On-Line Diagnosis and Fault State Classification Method of Photovoltaic Plant

Abstract

1. Introduction

2. Fault State Classification Method for Photovoltaic Plants

2.1. Performance Index of Photovoltaic Plants

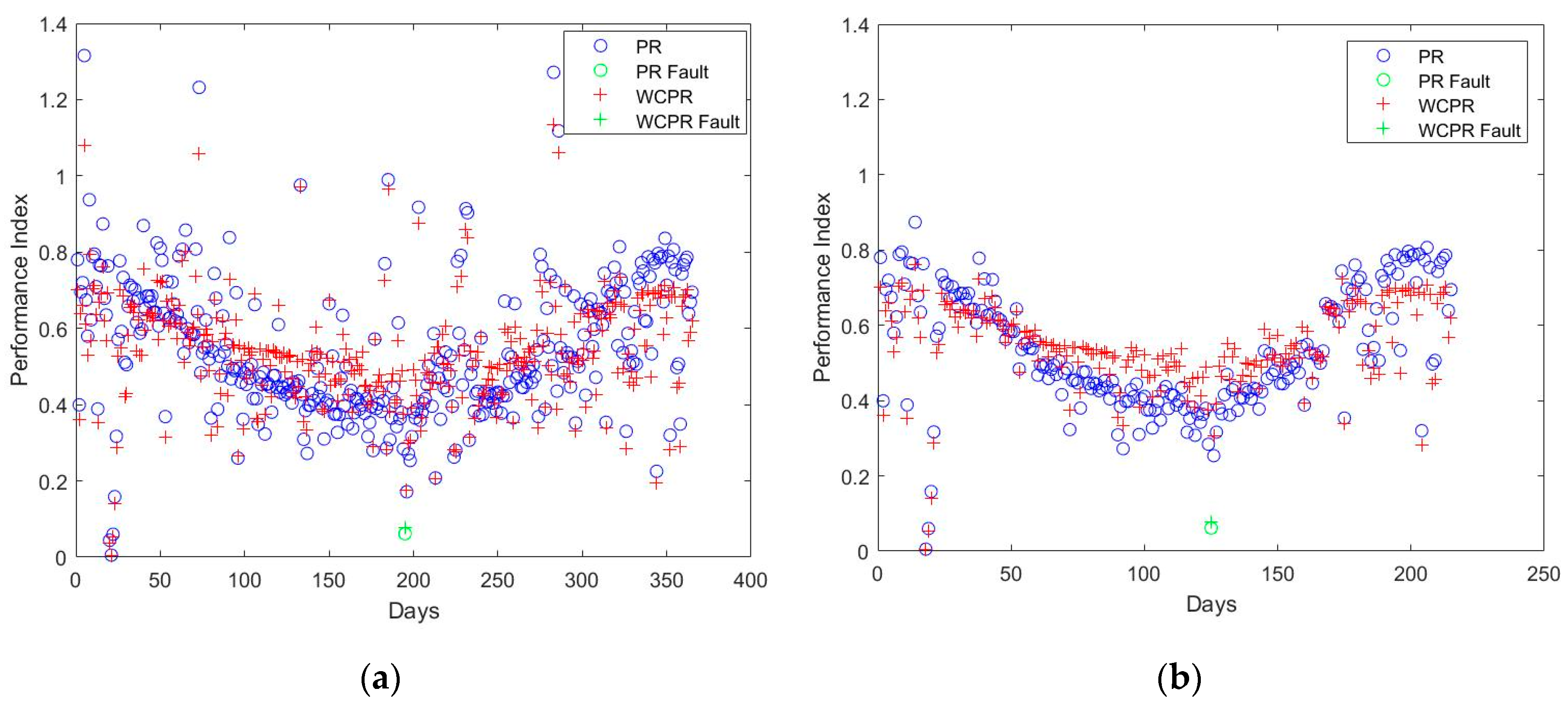

2.1.1. Performance Ratio (PR)

2.1.2. Weather-Corrected Performance Ratio (WCPR)

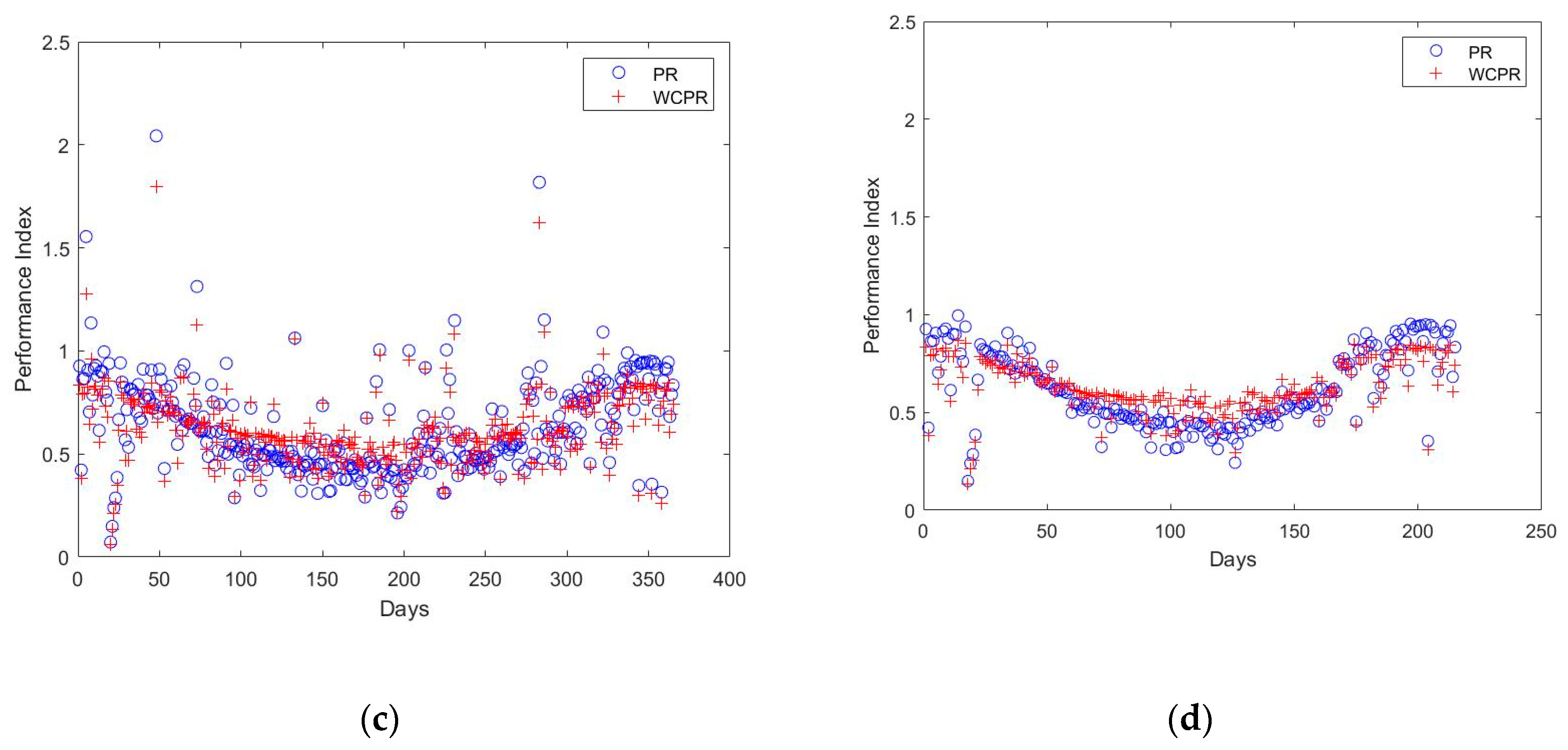

