Hydrochars as Emerging Biofuels: Recent Advances and Application of Artificial Neural Networks for the Prediction of Heating Values

Abstract

1. Introduction

2. Data Acquisition, Methods, and Review of Recent Literature

2.1. Data Acquisition and Methods

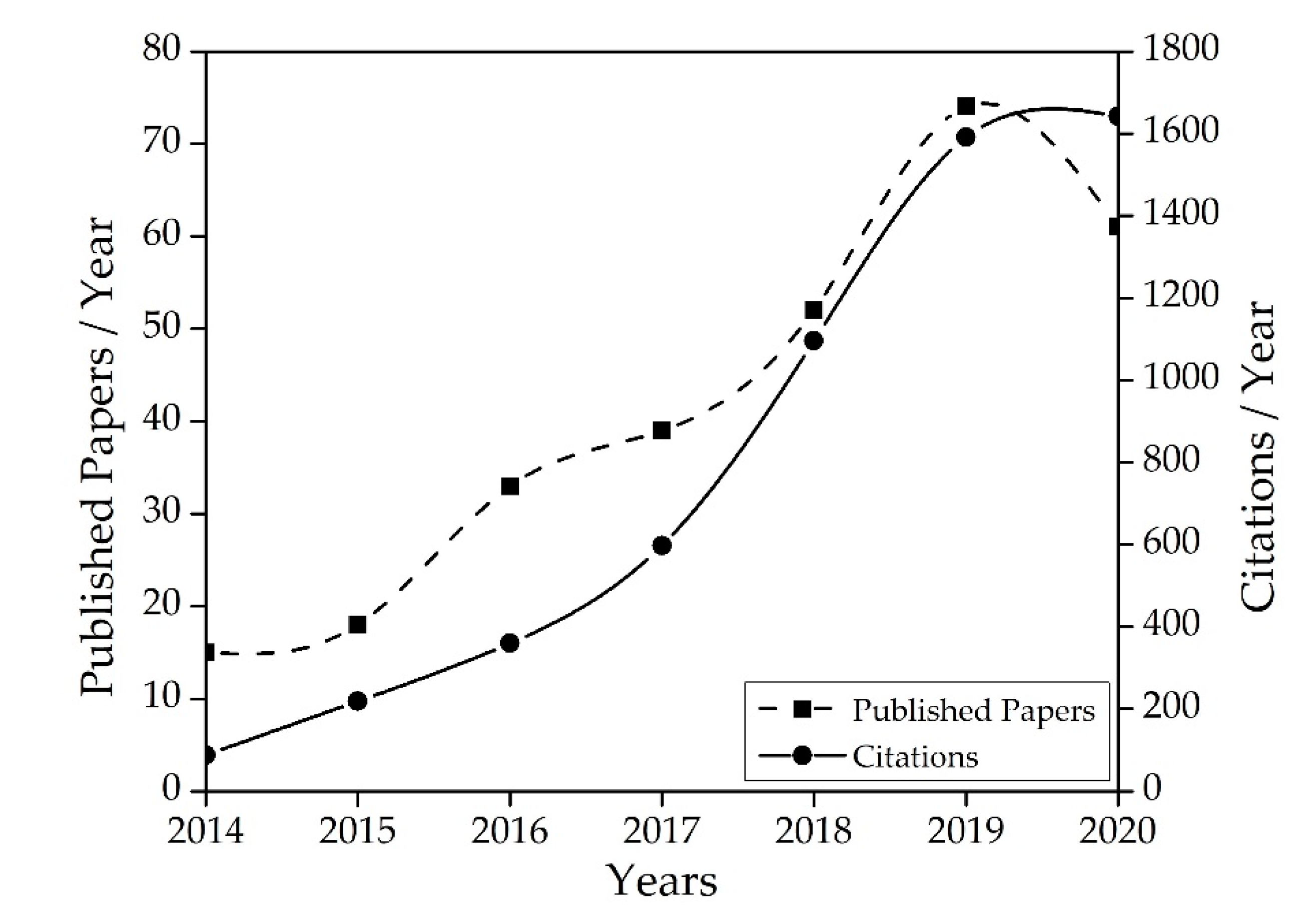

2.2. Basic Characteristics of the Reviewed Publications (2014–2020)

2.3. CiteSpace Recent Scientometric Analysis (2018–2020)

2.3.1. Valorization of Sewage Sludge for the Production of Fuel Hydrochar

2.3.2. Valorization of Food Waste for the Production of Fuel Hydrochar

3. Results and Discussion

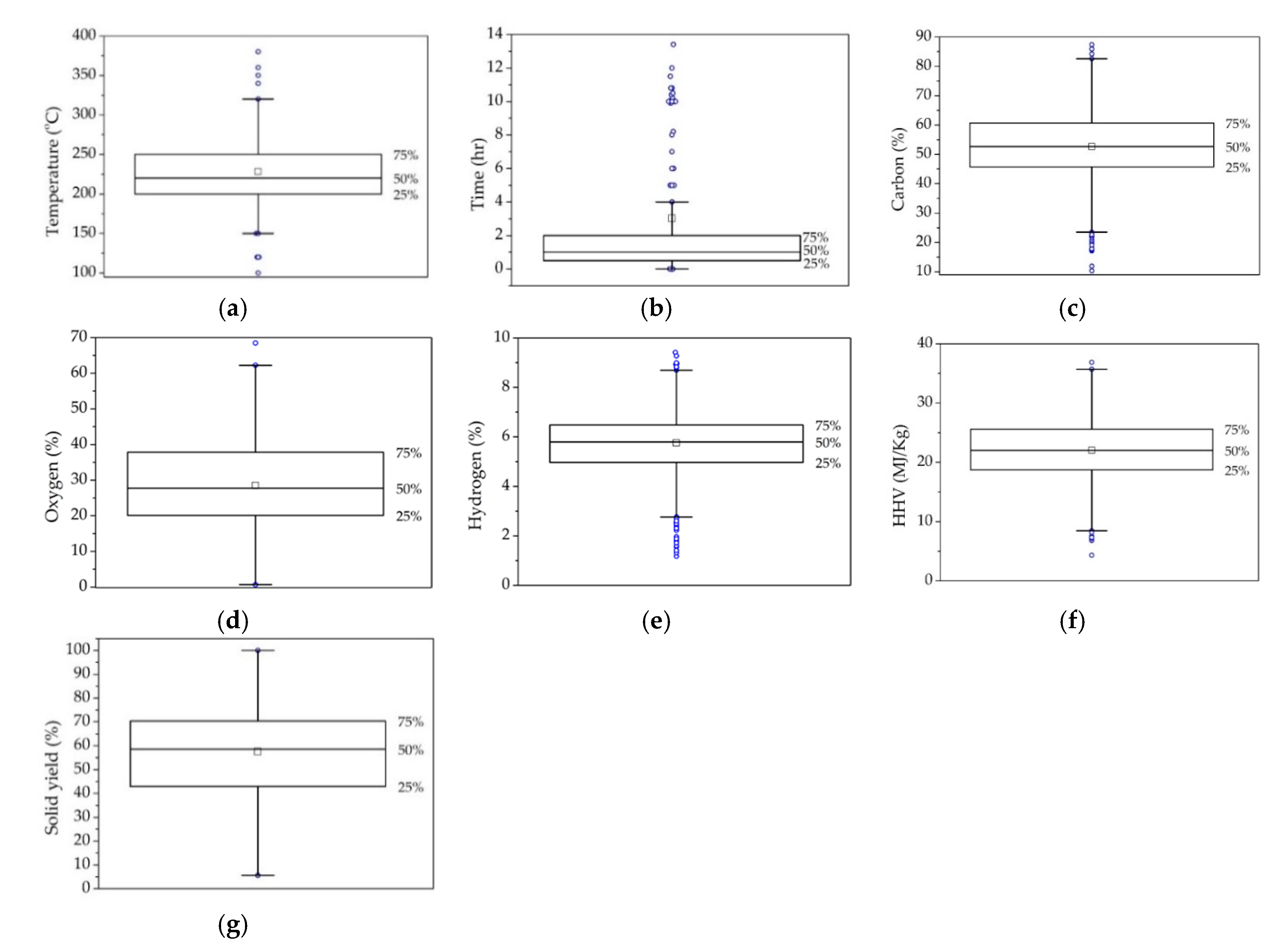

3.1. Statistical Analysis of Hydrochar Properties

3.2. Correlation Patterns between Hydrochar Properties

3.3. Artificial Neural Network Modeling

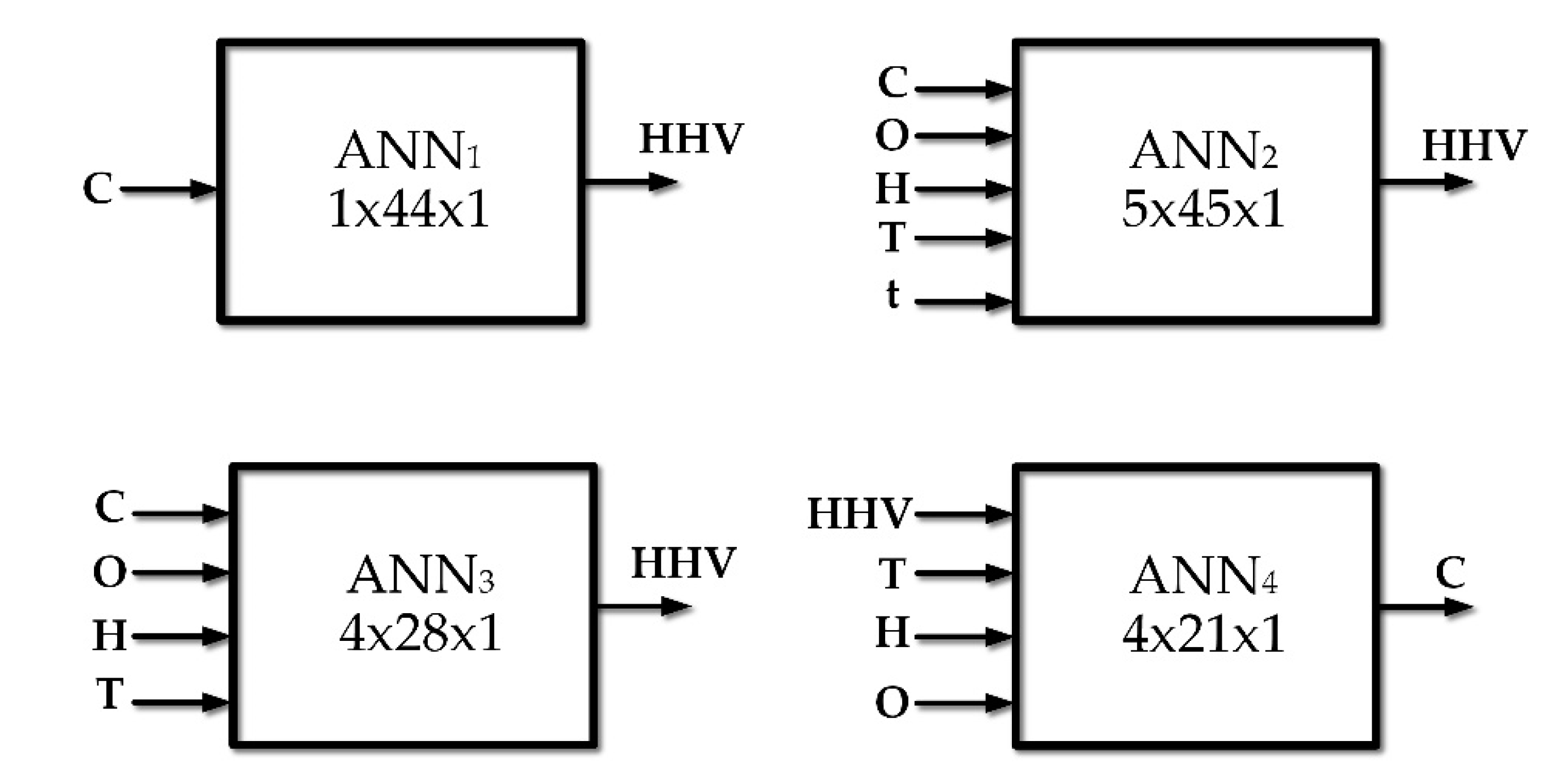

3.4. Data Preprocessing

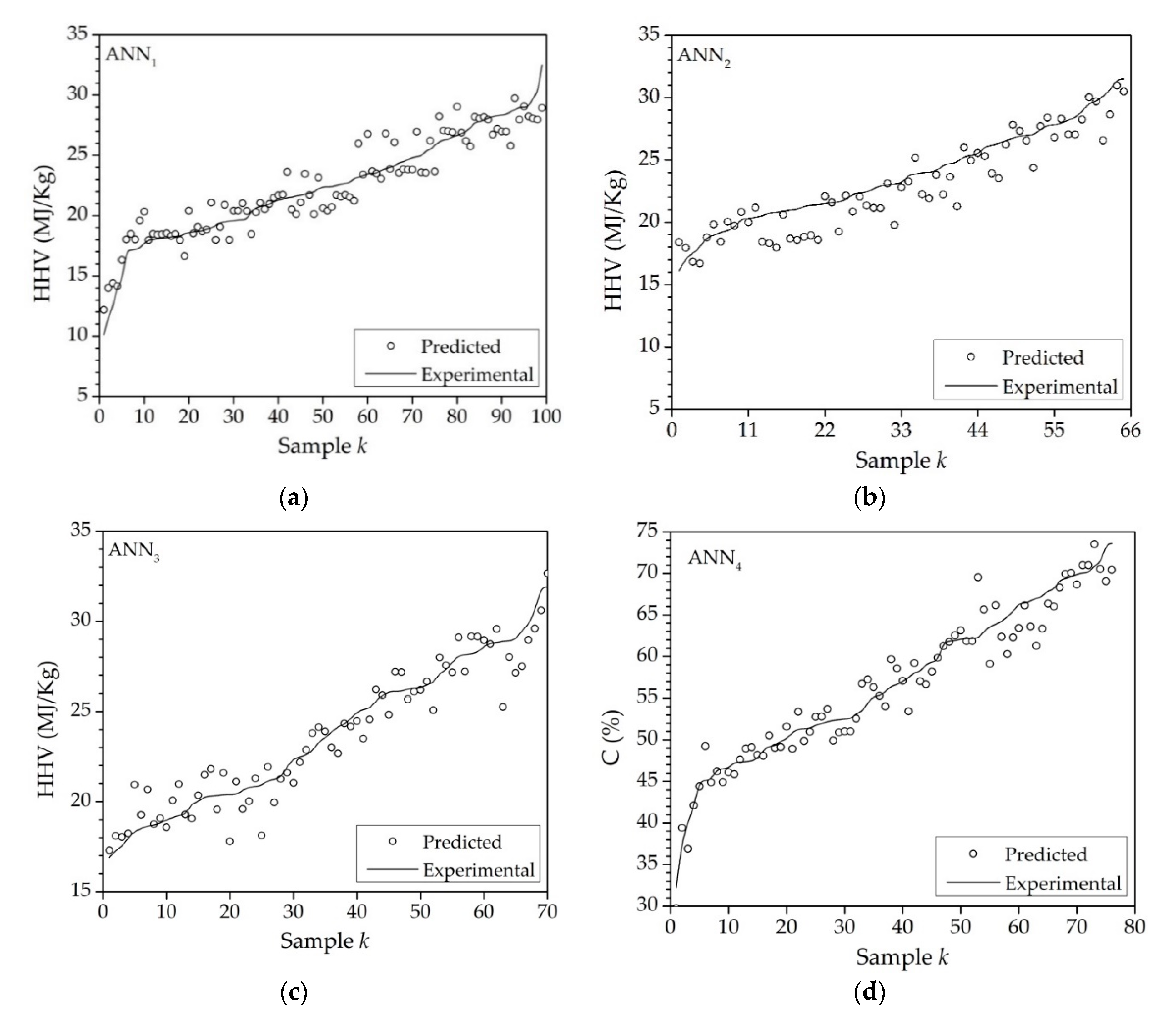

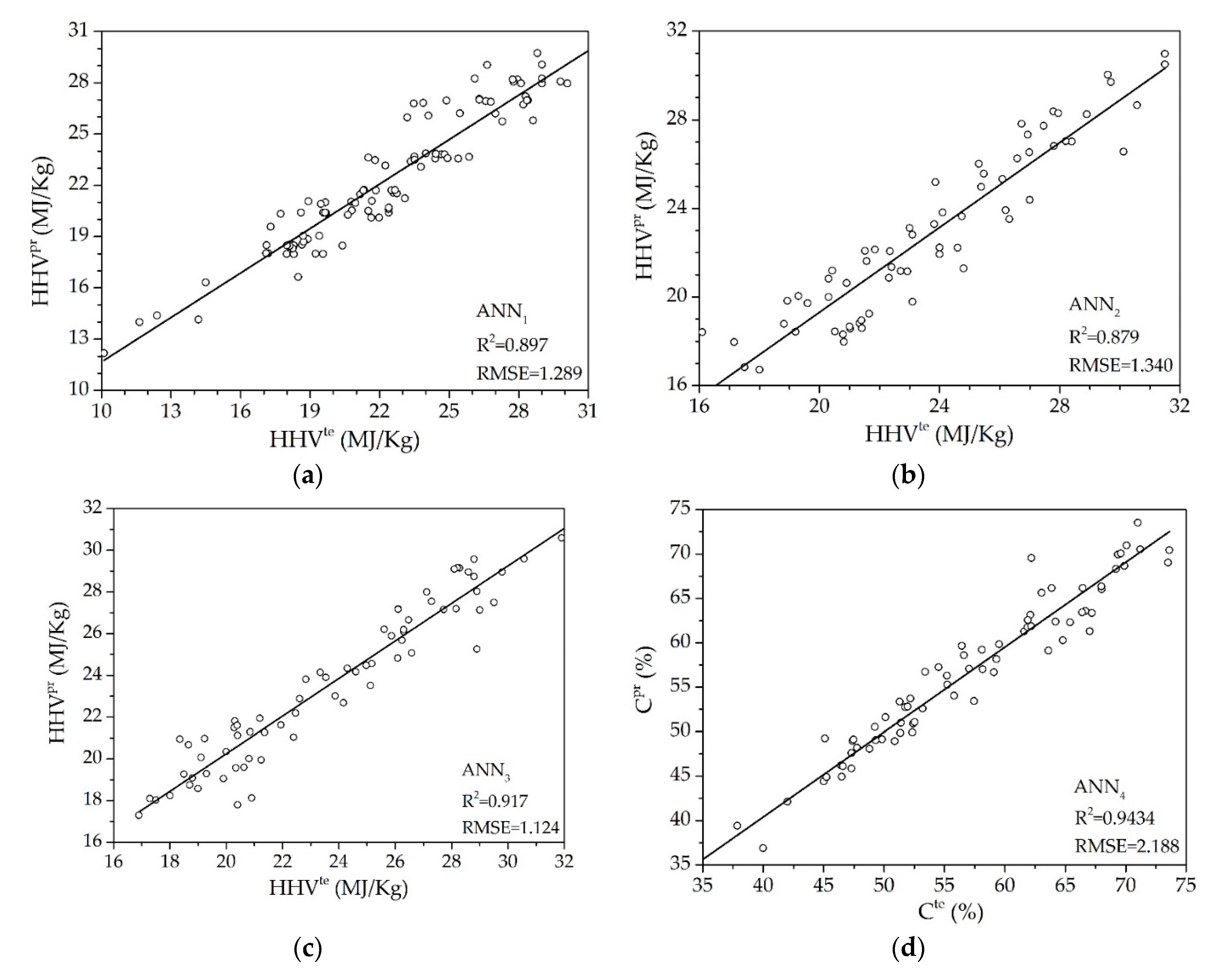

