Mechanical Integrity Assessment of Two-Side Etched Type Printed Circuit Heat Exchanger with Additional Elliptical Channel

Abstract

1. Introduction

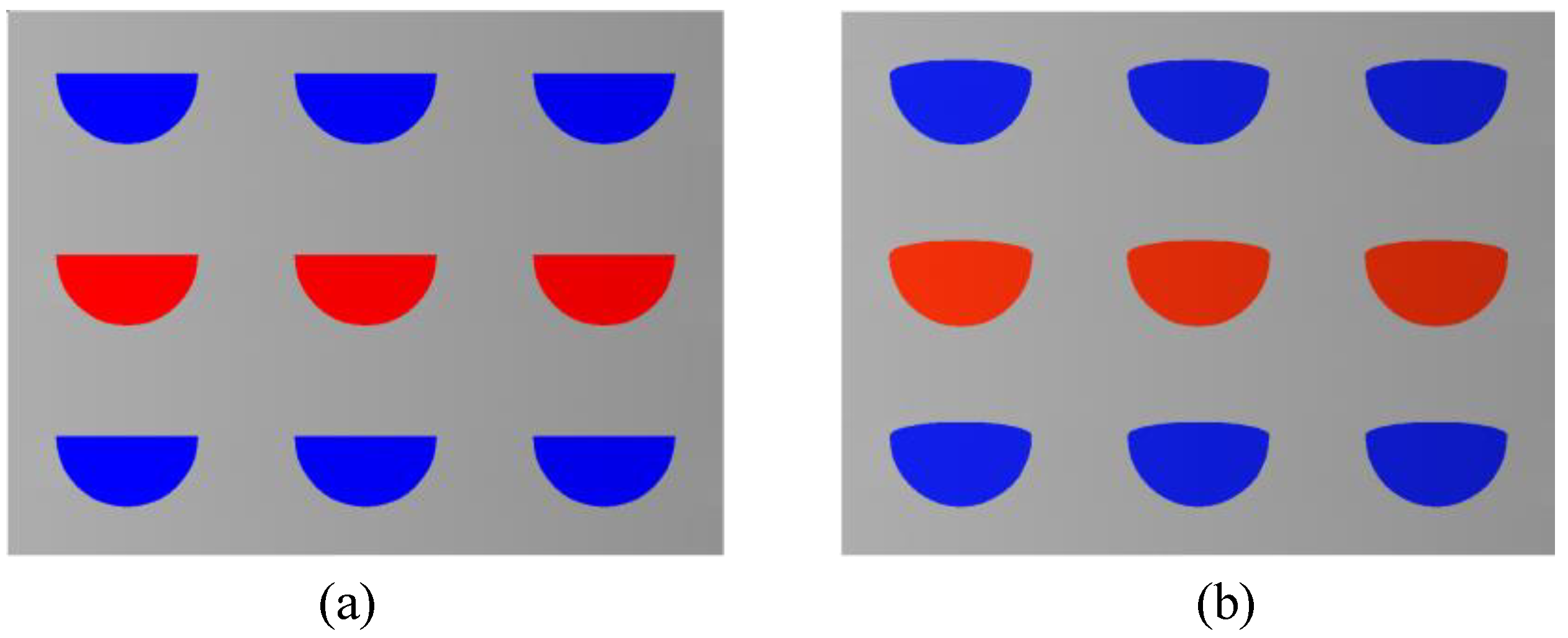

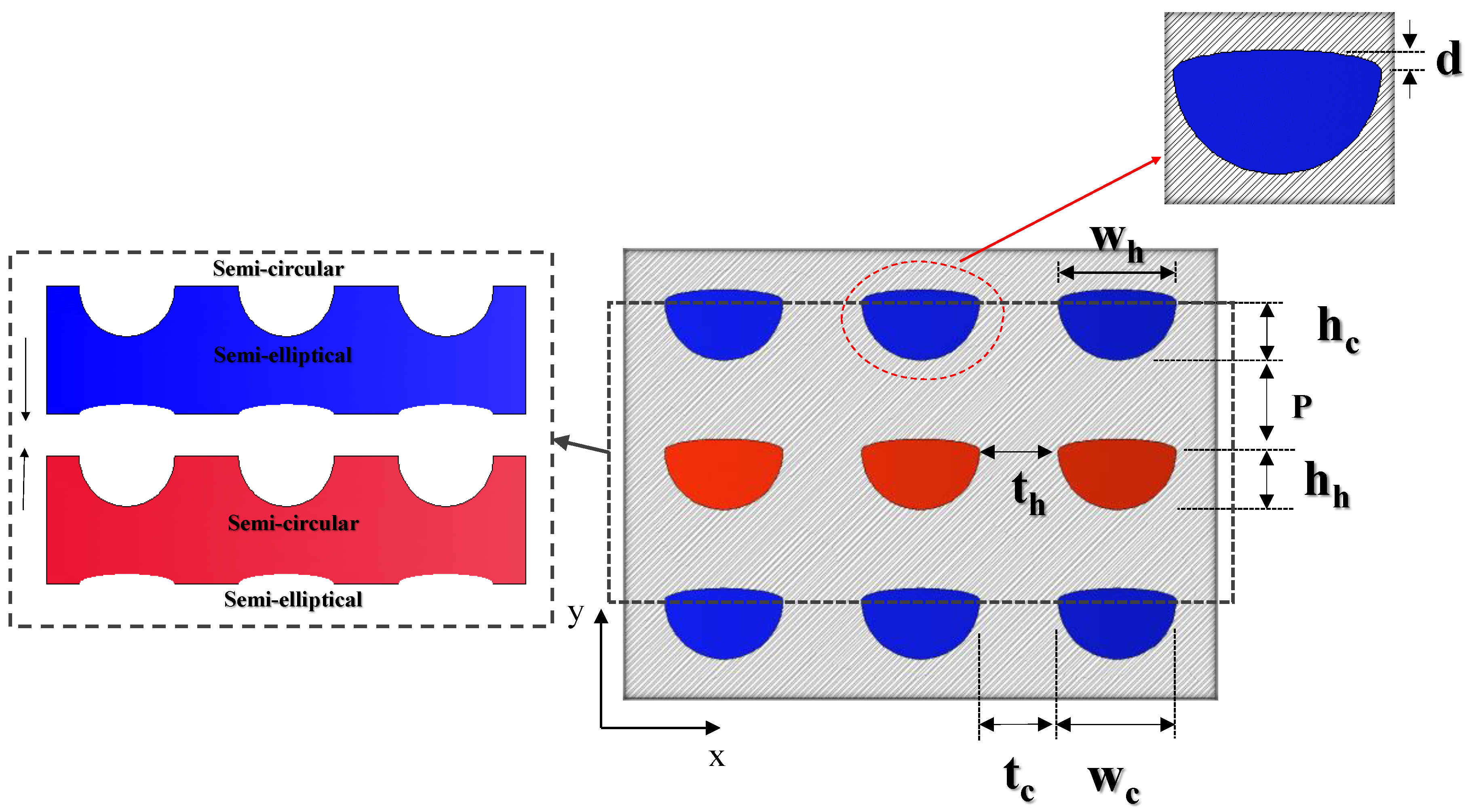

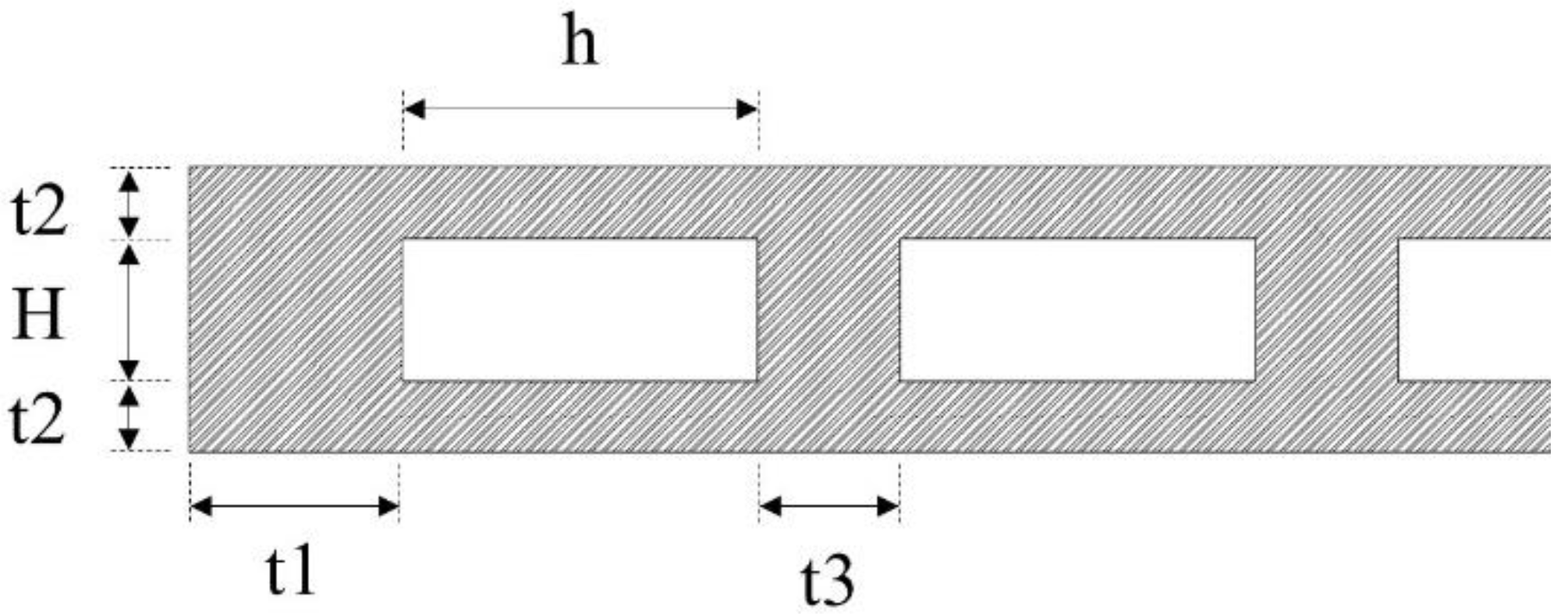