2.1.3. Linear Regression (LR) and Weather-Corrected Linear Regression (WCLR)

2.2. Solar Power Plant Resource Evaluation Index

2.2.1. Clearness Index (CI)

2.2.2. Proposed Variable Index (PVI)

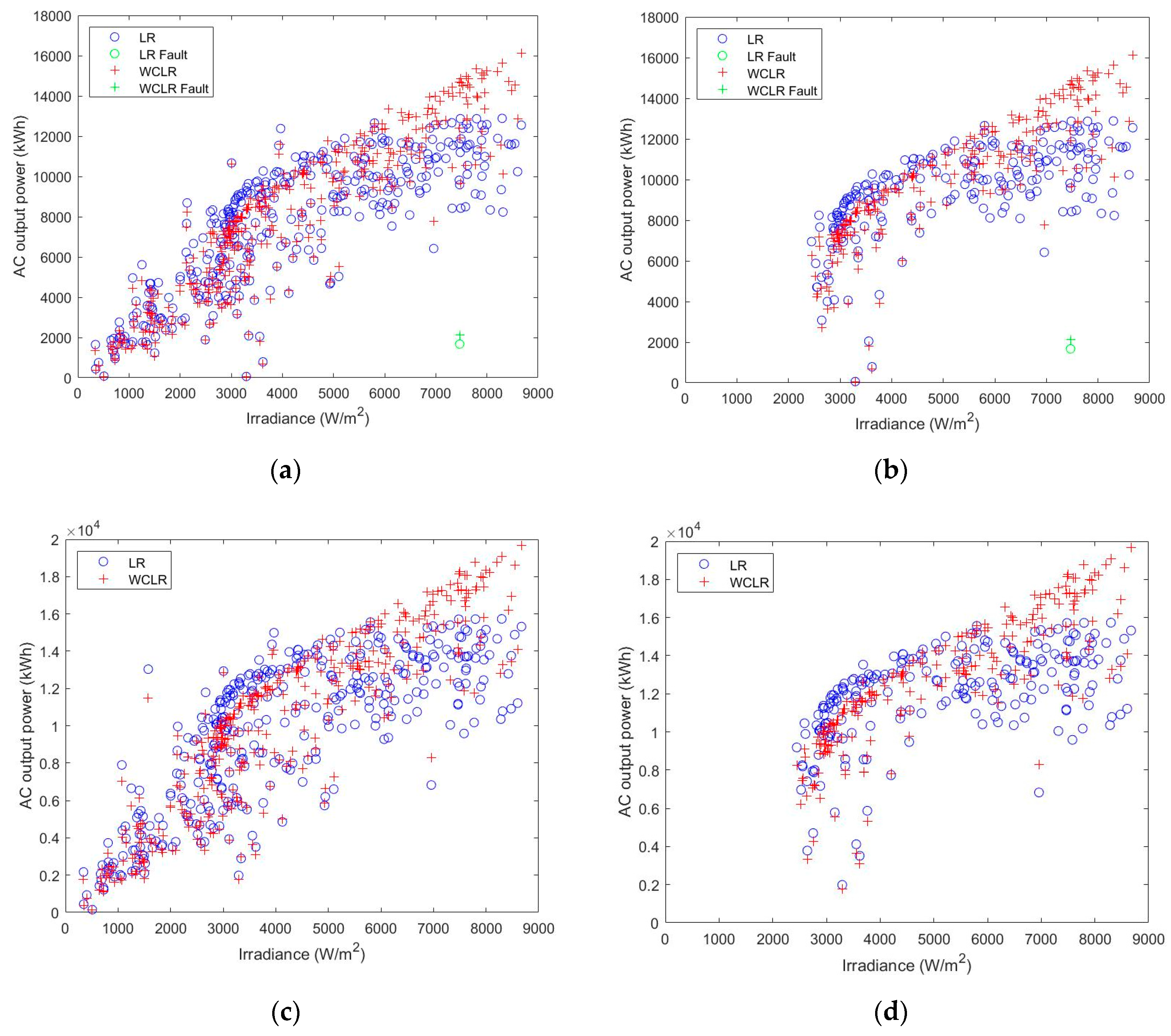

3. Outlier Mining Technique for Photovoltaic Power Plants

3.1. Estimated Error Matrix (EEM)

3.2. Estimated Square Error Index (ESEI)

3.3. One-Class Support Vector Machine (OCSVM)

3.4. Kernel Function

- -

- Polynomial Kernel Function:

- -

- Gaussian Kernel Function:

- -

- Sigmoid Kernel Function:where and are input variables of the input space, p is the degree of the polynomial, σ is the standard deviation, α is the slope, and c is the intercept constant.

