Techno-Economic and Environmental Assessment of Biomass Gasification and Fischer–Tropsch Synthesis Integrated to Sugarcane Biorefineries

Abstract

1. Introduction

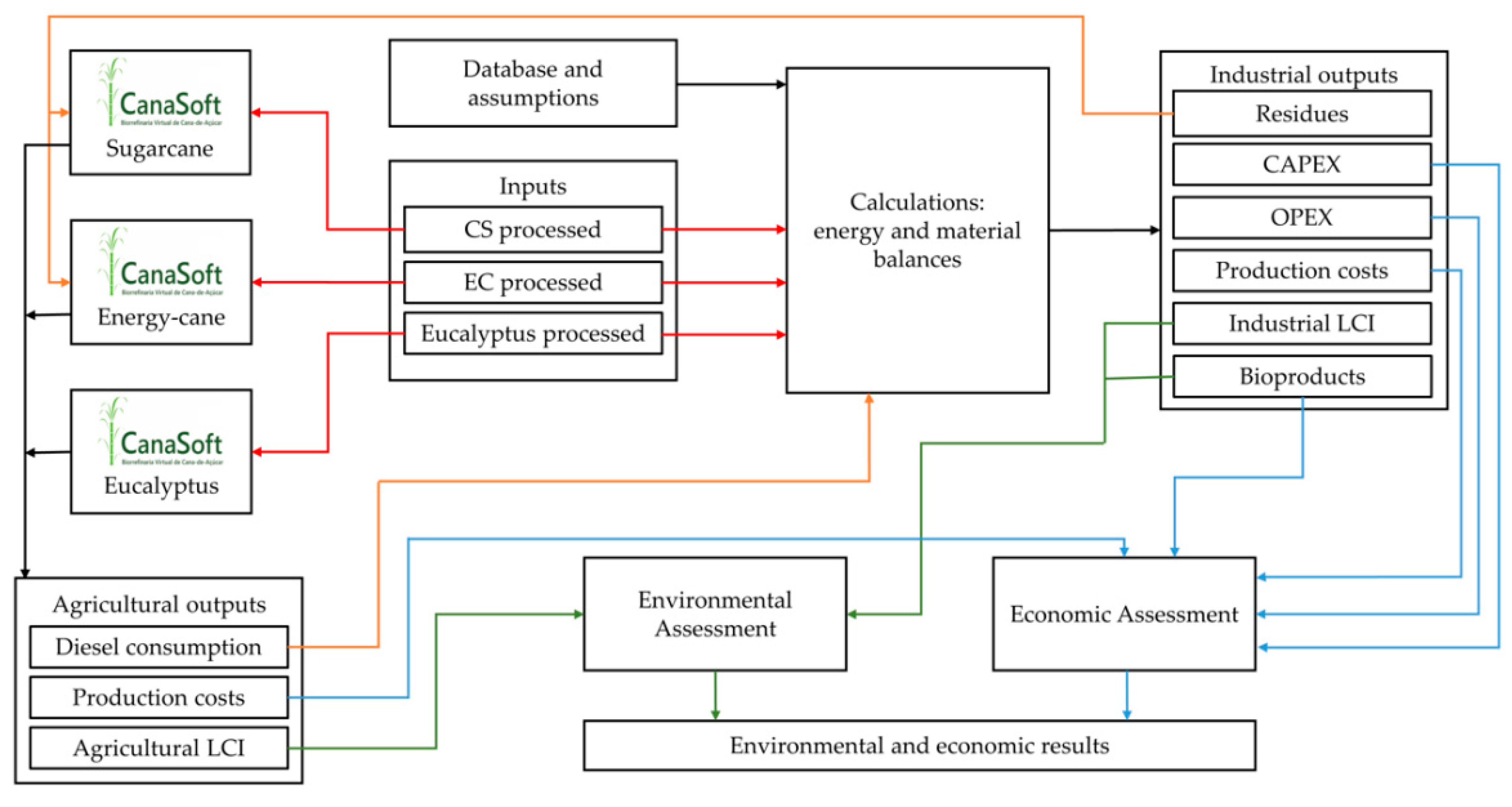

2. Materials and Methods

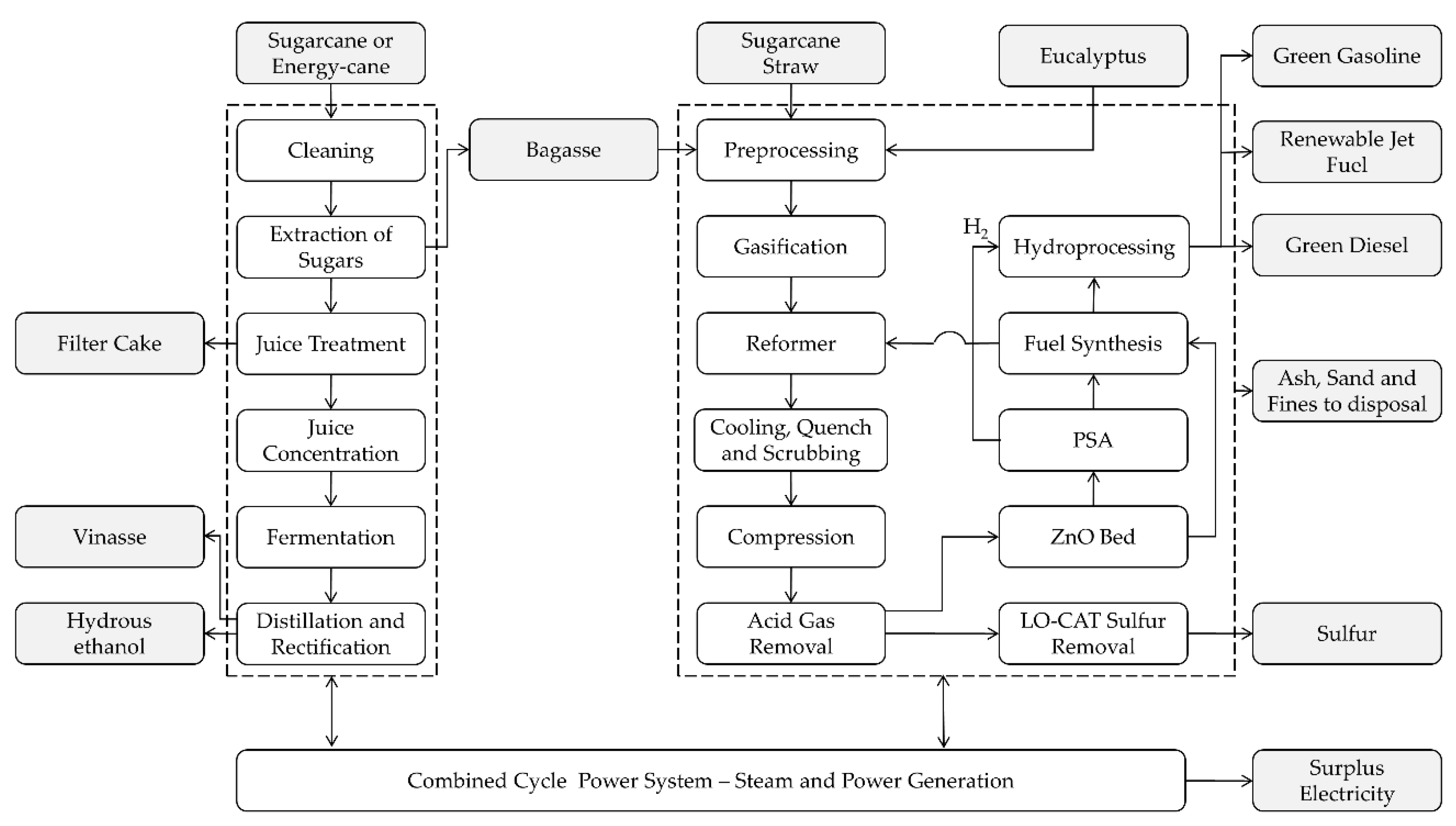

2.1. Biorefinery Configurations

2.2. Biomass Production Systems

2.3. Biomass Conversion Systems

2.3.1. Preprocessing Area

2.3.2. Gasification Area

2.3.3. Syngas Cleaning and Conditioning Area

2.3.4. Fuel Synthesis Area

2.3.5. Hydroprocessing Area

2.3.6. Steam and Power Generation and Utilities Areas

2.4. Climate Change Impacts

2.5. Economic Assessment

2.6. Uncertainty Analysis

3. Results and Discussion

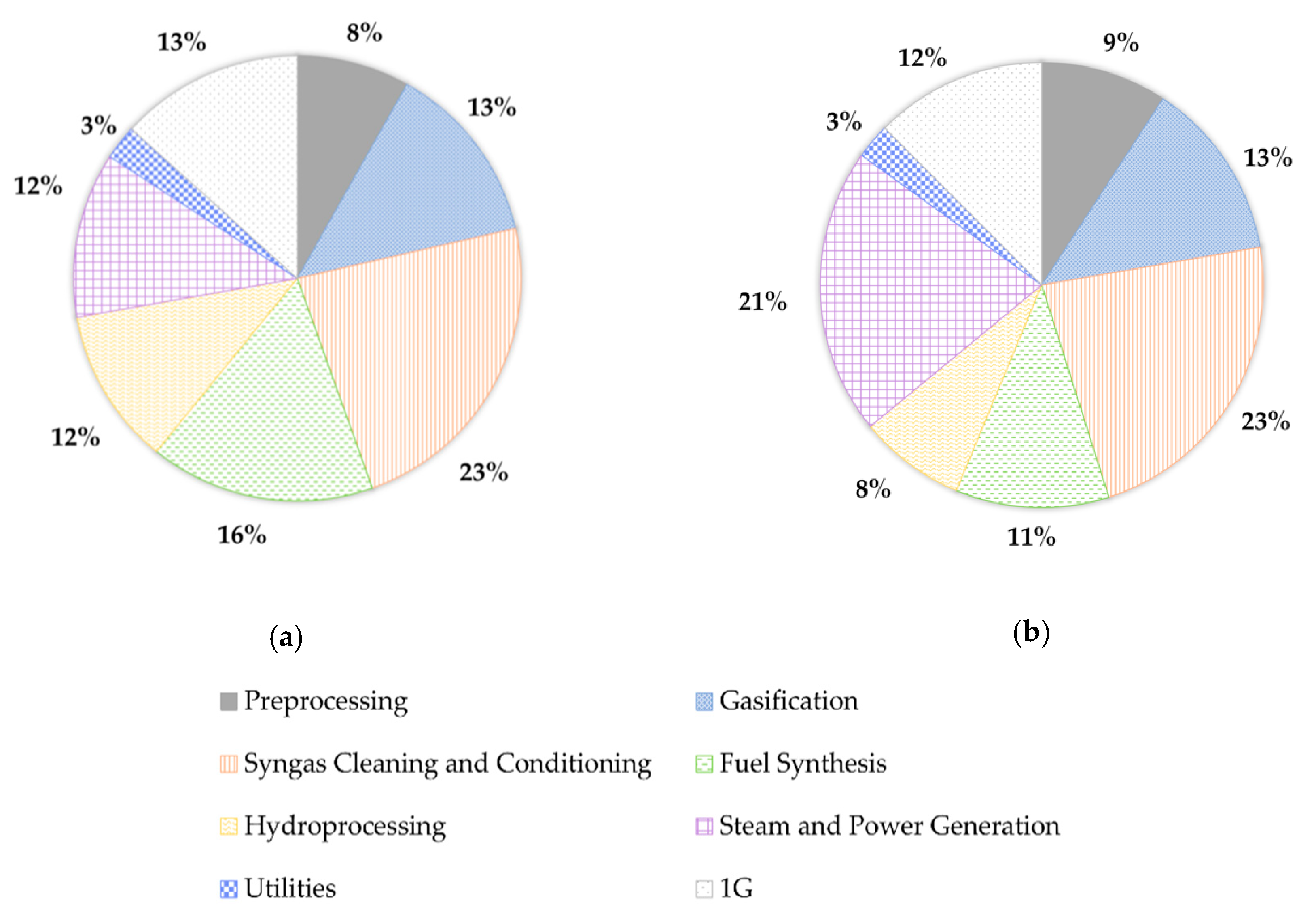

3.1. Techno-Economic Assessment of Biorefinery Scenarios

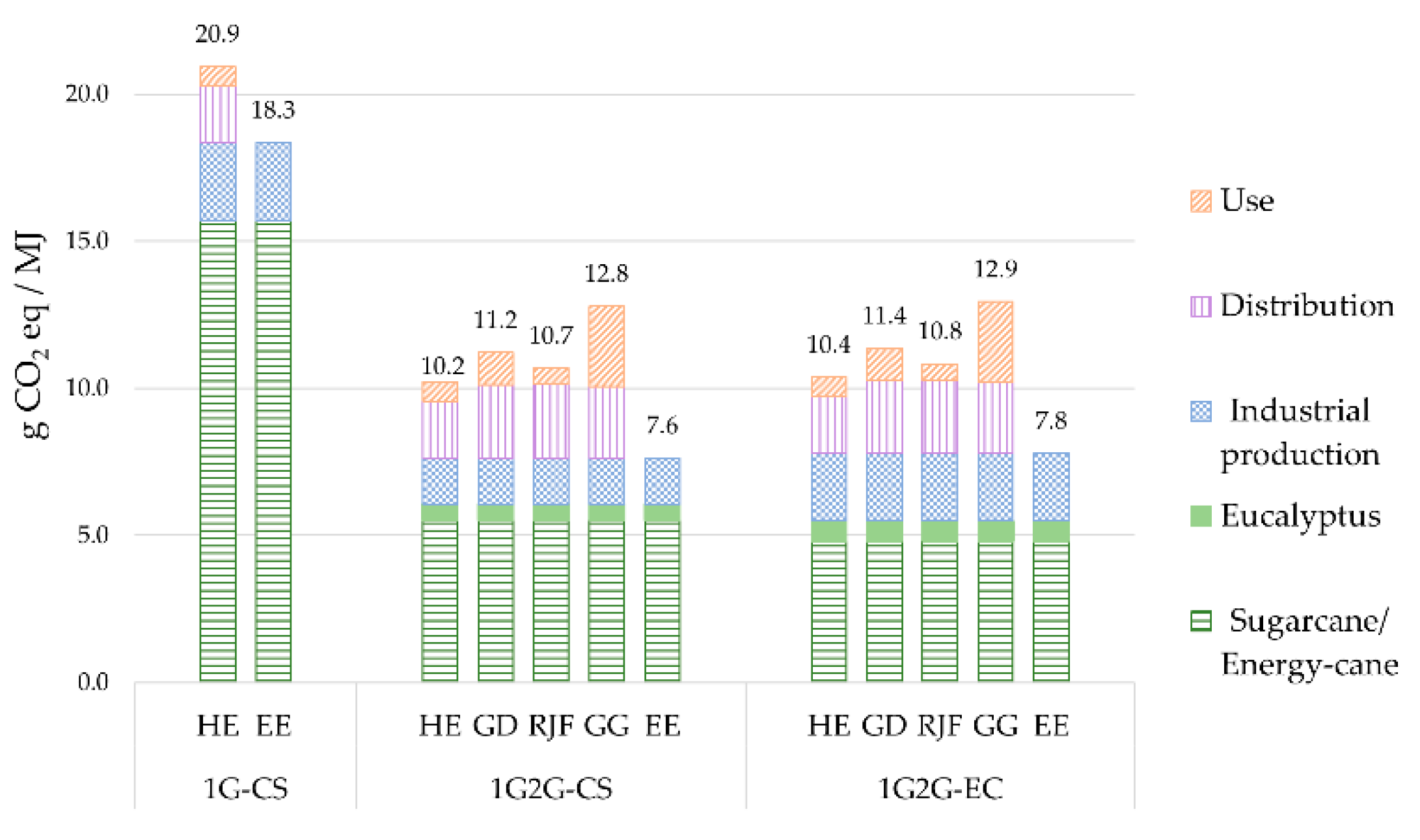

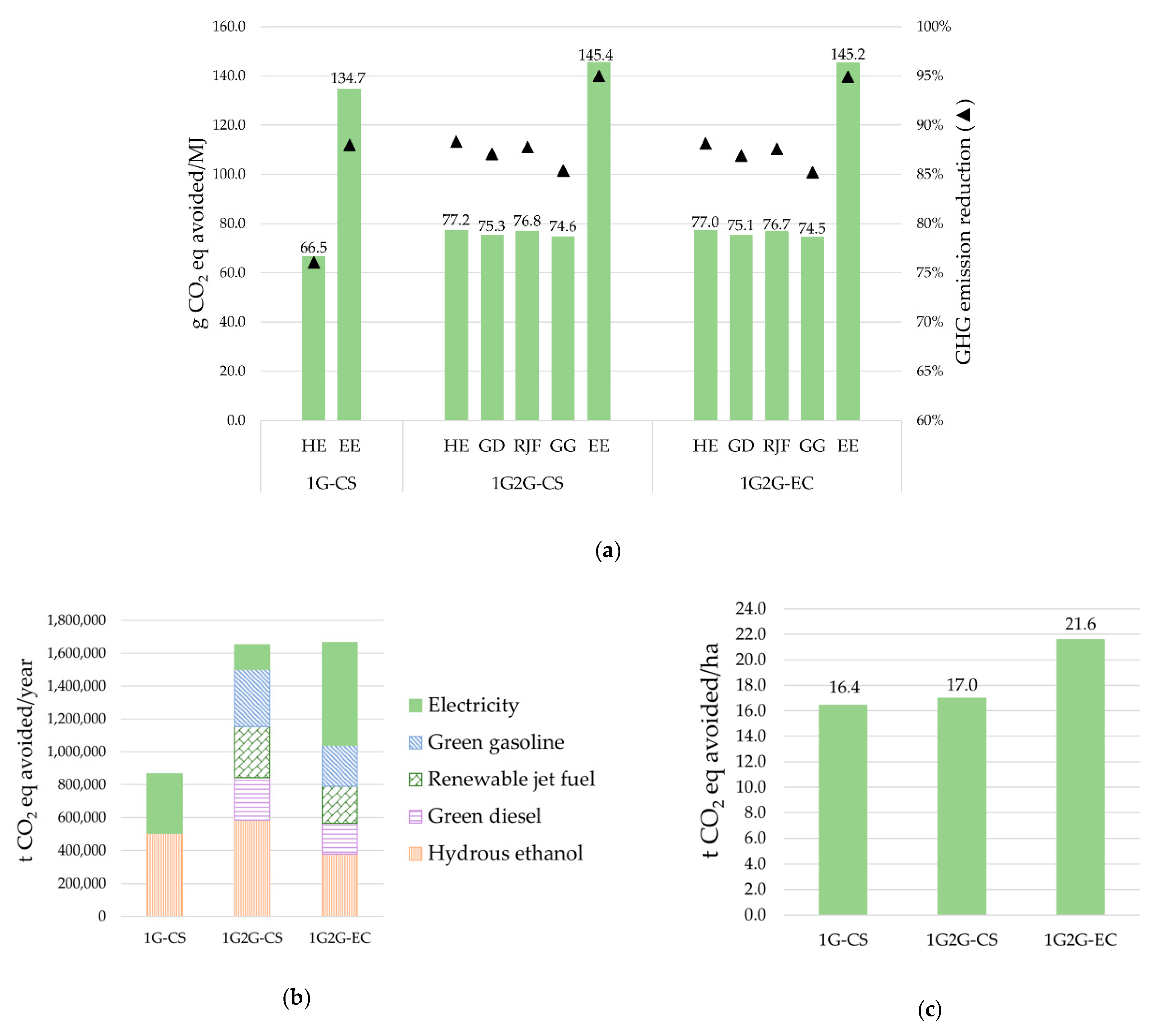

3.2. Climate Change Impacts of Biorefinery Scenarios

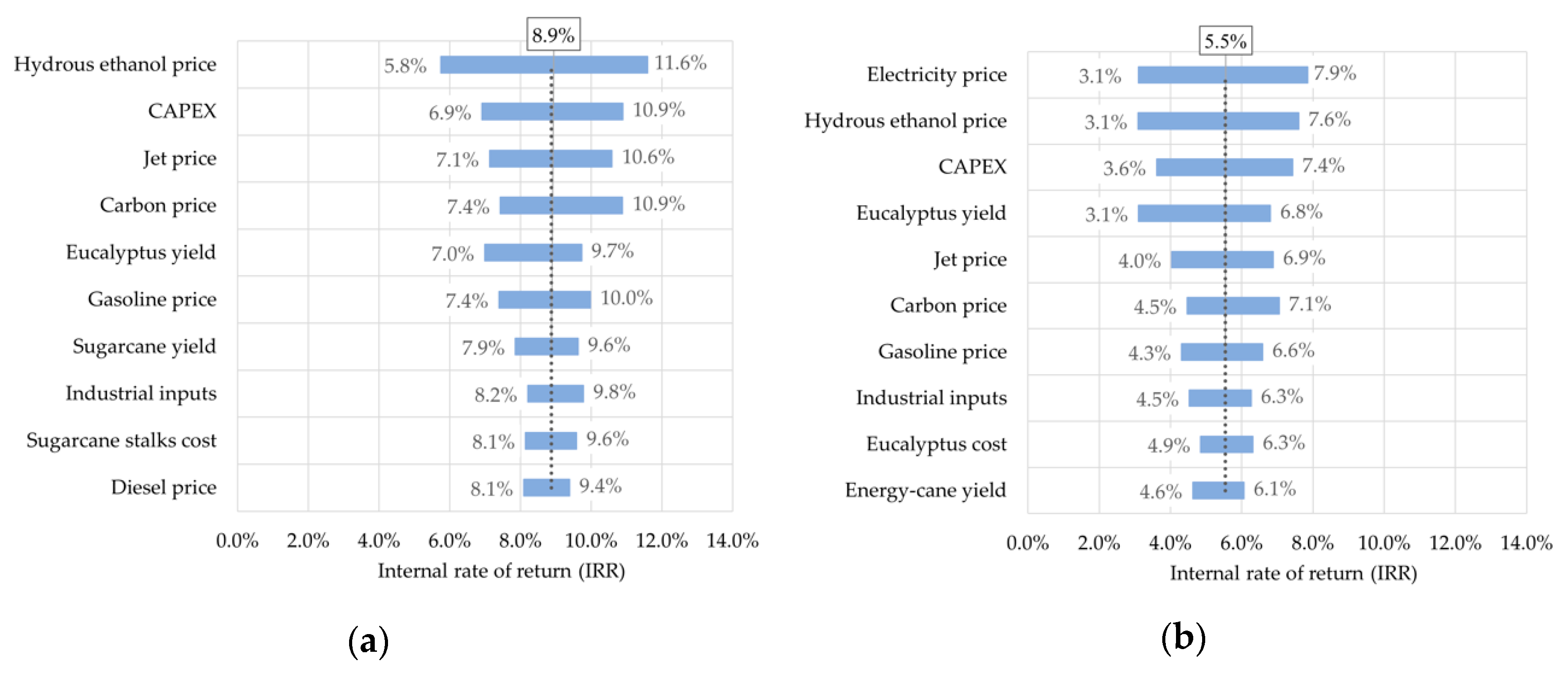

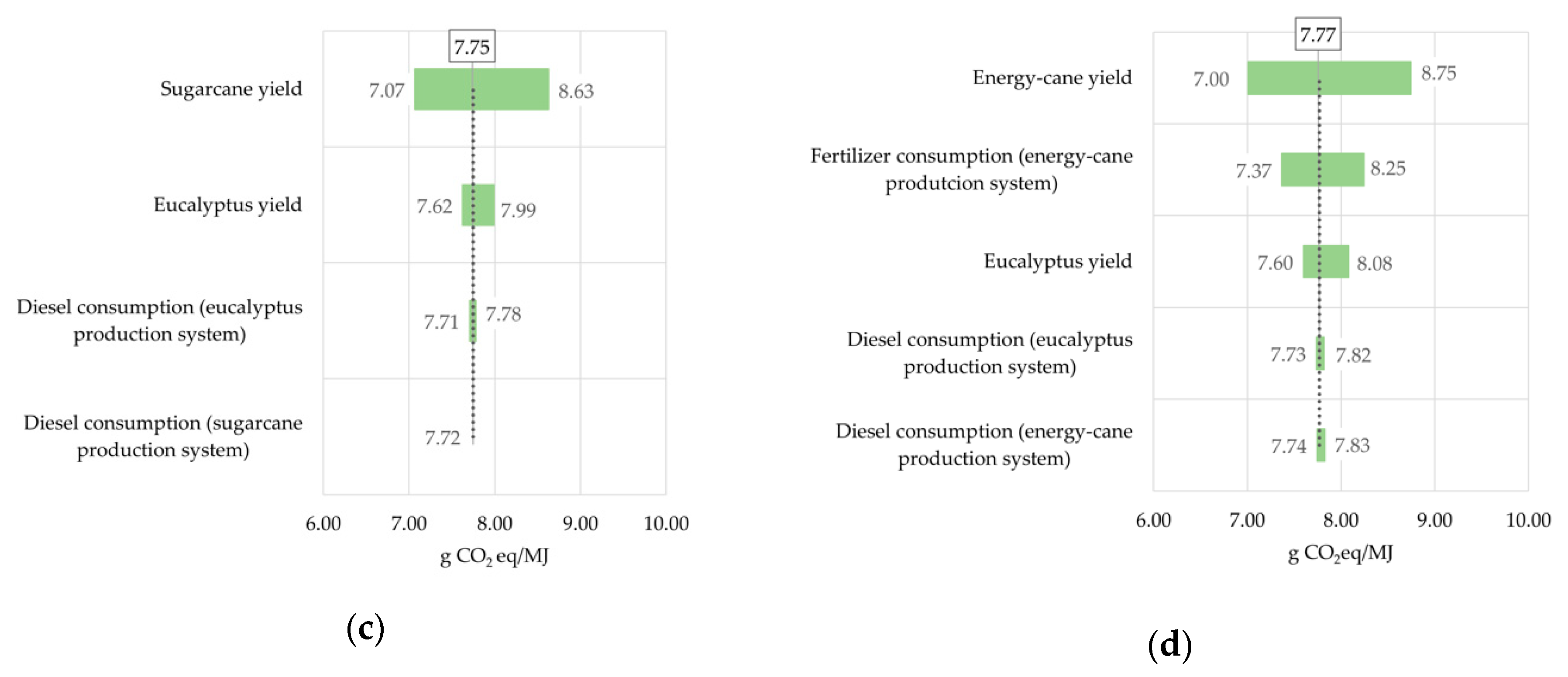

3.3. Uncertainty Analysis of Biorefinery Scenarios

4. Final Remarks

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 1G | First-generation |

| 1G2G | Integrated first and second-generation |

