A Generalized Approach to the Steady-State Efficiency Analysis of Torque-Adding Transmissions Used in Renewable Energy Systems

Abstract

1. Introduction

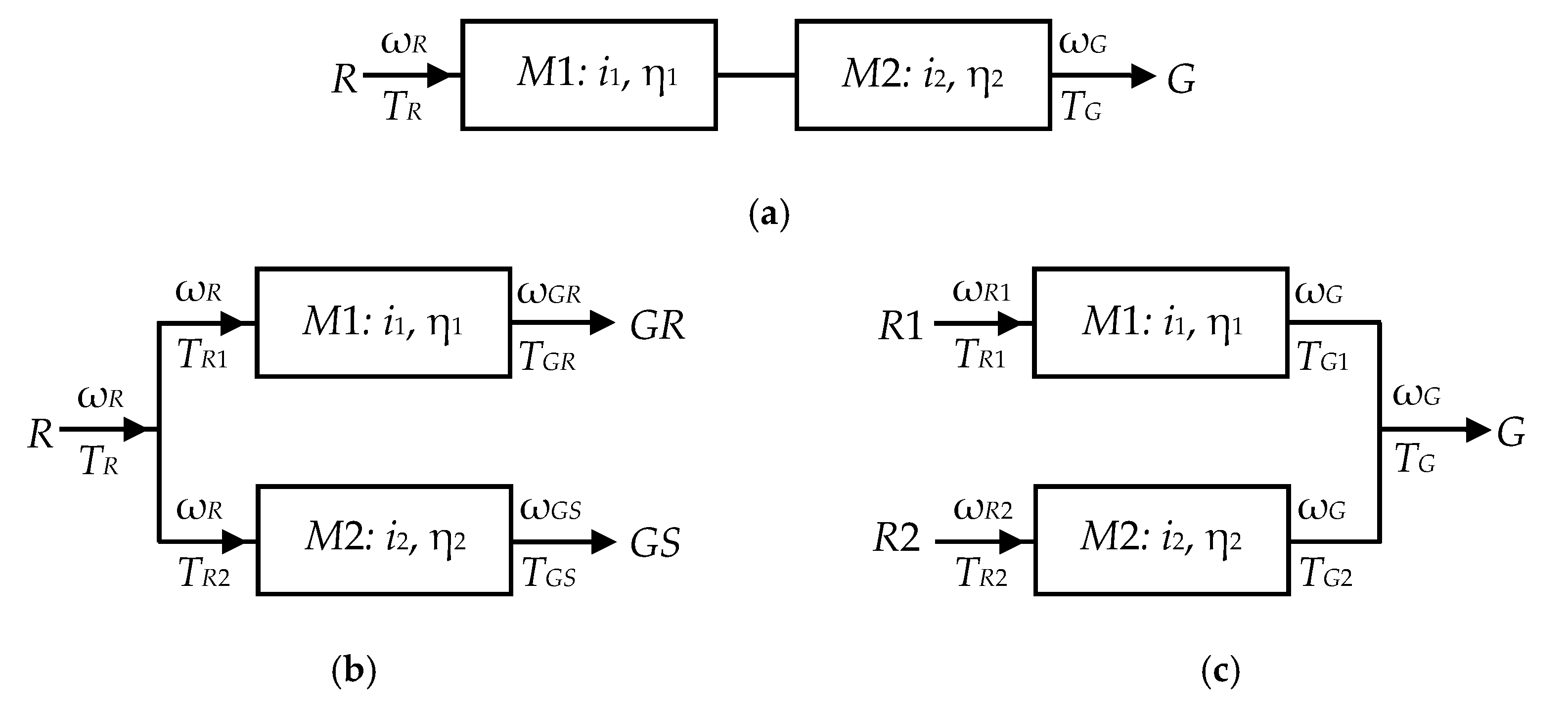

2. Problem Formulation

- Case A (Figure 2a): speed increaser with one input (R) and one output (G) for which,the efficiency is:

- Case C (Figure 2c): speed increaser with two inputs (R1 and R2) and one output (G).from where the efficiency of the transmission is calculated as:where kt is the input torque ratio:

