Isolated power systems (IPSs) have historically relied on diesel generation given the accessibility, reliability and maintainability of the technology. More recently IPSs have started to integrate renewable generation, as awareness of the economic and environmental impacts of diesel generation have become known [

1,

2]. Wind and solar photovoltaic (PV) represent the two most common renewable technologies employed to reduce diesel consumption, however, both are stochastic, and unable to eliminate diesel generation entirely [

3,

4]. To eliminate diesel generation, enabling technologies such as energy storage are required. Unfortunately, storage is currently expensive and complex, making it unsuited for the majority of IPSs [

5,

6]. In response, a number of IPSs with improved generation and load control have been created to mitigate the need for storage [

7,

8,

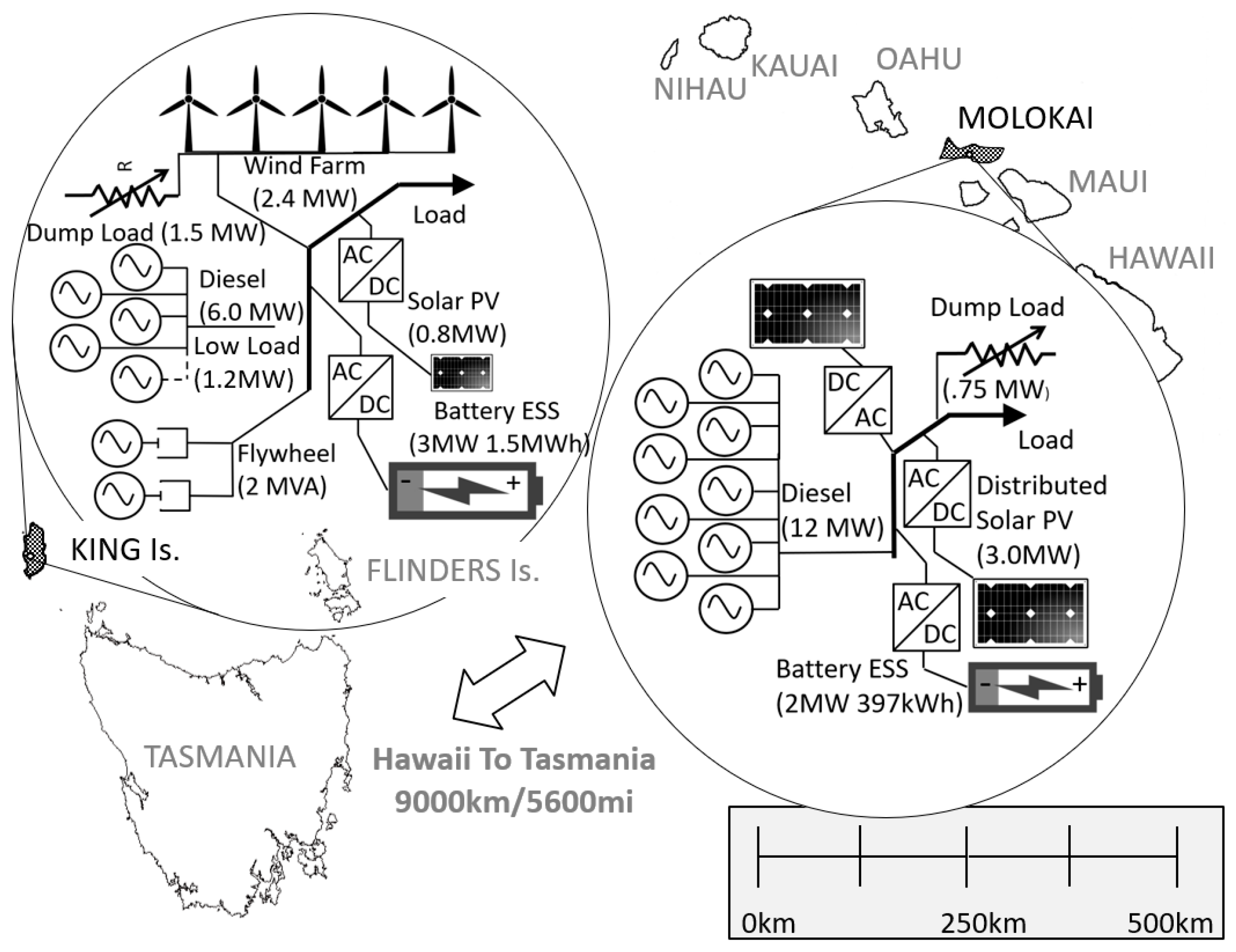

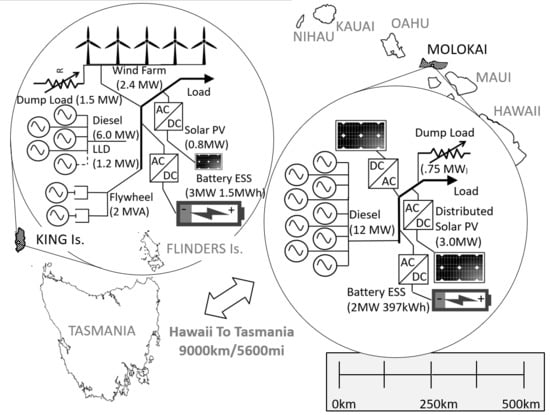

9]. To this end, this paper assesses the role of low-load diesel within two innovative case studies, King Island, Tasmania, a high-penetration wind IPS, and the island of Moloka`i, Hawai`i, a low-penetration solar PV IPS with ambitious near-term renewable targets. The novelty of this paper lies in identifying alternative approaches to energy storage integration, validating this approach via case study review within both wind- and solar-dominated IPSs. The case studies selected, Moloka`i Hawai`I, and King Island, Tasmania, Australia, represent the current best practice for renewable integration,

Figure 1.

Owing to their small size, high diesel fuel cost and resilient communities, islanded IPSs are some of the earliest adopters of renewable generation technologies [

10]. King Island is a case in point, representing one of the world’s first megawatt-scale highly renewable penetration power systems. Early adopters, such as King Island, have an important role to play in the adoption, testing and commercialisation of renewable generation and enabling technologies. The challenge in leveraging and redeploying experiences, such as those obtained on King Island, has always been how to scale these approaches for larger markets while consolidating capital cost [

11].

