Microclimate Conditions in Rooms: Their Impact on Mold Development in Buildings

Abstract

:1. Introduction

- complex process of mold growth and its high susceptibility to boundary and climatic conditions; they change dynamically and individually, depending on the use of the premises (described in the Section 2),

- a limited number of simulation tools for the design or diagnosis of partitions in the context of mold growth.

2. Materials and Methods

2.1. Factors Affecting the Development of Mold

2.1.1. Temperature

2.1.2. Humidity

- the 1st fungi group of the type Aspergillus repens, Aspergillus Versicolor, and others which have a xerophilic nature, i.e., they tolerate dry environment, are able to grow when the equilibrium index aw is above 0.80, which corresponds to the relative humidity of the air below 80%,

- the 2nd fungi group of the type Cladosporium for which the minimum index aw for the growth is within 0.80–0.90, which corresponds to the relative humidity of 80–90%,

- the 3rd group of fungi such as Phoma herbarium, various species of Ulocladium, Stachybortys atra, which grow only when the index aw is above 0.90, i.e., when the relative humidity is above 90%,

- It should be remembered that every change in temperature is followed by a change in the relative humidity of the air, and thus the process of fungi growth should be treated with simultaneous consideration of these two parameters. The dependence of the growth of mold on temperature and relative humidity is represented by the so-called isoplets.

2.1.3. Substrate

- o Substrate class 0:

- o Substrate class I:

- o Substrate class II:

2.1.4. Growth Time

2.1.5. pH Reaction

2.2. Analysis of Internal Conditions in Partition Modeling in Order to Avoid Mold Growth

- -

- equivalent indoor temperature,

- -

- water vapor pressure or other humidity parameter.

- -

- values measured for similar buildings in a similar climate,

- -

- results of hygrothermal simulations,

- -

- determination of the flow of the generated moisture and the multiplicity of ventilation, and on this basis the calculation of internal conditions should be carried out.