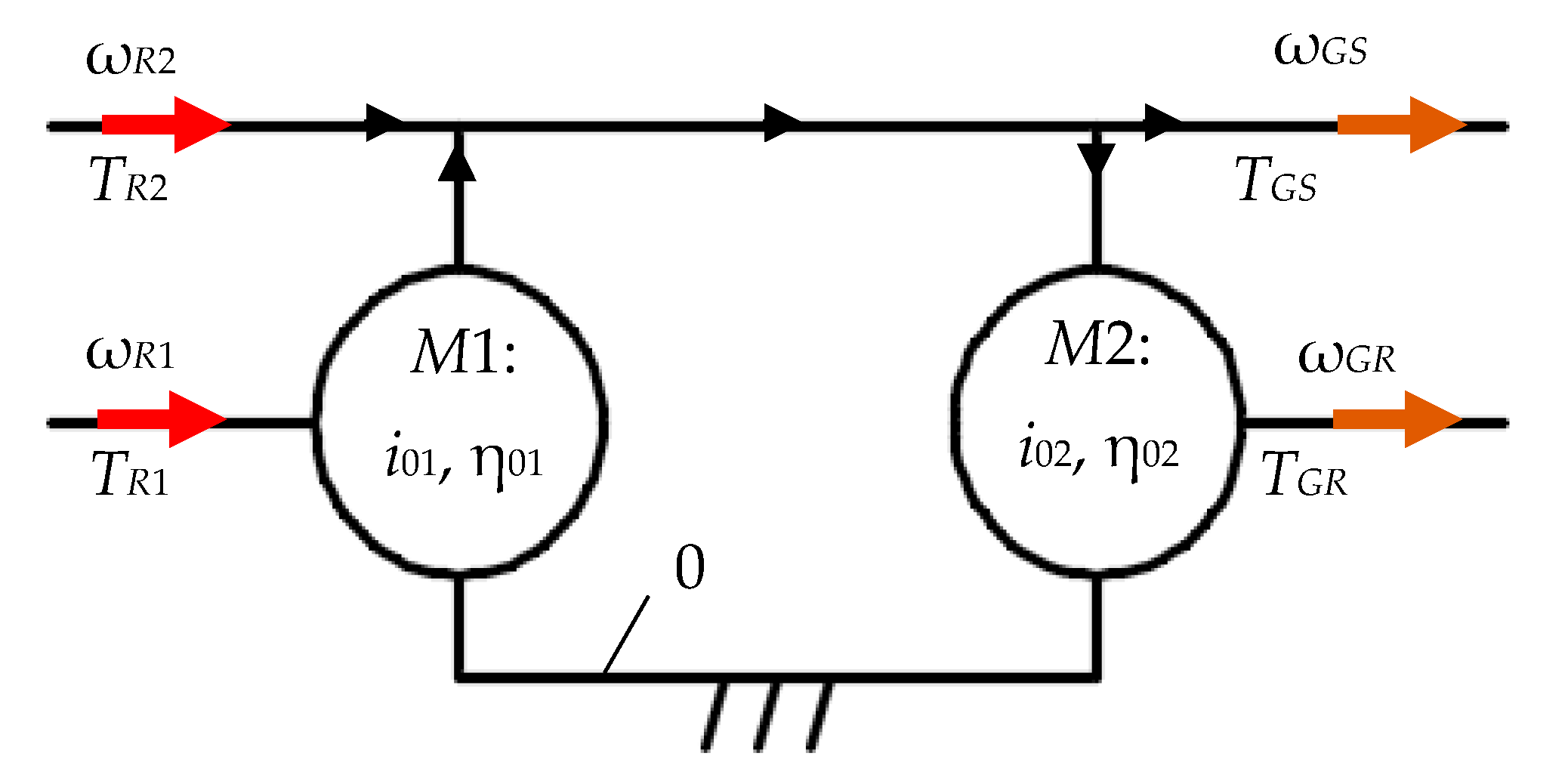

3. Generalized Speed and Steady-State Torque Equations for 1-DOF Speed Increasers with Two Inputs and Two Outputs

- (1)

- Variant V1: where both inputs R1 and R2, and both outputs GR and GS are active (L = 4). A system with two counter-rotating rotors and one counter-rotating electric generator is obtained.

- (2)