Larger systems are generally slower to reach high renewable penetrations, owing to the large capacity of renewable generation required. In this regard, the lessons learnt from IPSs can both accelerate and derisk renewable integration in larger markets. The island of Moloka`i, Hawai`i represents one such case study. Larger than King Island, and reliant on residential solar PV instead of wind, the island is looking to scale existing high renewable penetration experience, leveraging technologies such as those deployed on King Island to meet local targets for 100% renewable generation. In reviewing the technology options available to Moloka`i, this paper presents a general introduction to the legacy technology progression within Hawai`i and Australia in

Section 1.1, ahead of a case study review in

Section 1.2 and

Section 1.3. The paper’s modelling methodology, results, and conclusions are presented in

Section 2,

Section 3 and

Section 4, respectively.

1.1. The Technology Legacy of Hawaiian and Australian Isolated Power Systems.

Wind was first pioneered in Hawai`i as part of the US Department of Energy’s federal wind program. Administered by NASA, the program targeted the realisation of a sub 5 c/kWh levelized energy cost. This pioneering experience was quickly followed by multiple wind turbine developments across the islands of O`ahu, Maui, Hawai`i and Moloka`i,

Table 1. For most of the 1980s, Hawai`i led global wind technology development, hosting the world’s largest wind turbine, the Boeing Mod-5B, a 3.2 MW twin blade turbine presenting an impressive 97 m diameter rotor. The heyday of Hawaiian wind development, unfortunately, came to an end shortly afterwards, signaling a loss in social license for wind development across the islands [

12]. In stark contrast, Hawai`i has enthusiastically embraced solar PV, supported by attractive resource and net energy metering policy (2001–2015). Perhaps most importantly for Hawai`i, solar PV has also proven to be highly modular and scalable, placing the technology within community reach. Hawai`i currently generates approximately 11.2% of its load via combined centralised and distributed solar PV schemes [

12]. This compares favourably to Australian and US averages of 5.2% and 2.3%, respectively [

13,

14]. The uptake has been so successful that, for many of the Hawaiian Islands, the adoption of solar PV has reached, or is rapidly approaching, the system’s hosting capacity. Moloka`i is a case in point, exhibiting instantaneous midday solar penetrations exceeding 75%, despite a relatively low annual penetration of below 14%.