| 2G | Second-generation |

| CAPEX | Capital costs |

| CEPCI | Chemical Engineering Plant Cost Index |

| COP21 | 21st Conference of the Parties |

| CS | Conventional sugarcane |

| DME | Dimethyl ether |

| EC | Energy-cane |

| EE | Electricity |

| FT | Fischer-Tropsch |

| GD | Green diesel |

| GG | Green gasoline |

| GHG | Greenhouse gases |

| GWP | Global warming potential |

| HE | Hydrous ethanol |

| HRSG | Heat recovery steam generator |

| IGP-M | General Market Price Index |

| IRR | Internal rate of return |

| LCA | Life-cycle assessment |

| LCI | Life-cycle inventory |

| LCM | Lignocellulosic material |

| LHV | Low heating value |

| LNBR | Brazilian Biorenewables National Laboratory |

| LTFT | Low-temperature Fischer-Tropsch |

| MARR | Minimum attractive rate of return |

| MTG | Methanol-to-gasoline |

| NPV | Net present value |

| OPEX | Operating costs |

| PSA | Pressure swing adsorption |

| RJF | Renewable jet fuel |

| SSPs | Shared Socioeconomic Pathways |

| VSB | Virtual Sugarcane Biorefinery |

References

- Intergovernmental Panel on Climate Change (IPCC). Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5°C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; Available online: https://www.ipcc.ch/sr15/ (accessed on 10 August 2018).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Shukla, P.R., Skea, J., Buendia, E.C., Masson-Delmotte, V.H.-O., Pörtner, D.C., Roberts, P., Zhai, R., Slade, S., Connors, R., Van Diemen, M., et al., Eds.; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2019. [Google Scholar]

- O’Neill, B.C.; Kriegler, E.; Ebi, K.L.; Kemp-Benedict, E.; Riahi, K.; Rothman, D.S.; Van Ruijven, B.J.; Van Vuuren, D.P.; Birkmann, J.; Kok, K.; et al. The roads ahead: Narratives for shared socioeconomic pathways describing world futures in the 21st century. Glob. Environ. Chang. 2017, 42, 169–180. [Google Scholar] [CrossRef]

- Popp, A.; Calvin, K.; Fujimori, S.; Havlik, P.; Humpenöder, F.; Stehfest, E.; Bodirsky, B.L.; Dietrich, J.P.; Doelmann, J.C.; Gusti, M.; et al. Land-use futures in the shared socio-economic pathways. Glob. Environ. Chang. 2017, 42, 331–345. [Google Scholar] [CrossRef]

- Van den Wall Bake, J.D.; Junginger, M.; Faaij, A.; Poot, T.; Walter, A. Explaining the experience curve: Cost reductions of Brazilian ethanol from sugarcane. Biomass Bioenergy 2009, 33, 644–658. [Google Scholar] [CrossRef]