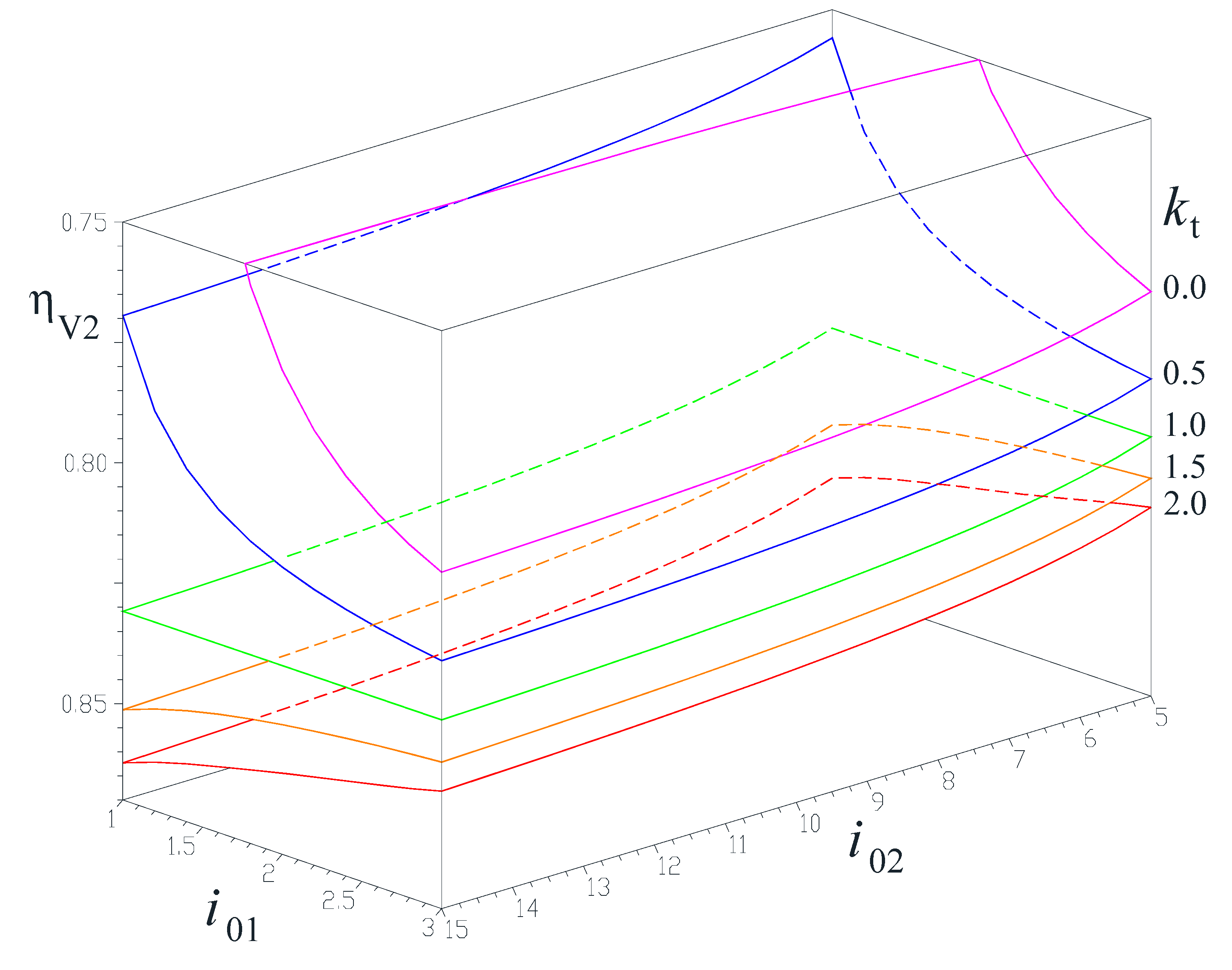

- Variant V2: where both inputs R1 and R2 and the electric-generator output GR are active (L = 3). In this case, a system with two counter-rotating rotors and a standard electric generator with ωGS = 0 is obtained.

- (3)

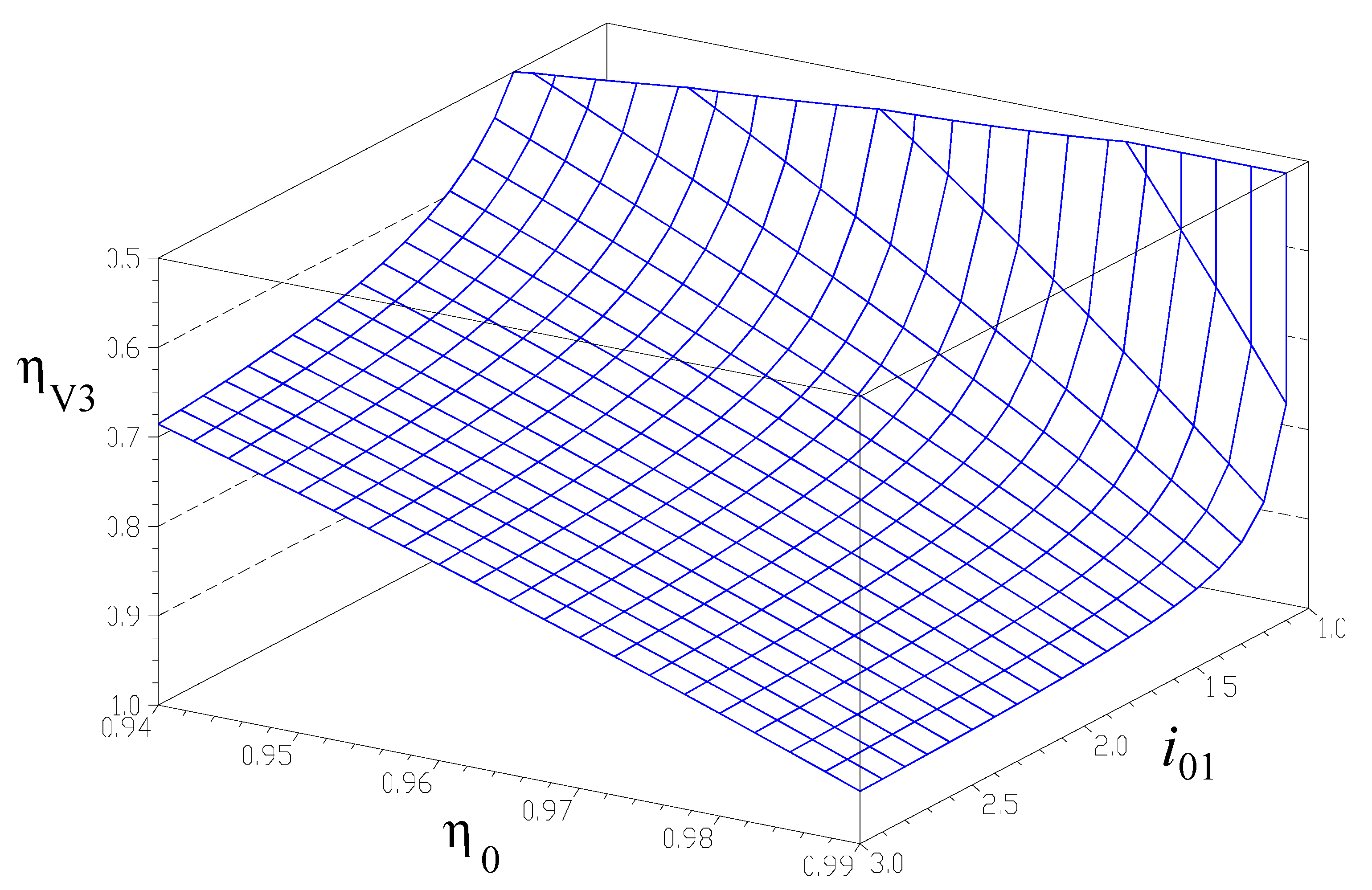

- Variant V3: where the main input R1 and both outputs are active (L = 3), case in which a system with one rotor (TR1 ≠ 0 and TR2 = 0) and one counter-rotating electric generator is obtained.