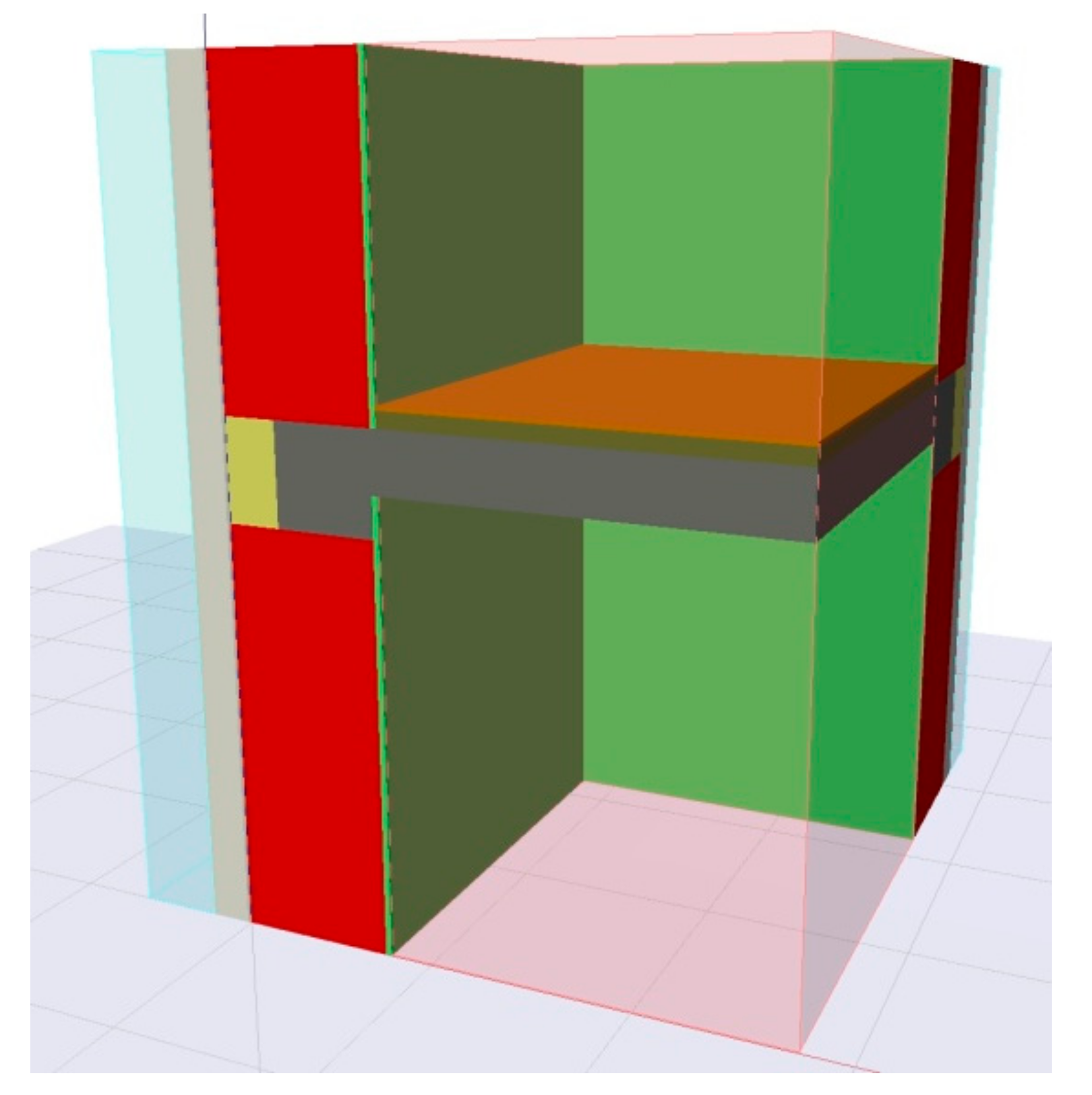

2.3. Research Stand

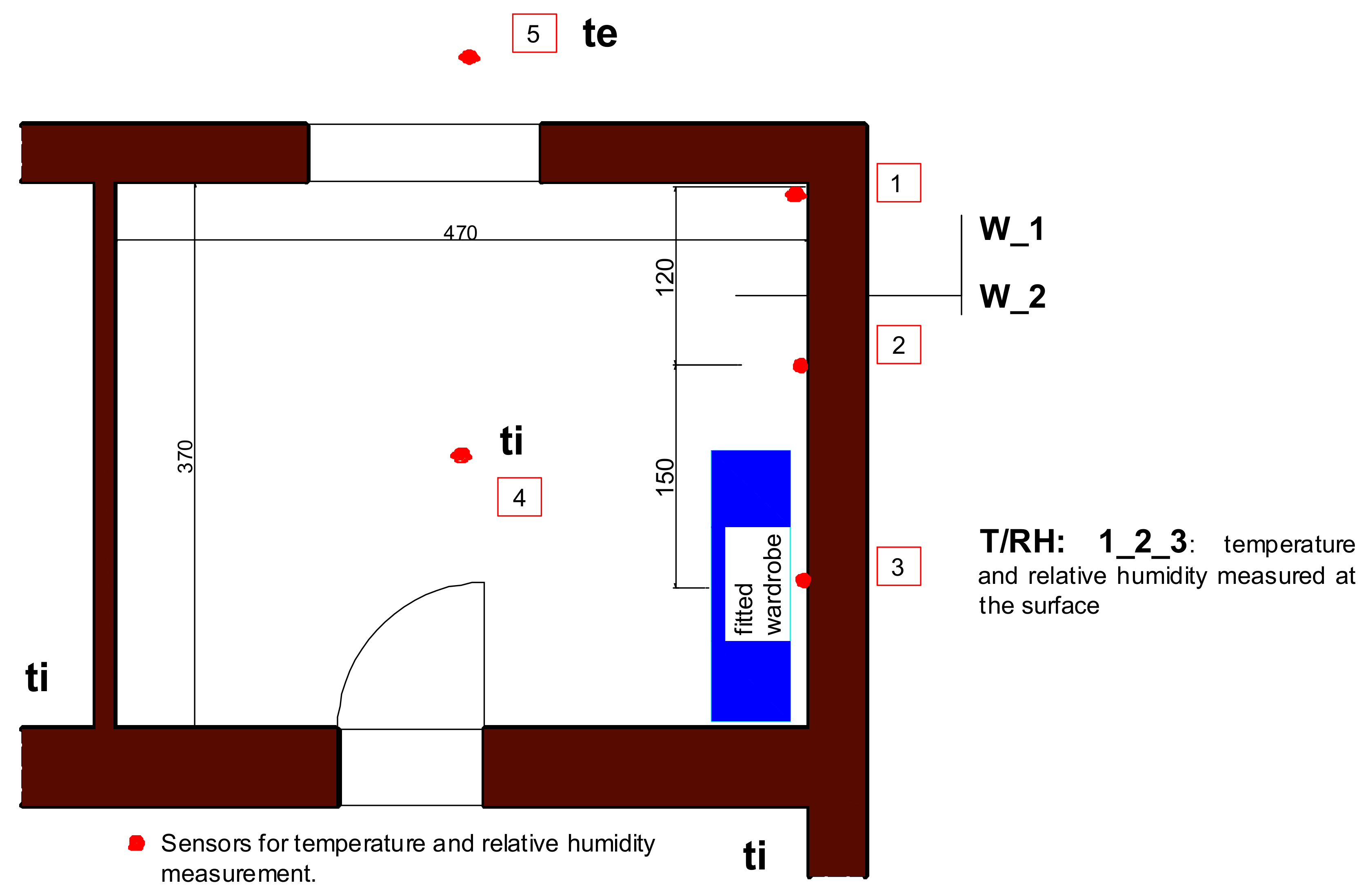

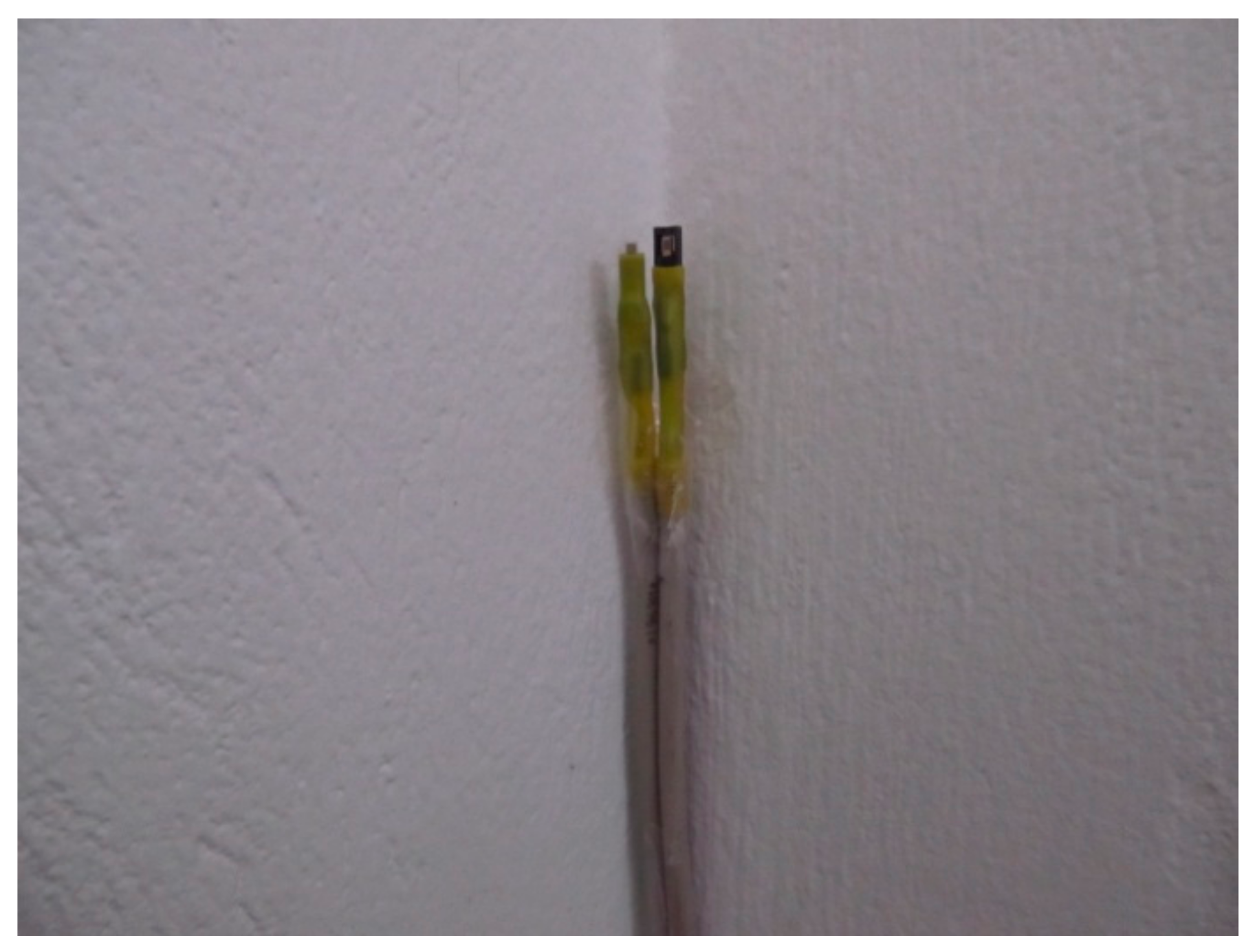

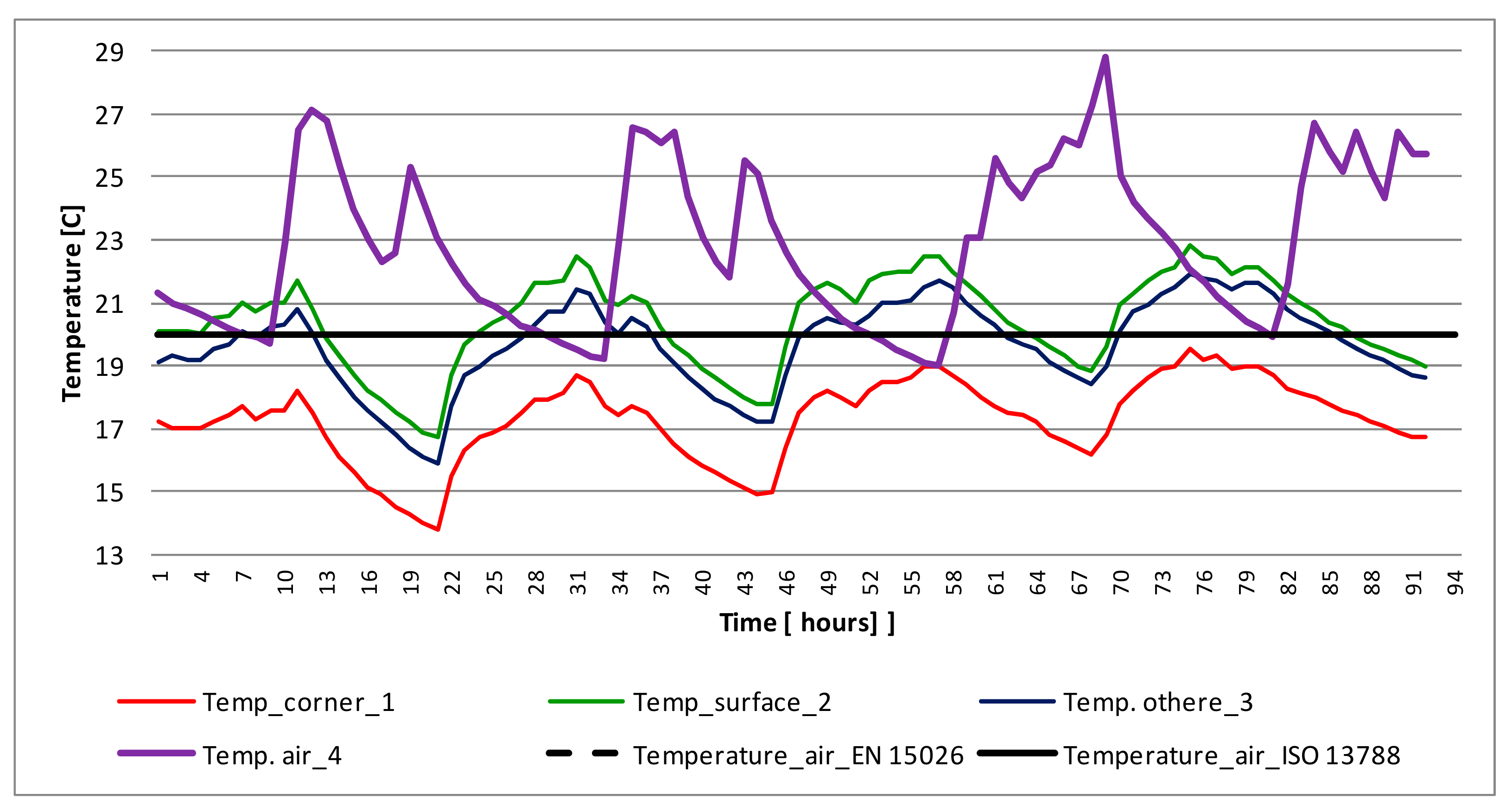

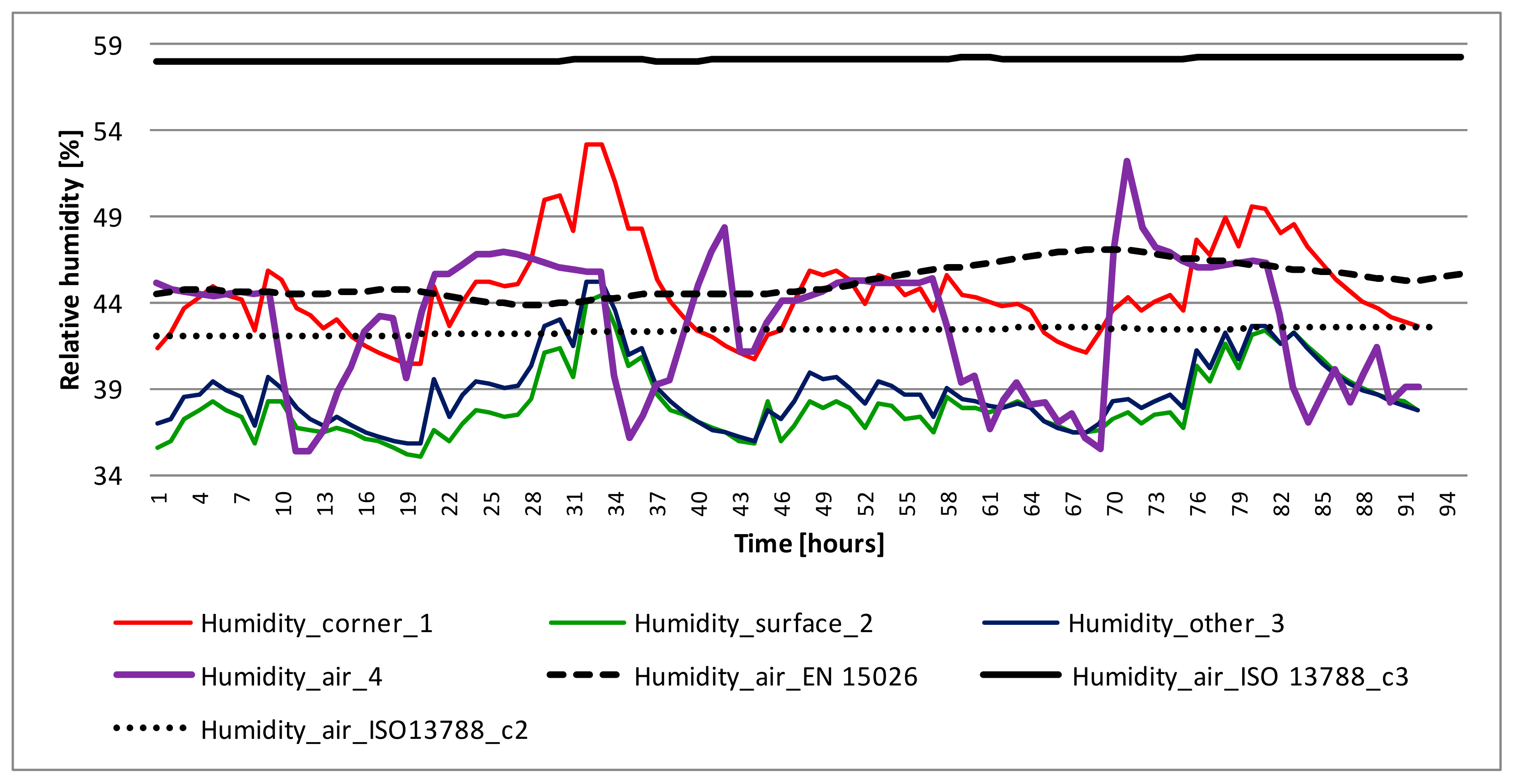

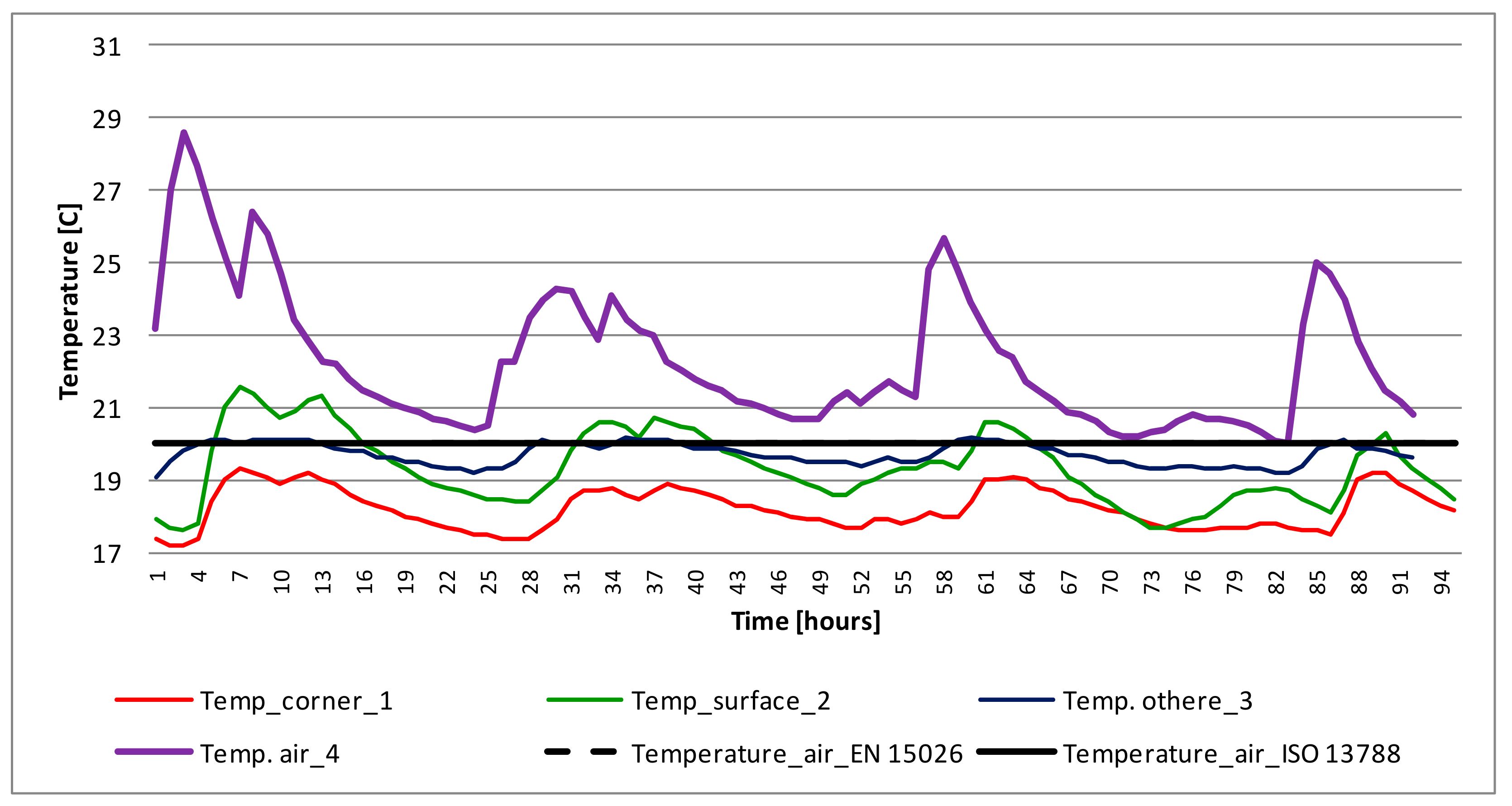

- 1-

- temperature, relative humidity of the air near the corner,

- 2-

- temperature, relative humidity of the air near the surface of a flat wall,

- 3-

- temperature, relative humidity of the air ‘behind the furniture’ (other),

- 4-

- temperature, relative humidity of the air in the room,

- 5-

- temperature, relative humidity of the outdoor air.