- Goldemberg, J. An hystorical account of bioenergy production in Brazil. In Proceedings of the BBEST—Bioethanol Science and Technology Conference, Campos do Jordão, Brazil, 14 August 2011; p. 14. [Google Scholar]

- Corrêa do Lago, A.; Bonomi, A.; Cavalett, O.; Pereira da Cunha, M.; Pinheiro Lima, M.A. Sugarcane as a carbon source: The Brazilian case. Biomass Bioenergy 2012, 46, 5–12. [Google Scholar] [CrossRef]

- Tolmasquim, M.T.; Gorini, R.; Matsumura, E.; Soares, J.B.; Oliveira, L.B.; Lisboa, M.L.V.; Faria, G.V.R.; Conde, M.R.; Moraes, N.G.; Silva, R.A.M. The Brazilian Commitment to Combating Climate Change: Energy Production and Use; Empresa de Pesquisa Energética (EPE): Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Empresa de Pesquisa Energética (EPE). Nota Técnica DEA 13/15—Demanda de Energia 2050; Empresa de Pesquisa Energética: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2016. Available online: https://www.iea.org/reports/world-energy-outlook-2016 (accessed on 7 July 2020).

- Ministério do Meio Ambiente (MMA). iNDC (Contribuição Nacionalmente Determinada). Available online: https://www.mma.gov.br/informma/item/10570-indc-contribuição-nacionalmente-determinada (accessed on 20 January 2020).