Effective in displacing diesel generation, however in general, their performance offered poor reliability and reliance [

15]. While early Australian trials were not to the extent of the Hawaiian research, they ushered in Australia’s first wind farm at Salmon Beach, Western Australia (1987), and then a second at Huxley Hill, King Island, Tasmania (1998). In contrast to the Hawaiian experience, Australia’s slow uptake found roots, with wind technology transitioning to broader network application. Tasmania currently generates approximately 9.7% of its total load via wind generation, ahead of the Australian and US national averages of 7.1% and 6.5%, respectively [

13,

14]. In contrast, 4.9% of Hawai`i’s energy is wind derived, despite modern wind projects realising the 5 c/kWh price point originally envisaged by the US department of energy [

16]. For reference, Hawai`i’s energy tariffs currently exceed 28 c/kWh across most islands.

Australia also adopted wind turbine technology during the 1980s, wind representing the only viable renewable technology of the era. The best of these early wind turbines proved to be cost

In this regard, our two case studies (

Table 2) are representative of broader regional preferences, with Moloka`i a solar-dominated decentralised IPS and King Island a wind-dominated centralised IPS.

1.2. King Island

Hydro Tasmania initially hybridised the King Island IPS to explore wind technologies in the late 1990s, with the system subsequently expanded via the integration of solar PV, batteries and flywheel technologies. This section considers the King Island experience, in particular efforts to reduce the cost and complexity of many of the developed applications.

Situated between Victoria and Tasmania, Australia, King Island is located within the strategic shipping channel of Bass Strait. The wind resource on King Island, averaging 9.0 m/s at 60 m elevation, is now employed to power King Island’s IPS. Over 50% of King Island’s annual demand is met via the 2.45 MW of installed wind capacity. The remainder of King Island generation consists of 0.8 MW of uncontrolled residential solar PV and 7.2 MW of diesel generation,

Table 3 [

17]. Annual renewable generation, wind and solar combined, contributed over 60% of the islands load last year,

Figure 2, with the system running diesel off for 20% of the year. To support system security a range of enabling technologies are employed on King Island, including a 3 MW, 1.5 MWh advanced lead acid battery energy storage system (BESS), a 2 MVA diesel coupled flywheel energy storage system, 0.1 MW of residential demand side management and a 1.5 MW resistive dump load. The King Island IPS is managed by an automated IPS controller, allowing the system to operate unattended.

The dispatch strategy adopted on King Island targets the maximum utilisation of the available wind generation. Solar PV generation is not a large determinant within the control methodology, as the utility has no visibility or control of this component of the system. Instead, dispatchable generation is scheduled to respond to load and resource variability. The diesel dispatch strategy progressively adds diesel capacity interchangeably, with the exception that the first diesel on and the last diesel off is the MTU low-load unit. In contrast the CAT engines, which adopt a 40% low-load limit, the MTU is warranted to 10% loading, assisting renewable penetration under high wind contribution.

Huxley Hill wind farm was commissioned in 1998, initially consisting of three Nordex N29 wind turbines (0.75 MW total). Huxley Hill wind farm initially reduced diesel consumption by one fifth. Encouraged, Hydro Tasmania integrated additional renewable capacity in 2004, adding two Vestas V52 turbines (1.7 MW total). In support, a 200 kW, 800 kWh vanadium redox flow battery (VRB) was also integrated the same year. The VRB uses aqueous vanadium electrolytes separated by a proton exchange membrane. Ion exchange provides an energy storage concept offering long service life and tolerance to high cycle rates and depths of discharge. Unfortunately, the flow battery proved complex and difficult to maintain. The failure of the VRB electrolyte containment resulted in the decommissioning of the battery shortly after installation. Without storage, system operation required the set point control of the wind production (renewable spillage) to ensure system security. Despite the failure of the VRB, renewable penetration exceeded one third of the system load, with King Island able to demonstrate medium levels of renewable penetration from 2005.