4. Case Study

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IEC 61724-1:2017. Photovoltaic System Performance—Part 1: Monitoring; IEC: Geneva, Switzerland, 2017. [Google Scholar]

- Basson, H.A.; Pretorius, H.A. Risk mitigation of performance ratio guarantees in commercial photovoltaic systems. In Proceedings of the International Conference on Renewable Energies and Power Qualty (ICREPQ’ 16), Madrid, Spain, 4–6 May 2016; pp. 120–125. [Google Scholar]

- Urrejola, E.; Antonanzas, J.; Ayala, P.; Salgado, M.; Ramírez-Sagner, G.; Cortés, C.; Pino, A.; Escobar, R. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in santiago, Chile. Energy Convers. Manag. 2016, 114, 338–347. [Google Scholar] [CrossRef]

- Bizzarri, F.; Brambilla, A.; Caretta, L.; Guardiani, C. Monitoring performance and efficiency of photovoltaic parks. Renew. Energy 2015, 78, 314–321. [Google Scholar] [CrossRef]

- Ventura, C.; Tina, G.M. Utility scale photovoltaic plant indicies and models for on-line monitoring and fault detection purposes. Electr. Power Syst. Res. 2016, 136, 43–56. [Google Scholar] [CrossRef]

- Chine, W.; Mellit, A.; Massi Pavan, A.; Kalogirou, S.A. Fault detection method for grid connected photovoltaic plants. Renew. Energy 2014, 66, 99–110. [Google Scholar] [CrossRef]

- Dierauf, T.; Growitz, A.; Kurtz, S.; Cruz, J.L.B.; Riley, E.; Hansen, C. Weather-Corrected Performance Ratio; NREL: Golden, CO, USA, 2013. [Google Scholar]

- Platon, R.; Martel, J.; Woodruff, N. Online Fault Detection in PV Systems. IEEE Trans. Sustain. Energy 2015, 6, 1200–1207. [Google Scholar] [CrossRef]

- Lima, L.C.; Ferreira, L.A.; Lima Moraris, F.D.B. Performance Analysis of a grid connected photovoltaic system in northeastern Brazil. Energy Sustain. Dev. 2017, 37, 79–85. [Google Scholar] [CrossRef]

- Chao, K.H.; Ho, S.H.; Wang, M.H. Modeling and fault diagnosis of a photovoltaic system. Electr. Power Syst. Res. 2008, 78, 97–105. [Google Scholar] [CrossRef]

- Guasch, D.; Silvestre, S.; Calatayud, R. Automatic failure detection in photovoltaic systems. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; Volume 3, pp. 2269–2271. [Google Scholar]

- Hamdaoui, M.; Rabhi, A.; Hajjaji, A.E.; Rahmoun, M.; Azizi, M. Monitoring and control of the performances for photovoltaic systems. In Proceedings of the International Renewable Energy Congress, Sousse, Tunisia, 5–7 November 2009; pp. 69–71. [Google Scholar]

- Takashima, T.; Yamaguchi, J.; Otani, K.; Oozeki, T.; Kato, K.; Ishida, M. Experimental studies of fault location in PV module strings. Sol. Energy Mater. Sol. Cells 2009, 93, 1079–1082. [Google Scholar] [CrossRef]

- Schirone, L.; Califano, F.P.; Pastena, M. Fault detection in a photovoltaic plant by time domain reflectometry. Prog. Photovolt. 1994, 2, 35–44. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. Multi-layer photovoltaic fault detection algorithm. High Volt. 2017, 4, 244–252. [Google Scholar] [CrossRef]

- Wang, J.Y.; Qian, Z.; Zareipour, H.; Wood, D. Performance assessment of photovoltaic modules based on daily energy generation estimation. Energy 2018, 165, 1160–1172. [Google Scholar] [CrossRef]

- Firth, S.K.; Lomas, K.J.; Rees, S.J. A simple model of PV system performance and its use in fault detection. Sol. Energy 2010, 84, 624–635. [Google Scholar] [CrossRef]

- Chouder, A.; Silvestre, S. Automatic supervision and fault detection of PV systems base on power losses analysis. Energy Convers. Manag. 2010, 51, 1929–1937. [Google Scholar] [CrossRef]

- Drews, A.; Keizer, A.C.; Beyer, H.G.; Lorenz, E.; Betcke, J.; Sark, W.G.J.H.M.; Heydenreich, W.; Wiemken, E.; Stettler, S.; Toggweiler, P.; et al. Monitoring and remote failure detection of grid-connected PV systems based on satellite observations. Sol. Energy 2007, 81, 548–564. [Google Scholar] [CrossRef]

- Chouder, A.; Silvestre, S.; Sadaoui, N.; Rahmani, L. Modeling and simulation of a grid connected PV system based on the evaluation of main PV module parameters. Simul. Model. Pract. Theory 2012, 20, 46–58. [Google Scholar] [CrossRef]