- República Federativa Do Brasil. Lei n°13.576/2017 Dispõe Sobre a Política Nacional de Biocombustíveis (RenovaBio) e dá Outras Providências; República Federativa Do Brasil: Brasília, Brasil, 2017. [Google Scholar]

- Klein, B.C.; Chagas, M.F.; Watanabe, M.D.B.; Bonomi, A.; Maciel Filho, R. Low carbon biofuels and the New Brazilian National Biofuel Policy (RenovaBio): A case study for sugarcane mills and integrated sugarcane-microalgae biorefineries. Renew. Sustain. Energy Rev. 2019, 115, 109365. [Google Scholar] [CrossRef]

- Cavalett, O.; Chagas, M.F.; Junqueira, T.L.; Watanabe, M.D.B.; Bonomi, A. Environmental impacts of technology learning curve for cellulosic ethanol in Brazil. Ind. Crops Prod. 2017, 106, 31–39. [Google Scholar] [CrossRef]

- Junqueira, T.L.; Chagas, M.F.; Gouveia, V.L.R.; Rezende, M.C.A.F.; Watanabe, M.D.B.; Jesus, C.D.F.; Cavalett, O.; Milanez, A.Y.; Bonomi, A. Techno-economic analysis and climate change impacts of sugarcane biorefineries considering different time horizons. Biotechnol. Biofuels 2017, 10, 1–12. [Google Scholar] [CrossRef]

- Foust, T.D.; Aden, A.; Dutta, A.; Phillips, S. An economic and environmental comparison of a biochemical and a thermochemical lignocellulosic ethanol conversion processes. Cellulose 2009, 16, 547–565. [Google Scholar] [CrossRef]

- Zhu, Y.; Rahardjo, S.T.; Valkenburg, C.; Snowden-Swan, L.; Jones, S.; Machinal, M. Techno-Economic Analysis for the Thermochemical Conversion of Biomass to Liquid Fuels (U.S. DOE); Department of Energy, Pacific Northwest National Laboratory: Richland, WA, USA, 2011. [Google Scholar]

- Swanson, R.M.; Satrio, J.A.; Brown, R.C.; Platon, A.; Hsu, D.D. Techno-Economic Analysis of Biofuels Productionbased on Gasification; National Renewable Energy Laboratory: Golden, CO, USA, 2010. [Google Scholar]

- Agusdinata, D.B.; Zhao, F.; Ileleji, K.; Delaurentis, D. Life cycle assessment of potential biojet fuel production in the United States. Environ. Sci. Technol. 2011, 45, 9133–9143. [Google Scholar] [CrossRef]

- Haarlemmer, G.; Boissonnet, G.; Imbach, J.; Setier, P.A.; Peduzzi, E. Second generation BtL type biofuels—A production cost analysis. Energy Environ. Sci. 2012, 5, 8445–8456. [Google Scholar] [CrossRef]

- Baliban, R.C.; Elia, J.A.; Floudas, C.A.; Gurau, B.; Weingarten, M.B.; Klotz, S.D. Hardwood biomass to gasoline, diesel, and jet fuel: 1 Process synthesis and global optimization of a thermochemical refinery. Energy Fuels 2013, 27, 4302–4324. [Google Scholar] [CrossRef]

- Diederichs, G.W.; Mandegari, M.A.; Farzad, S.; Görgens, J.F. Techno-economic comparison of biojet fuel production from lignocellulose, vegetable oil and sugar cane juice. Bioresour. Technol. 2016, 216, 331–339. [Google Scholar] [CrossRef]

- Im-orb, K.; Simasatitkul, L.; Arpornwichanop, A. Techno-economic analysis of the biomass gasification and Fischer-Tropsch integrated process with off-gas recirculation. Energy 2016, 94, 483–496. [Google Scholar] [CrossRef]

- Dimitriou, I.; Goldingay, H.; Bridgwater, A.V. Techno-economic and uncertainty analysis of Biomass to Liquid (BTL) systems for transport fuel production. Renew. Sustain. Energy Rev. 2018, 88, 160–175. [Google Scholar] [CrossRef]

- Carvalho, F.; Da Silva, F.T.F.; Szklo, A.; Portugal-Pereira, J. Potential for biojet production from different biomass feedstocks and consolidated technological routes: A georeferencing and spatial analysis in Brazil. Biofuels Bioprod. Biorefin. 2019, 13, 1454–1475. [Google Scholar] [CrossRef]

- Han, J.; Elgowainy, A.; Cai, H.; Wang, M.Q. Life-cycle analysis of bio-based aviation fuels. Bioresour. Technol. 2013, 150, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, P.; Malina, R.; Barrett, S.R.H. Environmental and economic tradeoffs of using corn stover for liquid fuels and power production. Energy Environ. Sci. 2015, 8, 1428–1437. [Google Scholar] [CrossRef]

- Wang, W.C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef]

- De Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 1–18. [Google Scholar] [CrossRef]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; De FátimaCardoso, T.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Capaz, R.S.; De Medeiros, E.M.; Falco, D.G.; Seabra, J.E.A.; Osseweijer, P.; Posada, J.A. Environmental trade-offs of renewable jet fuels in Brazil: Beyond the carbon footprint. Sci. Total Environ. 2020, 714, 136696. [Google Scholar] [CrossRef] [PubMed]

- Santos, C.I.; Silva, C.C.; Mussatto, S.I.; Osseweijer, P.; Van der Wielen, L.A.M.; Posada, J.A. Integrated 1st and 2nd generation sugarcane bio-refinery for jet fuel production in Brazil: Techno-economic and greenhouse gas emissions assessment. Renew. Energy 2018, 129, 733–747. [Google Scholar] [CrossRef]

- Furtado, J.C., Jr.; Palacio, J.C.E.; Leme, R.C.; Lora, E.E.S.; Da Costa, J.E.L.; Reyes, A.M.M.; Del Olmo, O.A. Biorefineries productive alternatives optimization in the brazilian sugar and alcohol industry. Appl. Energy 2020, 259, 113092. [Google Scholar] [CrossRef]

- Matsuoka, S.; Kennedy, A.J.; Santos, E.G.D.; Tomazela, A.L.; Rubio, L.C.S. Energy Cane: Its Concept, Development, Characteristics, and Prospects. Adv. Bot. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Carvalho-Netto, O.V.; Bressiani, J.A.; Soriano, H.L.; Fiori, C.S.; Santos, J.M.; Barbosa, G.V.; Xavier, M.A.; Landell, M.G.; Pereira, G.A. The potential of the energy cane as the main biomass crop for the cellulosic industry. Chem. Biol. Technol. Agric. 2014, 1, 1–8. [Google Scholar] [CrossRef]

- Milanez, A.Y.; Nyko, D.; Valente, M.S.; Souza, L.C.; Bonomi, A.; Jesus, C.D.F.; Watanabe, M.D.B.; Chagas, M.F.; Rezende, M.C.A.F.; Cavalett, O.; et al. De promessa a realidade : Como o etanol celulósico pode revolucionar a indústria da cana-de-açúcar—Uma avaliação do potencial competitivo e sugestões de política pública. Biocombustíveis BNDES Set. 2015, 41, 237–294. [Google Scholar]

- Boschiero, B.N.; De Castro, S.G.Q.; Da Rocha, A.E.Q.; Franco, H.C.J.; Carvalho, J.L.N.; Soriano, H.L.; Dos Santos, J.A.; Bressiani, J.A.; Kölln, O.T. Biomass production and nutrient removal of energy cane genotypes in Northeastern Brazil. Crop Sci. 2019, 59, 379–391. [Google Scholar] [CrossRef]

- Grassi, M.C.B.; Pereira, G.A.G. Energy-cane and RenovaBio: Brazilian vectors to boost the development of Biofuels. Ind. Crops Prod. 2019, 129, 201–205. [Google Scholar] [CrossRef]

