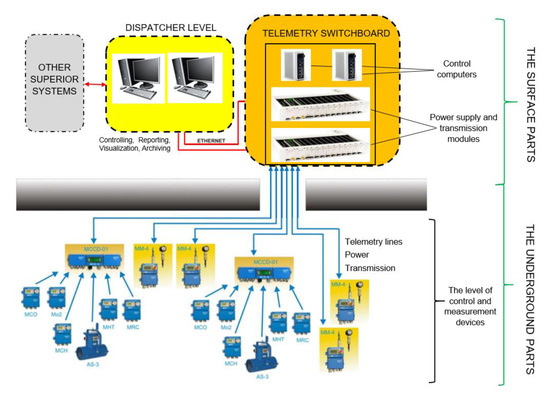

Ventilation parameters of the air, also known as the physical and chemical parameters (speed, pressure, and concentrations of gases in a mine) in the mine are measured by means of automatic gasometry sensors. These sensors include anemometers, automatic methane meters, oxygen meters, carbon monoxide, and carbon dioxide sensors, as well as absolute pressure, humidity, and temperature sensors. These sensors are part of the gasometric system of the mine (SMP system). They identify the composition and parameters of the underground air of the workings. This information is used to assess the hazard level in these workings. This can result, for example, in the automatic shutdown of the power supply to mining machines when the methane concentration exceeds the regulatory limit values [91]. The SMP system also provides a quasi-continuous communication with underground devices, such as sensors or voltage shutdown devices.

The applied automatic gasometry system distinguishes between the underground facility and the control stations located on the surface (Figure 4). The underground facility consists of sensors for measuring the ventilation parameters of air and underground stations, which perform the function of data concentrators and actuating systems. Surface stations, on the other hand, include data transmission systems and power supply systems. At the same time, they are an intermediate element for the computer part of the control system.

Figure 4.

Structure of the system for monitoring the parameters of the air in the underground workings (own elaboration based on [92]).

Automatic methane meters type MM4 (manufactured by SEVITEL, Poland) with digital data transmission were used in the mine record methane concentrations with a resolution of 0.1 CH4. The measurement is performed with a fixed sampling time of the recorded data. The measuring range ranges from 0 to 100%. These sensors are directly connected to the surface facility.

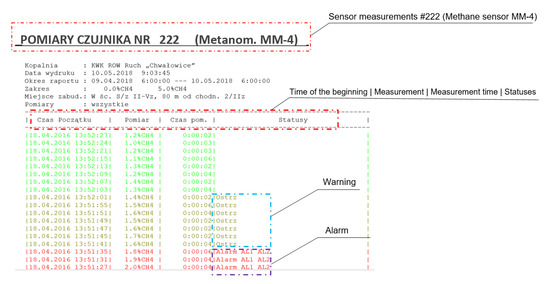

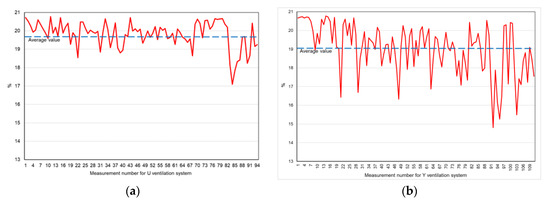

Anemometers, in turn, record air velocity with a resolution of up to 0.1 m/s, and barometric pressure gauges up to 1 hPa. An exemplary report of the results obtained from automatic methanometry is shown in Figure 5.

Figure 5.

Report presenting methane measurement using an automatic methanometric sensor.

In the initial stage of exploitation, the longwall was ventilated with the U-type system. However, due to the level of methane release hazard and the impossibility of maintaining a permissible concentration of methane in the air (2%), it was necessary to change the ventilation system to the Y-type system. The diagrams of the longwall with the directions of airflow and the location of gasometric protections for the ventilation systems used are shown in Figure 6.

Figure 6.

Diagrams of the tested longwall for the U-type (a) and Y-type (b) ventilation systems.

The measurement points for determining the actual concentration of methane released during the operation based on the U-type ventilation system were located in the longwall and the tailgate. Their detailed location is shown in Figure 6a. Sensor no. 1 (with the operating threshold of 1.0% CH4), was installed under the roof in the longwall in the zone of about 10 m from the crossing with the tailgate. Sensor no. 2 (with the operating threshold of 2.0% CH4) was installed under the roof in the longwall, at a distance of about 1/3 of the length of the longwall—counting from the outlet, in the place of the highest methane concentrations found. Sensor no. 3 (with the operating threshold of 2.0% CH4) was installed in the tailgate at a distance of no more than 2 m from the excavation’s liquidation line. Sensor no. 4 (with the operating threshold of 2.0% CH4), was installed in the tailgate at the top of the sidewall, at the height of the longwall outlet. Sensor no. 5 (with the operating threshold of 2.0 CH4) was installed in the tailgate at a distance of no more than 10 m from the outlet of the longwall.

The permissible concentration of methane, and consequently the operating thresholds of individual sensors, resulting in the exclusion of electricity supply to machines and equipment, depends on the place of their installation in excavations located in the area of the longwall on the basis of regulations applicable in Poland [91]. Methane sensors installed in the longwall area recorded methane concentrations with a resolution of 0.1% CH4. The location of these sensors was consistent with the regulations valid in Polish hard coal mines (Figure 6a).

When using the U-type ventilation system, a volume flow rate of 1050 m3/min was supplied to the longwall by means of the main gate. Moreover, an extra airflow of 400 m3/min also supplied to the longwall.

Starting from the seventh month of its operation, the ventilation system was changed from the U-type to the Y-type. The method of arrangement of measurement sensors for this system is shown in Figure 6b.

Sensor no. 1 was installed under the roof of the tailgate at a distance of about 75 m before the inlet to the longwall. Sensor no. 2 (with the operating threshold of 1.0% CH4), was installed under the roof in the longwall in the zone of about 10 m from the crossing with the tailgate. Sensor No. 3 (with the operating threshold of 2.0% CH4), was installed under the roof in the longwall, in the zone from 2 m to the outlet from the longwall. Sensor No. 4 was installed in the tailgate maintained along the goafs, 10 m behind the longwall outlet (its operating threshold was 2.0% CH4). Sensor No. 5 (with the operating threshold of 2.0 CH4), was installed under the roof in the research cross heading 1a, between 10 and 15 m from the intersection with the tailgate 1a. When using the longwall ventilation system, volume flow of air of 1200 m3/min (12.5% more than when using the U-system) was supplied to the longwall through the main gate; 450 m3/min (11.11% more than when using the U–system) was supplied to the longwall through the tailgate. The need to increase the amount of air supplied to the longwall resulted from the fact that with less air it was impossible to maintain the permissible concentrations of methane.

