1. Introduction

With the rapid development of wireless power transfer (WPT), its remarkable flexibility, convenience and portability have been widely used in portable electronic devices, implantable medical devices, drones, smart homes and other fields [

1,

2,

3,

4,

5]. It also provides noncontact power supply to special working conditions, such as oil wells, mud and explosion-proof environments. The battery power supply has a short life because of the limited capacity, and high-power equipment requires a large number of batteries, which also indicate the importance of WPT. Due to the problems of friction, corrosion, sparks, insulation and long-term exposure to harsh environments in traditional rail transit, the application of WPT technology to electric vehicles, high-speed rail trains and magnetic levitation trains has also become a research focus in recent years [

6,

7,

8]. Moreover, considering the technical difficulties of high-power charging, pro-environmental and the limitations of mechanical connection systems in the ocean, WPT has also been applied to ship wireless high-power battery charging [

9].

With the development of more applications, the rated power of WPT systems has been continuously increased from 3 kW to 100 kW or even higher [

10]. For a metal material in a coupled magnetic field, it will be subjected to electromagnetic force (EMF) due to the eddy current effect or magnetization effect of the magnetic field [

11,

12]. With the improvement of power, the increase of excitation current and spatial coupling magnetic field will enhance the EMF of metal objects. Therefore, EMF in high-power WPT systems cannot be ignored. The research on EMF is mainly focused on the problems of vibration, noise and mechanical deformation of traditional electrical equipment. In addition, it has also been widely used in electromagnetic forming [

13,

14], electromagnetic ejection [

15,

16] and magnetic levitation technology [

17]. Synergy of melting wave and electromagnetic force on the transition mechanism is studied in reference [

18] that the mutual promotion of melt waves and EMF may cause the surface of the conductor to ablate and generate flashes and smokes, which will greatly reduce the safety performance of the equipment. A study [

19] proposed to use multiple staggered AC and DC coils to provide both electrical and mechanical energy for micro-robots. This system consists of a pair of external AC and DC staggered coils and a pair of coils located inside the micro-robot. The two internal coils are used, respectively to receive electrical energy and to generate propulsion as an electromagnet.

However, WPT use space magnetic field coupling for power transmission. The noncontact structural characteristics of the transmitting coil and the receiving coil make the WPT system vulnerable to interference by foreign metal objects during the operation [

20]. To date, most of the studies on foreign metal objects focus on the detection of foreign objects and the impact on the performance of WPT systems. For the foreign body detection methods, one of the studied methods is to place additional coil sets with different structure between the transmitting coil and receiving coil, thereby determining the presence and location of foreign objects by obtaining the changes of parameter of the coil sets [

21,

22,

23]. One of the studied method is reducing the quality factor of the secondary coil [

24].In reference [

25], a prototype of an electric vehicle capacitive WPT system was built to study the effect of different foreign objects on the system performance when they approached the coupling mechanism from the outside. It is found that when the distance between the foreign body and the coupling mechanism is less than three centimeters, the system performance will be significantly affected. However, there have been few studies that explores the relative displacement of metal foreign bodies entering the coupling space of the WPT system under the action of EMF. Metal foreign bodies under EMF may bring danger to surrounding organisms and WPT systems.

In this paper, the characteristics of directional movement of metal foreign bodies under the EMF are studied on the basis of the high-power WPT system. The paper is organized as follows:

Section 2 establishes the equivalent parameter model of the circuit and the differential equations of motion of the metal foreign body subjected to EMF, based on the virtual displacement method. The finite-element simulation is used to analyze the longitudinal and horizontal motion of different types of metals under the action of EMF in

Section 3. In

Section 4, an experimental prototype is built to verify the correctness of the characteristics.

Section 5 draws conclusions about this paper.

3. Finite-Element Simulation

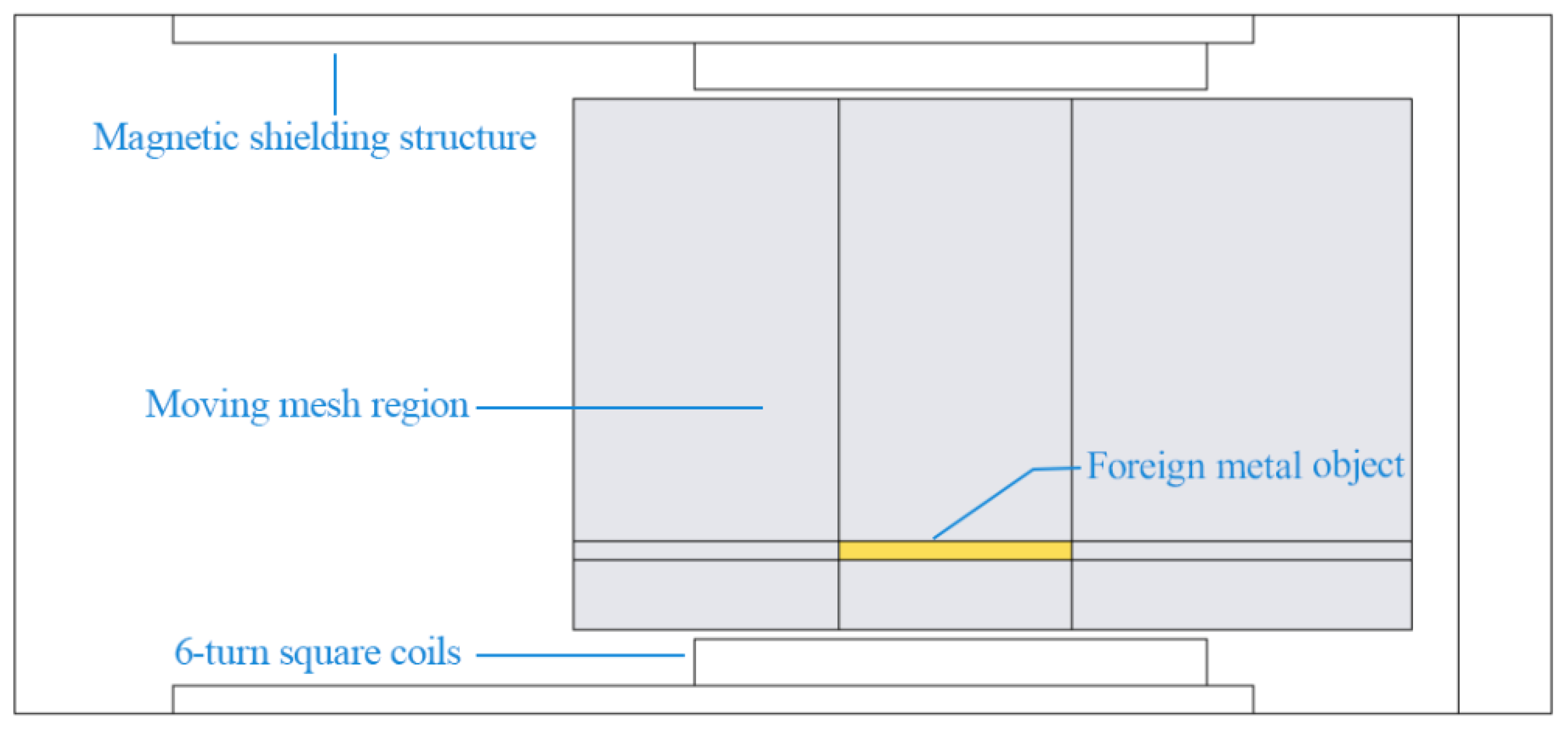

In order to further explore the motion characteristics of foreign metal object in different parameters, a simulation calculation model was established by finite-element analysis software—COMSOL Multiphysics as shown in

Figure 2. Both transmitting and receiving coils are 6-turn square coils with a size of 46.4 × 46.4 cm

2. The exciting current of the system is 171A, and the resonance frequency is 10 kHz. For the purpose of concentrating the magnetic field to get the best transmission efficiency, the coil is embedded in the E-type magnetic shielding structure to reduce leakage in space magnetic field.