- Indústria Brasileira de Árvore (IBÁ). Relatório 2017; Indústria Brasileira de Árvore: Brasília, Brazil, 2017. [Google Scholar]

- Stape, J.L.; Binkley, D.; Ryan, M.G.; Fonseca, S.; Loos, R.A.; Takahashi, E.N.; Silva, C.R.; Silva, S.R.; Hakamada, R.E.; Ferreira, J.M.; et al. The Brazil Eucalyptus Potential Productivity Project: Influence of water, nutrients and stand uniformity on wood production. For. Ecol. Manag. 2010, 259, 1684–1694. [Google Scholar] [CrossRef]

- Cantarella, H.; Nassar, A.M.; Cortez, L.A.B.; Baldassin, R. Potential feedstock for renewable aviation fuel in Brazil. Environ. Dev. 2015, 15, 52–63. [Google Scholar] [CrossRef]

- Jonker, J.G.G.; Van der Hilst, F.; Junginger, H.M.; Cavalett, O.; Chagas, M.F.; Faaij, A.P.C. Outlook for ethanol production costs in Brazil up to 2030, for different biomass crops and industrial technologies. Appl. Energy 2015, 147, 593–610. [Google Scholar] [CrossRef]

- Eufrade, H.J., Jr.; Melo, R.X.; Sartori, M.M.P.; Guerra, S.P.S.; Ballarin, A.W. Sustainable use of eucalypt biomass grown on short rotation coppice for bioenergy. Biomass Bioenergy 2016, 90, 15–21. [Google Scholar] [CrossRef]

- Wilcken, C.F.; Lima, A.C.V.; Dias, T.K.R.; Masson, M.V.; Filho, P.J.F.; Dal Pogetto, M.H.F.A. Guia Prático de Manejo de Plantações de Eucalipto; Fundação de Estudos e Pesquisas Agrícolas e Florestais: Botucatu, Brazil, 2008; Volume 1, p. 25. [Google Scholar]

- Bonomi, A.; Cavalett, O.; Pereira da Cunha, M.; Lima, M.A.P. Virtual Biorefinery—An Optimization Strategy for Renewable Carbon Valorization, 1st ed.; Green Energy and Technology; Springer International Publishing: Basel, Switzerland, 2016; ISBN 978-3-319-26043-3. [Google Scholar]

- Nitzsche, R.; Budzinski, M.; Gröngröft, A. Techno-economic assessment of a wood-based biorefinery concept for the production of polymer-grade ethylene, organosolv lignin and fuel. Bioresour. Technol. 2016, 200, 928–939. [Google Scholar] [CrossRef] [PubMed]

- Pala, L.P.R.; Wang, Q.; Kolb, G.; Hessel, V. Steam gasification of biomass with subsequent syngas adjustment using shift reaction for syngas production: An Aspen Plus model. Renew. Energy 2017, 101, 484–492. [Google Scholar] [CrossRef]

- Sampaio, I.L.M.; Cardoso, T.F.; Souza, N.R.D.; Watanabe, M.D.B.; Carvalho, D.J.; Bonomi, A.; Junqueira, T.L. Electricity Production from Sugarcane Straw Recovered through Bale System: Assessment of Retrofit Projects. Bioenergy Res. 2019, 12, 865–877. [Google Scholar] [CrossRef]

- Watanabe, M.D.B.; Morais, E.R.; Cardoso, T.F.; Chagas, M.F.; Junqueira, T.L.; Carvalho, D.J.; Bonomi, A. Process simulation of renewable electricity from sugarcane straw: Techno-economic assessment of retrofit scenarios in Brazil. J. Clean. Prod. 2020, 254, 120081. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef]

- Cavalett, O.; Chagas, M.F.; Magalhães, P.S.G.; Carvalho, J.L.N.; Cardoso, T.F.; Franco, H.C.J.; Braunbeck, O.A.; Bonomi, A. The Agricultural Production Model. In Virtual Biorefinery—An Optimization Strategy for Renewable Carbon Valorization; Bonomi, A., Cavalett, O., Pereira da Cunha, M., Lima, M.A.P., Eds.; Green Energy and, Technology; Springer International Publishing: Basel, Switzerland, 2016; pp. 13–51. [Google Scholar]

- Matsuoka, S.; Bressiani, J.; Maccheroni, W.; Fouto, I. Bioenergia de Cana. In Cana-de-Açúcar Bioenergia, Açúcar e Ácool; UFV: Viçosa, Brazil, 2012; pp. 544–577. [Google Scholar]

- De Lima Silva, J.P.; De Aquino, G.S.; Navroski, D.; De Souza, I.F.; Soriano, H.L.; Bressiani, J.A.; Ralisch, R. Biometrics, productivity and technological quality of 23 energy sugarcane hybrid clones with higher lignocellulosic biomass. Aust. J. Crop Sci. 2018, 12, 915–921. [Google Scholar] [CrossRef]

- Moreira, B.R.A.; Viana, R.S.; Lisboa, L.A.M.; Lopes, P.R.M.; Figueiredo, P.A.M.; Ramos, S.B.; Bonini, C.S.B.; Trindade, V.D.R.; Andrade, M.G.O.; May, A. Classifying Hybrids of Energy Cane for Production of Bioethanol and Cogeneration of Biomass-Based Electricity by Principal Component Analysis-Linked Fuzzy C-Means Clustering Algorithm. J. Agric. Sci. 2019, 11, 246. [Google Scholar] [CrossRef]

- Chagas, M.F.; Bordonal, R.O.; Cavalett, O.; Carvalho, J.L.N.; Bonomi, A.; La Scala, N. Environmental and economic impacts of different sugarcane production systems in the ethanol biorefinery. Biofuels Bioprod. Biorefin. 2016, 10, 89–106. [Google Scholar] [CrossRef]

- Instituto Agronômico (IAC)—FUNDAG. Boletim Técnico n.° 100—Recomendações de Adubação e Calagem Para o Estado de São Paulo; Instituto Agronômico (IAC)—FUNDAG: Campinas, Brazil, 1997. [Google Scholar]

- Instituto de Desenvolvimento Agroindustrial (IDEA). Indicadores de Desempenho da Agroindústria Canavieira—Safras 2012/13 e 2013/14; Instituto de Desenvolvimento Agroindustrial (IDEA): Ribeirao Preto, Brazil, 2014. [Google Scholar]

- Seixas, F.; Bauch, S.C.; De Oliveira, E.D., Jr. Balanço energético e econômico de duas alternativas de descascamento de madeira de eucalipto Energetic balance and economical study of two debarking alternatives for Eucalypts wood. Sci. For. 2005, 67, 37–43. [Google Scholar]

- Federação da Agricultura e Pecuária de Goiás (FAEG). Custo Operacional de Produção de Eucalipto em Goiás; Federação da Agricultura e Pecuária de Goiás (FAEG): Goiânia, Brazil, 2012. [Google Scholar]

- Amos, W.A. Report on Biomass Drying Technology; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Petersen, A.M.; Farzad, S.; Görgens, J.F. Techno-economic assessment of integrating methanol or Fischer-Tropsch synthesis in a South African sugar mill. Bioresour. Technol. 2015, 183, 141–152. [Google Scholar] [CrossRef]

- Feldmann, H.F.; Paisley, M.A.; Appelbaum, H.R.; Taylor, D.R. Conversion of Forest Residues To a Methane—Rich Gas in a High-Throughput Gasifier; Battelle: Columbus, OH, USA, 1988. [Google Scholar]

- Bain, R.L. Material and Energy Balances for Methanol from Biomass Using Biomass Gasifiers; National Renewable Energy Laboratory: Golden, CO, USA, 1992. [Google Scholar]

- Craig, K.R.; Mann, M.K. Cost and Performance Analysis of Biomass-Based Integrated Gasification Combined-Cycle (BIGCC) Power Systems; National Renewable Energy Laboratory: Golden, CO, USA, 1996. [Google Scholar]