The methane bearing capacity of the tested seam reached 5.3 m3/Mg of pure coal and the gas desorption intensity index for coal from this seam reached 0.96 kPa. Determination of the seam’s methane-bearing capacity is the foundation for determining the methane release hazard category under Polish regulations.

The tested longwall was located in the seam classified as category III methane hazard (as provided by Polish regulations). This means that the methane content of the accessible seam or its part is greater than 4.5 m3/Mg but not greater than 8 m3/Mg in terms of clean coal. The categories of methane release hazard in Poland are presented in Table 3.

Table 3.

Category of methane release hazard in Poland (own elaboration based on [91]).

Coal from the exploited seam was qualified to the IV group of spontaneous combustibility, i.e., with high susceptibility to spontaneous combustion. With a spontaneous combustibility index (Sza) of Sza = 116 °C/min and carbon oxidation activation energy (A) A = 47.9 kJ/mol, the spontaneous combustion incubation period determined under laboratory conditions was forty-seven days.

Due to the risk of coal spontaneous combustion, the area of the longwall was covered by an early detection system designed to report spontaneous combustion. Air samples were taken from chromatographic analysis on a weekly basis, which allowed determining the concentration of gases (ethane—C2H6, ethylene—C2H4, propane—C3H8, propylene—C3H6, acetylene—C2H6, carbon monoxide—CO, carbon dioxide—CO2, oxygen—O2, and hydrogen—H2). Figure 6a shows the location of the goaf air sampling when using the U-type ventilation system and Figure 6b when using the Y-type system.

The exploited seam did not show a tendency to tremble: there were no records of frequent tremors. This seam and the excavations of the longwall area are classified as class B coal dust explosion hazards.

3. Results

3.1. Analysis of the Methane Release Hazard

It should also be noted that ventilation methane is the volume amount of methane released to the excavations associated with the longwall area and is expressed in m3 per unit of time. On the other hand, total methane (absolute) should be understood as the sum of the amount of methane released into the mine workings (ventilation methane) and methane captured by methane drainage.

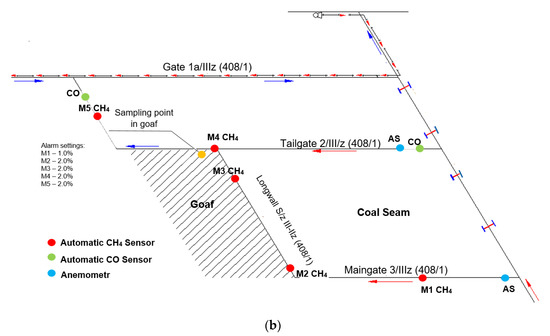

Based on the measurements of methane concentration, the courses were determined during ventilation of the longwall with the U-type system. The measurement points were put in the longwall and the top gate (Figure 6a). These courses represent weighted average values of methane concentration on subsequent days of the operation (Figure 7).

Figure 7.

Registered concertation of methane for the U-type ventilation.

The analysis of the obtained values proves that the highest mean daily methane concentration of 1.6% was recorded on the M3 sensor, placed in the tailgate, at a distance of no more than 2 m from the line of liquidation the gate. A slightly lower value of average methane concentration, reaching 1.4%, was recorded on the M4 sensor in the tailgate placed on the upper sidewall at the height of the outlet of the tailgate. Methane concentration values of 1.2% were recorded on the M5 sensor located not more than 10 m from the outlet of the longwall. A quite high concentration of methane remained also in the longwall itself, about 160 m from the inlet to the longwall, and reached about 1.0% (M2 sensor). The lowest average daily methane concentration was found in the longwall that was 10 m long (M1 sensor), counting from the inlet to the longwall, and reached about 0.1% CH4.

The analysis of the median values of average methane concentration on sensors located in the area of the longwall shows that for about half of the days of operation, on the M1 sensor, this value was about 0.1%. For the M2 sensor, the median value was 1.0%, whereas M3 and M4 sensors recorded (for half of the working days) an average value of methane higher than 1.4%. A slightly lower value occurred on the M5 sensor, of about 1.1%.

Taking into account the value of methane concentration in the case of 10% of measurements, the highest value of the 90th percentile occurred for the average concentrations recorded on the M3 sensor and was 1.8% and on the M5 sensor 1.6%. The 90th percentile value for the M4 sensor was 1.4%, and for the M2 sensor 1.3%. The lowest value was recorded on the M1 sensor and was 0.2%. The 10th percentile (mean concertation of methane in 90% of measurements) registered by the M1 sensor was 0.1%, M2—0.6%, M3—1.2%, M4—1.4%, and M5—0.9%.

Basic descriptive statistics for recorded measurements of methane concentrations at measurement points are presented in Table 4.

Table 4.

Descriptive statistics of recorded methane concentrations for individual sensors for the U-type ventilation system.

During the operation of the longwall and the use of the U-ventilation system, already in the first months of operation, a significant number of exceedances of the permissible methane concentrations of at least 2% were recorded on sensors M3 and M5. The number of these exceedances may be treated as an indicator related to the magnitude of methane release hazard in the area of conducted exploitation. Exceeding the permitted concentration of methane in the excavation causes a risk of ignition of methane.

When the U-type ventilation system was used, the methane exceedances that occurred, therefore, posed a serious risk of methane ignition and simultaneously prevented operation. The sensors located in the area of operation (in the longwall and on the main gates) recorded a total of 1295 cases when the permissible methane concentrations were exceeded. The highest number was recorded by the M4 sensor and was 776. A significant number of exceedances of the methane concentration limit—423 cases—were also recorded on the M3 sensor (Table 5). On the remaining sensors (M2 and M5), a total of 96 exceedances of methane concentration limits were recorded. The total time for exceeding methane concentrations was about 25,900 min, giving almost 18 days.

Table 5.

Summary of the number of exceedances of methane concentrations during longwall ventilation with the U-type ventilation system.

The main reason for exceeding the permissible concentration of methane on the M2 sensor was coal mining with a coal shearer or sudden gas outflows from relaxed rock mass (body of coal) during the operation. In turn, exceedances of the acceptable methane concentration recorded by the M4 and M3 sensors, located in the tailgate in the area of the intersection with the longwall, were most probably caused by methane outflows from the goafs. Taking into account the number of exceedances and the number of days during which the U-type ventilation system was applied, there were about 7.15 exceedances of the permitted concentration of methane per one day of extraction, which gives almost 2.5 h in total when the mining operation was halted.