In the process of calculating the dynamic characteristics of metal foreign bodies in the time-varying electromagnetic field, time-domain simulation is required. As the skin effect in high-frequency circuits cannot be neglected, in this paper, the boundary layer meshing method is used to analyze the induced current and electromagnetic force of the conductor in the time domain. We use the differential equations of motion derived in the

Section 2 and moving mesh to simulate the dynamic part of the foreign metal object. According to the different electrical parameters of metals, we choose three commonly used metals: aluminum, copper and iron for analysis. The characteristics of metal materials are listed in

Table 1.

3.1. Analysis of Longitudinal Dynamic Characteristics of Metal

Figure 2 shows that the system is axisymmetric, and the metal object is placed in the center of the coil. Hence, we selected a half of the simulation model with metal foreign bodies to calculate the magnetic field and induced eddy current—and consequently to get a more detailed mesh—which can also improve the accuracy and convergence speed of the transient solution.

In order to investigate the longitudinal dynamic characteristics of the non-ferromagnetic metal, we analyzed the movement of the 50 × 50 × 2 mm

3 -sized aluminum sheet after it enters the system by different initial positions. The transmission distance is set to 15 cm according to the actual chassis height of the electric vehicle or high-speed rail; the movable range of foreign metal objects in the longitudinal space is set to 1.8 cm–13.2 cm; the transient solution time is 150 cycles. When the initial entry position of the aluminum sheet is 2.5 cm, 6.8 cm and 12.5 cm, it is close to the transmitting coil, the intermediate position and the receiving coil, respectively.

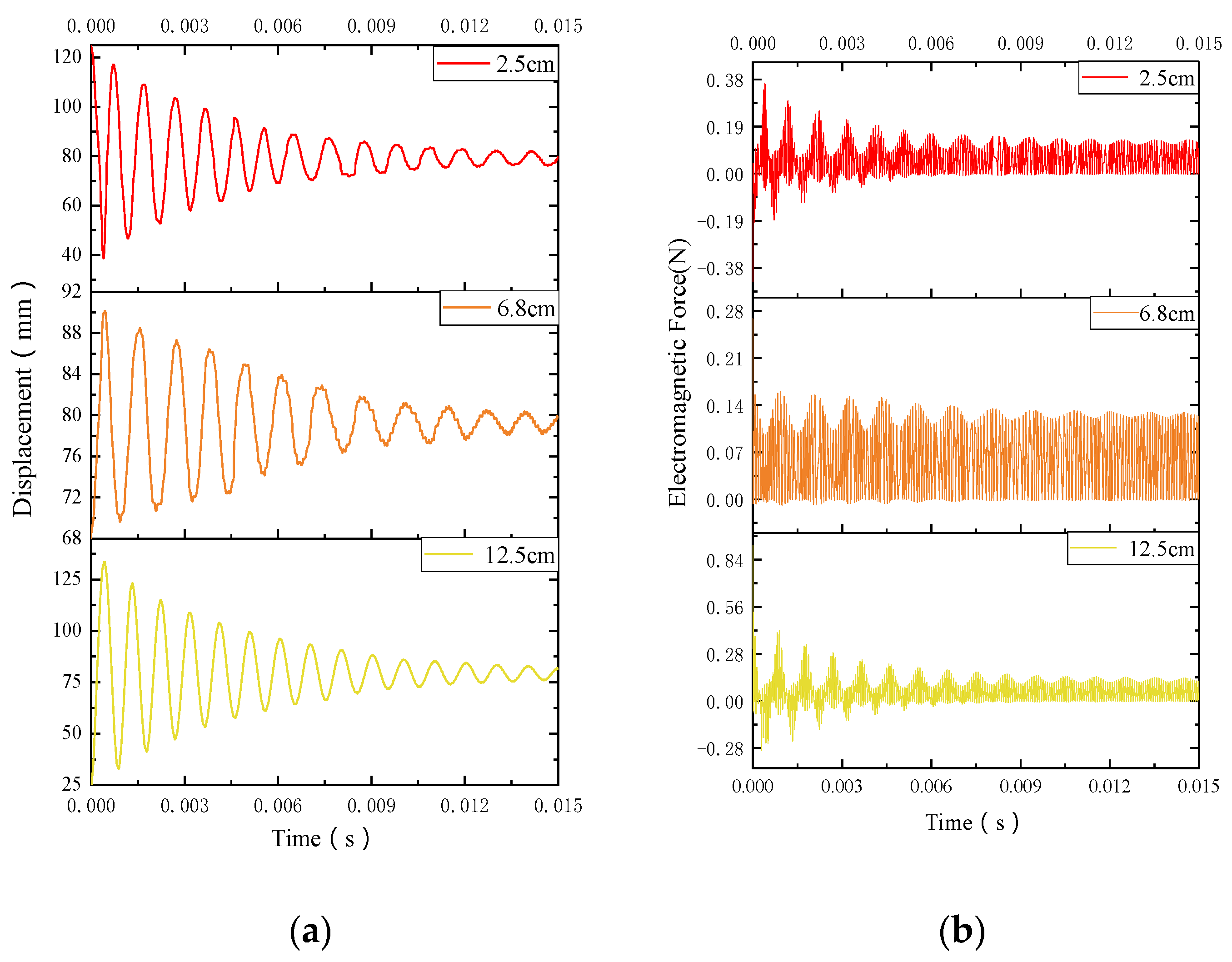

Figure 3 shows EMF and displacement at different initial positions.

When entering the spatial coupling area, due to electromagnetic repulsive, the aluminum sheet will move from the initial position be away from the coil, meanwhile, the rapid attenuation of EMF will make acceleration decrease gradually. With the balance of gravity and steady-state component of EMF, the displacement of the aluminum sheet gradually decreases, resulting in a damped oscillation process and eventually stabilized at the position of 78 mm, 79 mm and 82 mm positions, separately. By this time, the aluminum sheet has reached a relative stability, which can be regarded as a stable state. This shows that the entered position has less influence on the final stable position, however, it will affect the time of reaching stability and the movement state of metal foreign body. The closer the initial position is to the stable position, the faster the final equilibrium will be reached. When the initial position is 68 mm, metal only takes 0.009 s to achieve stability.