- Mellit, A.; Kalogirou, S.A. Artificial intelligence techniques for photovoltaic applications: A review. Prog. Energy Combust. Sci. 2008, 34, 574–632. [Google Scholar] [CrossRef]

- Platon, R.; Pelland, S.; Poissant, Y. Modelling the power production of a photovoltaic system: Comparison of Sugeno-type fuzzy logic and pvsat-2 models. In Proceedings of the ISES-Europe Solar Conference (EuroSun2012), Rijeka, Croatia, 18–20 September 2012. [Google Scholar]

- Mellit, A.; Kalogirou, S.A. ANFIS-based modelling for photovoltaic power supply system: A case study. Renew. Energy 2011, 36, 250–258. [Google Scholar] [CrossRef]

- Mellit, A.; Kalogirou, S.A. Chapter 2-1-D -A Survey on the application of artificial intelligence techniques for photovoltaic systems. In McEvoy’s Handbook of Photovoltaics, 3rd ed.; Academic Press: San Diego, CA, USA, 2018; pp. 735–761. [Google Scholar]

- Benedetti, M.D.; Leonardi, F.; Messina, F.; Santoro, C.; Vasilakos, A. Anomaly detection and predictive maintenance for photovoltaic systems. Neurocomputing 2018, 310, 59–68. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Li, D.; Kang, D.; Lv, Q.; Shang, L. Hierarchical Anomaly Detection and Multimodal Classification in Large-Scale Photovoltaic Systems. IEEE Trans. Sustain. Energy 2019, 10, 1351–1361. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; Pieri, D.D.; Kalogirou, S.A. A comparison between BNN and regression polynomial methods for the evaluation of the effect of soiling in large scale photovoltaic plants. Appl. Energy 2013, 108, 392–401. [Google Scholar] [CrossRef]

- Masters, G. Renewable and Efficient Electric Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