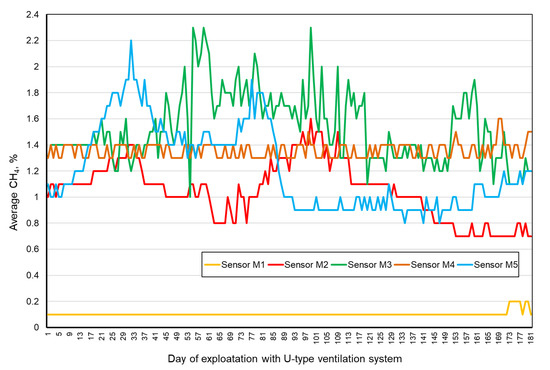

When using the U-type ventilation system, the absolute methane and longwall ventilation values changed with the progress of the operation. In general, it can be concluded that these methane substances showed an upward trend (Figure 8).

Figure 8.

Absolute methane, ventilation and methane drainage rate when using the U-type ventilation system.

The lowest mean absolute methane value occurred in the first month of the longwall mining and amounted to 15.39 m3/min, and the highest in the sixth month and amounted to 44.50 m3/min (when using the U-type system). In turn, the lowest mean value of the ventilation methane content occurred in the second month of operation and amounted to 14.11 m3/min, and the highest in the fourth month and amounted to 17.72 m3/min on average. The increase in absolute methane content was caused by the increase in the size of the relaxed zone in the rock mass and the gradual increase in extraction. The mean flow of methane volume captured by the system of methane drainage in the analysed period (from March 2018 to the end of August 2018), reached 19.13 m3/min and increased from 1.18 m3/min in the first month of exploitation to 28.09 m3/min in the sixth month. It can be seen in Figure 6 that the changes in the amount of methane captured by methane drainage systems are similar to the changes in the ventilation methane content during this period.

The analysis of the data presented in Figure 8 also shows that around the third month of operation there is some stabilisation in the range of the size of the methane flow captured by methane drainage systems and absolute and ventilation methane.

The number of exceedances of the permitted methane concentrations made it necessary to take measures to reduce the methane concentrations that persist in the air ventilation stream. To achieve this, it was decided to change the U-type ventilation system used and apply the Y-type system. For this purpose, it was necessary to carry out additional mining works in the form of excavations, which made it possible to change this ventilation system. The area of the longwall after the completion of the necessary mining works to enable the system to be changed is shown in Figure 6. The duration of mining work to change the ventilation system from the U-type to the Y-type was about one month.

Starting from the seventh month of its operation, the ventilation system has been changed from the U-type to the Y-type.

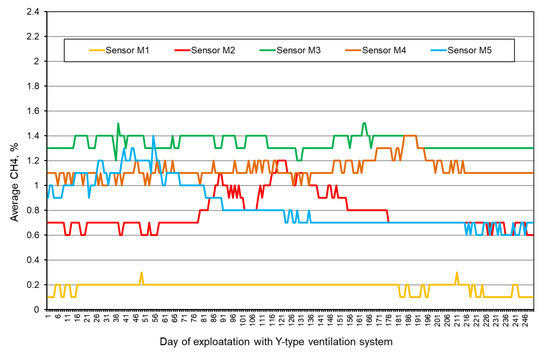

The weighted average daily methane concentrations when using the Y-type system are shown in Figure 9.

Figure 9.

Concentrations of methane when using the Y-type ventilation system.

The analysis of the obtained average values of methane concentration during the application of the Y-type ventilation system (Table 6) shows that the highest values of this concentration, amounting to 1.30%, were recorded by the M3 sensor that was placed under the roof at a distance of about 2 m from the longwall outlet. Slightly lower values, up to 1.10%, were recorded by the M4 sensor in the tailgate along the goafs. Significantly lower methane concentrations were also recorded by sensors 2 and 5, which amounted to about 0.80% CH4. The lowest concentration of methane was recorded in the air stream in the main gate (about 0.02% on average). The lowest concentrations of methane were recorded by the M1 sensor, due to the fact that this sensor is located at the inlet to the longwall, therefore it measures the methane content of the fresh air stream that is being fed to the longwall.

Table 6.

Descriptive statistics of recorded methane concentrations for individual sensors for the Y-type ventilation system.

The results from Table 5 show that for 50% of the days of the operation, the median value on M1 was 0.20%. For M2, the value was 0.70% and for M3, 1.30%. The median value for the M4 sensor was 1.10% and for the M1 sensor–0.80%.

The sensors distributed in the area of the longwall when using the Y-type ventilation system (251 days), only 47 exceedances of the allowed methane concentrations were recorded in total, the highest number of which was recorded by the M4 sensor and was 21. There are 17 exceeded methane concentrations on M5 and nine exceeded methane concentrations on M3 (Table 7).

Table 7.

Summary of the number of exceedances of methane concentrations during longwall ventilation with the Y-type ventilation system.

The total time for exceeding the permitted methane concentrations for this system was 940 min. Taking into account the number of exceedances and the number of days during which the Y-type ventilation system was used, there were 0.19 exceedances of the acceptable methane concentration per one day of extraction, which gives about 5 min of stoppage per day (for the U-type systems, it was 7.15 exceedances per working day, or about 2.5 h). This clearly means that the methane release hazard was many times lower when using the Y-type ventilation system than when using the U-type system.

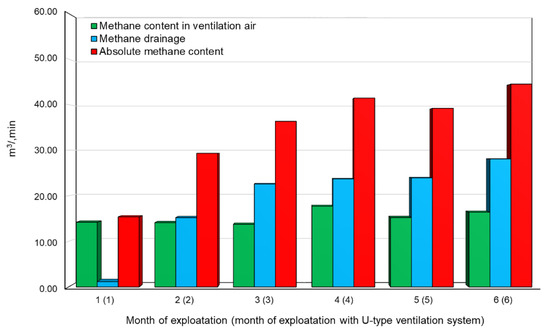

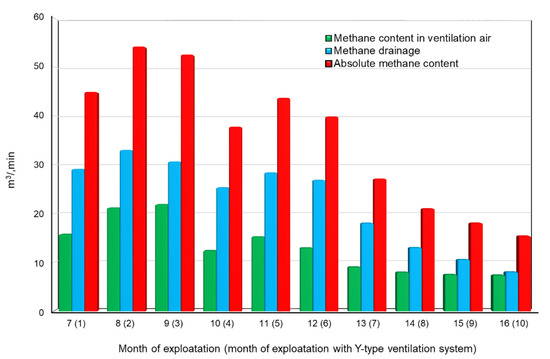

The absolute and ventilation methane content and the amount of the methane drained were gradually decreasing during subsequent months when using the Y-type system (Figure 10).