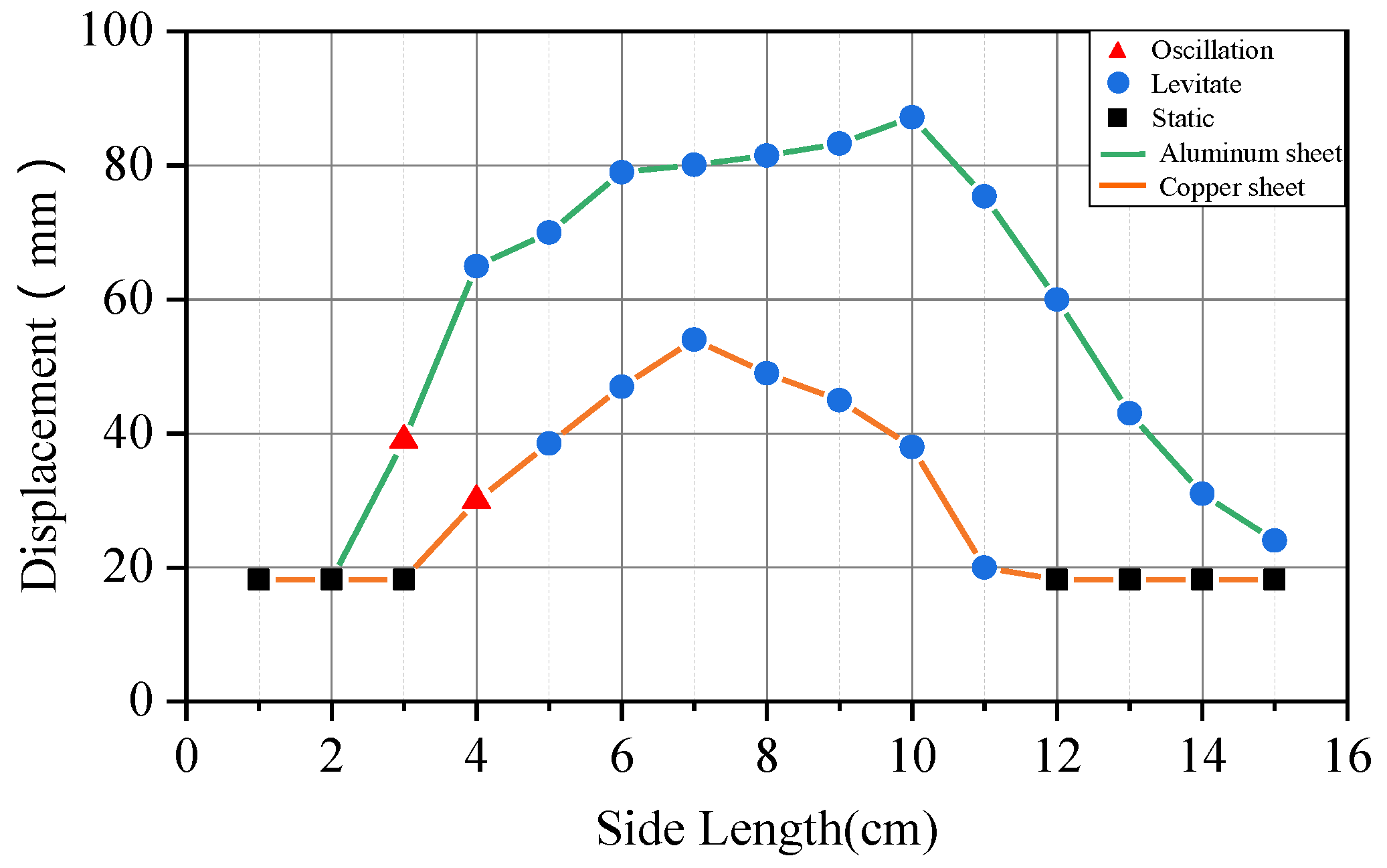

By analyzing aluminum and copper sheets of different sizes, we found that non-ferromagnetic metals have three motion states in longitudinal direction after entering a spatially coupled magnetic field of WPT system, as shown in

Figure 4. For the metal, different side lengths and densities will cause different values of EMF and gravity, and thus impact on final steady-state position. To sum up, the motion state of non-ferromagnetic metal foreign body is related to its own electromagnetic parameters, size and weight, that is, it mainly depends on whether the EMF applied to the metal foreign body during the exercise can finally balance with gravity.

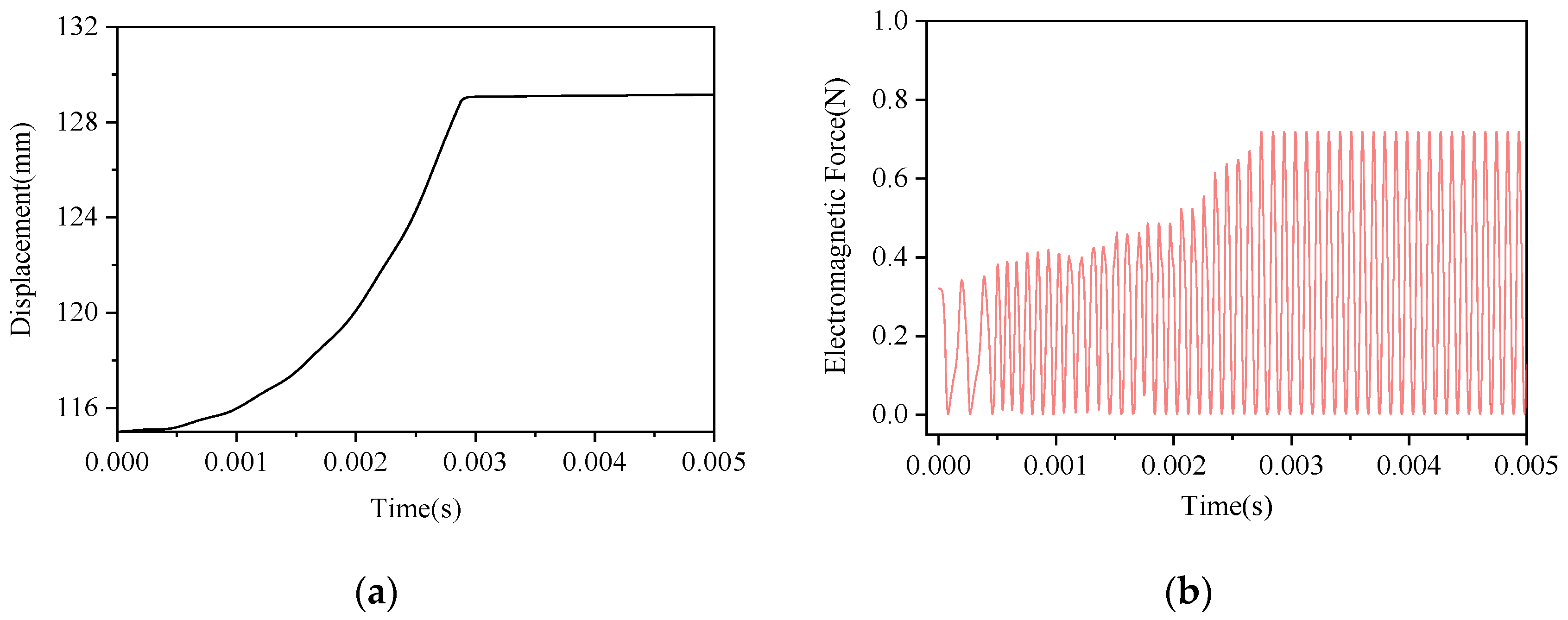

For ferromagnetic foreign matter, it is easily adsorbed on the surface of the coupling coil by electromagnetic attraction in the system. When the iron is close to the transmitting coil, the electromagnetic attraction is in the same direction as gravity, which increases the acceleration of its downward movement. The iron will quickly fall on the transmitting coil and be further attracted to the surface of the transmitting coil. When the iron keeps close to the receiving coil, it is subject to upward electromagnetic attraction. If the electromagnetic attraction force is larger than gravity, the iron will move upward and eventually adsorb on the surface of the receiving coil. As shown in

Figure 5, the iron piece in an initial position of 11.5 cm is subjected to the upward electromagnetic attraction, and it only takes 0.028 s to reach 12.8 cm where the receiving coil is. Ferromagnetic metal is easily magnetized and generates induced eddy current, its adsorption on the surface of the coil will quickly cause the rise of local temperature, power loss and high-frequency noise, which will impact the transmission efficiency, the operational safety and reliability of the WPT.