- (4)

- Variant V4: where only the main input R1 and the main output to the generator rotor GR are active (L = 2). This results in a system with one rotor (TR1 ≠ 0 and TR2 = 0) and a standard electric generator with ωGR ≠ 0 and ωGS = 0.

- (1)

- It has one independent external angular velocity, with ωR1 assumed the independent kinematic parameter;

- (2)

- It has three angular-velocity transmission functions, i.e., three of the external angular velocities depend on the independent velocity i.e., ωR2 = ωR2 (ωR1), ωRG = ωRG (ωR1), ωGS = ωGS (ωR1);

- (3)

- It has one torque-transmission function TR1 = TR1 (TR2, TGR, TGS) i.e., one dependent external torque (the primary rotor torque TR1) and three independent external torques i.e., TR2, TGR and TGS.

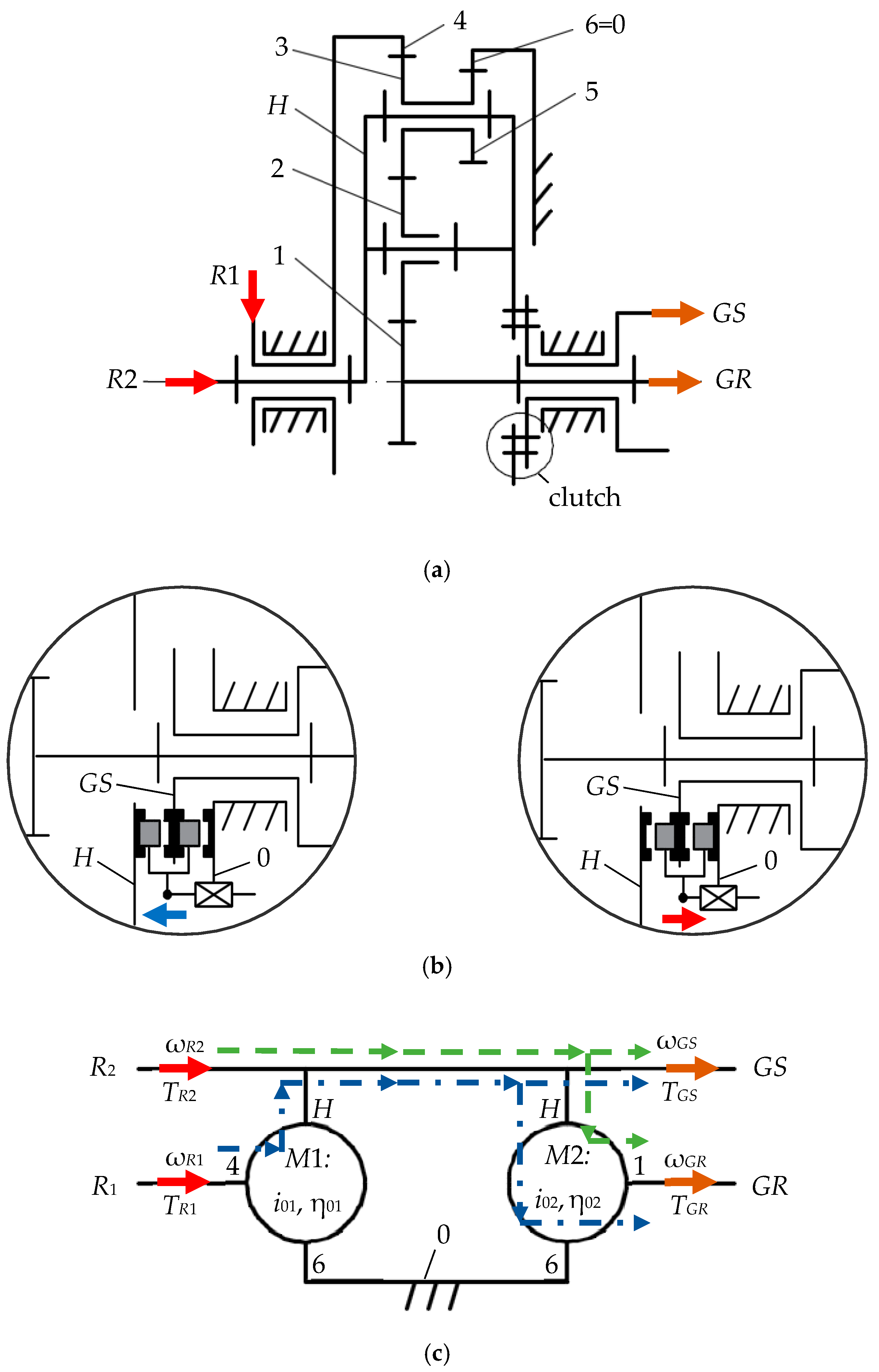

4. Case Study Analysis

- (1)

- Variant V1: a system with two inputs and two outputs (L = 4), in which both input R1 and R2 and both output GR and GS are active. The input-output torque ratio kt > 0 is controlled by the blade-pitch angle of either or both rotors R1 and R2, while the clutch is set to connect carrier H to GS (see Figure 4b-left);

- (2)

- Variant V2: a system with two inputs and one output (L = 3), in which the output is connected to the electric-generator rotor GR, and stator GS is fixed by the clutch as shown in Figure 4b-right;

- (3)

- Variant V3: a system with one input and two outputs (L = 3), obtained from V1 by deactivating the secondary rotor R2 (kt = 0);

- (4)

- Variant V4: a system with one input and one output (L = 2), obtained from variant V1 by deactivating the secondary rotor R2 (kt = 0) and by connecting the electric-generator stator to the frame (see Figure 4b-right).