| PV Module | TS-M390-NA2 |

|---|---|

| Temperature coefficient of Pmpp | −0.5 [%] |

| Cell Efficiency | 15.5 [%] |

| MEAN | STANDARD DEVIATION | |

|---|---|---|

| PR—Plant A | 0.5408 | 0.1812 |

| PR (CI > 0.5)—Plant A | 0.5293 | 0.1574 |

| WCPR—Plant A | 0.5364 | 0.1467 |

| WCPR (CI > 0.5)—Plant A | 0.5424 | 0.1158 |

| MEAN | STANDARD DEVIATION | |

|---|---|---|

| PR—Plant B | 0.6247 | 0.2277 |

| PR (CI > 0.5)—Plant B | 0.6176 | 0.1917 |

| WCPR—Plant B | 0.6178 | 0.1826 |

| WCPR (CI > 0.5)—Plant B | 0.6286 | 0.1346 |

| LR—Plant A | 0.6357 |

| LR (CI > 0.5)—Plant A | 0.3713 |

| WCLR—Plant A | 0.8060 |

| WCLR (CI > 0.5)—Plant A | 0.7000 |

| LR—Plant B | 0.5903 |

| LR (CI > 0.5)—Plant B | 0.2967 |

| WCLR—Plant B | 0.7944 |

| WCLR (CI > 0.5)—Plant B | 0.6998 |

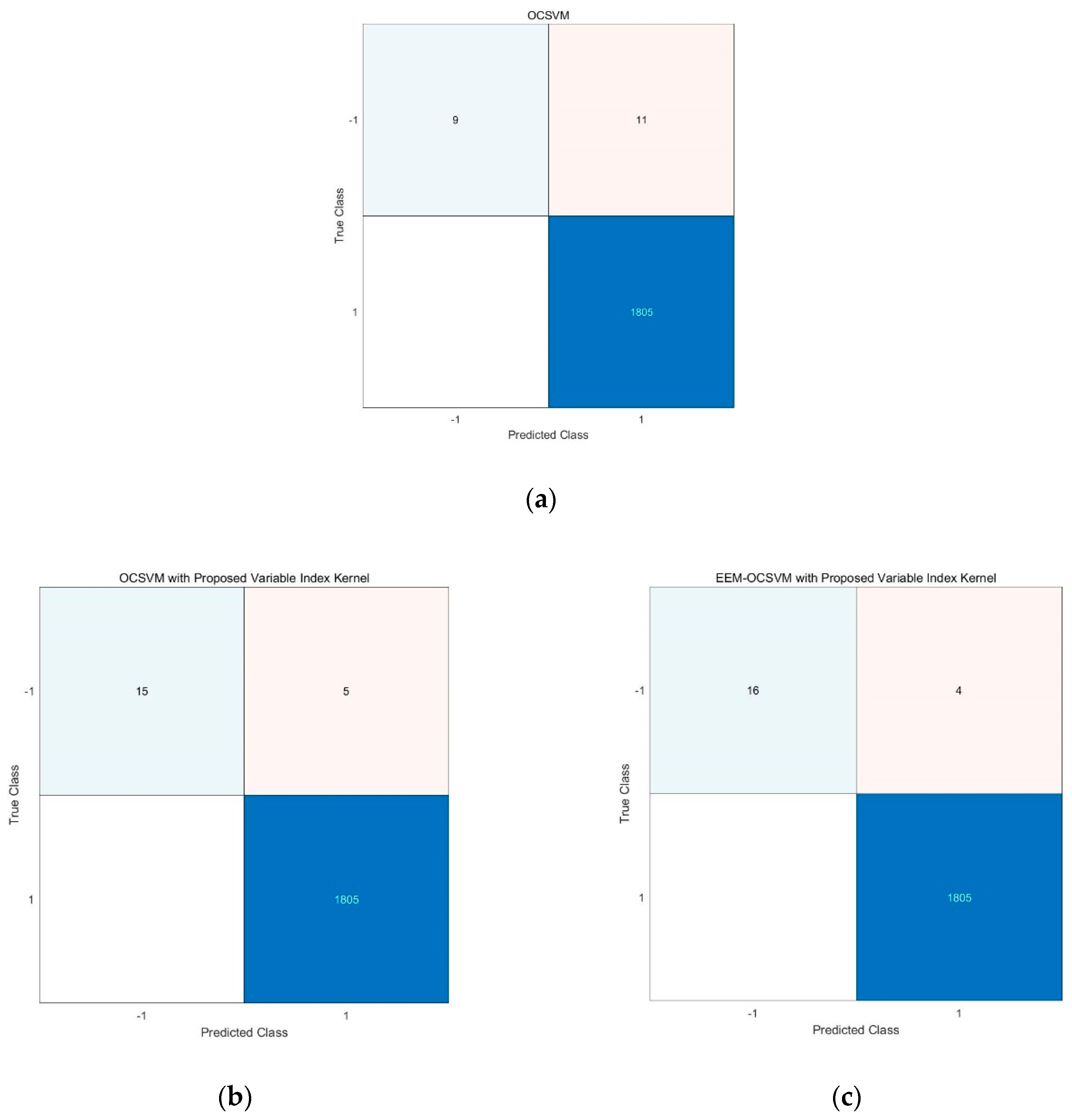

| TP | TN | FP | FN | Error Rate [%] | Classification Accuracy [%] | |

|---|---|---|---|---|---|---|

| OCSVM | 1805 | 9 | 11 | 0 | 0.6 | 99.4 |

| OCSVM with Proposed Variable Index Kernel | 1805 | 15 | 5 | 0 | 0.3 | 99.7 |

| EEM-OCSVM with Proposed Variable Index Kernel | 1805 | 16 | 4 | 0 | 0.2 | 99.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.-H.; Kim, J.-O. On-Line Diagnosis and Fault State Classification Method of Photovoltaic Plant. Energies 2020, 13, 4584. https://doi.org/10.3390/en13174584

Shin J-H, Kim J-O. On-Line Diagnosis and Fault State Classification Method of Photovoltaic Plant. Energies. 2020; 13(17):4584. https://doi.org/10.3390/en13174584

Chicago/Turabian StyleShin, Jun-Hyun, and Jin-O Kim. 2020. "On-Line Diagnosis and Fault State Classification Method of Photovoltaic Plant" Energies 13, no. 17: 4584. https://doi.org/10.3390/en13174584

APA StyleShin, J.-H., & Kim, J.-O. (2020). On-Line Diagnosis and Fault State Classification Method of Photovoltaic Plant. Energies, 13(17), 4584. https://doi.org/10.3390/en13174584