This milestone signified an important achievement for renewable integration within Australia. Leveraging this experience, Hydro Tasmania then embarked on a period of research and development encompassed by the King Island renewable integration program. King Island allowed Hydro Tasmania to assess a range of emergent renewable technologies, including, solar photovoltaics (2008), concentrated solar thermal (2009), flywheel energy storage (2011), biodiesel (2012), residential load shedding (2012), battery storage (2014), low-load diesel (2015) and wave generation (2020). The King Island renewable integration program is primarily responsible for the current system performance, exceeding 60% penetration. The technology successes and failures observed across this period remain relevant to a range of current applications and markets, including both isolated and networked power systems globally. Of the technologies to fail, both the concentrated solar thermal and dual axis solar PV systems were early casualties. The solar PV tracking failed due to repeat failures within the hydraulic tracking mechanism, and despite the solar PV panels being unaffected, remediation costs have prevented system reinstatement. In contrast, the concentrated solar thermal project, envisaged to consist of six 19T elevated graphite solar storage receivers, was never implemented. Ironically, the dynamic resistive heating element, developed as a complementary heating source has evolved into a flexible enabling technology in its own right. During the testing of the resistive load, it became clear that the fast and accurate response provided value as a dispatchable load, specifically offering fast frequency raise reserve. The adoption of a resistive dump load allowed Hydro Tasmania to operate wind generation unconstrained, providing improved system inertia and capacity firming. The resistive dump load provides capacity firming via either dispatch or the withdrawal of the load in a fraction of a second, as required to smooth the accompanying wind generation. In this manner, the resistive load contributes to frequency regulation, lowering the reserve requirements, and reducing diesel consumption and maintenance. The role of the resistor is illustrated in

Figure 3, where control transfers between the battery, resistor and diesel generation. The plot shows a transition from battery charging (hour 1), to discharging (hour 3). The system load dips mid-plot, during which the resistive load is used to spill surplus renewable generation. As the load increases, the battery resumes control, injecting energy until a drop in wind production triggers a diesel start (hour 4). Prior to this, the system was running diesel off.

The transient response of the BESS and resistive load is further illustrated in

Figure 4, inclusive of flywheel energy exchange. The plot covers a two-minute interval of steady system load, approximating 1.7 MW. A rapid drop in wind generation (t = 20 s) requires inertia support from the flywheel and a discontinuation of resistive spill. The battery responds to inject energy shortly after, allowing the flywheel to resume 50 Hz operation. Had the battery state of the charge been insufficient, the flywheel would have coupled to a paired diesel engine, performing a diesel fast start via the integrated mechanical clutch. In this instance the combination of the battery, resistor and flywheel mitigated the need to bring diesel generation online. The flywheel technology consists of two 12 T horizontal steel flywheels, each coupled to a 1 MVA diesel generator. These engines are not used outside of the provision of fast start diesel response, given the large mechanical loads and reduced service life imposed during the engagement of the mechanical clutch. The role of the flywheel within the King Island IPS is to provide inertia and a fast-start diesel contingency to both dampen and respond to variable renewable output. The fast start diesel response occurs over a few seconds, with the load transferred to the conventional diesel assets as they are brought online over a matter of minutes. The coupling of the flywheel to a diesel engine provides a system response extending beyond the 30 s of inertia available from the two flywheels. During diesel off operation, both flywheels will be operational. At other times of high renewable penetration, a single flywheel will typically be operational. Under medium or low renewable penetration, the flywheels are turned off to reduce the ~60 kW of parasitic load required to keep each unit spinning.

To allow for extended diesel off operation, a 3 MW, 1.5 MWh advanced lead acid BESS was integrated in 2014. The battery extended the time for which the system could remain diesel off, having accumulated over 12,000 h of diesel off operation to date. A typical daily load and generation profile is shown in

Figure 5, with the twin peak load profile evident. The plot shows a five-hour diesel off period from midday, as the afternoon sea breeze produces surplus renewable generation. Throughout this period, the battery transitions from an energy source (hours 9–10) to a sink (hours 10–11), until the resistor is deployed to spill surplus renewable (hours 11–1). As the afternoon load peaks, diesel generation is again brought back online. The battery charges into the evening, indicating the inability of diesel generation to reduce its output below its operational low-load limit. The role of low-load diesel within the King Island power system is to reduce the occurrence of excess renewable generation. This is achieved by permitting the low-load diesel unit to run down to 10% of its rated capacity during periods of high wind generation.

1.3. Moloka`i Hawai`i

Maui Electric Company (MECO) have established a target for Moloka`i to achieve 100% renewable energy (RE) by 2020 [

18]. In doing so, Moloka`i will be the first Hawai`i island to reach this milestone, setting a roadmap for the other islands of Hawai`i and US states to follow. This section considers to what role coordinated generation can be utilised in support of these goals. Modified diesel application is assessed via simulation of a low-load diesel operating scenario. This paper addresses operational dependencies between generation, load and storage, quantifying to what extent generation and load flexibility can provide improved near-term renewable hosting capacity.

