Steady-State Performance Prediction for a Variable Speed Direct Expansion Air Conditioning System Using a White-Box Based Modeling Approach

Abstract

1. Introduction

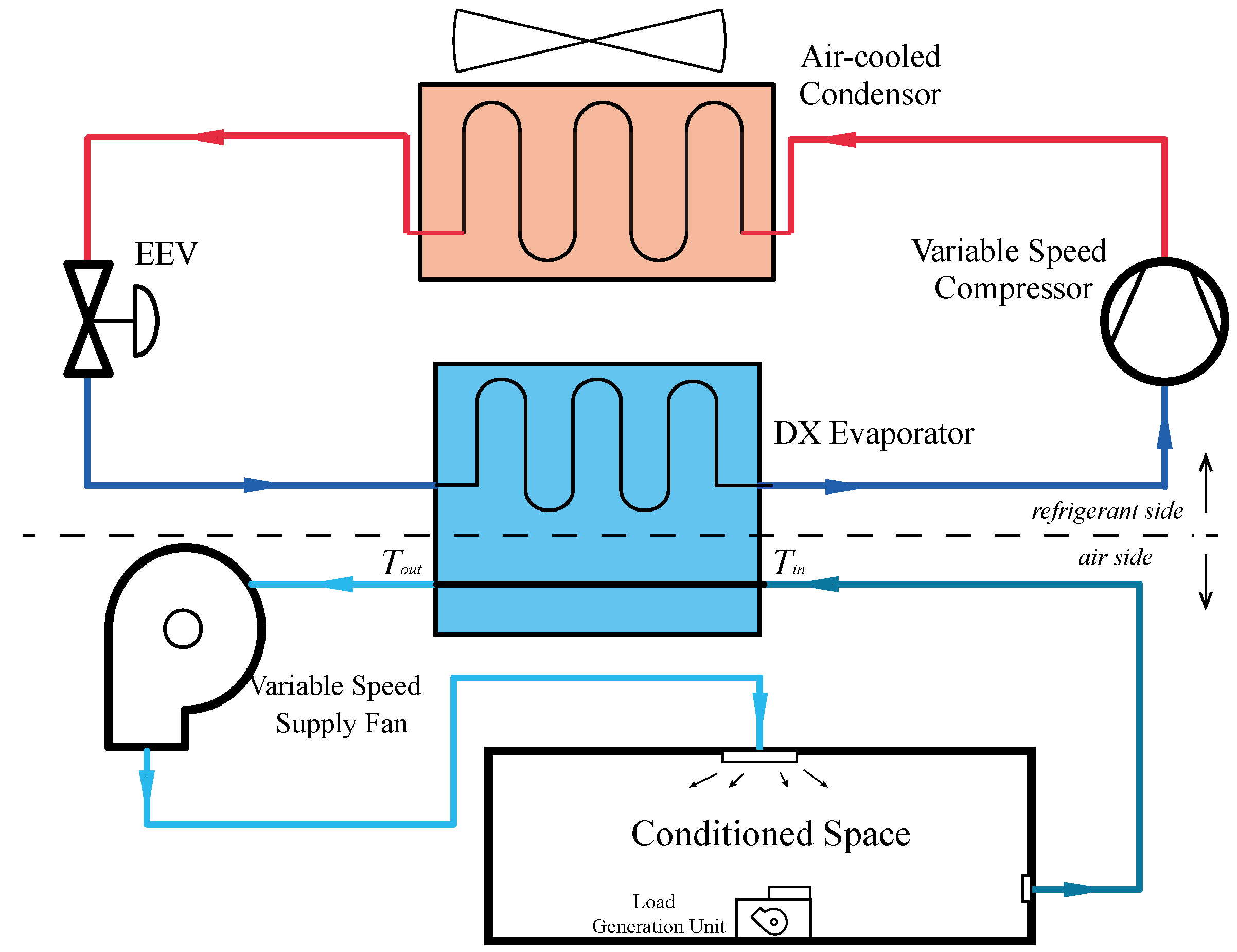

2. Model Development for a DX A/C System

2.1. Descriptions of the Modeled DX A/C System

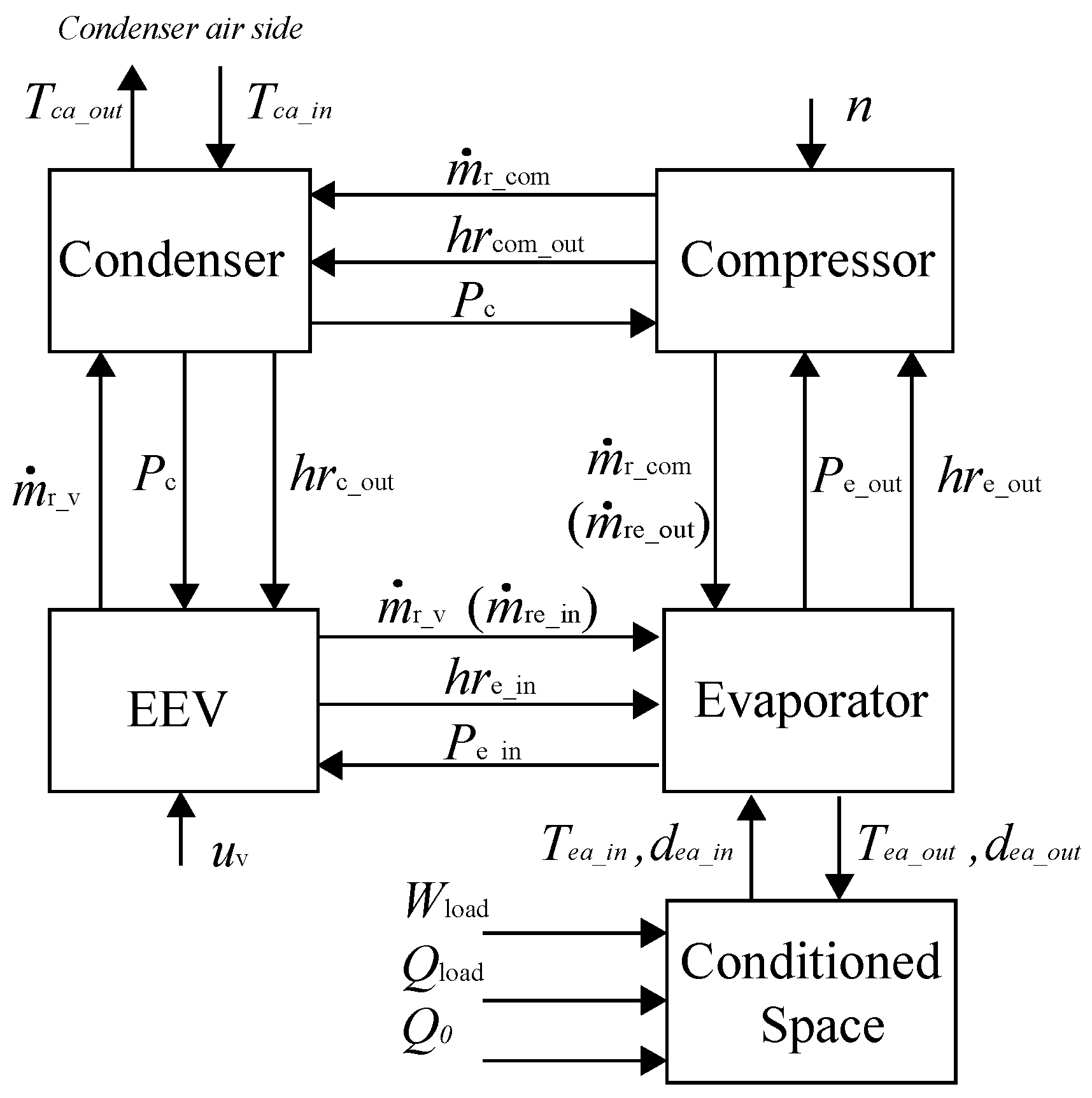

2.2. Model Development

2.2.1. Compressor Sub-Model

2.2.2. EEV Sub-Model

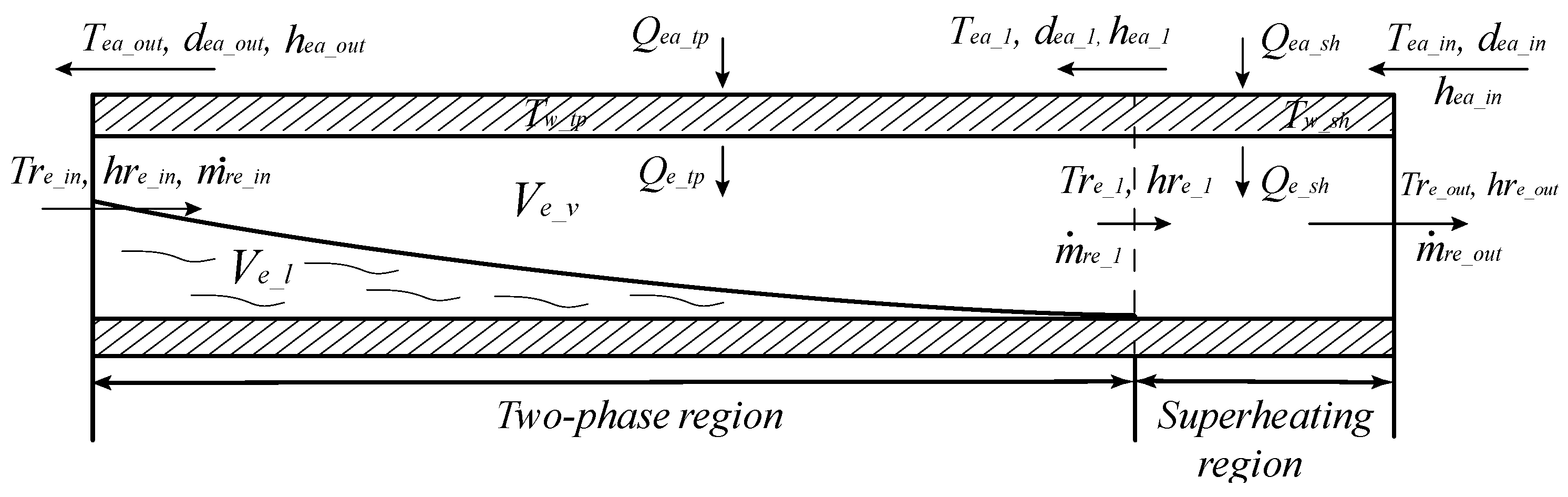

2.2.3. Evaporator and Condenser Sub-Models

Two-Phase Region

Superheating Region

2.2.4. Conditioned Space Sub-Model

2.2.5. Numerical Solution Procedure

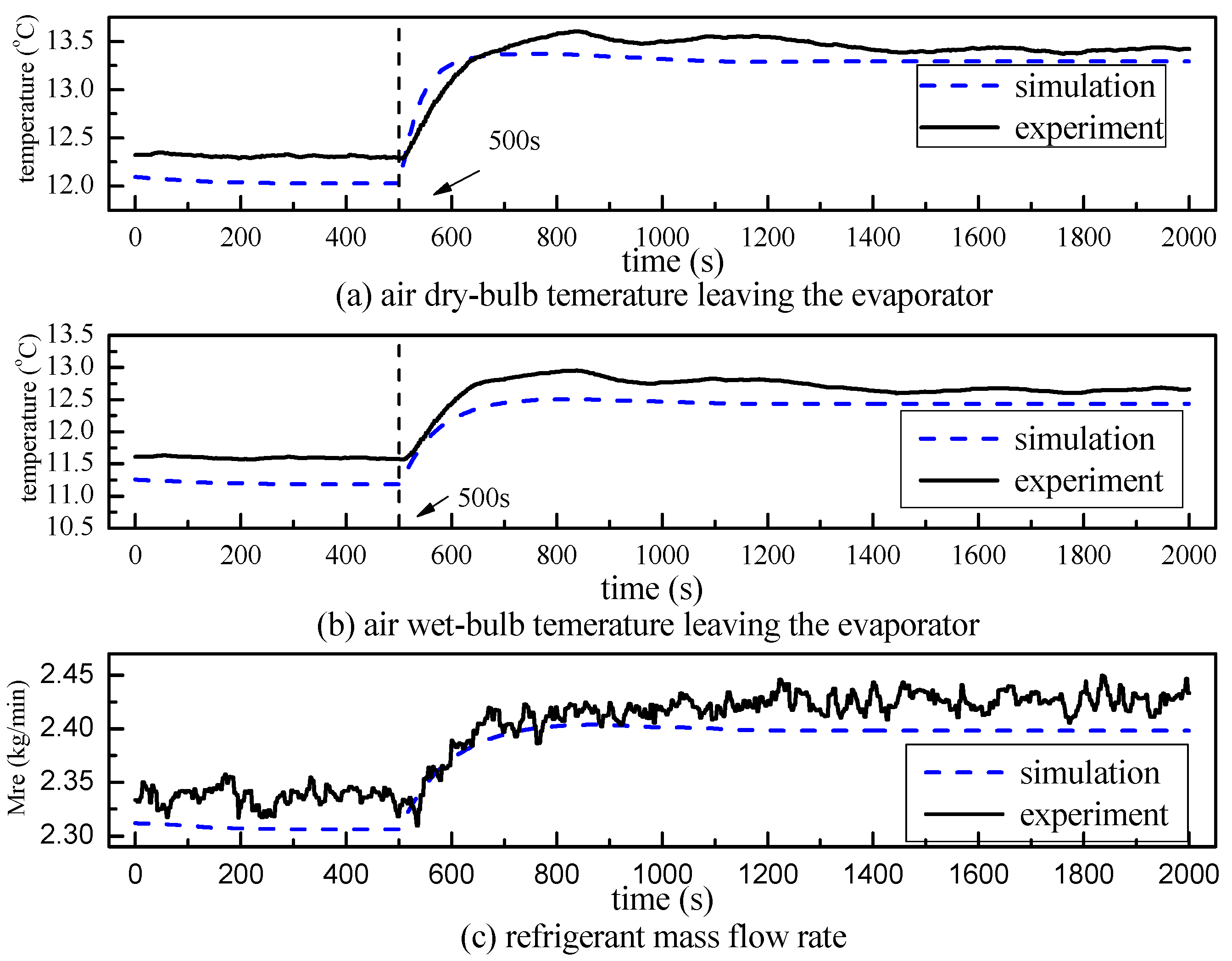

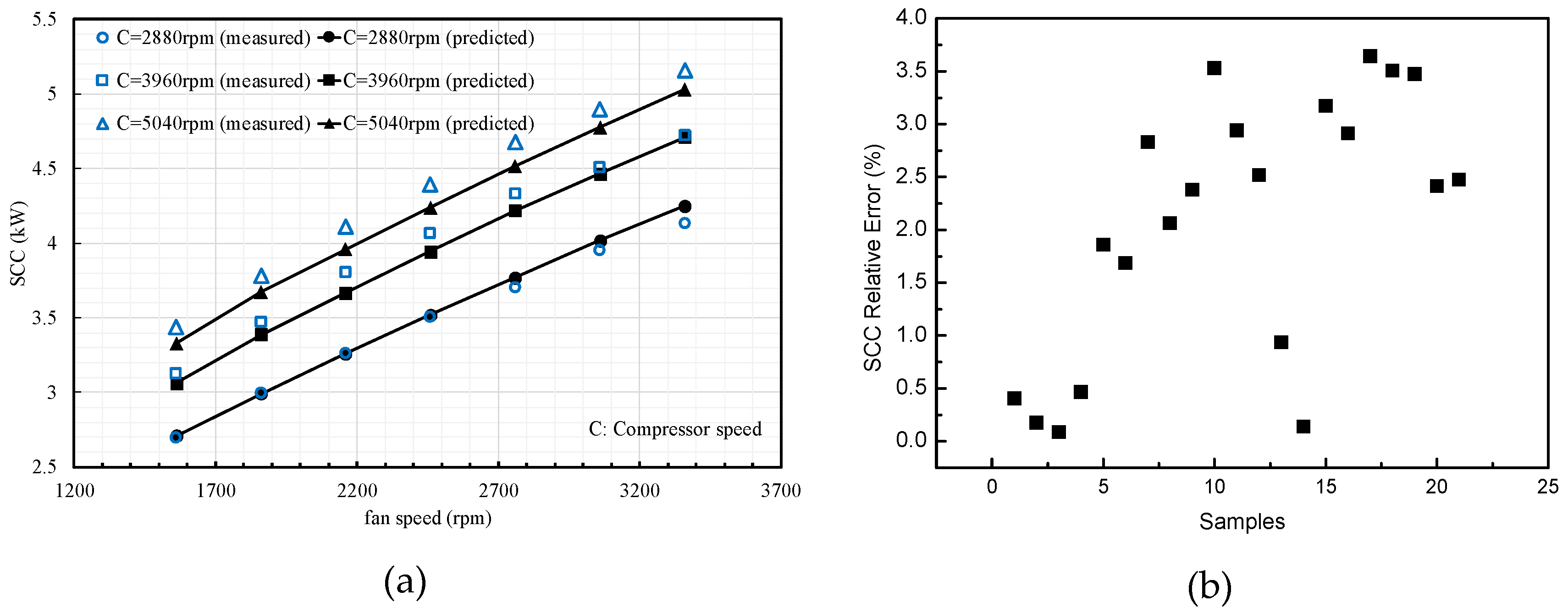

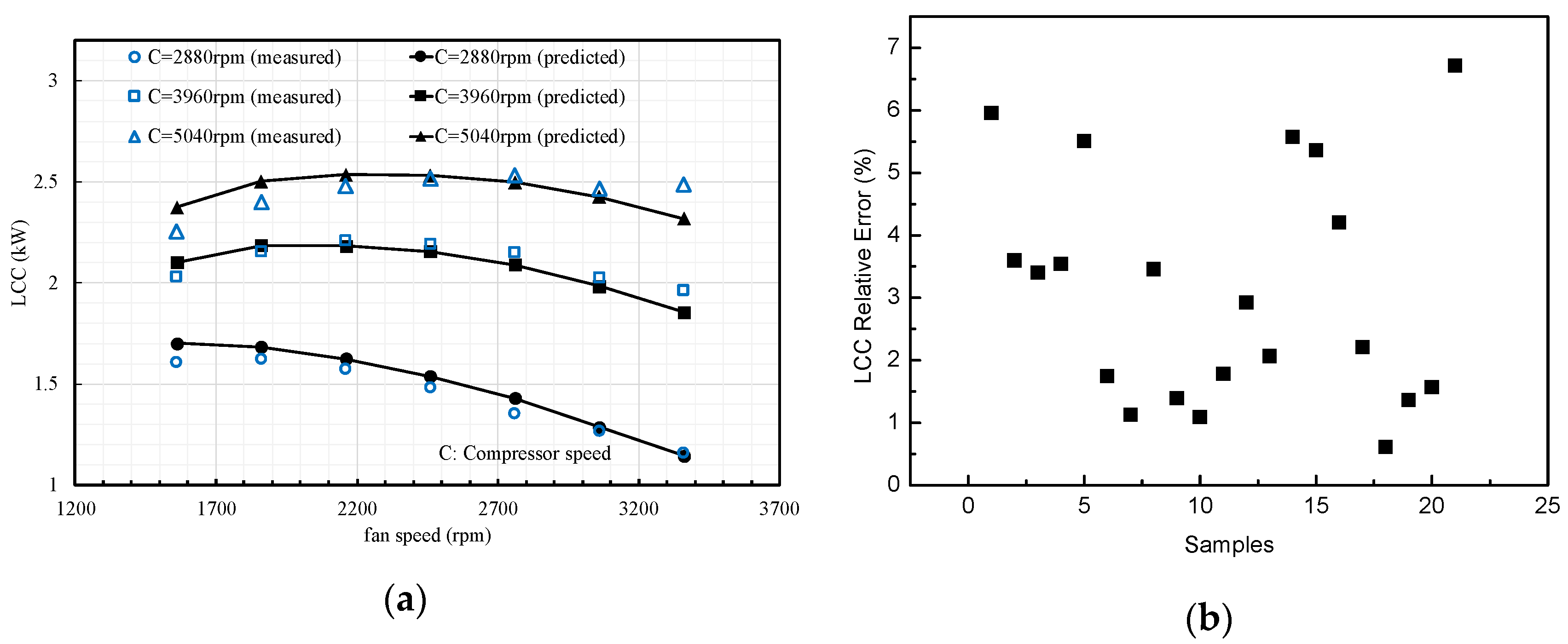

3. Model Validation

4. Operating Performance Prediction under Various Operational Conditions

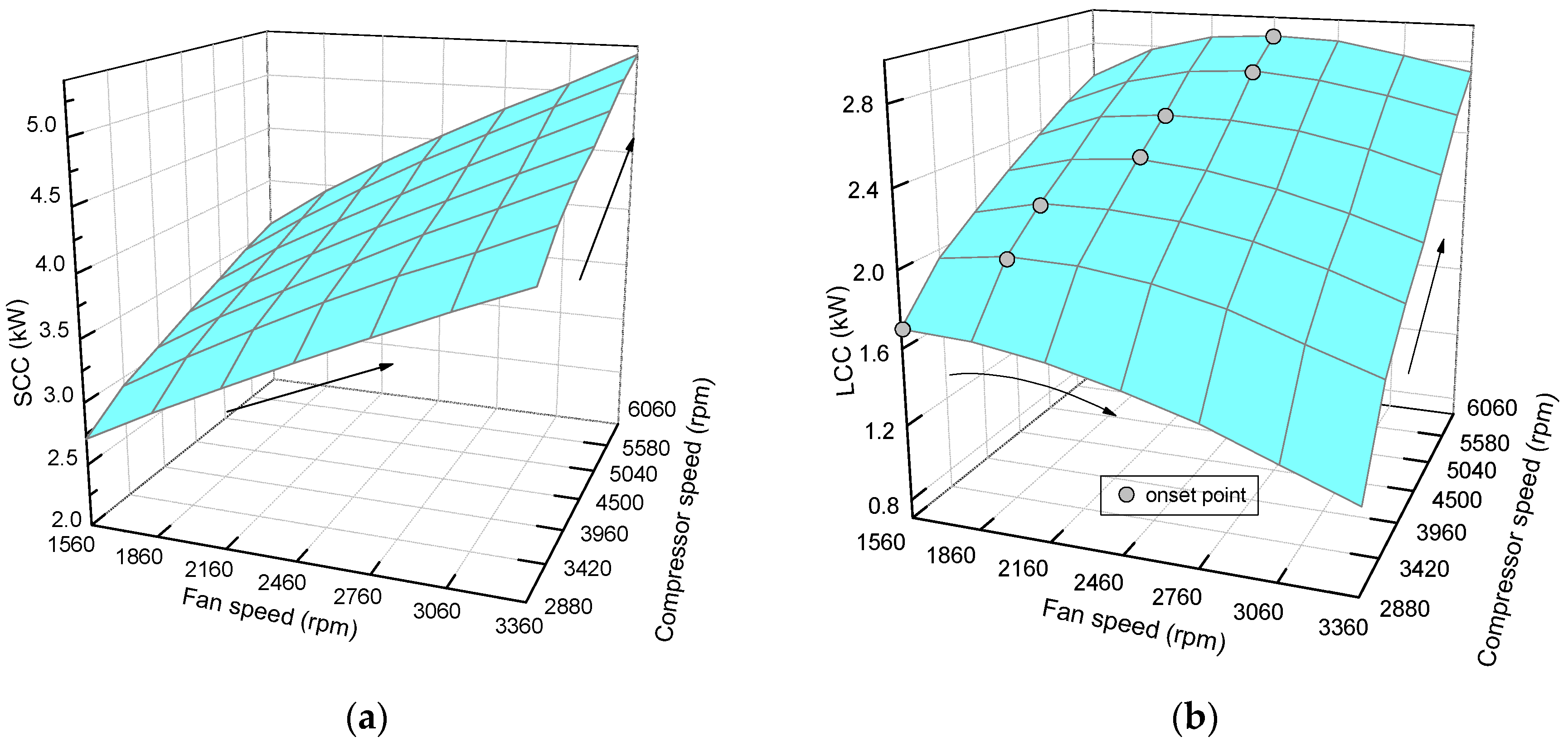

4.1. Relationships between SCC and LCC under Variable Speed Operation

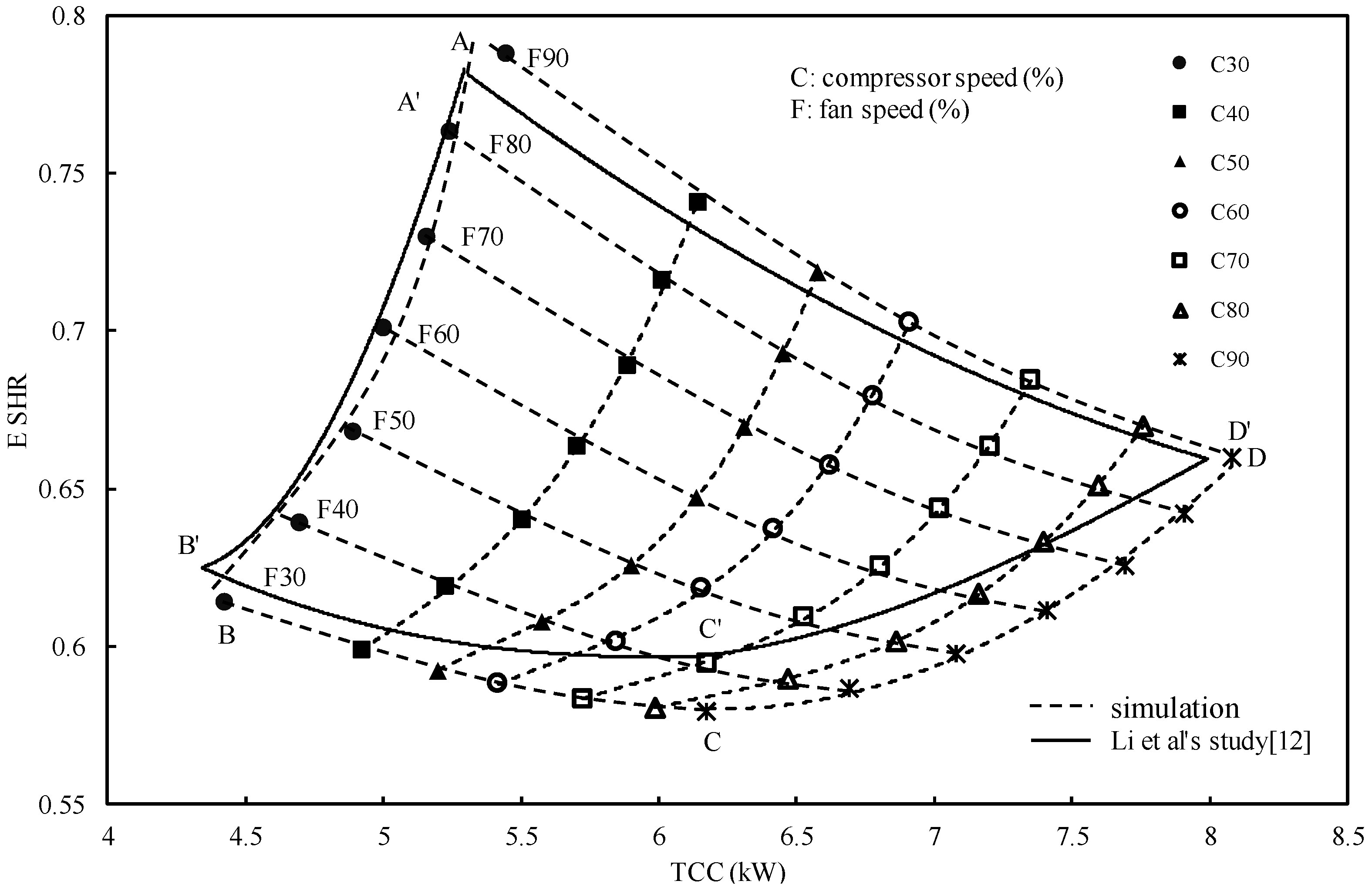