Figure 10.

Absolute methane, ventilation and methane drainage rate when using the Y-type ventilation system.

The mean value of absolute methane in the first month when the Y-type system was used reached 44.89 m3/min and was 0.39 m3/min higher than in the last month when the ventilation was based on the U-type system. The highest absolute methane value was reached in the second month of the Y-type system (and in the eighth month of the mining in general) and was 54.18 m3/min. The lowest mean daily absolute methane value occurred in the last month of the exploitation and amounted to 15.42 m3/min and was similar to that occurring during the first month of exploitation and at the same time when the U-type ventilation system was used. The mean absolute methane value when using the Y-type ventilation system reached 35.46 m3/min and was higher than the mean absolute methane value when using the U-type system by 1.1 m3/min. For the Y-type ventilation, the methane flow rate recorded in the system for the methane drainage was 22.31 m3/min on average and was higher than the flow rate recorded when using the U-type system by 3.18 m3/min. Ventilation methane for the Y-type system amounted on average to 13.15 m3/min and was lower than when using the U-type ventilation system by 2.1 m3/min.

The mean values of absolute methane, ventilation and methane drainage rate for both ventilation systems used are listed in Table 8. The average absolute methane content reached 34.37 m3/min in the case of the U-type ventilation system and 35.46 m3/min for the Y-type ventilation system. The average ventilation methane content related to the volume content of methane in the ventilation air for the U-type system was 15.24 m3/min and 13.15 m3/min for the Y-type system. The methane drainage system drained 19.13 m3/min of methane for the U-type ventilation system and 22.31 m3/min in the case of the Y-type ventilation system.

Table 8.

Mean absolute methane, ventilation and methane drainage values for the system on U and Y.

Generally, it can be stated that during the application of the Y-type ventilation system, the average ventilation methane content of the longwall decreased by 13.72%, while the absolute methane content of the longwall increased by 16.63%, and the methane volume flow captured by methane drainage systems increased by 3.18%.

During the sixteen months of operation, the total absolute methane content of the longwall amounted to 807 465.6 m3—of which 296,913.6 m3 was for the U-type ventilation system and 510,552 m3 for the Y-type ventilation system. The analysed ventilation methane content was 320,976 m3, of which 131,659.2 m3 of methane was released to the longwall area when using the U-type system, and 189,316.8 m3 for the Y-type system. The methane drainage system captured 486,489.6 m3 of methane.

However, it should be noted that period when the ventilation was based on the Y-type system was ten months, and the U-type system was used only for six months. The last four months of the operation when the Y-type system was applied were characterized by low absolute methane content (below 30 m3/min). When using the U-type ventilation system, this phenomenon only occurred for two months.

During the application of both ventilation systems, the average daily output of the longwalls remained at a similar level—about 2300 tonnes per day. In the last month of the operation, the longwall was prepared for decommissioning, which results in a significant reduction in extraction. During this period, the reduction in absolute and ventilation methane and the value of the methane captured by drainage systems are visible.

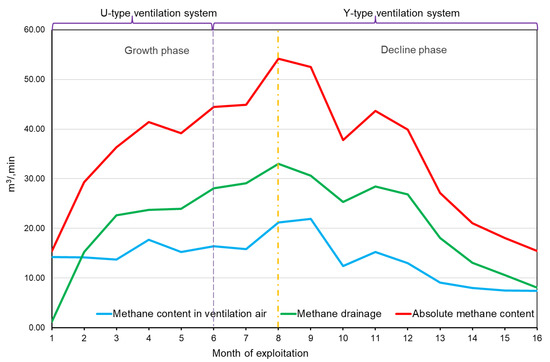

A gradual decrease in absolute methane content for the Y-type ventilation system during the subsequent months of the exploitation was caused by the gradual decrease in the methane content of the deposit. Generally, two phases can be distinguished that are related to the formation of methane—the growth phase and the decline phase (Figure 11). There is no stabilisation phase.

Figure 11.

Phases related to the formation of absolute methane, ventilation and methane drainage.

The results show a strong positive correlation between absolute and ventilation methane, and absolute methane and methane drainage during the operation based either on the U-type or the Y-type ventilation system. The smallest positive correlation, although still significant, was between ventilation methane and methane drainage (Table 9).

Table 9.

Correlations between absolute methane and methane drainage during the entire lifespan of the longwall.

The analysis of the correlations between absolute methane, ventilation and methane drainage rate when using both ventilation systems prove that a stronger correlation between the variables occurred when using the Y-type system (Table 10).

Table 10.

Correlations between absolute methane, ventilation and methane drainage for both longwall ventilation systems.