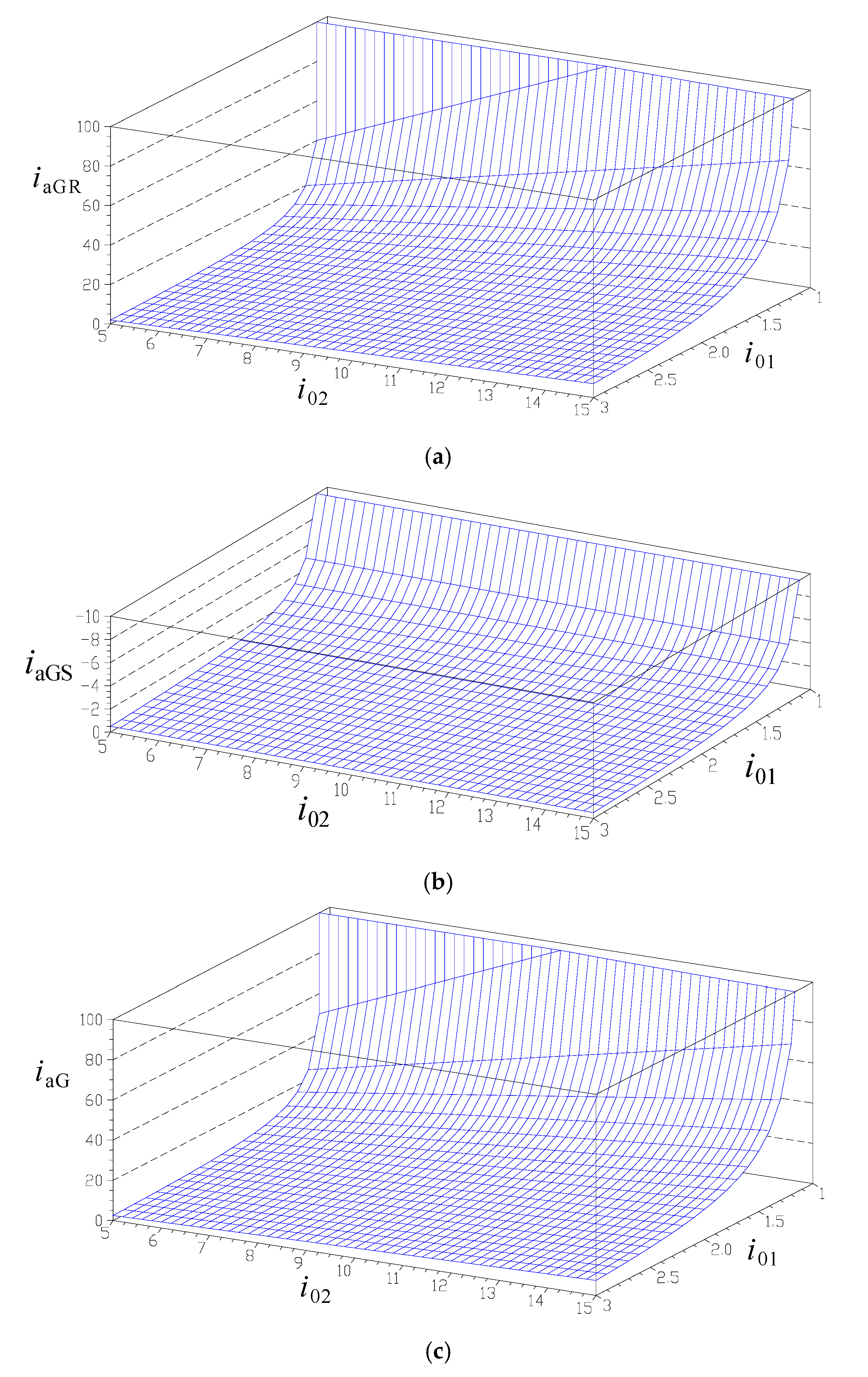

5. Numerical Simulations and Discussions

- −

- Efficiencies ηV1 and ηV2 increase as the input torque ratio kt increases. This is explicable by the relative increase of the power from the secondary wind or water rotor R2. It is worth mentioning that the power flow from R1 passes entirely through mechanism M1 and then through part of mechanism M2, while the power flow generated by R2 passes only partially through M2 and the rest is transmitted directly to the generator stator GS;

- −

- The interior kinematic ratio i01 influences strongly the speed-increaser efficiency in all four variants as kt approaching 0, particularly if 1 < i01 < 1.75. Furthermore, the mechanism locks (i.e., efficiency becomes negative) for i01 approaching 1;

- −

- The interior kinematic ratio i02 does not occur in the efficiency Equations (34) and (36) for the speed increaser variants V1 and V3 with counter-rotating electric generator. Instead, efficiencies ηV2 and ηV4 (the cases with electric generator with a fixed stator) have markedly lower values for small values of parameter i02, but increase with the increase of i02;