3.2. Analysis of Horizontal Dynamic Characteristics of Metal

From the derivation analysis in

Section 2, we know that the horizontal EMF on metal foreign bodies, entering the WPT system, is much smaller than the longitudinal EMF. Hence, it can be ignored in most cases. However, for the non-ferromagnetic metals, they will oscillate or suspend in the air. By this time, the horizontal EMF will cause a lateral movement of metal, may even fly out of the coupling area, which will affect the external safety.

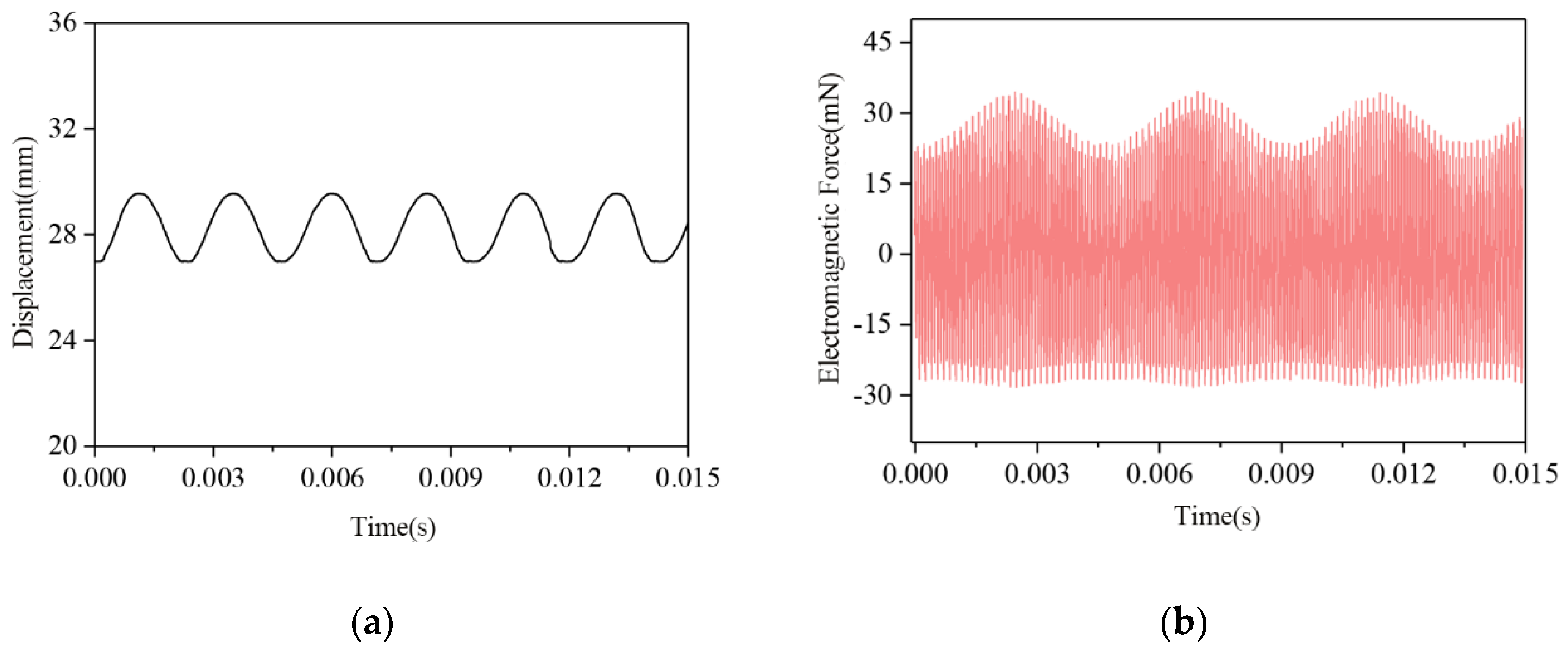

Figure 6 shows the horizontal EMF and lateral displacement of a copper sheet with the length of 5 cm and the horizontal initial position is at 27 cm in the middle of the coil.