3.2. Analysis of the Coal Spontaneous Combustion Hazard

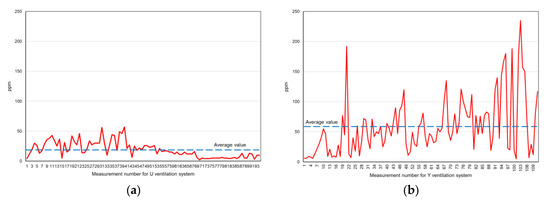

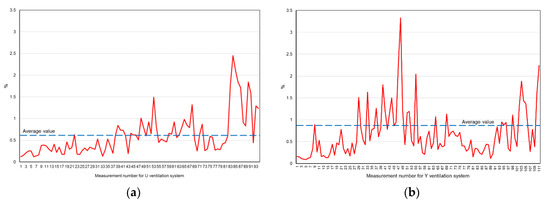

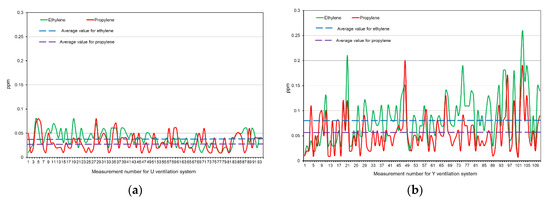

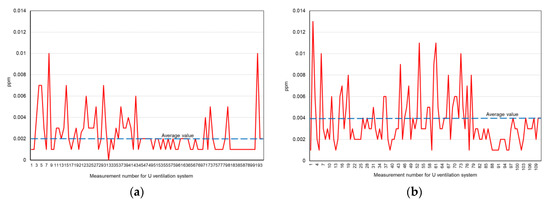

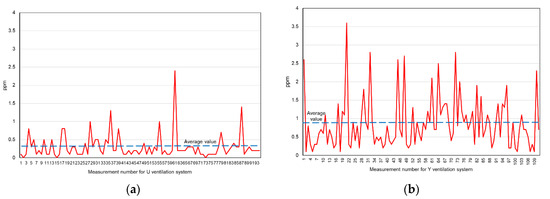

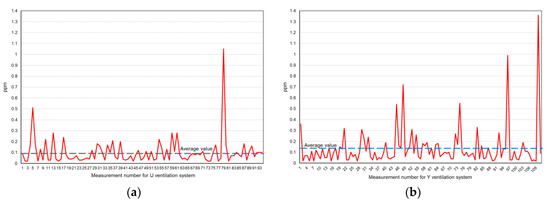

The Figure 12, Figure 13, Figure 14, Figure 15, Figure 16, Figure 17, Figure 18, Figure 19 and Figure 20 show the changes in gas concentration in the air samples taken from the goafs for both ventilation systems.

Figure 12.

Changes in concentrations of oxygen in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 13.

Changes in concentrations of carbon monoxide in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 14.

Changes in concentrations of carbon dioxide in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 15.

Changes in concentrations of hydrogen in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 16.

Changes in concentrations of ethylene and propylene in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 17.

Changes in concentrations of acetylene in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 18.

Changes in concentrations of ethane in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 19.

Changes in concentrations of propane in the goaf air—the U-type (a) and the Y-type ventilation system (b).

Figure 20.

Changes in concentrations of nitrogen in the goaf air—the U-type (a) and the Y-type ventilation system (b).

The analysis of the concentrations of gas changes in the air samples shows that the values depend on the type of ventilation and that the concentrations of oxygen (Figure 12) for the Y-type system were slightly lower than for the U-type system. This proves that the oxidation reactions of the coal in the goafs occurred. During such a reaction, the concentration of oxygen in the atmosphere in the goaf is reduced and the proportion of gases resulting from chemical reactions associated with the process of oxidation, spontaneous heating and spontaneous combustion is increased, which is confirmed by the concentrations of carbon monoxide, carbon dioxide, hydrogen and acetylene, and ethylene and propylene.

In hard coal mining, carbon monoxide is the basic indicator gas for the oxidation and spontaneous heating reactions that lead to spontaneous combustion of coal. The increase in its content (Figure 13) in the air for the Y-ventilation system in relation to the U-type system indicates the processes of the low-temperature oxidation of coal or spontaneous combustion of coal. This gas is present in the air only after these two processes occurred.

The characteristics of carbon dioxide concentrations (Figure 14) also indicate that for the Y-type system, the reactions of spontaneous combustion of coal occurred more intensively than for the U-type ventilation system. The process of spontaneous combustion increases the concentrations of carbon dioxide in the air (Figure 14) and the concentration of oxygen decreases (Figure 13). The dynamics of these changes are more or less the same. At the same time, it should be noted that in an underground hard coal mine, the presence of carbon dioxide is also connected with its secretion from the rock mass, so it should always be analysed, along with changes in concentrations of oxygen.

Analysis of changes in concentrations of hydrogen (Figure 15) ethylene and propylene (Figure 16), acetylene (Figure 17), propane (Figure 18) and ethane (Figure 20), were for the Y-type ventilation system compared to the U-type system. These gases are emitted as the temperature of coal increases, which means that the coal spontaneous heating when using the Y-type ventilation system is more intense.

Changes in nitrogen concentration for both the U-type and Y-type ventilation system (Figure 20), also indicate an increased risk of coal spontaneous heating for the Y-type system. During this process, the tendencies of changes in nitrogen content (Figure 20) and oxygen content (Figure 12) are divergent, because the nitrogen content in the air increases and the oxygen content decreases.

Table 11 presents basic descriptive statistics for the test gas concentrations for both ventilation systems. The results clearly show that for both systems, the level of probability of coal spontaneous combustion increases. This is evidenced by an increase in the concentrations of gases produced during chemical reactions associated with low-temperature oxidation, leading to coal spontaneous combustion with a simultaneous reduction in oxygen concentration.

Table 11.

Basic descriptive statistics for tested gas concentrations in air samples taken from goafs when using the U and Y venting system.

4. General Discussion

The process of underground mining is continuously associated with the occurrence of natural hazards. Currently, the most burdensome and dangerous are ventilation hazards. The case study presented in the paper shows that different types of hazards occur simultaneously. This co-occurrence often significantly limits the methods designed to limit their impact. Measures to reduce one type of hazard can simultaneously activate another.

Such a case is presented in this article. Two hazards—methane and coal spontaneous combustion—accumulated in tested longwall. Both are extremely dangerous and can cause serious disturbances in the production process and pose a great danger to the workers.

One method to limit the consequences of these hazards is to choose a proper ventilation system. However, a system that has the capacity to reduce the methane release hazard simultaneously increases the coal spontaneous combustion hazard. Nevertheless, it is clear that a proper ventilation system selected as early as at the stage of designing the operation is one of the key factors that will ensure safe and effective underground operation. The longwall ventilation system must have the capacity to reduce the hazardous concentrations of methane and gaseous products of the processes associated with the spontaneous combustion of coal and to provide conditions that will allow for continuous mining. Unfortunately, it is extremely difficult to find a system that will meet both conditions.

The mining process of the case presented in the paper was initially based on the U-type ventilation system, which later proved to be very ineffective in reducing the methane release hazard. This system made it practically impossible to continue the mining process. Very frequent exceedances of the methane concentration limits caused interruptions, which, in turn, completely disrupted the entire production cycle. This resulted in the need to change the ventilation system to a more favourable and efficient one in terms of methane. The Y-type ventilation system managed to significantly reduce the concentrations of methane, but it led to an increase in the coal spontaneous combustion tendency. The Y-type system caused most of the air to enter the goaf, which can activate the combustion.

The results presented in Section 3 clearly indicate that the U-type longwall ventilation system, in the case of high methane release hazard, characterized by exceeding the permissible concentrations of methane in the air, prevents safe and effective operation. At the same time, the use of this system limits the carbon oxidation reactions in the goaf leading to coal spontaneous heating and combustion, which is confirmed by the low concentrations of gases that are the products of these reactions. In turn, the Y-type ventilation system enables safe and effective operation in conditions where there is a methane release hazard but deteriorates the safety conditions related to spontaneous combustion of coal.