3.5. Performance of ANN Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jiménez-Carmona, M.M.; Luque de Castro, M.D. Isolation of eucalyptus essential oil for GC-MS analysis by extraction with subcritical water. Chromatographia 1999, 50, 578–582. [Google Scholar] [CrossRef]

- Jiménez-Carmona, M.M.; Ubera, J.L.; Luque De Castro, M.D. Comparison of continuous subcritical water extraction and hydrodistillation of marjoram essential oil. J. Chromatogr. A 1999, 855, 625–632. [Google Scholar] [CrossRef]

- Rovio, S.; Hartonen, K.; Holm, Y.; Hiltunen, R.; Riekkola, M.L. Extraction of clove using pressurized hot water. Flavour Fragr. J. 1999, 14, 399–404. [Google Scholar] [CrossRef]

- Yang, Y.; Jones, A.D.; Eaton, C.D. Retention behavior of phenols, anilines, and alkylbenzenes in liquid chromatographic separations using subcritical water as the mobile phase. Anal. Chem. 1999, 71, 3808–3813. [Google Scholar] [CrossRef]

- Yang, Y.; Li, B. Subcritical water extraction coupled to high-performance liquid chromatography. Anal. Chem. 1999, 71, 1491–1495. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Lagadec, A.J.M.; Kalderis, D.; Lilke, A.V.; Miller, D.J. Pilot-scale destruction of TNT, RDX, and HMX on contaminated soils using subcritical water. Environ. Sci. Technol. 2000, 34, 3224–3228. [Google Scholar] [CrossRef]