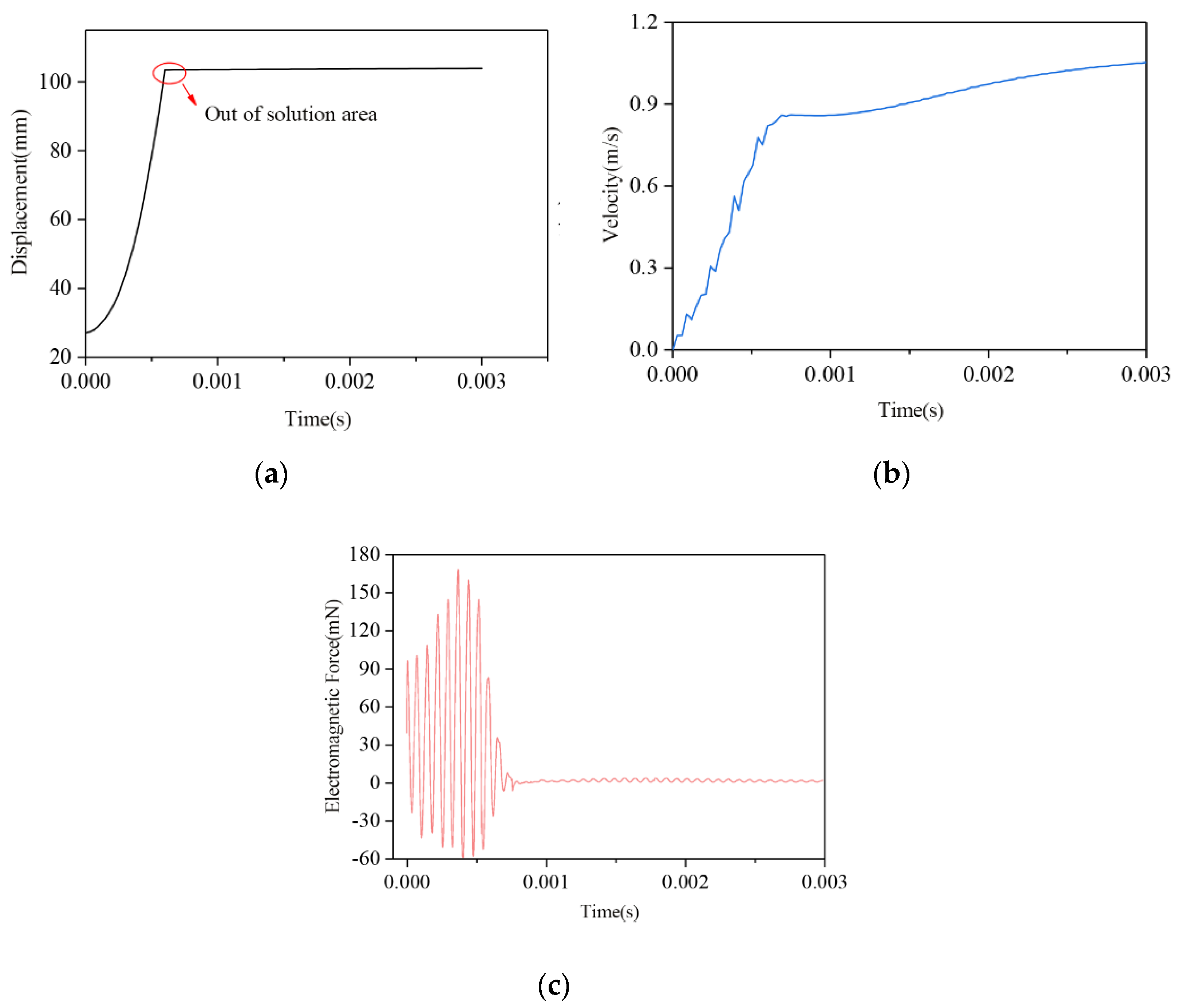

For metals with lower density such as aluminum, when it is large and thin, the effect of horizontal EMF will be very obvious. We calculated the displacement and EMF in the horizontal direction of the aluminum sheet with a size of 100 × 100 × 1 mm

3 as shown in

Figure 7. The EMF of aluminum sheet in the initial state is 37 mN, the direction is pointing out of the coil, and as the metal moves outward, the EMF gradually increases. The aluminum sheet takes around 1 ms to leave the coupling area of the system where the velocity is 0.82 m/s, as shown in

Figure 7. The horizontal EMF gradually decreases to 0 after leaving the coupling area.

4. Experiment and Discussion

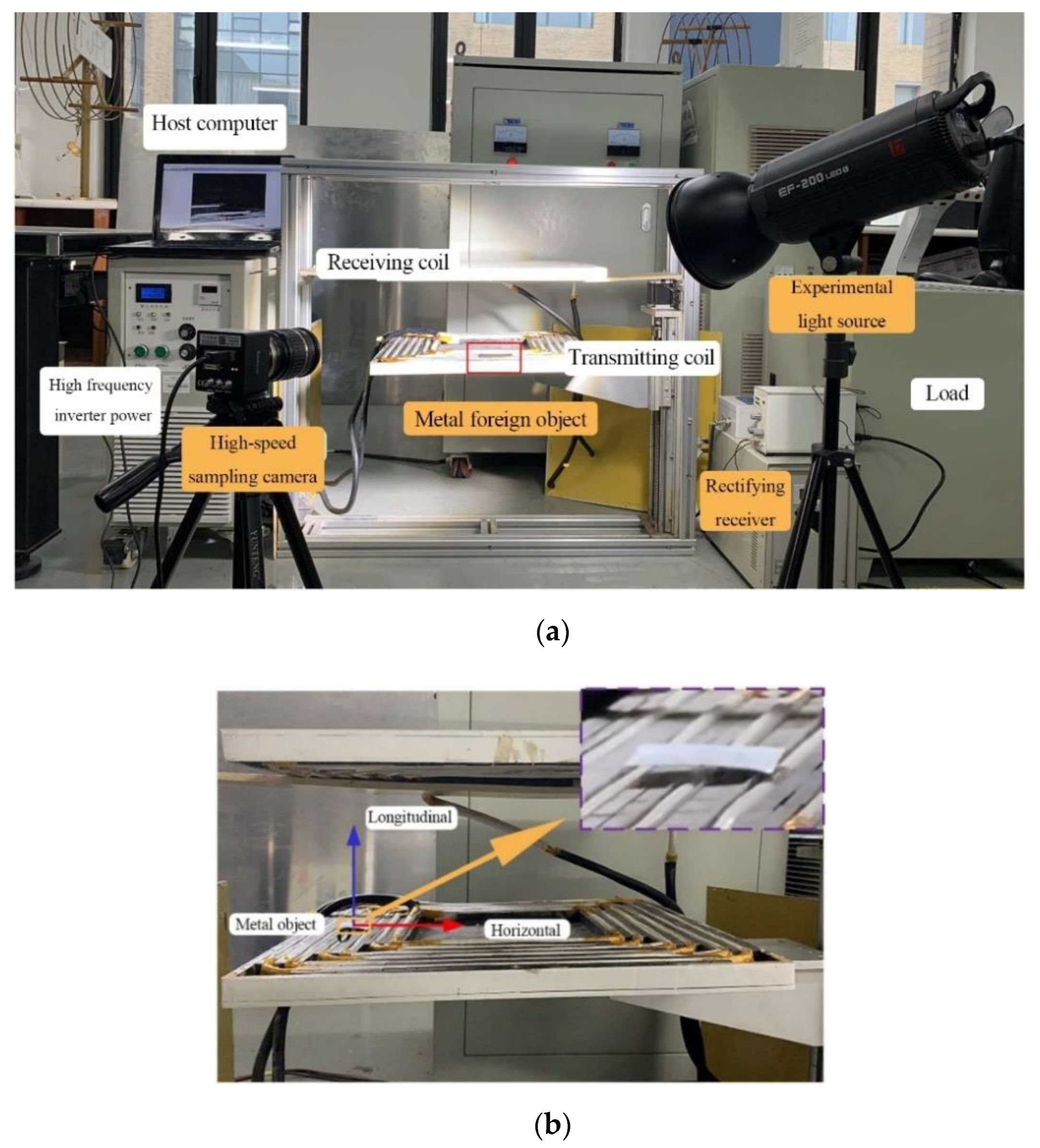

In this section, an isometric experimental prototype is built to verify the dynamic characteristics of metal foreign bodies as shown in

Figure 8 and initial power of the system is 5 kW. In order to display the motion trajectory and characteristics of metal objects intuitively, in this experiment, we used high-speed sampling camera to track and measure the movement of metal and analyze the motion characteristics of the objects according to the change in acceleration.