- non-insulated buildings, made in traditional technology, with walls made of 38 cm-thick bricks and insulation value of the envelope at the level of U = 2.00 ÷ 2.40 [W/m2K] (variant W_1), (Figure 8),

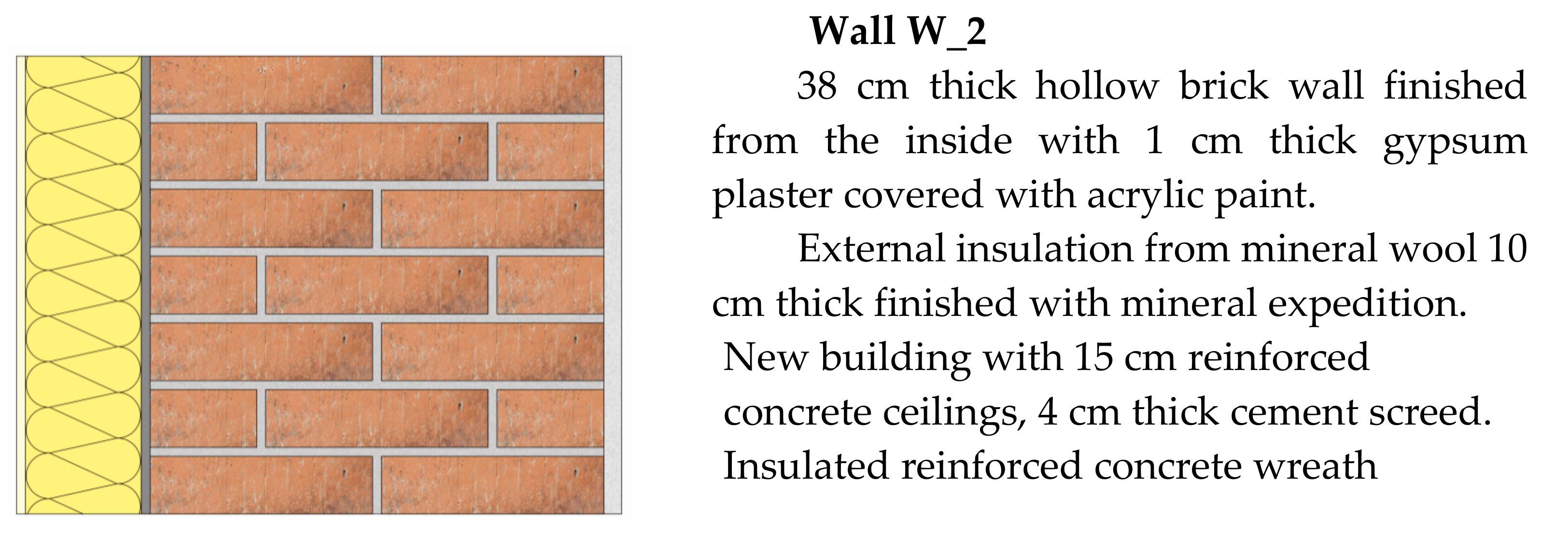

- insulated buildings, made in traditional technology, with wall insulation value at the level of U = 0.25 ÷ 0.30 [W/m2K] (variant W_2), (Figure 9).

- both groups of buildings had a gravity ventilation system, central heating, solid fuel stove, new PVC window frames.

3. Results and Discussion

3.1. In Situ Research

- -

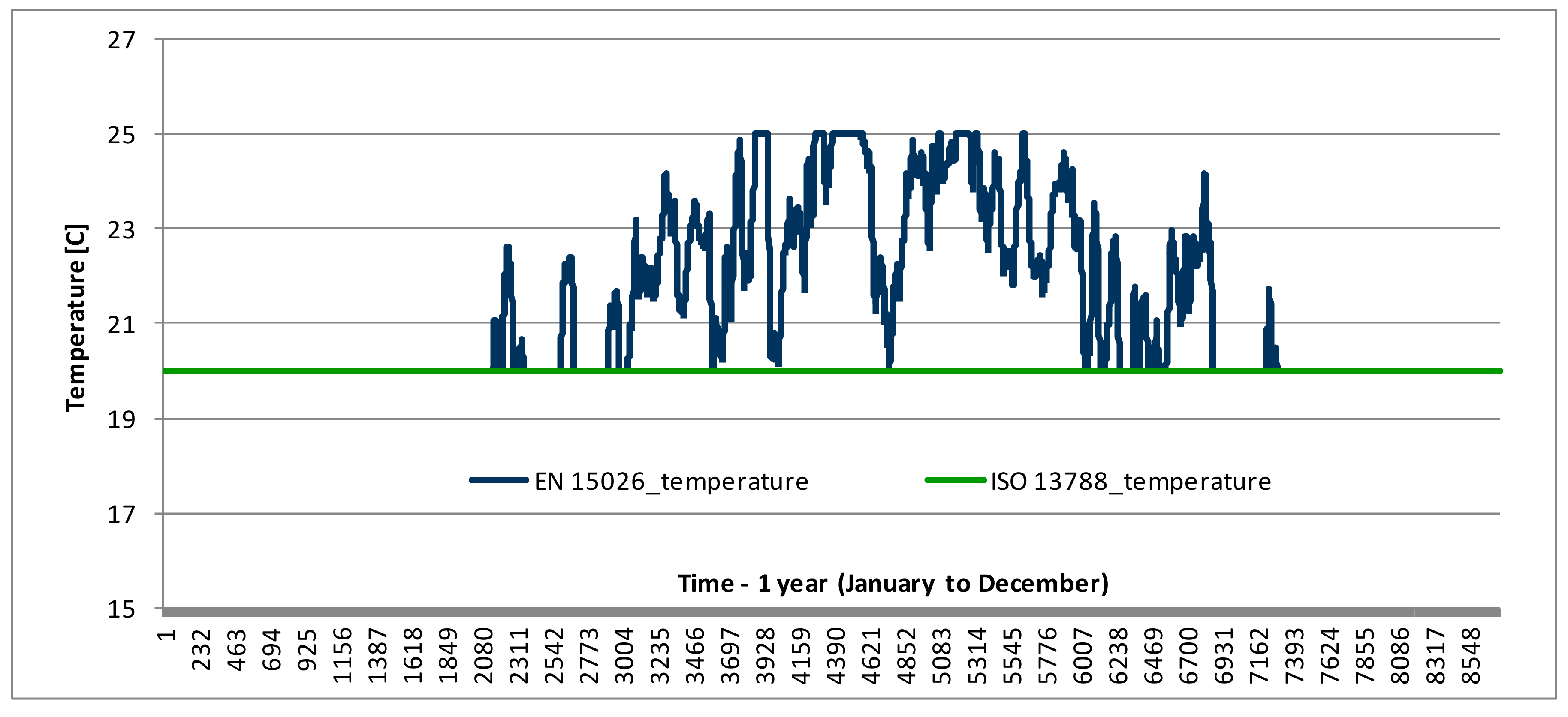

- lack of compliance in the values and in the changing trend involving the distribution of temperature for the measured and calculation values. In accordance with the assumptions of ISO 13788, a constant indoor air temperature of 20 °C is assumed. The standard EN 15026 assumes a constant value of the indoor air temperature in the period from November to April, and it also has the value of 20 °C. The calculation assumptions were adopted for typical residential buildings (both for ISO 13788 as well as for EN 15026). For both variants, the indoor air temperature was higher than the design temperature. What should be a matter of concern is that the temperatures in the remaining measuring points were much lower (than the design temperature values adopted in the standards).