- −

- The quality of the component gears and therefore the individual gear pair efficiencies η0, have a major influence upon the efficiency of the speed increaser, regardless of variant V1 to V4. Therefore, it is recommended that good quality gear pairs are used, in order to minimize losses and maximize the efficiency in transmitting mechanical power from wind or water rotors to the electric generator.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| CRWT | Counter-Rotating Wind Turbine |

| SI | Speed increaser |

| R | Rotor |

| R1 | Primary rotor |

| R2 | Secondary rotor |

| P | Power |

| ω | Angular speed |

| T | Torque |

| kt | Ratio of the input torques |

| z | Gear teeth number |

| H | Satellite carrier |

| a, b, c | Kinematic coefficients |

| A, B, C | Static coefficients |

| DOF | Degree of Freedom |

| M1, M2 | Mechanism 1 or 2 |

| L | Total number of inputs and outputs |

| G | Standard electric generator |

| GR | Electric generator rotor |

| GS | Electric generator stator |

| i | Kinematic ratio |

| i01,2 | Interior kinematic ratio of the mechanism M1,2 |

| ia | Amplification kinematic ratio |

| η | Efficiency of the speed increaser |

| η01,2 | Interior efficiency of the mechanism M1,2 |

| η0 | Efficiency of a gear pair |

References

- Dincer, I. (Ed.) Comprehensive Energy Systems; Elsevier Science & Technology: Amsterdam, The Netherlands, 2018; ISBN 978-0-12-809597-3. [Google Scholar]

- World Energy Resources Charting the Upsurge in Hydropower Development. 2015. Available online: www.worldenergy.org/publications/entry/charting-the-upsurge-in-hydropower-development-2015 (accessed on 19 August 2020).

- Jaliu, C.; Diaconescu, D.V.; Neagoe, M.; Saulescu, R. The eco-impact of small hydro implementation. Environ. Eng. Manag. J. 2009, 8, 837–841. [Google Scholar] [CrossRef]

- Hydro Power. Available online: https://ec.europa.eu/research/energy/index.cfm?pg=area&areaname=renewable_hydro (accessed on 19 August 2020).

- Visa, I.; Jaliu, C.; Duta, A.; Neagoe, M.; Comsit, M.; Moldovan, M.; Ciobanu, D.; Burduhos, B.; Saulescu, R. The Role of Mechanisms in Sustainable Energy Systems; Transilvania University Press: Brasov, Romania, 2015; ISBN 978-606-19-0571-3. [Google Scholar]

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained: Theory, Design and Application; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Pelikan, B.; Armand, F.; Schleiss, A.; Bollaert, B.; Manso, P.; Bard, J.; O’Nians, J.; Denis, V.; Corbet, J.-P.; Soderberg, C.; et al. Guide on How to Develop a Small Hydropower Plant; European Small Hidro-Power Association (ESHA): Brussels, Belgium, 2004. [Google Scholar]

- Shin, C. Multi-Unit Rotor Blade System Integrated Wind Turbine. U.S. Patent No. 5876181, 2 March 1999. [Google Scholar]

- Appa, K. Energy Innovations Small Grant (EISG) Program (Counter Rotating Wind Turbine System); EISG Final Report; EISG: Shores, CA, USA, 2002; Available online: https://www.eai.in/ref/invent/upload/00-09%2520FAR%2520Appendix%2520A.pdf (accessed on 19 August 2020).

- Jung, S.; No, T.; Ryu, K. Aerodynamic performance prediction of a 30 kW counter-rotating wind turbine system. Renew. Energy 2005, 30, 631–644. [Google Scholar] [CrossRef]

- Wacinski, A. Drive Device for a Windmill Provided with Two Counter–Rotative Propellers. U.S. Patent 7,384,239, 10 June 2008. [Google Scholar]

- Brander, M. Bi-Directional Wind Turbine. U.S. Patent Application 2008/0197639 A1, 21 August 2008. [Google Scholar]

- Climescu, O.; Saulescu, R.; Jaliu, C. Specific features of a counter-rotating transmission for renewable energy systems. Environ. Eng. Manag. J. 2011, 10, 1105–1113. [Google Scholar] [CrossRef]

- Hwang, B.; Lee, S.; Lee, S. Optimization of a counter-rotating wind turbine using the blade element and momentum theory. J. Renew. Sustain. Energy 2013, 5, 052013. [Google Scholar] [CrossRef]

- Didane, D.H.; Rosly, N.; Zulkafli, M.F.; Shamsudin, S.S. Performance evaluation of a novel vertical axis wind turbine with coaxial contra-rotating concept. Renew. Energy 2015, 115, 353–361. [Google Scholar] [CrossRef]

- Oprina, G.; Chihaia, R.A.; El-Leathey, L.A.; Nicolaie, S.; Babutanu, C.A.; Voina, A. A review on counter-rotating wind turbines development. J. Sustain. Energy 2016, 7, 91–98. [Google Scholar]

- Vasel-Be-Hagh, A.; Archer, C. Wind farms with counter-rotating wind turbines. Sustain. Energy Technol. Assess. 2017, 24, 19–30. [Google Scholar] [CrossRef]

- West, R. Wind Turbine System. U.S. Patent 10,316,820B2, 11 June 2019. [Google Scholar]

- Didane, D.H.; Rosly, N.; Zulkafli, M.F.; Shamsudin, S.S. Numerical investigation of a novel contra-rotating vertical axis wind turbine. Sustain. Energy Technol. Assess. 2019, 31, 43–53. [Google Scholar] [CrossRef]

- Jaliu, C.; Saulescu, R.; Diaconescu, D.V.; Neagoe, M. Conceptual design of a chain speed increaser for small hydropower stations. In Proceedings of the ASME 2009 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2009, San Diego, CA, USA, 30 August–2 September 2009; ISBN 978-0-7918-3856-3. [Google Scholar]

- Booker, J.D.; Mellor, P.H.; Wrobel, R.; Drury, D. A compact, high efficiency contra-rotating generator suitable for wind turbines in the urban environment. Renew. Energy 2010, 35, 2027–2033. [Google Scholar] [CrossRef]