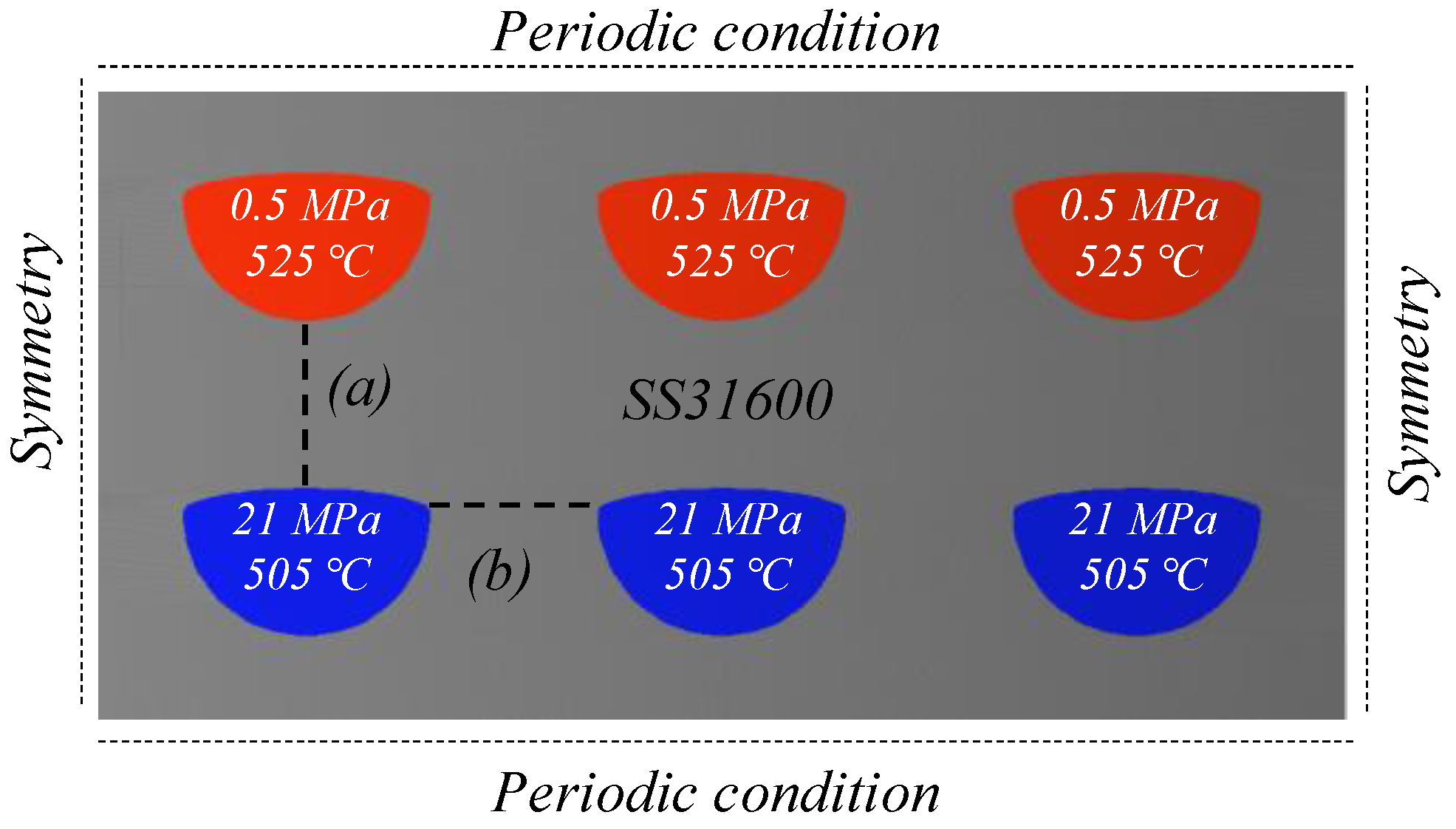

2. Design and Approach

3. Result and Discussion

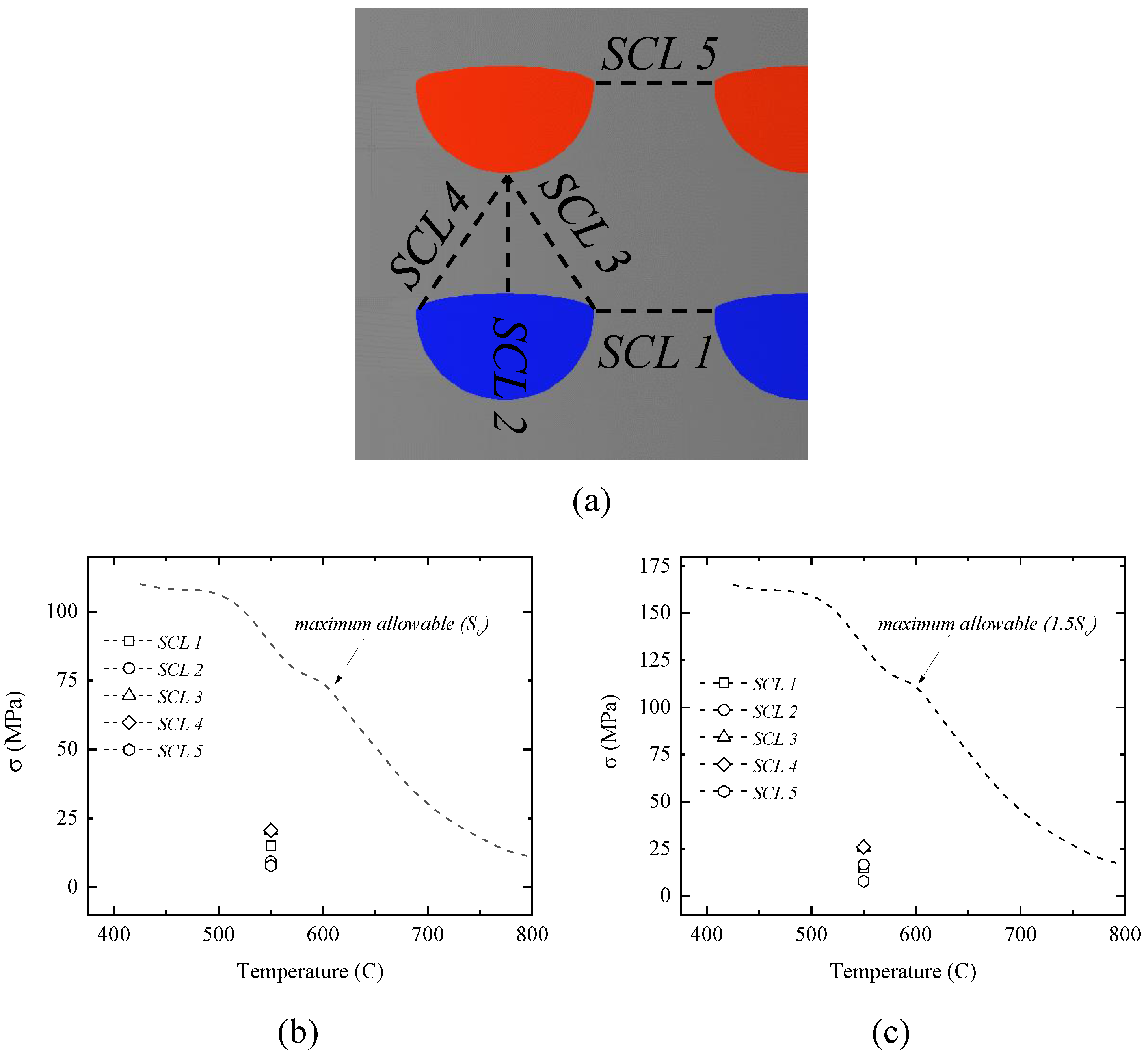

3.1. Simplified Design Assessment by Rule Assessment

- The membrane stress at the stayed plate shall not exceed the maximum allowable design stress:

- The membrane stress at the thin wall thickness shall not exceed the maximum allowable design stress:

- The total membrane and bending stress shall not exceed 1.5 times the design stress, where F is a joint factor which is recommended to be 0.7 for diffusion bonding block [24]:

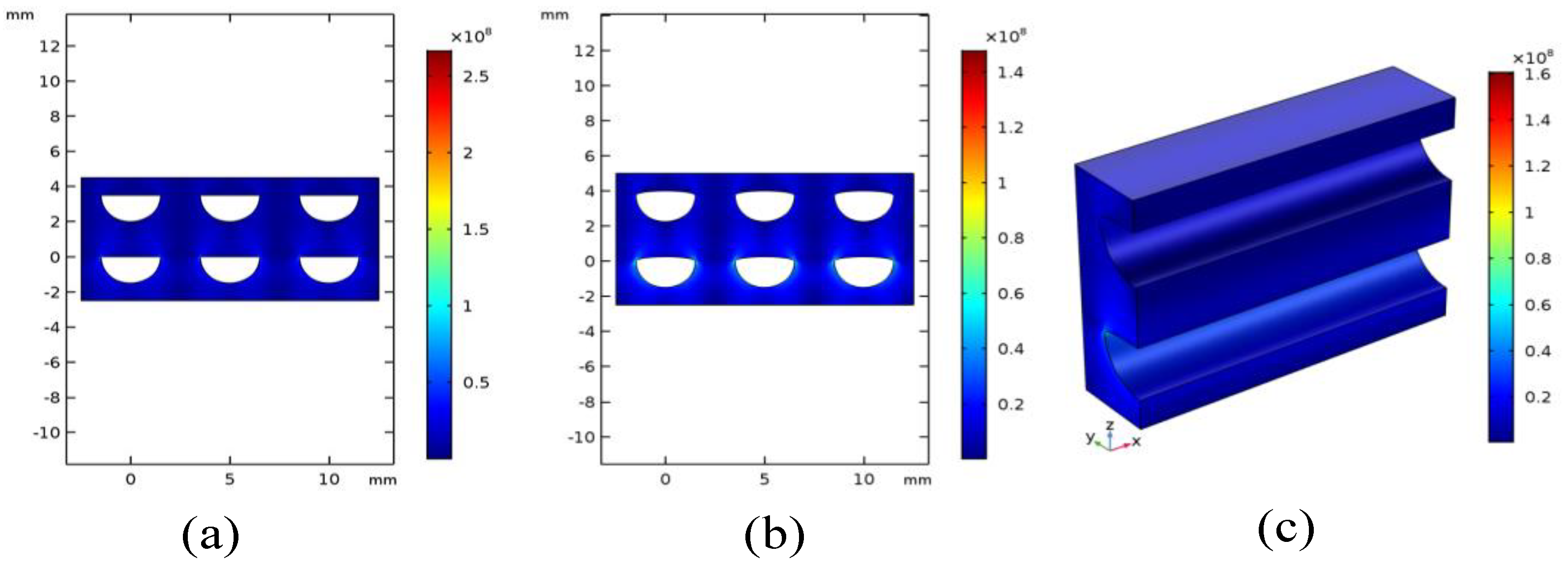

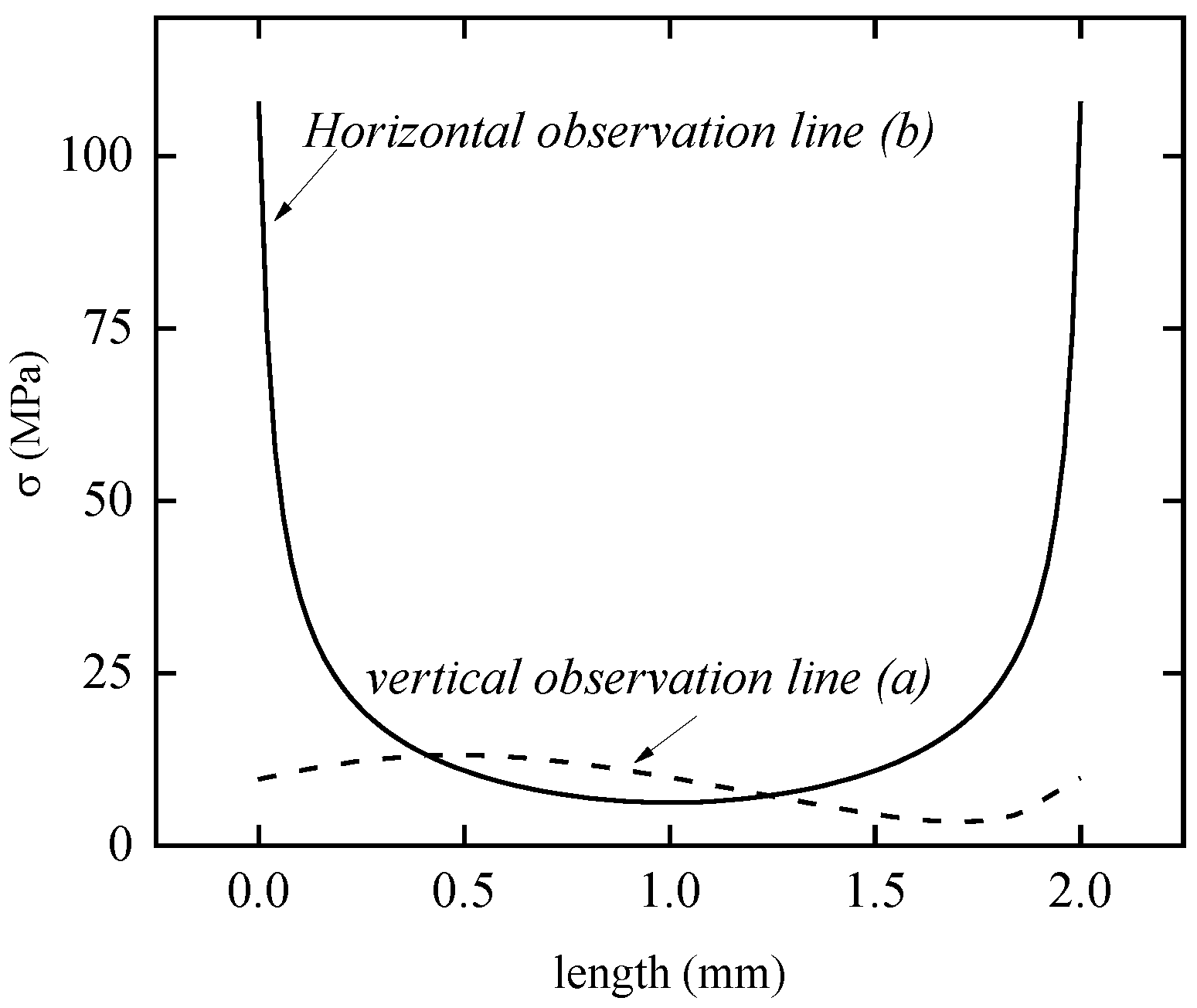

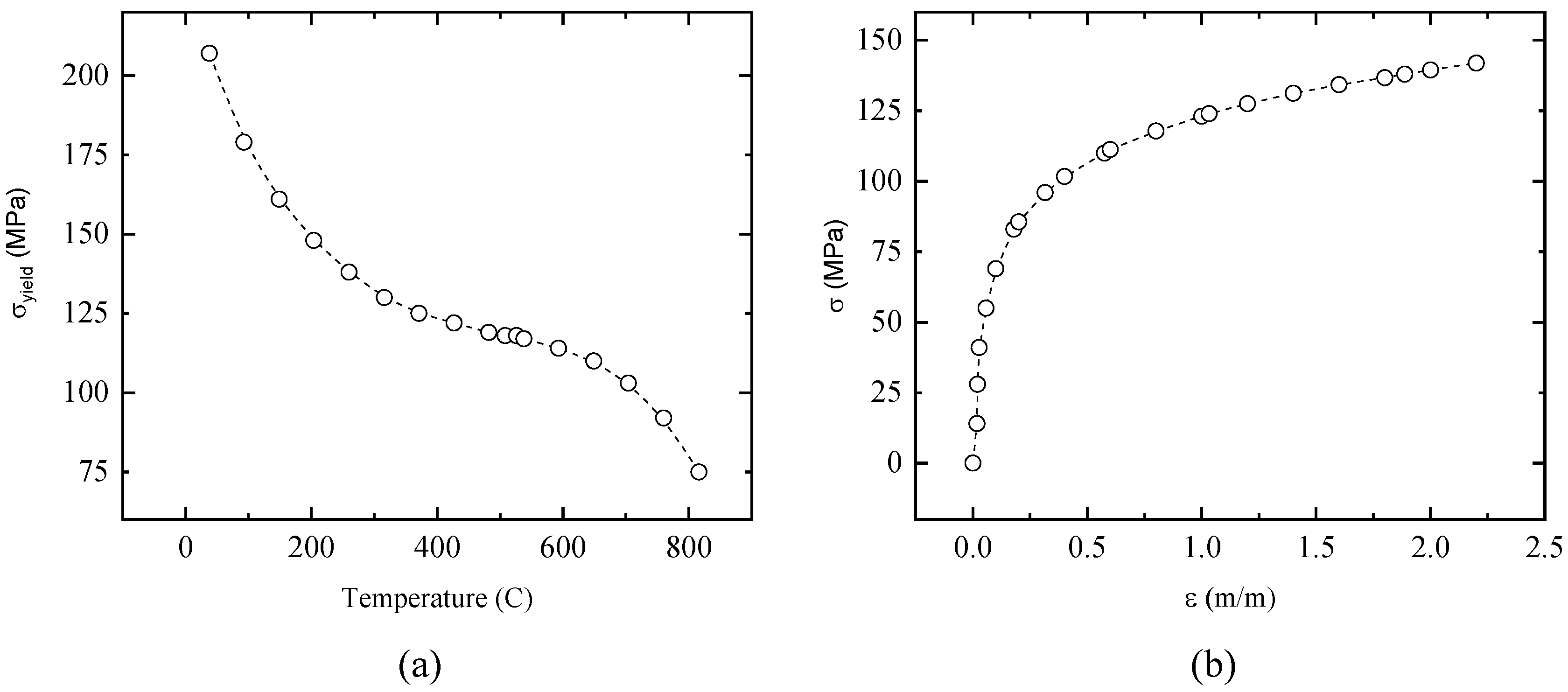

3.2. Mechanical Integrity Assessment by Finite Element Method Simulation

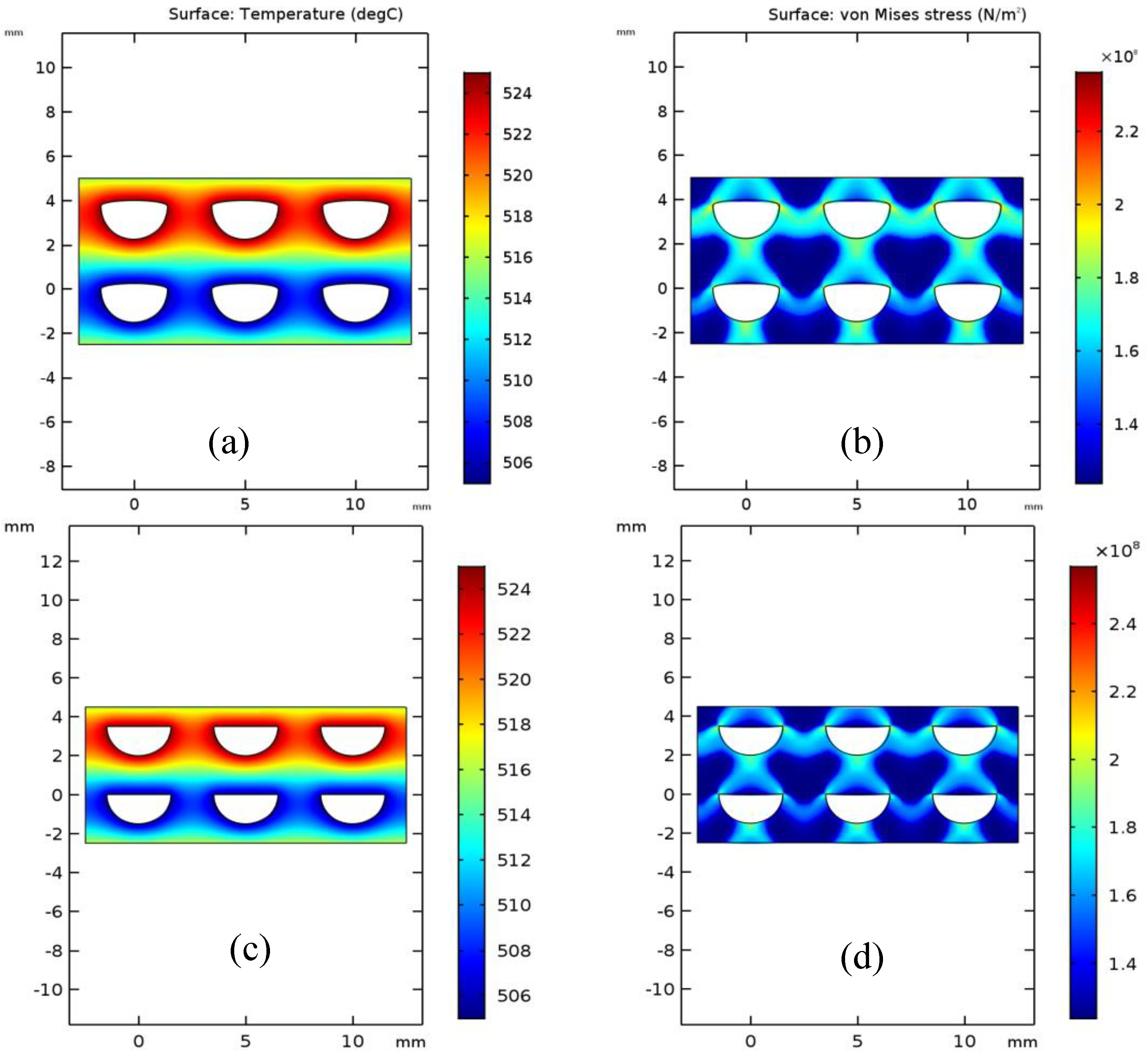

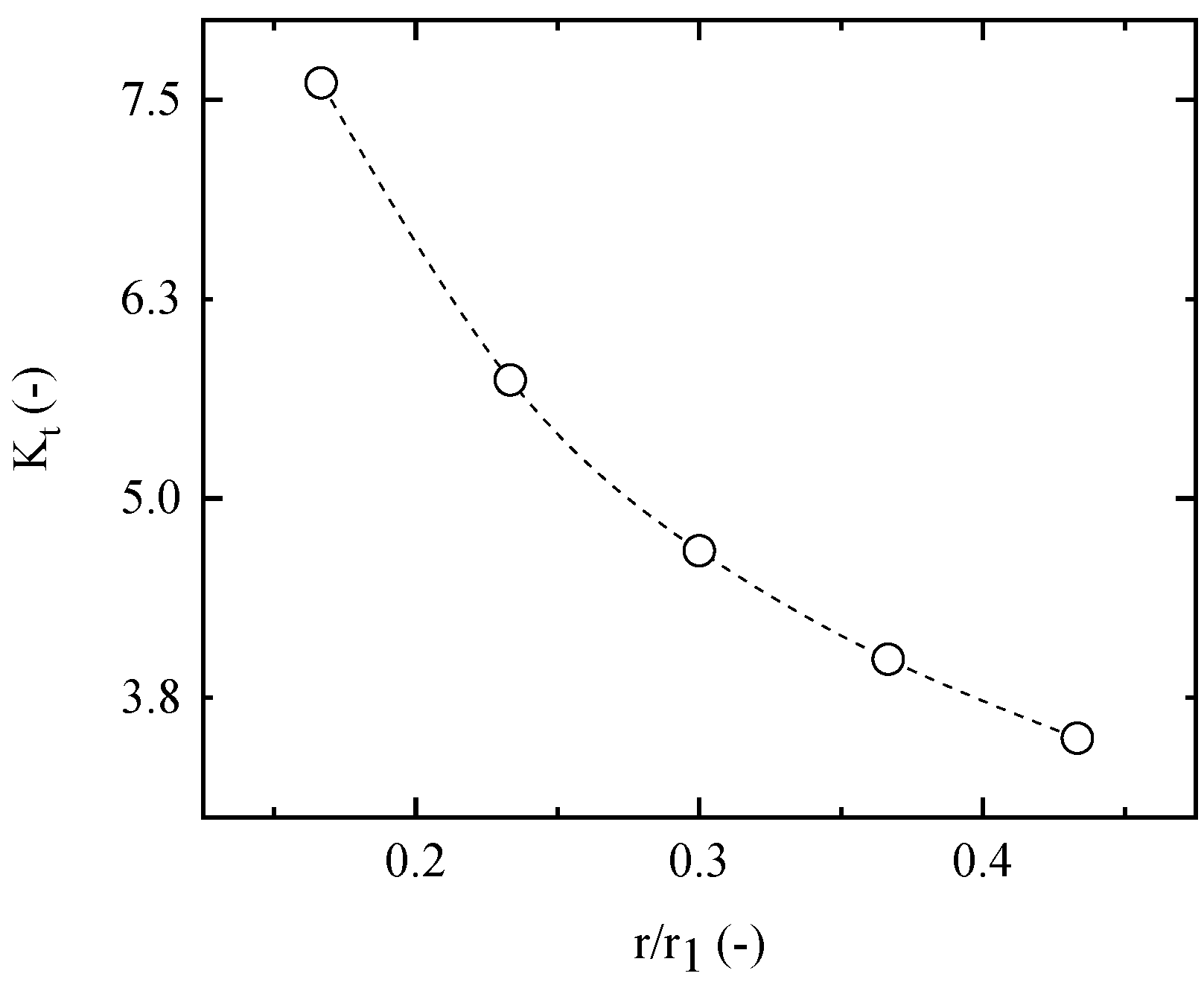

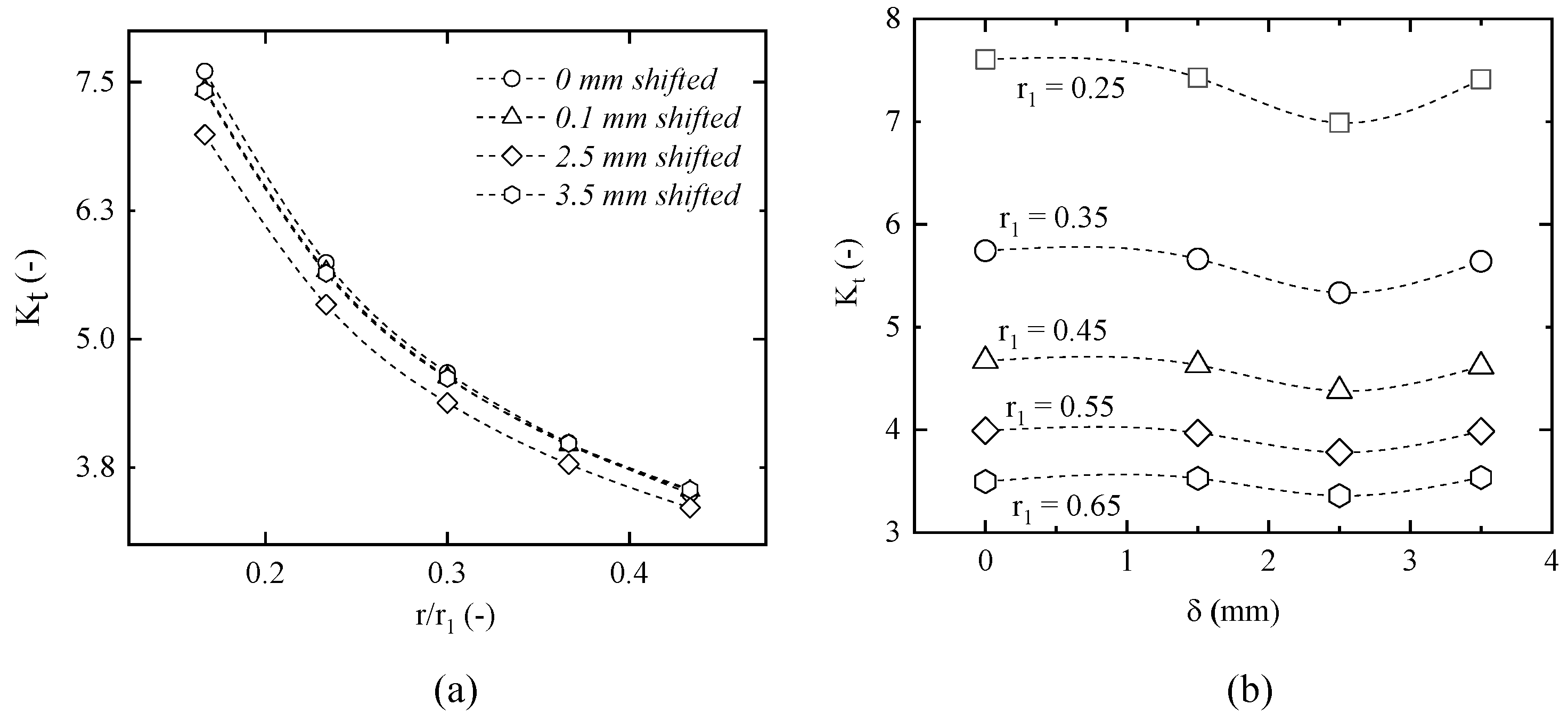

3.3. Effect of Additional Elliptical Channel Radius

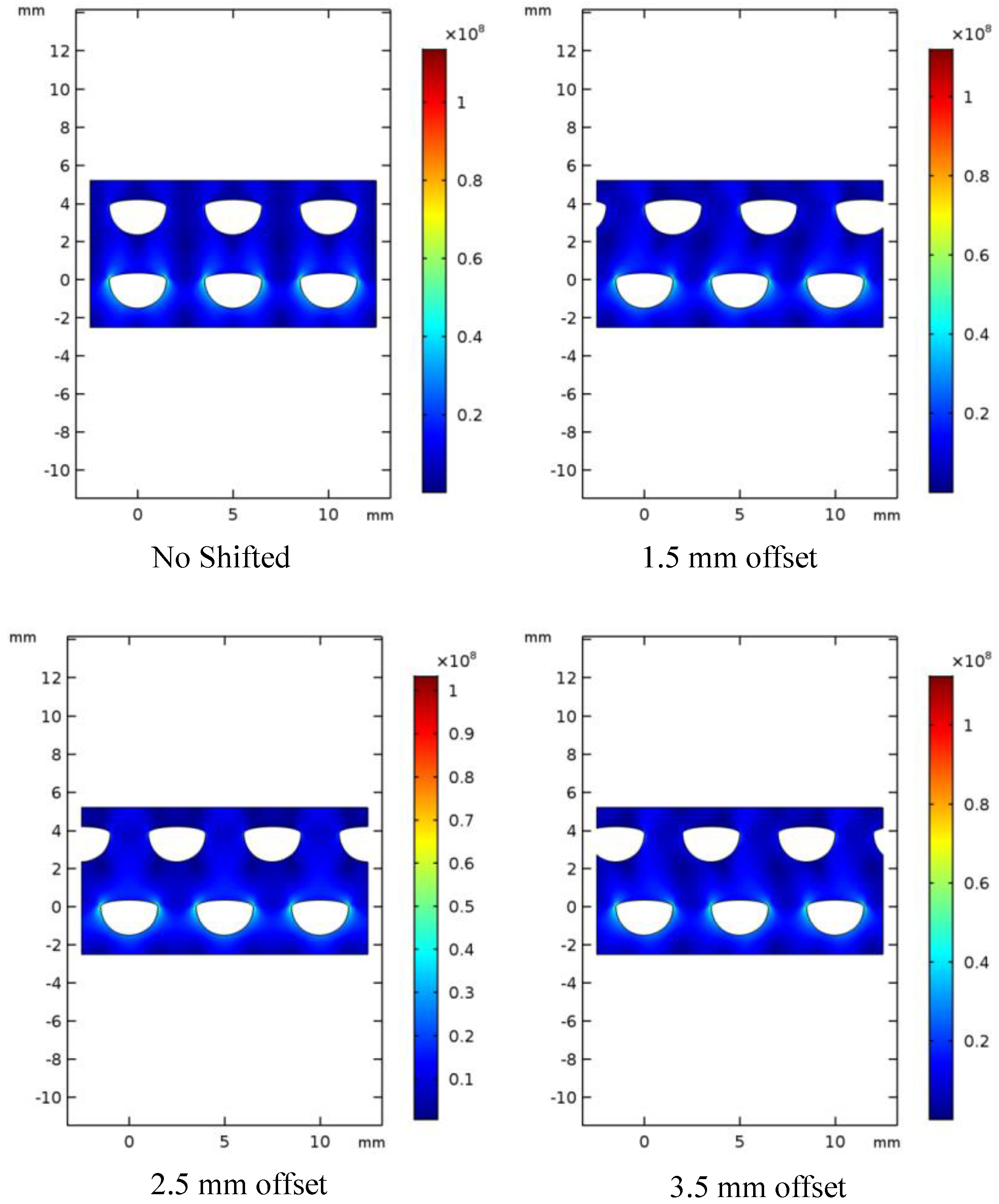

3.4. Effect of Shifted Channel Arrangement

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASME | American Society of Mechanical Engineers |

| PCHE | Printed Circuit Heat Exchanger |

| FEM | Finite Element Method |

| SCO2 | Supercritical Carbon dioxide |

| SFR | Sodium Fast-Cooled reactor |

| TES | Thermal Energy Storage |

| IHX | Intermediate Heat Exchanger |

| HTGR | High-Temperature Gas Reactor |

| SCL | Stress Classification Line |

| Symbol | |

| Sm | Membrane stress model of simplified design by ASME Code |

| Sb | Bending stress model of simplified design by ASME code |

| F | Joint factor (0.7 for diffusion bonding block) |

| So | Maximum allowable stress intensity |