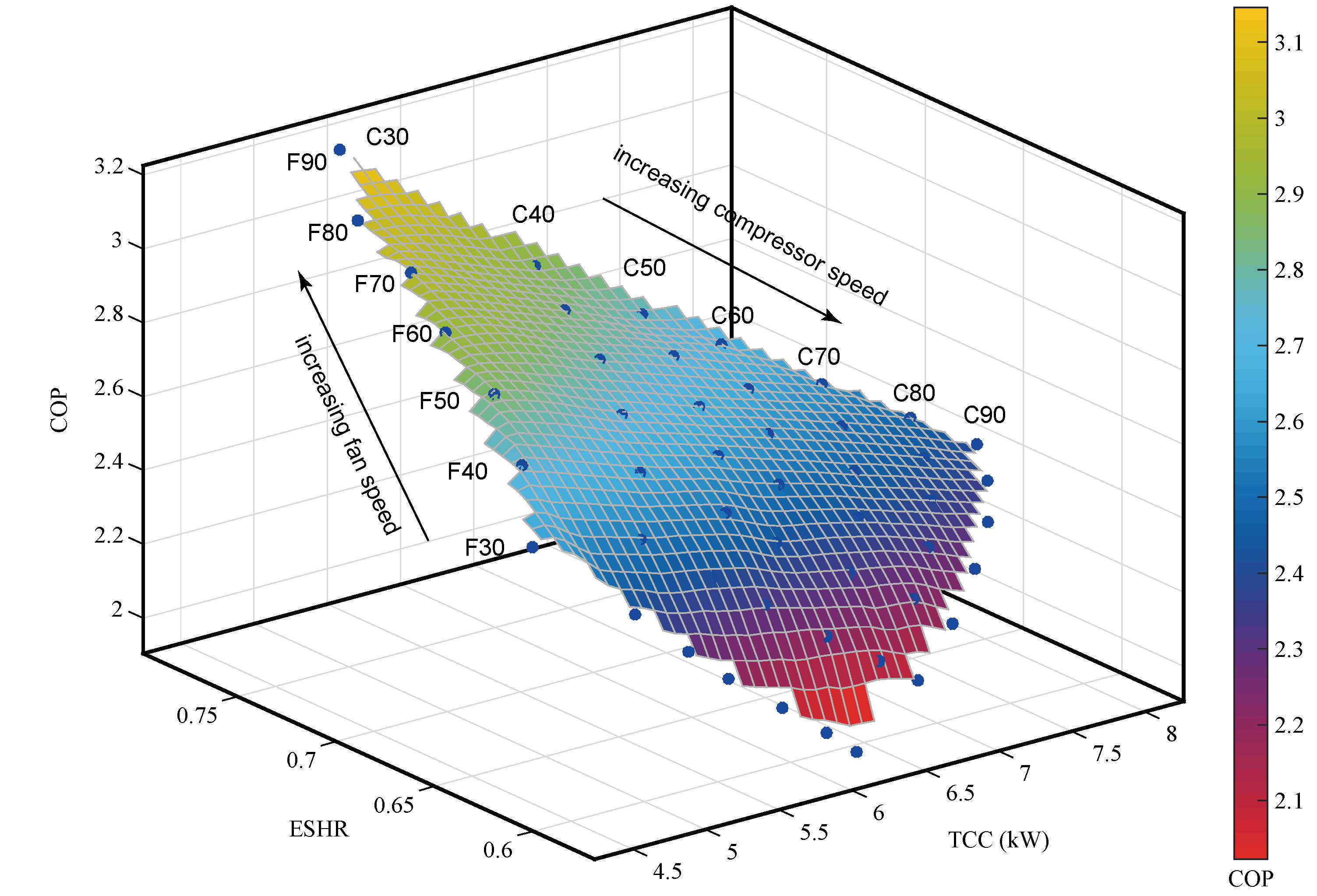

4.2. Improved Inherent Operating Performance in Terms of TCC E SHR and COP of the DX A/C System

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | Area, m2 |

| air flow rate, m3/s | |

| V | volume, m3 |

| T | Temperature, K |

| P | pressure, Pa |

| W | power, W |

| Q | heat transfer rate, W |

| h | enthalpy, J/kg |

| Cv | flow coefficient |

| Kv | valve opening per unit of pulse out |

| M | mass, kg |

| Cp | specific heat, J/(kg·K) |

| U0 | overall heat transfer coefficient, W/(m2·K) |

| d | moisture content, g/kg |

| refrigerant mass flow rate, kg/s | |

| l | stroke of compressor cylinder, m |

| r | radius of compressor rotor, m |

| uv | pulse output of EEV |

| Greek Letters | |

| α | heat transfer coefficient, W/(m2 ·K) |

| ε | relative eccentricity of rotor |

| λ | overall displacement coefficient |

| η | indicated coefficient of compressor |

| ρ | density, kg/m3 |

| Subscripts | |

| a | air side |

| r | refrigerant side |