- Erturk, E.; Sivrioglu, S.; Bolat, F.C. Analysis Model of a Small Scale Counter-Rotating Dual Rotor Wind Turbine with Double Rotational Generator Armature. Int. J. Renew. Energy Res. 2018, 8, 1849–1858. [Google Scholar]

- Hall, J.F.; Mecklenborg, C.A.; Chen, D.; Pratap, S.B. Wind energy conversion with a variable-ratio gearbox: Design and analysis. Renew. Energy 2011, 36, 1075–1080. [Google Scholar] [CrossRef]

- Jelaska, D.; Podrug, S.; Perkusic, M. A novel hybrid transmission for variable speed wind turbines. Renew. Energy 2015, 83, 78–84. [Google Scholar] [CrossRef]

- Saulescu, R.; Neagoe, M.; Munteanu, O.; Cretescu, N. Performance Analysis of a Novel Planetary Speed Increaser Used in Single-Rotor Wind Turbines with Counter-Rotating Electric Generator; Materials Science and Engineering—IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2016. [Google Scholar] [CrossRef]

- Neagoe, M.; Saulescu, R.; Jaliu, C.; Cretescu, N. Novel Speed increaser used in counter-rotating wind turbines. In New Advances in Mechanisms, Mechanical Transmissions and Robotics, Mechanisms and Machine Science 46; Springer: Berlin, Germany, 2017; pp. 143–151. [Google Scholar] [CrossRef]

- Jaliu, C.; Diaconescu, D.V.; Neagoe, M.; Saulescu, R. Dynamic features of speed increasers from mechatronic wind and hydro systems. Part I. Structure Kinematics. In Proceedings of the Second European Conference on Mechanism Science EUCOMES 08, Casino, Italy, 17–20 September 2008; Springer: Dordrecht, The Netherlands, 2008; pp. 355–363, ISBN 987-1-4020-8914-5. [Google Scholar]

- Jaliu, C.; Diaconescu, D.V.; Neagoe, M.; Saulescu, R. Dynamic features of speed increasers from mechatronic wind and hydro systems. Part II. Dynamic aspects. In Proceedings of the Second European Conference on Mechanism Science EUCOMES 08, Casino, Italy, 17–20 September 2008; Springer: Dordrecht, The Netherlands, 2008; pp. 365–373, ISBN 987-1-4020-8914-5. [Google Scholar]

- Bevington, C.M.; Bywaters, G.L.; Coleman, C.C.; Costin, D.P.; Danforth, W.L.; Lynch, J.A.; Rolland, R.H. Wind Turbine Having a Direct-Drive Drivetrain. U.S. Patent 7431567B1, 7 October 2008. [Google Scholar]

- Marjanovic, N.; Isailovic, B.; Marjanovic, V.; Milojevic, Z.; Blagojevic, M.; Bojic, M. A practical approach to the optimization of gear trains with spur gears. Mech. Mach. Theory 2012, 53, 1–16. [Google Scholar] [CrossRef]

- Qiu, J.; Liu, B.; Dong, H.; Wang, D. Type Synthesis of Gear-box in Wind Turbine. Procedia Comput. Sci. C 2017, 109, 809–816. [Google Scholar] [CrossRef]

- Climescu, O.; Jaliu, C.; Saulescu, R. Comparative Analysis of Horizontal Small Scale Wind Turbines for a Specific Application. In Proceedings of the 14th IFToMM World Congress, Taipei, Taiwan, 25–30 October 2015. [Google Scholar] [CrossRef]

- Saulescu, R.; Neagoe, M.; Jaliu, C. Improving the Energy Performance of Wind Turbines Implemented in the Built Environment Using Counter-Rotating Planetary Transmissions; Materials Science and Engineering—IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2016. [Google Scholar] [CrossRef]

- Saulescu, R.; Jaliu, C.; Neagoe, M. Structural and Kinematic Features of a 2 DOF Speed Increaser for Renewable Energy Systems. Appl. Mech. Mater. 2016, 823, 367–372. [Google Scholar] [CrossRef]

- Saulescu, R.; Neagoe, M.; Jaliu, C.; Munteanu, O. Comparative analysis of two wind turbines with planetary speed increaser in steady-state. Appl. Mech. Mater. 2016, 823, 355–360. [Google Scholar] [CrossRef]

- Saulescu, R.; Jaliu, C.; Munteanu, O.; Climescu, O. Planetary Gear for Counter-rotating Wind Turbines. Appl. Mech. Mater. 2014, 658, 135–140. [Google Scholar] [CrossRef]

- Saulescu, R.; Jaliu, C.; Climescu, O.; Diaconescu, D. On the use of 2 DOF planetary gears as “speed increaser” in small hydros and wind turbines. In Proceedings of the ASME International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2011, Washington, DC, USA, 25–31 August 2011. [Google Scholar]

- Herzog, R.; Schaffarczyk, A.P.; Wacinski, A.; Zürcher, O. Performance and stability of a counter–rotating windmill using a planetary gearing: Measurements and Simulation. In Proceedings of the European Wind Energy Conference & Exhibition, Warsaw, Poland, 20–23 April 2010. [Google Scholar]

- Neagoe, M.; Saulescu, R.; Jaliu, C. Design and Simulation of a 1 DOF Planetary Speed Increaser for Counter-Rotating Wind Turbines with Counter-Rotating Electric Generators. Energies 2019, 12, 1754. [Google Scholar] [CrossRef]