- Kubatova, A.; Lagadec, A.J.M.; Hawthorne, S.B. Dechlorination of lindane, dieldrin, tetrachloroethane, trichloroethene and PVC in Subcritical Water. Environ. Sci. Technol. 2002, 36, 1337–1343. [Google Scholar] [CrossRef]

- Daskalaki, V.M.; Timotheatou, E.S.; Katsaounis, A.; Kalderis, D. Degradation of Reactive Red 120 using hydrogen peroxide in subcritical water. Desalination 2011, 274, 200–205. [Google Scholar] [CrossRef]

- Kirmizakis, P.; Tsamoutsoglou, C.; Kayan, B.; Kalderis, D. Subcritical water treatment of landfill leachate: Application of response surface methodology. J. Environ. Manag. 2014, 146, 9–15. [Google Scholar] [CrossRef]

- Skubiszewska-Zi, J.; Charmas, B.; Leboda, R.; Staszczuk, P.; Kowalczyk, P.; Oleszczuk, P. Effect of hydrothermal modification on the porous structure and thermal properties of carbon-silica adsorbents (carbosils). Mater. Chem. Phys. 2003, 78, 486–494. [Google Scholar] [CrossRef]

- Yu, S.H.; Cui, X.; Li, L.; Li, K.; Yu, B.; Antonietti, M.; Cölfen, H. From starch to metal/carbon hybrid nanostructures: Hydrothermal metal-catalyzed carbonization. Adv. Mater. 2004, 16, 1636–1640. [Google Scholar] [CrossRef]

- Sarkar, N.B.; Sarkar, P.; Choudhury, A. Effect of hydrothermal treatment of coal on the oxidation susceptibility and electrical resistivity of HTT coke. Fuel Process. Technol. 2005, 86, 487–497. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuel Bioprod. Biorefin. 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.-M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Heidari, M.; Dutta, A.; Acharya, B.; Mahmud, S. A review of the current knowledge and challenges of hydrothermal carbonization for biomass conversion. J. Energy Inst. 2019, 92, 1779–1799. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- McGaughy, K.; Toufiq Reza, M. Hydrothermal carbonization of food waste: Simplified process simulation model based on experimental results. Biomass Convers. Biorefin. 2018, 8, 283–292. [Google Scholar] [CrossRef]