It is evident that the presented case is remarkably interesting from a scientific and practical perspective. It clearly demonstrates the advantages and disadvantages of both ventilation systems used in the same longwall. Moreover, such a case when two different ventilation methods are used is extremely rare.

The authors believe that when methane concentration stays above 1.5% (median) for half of the working day, with simultaneous application of all possible preventive measures, in a longwall maintained in the mine air in the area of the intersection of a longwall with a tailgate, after the full launch of the longwall and the nominal mining capacity, the initial ventilation system must be changed—for instance, to the Y–type system. This involves specific financial outlays, but if the longwall is economically balanced, such a solution can help to successfully complete the exploitation of the longwall.

5. Conclusions

The paper presents the results of the analysis of the impact that the longwall ventilation system has on the formation of two basic ventilation hazards during mining: the methane release hazard and spontaneous combustion of coal.

The following statements and conclusions are based on the measurements, calculations, and analyses carried out:

- -

- The average absolute methane content reached 34.37 m3/min in the case of the U-type ventilation system, and 35.46 m3/min for the Y-type ventilation system. The average ventilation methane content related to the volume content of methane in the ventilation air for the U-type system was 15.24 m3/min, and 13.15 m3/min for the Y-type system. The methane drainage system drained 19.13 m3/min of methane for the U-type ventilation system, and 22.31 m3/min in the case of the Y-type ventilation system;

- -

- The ventilation methane content of the longwall when using the U-type system was almost 14% higher compared to the Y-type system. At the same time, the absolute methane content of the longwall when using the U-type ventilation system was lower than in the case of the Y-type system;

- -

- The efficiency of the methane drainage system increased in the case of the Y-type ventilation system—on average, 14% more methane was drained compared to the U-type system;

- -

- The number of times the permitted methane concentrations were exceeded when using the U-type system was 1295, and as “only” ventilation 47 for the U-type system. The highest number of exceedances of the permissible methane concentrations when using the U-type ventilation system was recorded by the M4 sensor (776 cases), and when using the Y-type ventilation system by the M5 sensor (21 cases). There is a clear reduction in the number of exceedances, which is very important for the continuity and efficiency of the mining process;

- -

- The maximum average methane content in the ventilation air for the U-type ventilation system within the intersection of the longwall and the tailgate was 2.3%, and 1.5% for the Y-type ventilation system;

- -

- The average concentration of gases (ethane, ethylene, propane, propylene, acetylene, carbon monoxide, carbon dioxide, hydrogen) produced during the process of oxidation and spontaneous heating of coal left in the goaf leading to its spontaneous combustion were higher for the Y-type ventilation system compared to the U-type ventilation system. At the same time, the average values of oxygen concentration in the goaf for the Y-type system were lower than for the U-type ventilation system, which indicated an intensified process of coal oxidation. The average content of carbon monoxide in the air samples taken from the goaf when using the Y-type longwall ventilation system was almost three times higher than when using the U-type system. The average content of propylene and ethylene was twice as high when using the Y-type longwall ventilation system, compared to when using the U-type system. The average oxygen content when using the Y-type ventilation system was lower than when using the U-type system; this indicates an intensified process of coal oxidation, leading to its coal spontaneous heating;

- -

- In order to reliably assess the impact of the longwall ventilation system on the level of endogenous fire hazard in the goafs, it is necessary to conduct a full analysis of the change in the concentration of fire gases as a function of time treated as fire indicators. These gases include oxygen, nitrogen, carbon monoxide, and carbon dioxide, hydrogen, and unsaturated hydrocarbons. An analysis of the concentrations of individual gases does not provide a complete picture of the endogenous fire hazard and can lead to incorrect findings.

Following the tests carried out and the results obtained, it can be concluded that the methane release hazard is higher when using the U-type longwall ventilation system than when using the Y-type ventilation system. At the same time, the hazard of coal spontaneous combustion is lower when using the U-type system compared to the Y-type system. Such data are therefore very important, since it is necessary to ensure the safety of the coal extraction process.

The case presented by the authors is probably the first research of this kindconducted and presented. The authors hope that it will contribute to the discussion on the optimal selection and, if necessary, change of the ventilation system for active longwalls.

Author Contributions

Conceptualization, M.T. and J.B.; D.S.; L.S.; methodology, J.B. and M.T.; software, M.T. and J.B.; formal analysis, J.B. and M.T.; investigation, J.B. and M.T.; resources, M.T.; D.S.; J.B. and S.Z.; data curation, M.T.; D.S.; J.B. and L.S.; writing of the original draft preparation, M.T.; writing of review and editing, J.B.; M.T.; visualization, M.T.; supervision, M.T. and J.B.; project administration, M.T. and J.B.; funding acquisition, M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This publication was funded by the statutory research performed at Silesian University of Technology, Department of Safety Engineering, Faculty of Mining, Safety Engineering and Industrial Automation (06/030/BKM-20/0053).

Acknowledgments

This article is the result of statutory research performed at Silesian University of Technology, Department of Production Engineering, Faculty of Organization and Management (13/030/BK-20/0059) and the statutory research performed at Silesian University of Technology, Department of Safety Engineering, Faculty of Mining, Safety Engineering and Industrial Automation (06/030/BKM-20/0053). This article is the result of the research project No. PBS3/B6/25/2015, “Application of the Overall Equipment Effectiveness method to improve the effectiveness of the mechanized longwall system’s work in the coal exploitation process”, carried out in 2015–2018, financed by The National Centre for Research and Development.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gui, C.; Geng, F.; Tang, J.; Niu, H.; Zhou, F.; Liu, C.; Hu, S.; Teng, H. Gas–solid two-phase flow in an underground mine with an optimized air-curtain system: A numerical study. Process Saf. Environ. Prot. 2020, 20, 137–150. [Google Scholar] [CrossRef]

- Xiu, Z.; Nie, W.; Yan, J.; Chen, D.; Cai, P.; Liu, Q.; Du, T.; Yang, B. Numerical simulation study on dust pollution characteristics and optimal dust control air flow rates during coal mine production. J. Clean. Prod. 2020, 248, 119197. [Google Scholar] [CrossRef]

- Aguado, M.; Nicieza, C. Control and prevention of gas outbursts in coal mines, Riosa–Olloniego coalfield, Spain. Int. J. Coal Geol. 2007, 69, 253–266. [Google Scholar] [CrossRef]

- Cao, S.; Liu, Y.; Wang, Y. A forecasting and forewarning model for methane hazard in working face of coal mine based on LS-SVM. J. China Univ. Min. Technol. 2008, 18, 172–176. [Google Scholar] [CrossRef]