| e | evaporator |

| s | conditioned space |

| w | tube wall |

| l | liquid |

| v | vapor/valve |

| tp | two phase |

| sh | superheating |

| com | compressor |

| Abbreviations | |

| A/C | air conditioning |

| ANN | artificial neural network |

| DX | direct expansion |

| DS | degree of superheat, K |

| E SHR | equipment sensible heat ratio |

| EEV | electronic expansion valve |

| TCC | total cooling capacity |

| LCC | latent cooling capacity |

| SCC | sensible cooling capacity |

References

- Monitor, C.M. The Report on China Residential Air Conditioner Market in 2017. Available online: http://www.monitor.com.cn/newsinfo.aspx?nid=3984 (accessed on 11 September 2020).

- Yang, K.H.; Lee, M.L. Analysis of an Inverter-Driven Air-Conditioning System and Its Application in a Hot and Humid Area. Int. J. Energy Res. 1991, 15, 357–365. [Google Scholar] [CrossRef]

- Qureshi, T.Q.; Tassou, S.A. Variable-speed capacity control in refrigeration systems. Appl. Therm. Eng. 1996, 16, 103–113. [Google Scholar] [CrossRef]

- Yan, H.; Xia, Y.; Xu, X.; Deng, S. Inherent operational characteristics aided fuzzy logic controller for a variable speed direct expansion air conditioning system for simultaneous indoor air temperature and humidity control. Energy Build. 2018, 158, 558–568. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.G.; Deng, S.M.; Pan, D.M. A novel neural network aided fuzzy logic controller for a variable speed (VS) direct expansion (DX) air conditioning (A/C) system. Appl. Therm. Eng. 2015, 78, 9–23. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.; Deng, S.; Pan, D. A novel proportional-derivative (PD) law based fuzzy logic principles assisted controller for simultaneously controlling indoor temperature and humidity using a direct expansion (DX) air conditioning (A/C) system. Int. J. Refrig. 2015, 57, 239–256. [Google Scholar] [CrossRef]