| Pm | Primary membrane stress intensity (MPa) |

| Pb | Primary bending stress (MPa) |

| Sb | Primary bending stress |

| r | Semi-circular channel radius |

| r1 | Additional elliptical upper channel radius |

| Kt | Stress concentration factor |

| Offset length (center hot channel to center cold channel) | |

| k | Thermal conductivity |

| α | Coefficient thermal expansion |

| E | Young’s modulus |

| ρ | Density |

| ν | Poisson’s ratio |

| Cp | Specific heat at constant pressure |

References

- Ҫengel, Y.A. Heat Exchanger. In Heat Transfer a Practical Approach, 2nd ed.; McGraw Hill: New York, NY, USA, 2004; pp. 667–704. [Google Scholar]

- Thulukkanam, K. Heat Exchangers Introduction, Classification, and Selection. In Heat Exchanger Design Handbook, 2nd ed.; CRC Press: New York, NY, USA, 2013; pp. 1–34. [Google Scholar]

- Asadi, M.; Xie, G.; Sunden, B. A review of heat transfer and pressure drop characteristics of single and two phases microchannel. Int. J. Heat Mass Transf. 2014, 79, 34–53. [Google Scholar] [CrossRef]

- Chen, M.; Sun, X.; Christensen, R.N.; Shi, S.; Skavdahl, I.; Utgikar, V.; Sabharwall, P. Experimental and numerical study of a printed circuit heat exchanger. Ann. Nucl. Energy 2016, 97, 221–231. [Google Scholar] [CrossRef]

- Chen, M.; Sun, X.; Christensen, R.N.; Shi, S.; Skavdahl, I.; Utgikar, V.; Sabharwall, P. Pressure drop and heat transfer characteristic of a high-temperature printed circuit heat exchanger. Appl. Therm. Eng. 2016, 108, 1409–1417. [Google Scholar] [CrossRef]

- Li, X.; Le Pierres, R.; Dewson, S.J. Heat Exchanger for the Next Generation of Nuclear Reactors. In Proceedings of the International Congress on Advances in Nuclear Power Plants, Reno, NV, USA, 4–8 June 2006; pp. 201–209. [Google Scholar]

- Patil, R.; Anand, S. Thermo-structural fatigue analysis of shell and tube type heat exchanger. Int. J. Press. Vessel. Pip. 2017, 155, 35–42. [Google Scholar] [CrossRef]

- Mylavarapu, S.K.; Sun, X.; Glosup, R.E.; Christensen, R.N.; Patterson, M.W. Thermal Hydraulic Performance testing of Printed Circuit heat exchangers in a high-temperature helium test facility. Appl. Therm. Eng. 2014, 65, 605–614. [Google Scholar] [CrossRef]