- Saulescu, R.; Neagoe, M.; Jaliu, C. Conceptual Synthesis of Speed Increasers for Wind Turbine Conversion Systems. Energies 2018, 11, 2257. [Google Scholar] [CrossRef]

- Sapre, R.; Murkute, H.; Agrawal, R. Comparison between single axis wind turbine and counter wind turbine—A case study. Glob. J. Eng. Appl. Sci. 2012, 2, 144–146. [Google Scholar]

- Lee, S.; Kim, H.; Lee, S. Analysis of aerodynamic characteristics on a counter-rotating wind turbine. Curr. Appl. Phys. 2010, 10, S339–S342. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.; Son, E.; Lee, S. Effects of design parameters on aerodynamic performance of a counter-rotating wind turbine. Renew. Energy 2012, 42, 140–144. [Google Scholar] [CrossRef]

- Farahani, E.M.; Hosseinzadeh, N.; Ektesabi, M. Comparison of fault-ride-through capability of dual and single-rotor wind turbines. Renew. Energy 2012, 48, 473–481. [Google Scholar] [CrossRef]

- No, T.S.; Kim, J.E.; Moon, J.H.; Kim, S.J. Modelling, control, and simulation of dual rotor wind turbine generator system. Renew. Energy 2009, 34, 2124–2132. [Google Scholar] [CrossRef]

- Kubo, K.; Hano, Y.; Mitarai, H.; Hirano, K.; Kanemoto, T.; Galal, A.M. Intelligent wind turbine unit with tandem rotors (discussion of prototype performances in field tests). Curr. Appl. Phys. 2010, 10, S326–S331. [Google Scholar] [CrossRef]

- Chantharasenawong, C.; Suwantragul, B.; Ruangwiset, A. Axial Momentum Theory for Turbines with Co-axial Counter Rotating Rotors. In Proceedings of the Commemorative International Conference of the Occasion of the 4th Cycle Anniversary of KMUTT Sustainable Development to Save the Earth: Technologies and Strategies Vision 2050: (SDSE2008), Bangkok, Thailand, 11–13 December 2008. [Google Scholar]

- Zhamalov, A.Z.; Obozov, A.D.; Kunelbaev, M.M.; Baikadamova, L.S. Capacity and Power Characteristics of Disk Generator with Counter-Rotation of Double-Rotor Wind Turbine. Middle-East J. Sci. Res. 2013, 15, 1655–1662. [Google Scholar] [CrossRef]

- Kanemoto, T.; Galal, A.M. Development of intelligent wind turbine generator with tandem wind rotors and double rotational armatures. JSME Int. J. Ser. B 2006, 49, 450–457. [Google Scholar] [CrossRef]

- Caiozza, J. Wind Driven Electric Generator Apparatus. U.S. Patent 7227276 B2, 5 June 2007. [Google Scholar]

- Miloiu, G.; Dudita, F.l.; Diaconescu, D. Modern Mechanical Transmissions; Tehnica: Bucharest, Romania, 1980. (In Romanian) [Google Scholar]

- Santoso, S.; Le, H.T. Fundamental time–domain wind turbine models for wind power studies. Renew. Energy 2007, 32, 2436–2452. [Google Scholar] [CrossRef]

- Hall, J.F.; Chen, D. Dynamic Optimization of Drivetrain Gear Ratio to Maximize Wind Turbine Power Generation—Part 1: System Model and Control Framework. J. Dyn. Syst. Meas Control 2012, 135, 011016. [Google Scholar] [CrossRef]

- Neagoe, M.; Saulescu, R.; Jaliu, C.; Munteanu, O. Reconfigurable Adjustable Planetary Speed Increaser for Wind Turbines and Adjustment Method. Romanian Patent Application No. A/00224, 24 March 2020. [Google Scholar]

- Simionescu, P.A.; Smith, M.R. Single-valued function representations in linkage mechanisms design. Mech. Mach. Theory 2000, 35, 1709–1726. [Google Scholar] [CrossRef]

- Simionescu, P.A. Contributions to the Optimum Synthesis of Linkage-Mechanisms with Applications. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 1999. Available online: http://faculty.tamucc.edu/psimionescu/papers.html (accessed on 19 August 2020).

- Chen, T.H.; Tang, H.C. Meshing Efficiency Analysis of Straight Spur Gear Pair. Appl. Mech. Mater. 2015, 764–765, 314–318. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neagoe, M.; Saulescu, R.; Jaliu, C.; Simionescu, P.A. A Generalized Approach to the Steady-State Efficiency Analysis of Torque-Adding Transmissions Used in Renewable Energy Systems. Energies 2020, 13, 4568. https://doi.org/10.3390/en13174568

Neagoe M, Saulescu R, Jaliu C, Simionescu PA. A Generalized Approach to the Steady-State Efficiency Analysis of Torque-Adding Transmissions Used in Renewable Energy Systems. Energies. 2020; 13(17):4568. https://doi.org/10.3390/en13174568

Chicago/Turabian StyleNeagoe, Mircea, Radu Saulescu, Codruta Jaliu, and Petru A. Simionescu. 2020. "A Generalized Approach to the Steady-State Efficiency Analysis of Torque-Adding Transmissions Used in Renewable Energy Systems" Energies 13, no. 17: 4568. https://doi.org/10.3390/en13174568

APA StyleNeagoe, M., Saulescu, R., Jaliu, C., & Simionescu, P. A. (2020). A Generalized Approach to the Steady-State Efficiency Analysis of Torque-Adding Transmissions Used in Renewable Energy Systems. Energies, 13(17), 4568. https://doi.org/10.3390/en13174568