The direction coordinates and initial position of metal in the coil are shown in

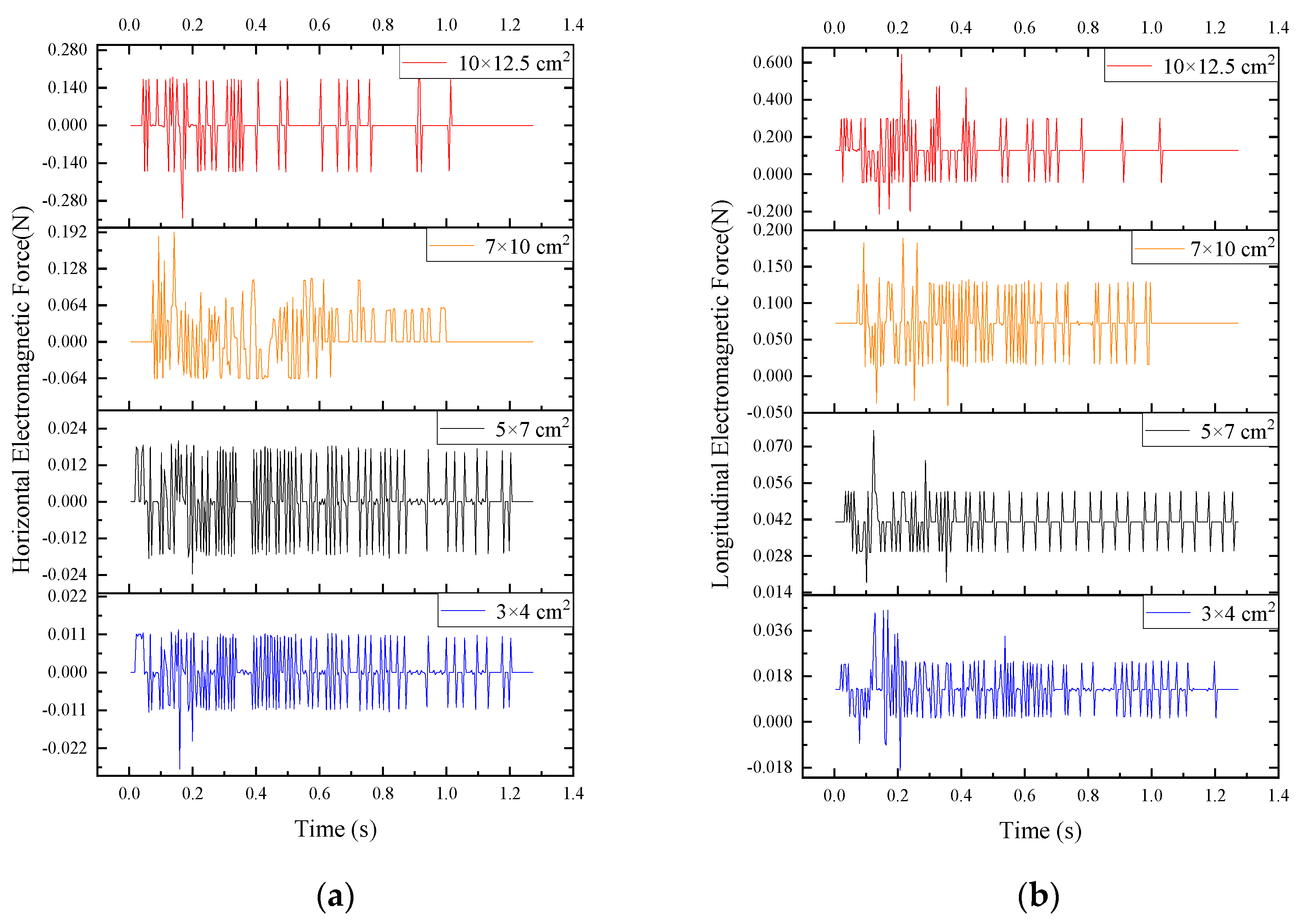

Figure 8b. By analyzing the movement trajectory of the metal foreign body, we obtained that the displacements and EMF of the aluminum sheets with dimensions of 3 × 4 cm

2, 5 × 7 cm

2, 7 × 10 cm

2 and 10 × 12.5 cm

2 in different directions in

Figure 9 and

Figure 10.

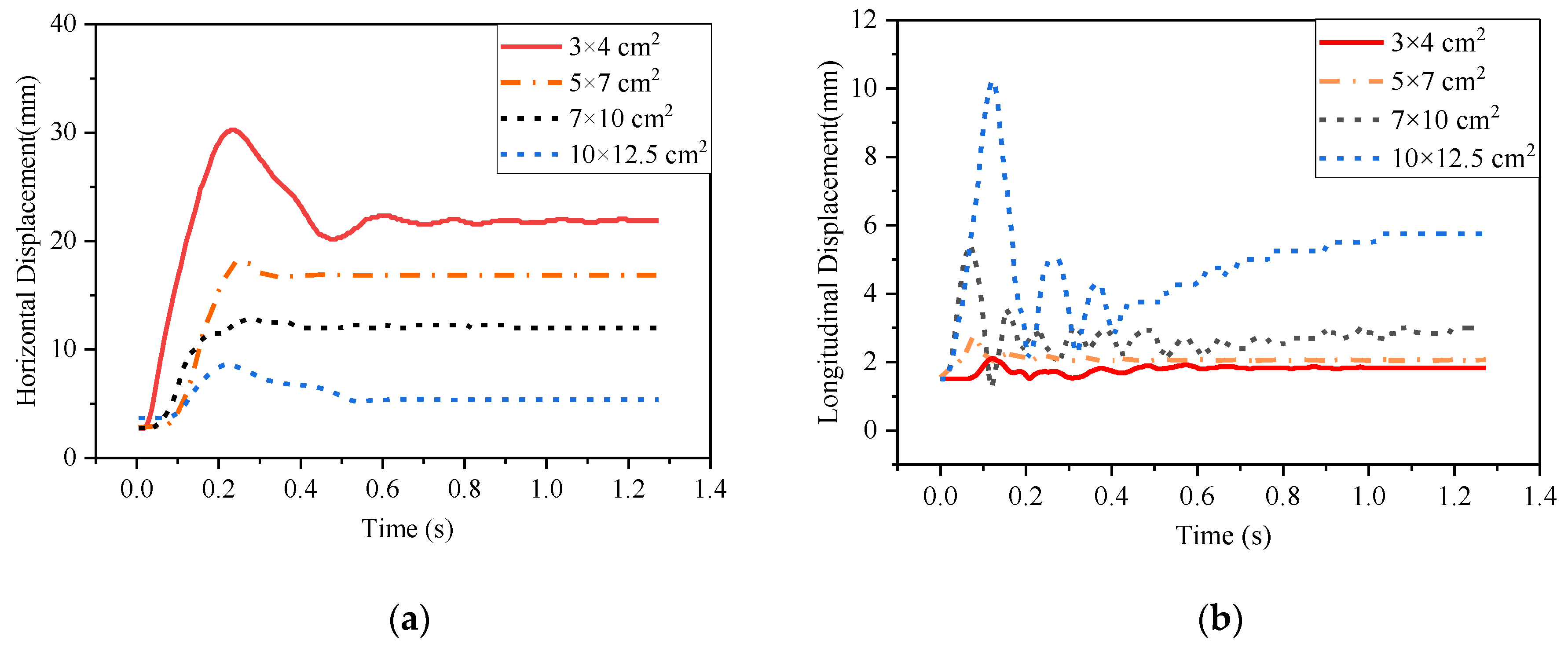

As we can see in

Figure 9—under the action of the horizontal EMF—the aluminum sheets have a positive displacement in the horizontal direction, that is, it moves from the outside of the coil to the middle position of the coil, and the displacement finally becomes a constant and forms a stable state. Relatively, the 3 × 4 cm

2 aluminum sheet is greatly affected by EMF due to its light weight. It will oscillate and finally stabilizes at 22.5 mm which is the middle position of the coil. It is consistent with the suspension state obtained in the simulation, which proves that the simulation is correct.

From

Figure 10, when the size of the aluminum sheet is increased to 10 × 12.5 cm

2, the increasing amplitudes of horizontal and longitudinal EMF are more obvious. Like the longitudinal movement, as the size of the aluminum sheet increases, the longitudinal EMF will enhance rapidly and be greater than the increase of its own gravity. When the suspended position of the 10 × 12.5 cm

2-sized aluminum sheet is at 5.7 mm, the acceleration of the upward movement reaches to maximum, which is consistent with the conclusions obtained in the simulation calculation.