- -

- lack of compliance in the values and in the changing trend involving the distribution of relative humidity for the measured and calculated values. According to the assumptions of ISO 13788, the humidity value in the analyzed period should not exceed 55% (for class 3) and ~43% (for class 2), according to the EN 15026 standard is ~45%.

3.2. Mold Risk Development Assessment

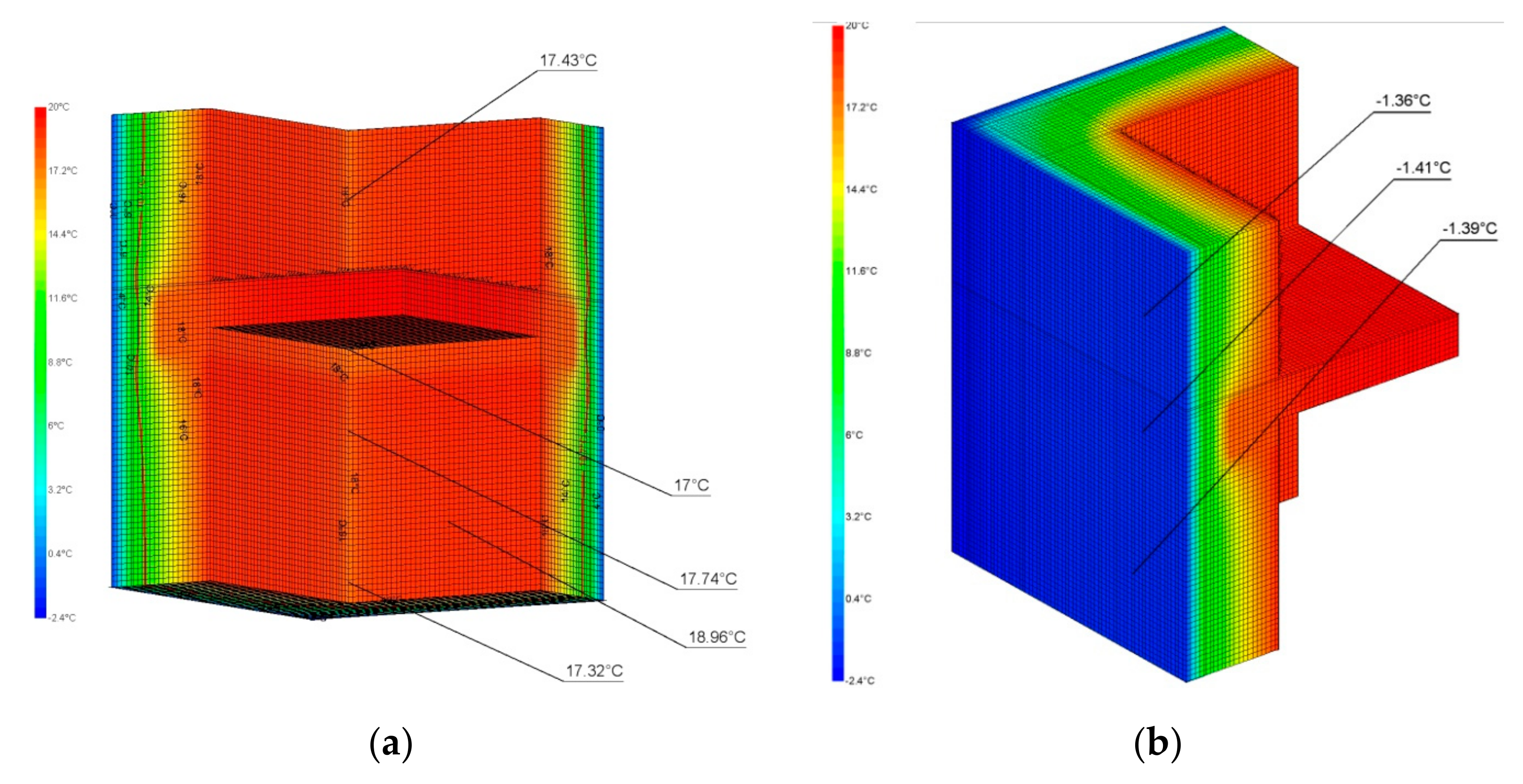

3.2.1. Temperature Factor on the Inner Surface fRsi

- in the first case, the boundary conditions were adopted based on the ISO 13 788 standard given in Table 2,