- Gallifuoco, A. A new approach to kinetic modeling of biomass hydrothermal carbonization. ACS Sustain. Chem. Eng. 2019, 7, 13073–13080. [Google Scholar] [CrossRef]

- Conag, A.T.; Villahermosa, J.E.R.; Cabatingan, L.K.; Go, A.W. Predictive HHV model for raw and torrefied sugarcane residues. Waste Biomass Valorization 2019, 10, 1929–1943. [Google Scholar] [CrossRef]

- Vallejo, F.; Díaz-Robles, L.A.; Vega, R.; Cubillos, F. A novel approach for prediction of mass yield and higher calorific value of hydrothermal carbonization by a robust multilinear model and regression trees. J. Energy Inst. 2020, 93, 1755–1762. [Google Scholar] [CrossRef]

- Akdeniz, F.; Biçil, M.; Karadede, Y.; Özbek, F.E.; Özdemir, G. Application of real valued genetic algorithm on prediction of higher heating values of various lignocellulosic materials using lignin and extractive contents. Energy 2018, 160, 1047–1054. [Google Scholar] [CrossRef]

- Kapetanakis, T.N.; Vardiambasis, I.O.; Ioannidou, M.P.; Maras, A. Neural network modeling for the solution of the inverse loop antenna radiation problem. IEEE Trans. Antennas Propag. 2018, 66, 6283–6290. [Google Scholar] [CrossRef]

- Sergaki, E.; Spiliotis, G.; Vardiambasis, I.O.; Kapetanakis, T.; Krasoudakis, A.; Giakos, G.C.; Zervakis, M.; Polydorou, A. Application of ANN and ANFIS for Detection of Brain Tumors in MRIs by Using DWT and GLCM Texture Analysis. In Proceedings of the IST 2018—International Conference on Imaging Systems and Techniques, Krakow, Poland, 16–18 October 2018; pp. 1–6. [Google Scholar]

- Bhange, V.P.; Bhivgade, U.V.; Vaidya, A.N. Artificial Neural Network Modeling in Pretreatment of Garden Biomass for Lignocellulose Degradation. Waste Biomass Valorization 2019, 10, 1571–1583. [Google Scholar] [CrossRef]

- Baruah, D.; Baruah, D.C.; Hazarika, M.K. Artificial neural network based modeling of biomass gasification in fixed bed downdraft gasifiers. Biomass Bioenergy 2017, 98, 264–271. [Google Scholar] [CrossRef]

- Nasrudin, N.A.; Jewaratnam, J.; Hossain, M.A.; Ganeson, P.B. Performance comparison of feedforward neural network training algorithms in modelling microwave pyrolysis of oil palm fibre for hydrogen and biochar production. Asia-Pac. J. Chem. Eng. 2020, 15. [Google Scholar] [CrossRef]

- Chen, C.; Liu, G.; An, Q.; Lin, L.; Shang, Y.; Wan, C. From wasted sludge to valuable biochar by low temperature hydrothermal carbonization treatment: Insight into the surface characteristics. J. Clean. Prod. 2020, 263, 121600. [Google Scholar] [CrossRef]

- Zheng, X.; Jiang, Z.; Ying, Z.; Song, J.; Chen, W.; Wang, B. Role of feedstock properties and hydrothermal carbonization conditions on fuel properties of sewage sludge-derived hydrochar using multiple linear regression technique. Fuel 2020, 271, 117609. [Google Scholar] [CrossRef]

- Chen, C.; Ibekwe-Sanjuan, F.; Hou, J. The Structure and Dynamics of Co-Citation Clusters: A Multiple-Perspective the Structure and Dynamics of Co-Citation Clusters: A Multiple-Perspective Co-Citation Analysis. J. Am. Soc. Inf. Sci. Technol. 2010, 61, 1386–1409. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Assoc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Fang, Y.; Yin, J.; Wu, B. Climate change and tourism: A scientometric analysis using CiteSpace. J. Sustain. Tour. 2018, 26, 108–126. [Google Scholar] [CrossRef]

- Wu, P.; Wang, Z.; Wang, H.; Bolan, N.S.; Wang, Y.; Chen, W. Visualizing the emerging trends of biochar research and applications in 2019: A scientometric analysis and review. Biochar 2020, 2, 135–150. [Google Scholar] [CrossRef]

- Teoh, S.K.; Li, L.Y. Feasibility of alternative sewage sludge treatment methods from a lifecycle assessment (LCA) perspective. J. Clean. Prod. 2020, 247, 119495. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Zhao, P.; Shen, Y.; Ge, S.; Yoshikawa, K. Energy recycling from sewage sludge by producing solid biofuel with hydrothermal carbonization. Energy Convers. Manag. 2014, 78, 815–821. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K.Y. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 2014, 130, 120–125. [Google Scholar] [CrossRef]

- Parshetti, G.K.; Liu, Z.; Jain, A.; Srinivasan, M.P.; Balasubramanian, R. Hydrothermal carbonization of sewage sludge for energy production with coal. Fuel 2013, 111, 201–210. [Google Scholar] [CrossRef]

- Gai, C.; Chen, M.; Liu, T.; Peng, N.; Liu, Z. Gasification characteristics of hydrochar and pyrochar derived from sewage sludge. Energy 2016, 113, 957–965. [Google Scholar] [CrossRef]

- Danso-Boateng, E.; Shama, G.; Wheatley, A.D.; Martin, S.J.; Holdich, R.G. Hydrothermal carbonisation of sewage sludge: Effect of process conditions on product characteristics and methane production. Bioresour. Technol. 2015, 177, 318–327. [Google Scholar] [CrossRef]

- Silva, R.D.V.K.; Lei, Z.; Shimizu, K.; Zhang, Z. Hydrothermal treatment of sewage sludge to produce solid biofuel: Focus on fuel characteristics. Bioresour. Technol. Rep. 2020, 11, 100453. [Google Scholar] [CrossRef]

- Mäkelä, M.; Fullana, A.; Yoshikawa, K. Ash behavior during hydrothermal treatment for solid fuel applications. Part 1: Overview of different feedstock. Energy Convers. Manag. 2016, 121, 402–408. [Google Scholar] [CrossRef]