- Kim, J.H.; Baek, S.; Jeong, S.; Jung, J. Hydraulic Performance of a microchannel PCHE. Appl. Therm. Eng. 2010, 30, 2157–2162. [Google Scholar] [CrossRef]

- Sung, J.; Lee, J.Y. Effect of tangled channels on the heat transfer in a printed circuit heat exchanger. Int. J. Heat Mass Transf. 2017, 115, 647–656. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, J.I. Structural assessment of intermediate printed circuit heat exchanger for sodium-cooled fast reactor with supercritical CO2 cycle. Ann. Nucl. Energy 2014, 73, 84–95. [Google Scholar] [CrossRef]

- Song, K.N.; Hong, S.D. Structural Integrity Evaluation of a Lab-Scale PCHE Proto-type under the Test Conditions of HELP. Sci. Technol. Nucl. Install. 2013, 1–7. [Google Scholar] [CrossRef]

- Simanjuntak, A.P.; Lee, J.Y. Mechanical Integrity Analysis of a Printed Circuit Heat Exchanger with Channel Misalignment. Appl. Sci. 2020, 10, 2169. [Google Scholar] [CrossRef]

- Winter, N.; Becton, M.; Zhang, L.; Wang, X. Effects of pore design on mechanical properties of nanoporous silicon. Acta Mater. 2017, 124, 127–136. [Google Scholar] [CrossRef]