- Spath, P.; Aden, A.; Eggeman, T.; Ringer, M.; Wallace, B.; Jechura, J. Biomass to Hydrogen Production Detailed Design and Economics Utilizing the Battele Columbus Laboratory Indirectly-Heated Gasifier; National Renewable Energy Laboratory: Golden, CO, USA, 2005. [Google Scholar]

- Xu, G.; Murakami, T.; Suda, T.; Matsuzawa, Y.; Tani, H. The superior technical choice for dual fluidized bed gasification. Ind. Eng. Chem. Res. 2006, 45, 2281–2286. [Google Scholar] [CrossRef]

- Corella, J.; Toledo, J.M.; Molina, G. A review on dual fluidized-bed biomass gasifiers. Ind. Eng. Chem. Res. 2007, 46, 6831–6839. [Google Scholar] [CrossRef]

- Dutta, A.; Talmadge, M.; Hensley, J.; Worley, M.; Dudgeon, D.; Barton, D.; Groenendijk, P.; Ferrari, D.; Stears, B.; Searcy, E.M.; et al. Process Design and Economics for Conversion of Lignocellulosic Biomass to Ethanol—Thermochemical Pathway by Indirect Gasification and Mixed Alcohol Synthesis; National Renewable Energy Laboratory: Golden, CO, USA, 2011. [Google Scholar]

- Nexant Inc. Equipment Design and Cost Estimation for Small Modular Biomass Systems, Synthesis Gas Cleanup, and Oxygen Separation Equipment—Task 2: Gas Cleanup Design and Cost Equipment Design and Cost Estimation for Small Modular Biomass Systems, Synthesis Gas; Work performed by Nexant Inc.: San Francisco, CA, USA; National Renewable Energy Laboratory: Golden, CO, USA, 2006. [Google Scholar]

- Francis, S.M.; Richard, E.T. Oilfield Processing of Petroleum: Natural Gas; PennWell Books: Tusla, OK, USA, 1991; Volume 1, ISBN 978-0878143436. [Google Scholar]

- Dry, M.E. The Fischer—Tropsch process: 1950–2000. Catal. Today 2002, 71, 227–241. [Google Scholar] [CrossRef]

- Tijmensen, M.J.A.; Faaij, A.P.C.; Hamelinck, C.N.; Van Hardeveld, M.R.M. Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. Biomass Bioenergy 2002, 23, 129–152. [Google Scholar] [CrossRef]

- Espinoza, R.L.; Steynberg, A.P.; Jager, B.; Vosloo, A.C. Low temperature Fischer-Tropsch synthesis from a Sasol perspective. Appl. Catal. A Gen. 1999, 186, 13–26. [Google Scholar] [CrossRef]

- Song, H.; Ramkrishna, D.; Trinh, S.; Wright, H. Operating strategies for Fischer-Tropsch reactors: A model-directed study. Korean J. Chem. Eng. 2004, 21, 308–317. [Google Scholar] [CrossRef]

- Klerk, A. De Fischer-Tropsch fuels refinery design. Energy Environ. Sci. 2011, 4, 1177–1205. [Google Scholar] [CrossRef]

- Rezaiyan, J.; Cheremisinoff, N.P. Gasification Technologies—A Primer for Engineers and Scientists; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0824722470. [Google Scholar]

- Basu, P. Biomass Gasification and Pyrolysis; Academic Press: Burlington, MA, USA, 2010; ISBN 9780123749888. [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR ISO 14044: Gestão Ambiental—Avaliação do Ciclo de Vida—Princípios e Estrutura; Brazilian Technical Standards Association: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR ISO 14044: Gestão Ambiental—Avaliação do Ciclo de Vida—Requisitos e Orientações; Brazilian Technical Standards Association: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; The Core Writing Team, R.K., Pachauri Meyer, L., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Agência Nacional do Petróleo Gás Natural E Biocombustíveis (ANP). Planilha RenovaCalc V.6.1 (Ferramenta de Cálculo da Intensidade de Carbono de Biocombustíveis). Available online: http://www.anp.gov.br/producao-de-biocombustiveis/renovabio/renovacalc (accessed on 16 July 2020).

- Ministério de Minas e Energia (MME). RenovaBio. Consulta Pública—Anexo da Nota Técnica no 12/2018/DBIO/SPG. Proposta de Metas Compulsórias Anuais de Redução de Emissões na Comercialização de Combustíveis. Available online: http://www.mme.gov.br/c/document_library/get_file?uuid=40d35ad0-582d-82e3-1de0-61979c5905ae&groupId=36224 (accessed on 13 July 2020).

- Agência nacional do Petróleo Gás Natural e Biocombustíveis (ANP). Preços de Produtores e Importadores de Derivados de Petróleo. Available online: http://www.anp.gov.br/precos-e-defesa-da-concorrencia/precos/precos-de-produtores (accessed on 6 December 2018).

- Centro de Estudos Avançados em Economia Aplicada (CEPEA). Indicador Mensal Etanol Hidratado CEPEA/ESALQ Combustível—Estado de São Paulo. Available online: http://cepea.esalq.usp.br/etanol/ (accessed on 9 December 2018).

- Câmara de Comercialização de Energia Elétrica (CCEE). Historical Prices of Electricity in the Regulated Market (Auctions). Available online: https://www.ccee.org.br/portal/faces/pages_publico/o-que-fazemos/como_ccee_atua/precos/historico_preco_semanal?_afrLoop=1103462852327649&_adf.ctrl-state=h9vdymyim_82#!%40%40%3F_afrLoop%3D1103462852327649%26_adf.ctrl-state%3Dh9vdymyim_86 (accessed on 12 April 2018).

- Newnan, D.G.; Eschenbach, T.G.; Lavelle, J.P. Engineering Economic Analysis, 9th ed.; Oxford University Press: New York, NY, USA, 2004; ISBN 0-19-516807-0. [Google Scholar]

- Watanabe, M.D.B.; Pereira, L.G.; Chagas, M.F.; Cunha, M.P.; Jesus, C.D.F.; Souza, A.; Rivera, E.C.; Maciel Filho, R.; Cavalett, O.; Bonomi, A. Sustainability Assessment Methodologies. In Virtual Biorefinery—An Optimization Strategy for Renewable Carbon Valorization; Springer International Publishing: Basel, Switzerland, 2016; pp. 155–188. [Google Scholar]

- INTRATEC. Location Factor for Brazil. Available online: https://www.intratec.us/indexes-and-pricing-data/location-factor/brazil (accessed on 3 September 2020).

- Programa de Disseminação das Estatísticas do Trabalho (PDET). Base de Dados Online. Available online: http://pdet.mte.gov.br/acesso-online-as-bases-de-dados (accessed on 22 October 2019).