- Mäkelä, M.; Yoshikawa, K. Ash behavior during hydrothermal treatment for solid fuel applications. Part 2: Effects of treatment conditions on industrial waste biomass. Energy Convers. Manag. 2016, 121, 409–414. [Google Scholar] [CrossRef]

- Smith, A.M.; Singh, S.; Ross, A.B. Fate of inorganic material during hydrothermal carbonisation of biomass: Influence of feedstock on combustion behaviour of hydrochar. Fuel 2016, 169, 135–145. [Google Scholar] [CrossRef]

- Parmar, K.R.; Ross, A.B. Integration of hydrothermal carbonisation with anaerobic digestion; Opportunities for valorisation of digestate. Energies 2019, 12, 1586. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Li, A. Hydrothermal carbonization for energy-efficient processing of sewage sludge: A review. Renew. Sustain. Energy Rev. 2019, 108, 423–440. [Google Scholar] [CrossRef]

- Tasca, A.L.; Puccini, M.; Gori, R.; Corsi, I.; Galletti, A.M.R.; Vitolo, S. Hydrothermal carbonization of sewage sludge: A critical analysis of process severity, hydrochar properties and environmental implications. Waste Manag. 2019, 93, 1–13. [Google Scholar] [CrossRef]

- Niinipuu, M.; Latham, K.G.; Boily, J.F.; Bergknut, M.; Jansson, S. The impact of hydrothermal carbonization on the surface functionalities of wet waste materials for water treatment applications. Environ. Sci. Pollut. Res. 2020, 27, 24369–24379. [Google Scholar] [CrossRef]

- Ma, J.; Chen, M.; Yang, T.; Liu, Z.; Jiao, W.; Li, D.; Gai, C. Gasification performance of the hydrochar derived from co-hydrothermal carbonization of sewage sludge and sawdust. Energy 2019, 173, 732–739. [Google Scholar] [CrossRef]

- Ma, J.; Luo, H.; Li, Y.; Liu, Z.; Li, D.; Gai, C.; Jiao, W. Pyrolysis kinetics and thermodynamic parameters of the hydrochars derived from co-hydrothermal carbonization of sawdust and sewage sludge using thermogravimetric analysis. Bioresour. Technol. 2019, 282, 133–141. [Google Scholar] [CrossRef]

- Song, Y.; Zhan, H.; Zhuang, X.; Yin, X.; Wu, C. Synergistic characteristics and capabilities of co-hydrothermal carbonization of sewage sludge/lignite mixtures. Energy Fuels 2019, 33, 8735–8745. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Zhang, X.; Yang, F.; Li, Y.; Yang, X.; Dong, S. Hydrothermal co-carbonization of sewage sludge and high concentration phenolic wastewater for production of solid biofuel with increased calorific value. J. Clean. Prod. 2020, 255, 120317. [Google Scholar] [CrossRef]

- Lee, J.; Sohn, D.; Lee, K.; Park, K.Y. Solid fuel production through hydrothermal carbonization of sewage sludge and microalgae Chlorella sp. from wastewater treatment plant. Chemosphere 2019, 230, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.X.; Song, H.; Zhang, S.; Tong, S.Q.; He, Z.X.; Wang, Q.; Li, B.; Hu, X. Co-hydrothermal carbonization of digested sewage sludge and cow dung biogas residue: Investigation of the reaction characteristics. Energy 2019, 187, 115972. [Google Scholar] [CrossRef]

- Zheng, C.; Ma, X.; Yao, Z.; Chen, X. The properties and combustion behaviors of hydrochars derived from co-hydrothermal carbonization of sewage sludge and food waste. Bioresour. Technol. 2019, 285, 121347. [Google Scholar] [CrossRef]

- He, C.; Zhang, Z.; Ge, C.; Liu, W.; Tang, Y.; Zhuang, X.; Qiu, R. Synergistic effect of hydrothermal co-carbonization of sewage sludge with fruit and agricultural wastes on hydrochar fuel quality and combustion behavior. Waste Manag. 2019, 100, 171–181. [Google Scholar] [CrossRef]

- Heilmann, S.M.; Molde, J.S.; Timler, J.G.; Wood, B.M.; Mikula, A.L.; Vozhdayev, G.V.; Colosky, E.C.; Spokas, K.A.; Valentas, K.J. Phosphorus reclamation through hydrothermal carbonization of animal manures. Environ. Sci. Technol. 2014, 48, 10323–10329. [Google Scholar] [CrossRef]

- Ovsyannikova, E.; Arauzo, P.J.; Becker, G.; Kruse, A. Experimental and thermodynamic studies of phosphate behavior during the hydrothermal carbonization of sewage sludge. Sci. Total Environ. 2019, 692, 147–156. [Google Scholar] [CrossRef]

- Becker, G.C.; Wüst, D.; Köhler, H.; Lautenbach, A.; Kruse, A. Novel approach of phosphate-reclamation as struvite from sewage sludge by utilising hydrothermal carbonization. J. Environ. Manag. 2019, 238, 119–125. [Google Scholar] [CrossRef]

- Cui, X.; Lu, M.; Khan, M.B.; Lai, C.; Yang, X.; He, Z.; Chen, G.; Yan, B. Hydrothermal carbonization of different wetland biomass wastes: Phosphorus reclamation and hydrochar production. Waste Manag. 2020, 102, 106–113. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.I.; Grasham, O.; Ross, A.B.; Dupont, V.; Camargo-Valero, M.A. Hydrothermal carbonization of sewage digestate at wastewater treatment works: Influence of solid loading on characteristics of hydrochar, process water and plant energetics. Renew. Energy 2020, 157, 959–973. [Google Scholar] [CrossRef]

- Marin-Batista, J.D.; Mohedano, A.F.; Rodríguez, J.J.; de la Rubia, M.A. Energy and phosphorous recovery through hydrothermal carbonization of digested sewage sludge. Waste Manag. 2020, 105, 566–574. [Google Scholar] [CrossRef]