According to the simulation analysis above, both the horizontal and longitudinal EMF of aluminum flakes increases with the area. Thereinto, the augment of longitudinal EMF is more obvious. When the side length of aluminum sheet is longer than coil width, the longitudinal EMF is large. As part of it is in the outside of the coil, the horizontal EMF is unevenly distributed, which will cause the aluminum sheet to fly out of the system. The experimental results are consistent with the simulation.

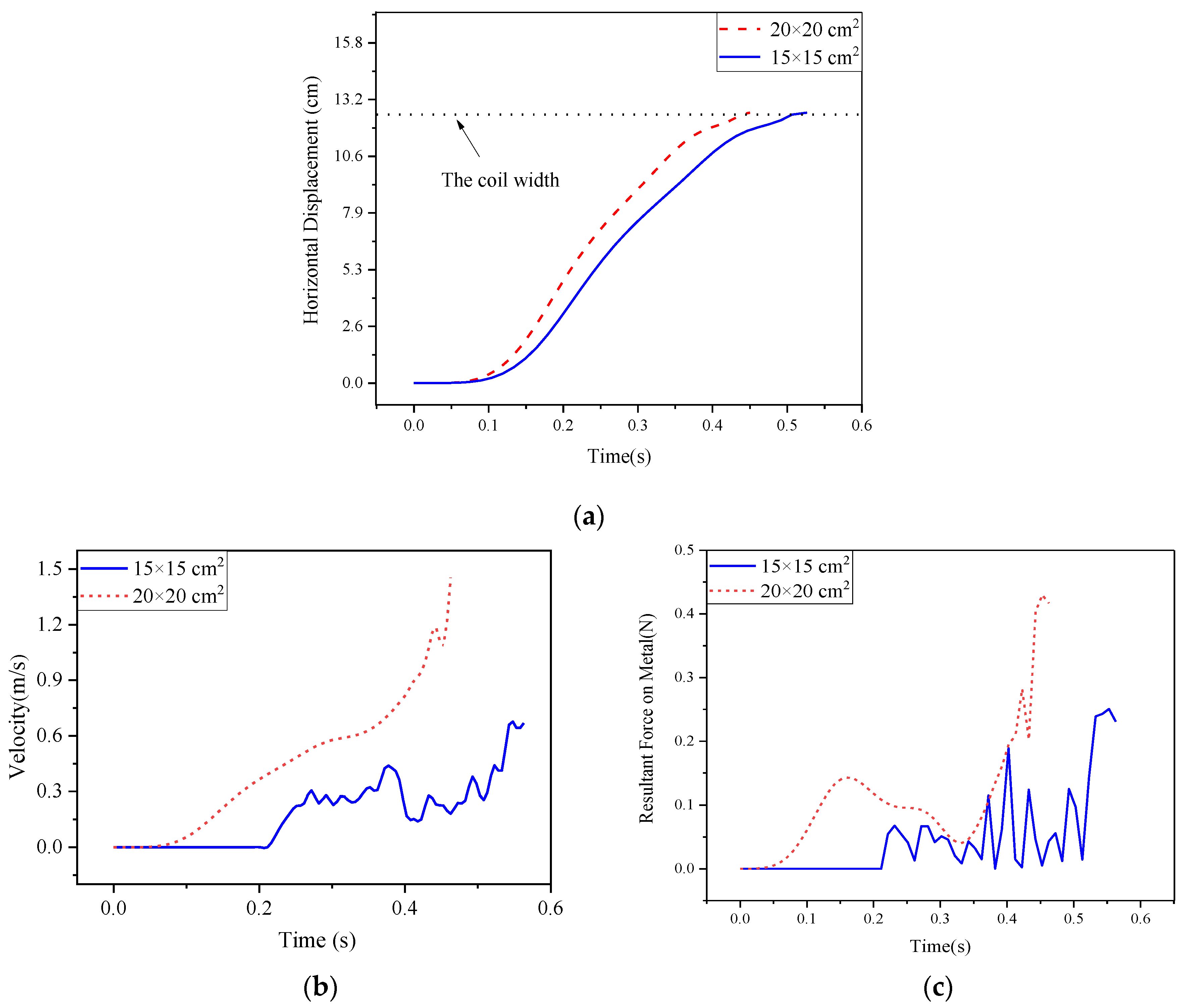

Horizontal displacement, velocity and resultant force are shown in

Figure 11 when aluminum sheets with size of 15 × 15 cm

2 and 20 × 20 cm

2 fly out. The enhance of velocity of the 20 × 20 cm

2 aluminum sheet is more obvious, and it will fly out of the system in only 0.45 s. The 15 × 15 cm

2 aluminum sheet has a smaller EMF, and the fluctuation of resultant force is obvious. It requires 0.52 s to fly out. In addition, the speeds of the two aluminum sheets are 0.67 m/s and 1.46 m/s, respectively. This indicates that the speed of flying out of the system is related positively to the size of the aluminum sheet.

A similar study was performed on the copper sheets with the same size, and we found that the copper sheet and aluminum sheet were subjected to similar EMF, while the difference of density is large. Therefore, after entering the system, the dynamic characteristics of the copper sheet are not obvious, basically remained stationary and only affect the power and transmission efficiency of the system.