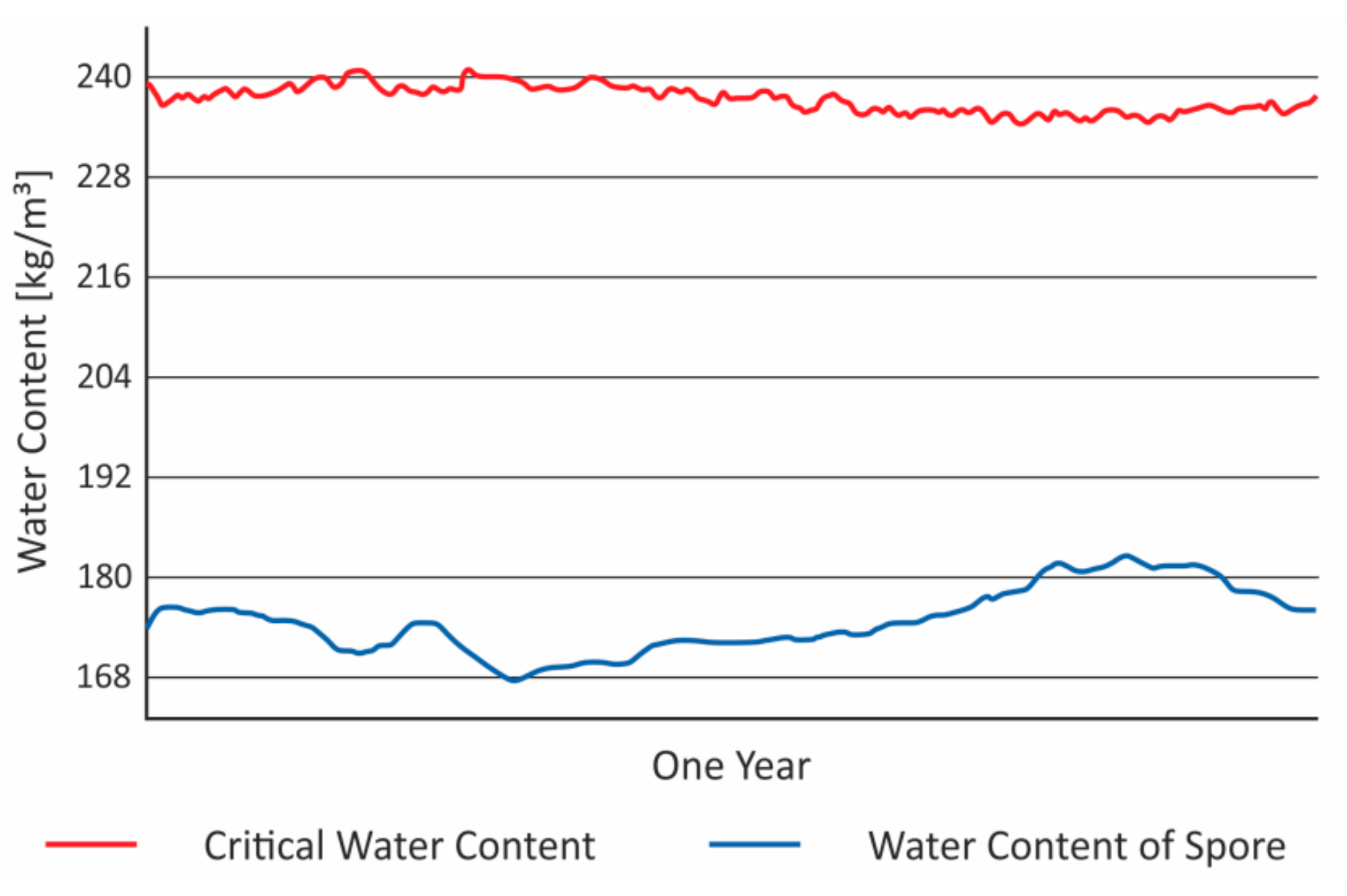

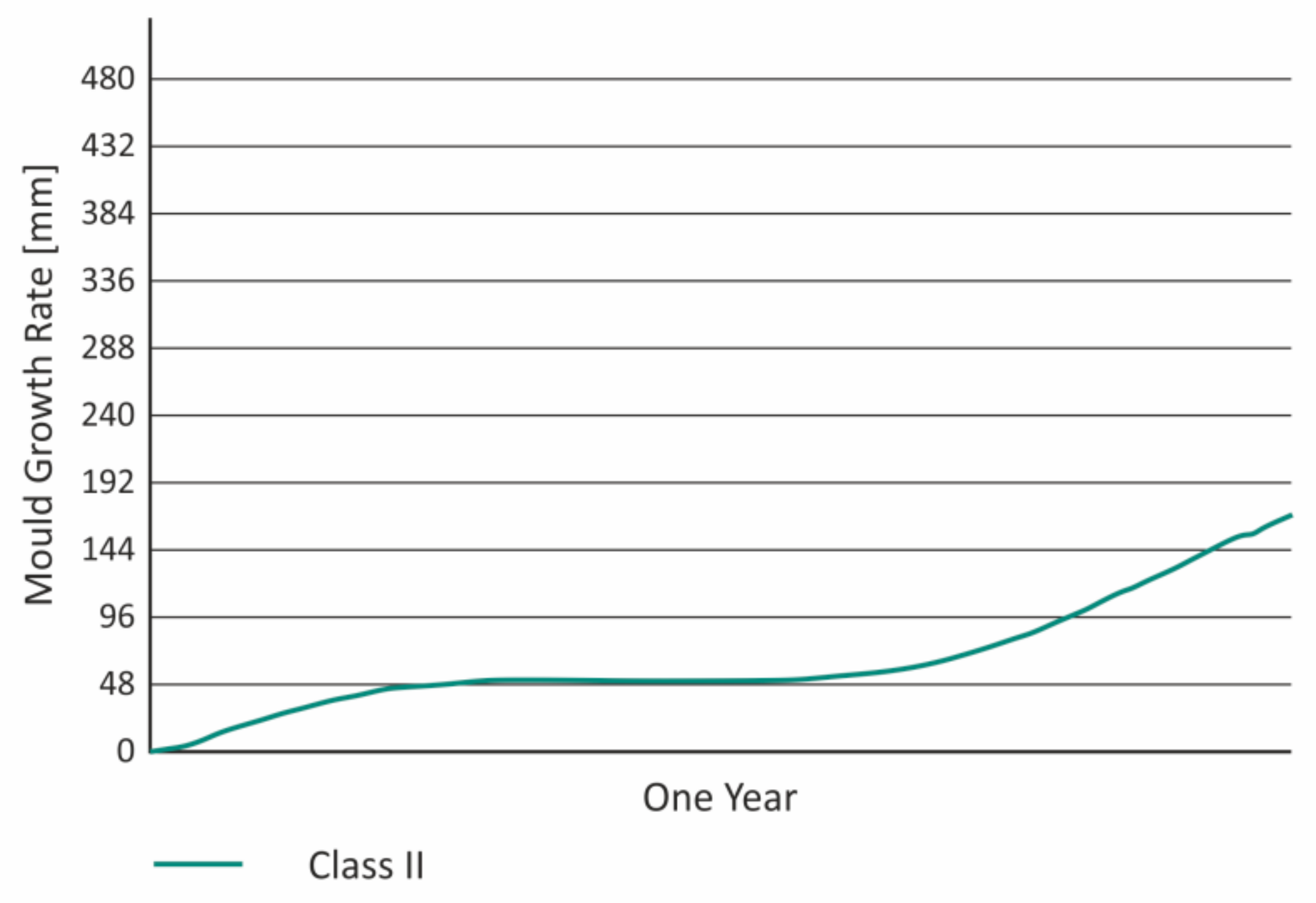

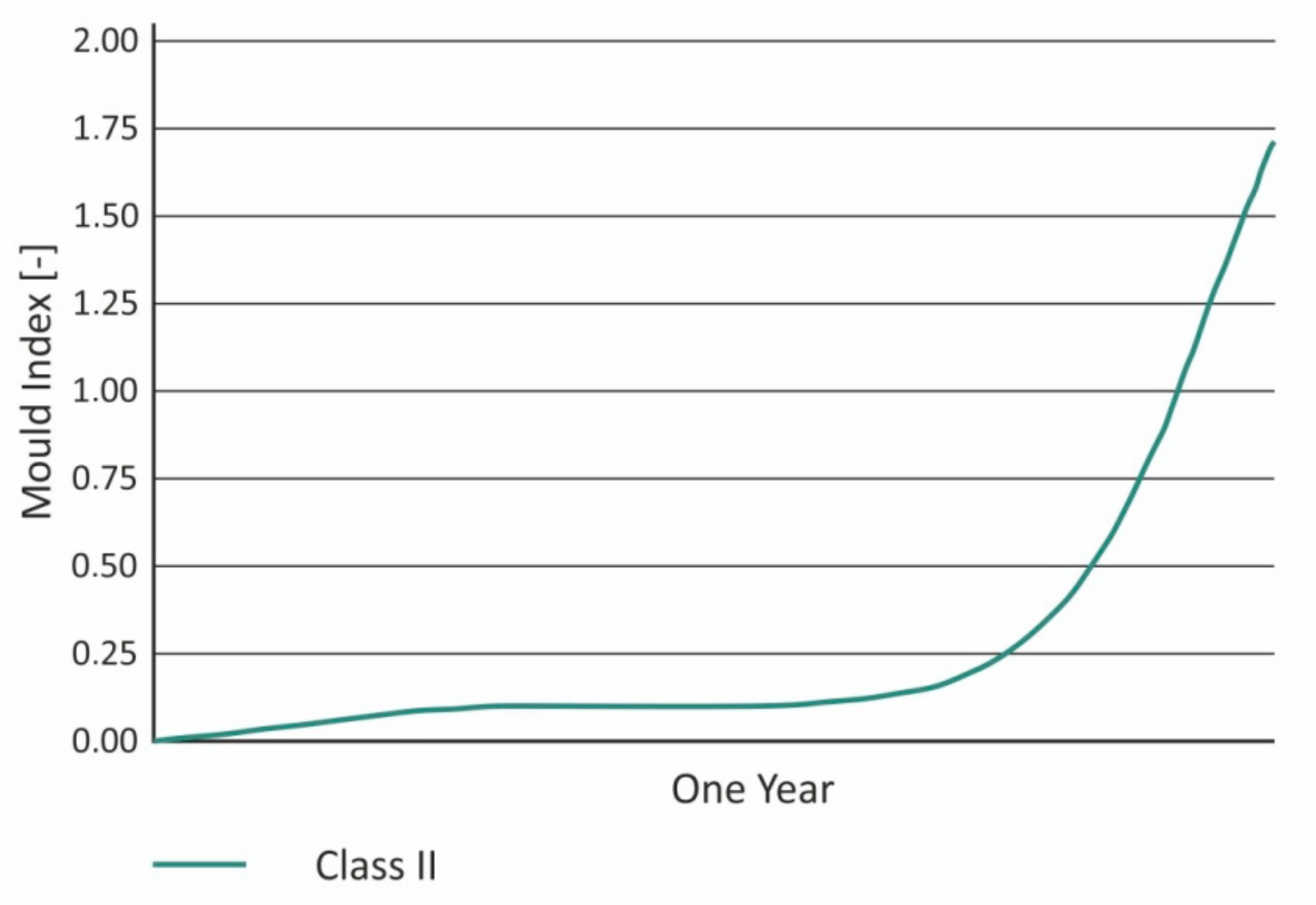

3.2.2. Biohygrothermal Model

- EN 15026

- ISO 13788

- the measurement data were taken from the research stand (temperature, humidity—for option No. 2)

4. Conclusions

Funding

Conflicts of Interest

References

- Viitanen, H.; Ojanen, T.; Peuhkuri, R. Mould growth modelling to evaluate durability of materials. In Proceedings of the 12DBMC—International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Viitanen, H.; Vinha, J.; Salminen, K.; Ojanen, T.; Peuhkuri, R.; Paajanen, L.; Lähdesmäki, K. Moisture and bio-deterioration risk of building materials and structures. J. Build. Phys. 2010, 33, 2010. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B. Interior insulation of masonry walls—Selected problems in the design. Energies 2019, 12, 3875. [Google Scholar] [CrossRef] [Green Version]

- Mudarri, D.; Fisk, W.J. Public health and economic impact of dampness and mold. Indoor Air 2007, 17, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Orlik-Kożdoń, B.; Rubin, J. Mould-based biodeterioration of human residential microenvironments. Izolacje 2019, 10, 52–55. [Google Scholar]

- Platt, S.D.; Martin, C.J.; Hunt, S.M.; Lewis, C.W. Damp housing, mould growth, and symptomatic health state. Br. Med J. 1989, 298, 1673–1678. [Google Scholar] [CrossRef] [Green Version]

- Piecková, E.; Jesenská, Z. Microscopic fungi in dwellings and their health implications in humans. Ann. Agric. Environ. Med. 1999, 6, 1–11. [Google Scholar]

- Howden-Chapman, P.; Saville-Smith, K.; Crane, J.; Wilson, N. Risk factors for mold in housing: A national survey. Indoor Air 2005, 15, 469. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Czerski, P.; Grześkowiak, W.; Kwaśniewska, P. Comfort of Use Assessment in Buildings with Interior Wall Insulation based on Silicate and Lime System in the Context of the Elimination of Mould Growth. Arch. Civ. Eng. 2020, 66, 89–104. [Google Scholar]

- Jaakkola, M.S.; Jaakkola, J.J.K. Indoor molds and asthma in adults. Adv. Appl. Microbiol. 2004, 55, 309–338. [Google Scholar] [CrossRef]

- Adan, O.; Samson, R. Fundamentals of Mould Growth in Indoor Environmens and Strategies for a Healthy Living; Wageningen Press Publisher: Wageningen, The Netherlands, 2011. [Google Scholar]

- Gradeci, K.; Labonnote, N.; Köhler, J.; Time, B. Mould Models Applicable to Wood-Based Materials—A Generic Framework. Energy Procedia 2017, 132, 177–182. [Google Scholar] [CrossRef]

- Szymanowska-Gwiżdż, A.; Orlik-Kożdoń, B.; Steidl, T. Selected problems involving the preservation of historical frame buildings in silesia in the context of their future thermo-renewal. ACEE Archit. Civ. Eng. Environ. 2019, 12. [Google Scholar] [CrossRef] [Green Version]