- Song, E.; Park, S.; Kim, H. Upgrading hydrothermal carbonization (HTC) hydrochar from sewage sludge. Energies 2019, 12, 2383. [Google Scholar] [CrossRef]

- Xu, Z.X.; Song, H.; Li, P.J.; He, Z.X.; Wang, Q.; Wang, K.; Duan, P.G. Hydrothermal carbonization of sewage sludge: Effect of aqueous phase recycling. Chem. Eng. J. 2020, 387, 123410. [Google Scholar] [CrossRef]

- Wang, R.; Wang, C.; Zhao, Z.; Jia, J.; Jin, Q. Energy recovery from high-ash municipal sewage sludge by hydrothermal carbonization: Fuel characteristics of biosolid products. Energy 2019, 186, 115848. [Google Scholar] [CrossRef]

- Hansen, L.J.; Fendt, S.; Spliethoff, H. Impact of hydrothermal carbonization on combustion properties of residual biomass. Biomass Convers. Biorefin. 2020. [Google Scholar] [CrossRef]

- Xu, Z.X.; Song, H.; Li, P.J.; Zhu, X.; Zhang, S.; Wang, Q.; Duan, P.G.; Hu, X. A new method for removal of nitrogen in sewage sludge-derived hydrochar with hydrotalcite as the catalyst. J. Hazard. Mater. 2020, 398, 122833. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, X.; Peng, X.; Yu, Z. Hydrothermal carbonization of typical components of municipal solid waste for deriving hydrochars and their combustion behavior. Bioresour. Technol. 2017, 243, 539–547. [Google Scholar] [CrossRef]

- Gallifuoco, A.; Taglieri, L.; Scimia, F.; Papa, A.A.; Di Giacomo, G. Hydrothermal carbonization of Biomass: New experimental procedures for improving the industrial Processes. Bioresour. Technol. 2017, 244, 160–165. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Li, H.; Zhu, Y.; Li, S.; Peng, C.; Wang, B.; Wang, Z.; Xi, Y.; Wang, S.; et al. Co-hydrothermal carbonization of food waste-woody biomass blend towards biofuel pellets production. Bioresour. Technol. 2018, 267, 371–377. [Google Scholar] [CrossRef]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of food waste via hydrothermal carbonisation and techno-economic feasibility assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Zhao, K.; Li, Y.; Zhou, Y.; Guo, W.; Jiang, H.; Xu, Q. Characterization of hydrothermal carbonization products (hydrochars and spent liquor) and their biomethane production performance. Bioresour. Technol. 2018, 267, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Saqib, N.U.; Baroutian, S.; Sarmah, A.K. Physicochemical, structural and combustion characterization of food waste hydrochar obtained by hydrothermal carbonization. Bioresour. Technol. 2018, 266, 357–363. [Google Scholar] [CrossRef] [PubMed]

- Tradler, S.B.; Mayr, S.; Himmelsbach, M.; Priewasser, R.; Baumgartner, W.; Stadler, A.T. Hydrothermal carbonization as an all-inclusive process for food-waste conversion. Bioresour. Technol. Rep. 2018, 2, 77–83. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Xiao, K.; Jin, M.; Xiao, H.; Yao, H. Combustion and Pyrolysis Characteristics of Hydrochar Prepared by Hydrothermal Carbonization of Typical Food Waste: Influence of Carbohydrates, Proteins, and Lipids. Energy Fuels 2020, 34, 430–439. [Google Scholar] [CrossRef]

- Akarsu, K.; Duman, G.; Yilmazer, A.; Keskin, T.; Azbar, N.; Yanik, J. Sustainable valorization of food wastes into solid fuel by hydrothermal carbonization. Bioresour. Technol. 2019, 292, 121959. [Google Scholar] [CrossRef]

- Atiqah Nasir, N.; Davies, G.; McGregor, J. Tailoring product characteristics in the carbonisation of brewers’ spent grain through solvent selection. Food Bioprod. Process. 2020, 120, 41–47. [Google Scholar] [CrossRef]

- Santos Santana, M.; Pereira Alves, R.; da Silva Borges, W.M.; Francisquini, E.; Guerreiro, M.C. Hydrochar production from defective coffee beans by hydrothermal carbonization. Bioresour. Technol. 2020, 300, 122653. [Google Scholar] [CrossRef]

- Zhang, B.; Heidari, M.; Regmi, B.; Salaudeen, S.; Arku, P.; Thimmannagari, M.; Dutta, A. Hydrothermal carbonization of fruit wastes: A promising technique for generating hydrochar. Energies 2018, 11, 2022. [Google Scholar] [CrossRef]

- Xiao, K.; Liu, H.; Li, Y.; Yi, L.; Zhang, X.; Hu, H.; Yao, H. Correlations between hydrochar properties and chemical constitution of orange peel waste during hydrothermal carbonization. Bioresour. Technol. 2018, 265, 432–436. [Google Scholar] [CrossRef]

- Tamelová, B.; Malaťák, J.; Velebil, J. Hydrothermal carbonization and torrefaction of cabbage waste. Agron. Res. 2019, 17, 862–871. [Google Scholar]

- Ul Saqib, N.; Sarmah, A.K.; Baroutian, S. Effect of temperature on the fuel properties of food waste and coal blend treated under co-hydrothermal carbonization. Waste Manag. 2019, 89, 236–246. [Google Scholar] [CrossRef] [PubMed]

- Mazumder, S.; Saha, P.; Reza, M.T. Co-hydrothermal carbonization of coal waste and food waste: Fuel characteristics. Biomass Convers. Biorefin. 2020. [Google Scholar] [CrossRef]

- Mazumder, S.; Saha, P.; McGaughy, K.; Saba, A.; Reza, M.T. Technoeconomic analysis of co-hydrothermal carbonization of coal waste and food waste. Biomass Convers. Biorefin. 2020. [Google Scholar] [CrossRef]

- Gupta, D.; Mahajani, S.M.; Garg, A. Effect of hydrothermal carbonization as pretreatment on energy recovery from food and paper wastes. Bioresour. Technol. 2019, 285, 121329. [Google Scholar] [CrossRef] [PubMed]