- Kędzior, S.; Dreger, M. Methane occurrence, emissions and hazards in the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2019, 211, 103226. [Google Scholar] [CrossRef]

- Shi, S.; Jiang, B.; Meng, X. Assessment of gas and dust explosion in coal mines by means of fuzzy fault tree analysis. Int. J. Min. Sci. Technol. 2018, 28, 991–998. [Google Scholar] [CrossRef]

- Yang, S.; Hu, X.; Liu, W.V.; Cai, J.; Zhou, X. Spontaneous combustion influenced by surface methane drainage and its prediction by rescaled range analysis. Int. J. Min. Sci. Technol. 2018, 28, 215–221. [Google Scholar] [CrossRef]

- Yu, Y.; Bai, J.; Wang, X.; Zhang, L. Control of the surrounding rock of a goaf-side entry driving heading mining face. Sustainability 2020, 12, 2623. [Google Scholar] [CrossRef]

- Mark, C.; Gauna, M. Evaluating the risk of coal bursts in underground coal mines. Int. J. Min. Sci. Technol. 2016, 26, 47–52. [Google Scholar] [CrossRef]

- Burtan, Z.; Stasica, Z.; Rąk, Z. The influence of natural hazards of disasters on the work safety conditions in Polish coal mining in the years 2000–2016. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią PAN 2017, 101, 7–18. [Google Scholar]

- Burtan, Z.; Chlebowski, D.; Kapusta, M. The scale and conditions of disasters induced by the occurrence of natural hazards in the coal mining sector in Poland. Bezpieczeństwo Pr. Ochr. Środowiska Górnictwie 2018, 7, 3–11. [Google Scholar]

- Liang, K.; Liu, J.; Wang, C. The coal mine accident causation model based on the hazard theory. Procedia Eng. 2011, 26, 2199. [Google Scholar] [CrossRef]

- Ramani, R.V. Mining disasters caused and controlled by mankind: The case for coal mining and other minerals Part 1: Causes of mining disasters. Nat. Resour. Forum 1995, 19, 233–242. [Google Scholar] [CrossRef]

- Saleh, J.H.; Cummings, A.M. Safety in the mining industry and the unfinished legacy of mining accidents: Safety levers and defense-in-depth for addressing mining hazards. Saf. Sci. 2011, 49, 764–777. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Shao, Z.; Xu, C.; Zhu, X.; Qi, X.; Liu, F. A statistical analysis of coal mine fires and explosions in China. Process Saf. Environ. Protect. 2019, 121, 357–366. [Google Scholar] [CrossRef]

- Harris, J.; Kirsch, P.A.; Shi, M.; Li, J.; Gagrani, A. Comparative analysis of coal fatalities in Australia, South Africa, India, China and USA, 2006–2010. Coal Oper. Conf. 2014, 399–407. [Google Scholar]

- Brodny, J.; Tutak, M. Analysing the utilisation effectiveness of mining machines using independent data acquisition systems: A case study. Energies 2019, 12, 2505. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Olea, R.A.; Goodman, G. Geostatistical modeling of the gas emission zone and its in-place gas content for Pittsburgh-seam mines using sequential Gaussian simulation. Int. J. Coal Geol. 2012, 90, 50–71. [Google Scholar] [CrossRef]

- Hu, S.; Yang, S.; Liu, W.V.; Zhou, X.; Sun, J.; Yu, H. A methane emission control strategy in the initial mining range at a spontaneous combustion-prone longwall face: A case study in coal 15, Shigang Mine, China. J. Nat. Gas Sci. Eng. 2017, 38, 504–515. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, J.; Wang, L.; Luo, H.; Ren, T. Forecasting spontaneous combustion of coal in underground coal mines by index gases: A review. J. Loss Prev. Proc. 2019, 57, 208–222. [Google Scholar] [CrossRef]

- Ma, D.; Qin, B.; Li, L.; Gao, A.; Gao, Y. Study on the methane explosion regions induced by spontaneous combustion of coal in longwall gobs using a scaled-down experiment set-up. Fuel 2019, 254, 115547. [Google Scholar] [CrossRef]

- Ma, L.; Zou, L.; Ren, L.; Chung, Y.; Zhang, P.; Shu, C. Prediction indices and limiting parameters of coal spontaneous combustion in the Huainan mining area in China. Fuel 2020, 264, 116883. [Google Scholar] [CrossRef]

- Wen, H.; Yu, Z.; Fan, S.; Zhai, X.; Liu, W. Prediction of spontaneous combustion potential of coal in the gob area using CO extreme concentration: A case study. Combust. Sci. Technol. 2017, 189, 1713–1727. [Google Scholar] [CrossRef]

- Xia, T.; Zhou, F.; Wang, X.; Zhang, Y.; Li, Y.; Kang, J.; Liu, J. Controlling factors of symbiotic disaster between coal gas and spontaneous combustion in longwall mining gobs. Fuel 2016, 182, 886–896. [Google Scholar] [CrossRef]

- Zhai, X.; Xu, Y.; Yu, Z. Numerical analysis on the evolution of CO concentration in return corner: A case study of steady U-type ventilation working face. Numer. Heat Trans. Part A Appl. 2018, 74, 1732–1746. [Google Scholar] [CrossRef]

- Zhuo, H.; Qin, B.; Qin, Q.; Su, Z. Modeling and simulation of coal spontaneous combustion in a gob of shallow buried coal seams. Process Saf. Environ. Protect. 2019, 131, 246–254. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Rossell, J.M.; Vintró, C. Study of Spanish mining accidents using data Mining techniques. Saf. Sci. 2015, 75, 49–55. [Google Scholar] [CrossRef]

- Gowrisankaran, G.; He, C.; Lutz, E.; Burgess, J. Productivity, Safety, and Regulation in Underground Coal Mining: Evidence from Disasters and Fatalities. Available online: https://www.nber.org/papers/w21129.pdf (accessed on 15 July 2020).