- Orlik-Kożdoń, B.; Steidl, T. Impact of internal insulation on the hygrothermal performance of brick wall. J. Build. Phys. 2017, 41, 120–134. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B.; Szymanowska-Gwiżdż, A. Impact of envelope structure on the solutions of thermal insulation from the insi de. ACEE Archit. Civ. Eng. Environ. 2018, 11. [Google Scholar] [CrossRef] [Green Version]

- Vereecken, E.; Vanoirbeek, K.; Roels, S. Towards a more thoughtful use of mould prediction models: A critical view on experimental mould growth research. J. Build. Phys. 2015, 39, 102–123. [Google Scholar] [CrossRef]

- Vereecken, E.; Saelens, D.; Roels, S. A comparison of different mould prediction models. In Proceedings of the Building Simulation 2011: 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011. [Google Scholar]

- Vereecken, E.; Roels, S. Review of mould prediction models and their influence on mould risk evaluation. Build. Environ. 2012, 51, 296–310. [Google Scholar] [CrossRef] [Green Version]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Sedlbauer, K. Prediction of Mould Fungus Formation on the Surface of and Inside Building Components; Fraunhofer Institute: Stuttgart, Germany, 2001. [Google Scholar]

- ISO 13788:2012. Hygrothermal Performance of building components and building elements—Internal surface temperature to avoid critical surface humidity and interstitial condensation—Calculation methods. EN ISO 2019, 46. [Google Scholar]

- Johansson, S.; Wadsö, L.; Sandin, K. Estimation of mould growth levels on rendered façades based on surface relative humidity and surface temperature measurements. Build. Environ. 2010, 45, 1153–1160. [Google Scholar] [CrossRef] [Green Version]

- Adan, O. On the Fungal Defacement of Interior Finishes. Ph.D. Thesis, University of Technology, Eindhoven, The Netherlands, 1994. [Google Scholar]

- Hukka, A.; Viitanen, H.A. A mathematical model of mould growth on wooden material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Ayerst, G. The effects of moisture and temperature on growth and spore germination in some fungi. J. Stored Prod. Res. 1969, 5, 127–141. [Google Scholar] [CrossRef]

- Smith, S.L.; Hill, S. Influence of temperature and water activity on germination and growth of Aspergillus restrictus and A. versicolor. Trans. Br. Mycol. Soc. 1982, 79, 558–560. [Google Scholar] [CrossRef]

- Clarke, J.; Johnstone, C.; Kelly, N.J.; McLean, R.; Anderson, J.; Rowan, N.J.; Smith, J. A technique for the prediction of the conditions leading to mould growth in buildings. Build. Environ. 1999, 34, 515–521. [Google Scholar] [CrossRef]

- Hens, H.L.S.C. Fungal Defacement in Buildings: A Performance Related Approach. HVAC&R Res. 1999, 5, 265–280. [Google Scholar]

- WUFI. PC-Program for Calculating the Coupled Heat and Moisture Transfer in Building Components Fraunhofer Institute for Building Physics. Available online: www.wufi-pro.com (accessed on 26 August 2020).