- Kapetanakis, T.N.; Vardiambasis, I.O.; Lourakis, E.I.; Maras, A. Applying neuro-fuzzy soft computing techniques to the circular loop antenna radiation problem. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 1673–1676. [Google Scholar] [CrossRef]

- Liodakis, G.; Arvanitis, D.; Vardiambasis, I.O. Neural network–based digital receiver for radio communications. WSEAS Trans. Syst. 2004, 3, 3308–3313. [Google Scholar]

| Network Modularity: 0.4122 | |||

|---|---|---|---|

| Cluster | Silhouette | Number of Papers | Most Frequently Reported Common Terms Among the Papers of Each Cluster a |

| 0 (solid fuel hydrochar) | 0.534 | 61 | microwave, synthesis, green waste, fuel properties |

| 1 (sludge-derived hydrochar) | 0.578 | 47 | sustainable biomass fuel, sewage sludge, pelletization technique |

| 2 (water source) | 0.467 | 40 | hydrochar properties, correlations, orange peel waste, chemical constitution |

| 3 (hydrothermal liquid product) | 0.648 | 38 | pyrolysis behaviour, pinewood sawdust, maize straw |

| 4 (food waste) | 0.59 | 37 | comprehensive investigation, water source, food waste, energy potential |

| 5 (gas emission) | 0.639 | 27 | solid biofuel production, effects, biogas generation, co-hydrothermal gasification |

| 6 (physicochemical properties) | 0.841 | 15 | faecal sludge treatment, molasses utilization, alternative solid fuel, gas emissions |

| 7 (corn stalk) | 0.847 | 13 | combustion kinetics, chilean biomass residues, corn stalk |

| Rank | Keyword | Frequency | Centrality |

|---|---|---|---|

| 1 | Hydrothermal carbonization | 134 | 0.01 |

| 2 | Carbonization | 132 | 0.01 |

| 3 | Thermochemistry | 109 | 0.03 |

| 4 | Hydrochar | 85 | 0.05 |

| 5 | Fuel | 74 | 0.07 |

| 6 | Carbon | 63 | 0.03 |

| 7 | Biome | 57 | 0.02 |

| 8 | Combustion | 54 | 0.07 |

| 9 | Temperature | 46 | 0.12 |

| 10 | Calorific value | 37 | 0.01 |

| Biomass | % Appearance in the Related Literature (2014–2020) |

|---|---|

| Sewage sludge | 21.4 |

| Food waste | 15 |

| Corn cob | 12.6 |

| Rice husk | 8.8 |

| Olive mill waste | 7.6 |

| Lower grades of coal | 7.6 |

| Coconut processing residues | 3.8 |

| Miscanthus | 3.8 |

| Banana residues | 3.8 |

| Sugarcane bagasse | <2 |

| Wood sawdust | <2 |

| Paper sludge | <2 |

| Cotton stalk | <2 |

| Eucalyptus leaves | <2 |

| Bamboo residues | <2 |

| Tobacco stalk | <2 |

| Orange peels | <2 |

| Organic fraction of municipal waste | <2 |

| Grape pomace | <2 |

| Poultry litter | <2 |

| Oil palm empty fruit bunch | <2 |

| PCC | Temperature | Time | Carbon | Hydrogen | Oxygen | HHV | Solid Yield |

|---|---|---|---|---|---|---|---|

| Temperature | 1.000 | −0.044 | 0.310 * | −0.158 * | −0.305 * | 0.321 * | −0.299 * |

| Time | −0.044 | 1.000 | 0.132 | 0.123 | −0.030 | 0.129 | 0.021 |

| Carbon | 0.310 * | 0.132 | 1.000 | 0.286 * | −0.284 * | 0.886 * | −0.182 * |

| Hydrogen | −0.158 * | 0.123 | 0.286 * | 1.000 | 0.074 | 0.345 * | −0.107 |

| Oxygen | −0.305 * | −0.030 | −0.284 * | 0.074 | 1.000 | −0.411 * | 0.254 * |

| HHV | 0.321 * | 0.129 | 0.886 * | 0.345 * | −0.411 * | 1.000 | −0.164 * |

| Solid Yield | −0.299 * | 0.021 | −0.182 * | −0.107 | 0.254 * | −0.164 * | 1.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vardiambasis, I.O.; Kapetanakis, T.N.; Nikolopoulos, C.D.; Trang, T.K.; Tsubota, T.; Keyikoglu, R.; Khataee, A.; Kalderis, D. Hydrochars as Emerging Biofuels: Recent Advances and Application of Artificial Neural Networks for the Prediction of Heating Values. Energies 2020, 13, 4572. https://doi.org/10.3390/en13174572

Vardiambasis IO, Kapetanakis TN, Nikolopoulos CD, Trang TK, Tsubota T, Keyikoglu R, Khataee A, Kalderis D. Hydrochars as Emerging Biofuels: Recent Advances and Application of Artificial Neural Networks for the Prediction of Heating Values. Energies. 2020; 13(17):4572. https://doi.org/10.3390/en13174572

Chicago/Turabian StyleVardiambasis, Ioannis O., Theodoros N. Kapetanakis, Christos D. Nikolopoulos, Trinh Kieu Trang, Toshiki Tsubota, Ramazan Keyikoglu, Alireza Khataee, and Dimitrios Kalderis. 2020. "Hydrochars as Emerging Biofuels: Recent Advances and Application of Artificial Neural Networks for the Prediction of Heating Values" Energies 13, no. 17: 4572. https://doi.org/10.3390/en13174572

APA StyleVardiambasis, I. O., Kapetanakis, T. N., Nikolopoulos, C. D., Trang, T. K., Tsubota, T., Keyikoglu, R., Khataee, A., & Kalderis, D. (2020). Hydrochars as Emerging Biofuels: Recent Advances and Application of Artificial Neural Networks for the Prediction of Heating Values. Energies, 13(17), 4572. https://doi.org/10.3390/en13174572