- Van Vliet, O.P.R.; Faaij, A.P.C.; Turkenburg, W.C. Fischer-Tropsch diesel production in a well-to-wheel perspective: A carbon, energy flow and cost analysis. Energy Convers. Manag. 2009, 50, 855–876. [Google Scholar] [CrossRef]

- Tock, L.; Gassner, M.; Maréchal, F. Thermochemical production of liquid fuels from biomass: Thermo-economic modeling, process design and process integration analysis. Biomass Bioenergy 2010, 34, 1838–1854. [Google Scholar] [CrossRef]

- Festel, G.W. Biofuels—Which is the most economic one? Chimia (Aarau) 2007, 61, 744–749. [Google Scholar] [CrossRef]

- Mustapha, W.F.; Bolkesjø, T.F.; Martinsen, T.; Trømborg, E. Techno-economic comparison of promising biofuel conversion pathways in a Nordic context—Effects of feedstock costs and technology learning. Energy Convers. Manag. 2017, 149, 368–380. [Google Scholar] [CrossRef]

| Parameter | Unit | Conventional Sugarcane (CS) | Energy-Cane (EC) | ||

|---|---|---|---|---|---|

| Value | Reference | Value | Reference | ||

| Fiber content 1 | % | 12.7 2 | [36] | 21.3 3 | [36] |

| Yield | t/ha/year | 80 4 | [45] | 140 5 | Average yield, based on [38,52,53,54] |

| Number of cuts per cycle | 5 | [55] | 10 | [36] | |

| Straw recovery | % | 50 | Assumption | 100 | Assumption |

| Spatial dispersion factor 6 | % | 6 | [45] | 6 | Based on [45] 7 |

| Urea-planting | kg N/ha/year | 30 | [55] | 30 | Based on [55] 7 |

| Single superphosphate-planting | kg P2O5/ha/year | 180 | [55] | 180 | Based on [55] 7 |

| Potassium chloride-planting | kg K2O/ha/year | 120 | [55] | 200 | Based on [56] 8 |

| Urea-ratoon | kg N/ha/year | 120 | [55] | 180 | Based on [56] 9 |

| Single superphosphate-ratoon | kg P2O5/ha/year | 0 | [55] | 40 | Based on [56] 10 |

| Potassium chloride-ratoon | kg K2O/ha/year | 150 | [55] | 220 | Based on [56] 11 |

| Vinasse application | m3/ha/year | 220 | [57] | 330 | Assumption 12 |

| Parameter | Unit | Value | Reference |

|---|---|---|---|

| Yield (including bark) | m3/ha | 323 | [58] |

| Production cycle | years | 7 | [58] |

| Effective harvest days per year | - | 350 | Assumed |

| Basic density | t/m3 | 0.39 | [58] |

| Bark content | % v/v | 14.4 | [58] |

| Spatial dispersion factor | % | 5.3 | Based on industry information |

| Single superphosphate–planting | kg P2O5/ha | 330 | [59] |

| NPK 04-30-10–planting | kg/ha | 420 | [59] |

| Potassium chloride-maintenance | kg K₂O/ha | 0.28 | [59] |

| Ammonium sulfate–maintenance | kg N/ha | 0.25 | [59] |

| Technical Results | Unit | 1G-CS | 1G2G-CS | 1G2G-EC | |

|---|---|---|---|---|---|

| Biomass delivered to industrial plant (per year) | CS (stalks) | Million t (wet basis) | 4 | 4 | - |

| CS straw1 (bale + vegetal impurities) | Million t (dry basis) | 0.28 | 0.28 | - | |

| EC | Million t (wet basis) | - | - | 4 | |

| Eucalyptus | Million t (dry basis) | - | 0.80 | 0.86 | |

| Total area for biomass production | ha | 52,632 | 97,107 | 76,985 | |

| Diesel consumption 2 | m3/year | 15,495 | 25,816 | 23,981 | |

| Biomass cost 3 | CS (stalks) | US$/wet t | 23.32 | 19.74 | - |

| CS straw | US$/dry t | 26.70 | 21.46 | - | |

| EC | US$/wet t | - | - | 14.44 | |

| Eucalyptus | US$/m3 | - | 26.17 | 26.18 | |

| Biomass production system greenhouse gas (GHG) emissions | CS | g CO2 eq/wet kg | 40.3 | 28.6 | - |

| EC | g CO2 eq/wet kg | - | - | 21.6 | |

| Eucalyptus | g CO2 eq/wet kg | - | 7.7 | 7.7 | |

| Product output (per year) | Hydrous ethanol | million L | 360 | 360 | 234 |

| Green diesel sold to market 4 | million L | - | 71 | 46 | |

| Renewable Jet Fuel | million L | - | 116 | 84 | |

| Green Gasoline | million L | - | 145 | 104 | |

| Electricity | GWh | 751 | 286 | 1194 | |

| Global efficiency 5 | % (LHV basis) | 45.4 | 57.7 | 50.9 | |

| FT reactor recycle ratio | (mole of recycle per mole of fresh feed) | - | 3.5 | 0.6 | |

| Overall FT reactor CO conversion (season) 6 | % | - | 96.1 | 63.4 | |

| 1G facility steam demand | t/h | 260.2 | 260.2 | 399.2 | |

| Parameter | 1G-CC | 1G2G-CC | 1G2G-EC |

|---|---|---|---|

| CAPEX (million US$) | 408.77 | 1096.58 | 1177.57 |

| Fixed capital investment 1G (million US$) | 371.60 | 132.45 | 134.28 |

| Fixed capital investment 2G (million US$) | - | 864.45 | 936.24 |

| Working capital (million US$) | 37.16 | 99.69 | 107.05 |

| OPEX (million US$ per year) | 118.03 | 231.26 | 207.28 |

| Feedstock | 98.18 | 136.59 | 115.76 |

| Other inputs | 3.33 | 51.66 | 45.67 |

| Employee costs | 2.77 | 6.13 | 6.24 |

| Maintenance | 11.15 | 29.51 | 32.12 |

| Insurance and others | 2.60 | 6.98 | 7.49 |

| Revenue (million US$ per year) | 221.90 | 387.65 | 323.95 |

| Electricity | 45.46 | 17.33 | 72.30 |

| Hydrous ethanol | 171.41 | 171.41 | 111.68 |

| Gasoline | - | 74.27 | 53.55 |

| Jet fuel | - | 69.61 | 50.19 |

| Diesel | - | 40.01 | 25.81 |

| Carbon credits | 5.03 | 15.02 | 10.40 |

| Minimum selling price | |||

| Electricity (US$/MWh) | 51.62 | 67.61 | 79.46 |

| Hydrous ethanol (US$/L) | 0.41 | 0.53 | 0.63 |

| Gasoline (US$/L) | - | 0.57 | 0.67 |

| Jet fuel (US$/L) | - | 0.67 | 0.79 |

| Diesel (US$/L) | - | 0.63 | 0.74 |

| Net present value (NPV) (million US$) | 131.87 | −179.55 | −404.35 |

| NPV/CAPEX | 0.32 | −0.16 | −0.34 |

| IRR (% per year) | 16.4 | 9.4 | 6.2 |

| Return of investment (years) | 4.9 | 8.0 | 10.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bressanin, J.M.; Klein, B.C.; Chagas, M.F.; Watanabe, M.D.B.; Sampaio, I.L.d.M.; Bonomi, A.; Morais, E.R.d.; Cavalett, O. Techno-Economic and Environmental Assessment of Biomass Gasification and Fischer–Tropsch Synthesis Integrated to Sugarcane Biorefineries. Energies 2020, 13, 4576. https://doi.org/10.3390/en13174576

Bressanin JM, Klein BC, Chagas MF, Watanabe MDB, Sampaio ILdM, Bonomi A, Morais ERd, Cavalett O. Techno-Economic and Environmental Assessment of Biomass Gasification and Fischer–Tropsch Synthesis Integrated to Sugarcane Biorefineries. Energies. 2020; 13(17):4576. https://doi.org/10.3390/en13174576

Chicago/Turabian StyleBressanin, Jéssica Marcon, Bruno Colling Klein, Mateus Ferreira Chagas, Marcos Djun Barbosa Watanabe, Isabelle Lobo de Mesquita Sampaio, Antonio Bonomi, Edvaldo Rodrigo de Morais, and Otávio Cavalett. 2020. "Techno-Economic and Environmental Assessment of Biomass Gasification and Fischer–Tropsch Synthesis Integrated to Sugarcane Biorefineries" Energies 13, no. 17: 4576. https://doi.org/10.3390/en13174576

APA StyleBressanin, J. M., Klein, B. C., Chagas, M. F., Watanabe, M. D. B., Sampaio, I. L. d. M., Bonomi, A., Morais, E. R. d., & Cavalett, O. (2020). Techno-Economic and Environmental Assessment of Biomass Gasification and Fischer–Tropsch Synthesis Integrated to Sugarcane Biorefineries. Energies, 13(17), 4576. https://doi.org/10.3390/en13174576