- Vo, T.; He, B.; Blum, M.; Damone, A.; Newell, P. Molecular scale insight of pore morphology relation with mechanical properties of amorphous silica using ReaxFF. Comput. Mat. Sci. 2020, 183, 109881. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, K.Y.; Kim, S.W. Multi-objective optimization of a double-faced type printed circuit heat exchanger. Appl. Therm. Eng. 2013, 60, 44–50. [Google Scholar] [CrossRef]

- Ma, T.; Pasquier, U.; Chen, Y.; Wang, Q. Numerical study on thermal-hydraulic performance of a two-sided etched zigzag-type high-temperature printed circuit heat exchanger. Energy Procedia 2017, 142, 3950–3955. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, K.Y. Comparative study on performance of a zigzag printed circuit heat exchanger with various channel shapes and configuration. Heat Mass Transf. 2013, 49, 1021–1028. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, K.Y. Thermal Performance of a Double-Faced Printed Circuit Heat Exchanger with Thin Plates. J. Thermophys. Heat Transf. 2014, 28, 251–257. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, J.; Lim, J.Y.; Cheon, J.S.; Lee, T.H.; Kim, S.K.; Lee, K.L.; Joo, H.K. Overall System Description and Safety Characteristics of Prototype Gen IV Sodium Cooled Fast Reactor in Korea. Nucl. Eng. Technol. 2016, 48, 1059–1070. [Google Scholar] [CrossRef]

- ASME. An. International Code 2015 ASME Boiler & Pressure Vessel Code Section III. Rules for Construction of Nuclear Facility Components Division 5 High. Temperature Reactors; American Society of Mechanical Engineer: New York, NY, USA, 2015. [Google Scholar]

- Nestell, J.; (MPR Associates, Inc., Washington DC, USA); Sham, T.L.; (Oak Ridge National Laboratory, Tennessee, USA). ASME Code Considerations for the Compact Heat Exchanger. Personal communication, 2015. [Google Scholar]

- ASME. An. International Code 2015 ASME Boiler & Pressure Vessel Code Section VIII. Rules for Construction of Pressure Vessel Division 2; American Society of Mechanical Engineer: New York, NY, USA, 2015. [Google Scholar]

- Pierres, R.L.; Southal, D.; Osborne, S. Impact of Mechanical Design Issues on Printed Circuit Heat Exchangers. In Proceedings of the SCO2 Power Cycle Symposium, Boulder, CO, USA, 24–25 May 2011. [Google Scholar]

- Comsol Multiphysics Official Website. Available online: www.comsol.com (accessed on 17 July 2020).

| Condition | Cold Channel | Hot Channel | ||

|---|---|---|---|---|

| Pressure (MPa) | Temperature (°C) | Pressure (MPa) | Temperature (°C) | |

| inlet | 19.7 | 230.0 | 0.5 | 528.0 |

| outlet | 19.7 | 503.0 | 0.5 | 322.0 |

| Geometric Parameter | Description | ||

|---|---|---|---|

| hc | H (cold) | 0.9 mm | Cold channel height |

| hh | H (hot) | 0.95 mm | Hot channel height |

| wh | h (hot) | 1.80 mm | Hot channel width |

| wc | h (cold) | 1.9 mm | Cold channel width |

| p | t3 | 2 mm | Hot–cold channel ligament |

| tc | t2 (cold) | 0.60 mm | Cold–cold channel ligament |

| th | t2 (hot) | 0.70 mm | Hot–hot channel ligament |

| Temperature (°C) | Maximum Allowable Stress Intensity (MPa) | ||||

|---|---|---|---|---|---|

| SS 304 | SS 316 | Alloys N08810 | 21/4 Cr-1Mo | 9Cr-1Mo-V | |

| 425 | 105 | 110 | 105 | 116 | 172 |

| 450 | 102 | 108 | 104 | 116 | 165 |

| 475 | 101 | 108 | 103 | 99 | 154 |

| 500 | 99 | 107 | 101 | 81 | 133 |

| 525 | 86 | 101 | 99 | 64 | 117 |

| 550 | 74 | 88 | 89 | 48 | 102 |

| 575 | 69 | 77 | 74 | 35 | 81 |

| 600 | 65 | 76 | 68 | 26 | 62 |

| 625 | 51 | 62 | 62 | - | 46 |

| 650 | 42 | 51 | 51 | - | 29 |

| 675 | 34 | 39 | 41 | - | - |

| 700 | 27 | 30 | 34 | - | - |

| 725 | 21 | 23 | 28 | - | - |

| 750 | 17 | 18 | 23 | - | - |

| 775 | 14 | 13 | - | - | - |

| 800 | 11 | 11 | - | - | - |

| Number of Elements | Max. Stress Intensity (MPa) | ||||

|---|---|---|---|---|---|

| r1 = 0.25 mm | r1 = 0.35 mm | r1 = 0.45 mm | r1 = 0.55 mm | r1 = 0.65 mm | |

| 32,942 | 152.69 | 115.08 | 94.16 | 79.72 | 69.89 |

| 10,379 | 151.18 | 114.91 | 93.59 | 79.72 | 70.96 |

| 8815 | 152.43 | 115.92 | 94.84 | 80.95 | 70.81 |

| 4492 | 152.97 | 116.13 | 94.53 | 81.59 | 71.56 |

| Number of Elements | Max. Stress Intensity (MPa) | |||

|---|---|---|---|---|

| δ = 0 mm | δ = 1.5 mm | δ = 2.5 mm | δ = 3.5 mm | |

| 32,942 | 152.69 | 148.57 | 139.80 | 148.25 |

| 10,379 | 151.18 | 144.99 | 138.37 | 147.57 |

| 8815 | 152.43 | 147.48 | 138.30 | 146.94 |

| 4492 | 152.97 | 149.66 | 140.43 | 149.11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simanjuntak, A.P.; Lee, J.-Y. Mechanical Integrity Assessment of Two-Side Etched Type Printed Circuit Heat Exchanger with Additional Elliptical Channel. Energies 2020, 13, 4711. https://doi.org/10.3390/en13184711

Simanjuntak AP, Lee J-Y. Mechanical Integrity Assessment of Two-Side Etched Type Printed Circuit Heat Exchanger with Additional Elliptical Channel. Energies. 2020; 13(18):4711. https://doi.org/10.3390/en13184711

Chicago/Turabian StyleSimanjuntak, Armanto P., and Jae-Young Lee. 2020. "Mechanical Integrity Assessment of Two-Side Etched Type Printed Circuit Heat Exchanger with Additional Elliptical Channel" Energies 13, no. 18: 4711. https://doi.org/10.3390/en13184711

APA StyleSimanjuntak, A. P., & Lee, J.-Y. (2020). Mechanical Integrity Assessment of Two-Side Etched Type Printed Circuit Heat Exchanger with Additional Elliptical Channel. Energies, 13(18), 4711. https://doi.org/10.3390/en13184711