The island of Moloka`i is located centrally within the Hawaiian archipelago, between the larger islands of O`ahu, to the west, and Maui, to the East. Approximately 90 km east of Honolulu, the coastal proximity to both O`ahu and Maui is under 40 km. The island’s population is approximately 8000, of which around 40% assert native Hawaiian ancestry. Tourism, cattle, and diversified agriculture represent the island’s major economies. The electrical demand on Moloka`i peaks at around 4500 kW, presenting the typical twin peak profile common to many island communities,

Figure 6. Notably, in recent years, the increase in the capacity of residential solar PV has had a notably depressed midday load. It is also interesting to note the absence, for the time being, of centralised utility renewable development on the island, in part due to strong local opposition to large-scale development, viewed as incompatible with local customs and culture [

12].

Blessed with abundant wind and solar resources, it is somewhat surprising to note the absence of centralised renewable generation on Moloka`i. The scenario is even more surprising considering MECO’s early exposure to renewable generation. Unfortunately, the failure of these early projects to be inclusive of community concerns, combined with disinterest from MECO to own and operate renewable assets, have reduced the investment in centralised generation. In contrast, since 2009, the installed capacity of uncontrolled (unable to receive a utility set point) residential solar PV has increased markedly on Moloka‘i, so much so that from 2015 to 2018 further solar PV interconnection was restricted, with the system’s hosting capacity for uncontrolled solar PV saturated. Solar PV hosting capacity is the ability of the system to accept additional PV generation without pushing the midday load below the systems reserve requirements, as set by the minimum load setpoint of the systems thermal generation, P

min. In response, MECO in partnership with the Hawai`i Natural Energy Institute (HNEI) installed a number of enabling or ancillary technologies, including, a 2 MW 397 kWh lithium BESS and a 750-kW resistive load bank. These technologies were instrumental in relief to hosting capacity constraint, allowing the solar PV interconnection queue to reopen. Both technologies allowed for a reduced reserve requirement, providing system flexibility to manage solar resource variability. The impact of additional solar PV capacity is evident in

Figure 6, where a Moloka`i daily load profile is shown inclusive of the solar PV as negative load. Notably, the reduced midday minimum loading evident in 2018, approaches P

min, suggesting a limited ability to further integrate additional solar PV capacity. Despite midday instantaneous solar PV saturation, annual average solar PV penetration remains low at around 14%. Considering the aggressive development timeframe outlined for a 100% renewable transition, MECO are prioritising integration of near-term enabling technologies, in parallel with discontinued replacement or purchase of diesel generation. The generators supplying Moloka‘i’s Pālā‘au Power Station,

Table 4, consist of a range of high-, medium- and low-speed diesel generation.

In general, high speed engines typically offer an improved generator response, while lower speeds offer improved inertia and peak efficiency. Heat release curves for all units were provided by the MECO, with efficiency varying significantly between engines. Part of this variation can be attributed to the significant age of the diesel asset base. Where outlier unit efficiencies were identified this data was flagged for low reliance and not used within subsequent analysis. Moloka‘i’s diesel asset base shares similarities with that of King Island, with a number of the King Island strategies adopted in advancing Moloka‘i’s renewable transition.