- Li, N.; Xia, L.; Deng, S.M.; Xu, X.G.; Chan, M.Y. On-line adaptive control of a direct expansion air conditioning system using artificial neural network. Appl. Therm. Eng. 2013, 53, 96–107. [Google Scholar] [CrossRef]

- Xia, Y.; Yan, H.; Deng, S.; Chan, M.-Y. A new capacity controller for a direct expansion air conditioning system for operational safety and efficiency. Build. Serv. Eng. Res. Technol. 2018, 39, 21–37. [Google Scholar] [CrossRef]

- Al-Azba, M.; Cen, Z.H.; Remond, Y.; Ahzi, S. An Optimal Air-Conditioner On-Off Control Scheme under Extremely Hot Weather Conditions. Energies 2020, 13, 1021. [Google Scholar] [CrossRef]

- Li, Z.; Deng, S.M. An experimental study on the inherent operational characteristics of a direct expansion (DX) air conditioning (A/C) unit. Build. Environ. 2007, 42, 1–10. [Google Scholar] [CrossRef]

- Xu, X.G.; Xia, L.A.; Chan, M.Y.; Deng, S.M. Inherent correlation between the total output cooling capacity and equipment sensible heat ratio of a direct expansion air conditioning system under variable-speed operation. Appl. Therm. Eng. 2010, 30, 1601–1607. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.; Deng, S.; Pan, D. Further study on the inherent operating characteristics of a variable speed direct expansion air conditioning system. Appl. Therm. Eng. 2014, 66, 206–215. [Google Scholar] [CrossRef]

- Chen, W.; Chan, M.-y.; Weng, W.; Yan, H.; Deng, S. An experimental study on the operational characteristics of a direct expansion based enhanced dehumidification air conditioning system. Appl. Energy 2018, 225, 922–933. [Google Scholar] [CrossRef]

- Yang, L.; Yan, H.; Deng, S.; Li, W. An experimental investigation on the operational characteristics of a novel direct expansion based air conditioning system with a two-sectioned cooling coil. Int. J. Refrig. 2020, 118, 131–138. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F. Review of modeling methods for HVAC systems. Appl. Therm. Eng. 2014, 67, 507–519. [Google Scholar] [CrossRef]

- Beghi, A.; Cecchinato, L. A simulation environment for dry-expansion evaporators with application to the design of autotuning control algorithms for electronic expansion valves. Int. J. Refrig. 2009, 32, 1765–1775. [Google Scholar] [CrossRef]

- Rasmussen, B.P.; Alleyne, A.G. Dynamic Modeling and Advanced Control of Air Conditioning and Refrigeration Systems; Air Conditioning and Refrigeration Center, College of Engineering, University of Illinois: Urbana, IL, USA, 2006. [Google Scholar]

- Chen, W.; Deng, S.M. Development of a dynamic model for a DX VAV air conditioning system. Energy Convers. Manag. 2006, 47, 2900–2924. [Google Scholar] [CrossRef]

- Deng, S.M. A dynamic mathematical model of a direct expansion (DX) water-cooled air-conditioning plant. Build. Environ. 2000, 35, 603–613. [Google Scholar]

- Xia, Y.; Ding, Q.; Jiangzhou, S.; Zhang, X.; Deng, S. A simulation study on the operational stability of an EEV-controlled direct expansion air conditioning system under variable speed operation. Int. J. Refrig. 2019, 103, 115–125. [Google Scholar] [CrossRef]