- Senkpiel, K.; Ohgke, H. Beurteilung der “Schimmelpilz”-Sporen- konzentration in der Innenraumluft und ihre gesundheitlichen Auswirkungen. Festleg. eines Erfahr. Gesundh. 1992, 113, 42–45. [Google Scholar]

- Schwantes, H.O. Biologie der Pilze; Eugen Ulmer-Verlag: Stuttgart, Germany, 1996. [Google Scholar]

- Grant, C.; Hunter, C.; Flannigan, B.; Bravery, A. The moisture requirements of moulds isolated from domestic dwellings. Int. Biodeterior. 1989, 25, 259–284. [Google Scholar] [CrossRef]

- Hunter, C.; Grant, C.; Flannigan, B.; Bravery, A. Mould in buildings: The air spora of domestic dwellings. Int. Biodeterior. 1988, 24, 81–101. [Google Scholar] [CrossRef]

- Block, S.S. Humidity Requirements for Mold Growth. Appl. Microbiol. 1953, 1, 287–293. [Google Scholar] [CrossRef] [Green Version]

- Coppock, J.B.M.; Cookson, E.D. The effect of humidity on mould growth on constructional materials. J. Sci. Food Agric. 1951, 2, 534–537. [Google Scholar] [CrossRef]

- Pasanen, A.-L.; Juutinen, T.; Jantunen, M.; Kalliokoski, P. Occurrence and moisture requirements of microbial growth in building materials. Int. Biodeterior. Biodegrad. 1992, 30, 273–283. [Google Scholar] [CrossRef]

- Gobakken, L.R.; Høibø, O.A.; Solheim, H. Factors influencing surface mould growth on wooden claddings exposed outdoors. Wood Mater. Sci. Eng. 2010, 5, 1–12. [Google Scholar] [CrossRef]

- Reiß, J.; Erhorn, H. Instationäre Bauphysikalische Randbedingungen zum Einsetzen des Schimmelpilzwachstums auf Bauteiloberflächen; IBP-Bericht WB 78/1994 des Fraunhofer-Instituts für Bauphysik: Stuttgart, Germany, 1994. [Google Scholar]

- Bieberstein, H. Schimmelpilze in Wohnräumen—Was Ist Zu Tun? Alpha & Omega-Verlag: Stuttgart, Germany, 1995. [Google Scholar]

- Ritschkoff, A.C.; Viitanen, H.; Koskela, K. The response of building materials to the mould exposure at different humidity and temperature conditions. In Proceedings of the Healthy Buildings 2000, Espoo, Finland, 6–10 August 2000; pp. 317–322. [Google Scholar]

- Gertis, K.; Erhorn, H.; Reiß, J. Klimawirkungen und Schimmelpilzbildung Bei Sanierten Gebäuden. In Proceedings of Bauphysik Kongreß; DFG-Forschungsschwerpunkt: Berlin, Germany, 1999; pp. 241–253. Available online: http://publica.fraunhofer.de/dokumente/PX-20556.html (accessed on 26 August 2020).

- Verdier, T.; Coutand, M.; Bertron, A.; Roques, C. A review of indoor microbial growth across building materials and sampling and analysis methods. Build. Environ. 2014, 80, 136–149. [Google Scholar] [CrossRef] [Green Version]

- Zöld, A. Mindestluftwechsel im praktischen Test. HLH—Heiz. Lüftung Haustech. 1990, 41, 620–622. [Google Scholar]

- Cziesielski, E.; Schimmelpilz—Ein komplexes Thema. Wo liegen die Fehler? Wksb—Zeit-schrift für Wärmeschutz—Kälteschutz—Schallschutz—Brandschutz 44 (1999), H. 43, S. 25–28. Available online: http://scholar.google.com/scholar_lookup?title=Schimmelpilz%20%E2%80%93%20ein%20komplexes%20Thema.%20Wo%20liegen%20die%20Fehler%3F&author=E..%20Cziesielski&journal=wksb%20%E2%80%93%20Zeitschrift%20f%C3%BCr%20W%C3%A4rmeschutz%20%E2%80%93%20K%C3%A4lteschutz%20%E2%80%93%20Schallschutz%20%E2%80%93%20Brandschutz&volume=44&issue=43&pages=25-28&publication_year=1999 (accessed on 26 August 2020).

- Richter, W. Verhinderung der Schimmelpilzbildung—Welche Möglichkeiten bietet die Fensterlüftung. Vortr. -Manuskr. Rosenh. Fenstertage 1999, 14, 15. [Google Scholar]

- Deacon, J.W. Modern Mycology, 3rd ed.; Wiley: Hoboken, NJ, USA, 1997. [Google Scholar]

- Goesten, A.J.P.M. Hygrothermal Simulation Model: Damage as a Result of Insulating Historical Buildings. Master’s Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2016. [Google Scholar]

- EN 15026-2007. Hygrothermal Performance of Building Components and Building Elements. Assessment of Moisture Transfer by Numerical Simulation. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030124008 (accessed on 26 August 2020).

- Krus, M.; Sedlbauer, K.; Seidler, C.M. Übertragung des Mould-Indexes auf das biohygrothermische Modell zur Schimmelpilzvorhersage. GI-Gesundh. Ing. 2011, 132, 32. [Google Scholar]

| Minimal Relative Humidity (1) [%] | Temperature [°C] | Duration [h/d] (2) | Comments | |

|---|---|---|---|---|

| Time Per Day [h/d] | Number of Days [d] (3) | |||

| 75 | Below 20 °C | 12 | 5 | Different materials |

| 80 | TOW method | 12 | Every day | Gypsum board |

| 95 | 14 | <24 | 6 weeks | Plasters and paint coatings (free of dirt) |

| 18.5 | 6 | |||

| 14 | <24 | Plaster with slight dirt | ||

| 6 | Dispersion paint, plasterboard (with dirt) | |||

| 18.5 | 1 | |||

| Material/Layer | Thickness [m] | Thermal Conductivity Coefficient λ [W/mK] | Diffusion Resistance Coefficient µ [-] | Bulk Density [kg/m3] | Porosity ε [-] |

|---|---|---|---|---|---|

| Gypsum plaster | 0.010 | 0.20 | 8.3 | 850 | 0.65 |

| Cement lime plaster | 0.015 | 0.80 | 16 | 1900 | 0.24 |

| Solid brick | 0.38 | 0.60 | 15 | 1800 | 0.31 |

| Porous hollow brick | 0.38 | 0.16 | 5 | 180 | 0.89 |

| Mineral wool | 0.10 | 0.038 | 1 | 25.2 | 0.95 |

| Elevation mineral plaster | 0.01 | 0.87 | 8 | 1024 | 0.61 |

| Heat transfer resistance on the outdoor surface Rse 0.04 [m2K/W] Heat transfer resistance on the indoor surface (condensation hazard in the corner) Rsi:0.25 [m2K/W] The quantities were measured on the research stand for the corner-type place (average values for the month of February (the worst climate conditions), Upper Silesia (Katowice)—Poland: ti: 20 °C, te: (−2.4) °C (www.climateonebuilding.org). The case where the measurement data obtained for variant 2 was adopted was also considered. Mold growth is still observed in the corners. Calculations were made for the following data: temperature on the wall surface in the corner (measurement) θsi: 18.2 °C; outside temperature (measurement) te: (−0.72 °C), inside air temperature (measurement) ti: 21.6 °C. | |||||

| Outdoor Climate Te [oC] | Indoor Climate Ti [oC] | Flat Surface θi [oC] | Corner Surface θi [oC] | |

|---|---|---|---|---|

| Measurement (average values for the month of February) | −0.72 | 21.6 | 19.23 | 18.23 |

| Standard conditions ISO 13788(3D calculations) | −2.4 | 20.0 | 18.96 | 17.32 |

| Factor fRsi | Measurement | 0.895 | 0.850 | |

| Modeling | 0.953 | 0.880 | ||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orlik-Kożdoń, B. Microclimate Conditions in Rooms: Their Impact on Mold Development in Buildings. Energies 2020, 13, 4492. https://doi.org/10.3390/en13174492

Orlik-Kożdoń B. Microclimate Conditions in Rooms: Their Impact on Mold Development in Buildings. Energies. 2020; 13(17):4492. https://doi.org/10.3390/en13174492

Chicago/Turabian StyleOrlik-Kożdoń, Bożena. 2020. "Microclimate Conditions in Rooms: Their Impact on Mold Development in Buildings" Energies 13, no. 17: 4492. https://doi.org/10.3390/en13174492

APA StyleOrlik-Kożdoń, B. (2020). Microclimate Conditions in Rooms: Their Impact on Mold Development in Buildings. Energies, 13(17), 4492. https://doi.org/10.3390/en13174492