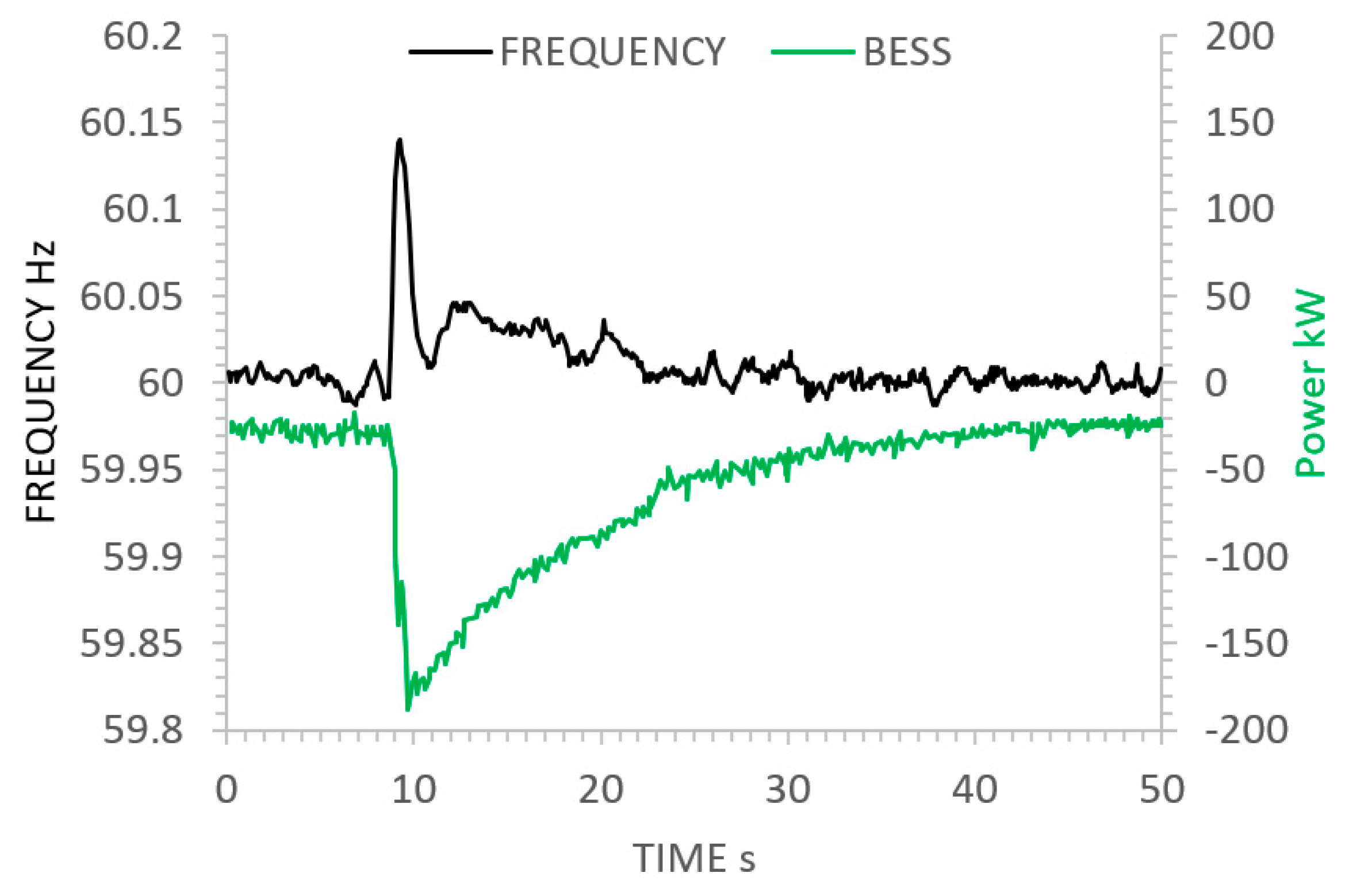

The role of the Moloka‘i battery is to provide fast-acting coordinated frequency support, improving system stability by providing the diesel generators time to respond. In this manner, the battery state of charge is maintained at 50% to provide for both the frequency rise and the lower reserve. The battery is provided with six raised and six lower set points, defining a rapid step response followed by a gradual load transfer in both over and under frequency events,

Figure 7. Significant effort has been undertaken by HNEI to improve the response time of the BESS, with a revised control architecture reducing the response latency from ~250 ms to ~60 ms, [

20]. The Moloka‘i battery is the third battery ESS installed in partnership between HECO and HNEI, with batteries also in place on O`ahu and Hawai`i island [

21]. All three batteries target fast response frequency regulation or power-smoothing applications. Additional issues encountered across BESS integration include, high inverter temperatures and communications faults. Inverter temperatures were resolved by constraint of the inverter’s reactive setpoint. Communication issues were resolved via hardware replacement.

The role of the load bank is to manage the system frequency during periods of excess solar PV generation, subject to BESS state of charge. In this application, the load bank reduces Moloka`i’s reserve requirement, providing a discretionary load to balance the grid during periods of excess energy. In assessing what additional near-term applications may further benefit Moloka`i, this paper explores the role of low-load diesel to support generator flexibility and co-ordination.