- Chen, W.; Chan, M.-y.; Weng, W.; Yan, H.; Deng, S. Development of a steady-state physical-based mathematical model for a direct expansion based enhanced dehumidification air conditioning system. Int. J. Refrig. 2018, 91, 55–68. [Google Scholar] [CrossRef]

- Kim, J.-H.; Seong, N.C.; Choi, W. Modeling and Optimizing a Chiller System Using a Machine Learning Algorithm. Energies 2019, 12, 2860. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M. Modelling of a vertical ground coupled heat pump system by using artificial neural networks. Expert Syst. Appl. 2009, 36, 10229–10238. [Google Scholar] [CrossRef]

- Hosoz, M.; Ertunc, H.M. Artificial neural network analysis of an automobile air conditioning system. Energy Convers. Manag. 2006, 47, 1574–1587. [Google Scholar] [CrossRef]

- Li, N.; Xia, L.; Deng, S.; Xu, X.; Chan, M.-Y. Steady-state operating performance modelling and prediction for a direct expansion air conditioning system using artificial neural network. Build. Serv. Eng. Res. Technol. 2012, 33, 281–292. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F. Gray-box modeling and validation of residential HVAC system for control system design. Appl. Energy 2015, 137, 134–150. [Google Scholar] [CrossRef]

- Xu, X.; Huang, Z.; Wang, X.; Zhong, Z.; Zhang, X. A control-oriented hybrid model for a direct expansion air conditioning system. Energy Build. 2017, 155, 76–87. [Google Scholar] [CrossRef]

- Chen, W. Modeling and Control of a Direct Expansion (DX) Variable-Air-Volume (VAV) Air Conditioning (A/C) System; The Hong Kong Polytechnic University: Hong Kong, China, 2005. [Google Scholar]

- Kandlikar, S.G. A General Correlation for Saturated Two-Phase Flow Boiling Heat Transfer Inside Horizontal and Vertical Tubes. J. Heat Transf. 1990, 112, 219–228. [Google Scholar] [CrossRef]

- Zivi, S.M. Estimation of Steady-State Steam Void-Fraction by Means of the Principle of Minimum Entropy Production. J. Heat Transf. 1964, 86, 247. [Google Scholar] [CrossRef]

- Wang, C.C.; Lin, Y.T.; Lee, C.J. An airside correlation for plain fin-and-tube heat exchangers in wet conditions. Int. J. Heat Mass Transf. 2000, 43, 1869–1872. [Google Scholar] [CrossRef]

- Cleland, A.C. Computer subroutines for rapid evaluation of refrigerant thermodynamic properties. Int. J. Refrig. 1986, 9, 346–351. [Google Scholar] [CrossRef]

| Components | Specifications |

|---|---|

| Compressor | Allowable Frequency range: 15~110 Hz |

| Rated Capacity: 9900 W at 90 Hz | |

| Displacement: 3.04 mL/rev | |

| EEV | Pulse range: 0~480 Pulse |

| Rated capacity: 10,500 W | |

| Port diameter: 1.8 mm | |

| Evaporator | Length of the windward area: 420 mm |

| Height of the windward area: 450 mm | |

| Transverse tube pitch: 25 mm | |

| Longitude tube pitch: 21.65 mm | |

| Fin Pitch: 2 mm | |

| Fin thickness: 0.15 mm | |

| Heat exchange external area: 24.7 m2 | |

| Condenser | Length of the windward area: 420 mm |

| Height of the windward area: 450 mm | |

| Transverse tube pitch: 25 mm | |

| Longitude tube pitch: 21.65 mm | |

| Fin Pitch: 2 mm | |

| Fin thickness: 0.15 mm | |

| Heat exchange external area: 38.5 m2 |

| Percent of Max Speed | 30 | 40 | 50 | 60 | 70 | 80 | 90 | |

|---|---|---|---|---|---|---|---|---|

| Compressor | VSD Freq. (Hz) | 48 | 57 | 66 | 75 | 84 | 92 | 101 |

| Speed (rpm) | 2880 | 3420 | 3960 | 4500 | 5040 | 5520 | 6060 | |

| Supply fan | VSD Freq. (Hz) | 26 | 31 | 36 | 41 | 46 | 51 | 56 |

| Speed (rpm) | 1560 | 1860 | 2160 | 2460 | 2760 | 3060 | 3360 | |

| Air flow rate (m3/s) | 0.14 | 0.17 | 0.20 | 0.23 | 0.26 | 0.29 | 0.32 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Jiangzhou, S.; Zhang, X.; Zhang, Z. Steady-State Performance Prediction for a Variable Speed Direct Expansion Air Conditioning System Using a White-Box Based Modeling Approach. Energies 2020, 13, 4757. https://doi.org/10.3390/en13184757

Xia Y, Jiangzhou S, Zhang X, Zhang Z. Steady-State Performance Prediction for a Variable Speed Direct Expansion Air Conditioning System Using a White-Box Based Modeling Approach. Energies. 2020; 13(18):4757. https://doi.org/10.3390/en13184757

Chicago/Turabian StyleXia, Yudong, Shu Jiangzhou, Xuejun Zhang, and Zhao Zhang. 2020. "Steady-State Performance Prediction for a Variable Speed Direct Expansion Air Conditioning System Using a White-Box Based Modeling Approach" Energies 13, no. 18: 4757. https://doi.org/10.3390/en13184757

APA StyleXia, Y., Jiangzhou, S., Zhang, X., & Zhang, Z. (2020). Steady-State Performance Prediction for a Variable Speed Direct Expansion Air Conditioning System Using a White-Box Based Modeling Approach. Energies, 13(18), 4757. https://doi.org/10.3390/en13184757