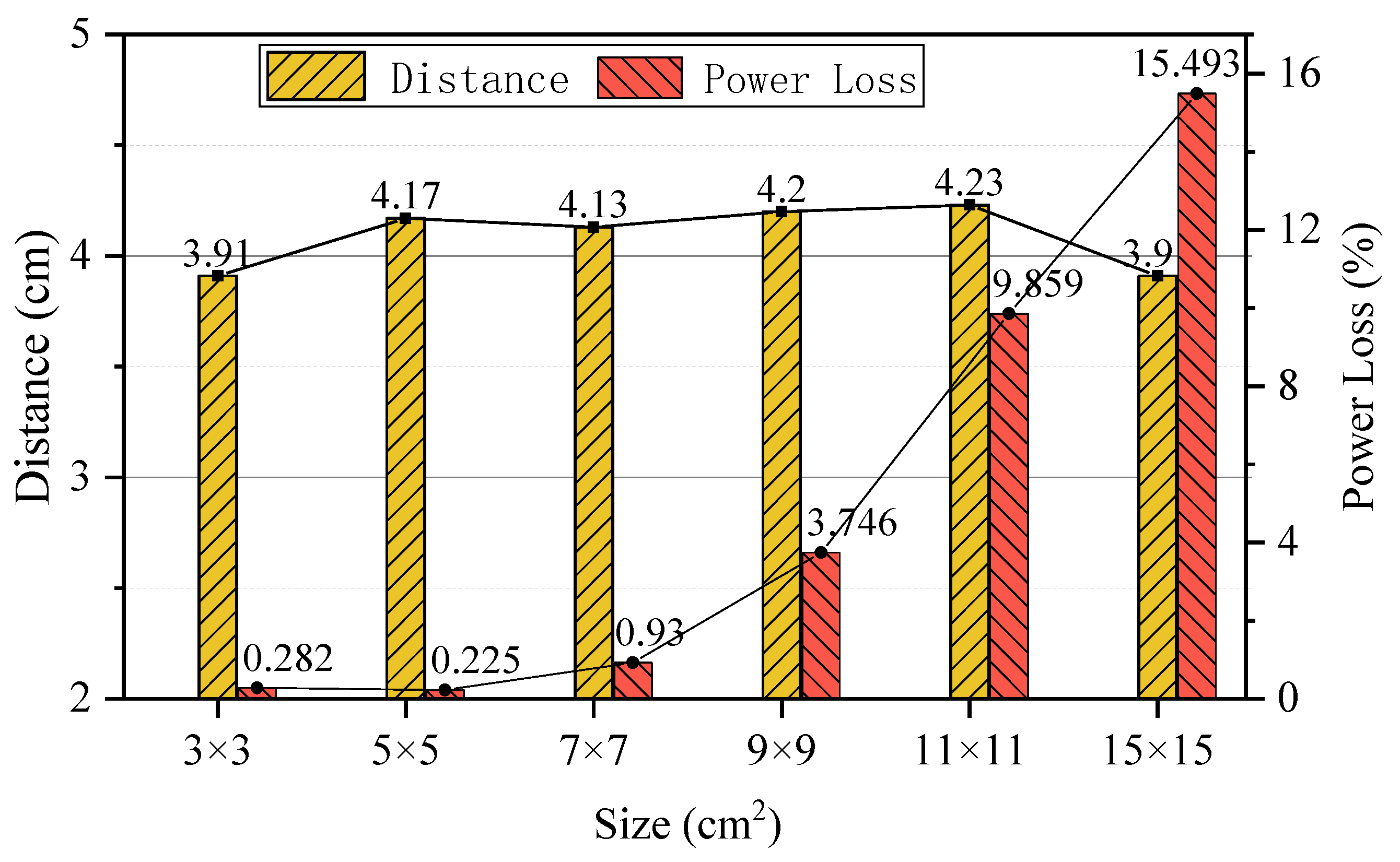

According to the simulation results, ferromagnetic objects only move longitudinally under the electromagnetic attraction. Because the electromagnetic attraction near the transmitting coil is not easy to display, the dynamic characteristics of the ferromagnetic metal around the receiving coil are analyzed. The initial position of iron sheet is the middle position of the transmission distance, gradually raise the iron piece and measure the distance that the iron piece can be completely attracted by the receiving coil, the results are consistent with simulation, as shown in

Figure 12, which also shows the power loss of the system during the iron sheet being adsorbed.

As the size of the iron piece gradually increases, the distance that iron pieces can be adsorbed shows an increasing trend, which means that the resultant force of electromagnetic attraction and gravity gradually increases. However, for an iron piece of 5 × 5 cm2, considering that the power loss of the system is slightly reduced while the space magnetic field is more concentrated, the distance that the piece of iron can be adsorbed increases slightly to 4.17 cm. For a 15 × 15 cm2 piece of iron that is wider than the coil, when the iron piece is rapidly magnetized to generate a large amount of eddy current loss, the power loss of the system can reach 15.493%. Simultaneously, the space magnetic field is attenuated, which reduces the enhance of the electromagnetic attraction force. The adsorption distance dropped to 3.9 cm.

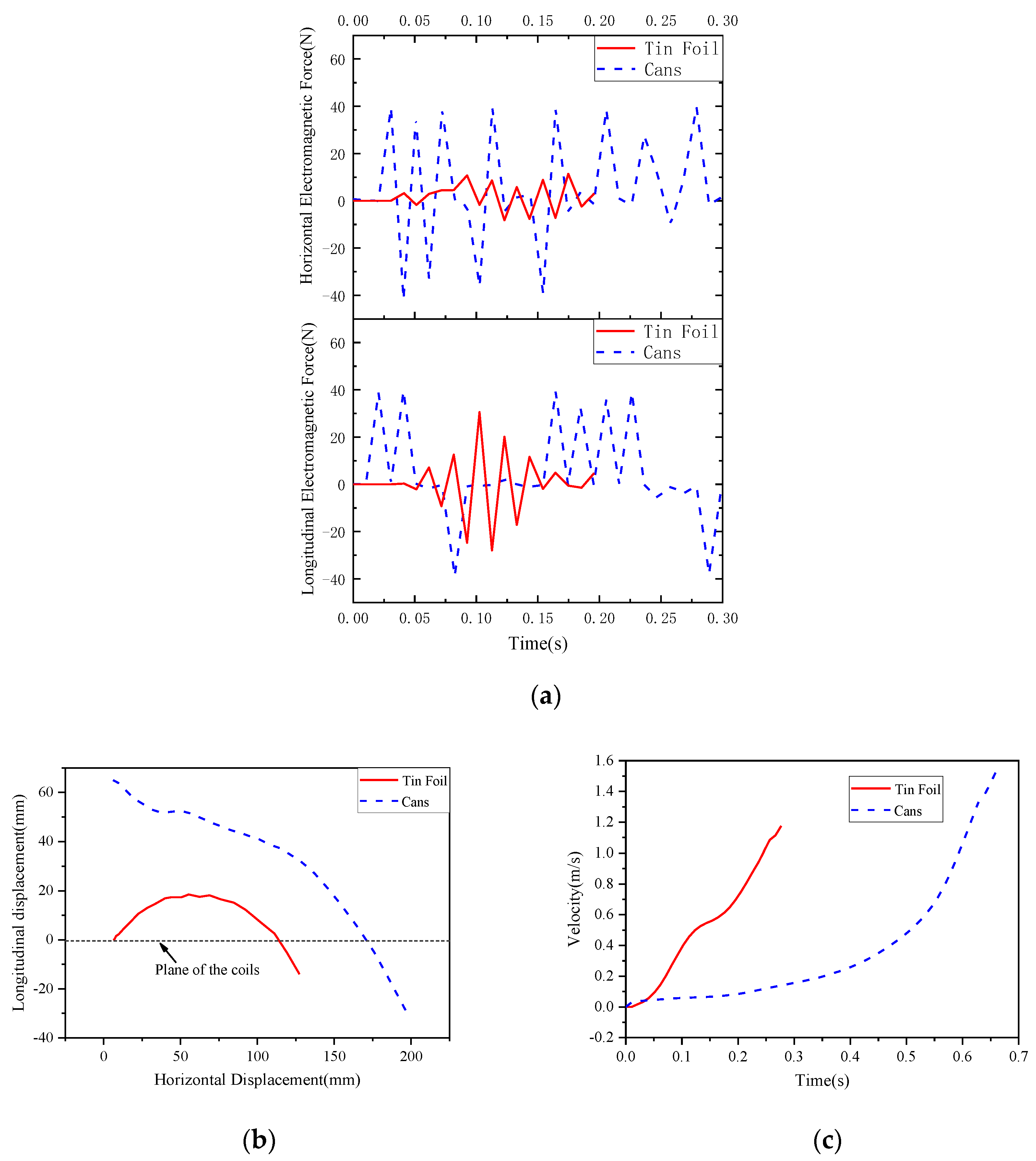

In order to further study the effect of foreign metal objects on the system security under the effect of EMF. we measured and analyzed some common foreign metal objects mentioned in SAE J2954 standard [

26], such as paper clips, coins, tin foil and cans. The results are shown in

Table 2 and

Figure 13.

It can be seen from

Table 2 that paper clips and coins of different denominations will be attracted to the coil surface by electromagnetic attraction and cause a power loss.

Figure 13 shows that aluminum packaging such as cans and foils are subject to electromagnetic repulsion and flying out of the system, because they are thinner and wider than the coil of the system. The speed of the foil and cans flying out of the system can reach 1.17 m/s and 1.53 m/s, respectively, which will bring hidden danger to the external environment of the system.