- Xu, Y.; Li, Z.; Zhai, X.; Yu, Z. Potential dangerous zone of coal spontaneous combustion and gas coupled hazard in goaf under mining condition. J. China Coal Soc. 2019. [Google Scholar] [CrossRef]

- Ma, L.; Guo, R.Z.; Gao, Y.; Ren, L.F.; Wei, G.M.; Li, C.H. Study on coal spontaneous combustion characteristics under methane-containing atmosphere. Combust. Sci. Technol. 2019, 191, 1456–1472. [Google Scholar] [CrossRef]

- Massanés, M.B.; Pera, L.S.; Moncunill, J.O. Ventilation management system for underground environments. Tunn. Undergr. Space Technol. 2015, 205, 516–522. [Google Scholar] [CrossRef]

- Szurgacz, D.; Tutak, M.; Brodny, J.; Sobik, L.; Zhironkina, O. The Method of Combating Coal Spontaneous Combustion Hazard in Goafs—A Case Study. Energies 2020, 13, 4538. [Google Scholar] [CrossRef]

- Su, H.T.; Zhou, F.B.; Song, X.L.; Qiang, Z.Y. Risk analysis of spontaneous coal combustion in steeply inclined longwall gobs using a scaled-down experimental set-up. Process. Saf. Environ. Prot. 2017, 111, 1–12. [Google Scholar] [CrossRef]

- Tang, M.Y.; Jiang, B.Y.; Zhang, R.Q.; Yin, Z.Q.; Dai, G.L. Numerical analysis on the influence of gas extraction on air leakage in the gob. J. Nat. Gas Sci. Eng. 2016, 33, 278–286. [Google Scholar] [CrossRef]

- Wu, J.J.; Liu, X.C. Risk assessment of underground coal fire development at regional scale. Int. J. Coal Geol. 2011, 86, 87–94. [Google Scholar] [CrossRef]

- Fernánez-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bernardo-Sánchez, A.; Bascompta, M. Analysis of the fire propagation in a sublevel coal mine. Energies 2020, 13, 3754. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. The impact of the strength of roof rocks on the extent of the zone with a high risk of spontaneous coal combustion for fully powered longwalls ventilated with the y-type system—A case study. Appl. Sci. 2019, 9, 5315. [Google Scholar] [CrossRef]

- Mine Ventilation Systems. Available online: http://web.mst.edu/~tien/218/lab8-systems.pdf (accessed on 15 July 2020).

- Kingery, D.S. Introduction to Mine Ventilating Principles and Practices; United States Government printing office: Washington, DC, USA, 1960.

- Szlązak, J.; Szlązak, N. Filtracja Powietrza Przez Zroby Ścian Zawałowych w Kopalniach Węgla Kamiennego; AGH Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2005. [Google Scholar]

- Kłeczek, Z. Geomechanika Górnicza; Śląskie Wydawnictwo Techniczne: Katowice, Poland, 1994. [Google Scholar]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. J. Environ. Geol. 2003, 44, 28. [Google Scholar] [CrossRef]

- Brune, J.; Grubb, J.; Bogin, G.; Zipf, R.; Marts, J.; Gilmore, R.; Lolon, S.; Saki, S. A Critical Look at Longwall Bleeder Ventilation. Available online: https://www.semanticscholar.org/paper/A-Critical-Look-at-Longwall-Bleeder-Ventilation-Brune-Grubb/bb0d5819f17103a1e9faddb336930441510fc537 (accessed on 15 August 2020).

- Chen, P.; Zhang, L.; Zou, D. Study of three-dimensional distribution of permeability in gob based on o-shape circle theory. Min. Saf. Environ. Prot. 2015, 42, 38–41. [Google Scholar]

- Das, S.K. Observations and classification of roof strata behaviour over longwall coal mining panels in India. Int. J. Rock Mech. Min. Sci. 2000, 37, 585–597. [Google Scholar] [CrossRef]

- Wang, K.; Tang, H.; Miao, Y.; Liu, D. Research on complex air leakage method to prevent coal spontaneous combustion in longwall goaf. PLoS ONE 2019, 14, e0213101. [Google Scholar] [CrossRef]

- Gilman, A.; Beckie, R. Flow of coal-bed methane to a gallery. Transp. Porous Media 2000, 41, 1–16. [Google Scholar] [CrossRef]

- Valliappan, S.; Wohua, Z. Numerical modelling of methane gas migration in dry coal seams. Int. J. Numer. Anal. Methods Geomech. 1996, 20, 571–593. [Google Scholar] [CrossRef]

- Barker-Read, G.R.; Radchenko, S.A. Methane emission from coal and associated strata samples. Int. Min. Ceol. Eng. 1989, 7, 101–126. [Google Scholar] [CrossRef]

- Bertrard, C.; Bruyet, B.; Gunther, J. Determination of desorb able gas concentration of coal (direct method). Int. Rock Mech. Min. Sci. 1970, 7, 43–65. [Google Scholar] [CrossRef]

- Jolly, D.C.; Morris, H.; Hinsley, F.B. An investigation into the relationship between the methane sorption capacity of coal and gas pressure. Min. Eng. 1968, 127, 539–548. [Google Scholar]

- Hildenbrand, A.; Krooss, B.M.; Busch, A.; Gaschnitz, R. Evolution of methane sorption capacity of coal seams as a function of burial history—A case study from the Campine Basin, NE Belgium. Int. J. Coal Geol. 2006, 66, 179–203. [Google Scholar] [CrossRef]

- Kam, A.Y.; Hixson, A.N.; Perlmutter, D.D. The oxidation of bituminous coal—I Development of a mathematical model. Chem. Eng. Sci. 1976, 31, 815–819. [Google Scholar] [CrossRef]

- Kam, A.Y.; Hixson, A.N.; Perlmutter, D.D. The oxidation of bituminous coal—II experimental kinetics and interpretation. Chem. Eng. Sci. 1976, 31, 821–834. [Google Scholar] [CrossRef]

- Lu, P.; Liao, G.X.; Sun, J.H.; Li, P.D. Experimental research on index gas of the coal spontaneous at low-temperature stage. J. Loss Prevent. Proc. 2004, 17, 243–247. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Z.P.; Ma, L.; Ziai, X.W. Research on correspondence relationship between coal spontaneous combustion index gas and feature temperature. Coal Sci. Technol. 2008, 36, 47–51. [Google Scholar]

- Adamus, A.; Sancer, J.; Guranova, P.; Zubicek, V. An investigation of the factors associated with interpretation of mine atmosphere for spontaneous combustion in coal mines. Fuel Process. Technol. 2011, 92, 663–670. [Google Scholar] [CrossRef]

- Arisoy, A.; Beamish, B. Mutual effects of pyrite and moisture on coal self-heating rates and reaction rate data for pyrite oxidation. Fuel 2015, 139, 107–114. [Google Scholar] [CrossRef]

- Dai, G.L. Study on the gaseous products in coal oxidation at low temperature. Coal Mine Saf. 2007, 1, 1–4. [Google Scholar]